Spray head moisturizing system for digital textile printing equipment

A printing and equipment technology, applied in the field of nozzle moisturizing system for digital textile printing equipment, can solve the problems such as difficulty in controlling and guaranteeing moisturizing effect of moisturizing box, decreasing printing accuracy of printing nozzles, clogging of printing nozzles, etc. The effect of nozzle clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

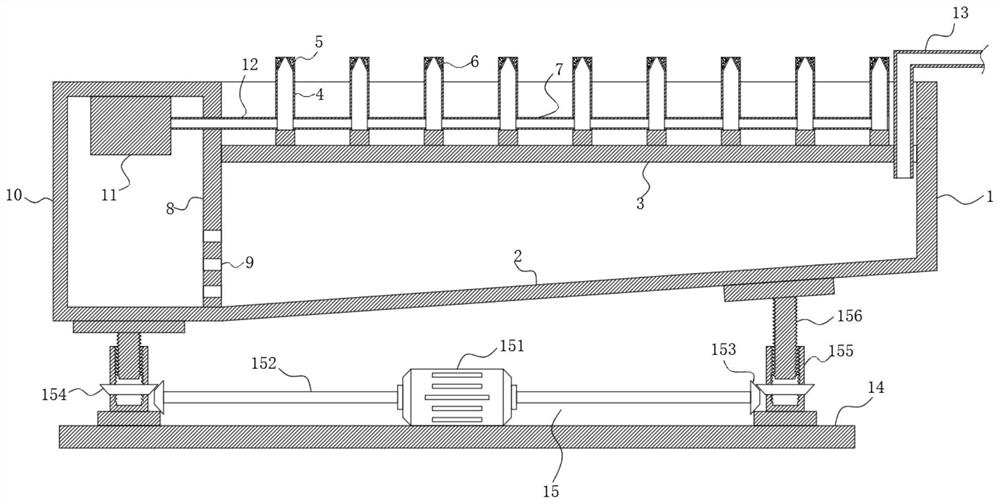

[0018] see figure 1 , The present invention provides a technical solution: a nozzle moisturizing system for digital textile printing equipment, comprising a water tank 1, a bottom plate 2 at the bottom end of the water tank 1 is inclined and arranged, a partition 8 is fixedly connected to the side of the water tank 1, and a side of the partition 8 is fixedly connected with The steam generating box 10, the bottom of the partition 8 is provided with a plurality of through holes 9 arranged at equal intervals, the through holes 9 communicate with the inner cavity of the water tank 1 and the inner cavity of the steam generating box 10, the bottom plate 2 is inclined to one side of the steam generating box 10, and the bottom plate 2. The angle formed with the horizontal line is an acute angle. A steam generator 11 is arranged in the steam generating box 10. The water in the water tank 1 flows into the steam generating box 10 through the through hole 9 due to gravity. The water in th...

