Perovskite fiber boy compound oxide catalyst for treating automobile's waste gas, and method for preparing same

A composite oxide, perovskite-type technology, used in physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve the problems of uneven heating, thermal stress damage, and high quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

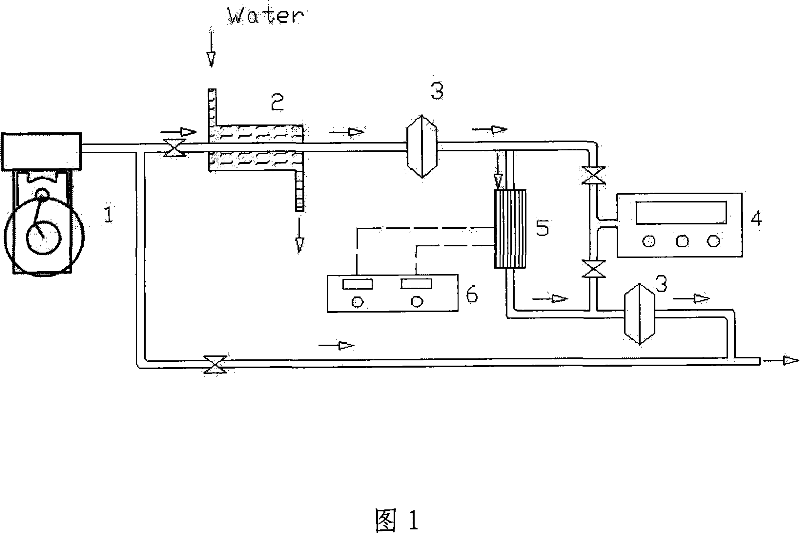

Method used

Image

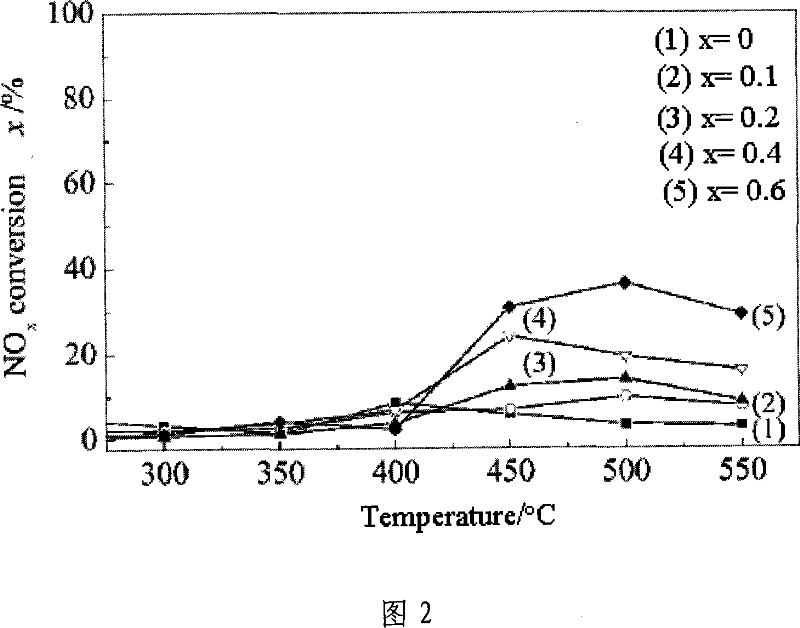

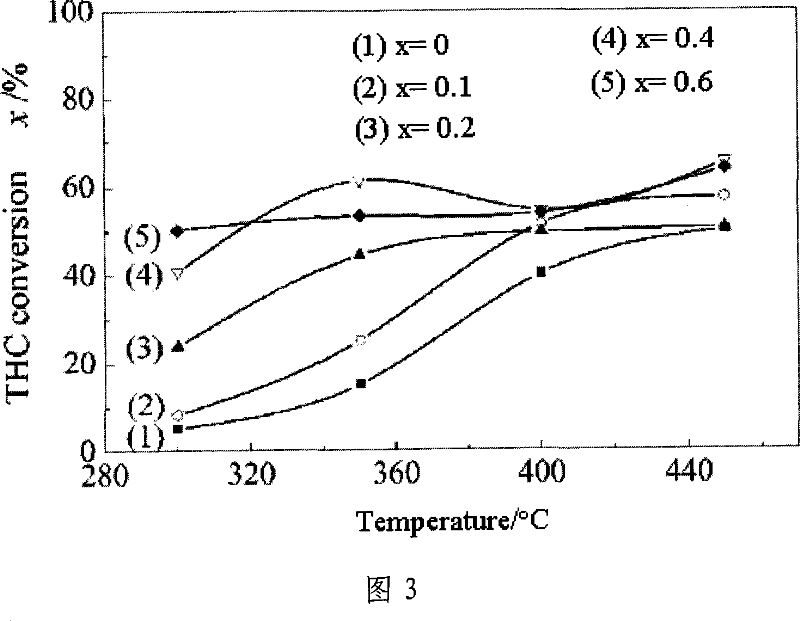

Examples

Embodiment 1

[0041] Weigh 2.9g of lanthanum oxide and dissolve it in a solution of 15ml of dilute nitric acid (30%, w / w); then add 6ml of ammonia water to the resulting clear solution to completely precipitate the lanthanum ions into La(OH) 3 Suction filtration, and repeatedly flushing with distilled water to the pH of filtrate is neutral; Gained filter cake is dispersed in the aqueous solution (1.0mol / L) of 30ml citric acid, obtains white emulsion; In gained system, drip ammoniacal liquor, until Clarify, at this time the solution pH ≈ 5.0 ~ 7.5.

[0042] Another weighed 4.5g Co(CH 3 COO) 2 4H 2 O and 3.8 g of citric acid were dissolved in 20 ml of distilled water to obtain a purple-red clear solution. The pre-prepared La citrate complex solution is mixed with it to obtain a precursor solution. The resulting solution is aged in a water bath at 40-80°C for about 4-12 hours to form LaCoO 3 Precursor sol.

[0043] The high-voltage DC power supply with positive voltage output provides a ...

Embodiment 2

