Patents

Literature

256results about "Liquid/gas/vapor removal by suction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spunlace nonwoven fabric and manufacture method

InactiveCN105220357AHas anti-inflammatory propertiesGood hygroscopicityLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor removal by suctionEngineeringMoisture absorption

The invention discloses spunlace nonwoven fabric and a manufacture method. Aloe is adopted by raw material and the spunlace nonwoven fabric is manufactured by a spunlacing method. The manufacture method comprises following steps of: (1) extraction of raw material; (2) opening and mixing; (3) combing; (4) cross lapping; (5) drafting; (6) pre-wetting; (7) afterfinish; (8) drying; (9) winding into finished products. The spunlace nonwoven fabric and the manufacture method have following beneficial effects: the spunlace nonwoven fabric adopts aloe as raw material and manufactured by the manufacture method and has the anti-inflammatory function of the human skin and is also characterized by being high in moisture absorption and strength, low in fuzzing performance, good in breathability, soft in handfeel and fine in drapability.

Owner:徐波

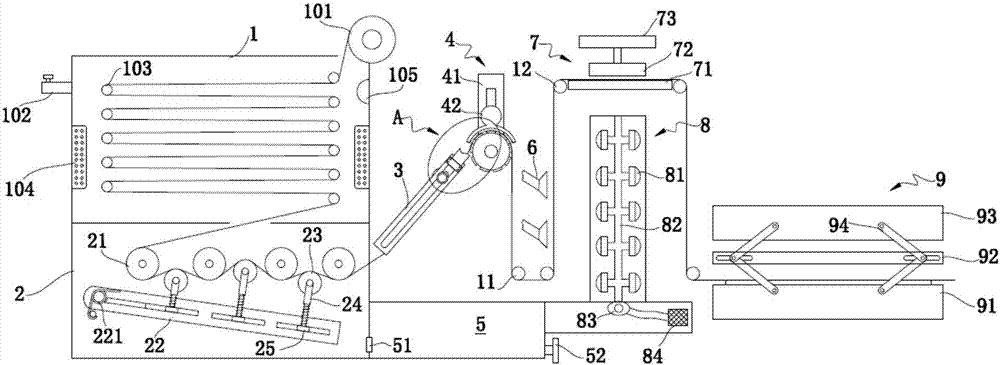

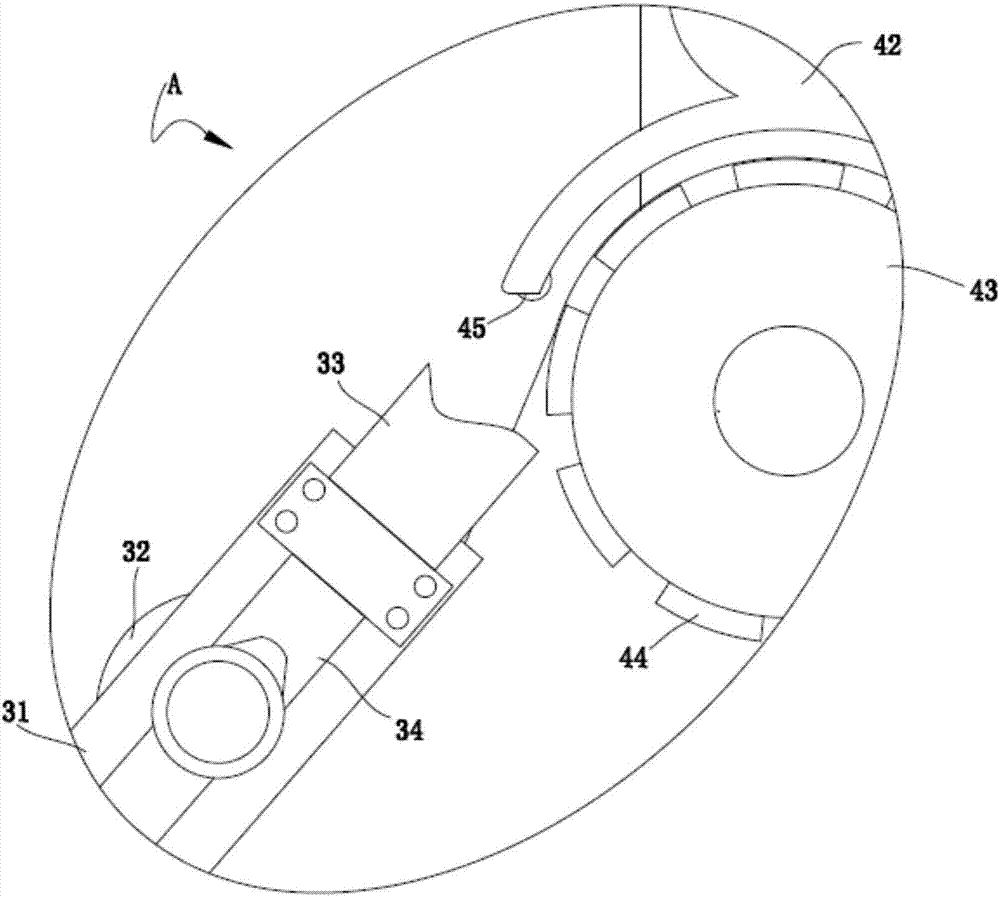

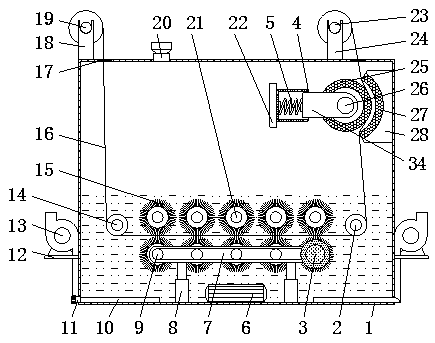

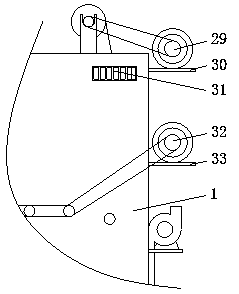

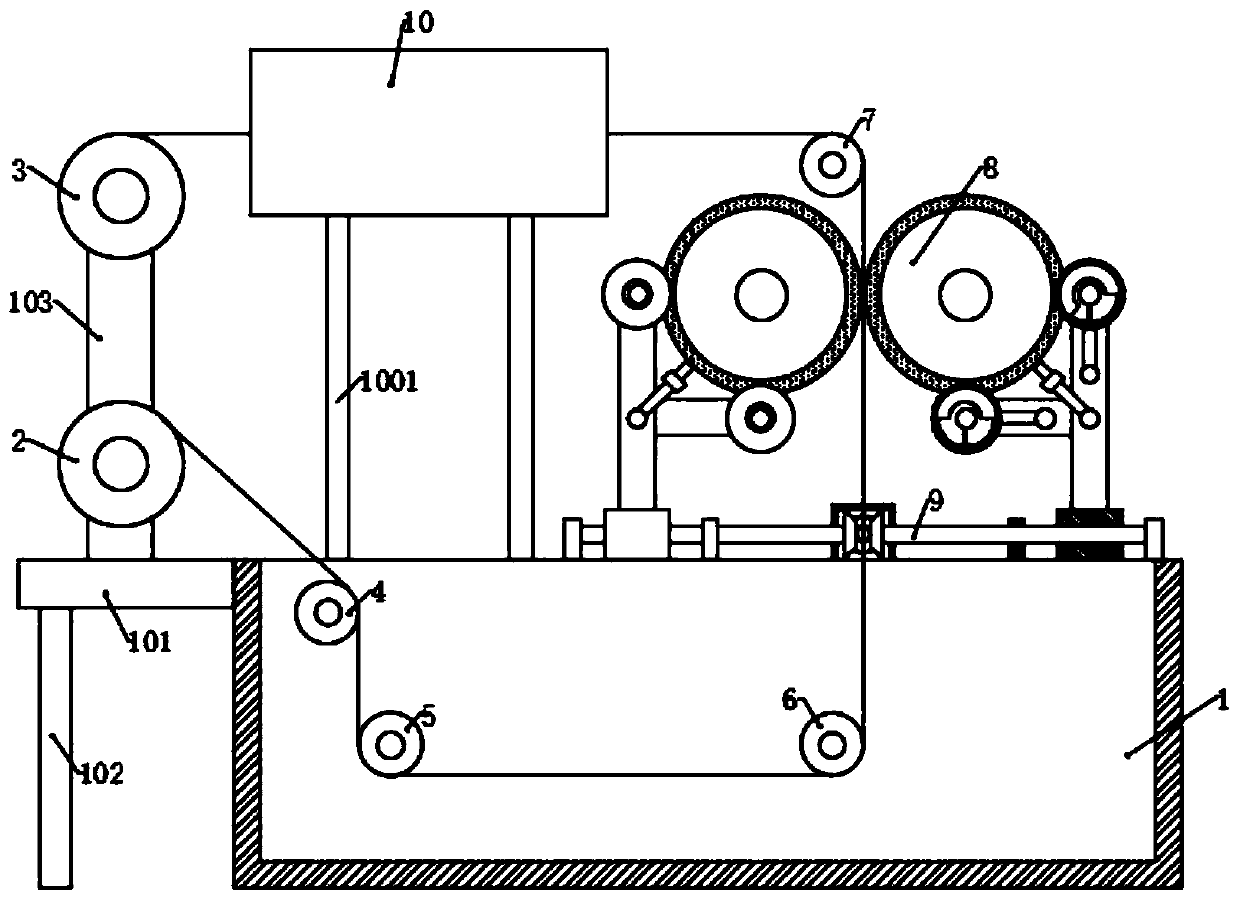

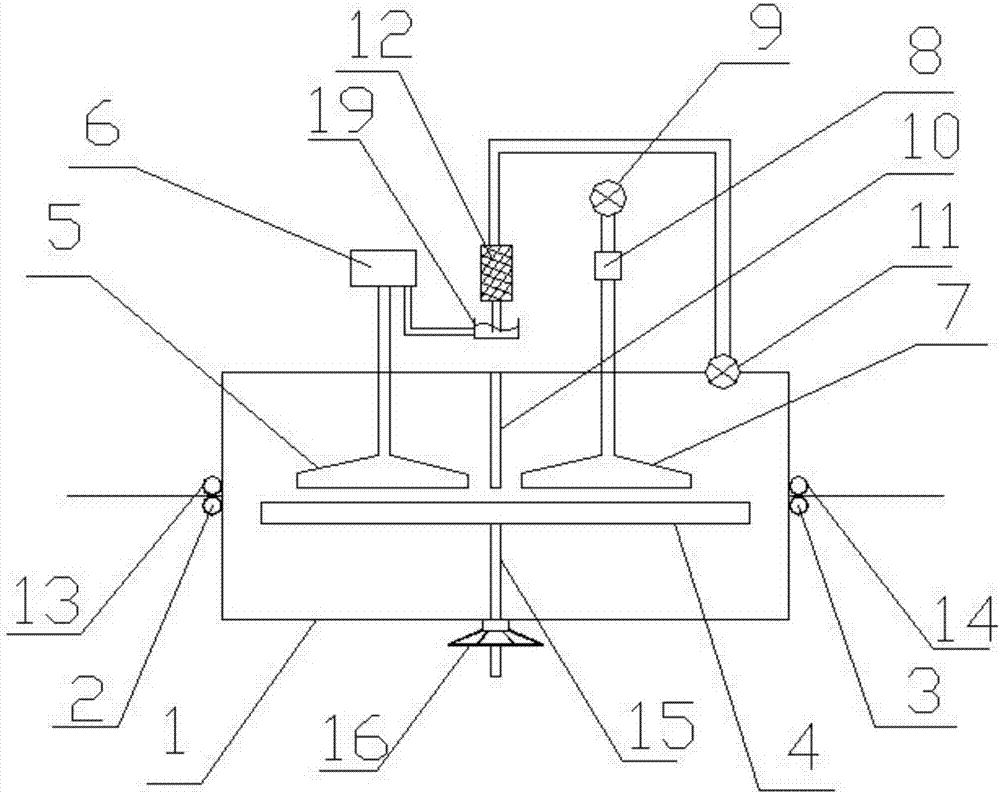

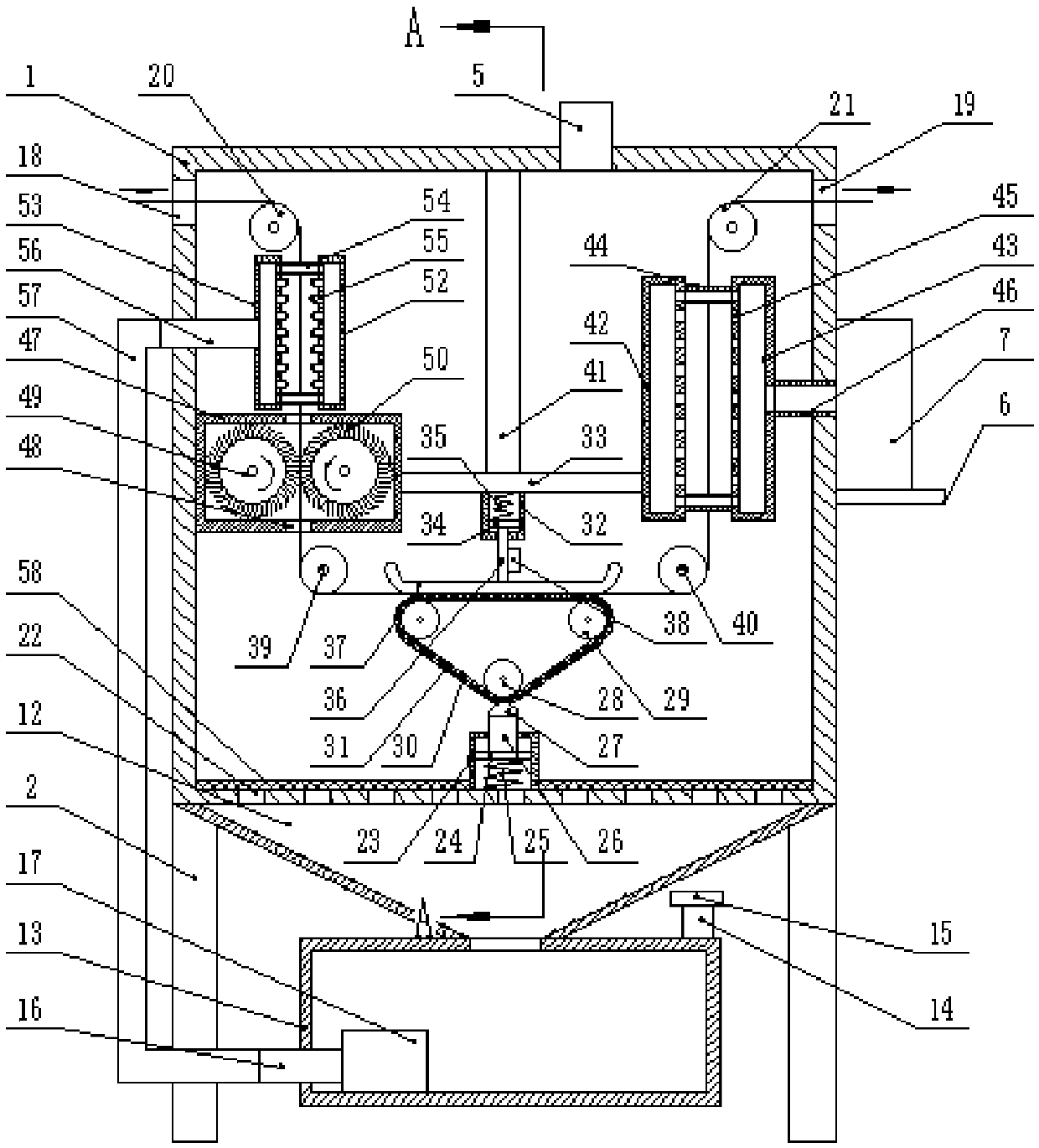

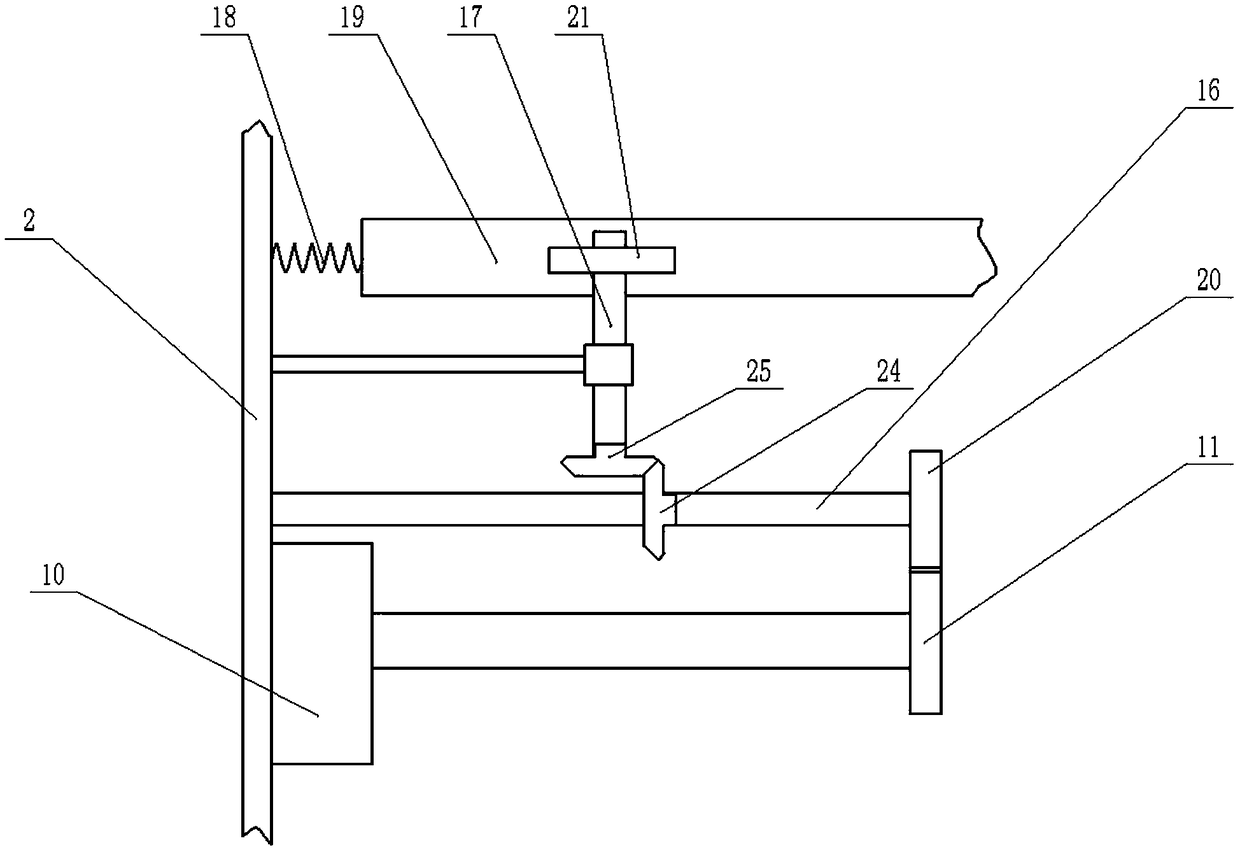

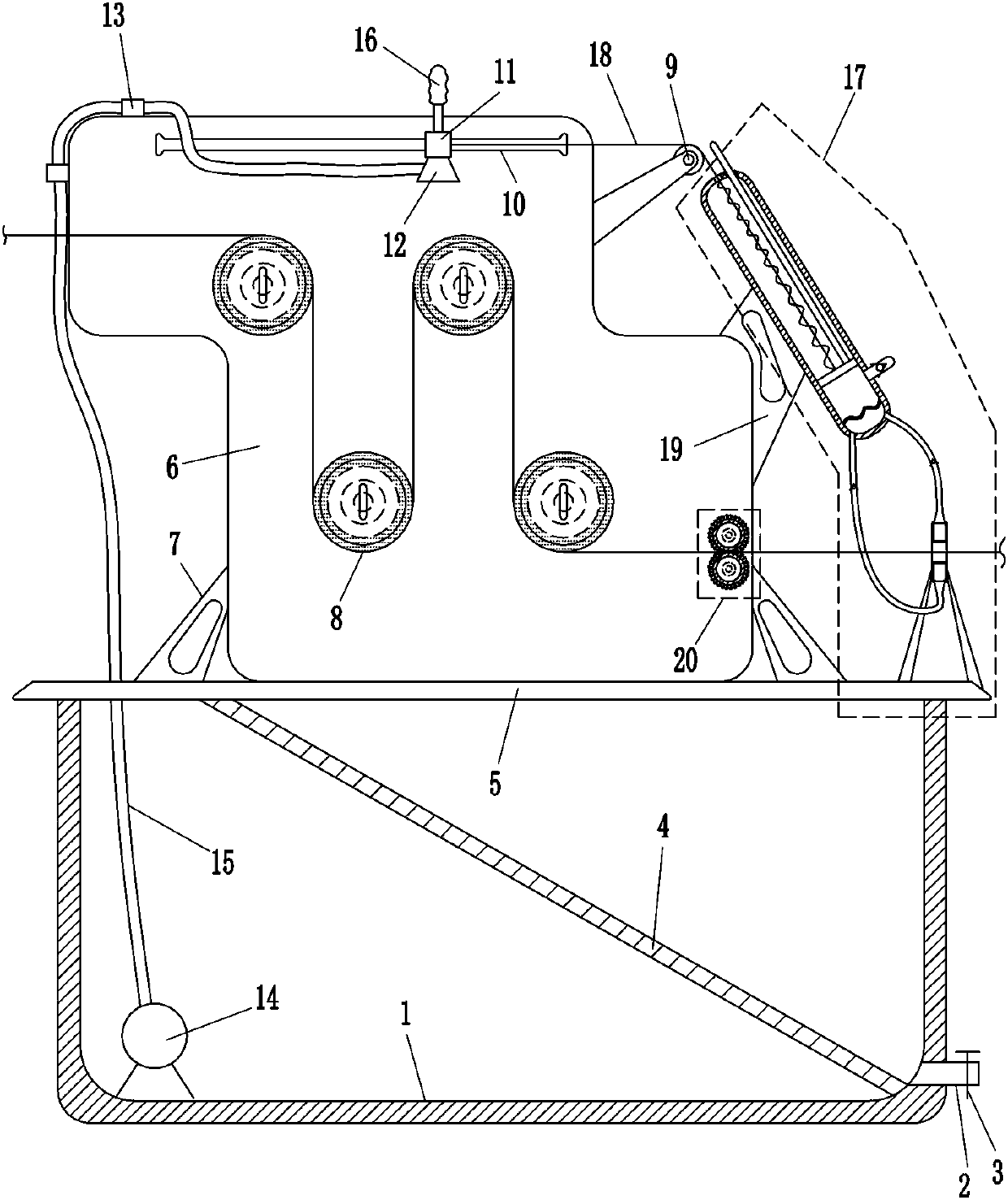

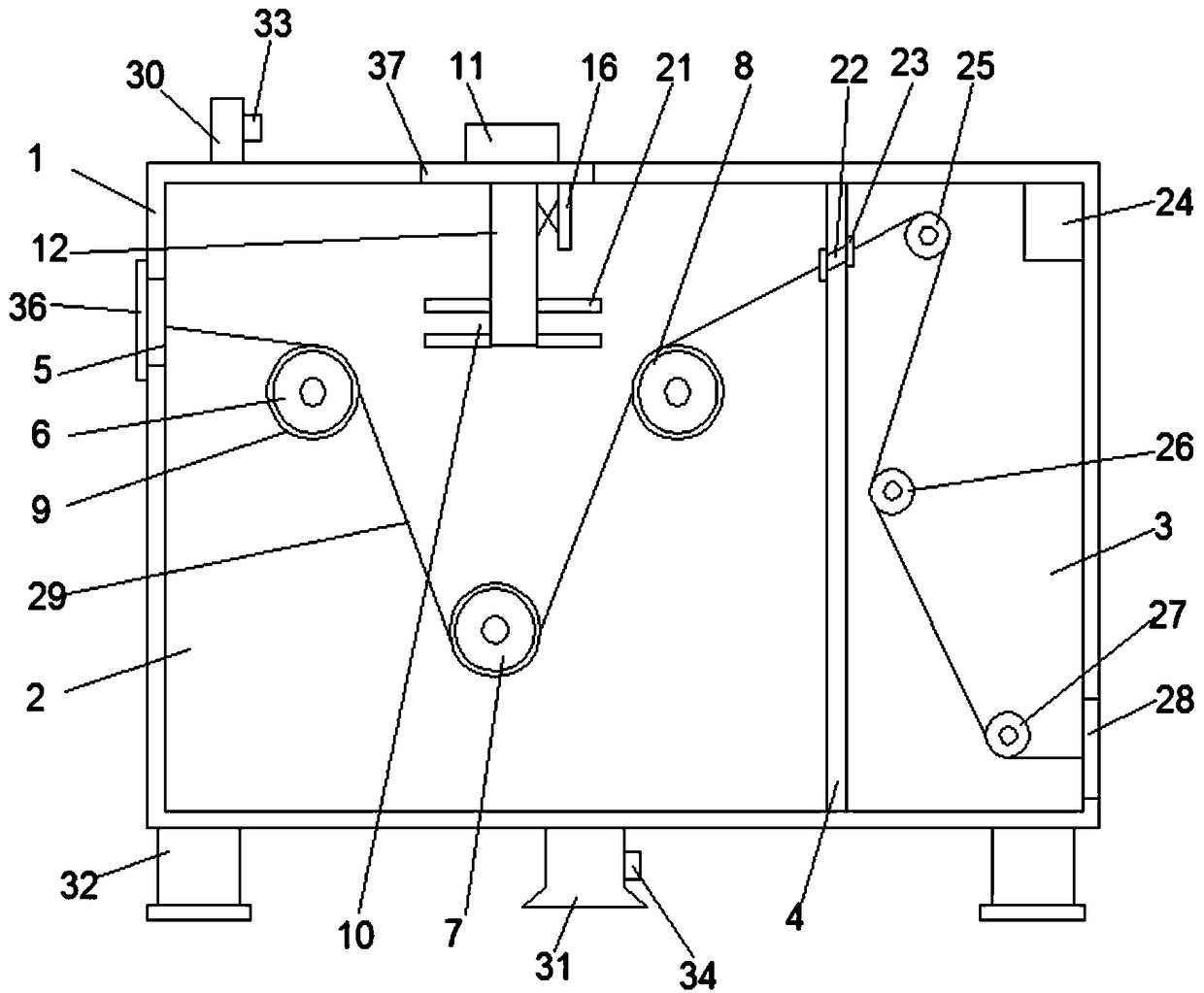

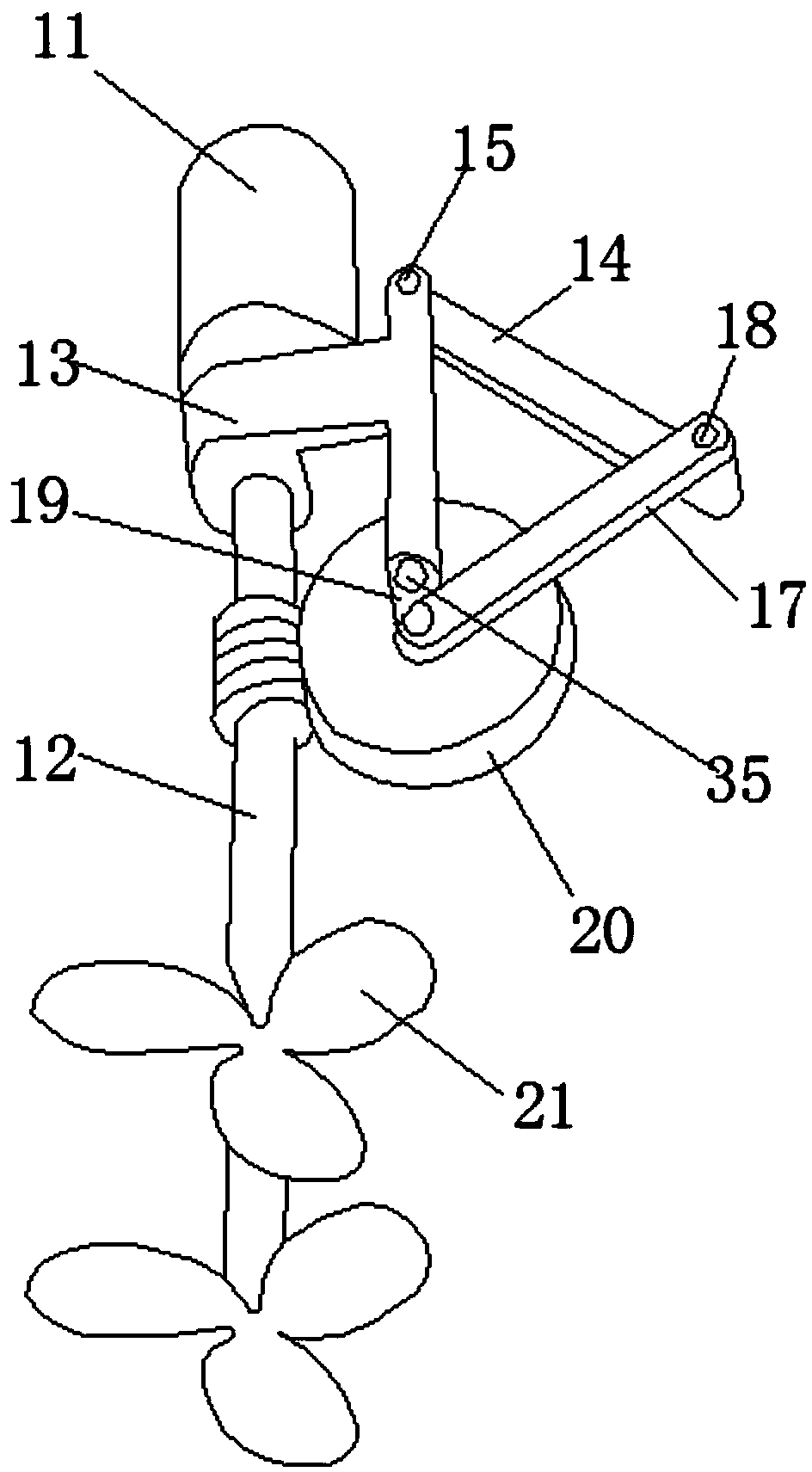

