Patents

Literature

45results about How to "Little consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

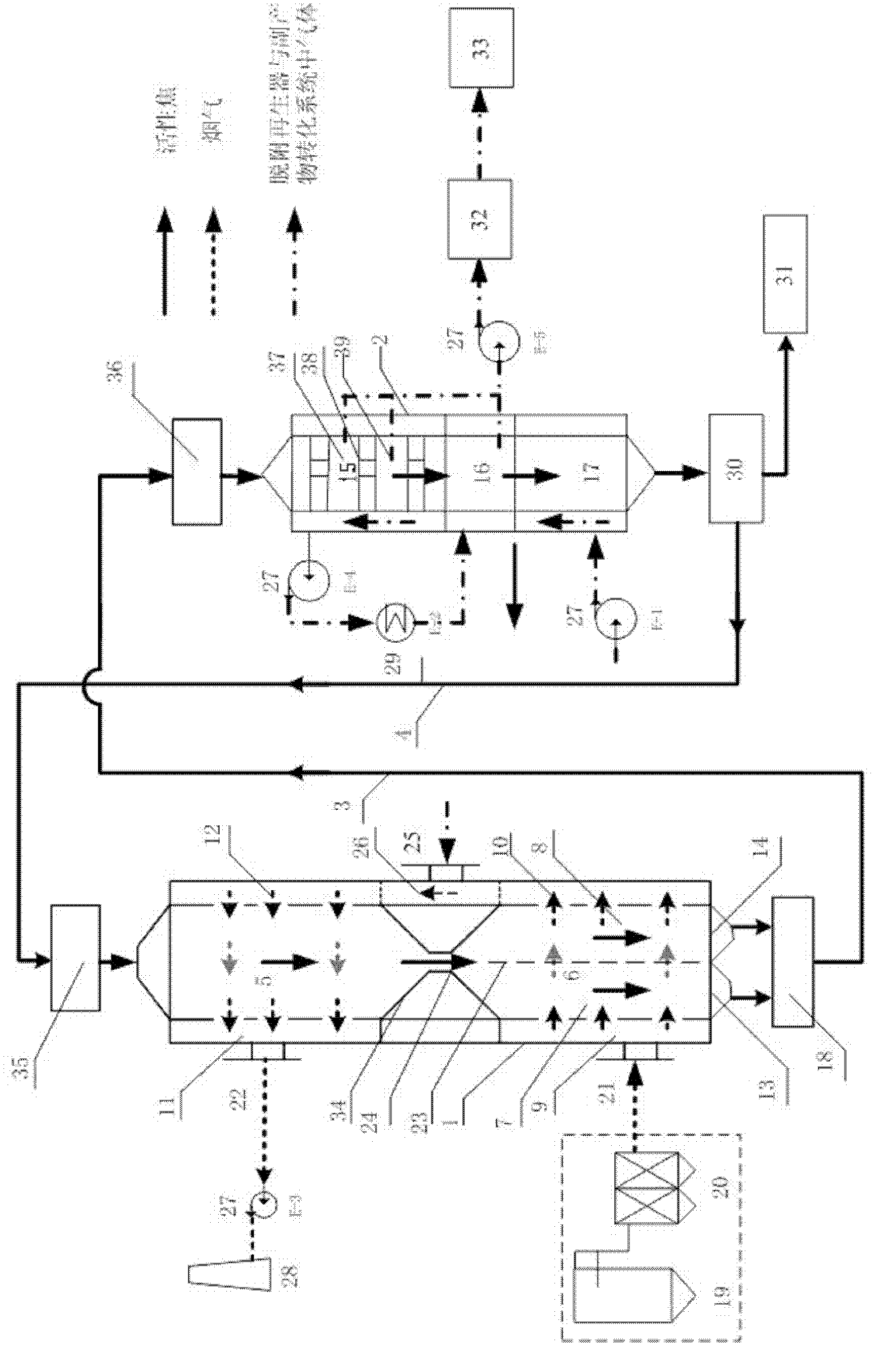

System for desulfurizing and denitrating active coke flue gas, and process method

ActiveCN102430318AIntegrated purification effect is obviousImprove utilization efficiencyDispersed particle separationSulfurDesorption

