Textile cloth spray-drying system

A drying system and technology for textile fabrics, applied in textile and papermaking, textile material processing, textile material carrier processing, etc., can solve the problems of waste, uneven drying, poor drying effect of cloth, etc., and improve the utilization rate , reduce costs and save dyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

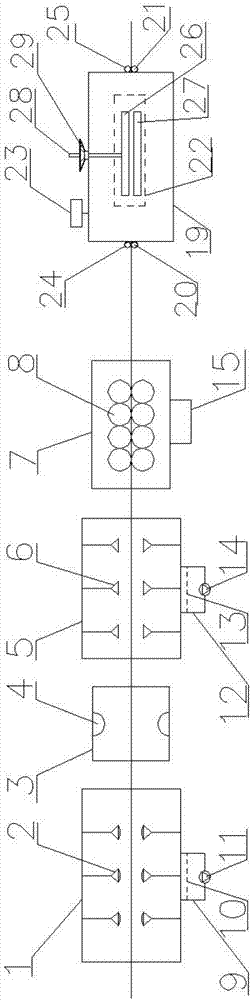

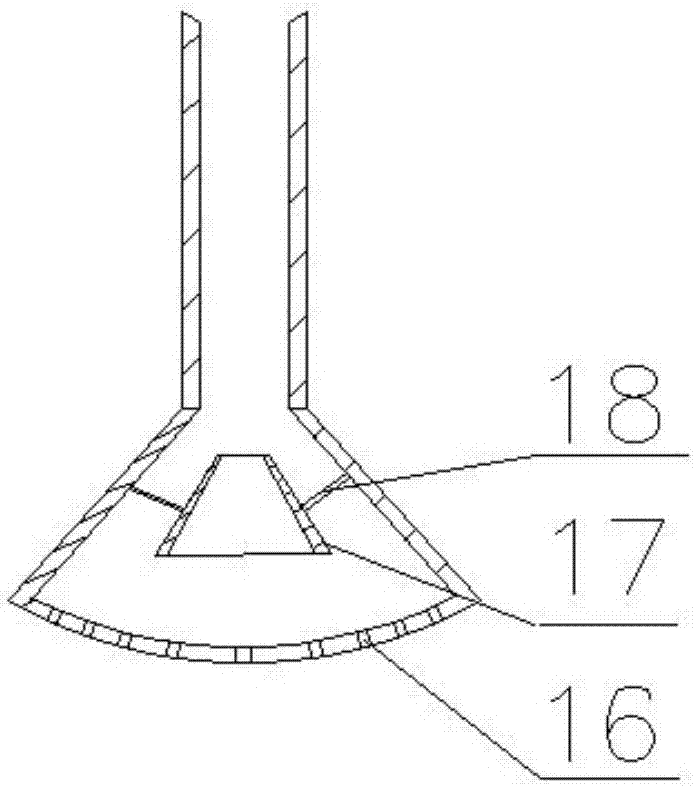

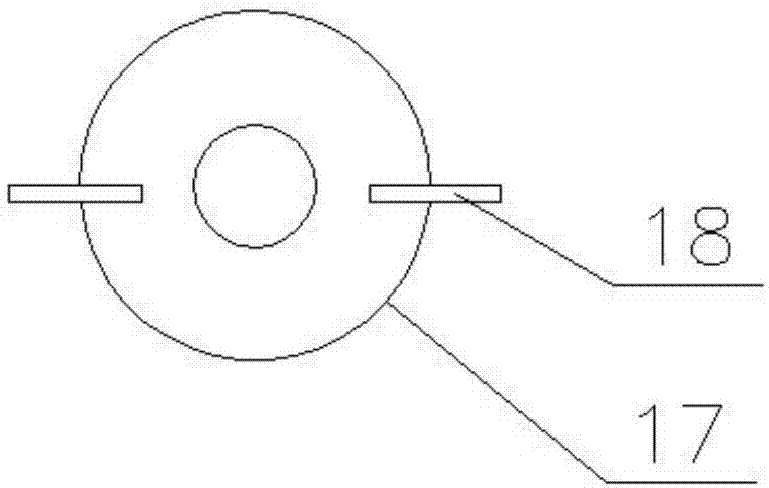

[0019] Example. A kind of textile cloth spray drying system, its composition is as follows Figures 1 to 3 As shown, including the dye box 1, the top surface and the bottom surface of the dye box 1 are respectively provided with a plurality of dye nozzles 2, and every 10 dye nozzles 2 form a row, and the top surface of the dye box 1 is provided with three rows, and the bottom surface is provided with three rows; One end of the dye box 1 is provided with a heating box 3; the other end of the heating box 3 corresponding to the dye box 1 is provided with a rinsing box 5; the bottom of the dye box 1 is connected with a dye filter 9, and a No. 1 filter screen 10 is arranged in the dye filter 9; The bottom of the dye filter 9 is provided with a No. water pump 11, and the No. 1 water pump 11 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com