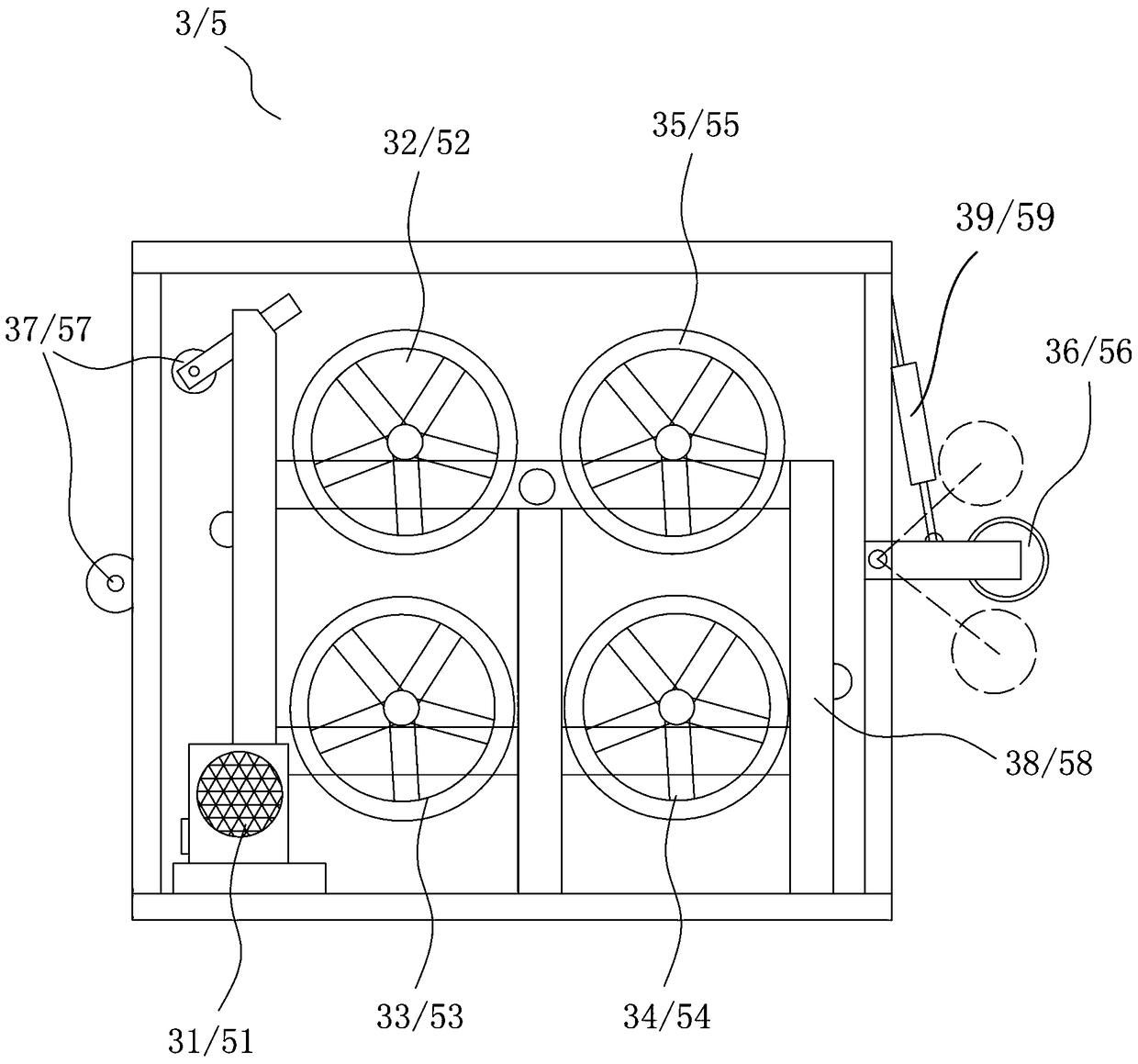

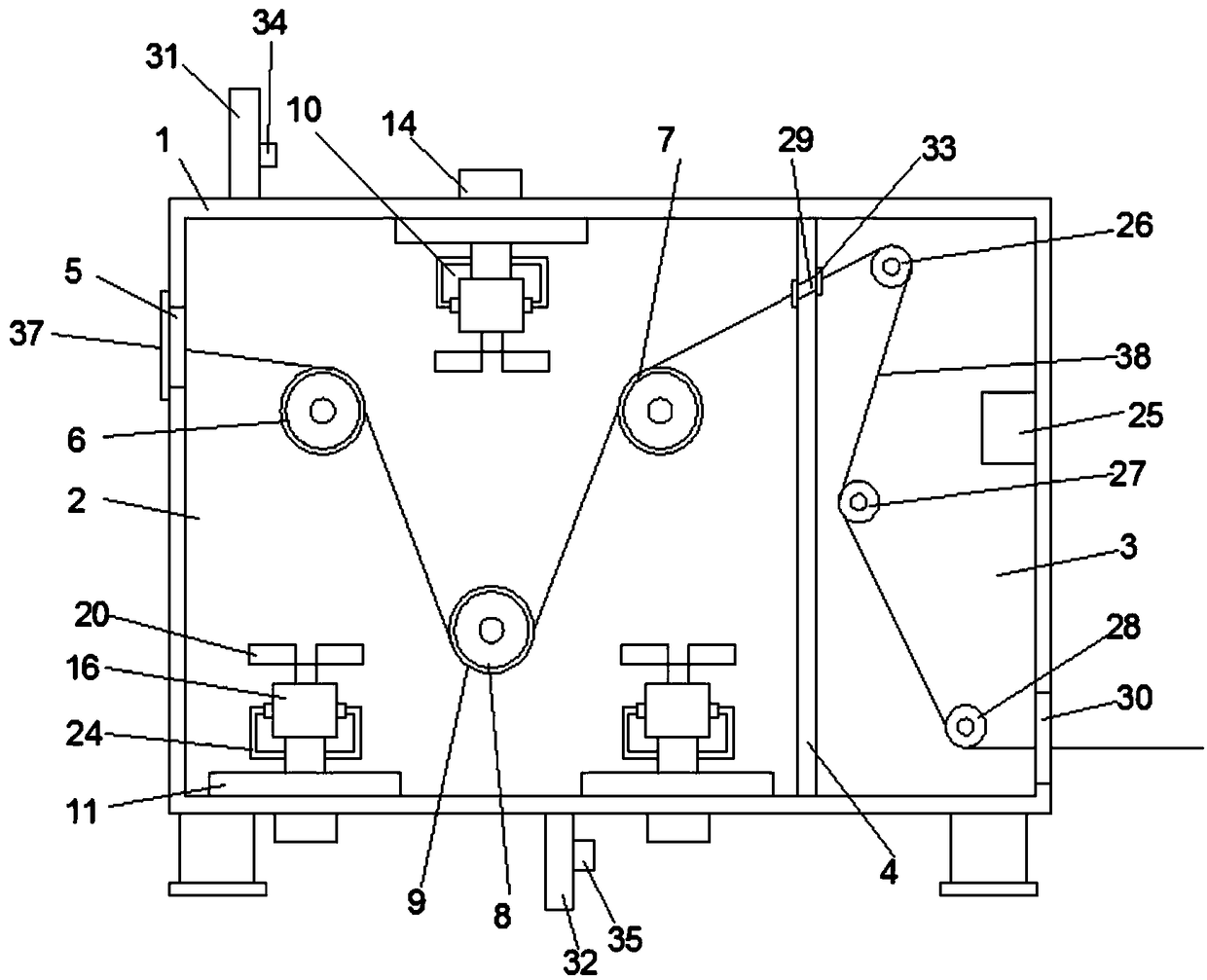

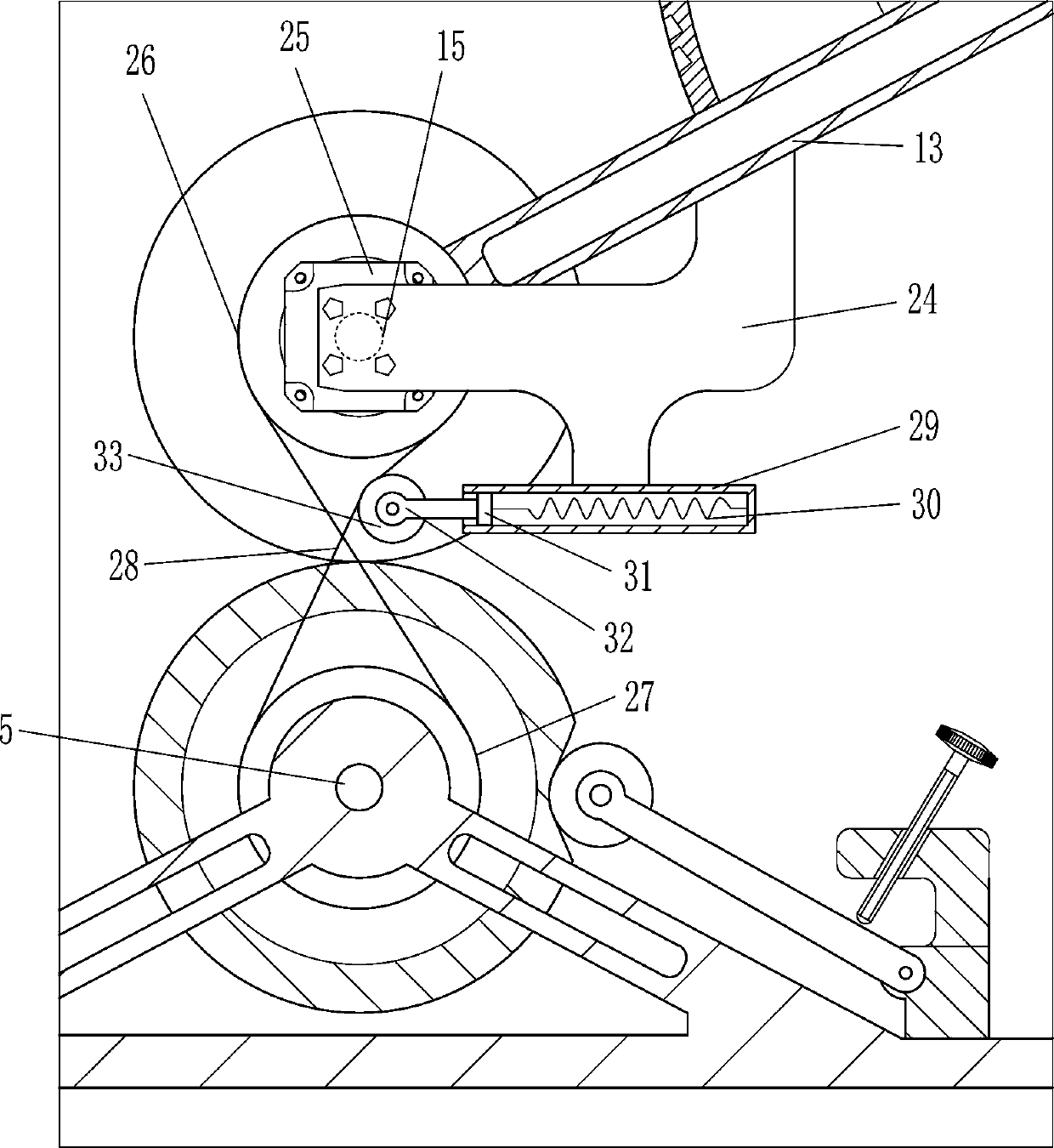

Printing and dyeing equipment

ActiveCN107974786AUniform dyeingAutomatically adjust the tensionLiquid/gas/vapor treatment machines driving mechanismsLiquid/gas/vapor removal by squeezing rollersPulp and paper industryTextile dyeing

The invention provides printing and dyeing equipment. The printing and dyeing equipment comprises a dyeing box, a dewatering and drying mechanism and a printing machine which are arranged from left toright sequentially. The dewatering and drying mechanism comprises a dewatering mechanism, a water absorbing mechanism, an ironing mechanism and a drying machine which are arranged from left to rightsequentially. The dewatering mechanism comprises a guide rail frame. A water pressing roller is mounted in a groove of the guide rail frame movably through a wheel. An air cylinder is arranged on theright side of the guide rail frame. A piston rod of the air cylinder is connected with the water pressing roller. The water absorbing mechanism comprises a water pressing plate and a water absorbing roller. The printing and dyeing equipment has the advantages that centrifugal dewatering is not needed after textile dyeing through the dewatering and drying mechanism, so that flattening degree of textiles is guaranteed, and flattening on a scutcher is not needed; the dyeing equipment, the dewatering and drying equipment and the printing equipment are combined, so that equipment replacement time during working is reduced, dyeing and printing can be completed on one equipment, and working efficiency is improved.