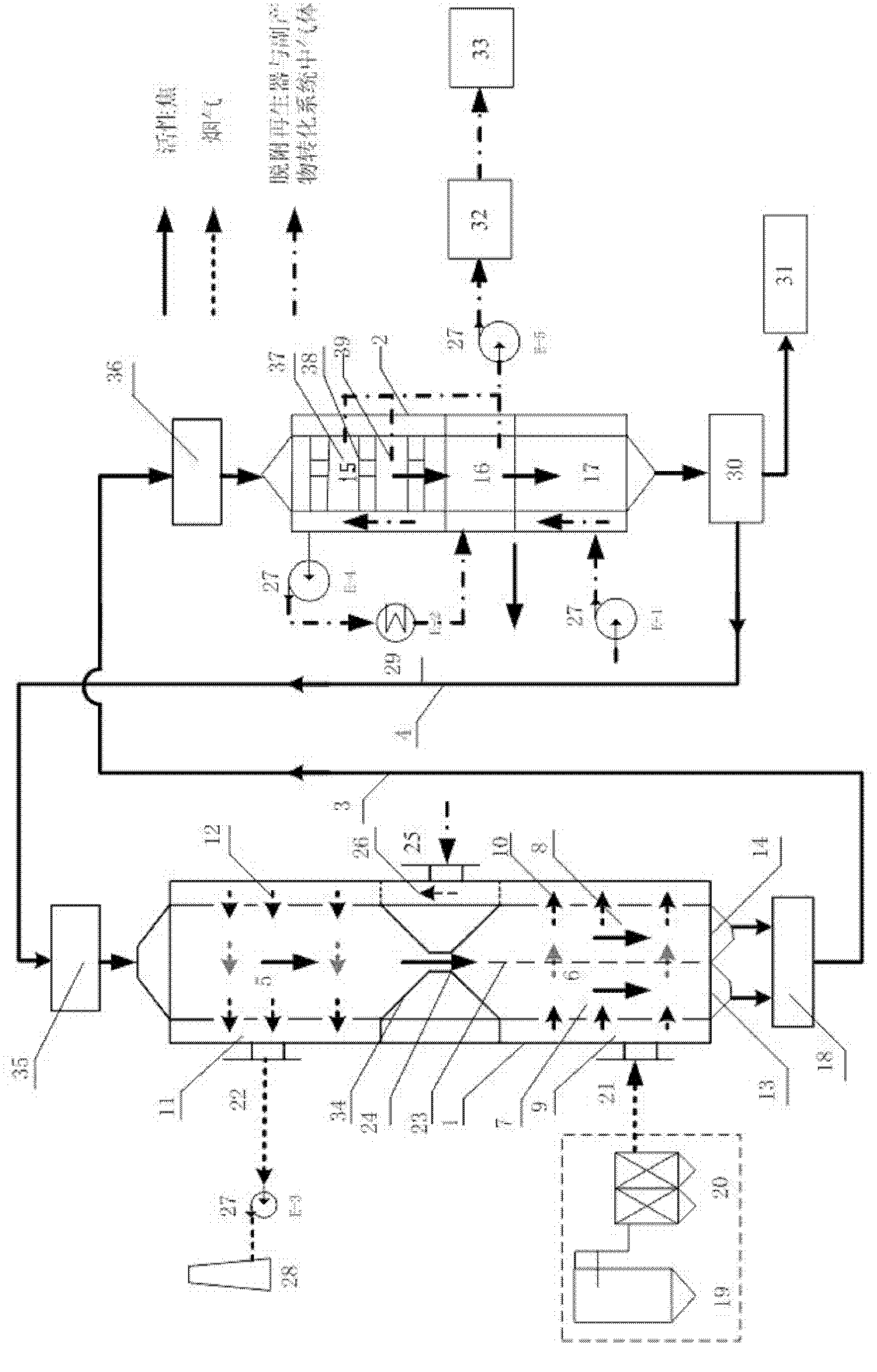

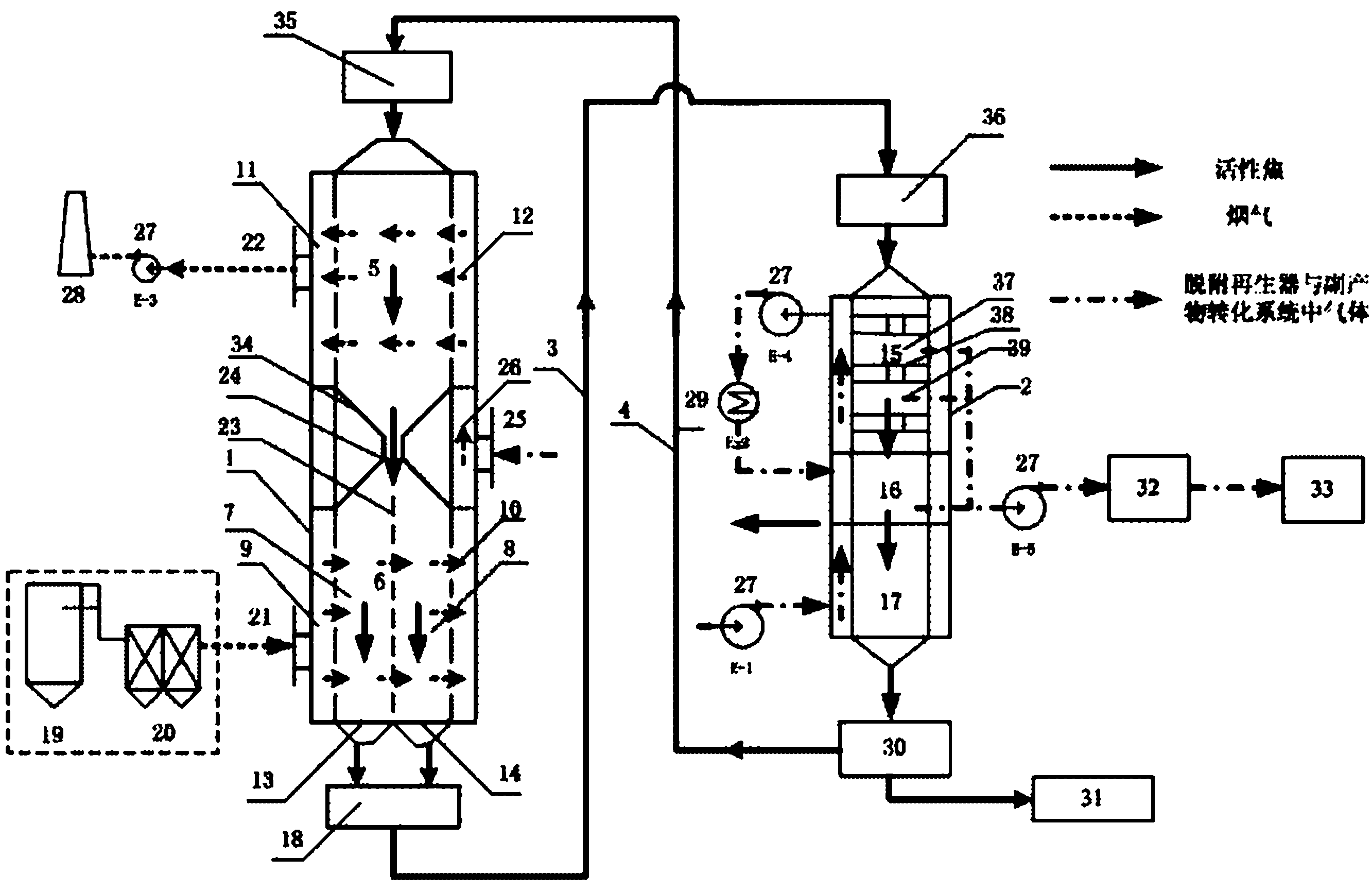

The invention discloses a system for desulfurizing and denitrating active coke flue gas, and a process method. The system comprises an adsorption reactor, a desorption regenerator, a material conveying device and a byproduct conversion device, wherein the devices are connected by specific pipelines and functions of the devices are realized by using a specific process method; the adsorption reactor is a composite layer double-section cross flow moving bed and consists of a denitration section and a desulfurization section, so that SO2, NOx, dioxin, mercury and smoke dust in flue gas are purified in an integrated mode; the desorption regenerator is divided into a preheating area, a regeneration area and a cooling area, so that active coke on which the mercury, and the dioxin are enriched are extracted, and subsequent harmless treatment of the active coke is realized; the desorption regenerator performs heat exchange by a heater and circulates heat energy for recovering, and the byproduct conversion device is used for performing sulphur recycling on desorption regenerated gas generated in the regeneration process; and by the process method, the integrated purification of the flue gas and the harmless treatment of the active coke can be realized.

