Desizing washing after-treatment equipment

A post-treatment and desizing technology, applied in the field of textile dyeing and finishing, can solve the problems of insufficient water penetration, low reuse rate, secondary pollution of fabrics, etc., to save drying energy, improve washing efficiency, and facilitate washing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

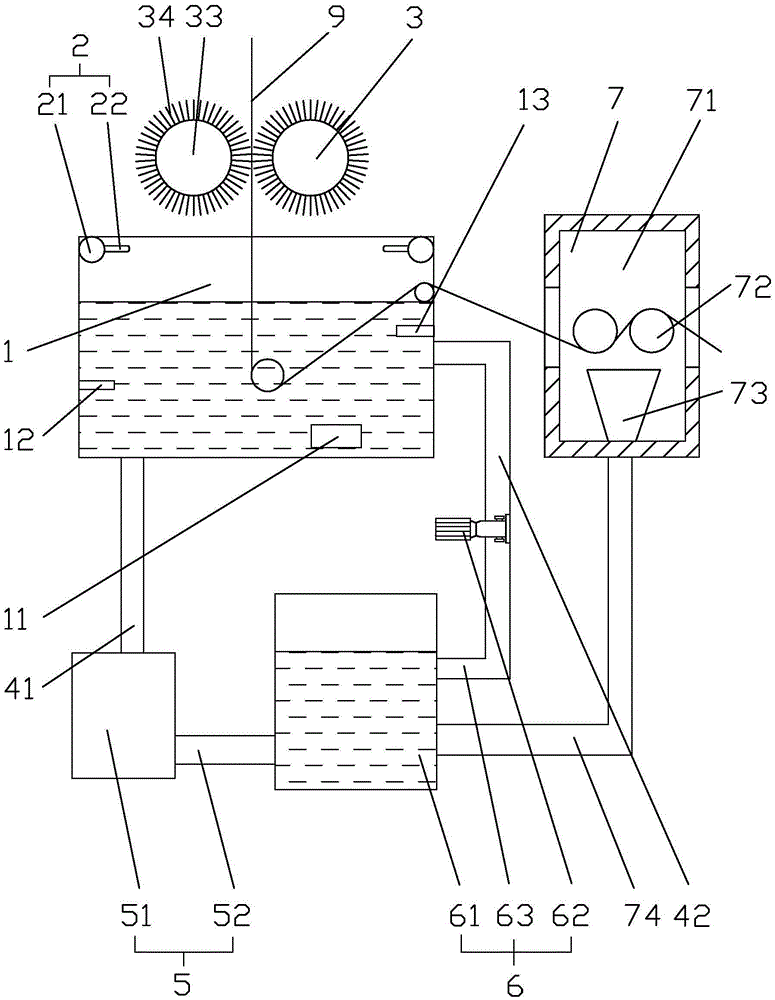

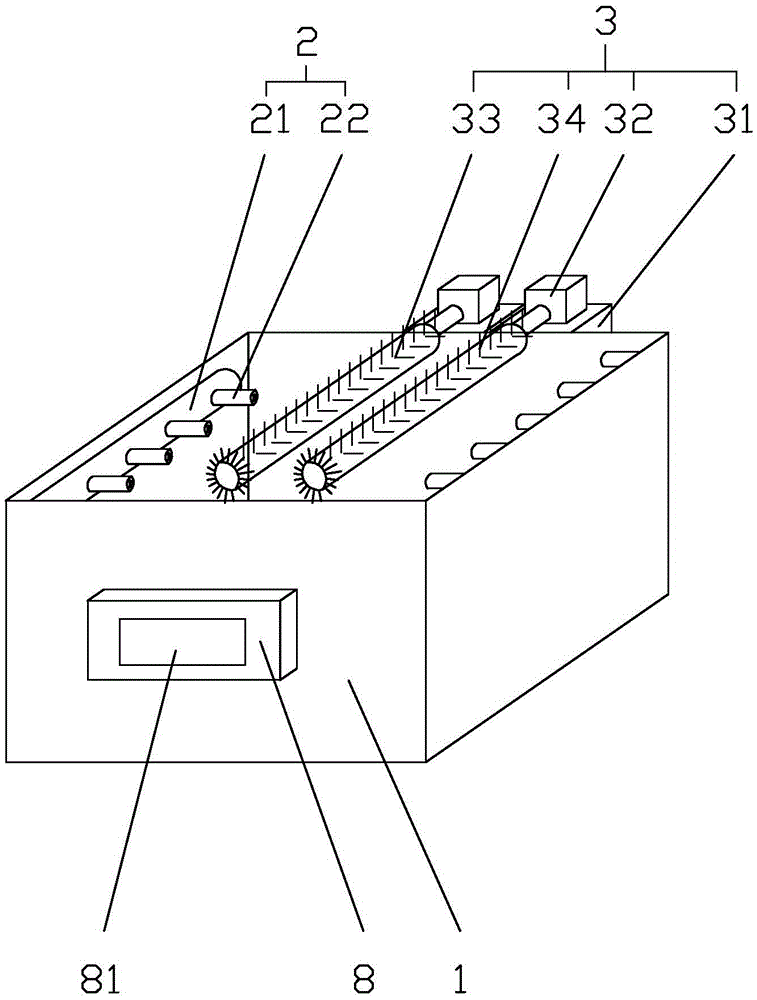

[0017] Such as Figure 1-2 The post-processing equipment for desizing and washing shown includes an oscillating washing box 1, in which two spraying devices 2, a cloth brushing device 3, a heater 11, a temperature sensor 12 and a water level sensor 13 are arranged. . The heater 11 is located at the bottom of the oscillating washing box 1. The water in the oscillating washing box 1 has an oscillating effect, which can fully clean the fabric 9. The heater 11 is heated to improve the washing effect, and simultaneously Some water-soluble slurries wash down. The spraying device 2 is symmetrically arranged on the left and right sides of the oscillating water washing tank 1 , and the spraying device 2 is composed of a spraying pipeline 21 and at least two nozzles 22 , and the nozzles 22 are evenly arranged on the spraying pipeline 21 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com