Owner:TONGXIANG LONGXIANG PRINTING & DYEING CO LTD

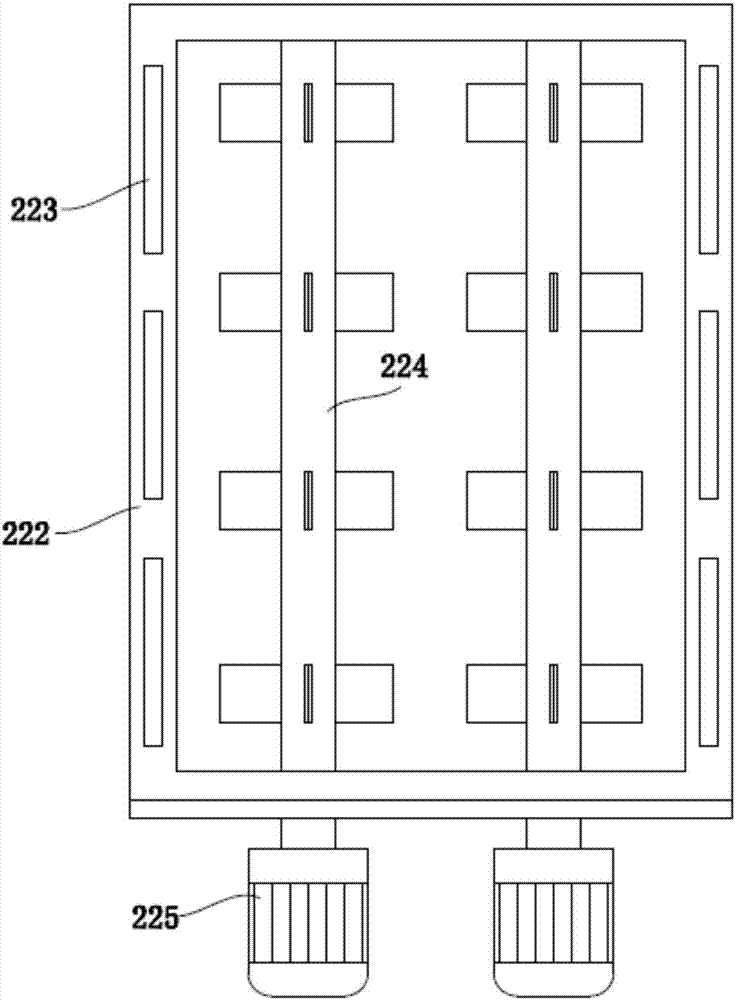

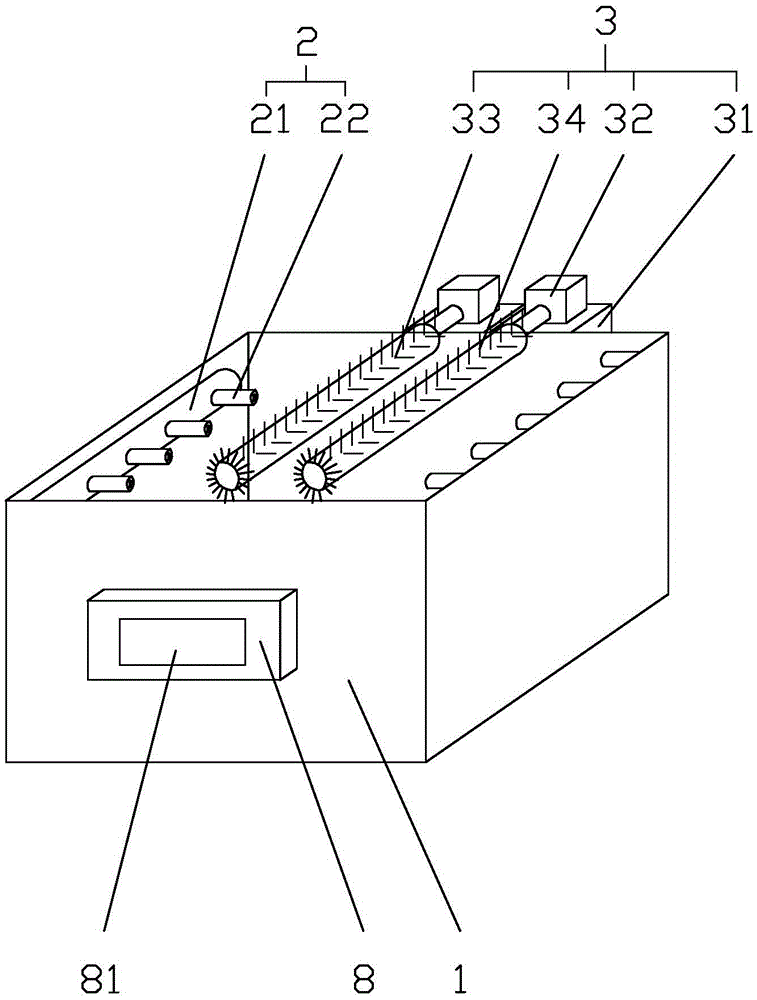

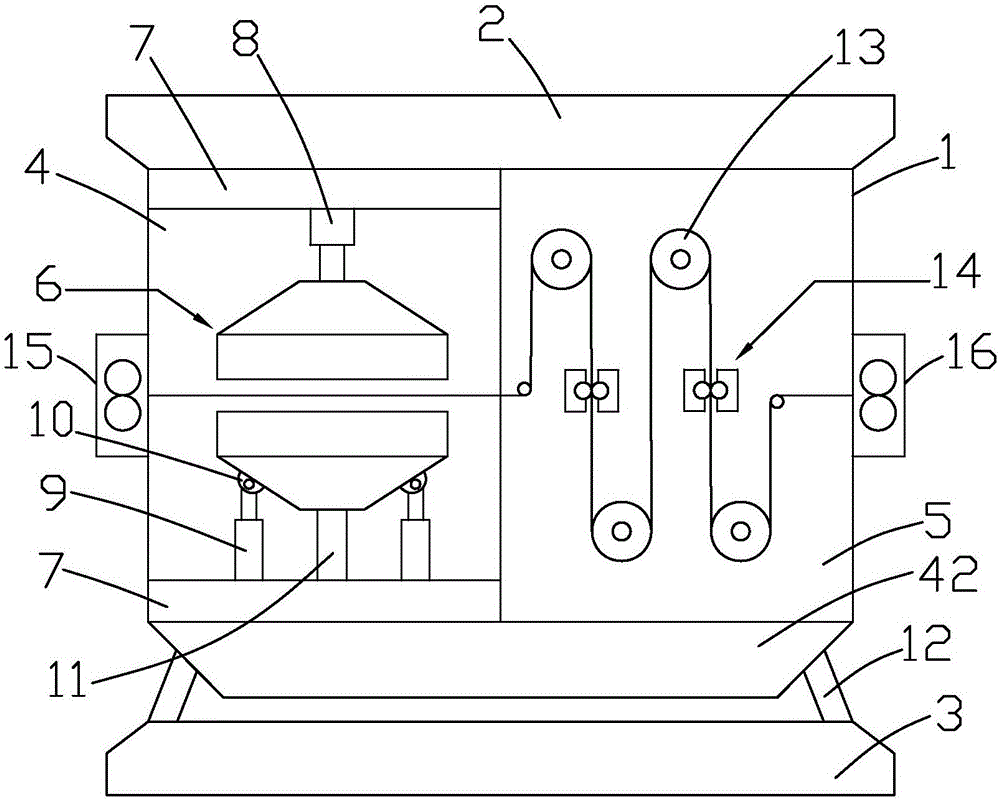

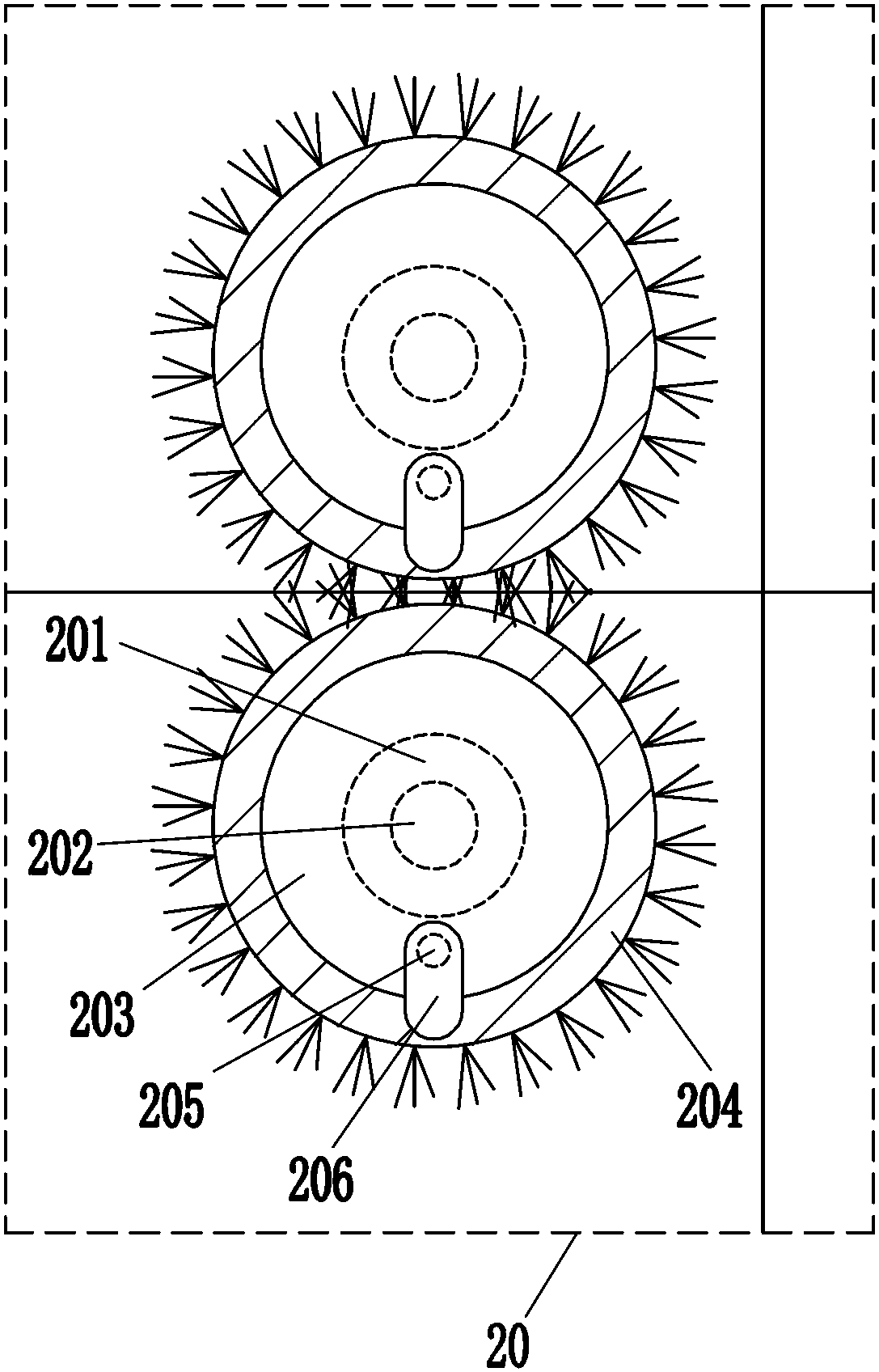

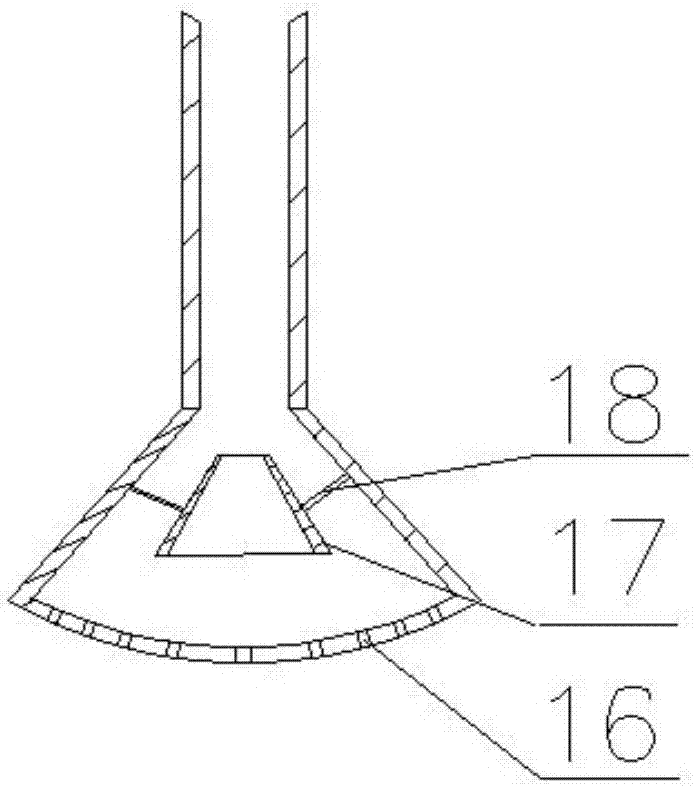

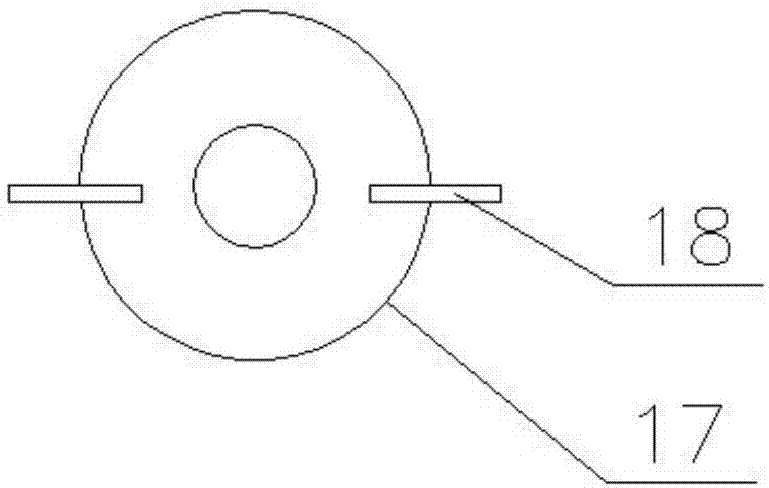

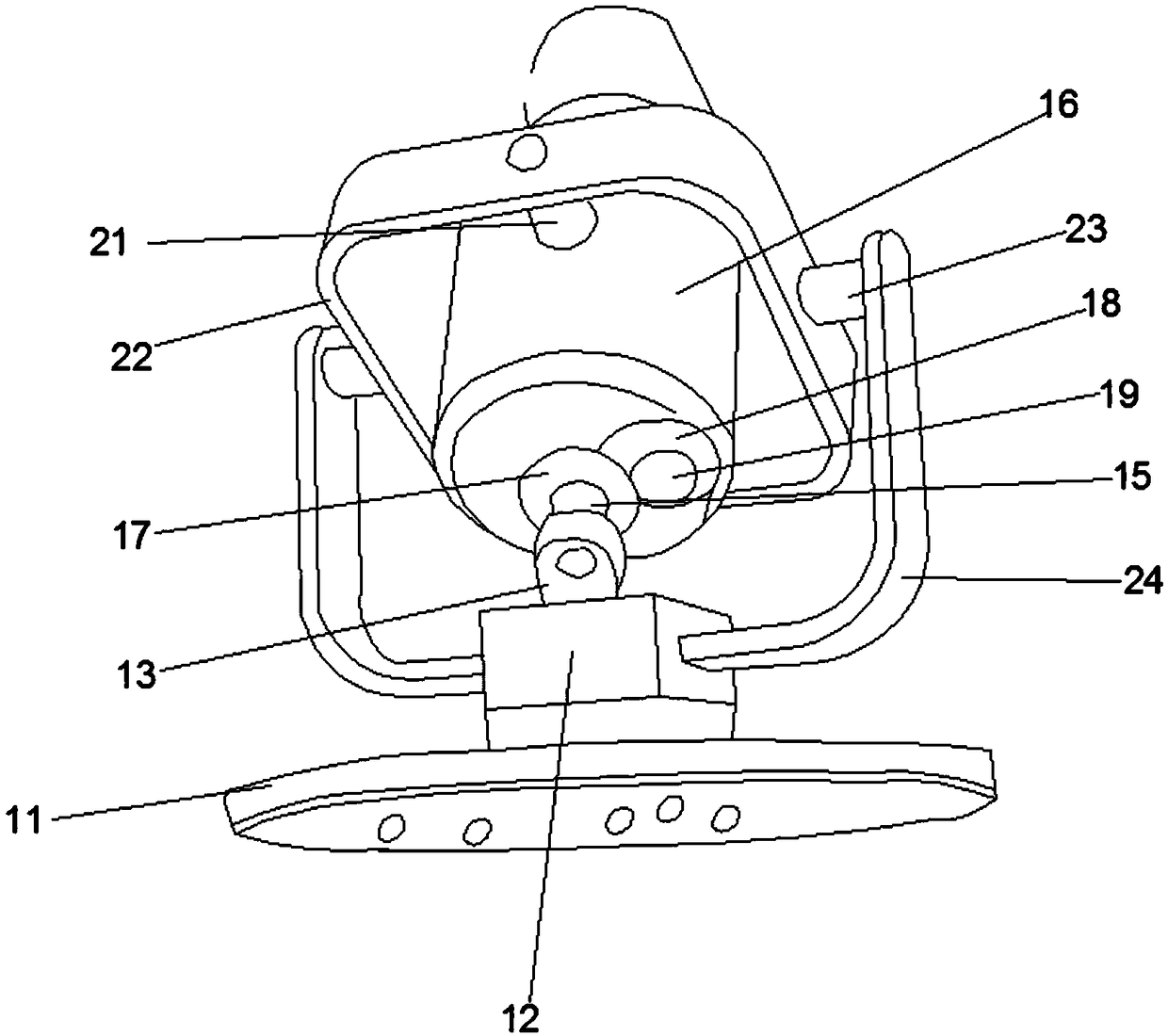

Non-woven fabric rapid cleaning, dewatering and clearing device for textile production

InactiveCN111748941ASolve efficiency problemsResolution timeLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor removal by suctionStructural engineeringNonwoven fabric

The invention relates to the technical field of non-woven fabric processing equipment, and discloses a non-woven fabric rapid cleaning, dewatering and clearing device for textile production. The non-woven fabric rapid cleaning, dewatering and clearing device comprises a fixing plate, wherein the fixing plate comprises a guide block, a fixing block, a sliding rod, a third spring and a second guideroller; a magnet piston comprises a vent groove, an arc-shaped groove and a swing plate; an arc-shaped magnetic block is arranged on the inner wall of a driving roller; a T-shaped magnetic block is connected to the interior of the guide block in a sliding mode; and a rubber ball is connected to the outer side end of a rope. The arc-shaped magnetic block moves upwards, the arc-shaped magnetic blockadsorbs the magnet piston to move downwards, and gas in the magnet piston enters an air bag through an air inlet pipe; and when the arc-shaped magnetic block moves to the upper side, the arc-shaped magnetic block adsorbs the magnet piston to move upwards, the lower part of the T-shaped magnetic block drives the rope to pull the rubber ball through the second guide roller, and the gas in the air bag clears fluff on sponge, so that the fluff on the sponge is prevented from being adhered to the non-woven fabric again or accumulated on the sponge again.

Owner:池志琴

Cleaning device for textile fabric

InactiveCN107904827AEasy to cleanSolve the problem of unsatisfactory cleaning effect and reduce the quality of fabric productionTextile treatment machine partsLiquid/gas/vapor removal by squeezing rollersEngineeringUltrasonic generator

The invention discloses a textile cloth cleaning device, which comprises a shell, an ultrasonic generator is fixedly installed at the middle end of the bottom of the inner cavity of the shell, an electric telescopic rod is fixedly connected to the bottom of the inner cavity of the shell and located outside the ultrasonic generator, and the electric The top of the telescopic rod is fixedly connected with a movable plate, the inner surface of the movable plate is movably installed with a second cleaning roller, and the right end of the outer surface of the movable plate is fixedly installed with a third motor, and the output shaft of the third motor is fixedly connected with the second cleaning roller . In the present invention, cleaning brushes are fixedly connected to the outer surfaces of the first cleaning roller and the second cleaning roller, and through the effects of bubblers, pipelines and ultrasonic generators, the cleaning effect on the cloth can be improved, and at the same time, the electric telescopic rod can Adjusting the horizontal position between the second cleaning roller and the first cleaning roller enhances the cleaning strength of the cloth, and solves the problem that the cleaning effect of the existing cleaning device is not satisfactory and the production quality of the cloth is reduced.

Owner:吴江市恒达纺织整理有限公司

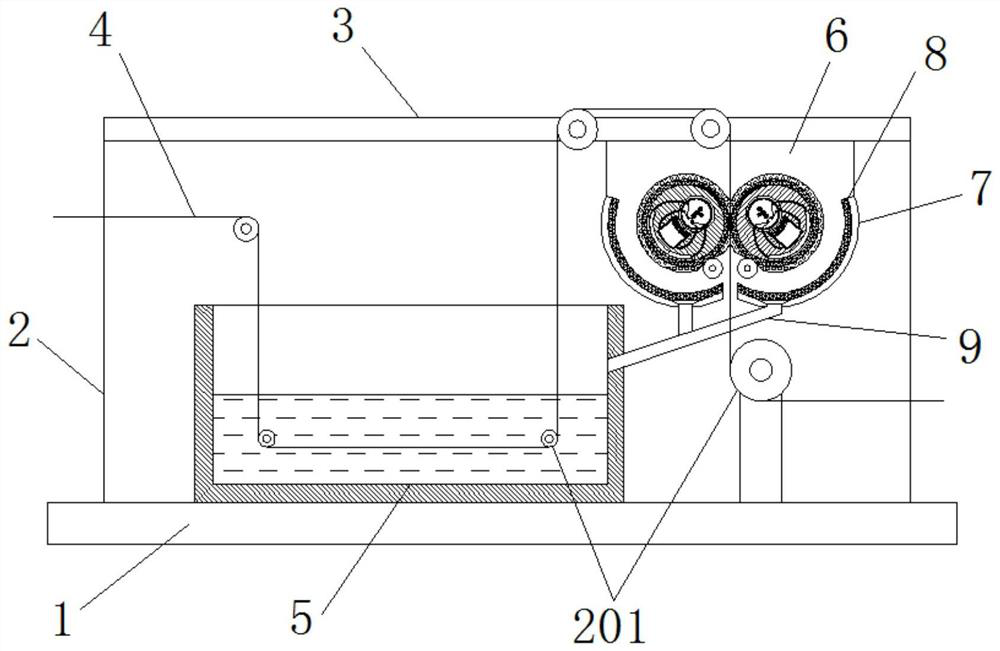

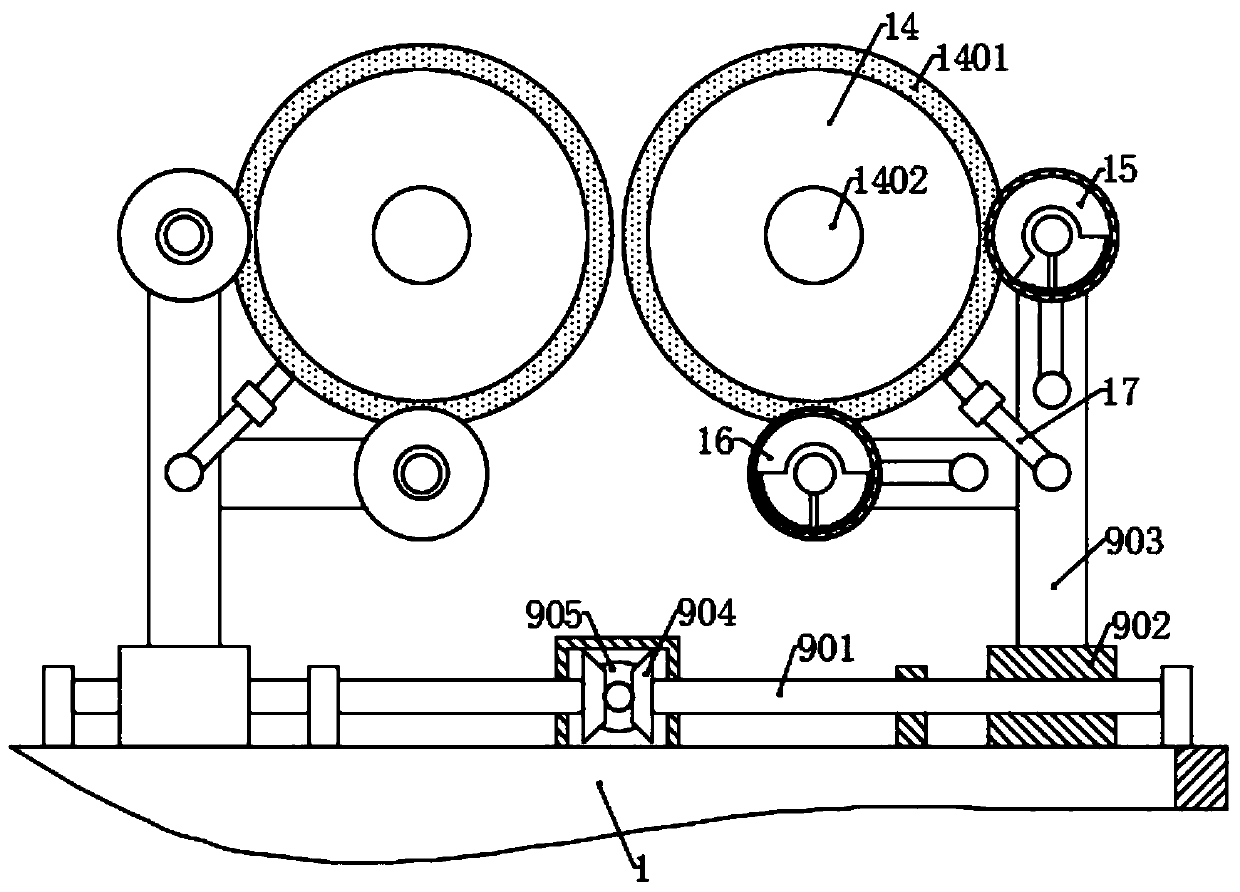

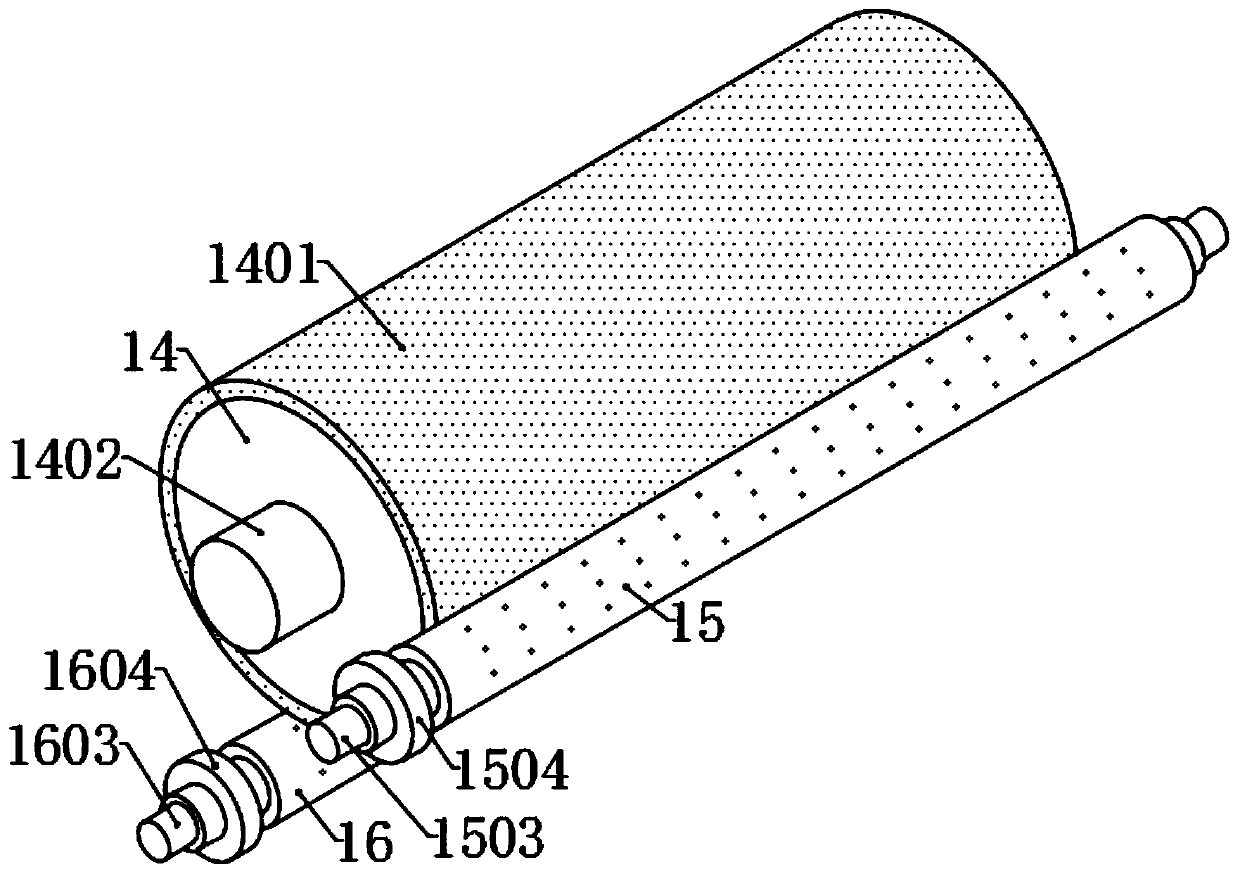

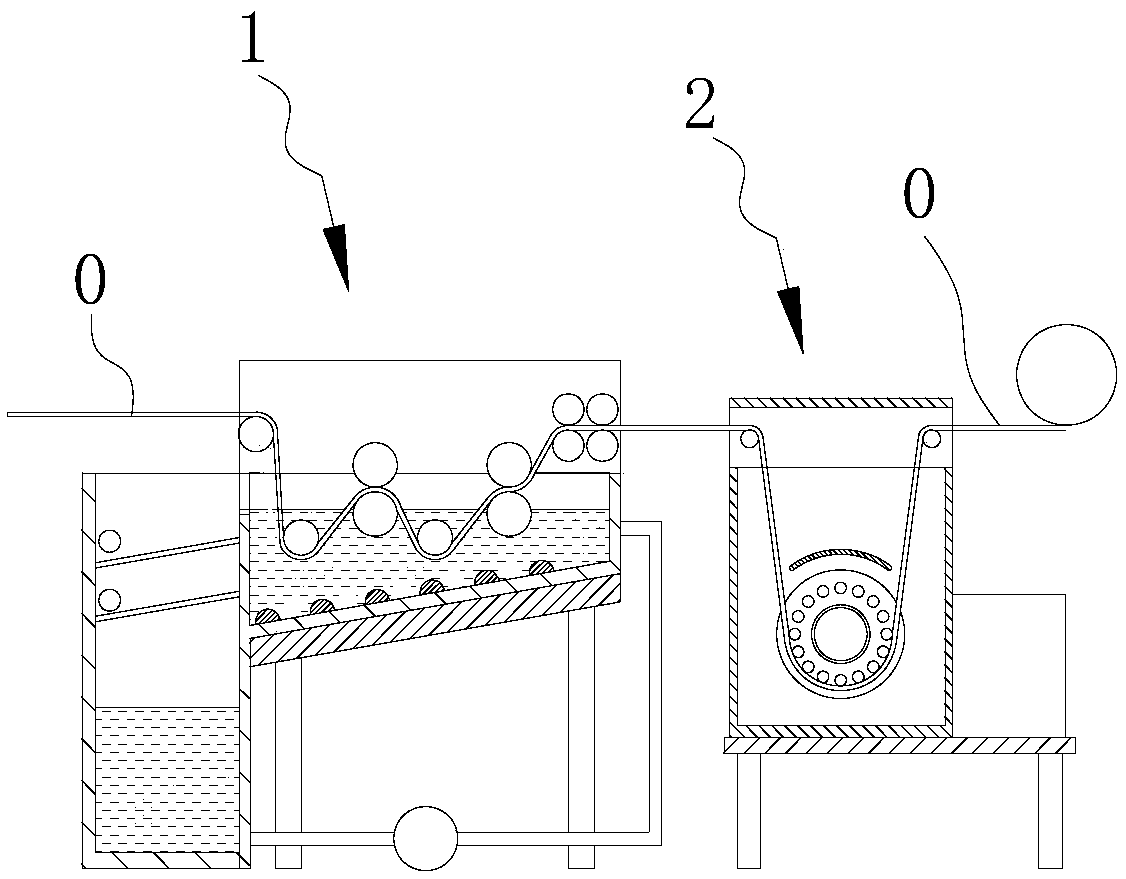

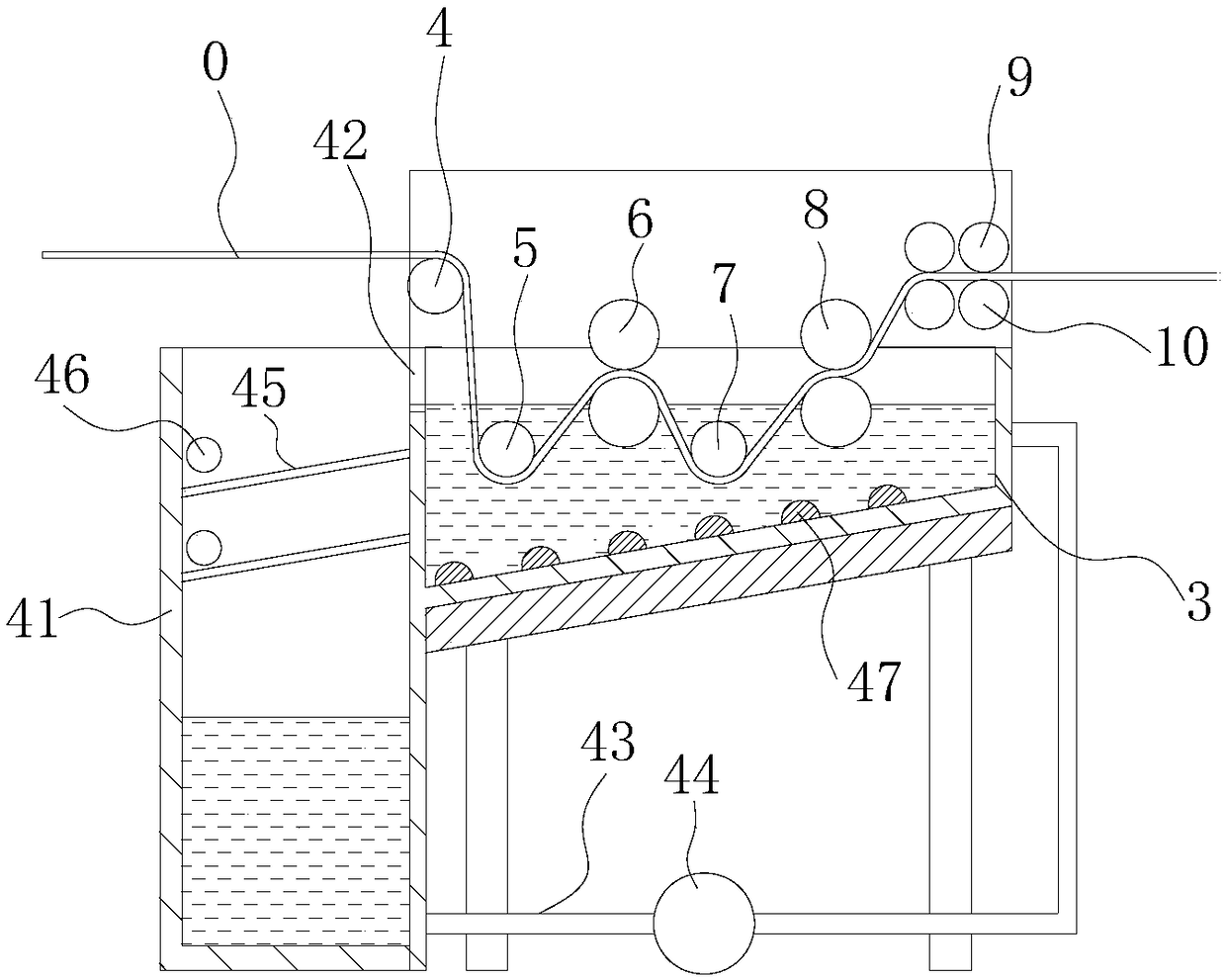

Rapid cloth cleaning equipment for textile processing

InactiveCN110924001AEasy to cleanEasy to dryLiquid/gas/vapor removal by suctionTextile treatment cleaning apparatusProcess engineeringMechanical engineering

The invention discloses rapid cloth cleaning equipment for textile processing, and belongs to the technical field of textile processing. The rapid cloth cleaning equipment comprises a cleaning tank, adischarging cylinder, a material collecting cylinder, a drying mechanism, a hot air drying mechanism and adjusting mechanisms. According to the rapid cloth cleaning equipment for textile processing,the cloth is discharged through the discharging cylinder, and then the cloth is movably cleaned in water through the effects of a first guide wheel, a second guide wheel and a third guide wheel; thenwater absorption is carried out through sponge layers on two oppositely rotating drying cylinders after cleaning is performed, and hot air drying is conducted through the hot air drying mechanism after water absorption is performed; when the sponge layer after water absorption is subjected to the extrusion of a first water squeezing cylinder, the sponge layer is kept at relative humidity so as tocontinuously absorb water and dry the subsequent cloth; a second water squeezing cylinder further squeezes the sponge layer, and after the sponge layer works for a period of time, the sponge layer issprayed with clean water through a water outlet pipe; and then a second water collecting pipe is adopted for squeezing and de-watering, and the sponge layer is cleaned, so that the sponge layer is kept relatively clean.

Owner:安徽云至信电子商务有限公司

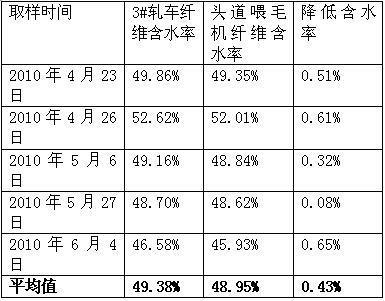

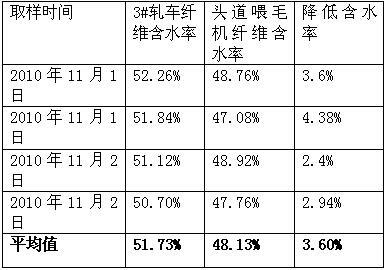

Drying process during viscose production

ActiveCN102080316AReduce moisture contentIncrease productionLiquid/gas/vapor removal by suctionTextile treatment machine arrangementsPulp and paper industryViscose fiber

The invention relates to a drying process during the viscose production, which can improve the drying capability to solve the problem that the improvement of the drying capability is limited by various reasons and can not be improved in prior art. In the invention, working procedures are added between wet cotton opening and a feeder, and waste hot air discharged during the drying passes through a heater to heat the fiber so as to achieve the purpose of reducing the water content of the fibers; therefore, 3-5% of water content of the fibers after the wet cotton opening is reduced, and the yield is greatly increased.