Owner:SHANGHAI CLEAR ENVIRONMENTAL PROTECTION SCI & TECH

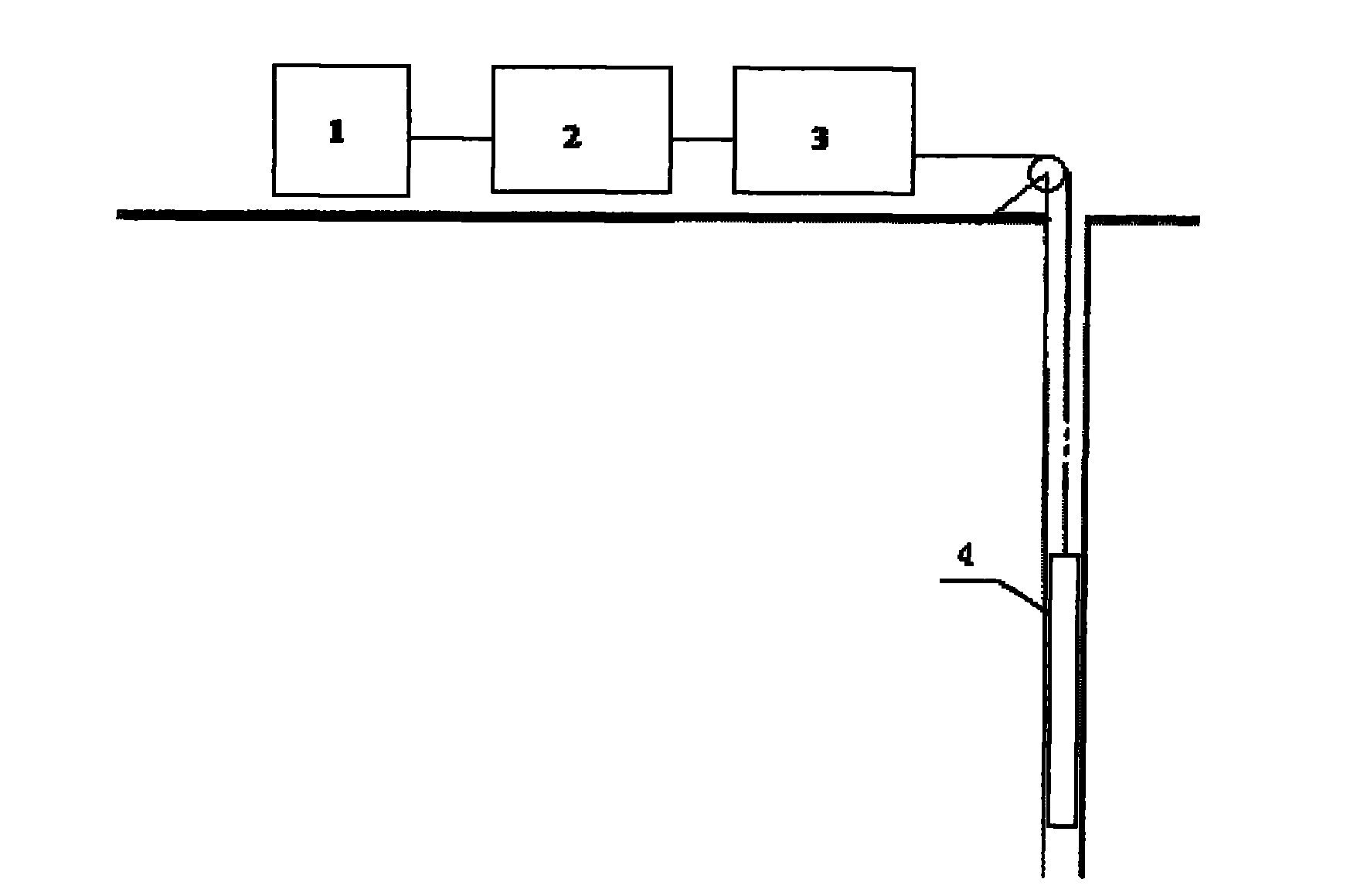

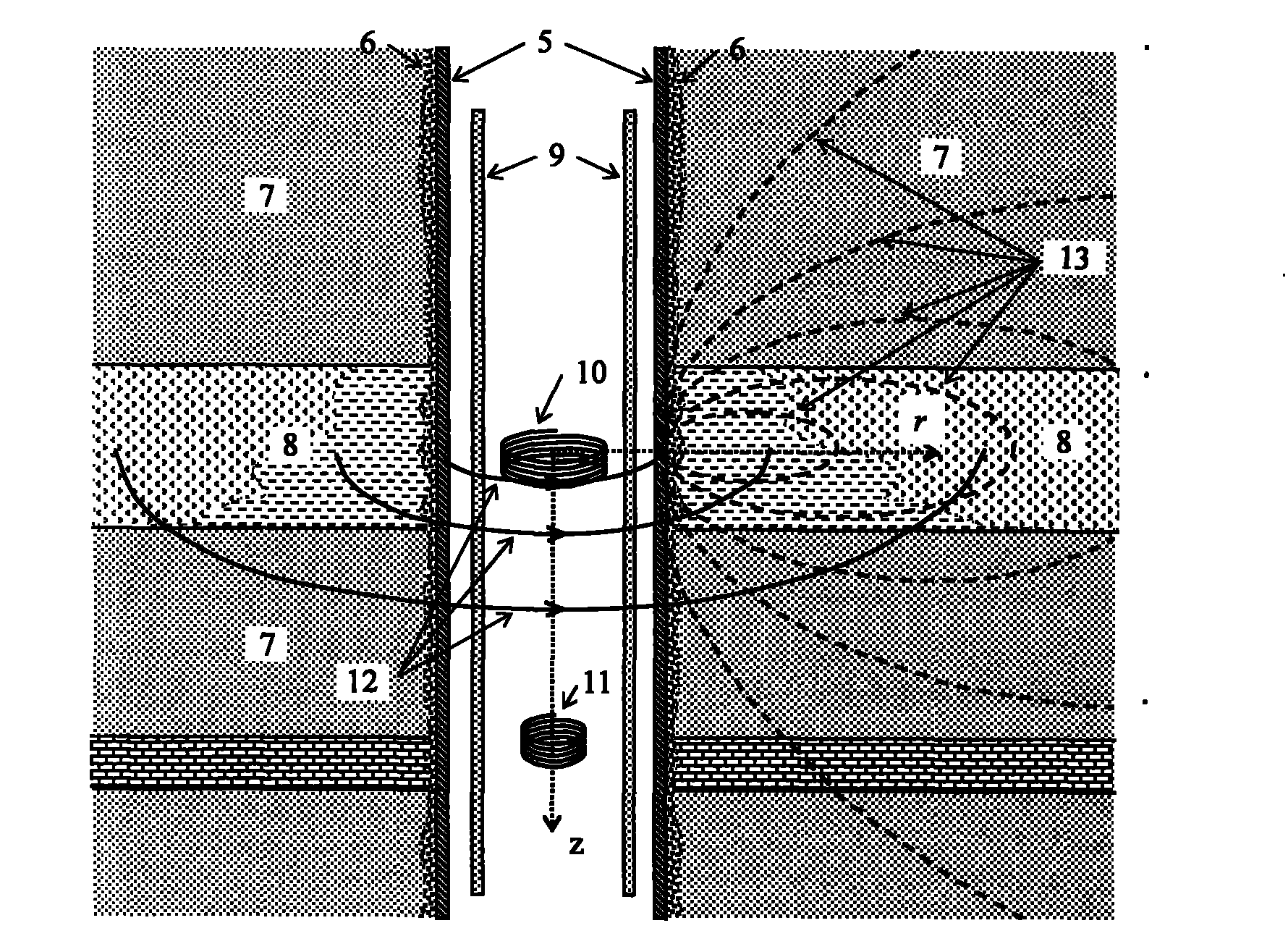

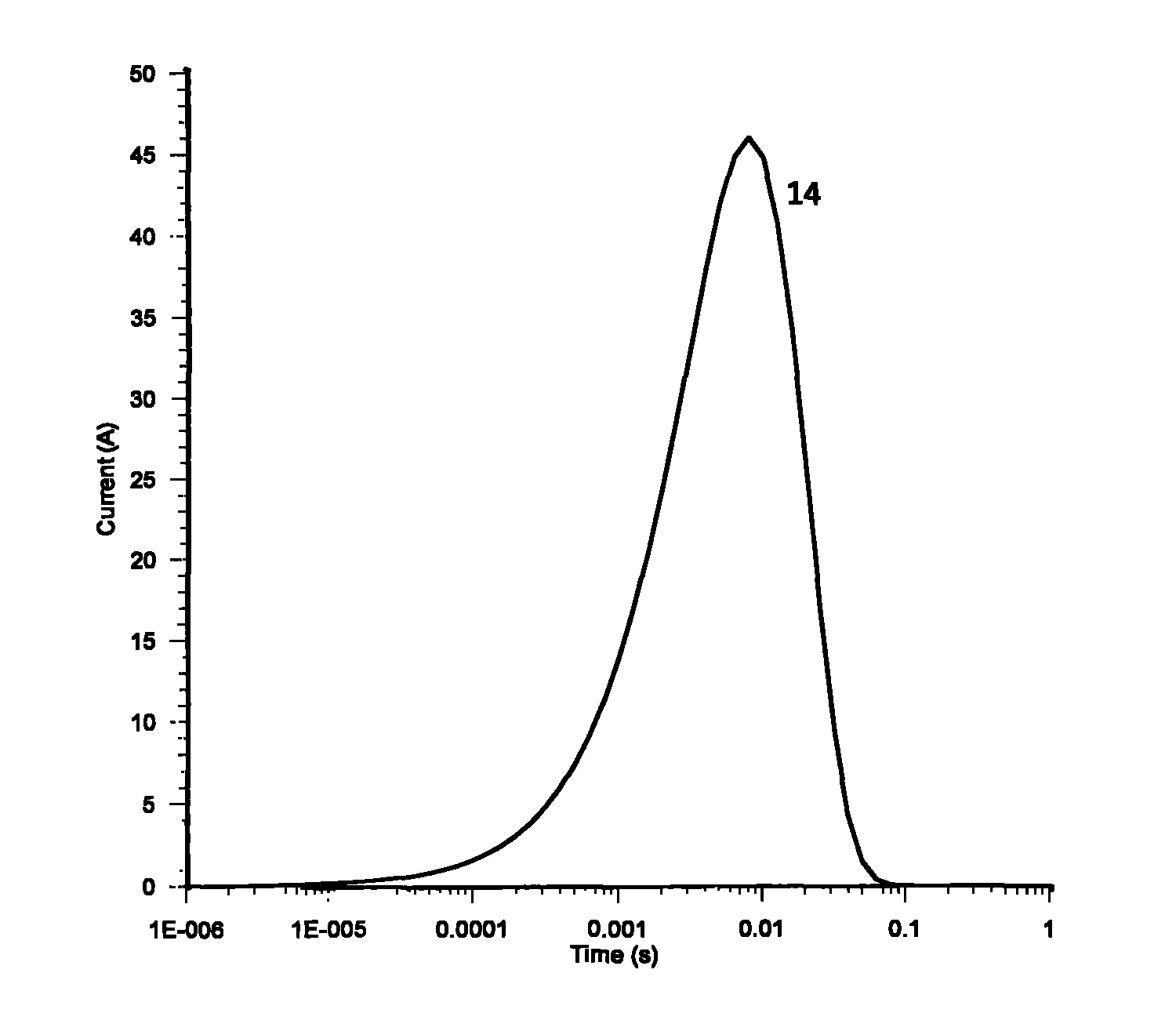

Borehole time domain pulse electromagnetic method for detecting electrical resistivity of stratum out of metal bushing

