Ultrasonic wave desizing device

An ultrasonic and desizing technology, used in textiles and papermaking, vibration treatment, textile processing machine accessories, etc., can solve the problems of textile pollution, low energy consumption, low water consumption, etc., to achieve low power consumption and reduce water consumption. , Solve the effect of large water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

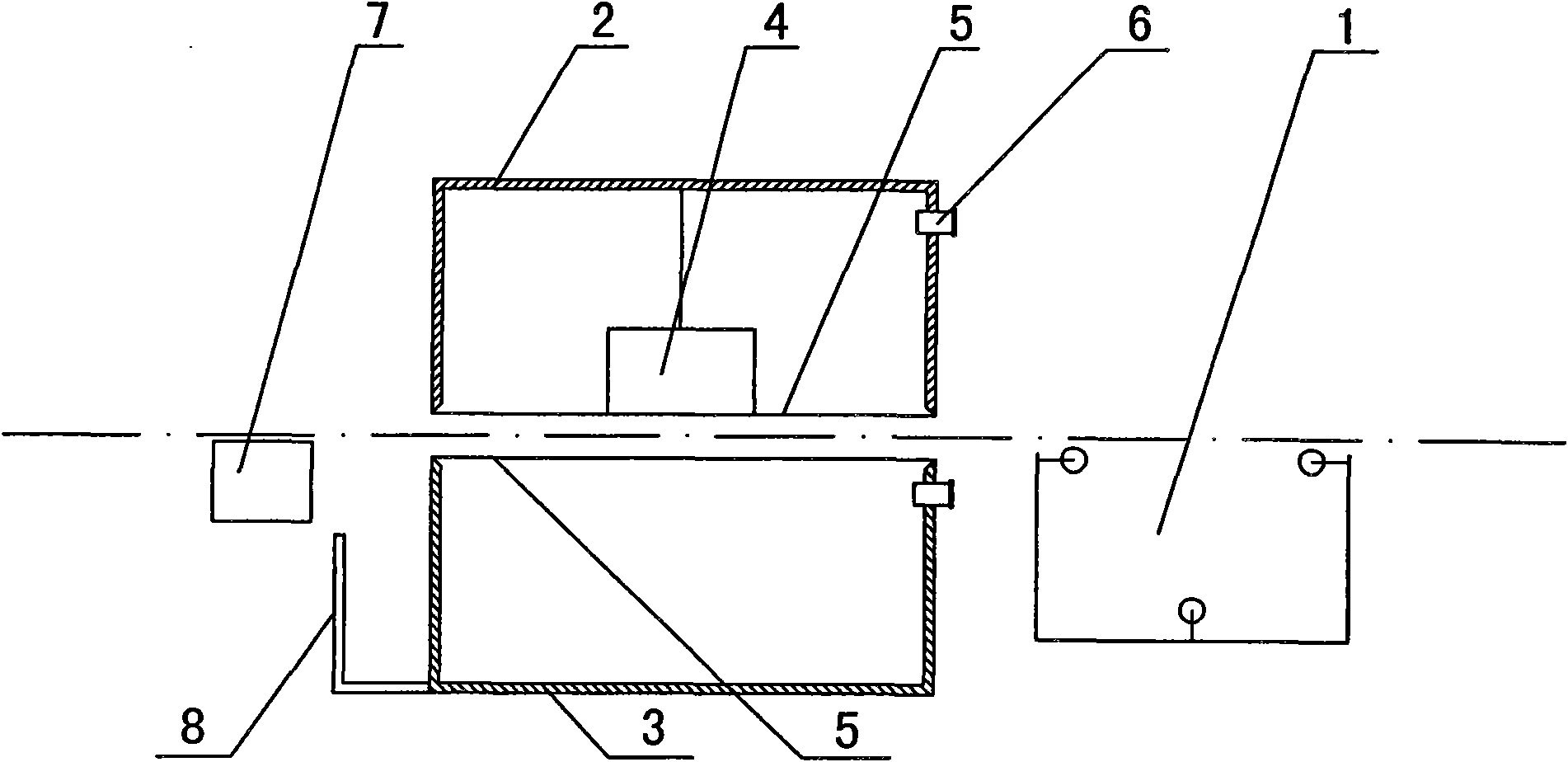

[0026] Embodiment 1: a kind of ultrasonic desizing cleaning device, comprises water tank 1, water tank device and blower 7, as figure 1 As shown, the water tank device includes two semi-closed water tanks: water tank A2 and water tank B3. The unclosed side of water tank A2 is closed by membrane 5, and the unclosed side of water tank B3 is closed by membrane 5. Two layers of membranes 5 are parallel, and the middle It is a gap with a distance not greater than 3mm (to ensure that the wet textiles and the membrane are closely attached); the water tank A2 is provided with an ultrasonic transducer 4, and the ultrasonic transducer 5 is fixed on the inner wall of the water tank; the water tank A2 and the water tank B3 Water inlets 6 are provided on the top; the water tank 1 is located on the left side of the water tank device, and the water suction machine 7 is located on the right side of the water tank device. A recovery tank 8 is provided on the lower side of the water tank B3.

...