Owner:CHENGDU GRACE FIBER +1

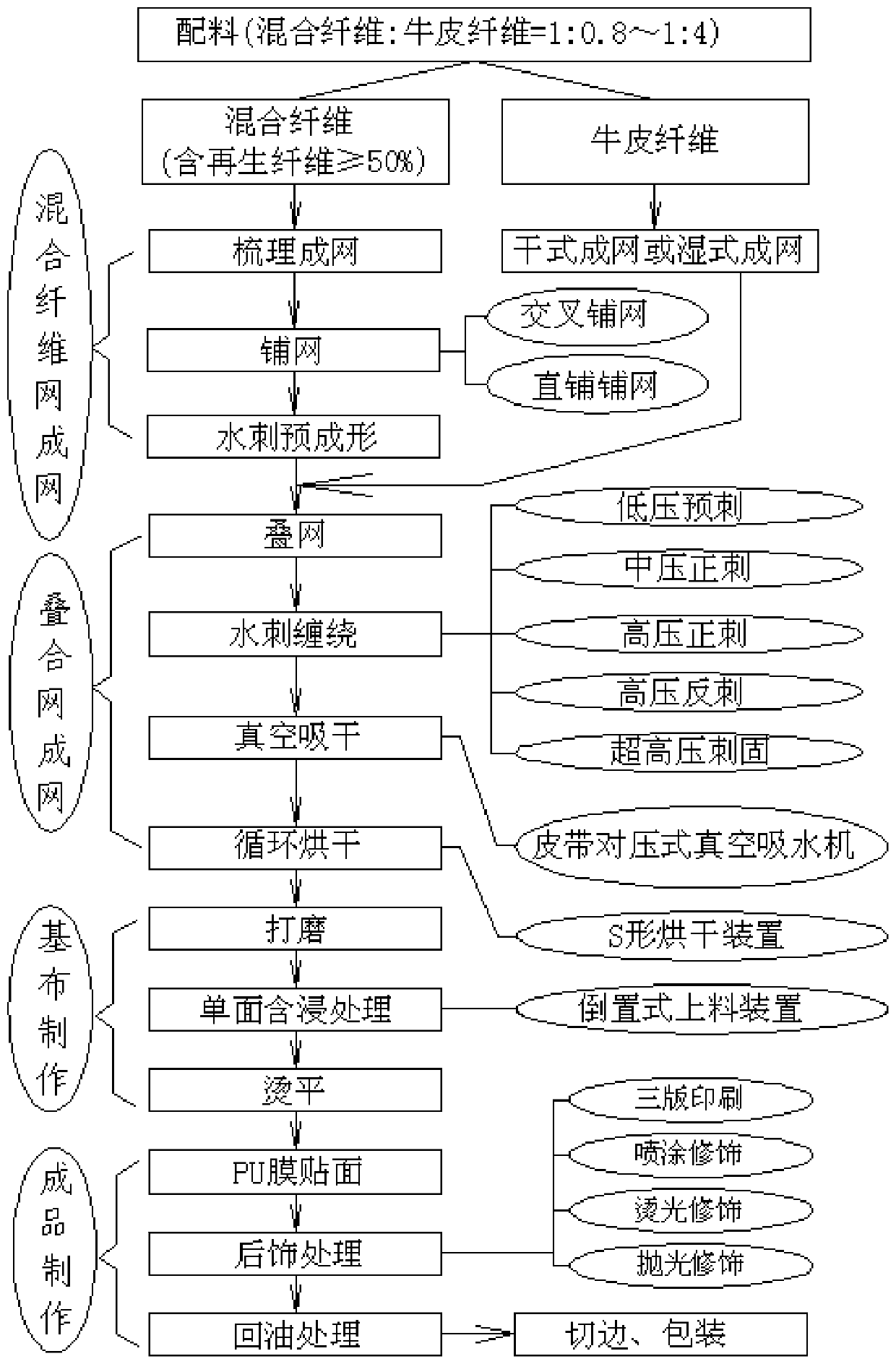

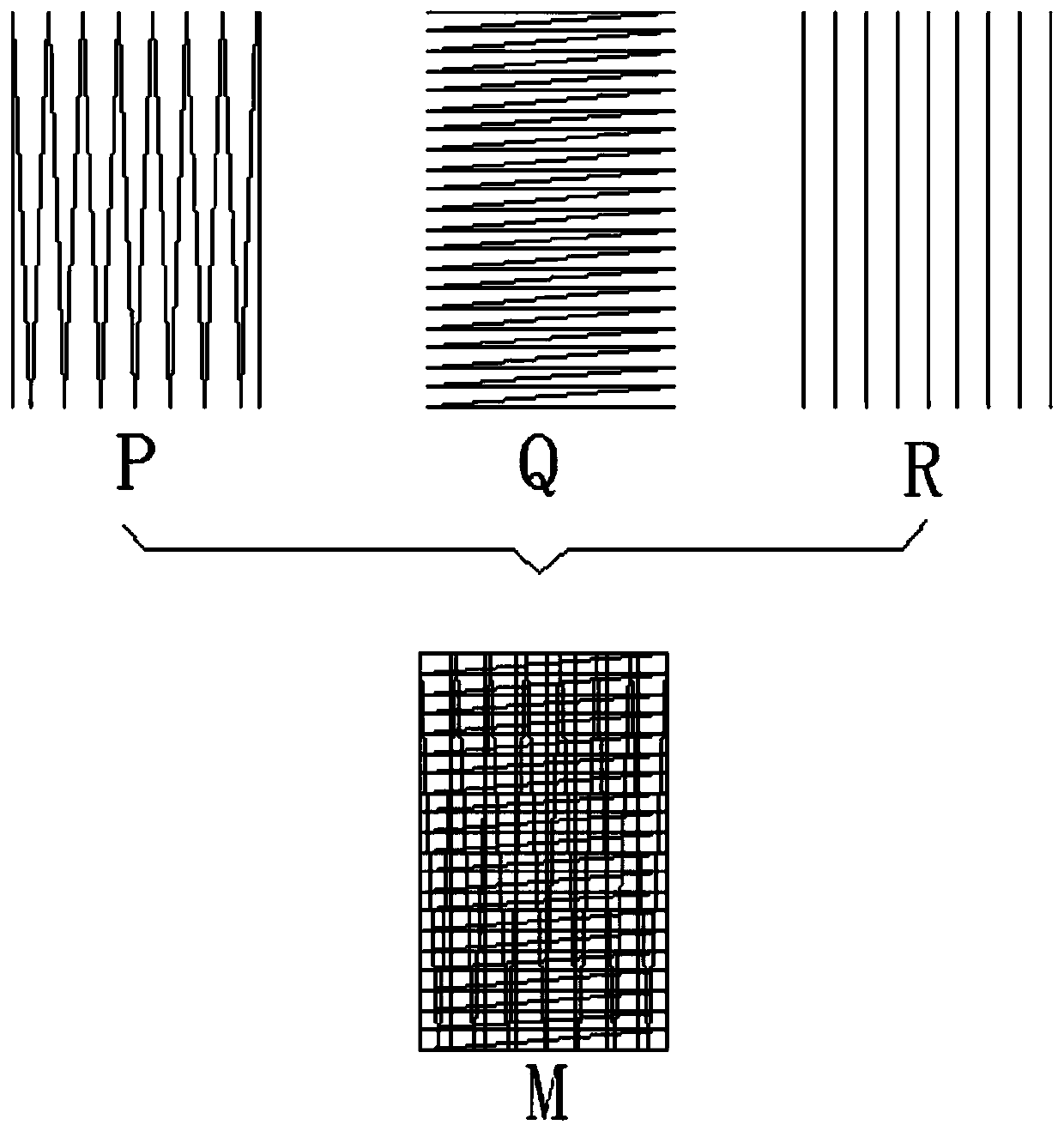

Preparation process of spunlace winding type cyclic cow leather

ActiveCN110331516AImprove physical performanceIncreased durabilityLamination ancillary operationsDrying solid materials without heatWater basedFiber

The invention relates to the technical field of leather manufacturing and discloses a preparation process of spunlace winding type cyclic cow leather. The preparation process comprises a matching process, a cow leather fiber web forming process as well as a mixed fiber web forming process, a stacked web forming process, a base cloth production process and a finished cow leather product productionprocess which are set sequentially according to the preparation process; the base cloth production process comprises a polishing process, a single-sided impregnation process and an ironing process which are set sequentially to produce a stacked web into base cloth; the single-sided impregnation process includes performing single side coating treatment with a water-based PU material or an oil-basedPU material as a coating on a single side of the base cloth by adopting an inverted feeding device so as to form a single-sided permeation impregnation layer of the base cloth. The physical performance and hand feel of the cow leather product are improved, the sense of genuine leather is enhanced, and meanwhile, energy consumption in the production process is reduced.

Owner:JIANGYIN JUNHUA TEXTILE TECH

Desizing washing after-treatment equipment

InactiveCN105483963AGuaranteed cleanlinessImprove cleaning penetrationMechanical cleaningSucessive textile treatmentsBristleMotor drive

The invention mainly discloses desizing washing after-treatment equipment. According to the technical scheme, the desizing washing after-treatment equipment comprises an oscillating washing box. Two spraying devices, a fabric brushing device, a heater, a temperature sensor and a water level sensor are arranged in the oscillating washing box. The spraying devices are symmetrically arranged on the two sides of the oscillating washing box. The fabric brushing device is located above the spraying devices. The fabric brushing device comprises a fixed seat, a motor, a brush roll and bristles. The motor drives the bristles to brush fabric. A blow-off pipe and a water inflow pipe are further arranged in the oscillating washing box. The blow-off pipe is connected with a filtering device, the water inflow pipe is connected with a water replenishing device, the other side of the filtering device is connected with the water replenishing device, the fabric outlet side of the oscillating washing box is provided with a vacuum water absorption device connected with the water replenishing device, and an operating panel is arranged on the outer side of the oscillating washing box. The desizing washing after-treatment equipment is simple in structure, convenient to use and good in washing effect, working efficiency is improved, and water resources are saved.

Owner:SHENGZHOU YIHAI MOTOR PARTS FACTORY

Weftless cloth cleaning device having good cleaning effect

InactiveCN107385725AEasy to cleanClean upMechanical cleaningPressure cleaningWaste collectionEngineering

The invention provides a weft-free cloth cleaning device with good cleaning effect, which relates to the textile field. The non-weft cloth cleaning device with good cleaning effect includes a cleaning box, a fixed box is fixedly installed on the top of the cleaning box, a first motor is fixedly connected to one side of the inner wall of the fixed box, and the output end of the first motor is fixedly connected to There is a threaded rod, the end of the threaded rod away from the first motor is threadedly connected with a bearing seat, the end of the bearing seat away from the threaded rod is fixedly connected with the inner wall of the fixed box, and the inside of the fixed box is provided with a movable sleeve. The non-weft cloth cleaning device with good cleaning effect has a simple structure and is easy to operate. Through the action of the vacuum cleaner installed on one side of the cleaning box, some sundries on the produced non-weft cloth are absorbed by the waste collection container on the side of the vacuum cleaner. The interior will be more clean during cleaning, which is convenient for the cleaning of the non-weft cloth, which solves the troublesome problem of the current non-weft cloth cleaning.

Owner:范威

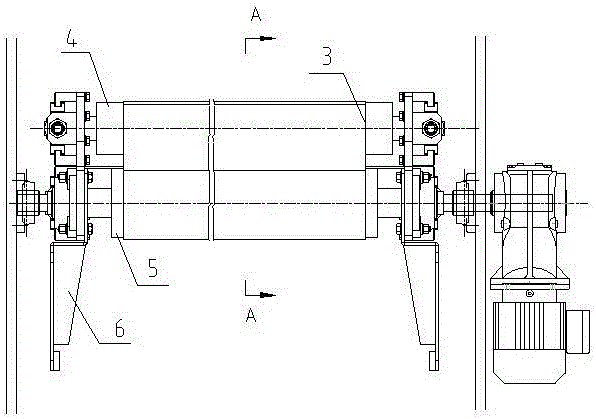

Quick-dry type sizing machine

ActiveCN109440333ALow moisture regainReduce energy consumptionLiquid/gas/vapor removal by suctionTextile treatment machine arrangementsYarnPulp and paper industry

The invention relates to the technical field of textiles and aims to provide a quick-dry type sizing machine capable of sharply reducing moisture regain before drying. The technical scheme includes that the quick-dry type sizing machine comprises a sizing machine body and a drying box in sequential arrangement along a yarn conveying direction; the sizing machine body comprises a sizing tank whichis provided with a sizing mechanism; the sizing mechanism comprises a yarn guide roller, a first immersion roller, a first sizing roller group, a second immersion roller, a second sizing roller groupand a dewatering roller group in sequential arrangement along a yarn conveying direction. Each of the first sizing roller group and the second sizing roller group comprises an upper pressing roller and a lower sizing roller, and yarns penetrate a space between the upper sizing roller and the pressing roller. The dewatering roller group comprises an upper suction roller and a lower suction roller,and the yarns penetrate a space between the upper suction roller and the lower suction roller. Before the yarns enter the drying box, the yarn moisture regain can be reduced, and subsequent drying isfacilitated.

Owner:叶江波

Textile processing equipment

ActiveCN108517639AReduce speedHigh degree of automationLiquid/gas/vapor removal by suctionTextile treatment machine arrangementsMotor driveElectric machinery

The invention relates to the field of textile processing, and particularly discloses textile processing equipment. The textile processing equipment comprises a rack, and further comprises a water wiping mechanism, a water absorbing roller, an ironing mechanism, a drying roller, a material collecting roller, a first motor and a second motor, wherein the water wiping mechanism, the water absorbing roller, the ironing mechanism, the drying roller, the material collecting roller, the first motor and the second motor are arranged on the rack in the horizontal direction in sequence, the first motordrives the water absorbing roller, and the second motor drives the material collecting roller; the water wiping mechanism is arranged at the discharging end of a textile, the material collecting roller is arranged at the material collecting end of the textile, the water wiping mechanism comprises several water wiping rollers facing the water absorbing roller, the water wiping rollers are divided into a first water wiping set and a second water wiping set, the first water wiping set and the second water wiping set are opposite, the first water wiping set is rotatably connected with the rack, and a water wiping plate is fixedly connected to the second water wiping set. The textile is processed through the four motions of water wiping, water absorbing, ironing and drying in sequence, and thenthe textile is also reeled after being processed; the automated degree is high, and the processing efficiency is high; moreover, when processed by multiple processing steps, the textile does not needto be carried and can be processed at a time, and the time and labor are saved.

Owner:NINGBO WENZE TEXTILE CO LTD

Textile dyeing device having drying effect

ActiveCN107503051AEasy to dryColoring firmLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor removal by suctionAir filterEngineering

A textile dyeing device having drying effect comprises a box, one side of the bottom of an inner cavity of the box is fixedly connected with a drainage tank, a position, below a supporting frame, of the bottom of the inner cavity of the box is fixedly connected with an air filtering device, the top of the supporting frame is fixedly connected with an air heating device, the top, positioned on one side of a through groove, of a supporting plate is fixedly connected with a dye box, a nozzle is positioned between the supporting plate and the drainage tank, one side, away from the through groove, of the bottom of the supporting plate is fixedly connected with a water extruding device, and an exhaust device is fixedly connected at a position, right above the air heating device, of the top of the box. The invention relates to the technical field of textile processing. The textile dyeing device can quickly dry and dye cloth for the convenience of the next process, product quality is ensured, quick and efficient dyeing is realized, uniformity and thoroughness in dyeing are guaranteed, no flaw is about to be generated, and redundant water and dye are enabled to leave the cloth and can be recycled, so that resources are saved, and environment is protected.

Owner:天龙数码印染科技有限公司

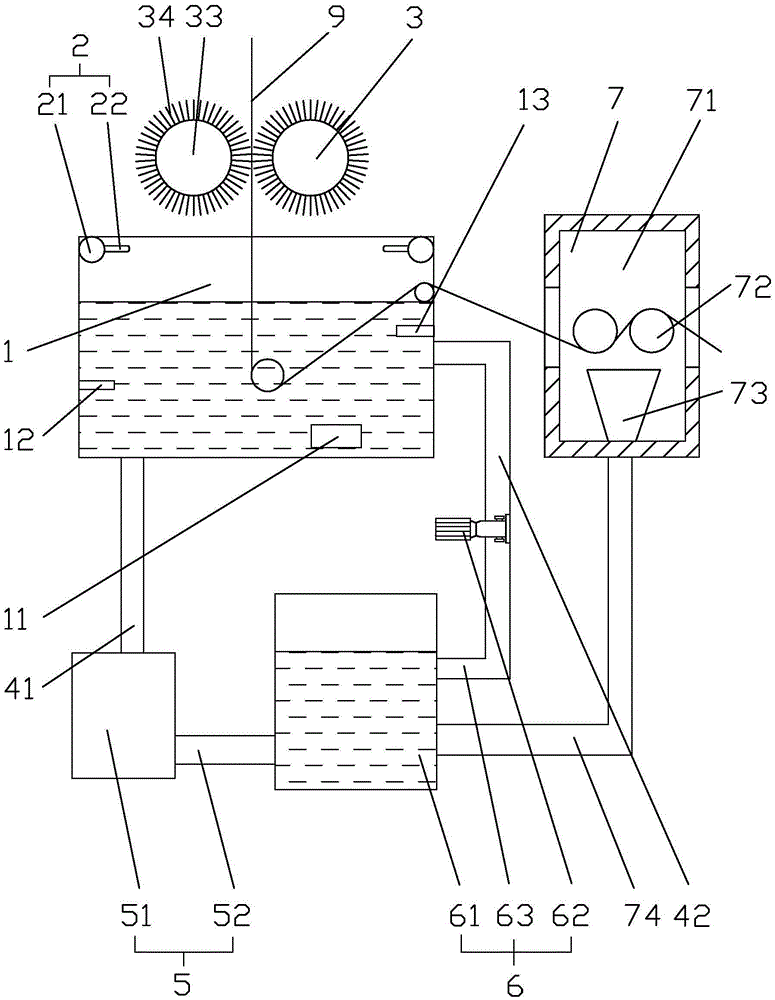

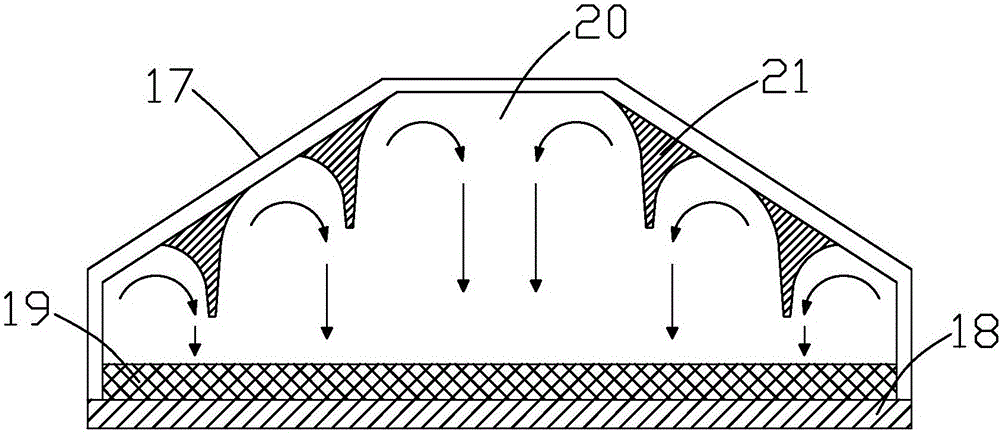

Steam ironing type cloth drying machine

InactiveCN106995993AIron evenlyEvenly heatedSucessive textile treatmentsTextile treatment containersPulp and paper industryEnergy consumption

The invention discloses a steam ironing type cloth drying machine which comprises a drying case (1). A cloth feeding roll (2) and a cloth pulling roll (3) are connected with two ends of the drying case (1); an arranging plate (4) is arranged inside the drying case (1), a steam plate (5) is arranged above the end, which is close to the cloth feeding roll (2), of the arranging plate (4), and a steam generator (6) is connected onto the steam plate (5); a hot wind plate (7) is arranged above the other end of the arranging plate (4), a heater (8) is connected onto the hot wind plate (7), and a blower (11) is connected onto the heater (8); a partition plate (10) is arranged between the steam plate (5) and the hot wind plate (7); an exhaust fan (11) is arranged on the top surface of the drying case (1), and a condenser (12) is connected onto the exhaust fan (11). The steam ironing type cloth drying machine has the advantages that good cloth drying effects can be realized, deformation of cloth can be eliminated, energy consumption can be reduced, the steam ironing type cloth drying machine is wide in application range, convenient to adjust and high in drying efficiency, and resources can be saved.

Owner:湖州南浔凯普纺织有限公司

High-performance sizing machine

ActiveCN109440334AEfficient removalQuality improvementLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor removal by suctionYarnEngineering

The invention relates to the technical field of textile, and aims to provide a high-performance sizing machine capable of improving yarn performances. The technical scheme includes that the high-performance sizing machine comprises a sizing machine body and a drying box which are sequentially arranged along the conveying direction of yarns, the sizing machine body comprises a stock tank and a return tank, a sizing mechanism is arranged on the stock tank, the return tank is positioned on one side, close to the incoming direction of the yarns, of the stock tank, an overflow port is formed in thetop of a tank plate between the stock tank and the return tank, redundant slurry in the stock tank can flow towards the return tank, the bottom of the return tank is communicated with the stock tankthrough a circulating pipe, a circulating pump is arranged on the circulating pipe, and a cleaning filter screen is arranged on the inner upper portion of the return tank and positioned on the lower portion of the overflow port. Impurities in the slurry can be effectively removed, the quality of the slurry is improved, the hairiness quantity of the yarns is decreased, and yarn quality is improved.