InactiveCN102121374AConsumes a lotNot boundElectric/magnetic detection for well-loggingSurveyElectromotive forceSignal transition

The invention discloses a borehole time domain pulse electromagnetic method for detecting the electrical resistivity of the stratum out of a metal bushing, comprising the following steps of: 1) building a large-power pulse emitting source underground; receiving the time variable data of induced electromotive force e produced by a magnetic field vertical component Bz recorded in the recording system; and simultaneously recording emitting wave type and receiving signal; 2) emitting and receiving several times, and overlapping signals to improve the signal to noise ratio; 3) calculating bushing response according to the bushing parameter and the recorded emitting source current wave type to obtain the induced electromotive force delta epsilon f relative to the stratum out of metal bushing; 4) correcting the relative induced electromotive force; 5) one-dimensionally reversing and transforming the time variable observed signal into the radial variation information of the electrical resistivity of the stratum around the well; 6) obtaining the longitudinal and radial two-dimensional images of the electrical resistivity of the stratum out of the borehole bushing through the reversed electrical resistivity; 7) confirming the distributing situation of the surplus oil in the storage layer through the distribution of the electrical resistivity of the storage layer out of the bushing according to the survey data and the explained result when well completion.

Owner:YANGTZE UNIVERSITY

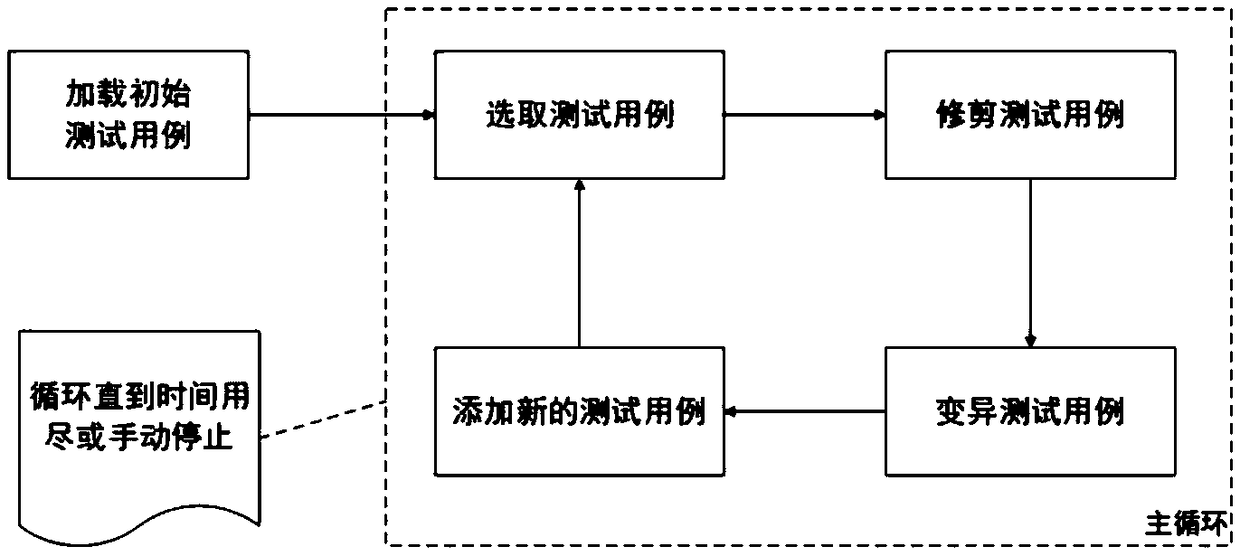

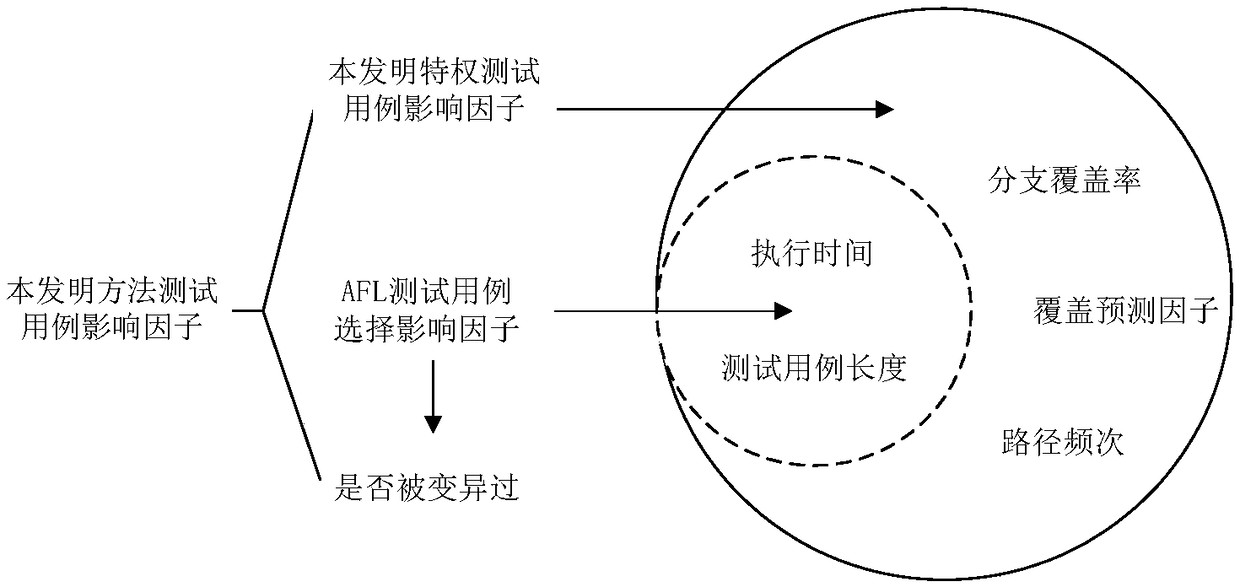

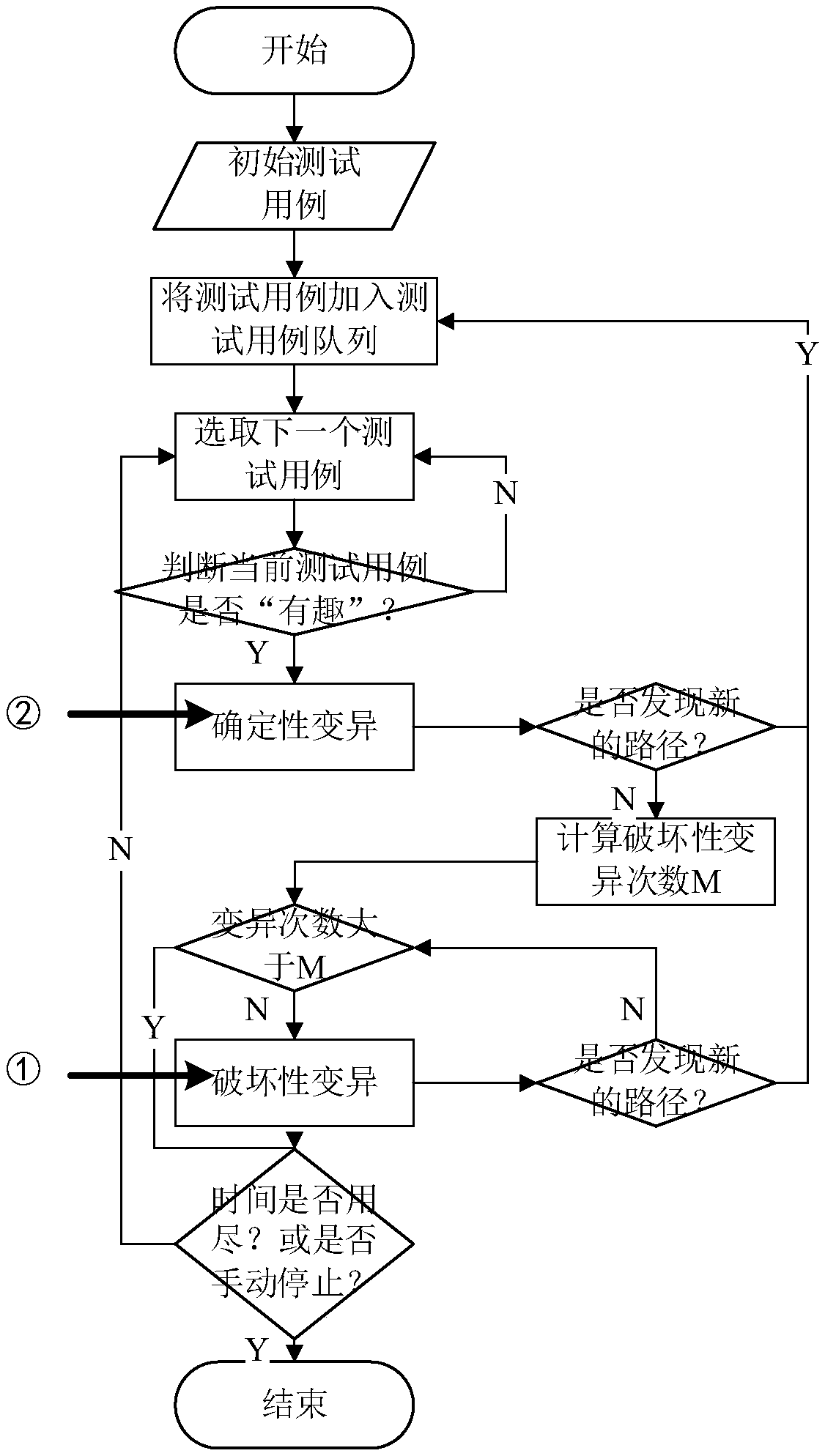

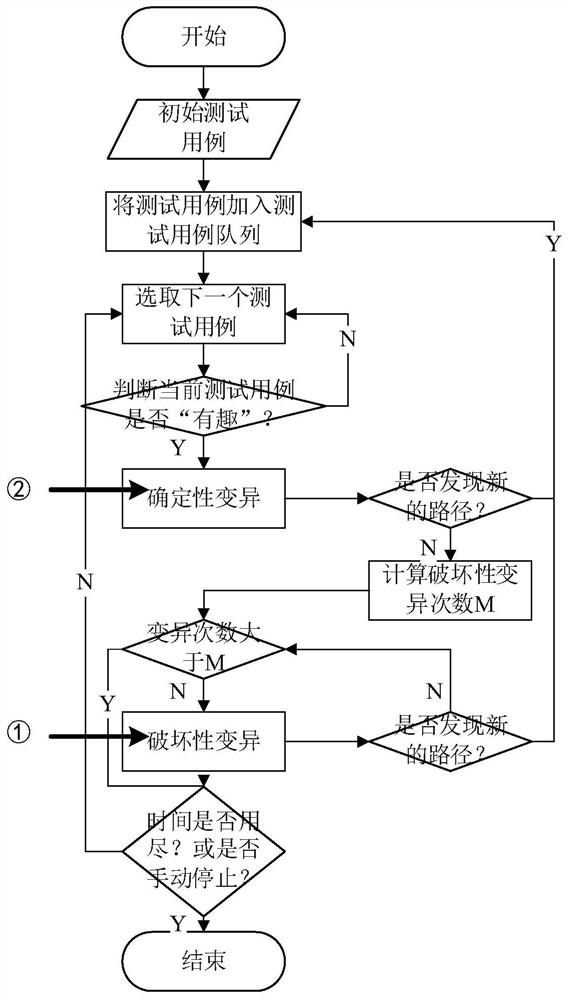

A fuzzy testing framework based on AFL

The invention discloses a fuzzy test framework based on AFL, which comprises a test case preprocessing module and an AFL processing module. In the AFL processing module, the test case selection sub-module sequentially selects the next test case to be mutated from the test case queue; before selection, according to the historical variation of test cases, those test cases with greater probability tofind new paths are identified as privileged test cases, and are selected as test cases to be mutated first. The test case mutation quantity determining sub-module adjusts the energy allocated to eachtest case according to the historical mutation of the test case, and then adjusts the mutation quantity of the test case to be mutated. The test case mutation sub-module determines the mutation byteaccording to the valid byte in the test case. The mutation is then performed according to the number of mutations and the mutation bytes. The invention solves the blindness problem of the current AFLtool in the test case generation strategy, and the insufficiency that the effective test case cannot be generated according to the highly structured data format.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