Embodiment 2

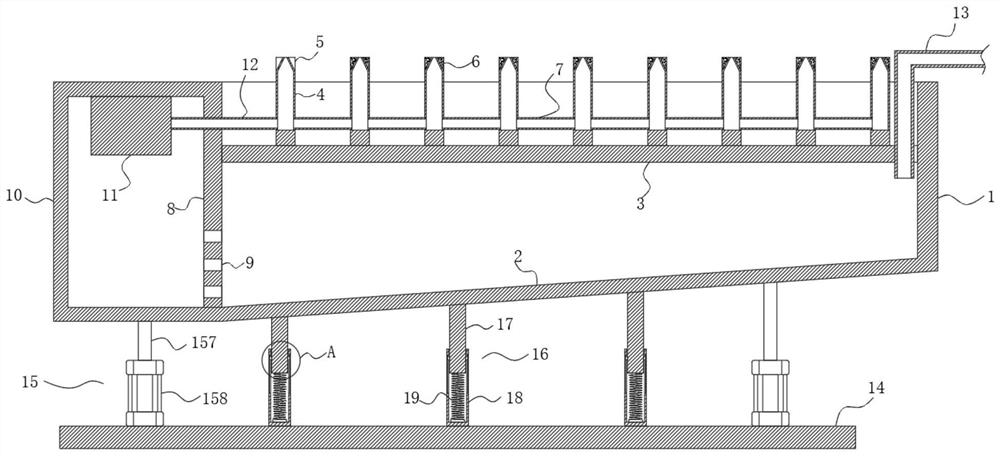

[0024] see Figure 2-3 , the present invention provides a solution different from the first embodiment: the lifting mechanism 15 includes a piston rod 157, a cylinder 158 and a telescopic support rod 16, the cylinder 158 is fixedly connected to the upper end of the mounting plate 14, there are at least two cylinders 158, and the cylinder 158 The upper end is provided with a piston rod 157, the upper end of the piston rod 157 is fixedly connected to the bottom end of the bottom plate 2, the cylinder 158 is connected to an external power supply and a control switch, after the cylinder 158 is activated, the piston rod 157 drives the water tank 1 to rise and fall;

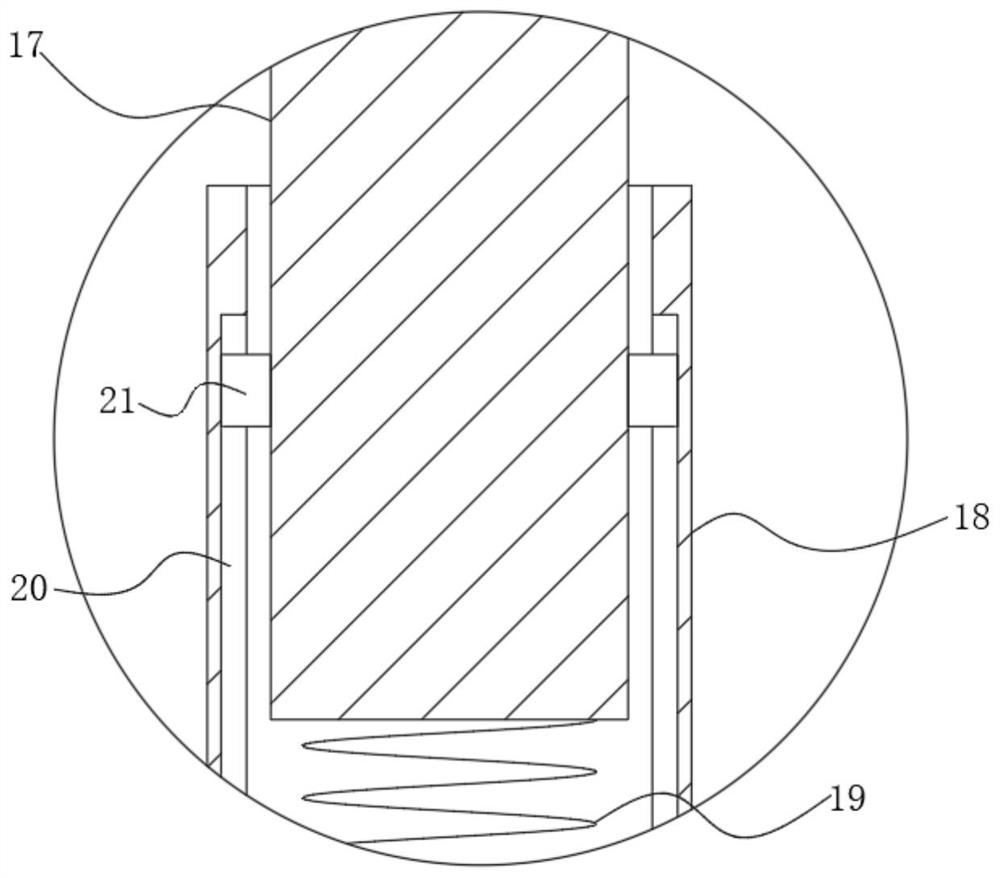

[0025] A telescopic support rod 16 is arranged between the bottom end of the bottom plate 2 and the mounting plate 14, and a plurality of telescopic support rods 16 are arranged at equal intervals. The telescopic support rod 16 includes a first support rod 17, a second support rod 18 and a spring 19. The upper end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com