Owner:叶江波

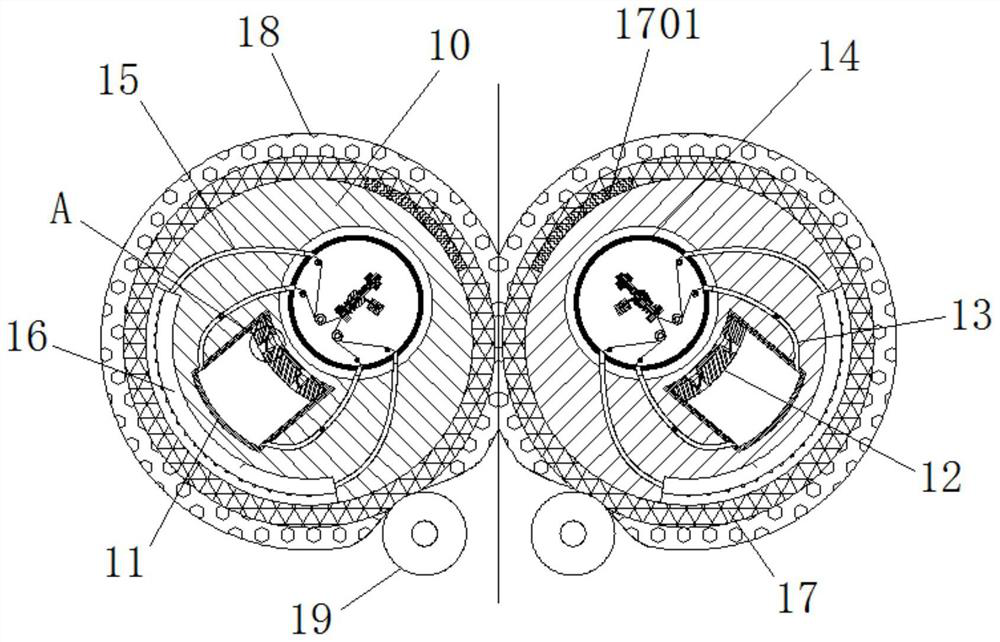

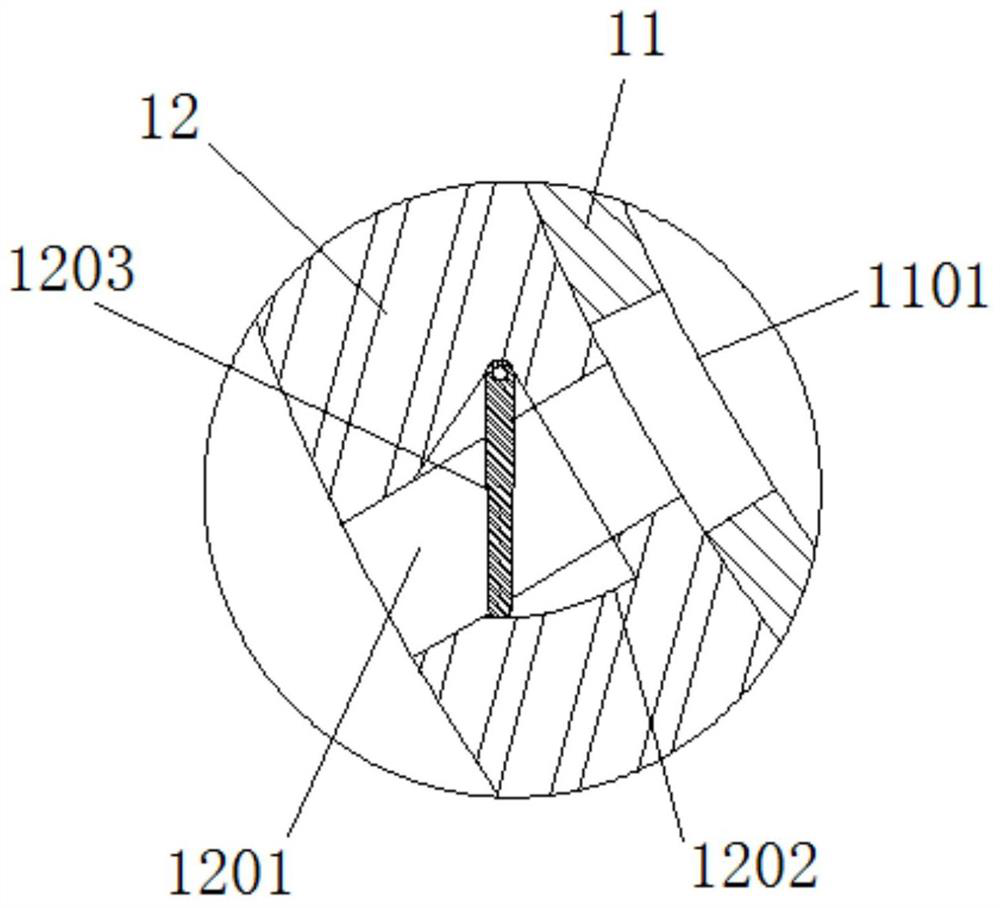

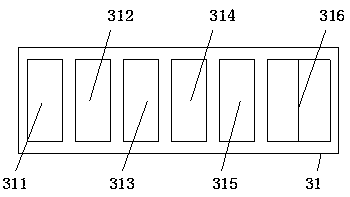

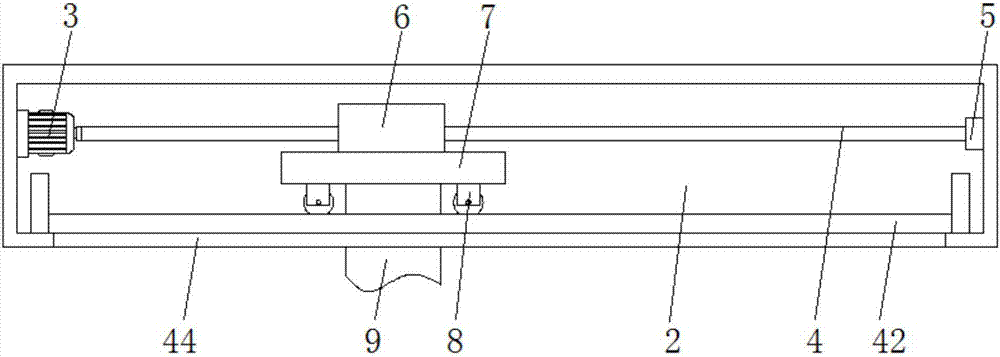

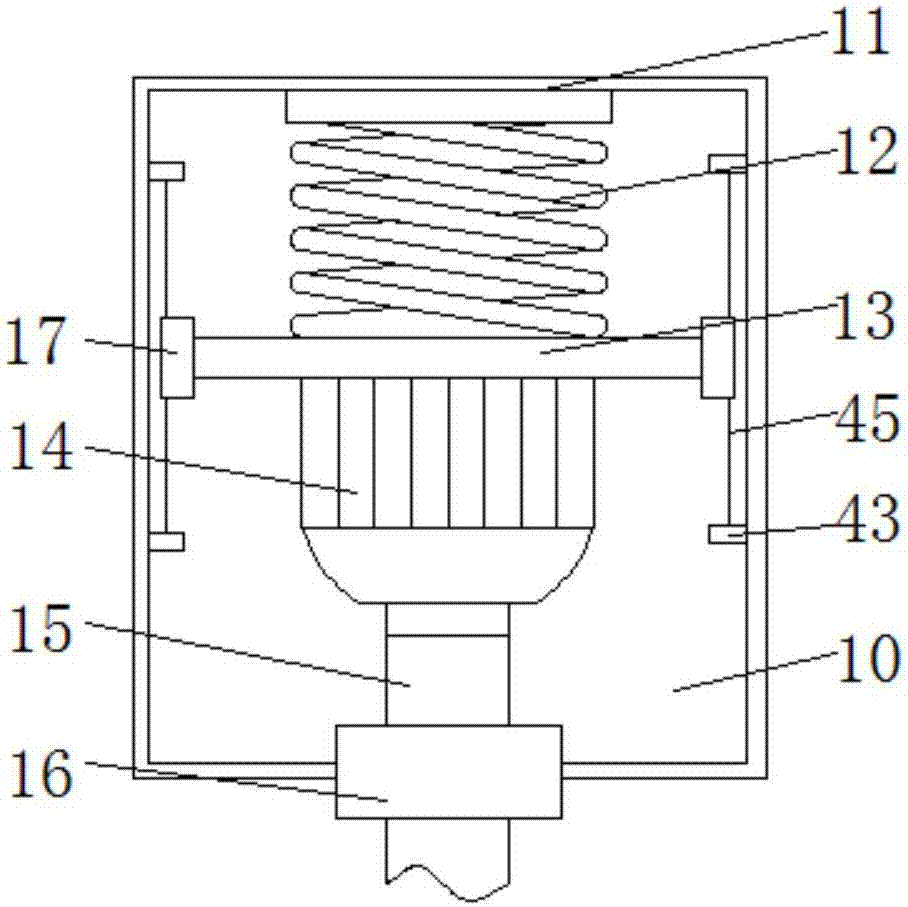

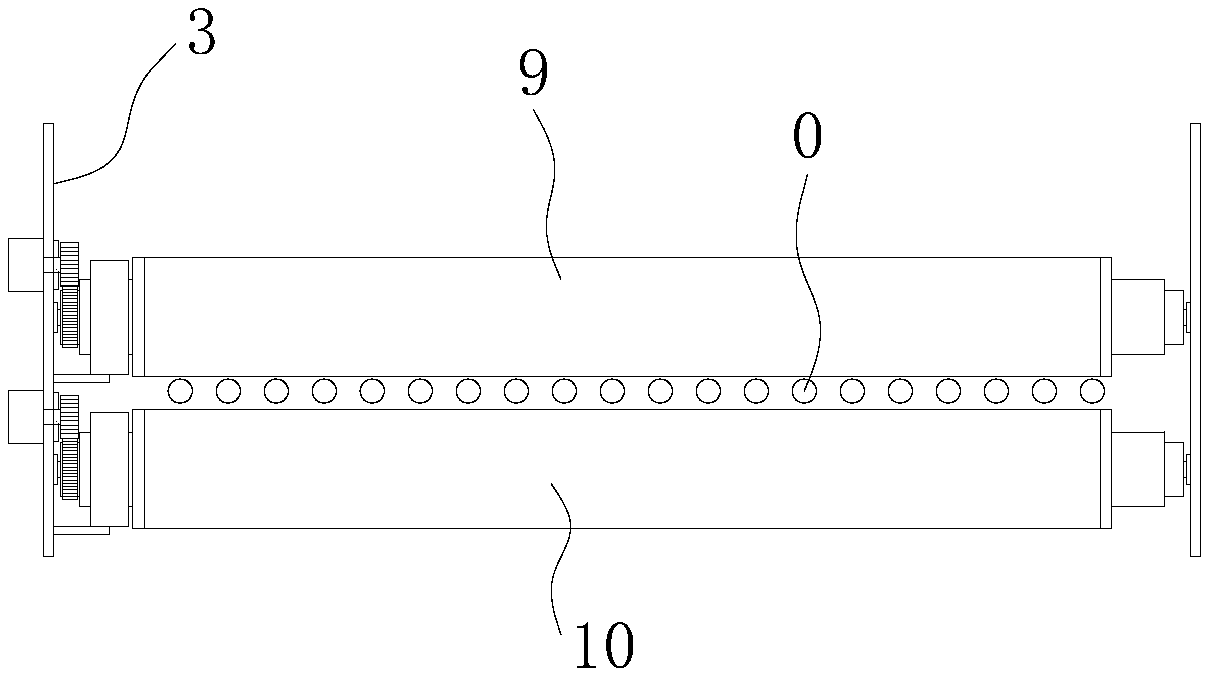

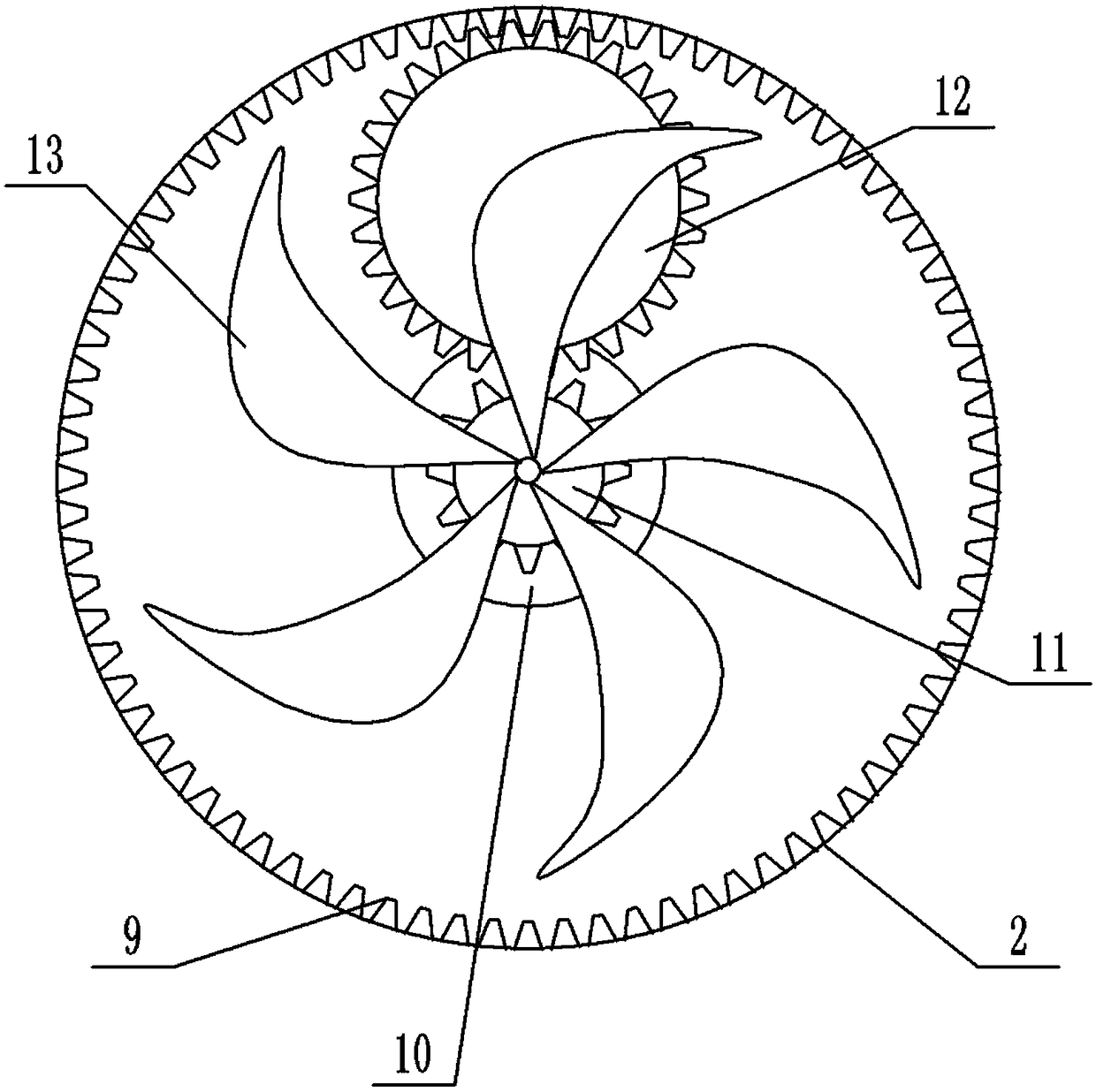

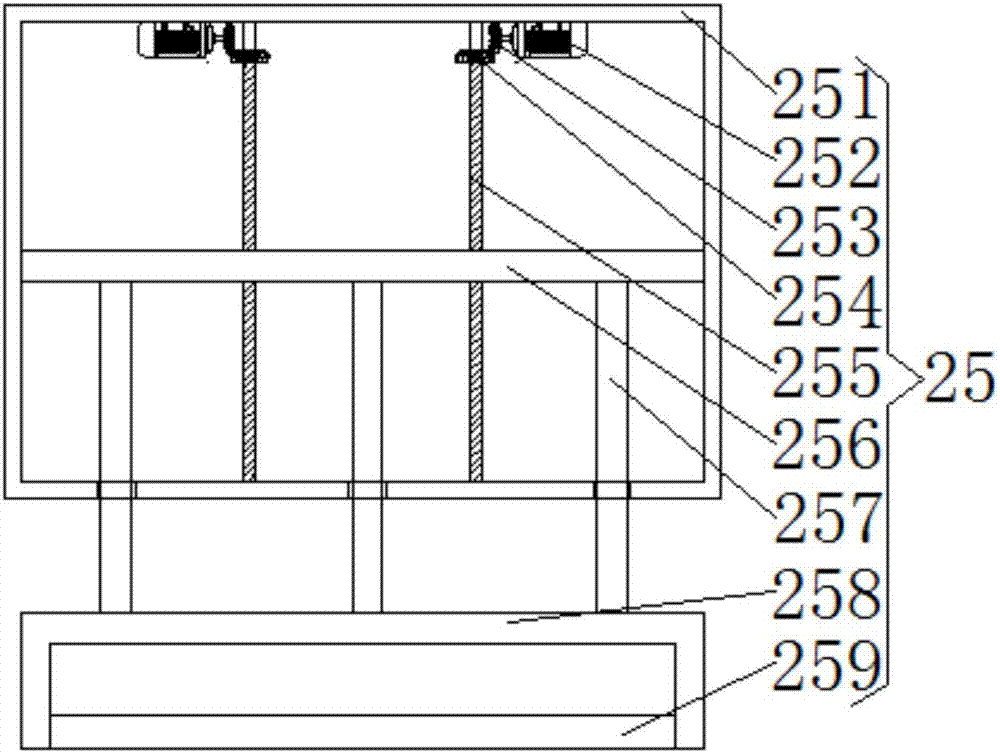

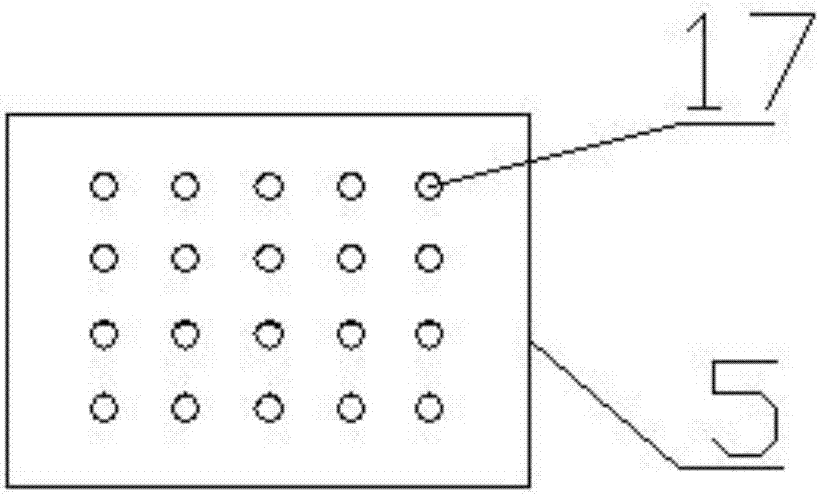

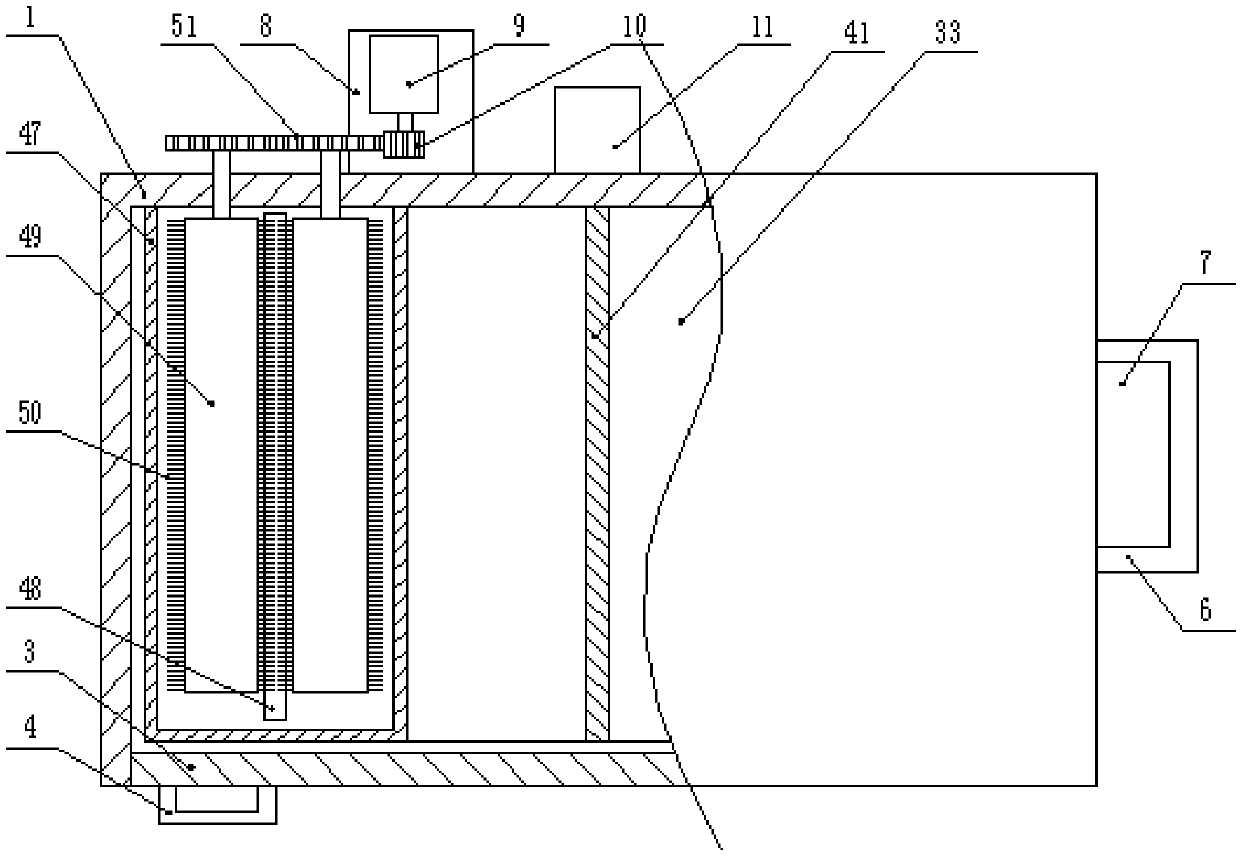

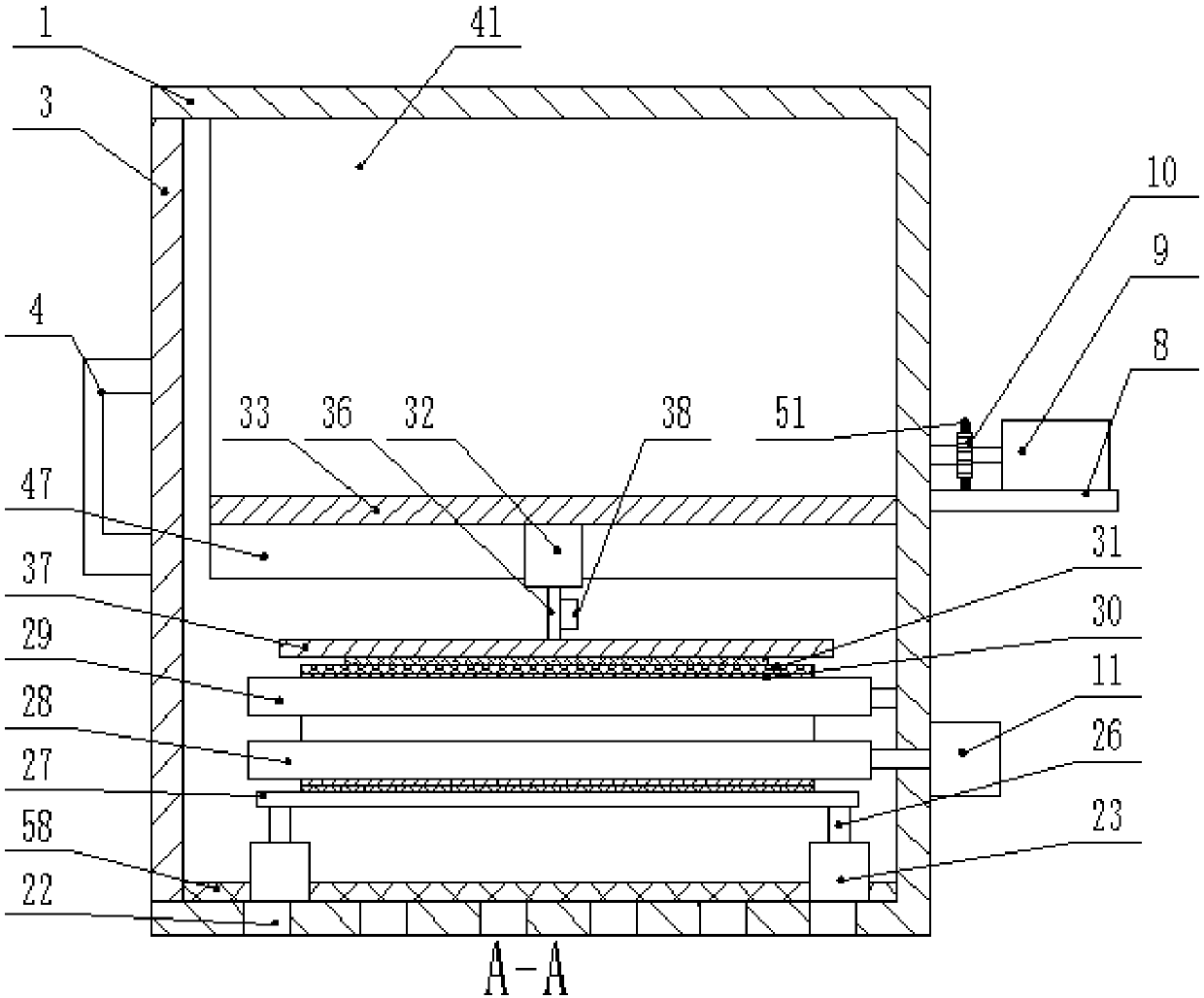

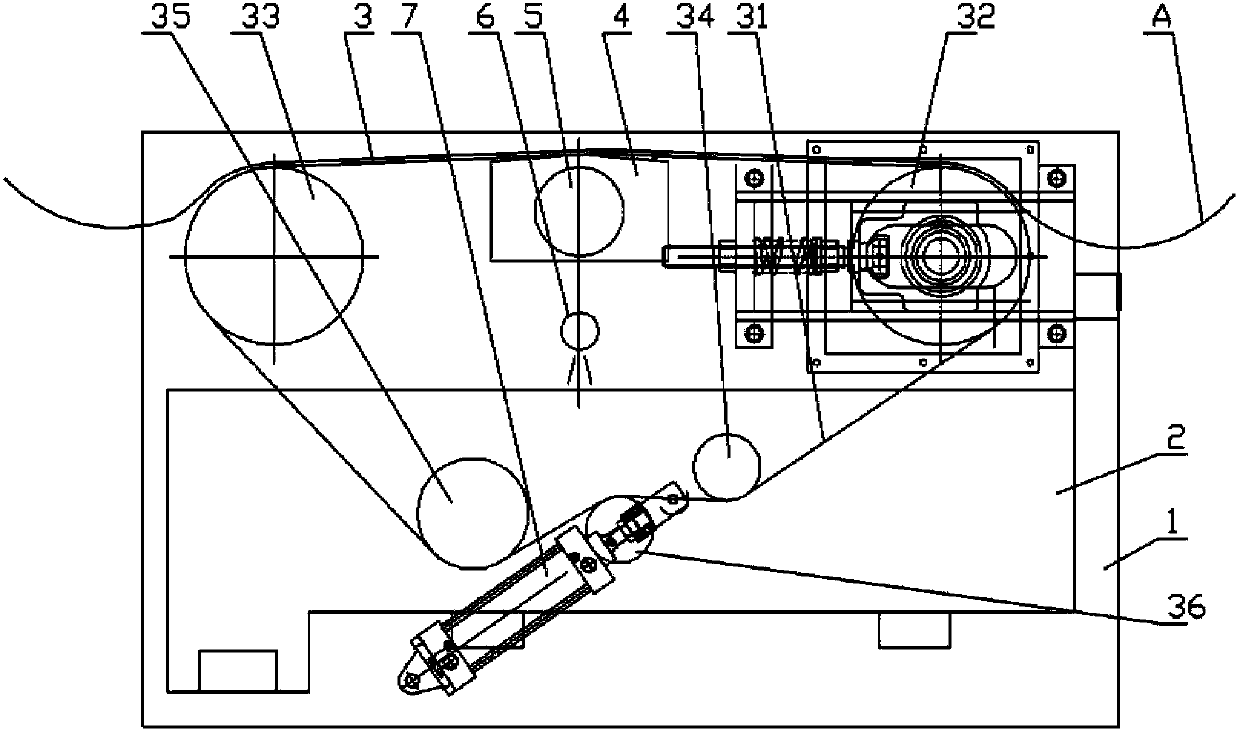

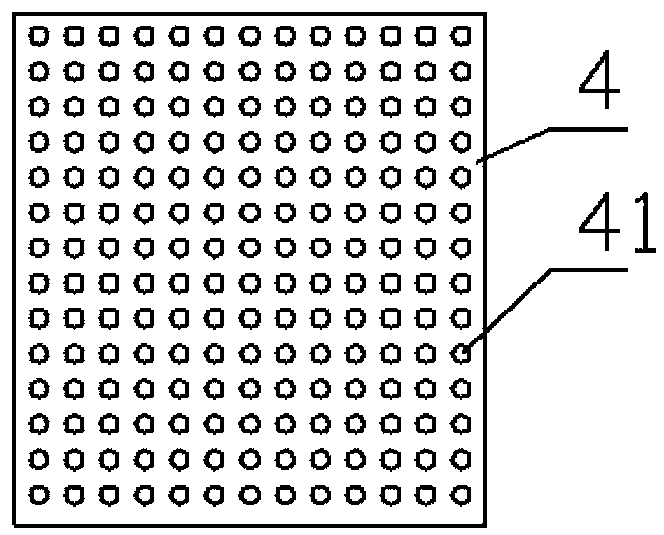

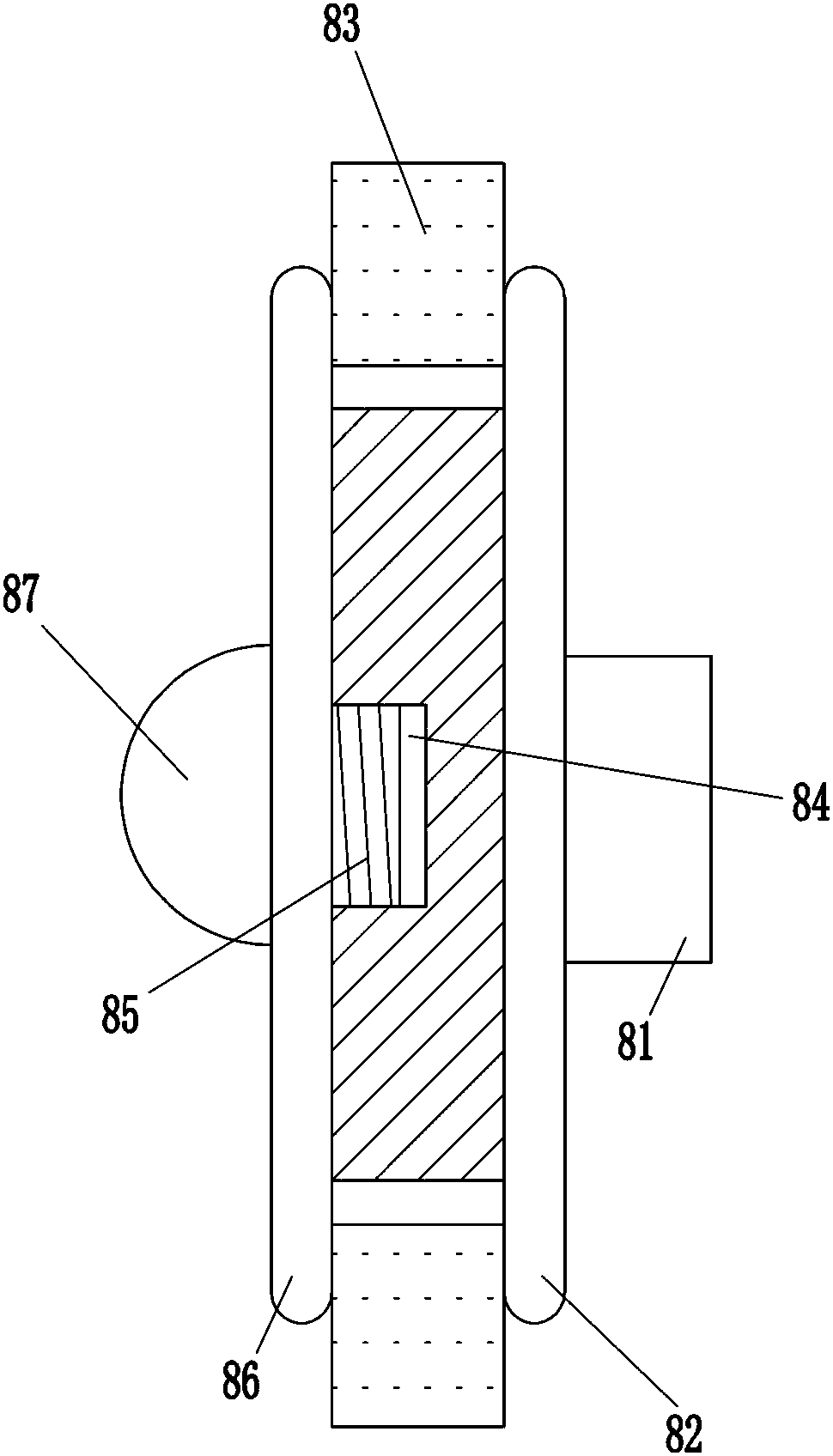

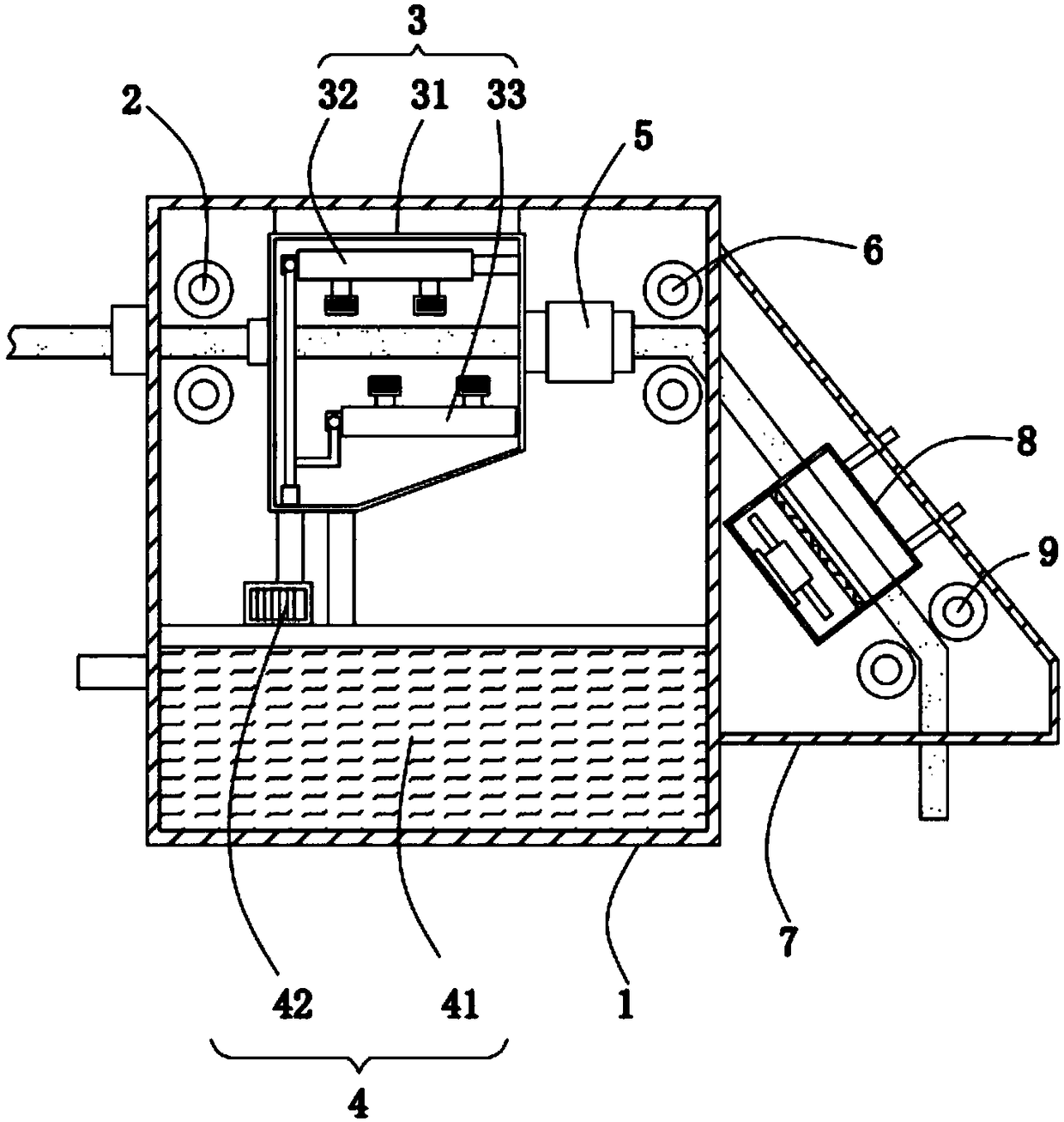

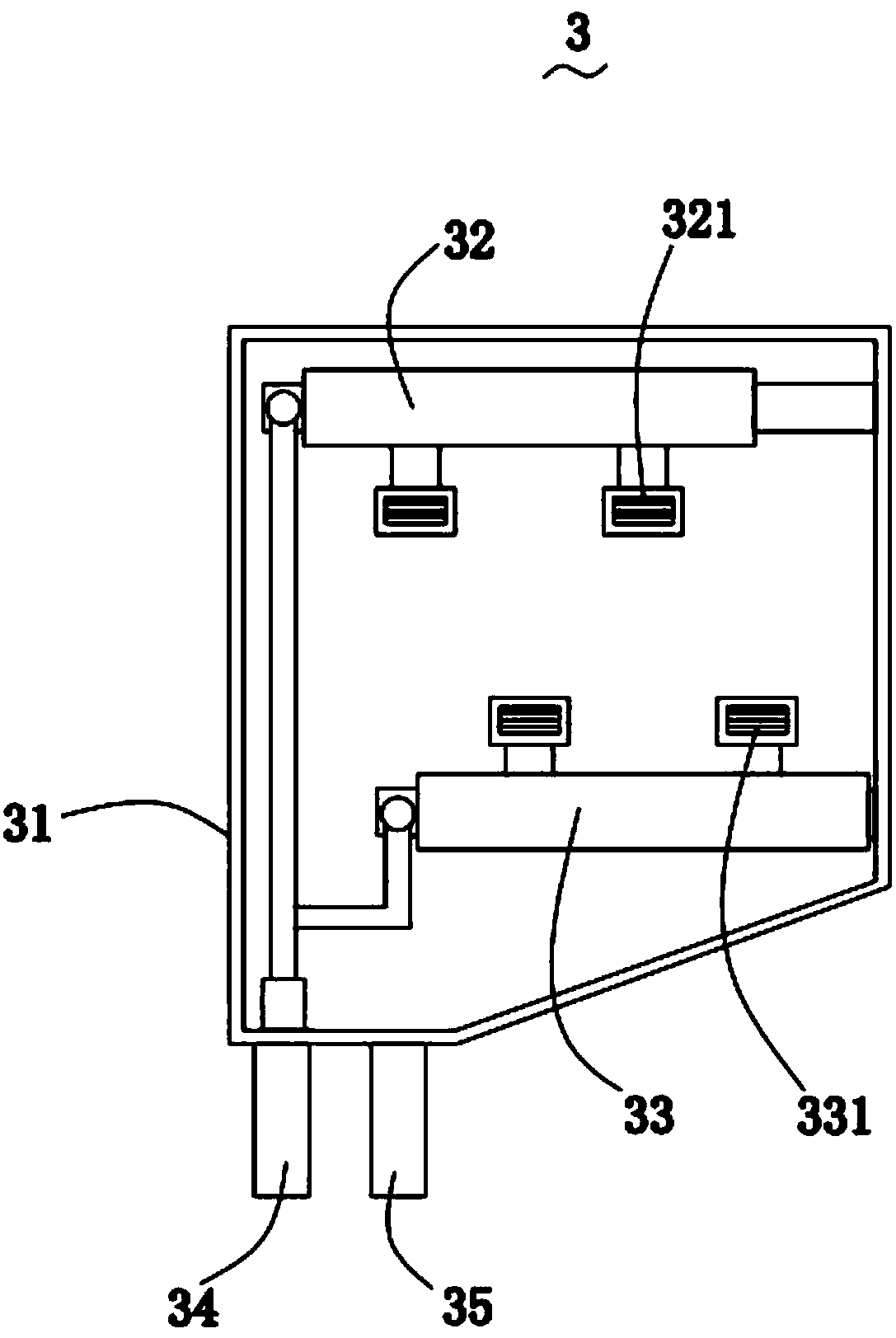

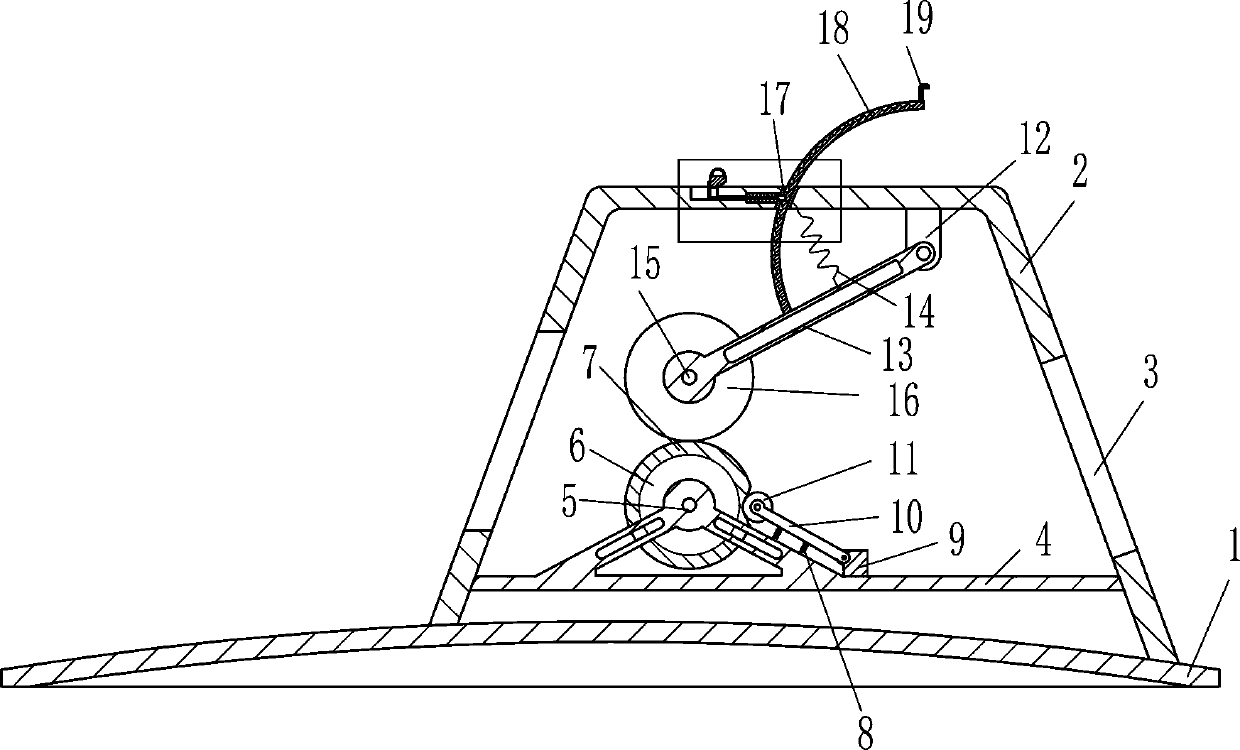

Full-width vacuum water suctioning device for knitting

ActiveCN106087312AEasy accessImprove stabilityLiquid/gas/vapor removal by suctionPulp and paper industryPermeation

The invention discloses a full-width vacuum water suctioning device for knitting. The full-width vacuum water suctioning device comprises a box body, wherein the box body is internally provided with a vacuum water suctioning cavity and a balanced extrusion cavity; the vacuum water suctioning cavity is internally provided with a vacuum water suctioning mechanism; first sliding grooves are arranged in the top surface and the bottom surface of the vacuum water suctioning cavity in parallel; the vacuum water suctioning mechanism is movably connected between the first sliding grooves; the balanced extrusion cavity is internally provided with traction rollers which are distributed in an S shape; a dragging mechanism is arranged between the upper traction roller and the lower traction roller; a supporting plate is arranged at the bottom part of the box body. The full-width vacuum water suctioning device disclosed by the invention has the advantages that the structure is simple, and the practicability is strong; by adoption of the vacuum water suctioning device, not only can semi-finished mercerized fabrics be forcibly permeated under the negative pressure in process liquid of strong caustic soda, no permeation can be realized, coils are not damaged, alkaline-containing liquid of fewer fabrics can enter the alkaline removing procedure, so that the alkaline removing load can be reduced; when the fabric suctions water, no additional tension for the fabric can be realized, and the alkaline removing effect is good and the energy-saving effect in the following process can be easily realized.

Owner:浙江瑞格机械科技有限公司

Cotton cloth dyeing device

InactiveCN109097927AImprove dyeing effectSolve wasteTextile treatment machine partsLiquid/gas/vapor removal by suctionCotton clothEngineering