Embodiment 2

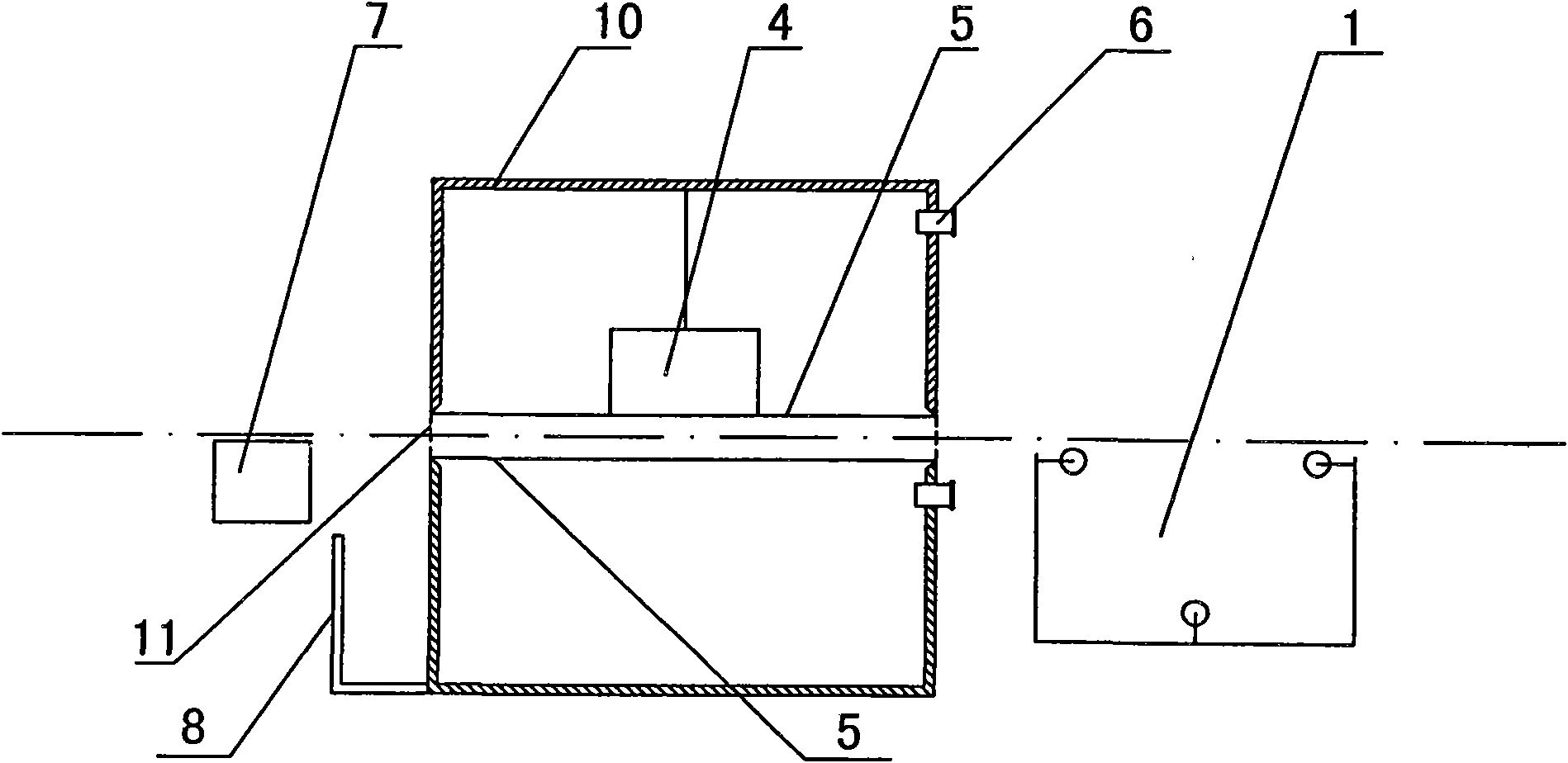

[0032] Embodiment 2: a kind of ultrasonic desizing cleaning device, comprises water tank 1, water tank device and blower 7, as image 3 As shown, the water tank device includes a water tank 10, the opposite side of the water tank 10 is provided with two relative slits 11, at least two layers of membrane 5 are arranged between the two slits 11, and the inner space of the water tank 10 is divided into two closed areas. Part, between the two layers of film 5 is a gap with a distance not greater than 3mm; an