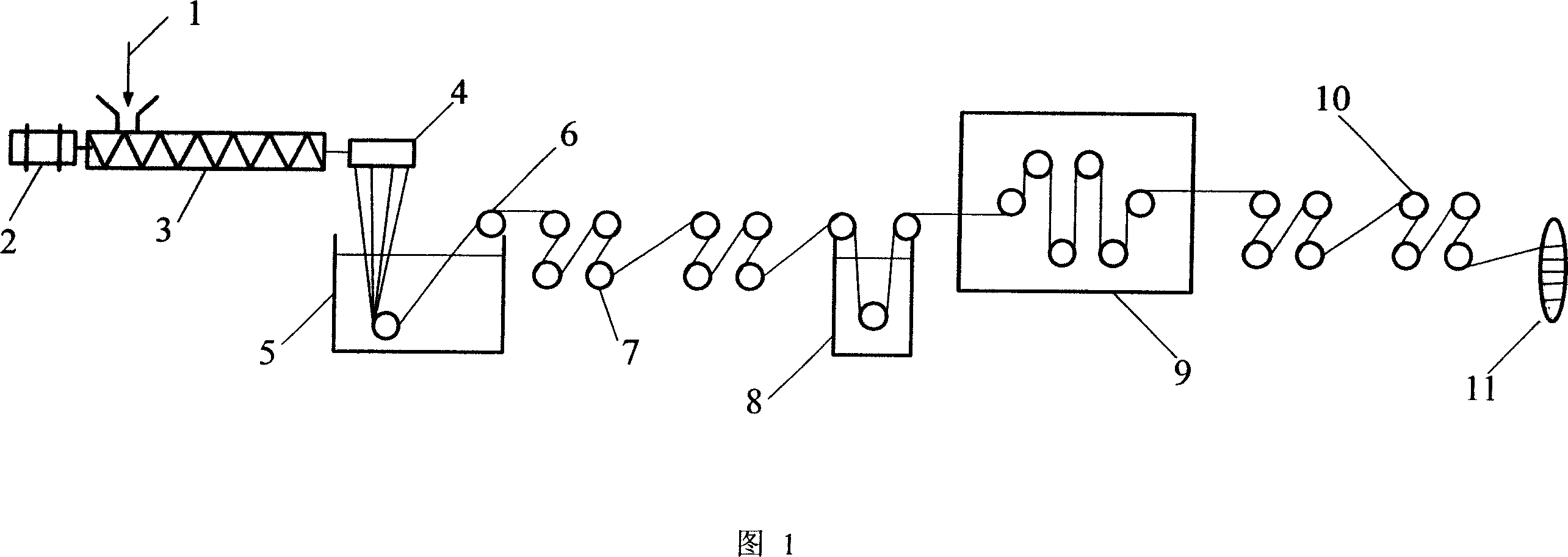

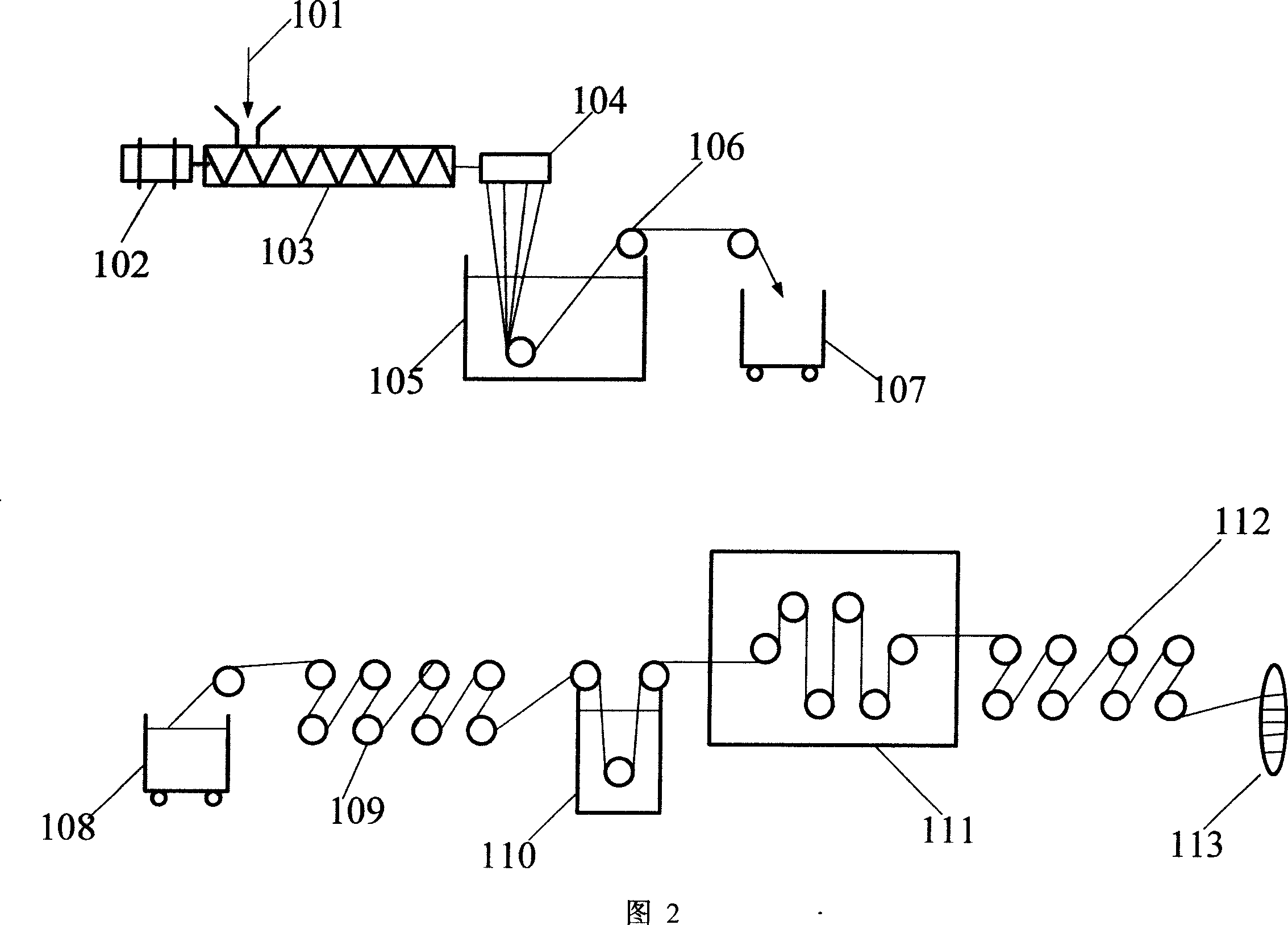

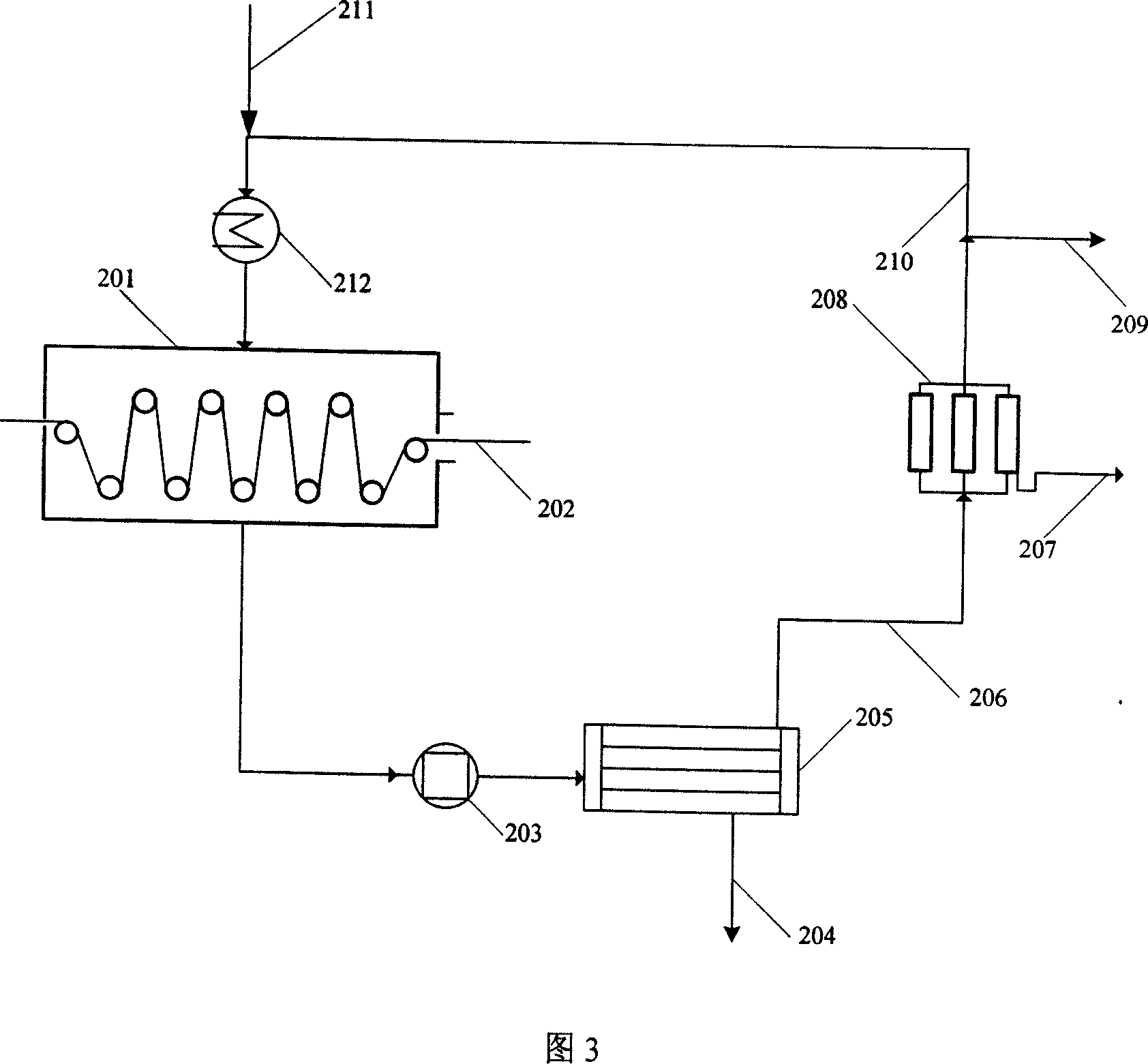

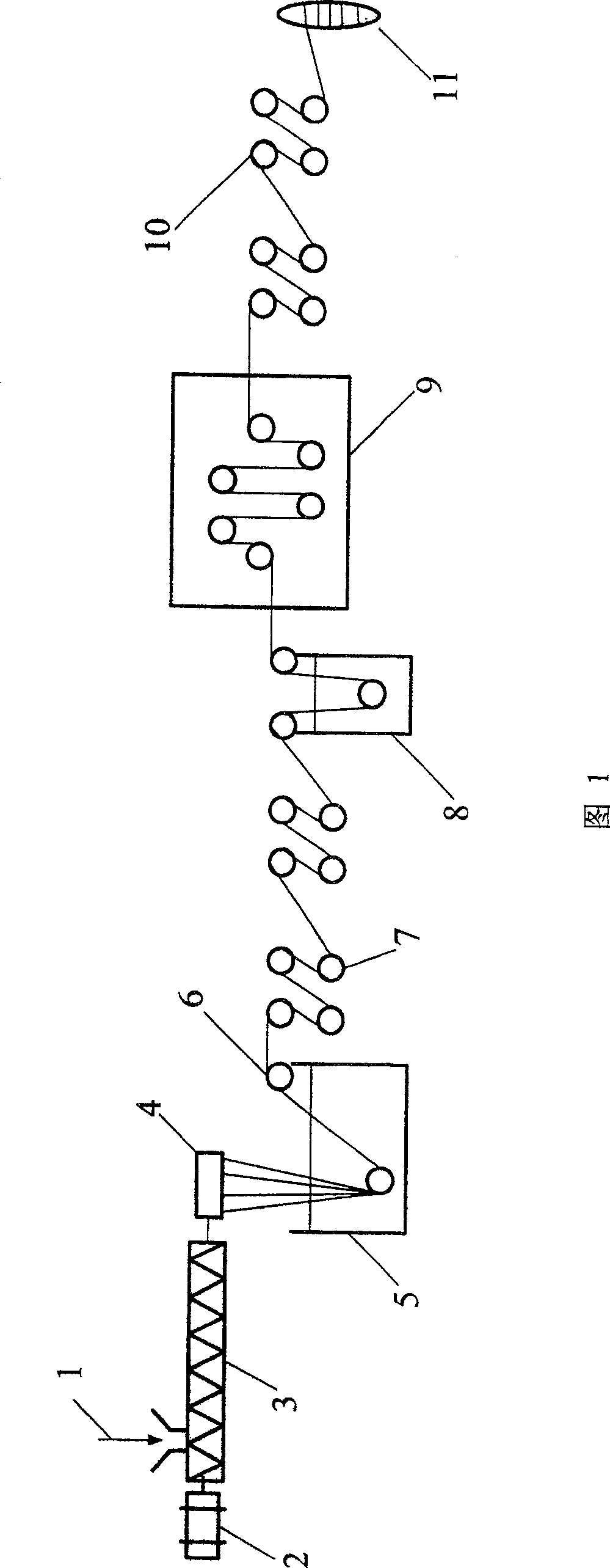

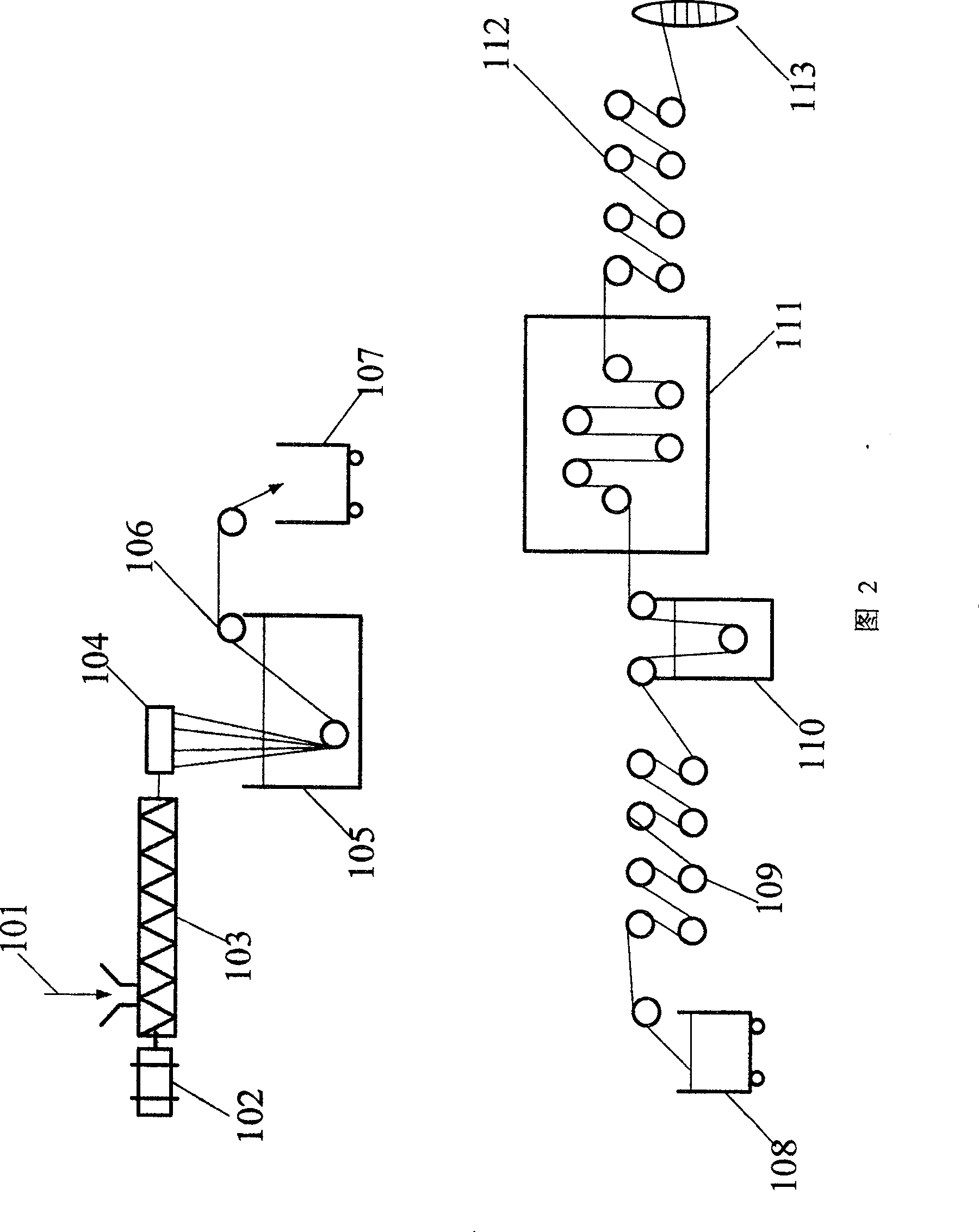

Extraction and desiccation method in preparing process of polyvinyl fibre with super high molecular weight

ActiveCN101012577AReduce oil contentHigh strengthArtificial filament washing/dryingMonocomponent polyolefin artificial filamentFiberPolymer science

The invention relates to extracting and drying methods in the process for preparing uhmwpe fiber, belonging to the field for polymers preparing technology. The method comprises that the uhmwpe powder, assistant and solvent is solidified by extruding after they are mixed in uniformity and solved sufficiently; the solvent is eliminated in extracting process and the extraction agent is eliminated by drying technology; the final product is formed by heat drawing. It is characterized in that because dichloromethane is used as the extraction agent, there is good safety, low boiling point and it is eliminated easily. Because countercurrent extraction operation is adopted in the extracting process and there is no ultrasonic wave, it is provided with low drying temperature, simple technology, high intensity of fiber product, high modulus and low oil percentage of fiber.