The invention discloses a cotton cloth dyeing device which comprises a box. A supporting rod is fixed at each of four corners at the bottom end of the box, a box door is hinged on one side of the box,a handle is fixedly arranged on the box door, and an exhaust pipe is fixed at the top end of the box and communicated with the inside of the box. Pigment is sprayed to two sides of cloth from nozzleson a first pigment spraying box and a second pigment spraying box through a pigment supply pump, then two pigment brushing rollers are rotated through a motor, in this way, hairbrushes on the pigmentbrushing rollers can uniformly brush the pigment sprayed on the cloth to be flat, so that cloth dyeing effect is improved effectively; surplus pigment on the surface of the cloth is absorbed througha water absorbing sponge layer on a belt, so that the problem of pigment waste is solved effectively; the two sides of the cloth are dried from through holes in a first air box and a second air box through a hot air blower, so that a function of integrating dyeing with drying is realized effectively.

Owner:开平顺丰纺织有限公司

Cloth cleaning device

ActiveCN108166184ASolve the problem of residual water with floating colorsLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor removal by suctionYarnBobbin

The invention belongs to the technical field of textile auxiliary equipment, and particularly discloses a cloth cleaning device. The cloth cleaning device comprises a frame and a cleaning box; The cleaning box is arranged on the frame; a yarn guiding roller, a first motor and a yarn winding bobbin, and a recycling mechanism are arranged on the frame; the recycling mechanism comprises a recycling barrel, a recycling passage, a first squeeze roller and a second squeeze roller, wherein the first squeeze roller and the second squeeze roller are rotatably connected to the frame, and the recycling barrel communicates with the recycling passage; spraying nozzles and a water absorbing mechanism are arranged in the cleaning box, wherein the spraying nozzles are disposed at the bottom of the cleaning box; the water absorbing mechanism comprises a second motor and a first rotating rod, wherein the second motor is fixedly arranged on an inner wall of the cleaning box, and an output end of the second motor has an incomplete gear; a first gear is arranged on the first rotating rod, and the first gear is meshed with the incomplete gear; and a plurality of supporting rods are arranged on the firstrotating rod in the circumferential direction, and each of the supporting rod has a water suction roller. The object of the present invention is to solve the problem that after the spray nozzles spray a lower part of the cloth with water, water with floating color remains on the cloth.

