Splicing-interference-detection aspheric surface shape apparatus using distorting lens and method thereof

A technology of interference detection and deformable mirror, applied in the field of optical detection, can solve the problems of low detection efficiency, large mechanical error, long detection time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

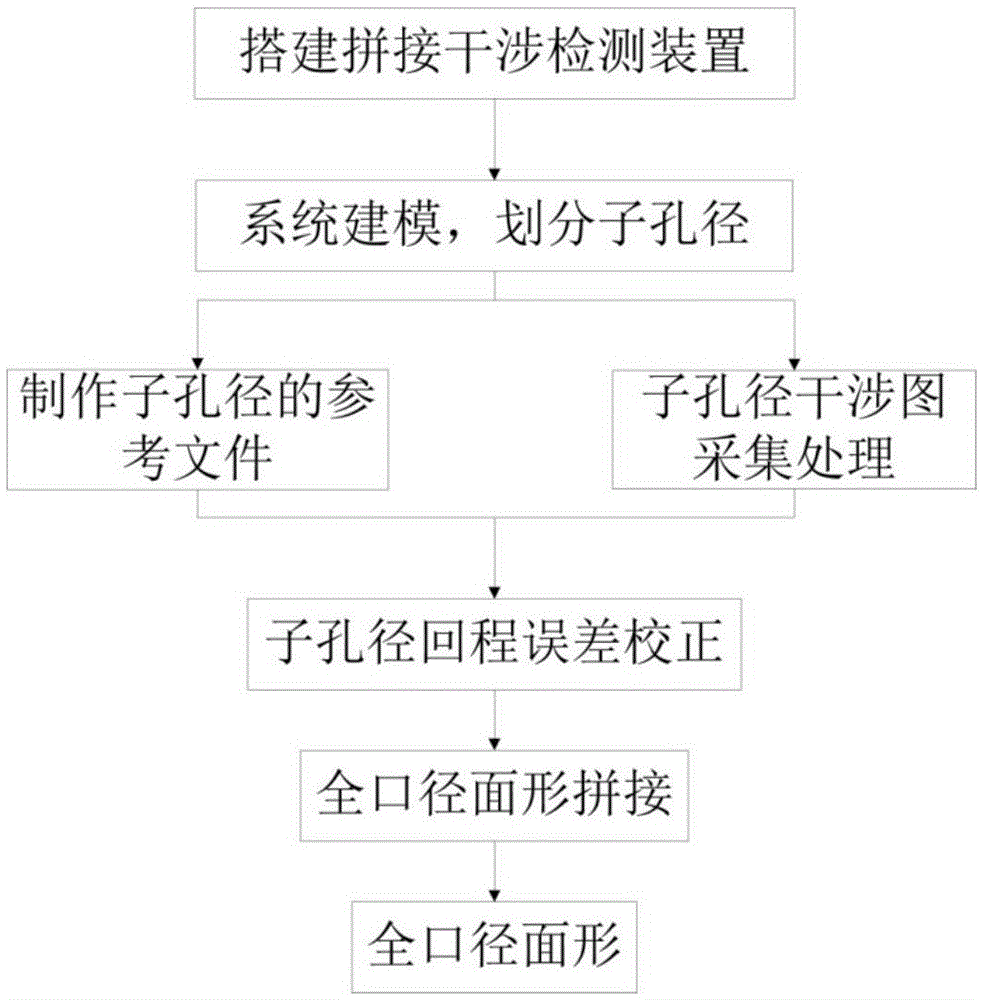

[0057] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

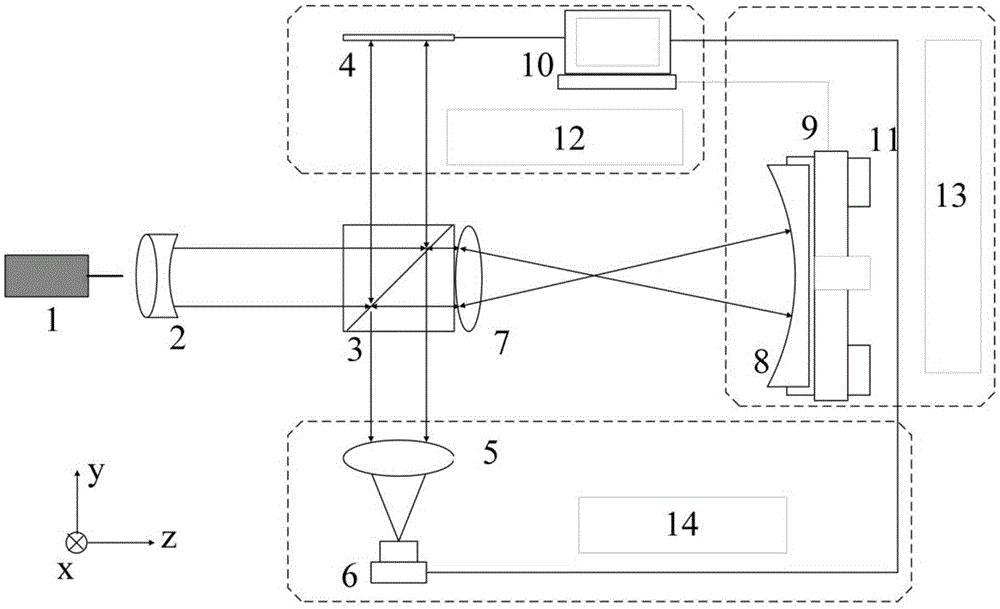

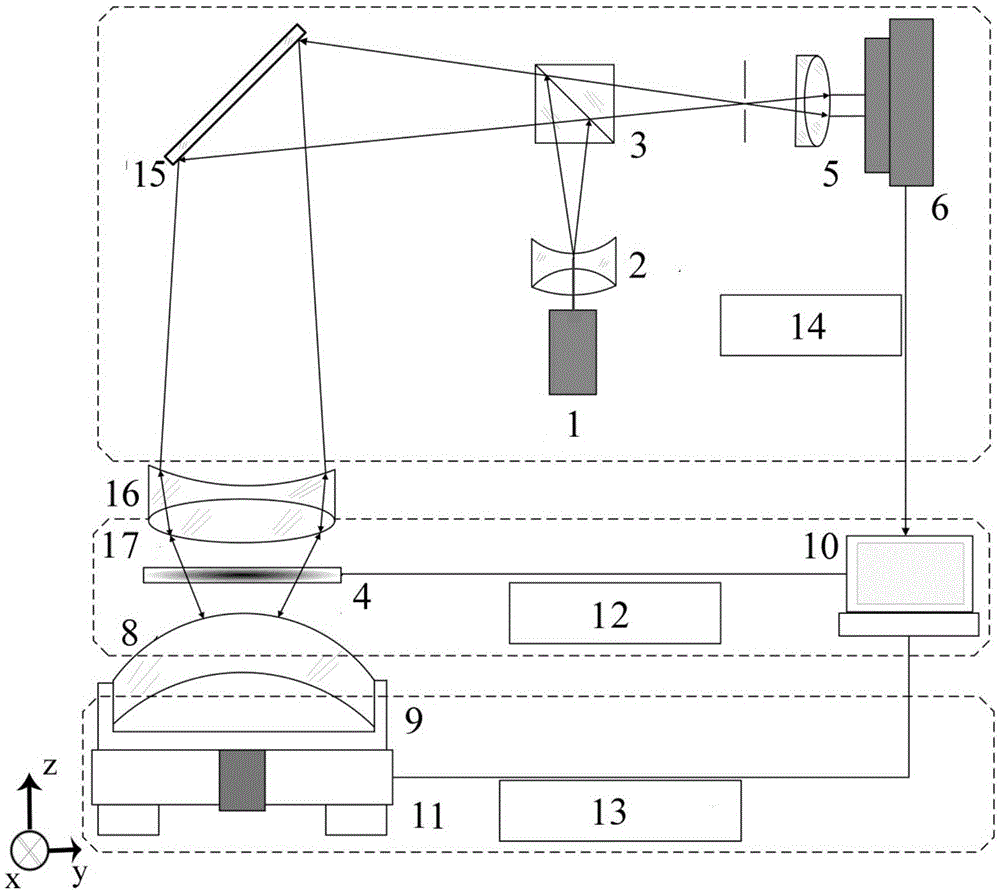

[0058] The device of the present invention adopting splicing interference detection of deformable mirrors to detect aspheric surface shape comprises a deformable mirror compensation system, an interference detection system, a mechanical adjustment mechanism and a computer data processing module;

[0059] The computer data processing module includes a deformable mirror control unit 12, a multi-dimensional adjustment table control unit 13, an interferogram acquisition processing unit 14, a backhaul error correction unit and a sub-aperture splicing algorithm unit;

[0060] The aspherical surface 8 to be detected is fixed on the mechanical adjustment mechanism, and the interference detection system compensates the optical path difference with the reflected light from the aspheric surface 8 to be detected through a deformation mirror compensation system. The i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com