[0046] Weigh 2.9g of lanthanum oxide and dissolve it in a solution of 15ml of dilute nitric acid (30%, w / w); then add excess ammonia water to the resulting clear solution to completely precipitate the lanthanum ions into La(OH) 3 Suction filtration, and repeatedly flushing with distilled water until the pH of the filtrate is neutral; Gained filter cake is dispersed in the aqueous solution of 30ml citric acid (1.0mol / L), obtains white emulsion; In the gained system, drip ammoniacal liquor, until clarification , at this time the solution pH ≈ 5.0 ~ 7.5.

[0047] Also called CH 3 COOK(0.2g), Co(CH 3 COO) 2 4H 2 O (4.0 g) and citric acid (3.8 g) were dissolved in 20 ml of distilled water to give a clear purple-red solution. The pre-prepared La citrate complex solution is mixed with it to obtain a precursor solution. The resulting solution was aged in a water bath at 60°C for about 4 to 12 hours to form La 1-X K X CoO 3 Precursor sol.

[0048] The high-voltage DC power sup...

Embodiment 3

[0051] Weigh 2.9g of lanthanum oxide and dissolve it in a solution of 15ml of dilute nitric acid (30%, w / w); then add excess ammonia water to the resulting clear solution to completely precipitate the lanthanum ions into La(OH) 3 Suction filtration, and repeatedly flushing with distilled water until the pH of the filtrate is neutral; Gained filter cake is dispersed in the aqueous solution of 30ml citric acid (1.0mol / L), obtains white emulsion; In the gained system, drip ammoniacal liquor, until clarification , at this time the solution pH ≈ 5.0 ~ 7.5.

[0052] Also called CH 3 COOK(0.5g), Co(CH 3 COO) 2 4H 2 O (3.1 g) and citric acid (3.8 g) were dissolved in 20 ml of distilled water to give a clear purple-red solution. The pre-prepared La citrate complex solution is mixed with it to obtain a precursor solution. The resulting solution was aged in a water bath at 60°C for about 4 to 12 hours to form La 1-X K X CoO 3 Precursor sol.

[0053] The high-voltage DC power sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com