Owner:NINGBO WENZE TEXTILE CO LTD

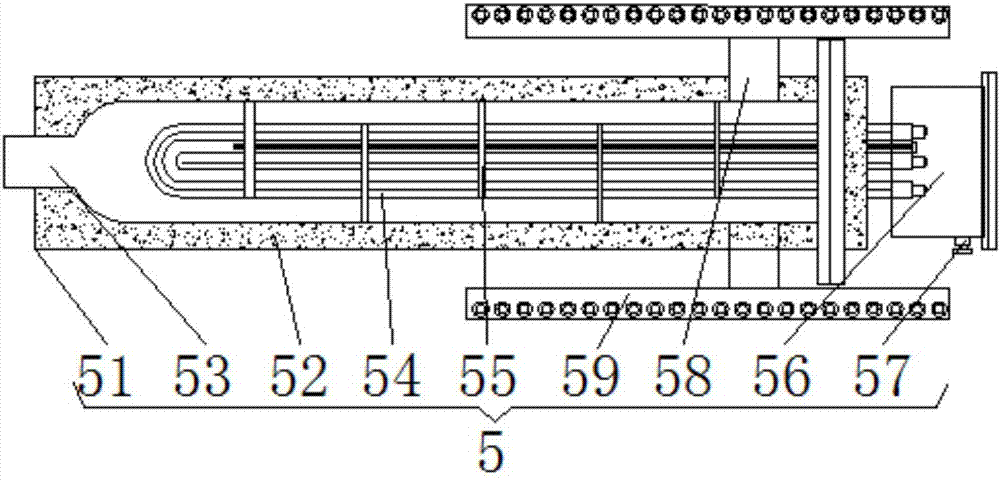

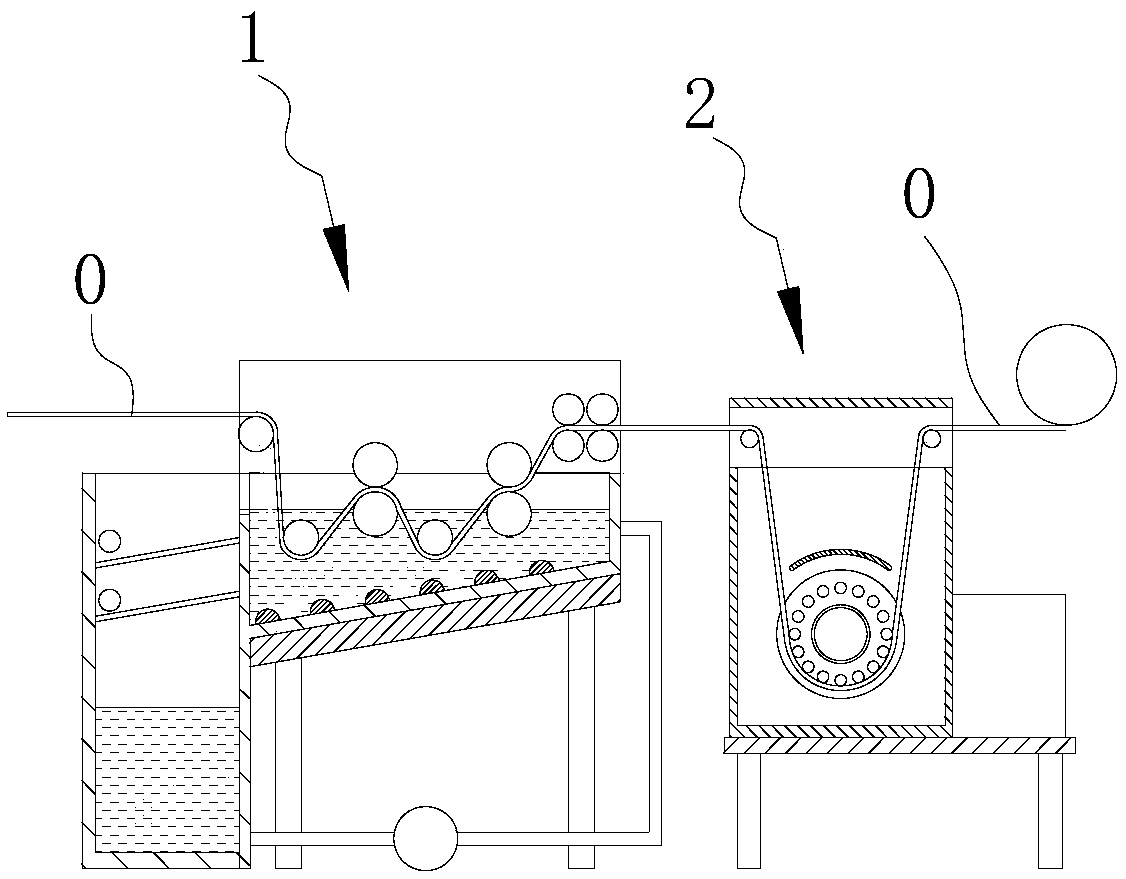

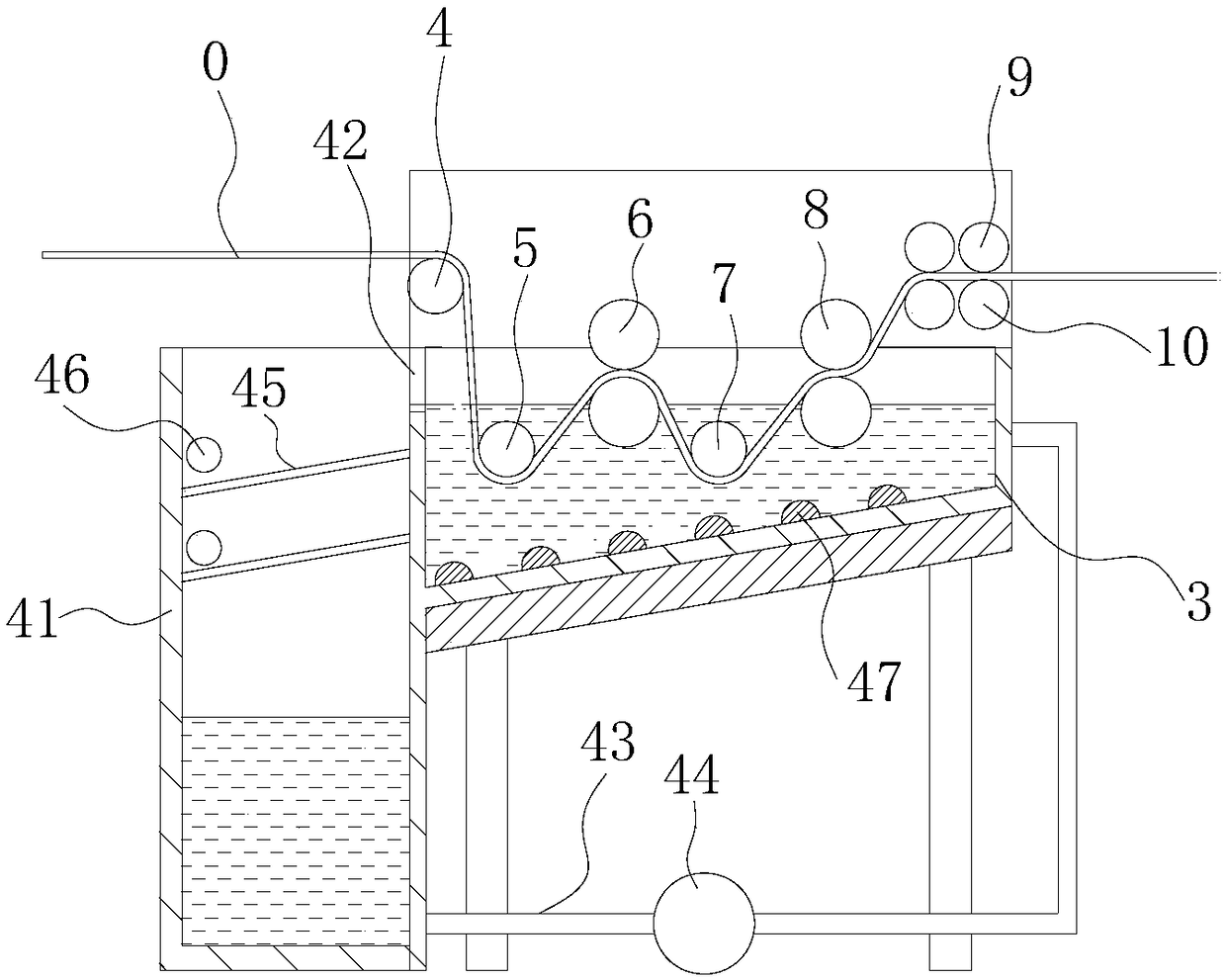

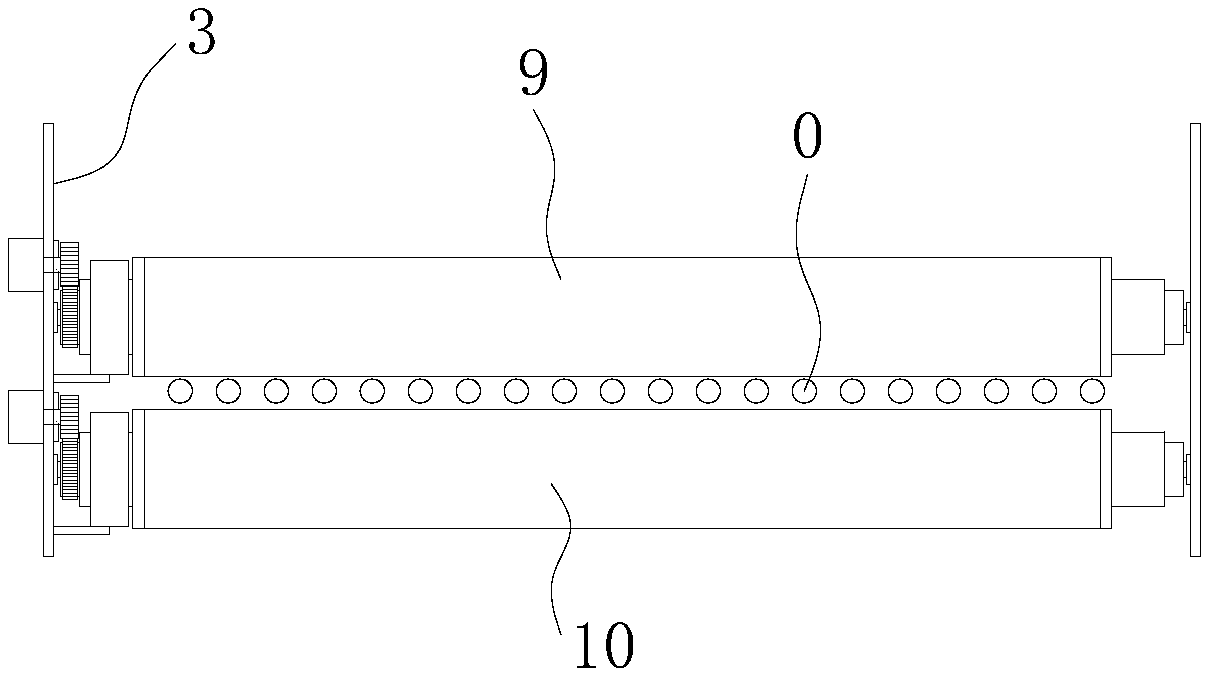

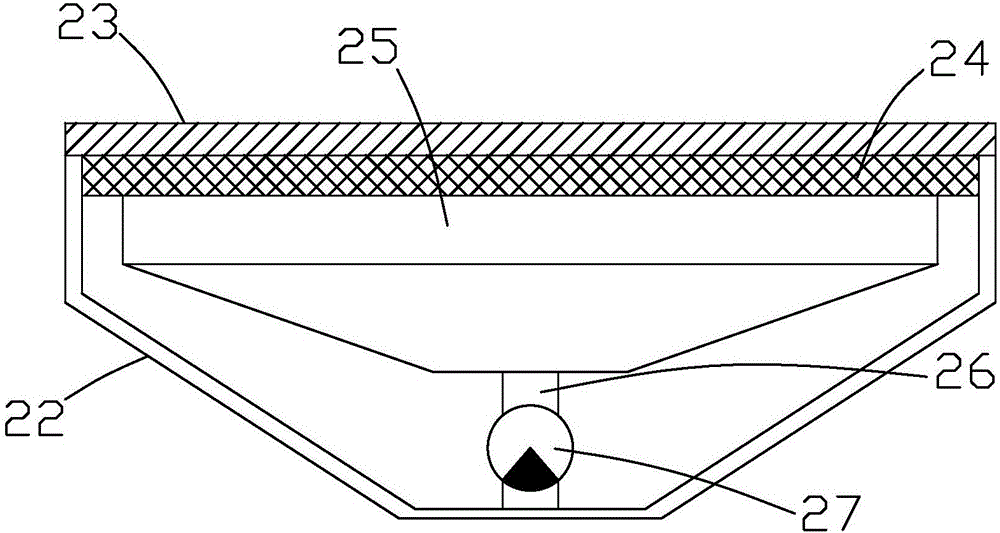

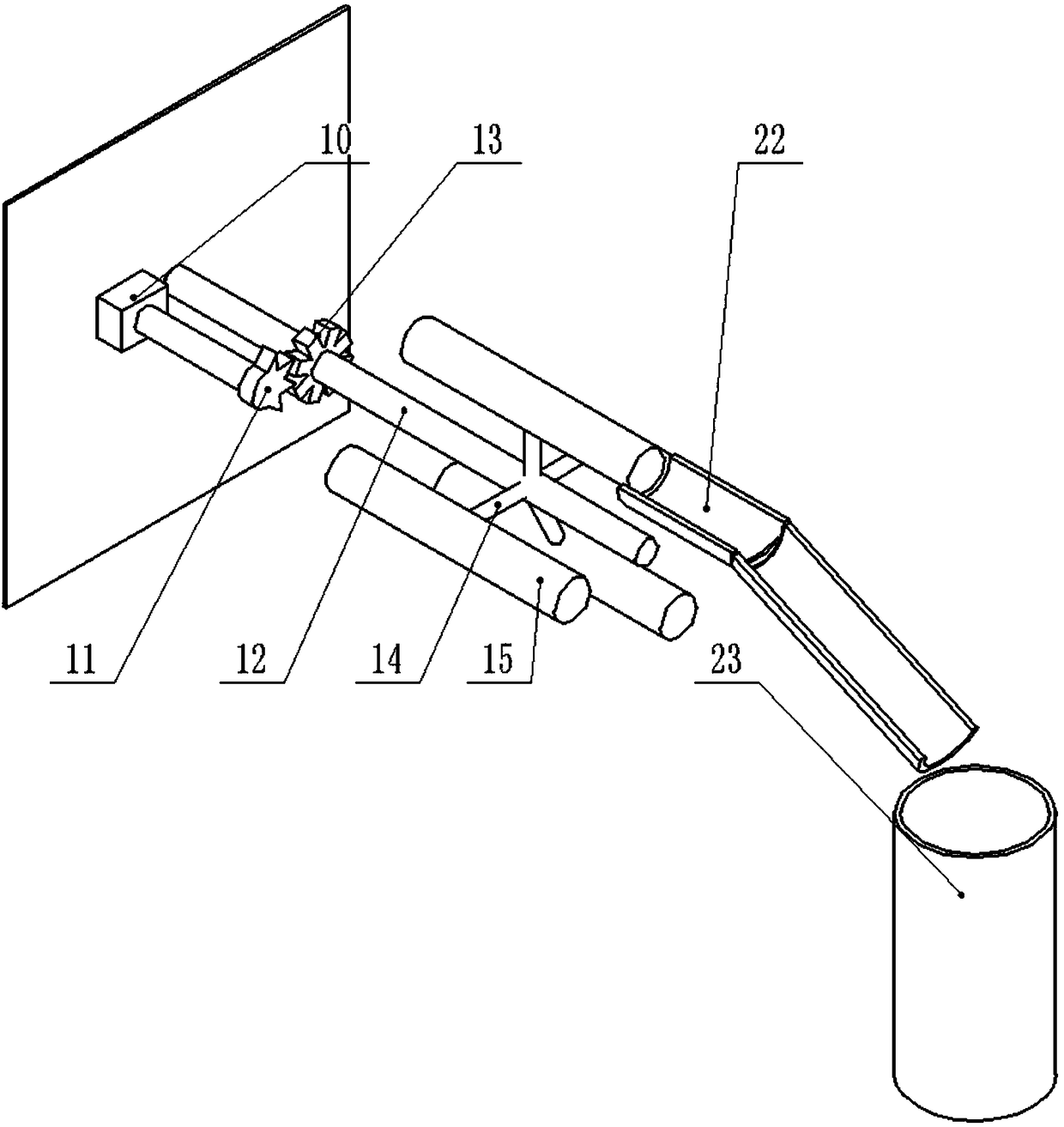

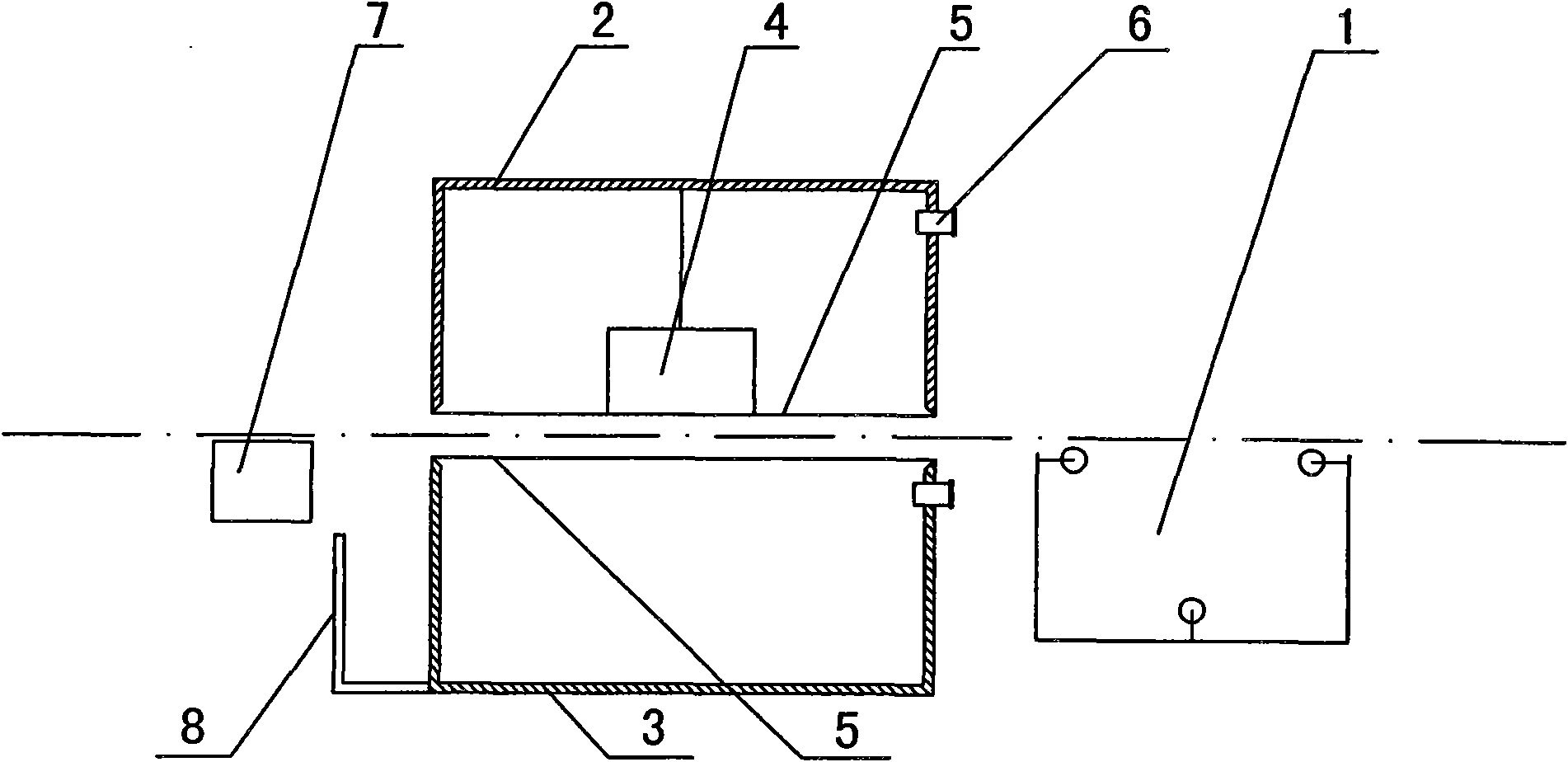

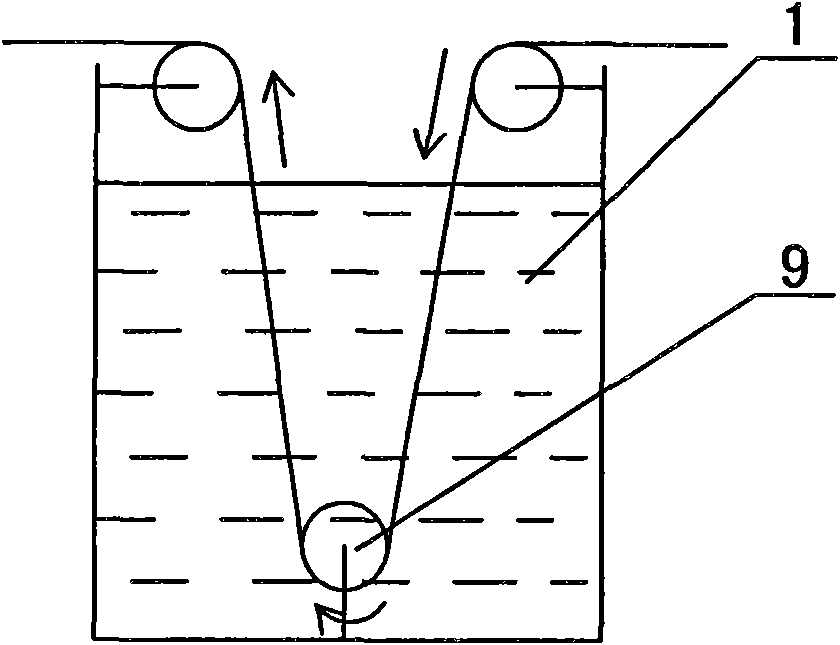

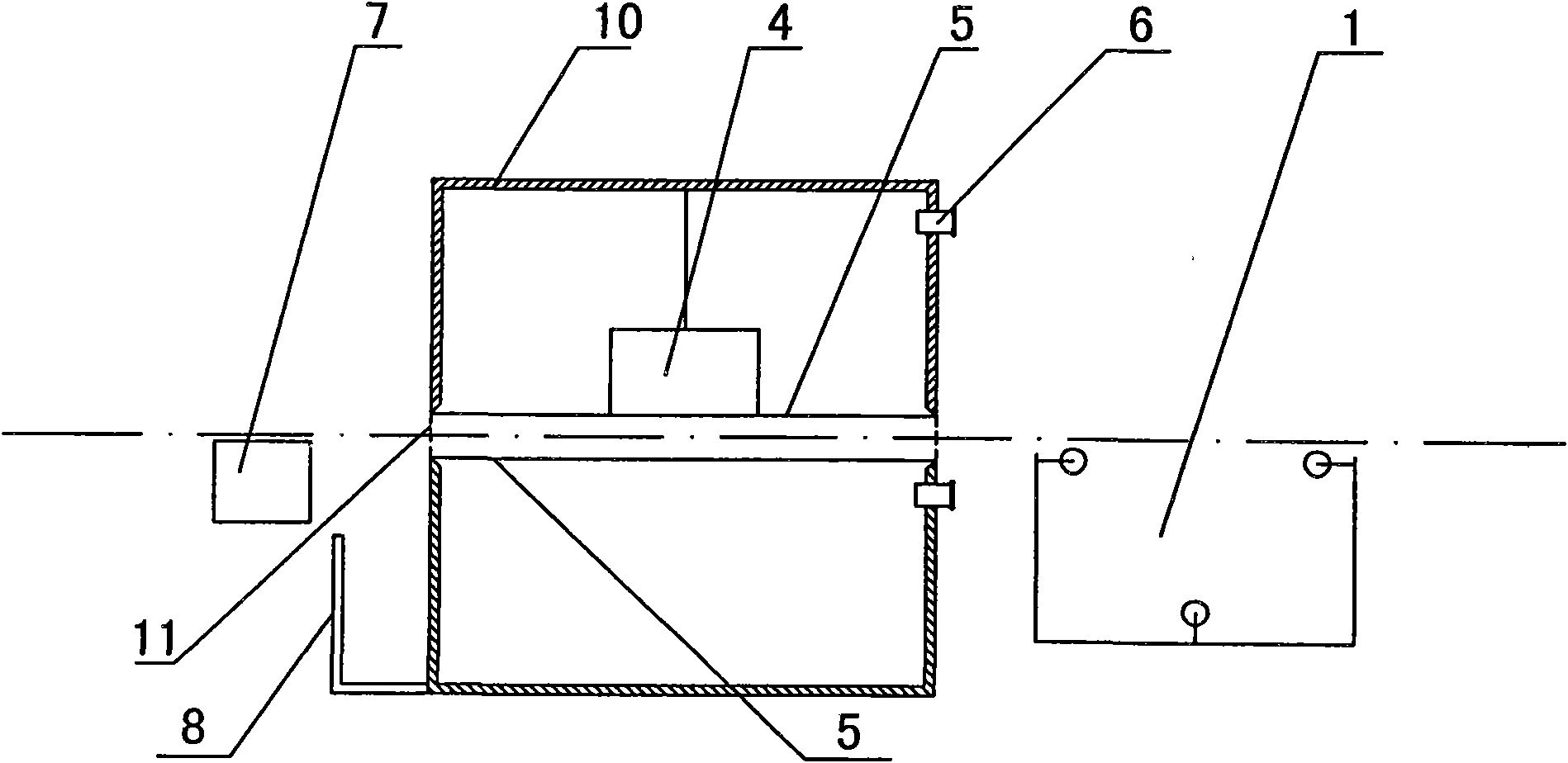

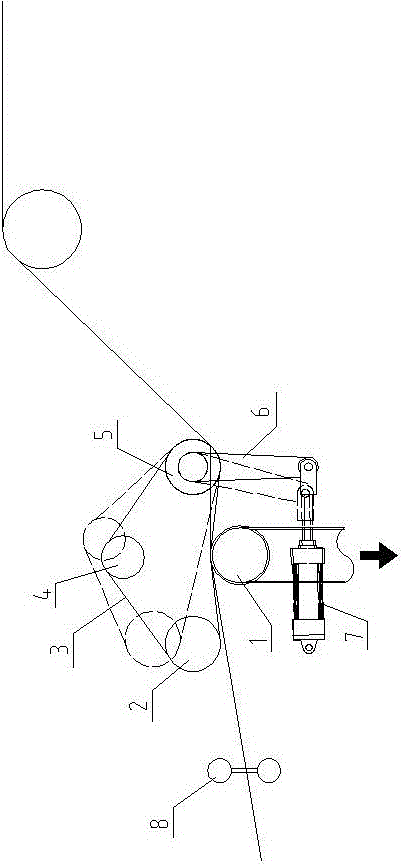

Wet cloth vacuum dewatering machine

InactiveCN103388249AImprove dehydration effectLow costLiquid/gas/vapor removal by suctionPulp and paper industryContinuous operation

The invention relates to a wet cloth vacuum dewatering machine, which comprises a case. A water receiving pool is arranged in the case. A mesh conveying belt is arranged in the case. A dewatering box is fixedly arranged on the case. A plurality of dewatering holes are formed in the top of the dewatering box. The dewatering holes are in close contact with the lower part of the mesh conveying belt. An air inlet pipe of a vacuumizer is communicated with the dewatering box. An air outlet pipe of the vacuumizer is communicated with an air-water separator. A water outlet of the air-water separator aims at the water receiving pool. The wet cloth vacuum dewatering machine can dewater wet cloths before the wet cloths enter a drying machine, the dewatering effect is good, the effect of continuous operation can be realized and the equipment cost is low.

Owner:WUJIANG SHIHUA SILK

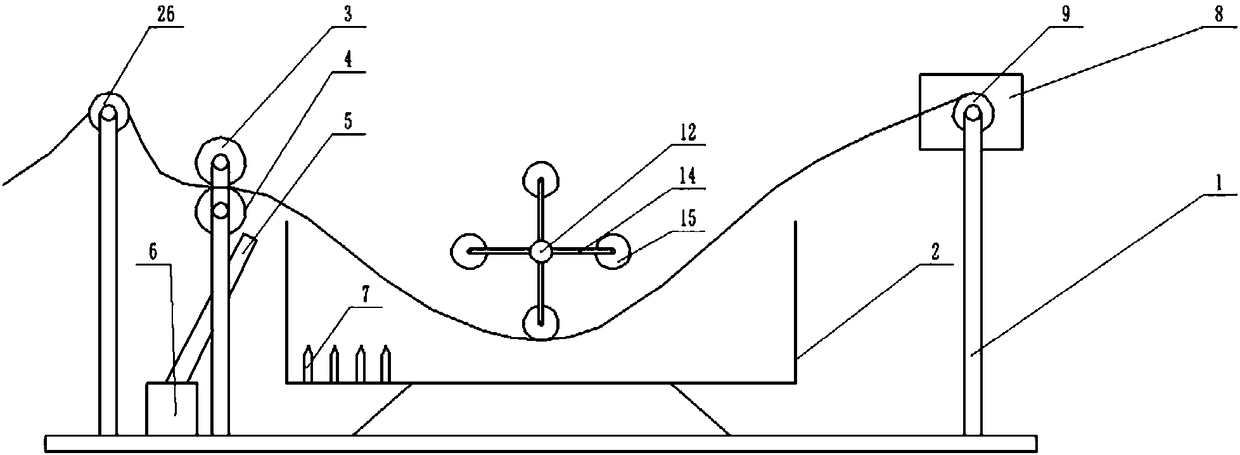

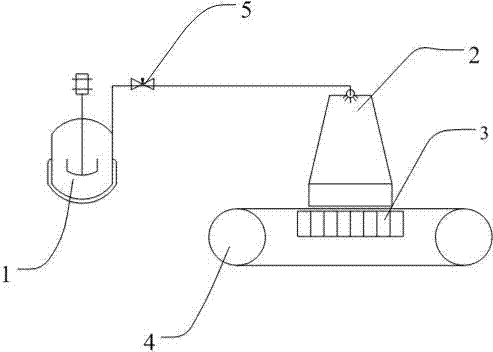

Yarn washing and drying machine

ActiveCN109629142AFast dryingImprove work efficiencyLiquid/gas/vapor removal by suctionLiquid/gas/vapor removal by gas jetsYarnPulp and paper industry

The invention relates to a drying machine, in particular to a yarn washing and drying machine. Thus, the yarn washing and drying machine aims at achieving the technical purposes that the working efficiency can be improved, and the yarn drying speed can be increased. According to the technical scheme, the yarn washing and drying machine comprises a water frame, a water outflow pipe, a valve, a partition plate, a mounting plate, a vertical plate, a supporting plate, a washing device, a first pulley, a sliding rail, a sliding block, a sprayer, a guide sleeve, a water pump and the like. The lowerportion of the right side of the water frame is connected with the water outflow pipe used for draining dirty water, the valve is arranged on the water outflow pipe, the partition plate is obliquely connected to the right side of the bottom in the water frame, the front side and the rear side of the partition plate are connected with the inner wall of the water frame, the mounting plate is fixedlyconnected to the top of the water frame, and the bottom of the mounting plate is connected with the top of the partition plate. Whole yarn can be washed through the washing device, the whole yarn canbe dried through a drying device, thus, washing and drying are simultaneously carried out, and therefore the working efficiency can be improved.

Owner:莒南县罗缔化纤有限公司

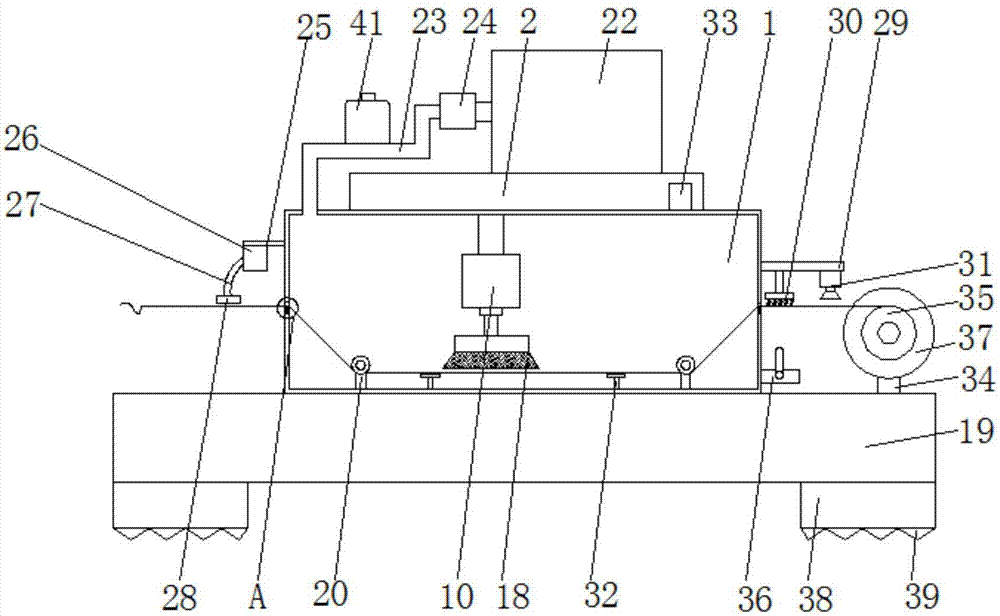

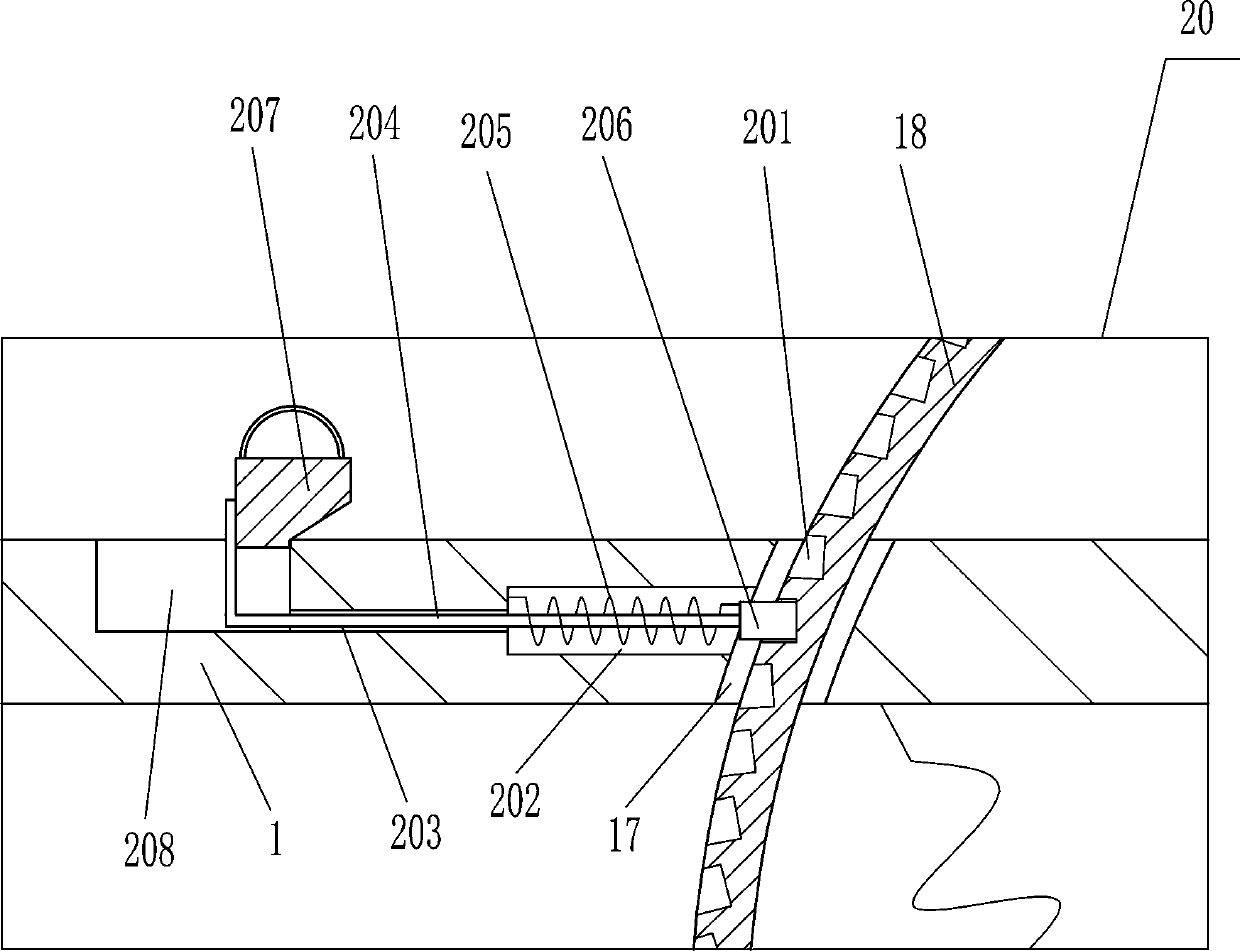

Textile cloth spray-drying system

InactiveCN106995992AGood effectUniform spray holeSucessive textile treatmentsLiquid/gas/vapor removal by squeezing rollersEngineeringUtilization rate

The invention discloses a textile cloth spray-drying system, comprising a dye box (1); a plurality of dye nozzles (2) are arranged in the dye box (1); one end of the dye box (1) is provided with a heating box (3); the other end of the heating box (1) correspond to the dye box (1) is provided with a rinsing box (5); a dye filter (9) is connected below the bottom of the dye box (1); the other end of the rinsing box (5) corresponding to the heating box (3) is provided with a dewatering box (7); the other end of the dewatering box (7) corresponding to the rinsing box (5) is provided with a drying box (19); two cloth feeding rollers (20) and two cloth drawing rollers (21) are connected to two ends of the drying box (19) respectively; an electric heating plate (22) is arranged in the drying box (19); a controller (23) is arranged at the top end of the drying box (19). The textile cloth spray-drying system is good in dyeing uniformity, lower in cost, higher in dye utilization rate, and good in environment-protecting and dyeing effect, and also has the advantages of good cloth-drying effect and zero cloth deformation.

Owner:湖州南浔凯普纺织有限公司

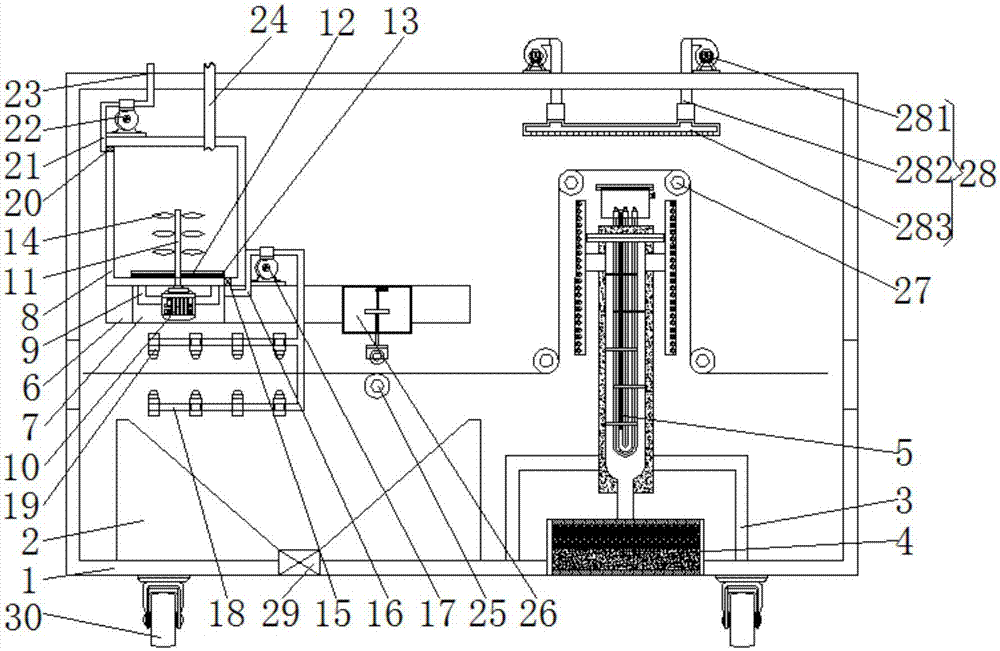

Integrated device for cleaning, sterilizing and drying textile cloth

InactiveCN108866879AThorough cleaning and disinfectionImprove cleaning efficiencyLiquid/gas/vapor removal by suctionTextile treatment machine arrangementsBristleEngineering

The invention discloses an integrated device for cleaning, sterilizing and drying textile cloth. The device comprises a shell, the shell is of a cavity structure, and a cleaning sterilization chamberand a drying chamber which is located at one side of the cleaning sterilization chamber are formed in the shell; a partition plate is arranged between the cleaning sterilization chamber and the dryingchamber, a cloth inlet is formed in an opening, in one side of the top of the cleaning sterilization chamber, of the shell, and a first cleaning roller, a second cleaning roller and a third cleaningroller are arranged in the cleaning sterilization chamber in sequence and arranged in a triangular shape; bristles are arranged at the outer walls of the first cleaning roller, the second cleaning roller and the third cleaning roller respectively, and a stirring mechanism is arranged in the middle of the top in the cleaning sterilization chamber. The integrated device has the advantages that the textile cloth is beaten and flushed through sterilization fluid and can be completely cleaned and sterilized, the cleaning efficiency is high, and after being cleaned, the textile cloth enters the drying chamber for drying; the textile cloth can be integrally cleaned, sterilized and dried through the device, the device operates stably, and the processing quality of the textile cloth is improved.