ultrasonic transducer 4 is arranged in the water tank 10, and the ultrasonic transducer 4 is fixed on the inner wall of the water tank 10; the water tank 10 is provided with two water inlets 6. Sink 1 is located at the left side of water tank 10, and blower 7 is located at the right side of water tank 10. The lower side of the water tank 10 is provided with a recovery tank 8 .

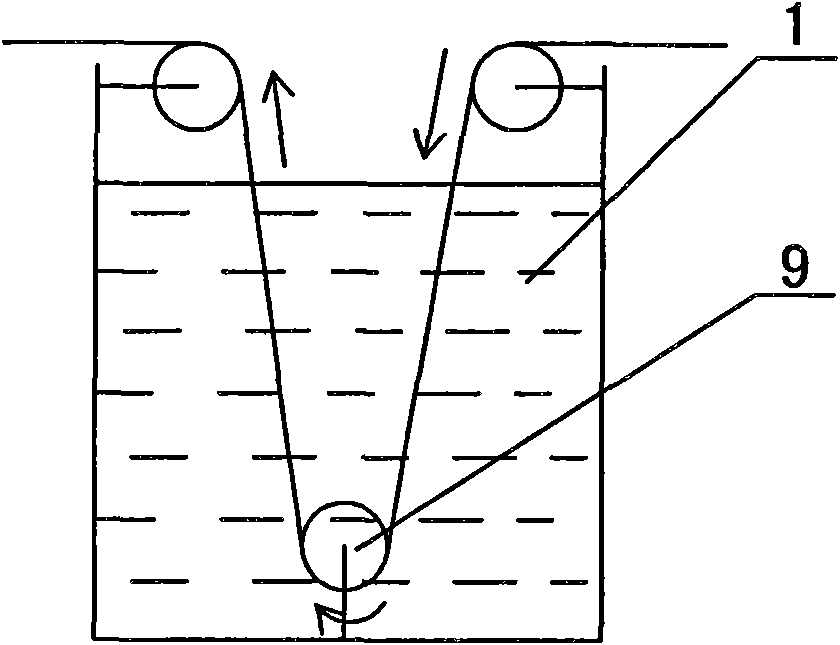

[0033] Described tank 1 is provided with three fixed pulleys 9, as figure 2 As shown, there is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com