Owner:芜湖瀚德信息科技有限公司

Ultrasonic wave desizing device

InactiveCN101629368AReduce dosageLittle consumptionTextile treatment containersLiquid/gas/vapor removal by suctionWater savingTransducer

The invention discloses an ultrasonic wave desizing device, comprising a water tank unit; the water tank unit consists of two semi-enclosed water tanks, namely a water tank A and a water tank B; one unenclosed side of the water tank A is enclosed by at least one layer of film, so is one unenclosed side of the water tank B; the two outmost layers of films of the two water tanks are parallel, and a gap with the distance of less than 3mm is left between the two outmost layers of films; at least one ultrasonic wave transducer is mounted in the water tank A or the water tank B and is fixed on the inner wall of the water tank; water inlets are mounted on both the water tank A and the water tank B. The invention can completely remove sizing agent attached to the textile products in the desizing technique, and the sizing agent and water can be recycled and reused, thus greatly reducing water usage and lowering processing cost with small power consumption. The invention also features energy saving, water saving, no pollution and the like.

Owner:李建华

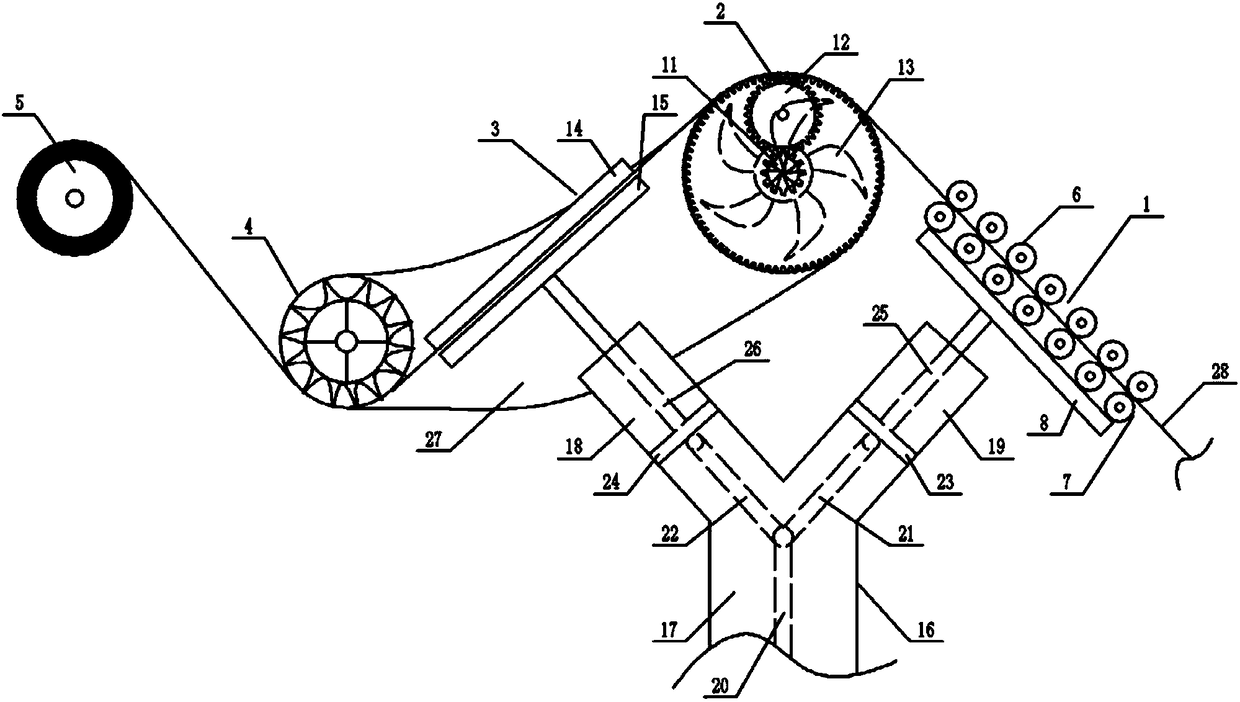

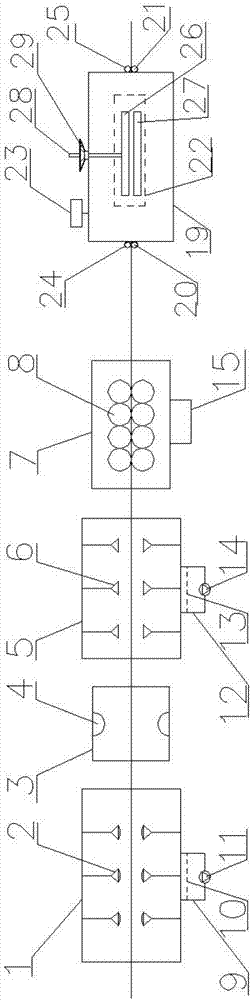

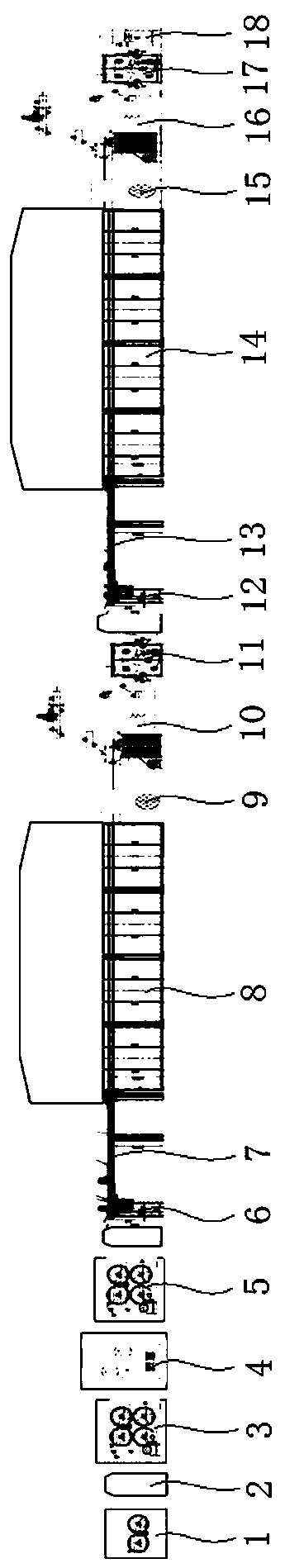

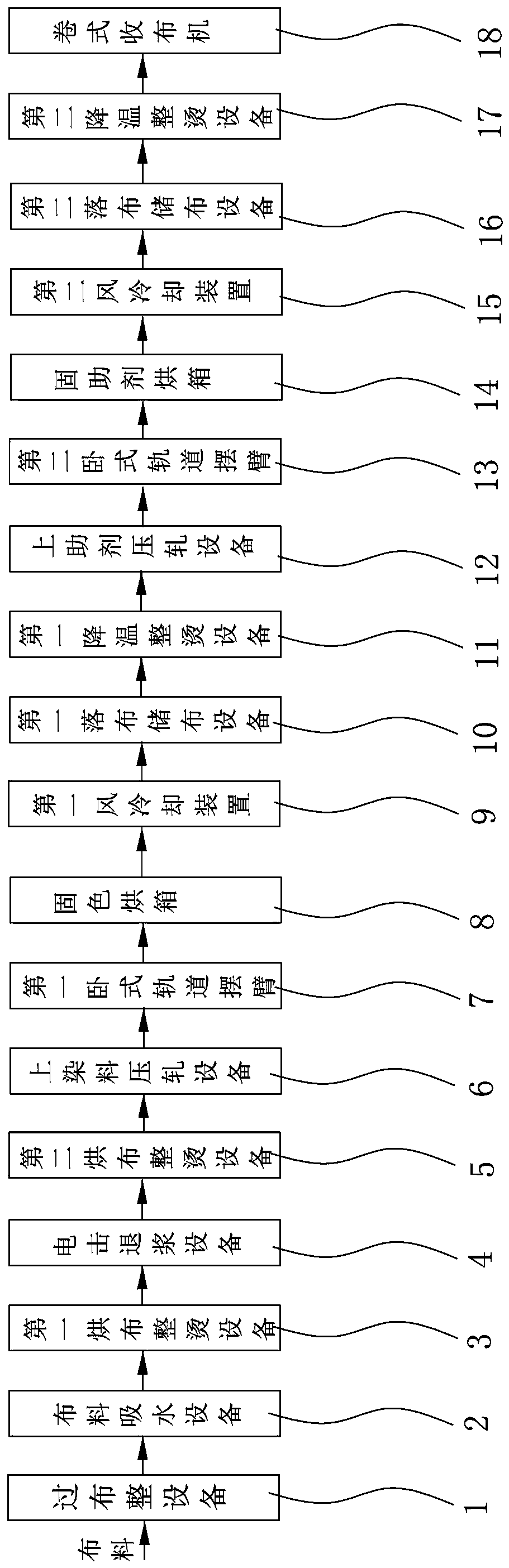

Continuous cloth printing and dyeing production line and printing and dyeing production technology thereof

PendingCN109371611AHigh lusterImprove dyeing effectSucessive textile treatmentsHeating/cooling textile fabricsProduction lineEngineering

The invention discloses a continuous cloth printing and dyeing production line and a printing and dyeing production technology thereof. Along with the continuous cloth printing and dyeing production line, cloth passing and leveling equipment, cloth water absorbing equipment, first cloth drying and ironing equipment, electric shock desizing equipment, second cloth drying and ironing equipment, dyefeeding and rolling equipment, a first horizontal track swing arm, a color fixation and oven, a first air cooling device, first cloth falling and storage equipment, first cooling and ironing equipment, auxiliary feeding and rolling equipment, a second horizontal track swing arm, an auxiliary solidifying and oven, a second air cooling device, second cloth falling and storage equipment, second cooling and ironing equipment and a winding-type cloth collector are sequentially arranged. By means of the continuous cloth printing and dyeing production line, redundant moisture in cloth can be absorbed, the cloth can be desized, various auxiliaries can be added after the cloth is subjected to dyeing and color fixation, the auxiliaries are automatically solidified, and the cloth is wound.

Owner:广东省迪利安环保固色科技有限公司

Printing and dyeing method for fabric

InactiveCN102852011AUniform particlesFine particleLiquid/gas/vapor removal by suctionLiquid/gas/vapor treatment of indefinite length materialsAqueous mediumSupercritical carbon dioxide

The invention discloses a printing and dyeing method for a fabric. The method comprises the following steps: contacting one surface of the fabric with an atomizer chamber and the other surface of the fabric with a vacuum system; dispersing a dye into a supercritical carbon dioxide medium; then injecting the dye into the atomizer chamber for atomization; and starting the vacuum so as to allow the atomized dye to be adsorbed by the fabric. According to the invention, the supercritical carbon dioxide medium is used; a water treatment step before printing and dyeing and subsequent procedures like dye fixation and rinsing are not needed, which enables the process to be simplified; compared to particles obtained through atomization in an aqueous medium, particles obtained through atomization in the supercritical carbon dioxide medium are more uniform and finer, and the fabric obtained in the invention has a more brilliant color.

Owner:WUXI SINTEX PRINTING & DYEING CO LTD

Method for improving softness performance of pigment dyed fabric

ActiveCN105239296AGood flexibilityReduce contentSucessive textile treatmentsLiquid/gas/vapor removal by suctionYarnSoaking Procedure

The invention relates to a method for improving softness performance of pigment dyed fabric, particularly relates to a method for performing physical pre-processing after the fabric is soaked with padding liquor and before the fabric is pre-dried so as to improve the softness performance of the fabric, and belongs to the field of textile processing. In the whole pigment dyeing process of fabric D, a negative-pressure air suction device is arranged between the padding liquor soaking procedure and the pre-drying procedure of the fabric D, pigment in gap holes of the fabric is removed in a negative pressure suction mode, the processed fabric D is pre-dried, pre-drying temperature is 80-100 DEG C, and pre-drying time is 5-10 min. The pigment dyed fabric D processed through the technological method can suck out pigment dye liquor affecting the softness performance of the fabric D, adhesion between yarn is reduced, and the softness degree of the fabric D is improved obviously.

Owner:WUHAN TEXTILE UNIV

Cleaning and sterilizing device for woven cloth

InactiveCN108866880AThorough cleaning and disinfectionImprove processing qualityLiquid/gas/vapor removal by suctionTextile treatment machine arrangementsBristleBiochemical engineering

The invention discloses a cleaning and sterilizing device for woven cloth. The cleaning and sterilizing device comprises a shell of a cavity structure, a cleaning and sterilizing chamber and a dryingchamber are arranged in the shell, the drying chamber is located in one side of the cleaning and sterilizing chamber, a partitioning plate is arranged between the cleaning and sterilizing chamber andthe drying chamber, a cloth inlet is formed in the opening, located in one side of the top end of the cleaning and sterilizing chamber, of the shell, a first cleaning roller, a second cleaning rollerand a third cleaning roller are sequentially arranged inside the cleaning and sterilizing chamber triangularly, brushing bristles are arranged on the outer wall of the first cleaning roller, the outerwall of the second cleaning roller and the outer wall of the third cleaning roller respectively, vibrating mechanisms are arranged at the two sides of the bottom end and in the middle of the top endinside the cleaning and sterilizing chamber respectively and comprise supporting discs, and boxes are arranged at the top ends of the supporting discs. The cleaning and sterilizing device has the advantages that cleaning efficiency is high, the woven cloth enters the drying chamber to be dried after being cleaned, and can be integrally cleaned, sterilized and dried with the device, operation is stable, and the processing quality of the woven cloth is improved.

Owner:芜湖瀚德信息科技有限公司

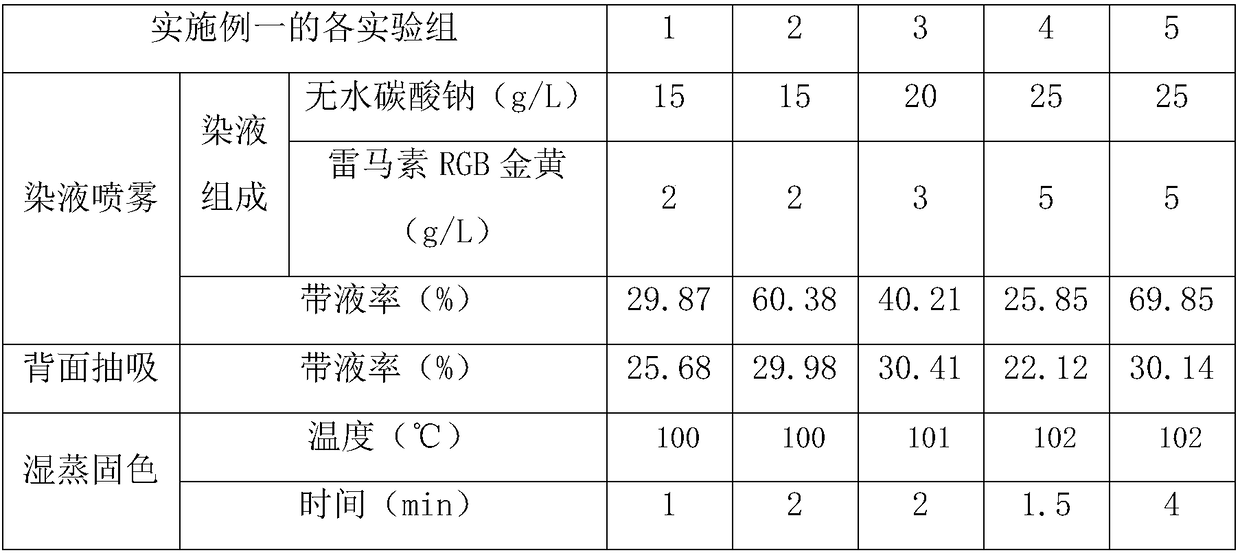

Method for spraying wet steaming and dyeing cotton fabric by using reactive dye

PendingCN109440325AApply evenlyAvoid problems such as swimmingTextile treatment containersLiquid/gas/vapor removal by suctionTextile printerEngineering

The invention provides a method for spraying wet steaming and dyeing fabric by using reactive dye, which belongs to the technical field of textile printing and dyeing. The fabric and the baffle plateform an opening atomizing box, dye liquor containing a fixing agent is sprayed into the atomizing box through an atomizing device, and then a suction is carried out on the back surface of the fabric at the bottom position of the atomizing box. After the fabric passes through the atomizing box, the fabric is steamed and fixed in normal pressure saturated steam, and then the dyeing process is finished after water washing and soaping treatment. By adopting the method for carrying out reactive dye spraying wet steaming and dyeing on fabric, the large fluctuation of steaming and color fixing conditions caused by the fact that the fabric with high liquid content enters a steaming box can be avoided, the temperature rise rate of the fabric is improved, the color fixing time is shortened, and thehydrolysis of dye on the fabric in damp-heat and alkaline environments is reduced, which is favorable for improving the fixation rate of the reactive dye, and fabrics with different dyeing effects canbe obtained by adjusting spray and suction mode and dye liquor ratio.

Owner:SHANGHAI UNIV

Method for improving cloth dyeing effect

InactiveCN108532202AImprove dyeing effectImprove preshrinking effectShrinkingLiquid/gas/vapor removal by suctionEngineeringEquipment/device

Owner:佛山市三水顺联染整有限公司

Textile soaking collector

InactiveCN109594261AEasy to adjustCollect obstaclesTextile treatment machine partsLiquid/gas/vapor removal by squeezing rollersEngineeringMechanical engineering

The invention relates to a collector, in particular to a textile soaking collector. By the textile soaking collector, the labor intensity can be reduced, and the collecting efficiency can be improved.According to the technical scheme, the textile soaking collector comprises a base, a stand, a support, a first rotating shaft, a first roller, a sponge block, a first spring, a first oscillating seat, an oscillating rod, an extrusion wheel, a second oscillating seat and the like; and the stand is mounted on the right side of the top of the base, through holes are separately formed in the left side and the right side of the stand, the support is fixed between the lower portions of the left side and the right side of the inside of the stand, and the left portion of the support is rotatably connected with the first rotating shaft. A second roller can be limited by a clamping device, thus, the second roller can cooperate with the sponge block to extrude and absorb liquid on textiles, the labor intensity of a user is reduced, and the textile collecting efficiency can be improved.

Owner:曾凡津

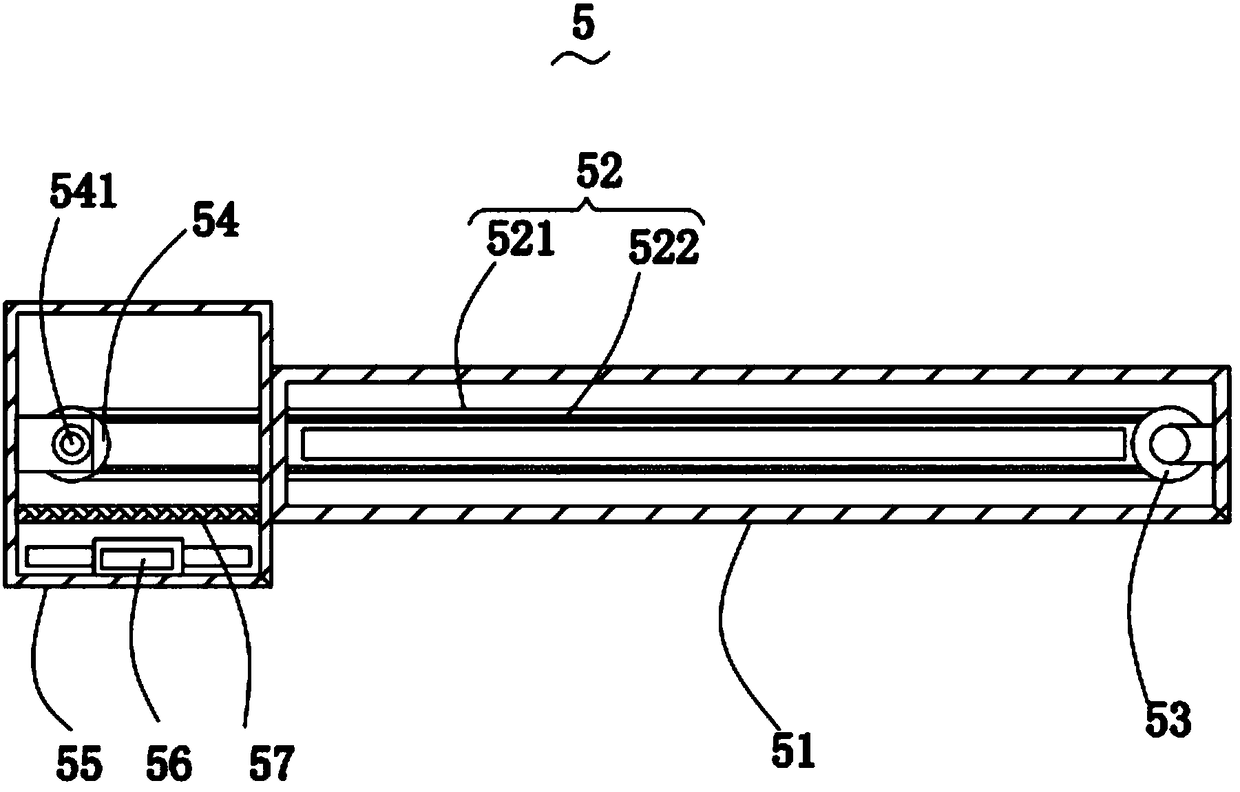

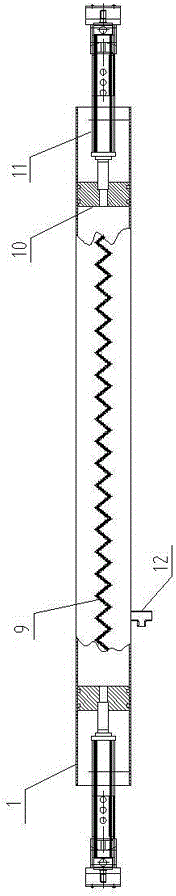

Pressure belt type vacuum dewatering device

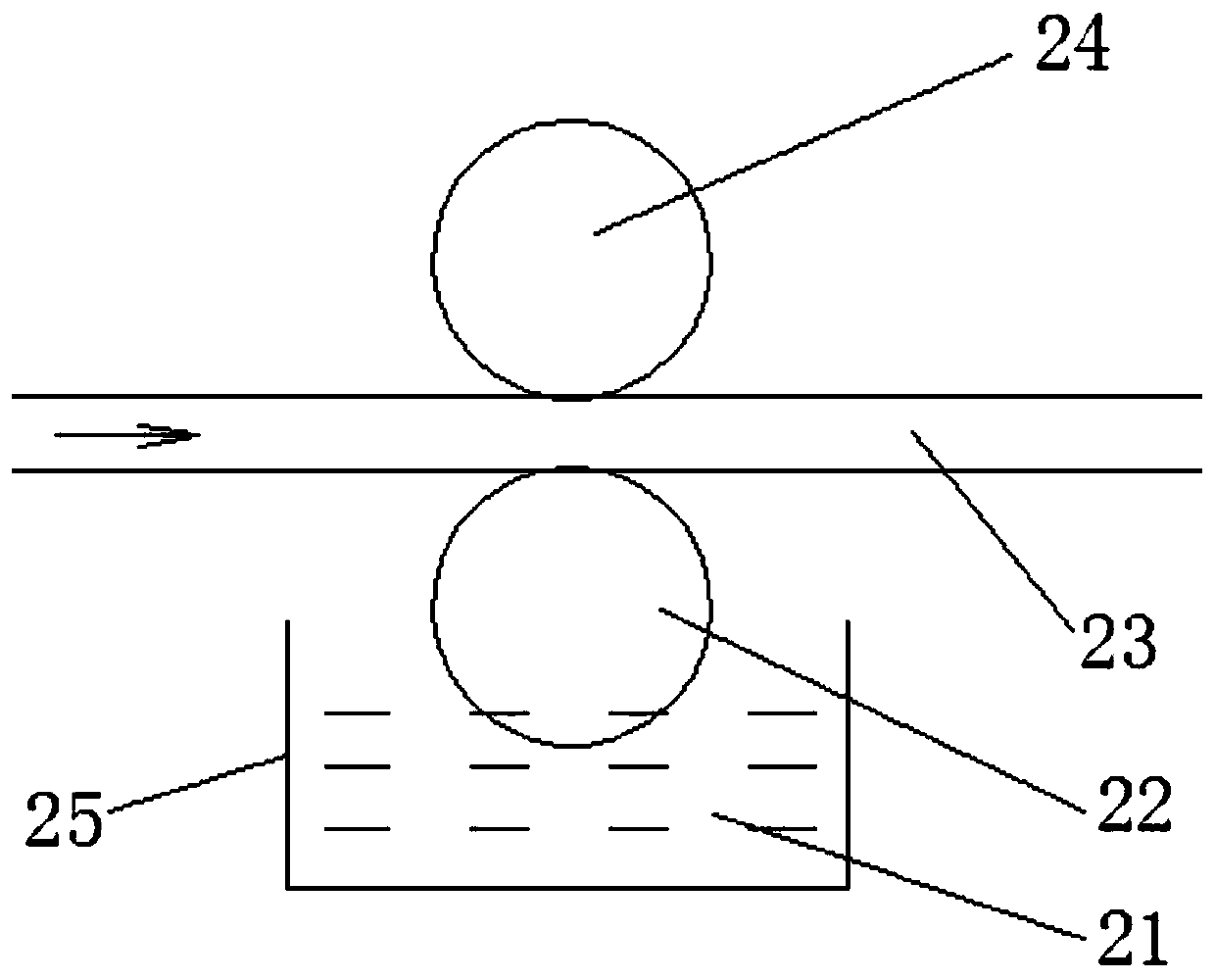

ActiveCN105755718AGuaranteed effective vacuum areaReduce frictionLiquid/gas/vapor removal by suctionWoven fabricsVentilation volumePulp and paper industry

The invention discloses a pressure belt type vacuum dewatering device which comprises a vacuum water absorption device for absorbing fabric moisture and a rotary pressure belt mechanism arranged above the vacuum water absorption device and used for adjusting the fabric water permeability; the vacuum water absorption device is provided with a vacuum suction pipe, water absorption openings are formed in the pipe wall of the vacuum suction pipe from one end to the other end in the axial direction, sealed pistons corresponding to an absorbed fabric in breadth are arranged at the two ends of the vacuum suction pipe, servo drive mechanisms for driving the sealed pistons are arranged outside the vacuum suction pipe, a photoelectric detection device for detecting the breadth of the fabric is arranged on the cloth inlet side of the vacuum suction pipe and is connected with the servo drive mechanisms through control units. According to the pressure belt type vacuum dewatering device disclosed by the invention, the fabric on the vacuum suction pipe is compacted through a pressure belt to keep the proper ventilation volume of the fabric, and the pressure belt type vacuum dewatering device is particularly suitable for knitted plush and blanket type products with strong air permeability; according to a cloth edge distance signal collected by a photoelectric pipe, through the control units and the servo drive mechanisms, the tracking seal of the sealed pistons for the water absorption ports uncovered by the fabric is realized.

Owner:JIANGSU YINGYOU TEXTILE MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com