Owner:安徽威亚新材料技术有限公司

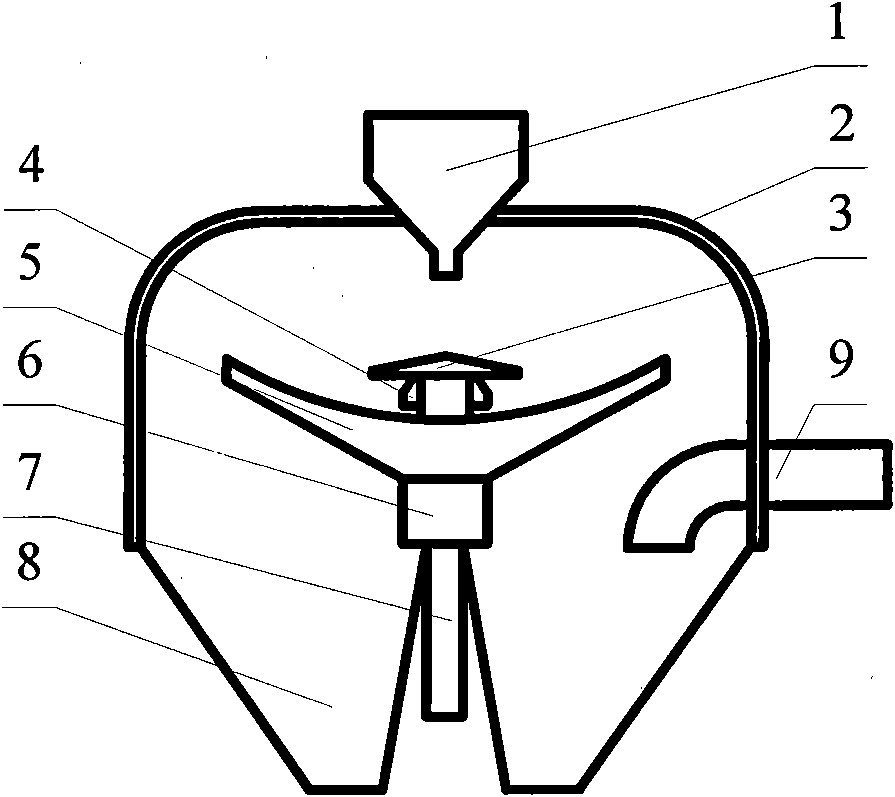

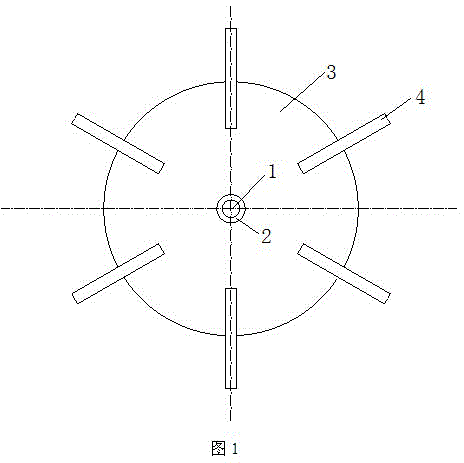

Liquid blast furnace slag granulation device and granulation method thereof

InactiveCN101824499AIncrease consumptionHigh activityRecycling and recovery technologiesSlagSolid particle

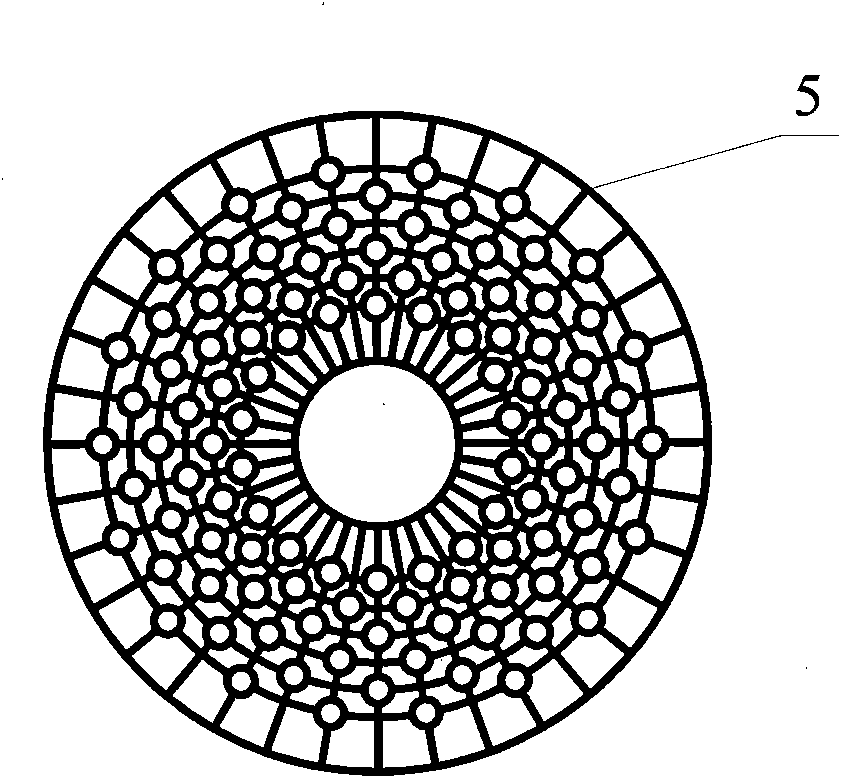

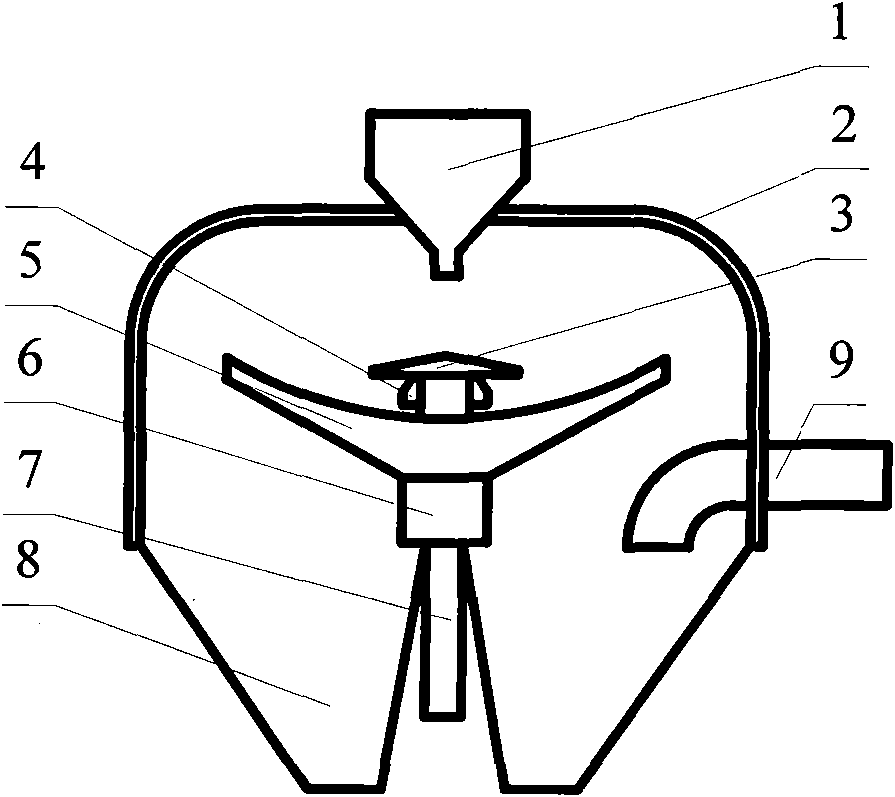

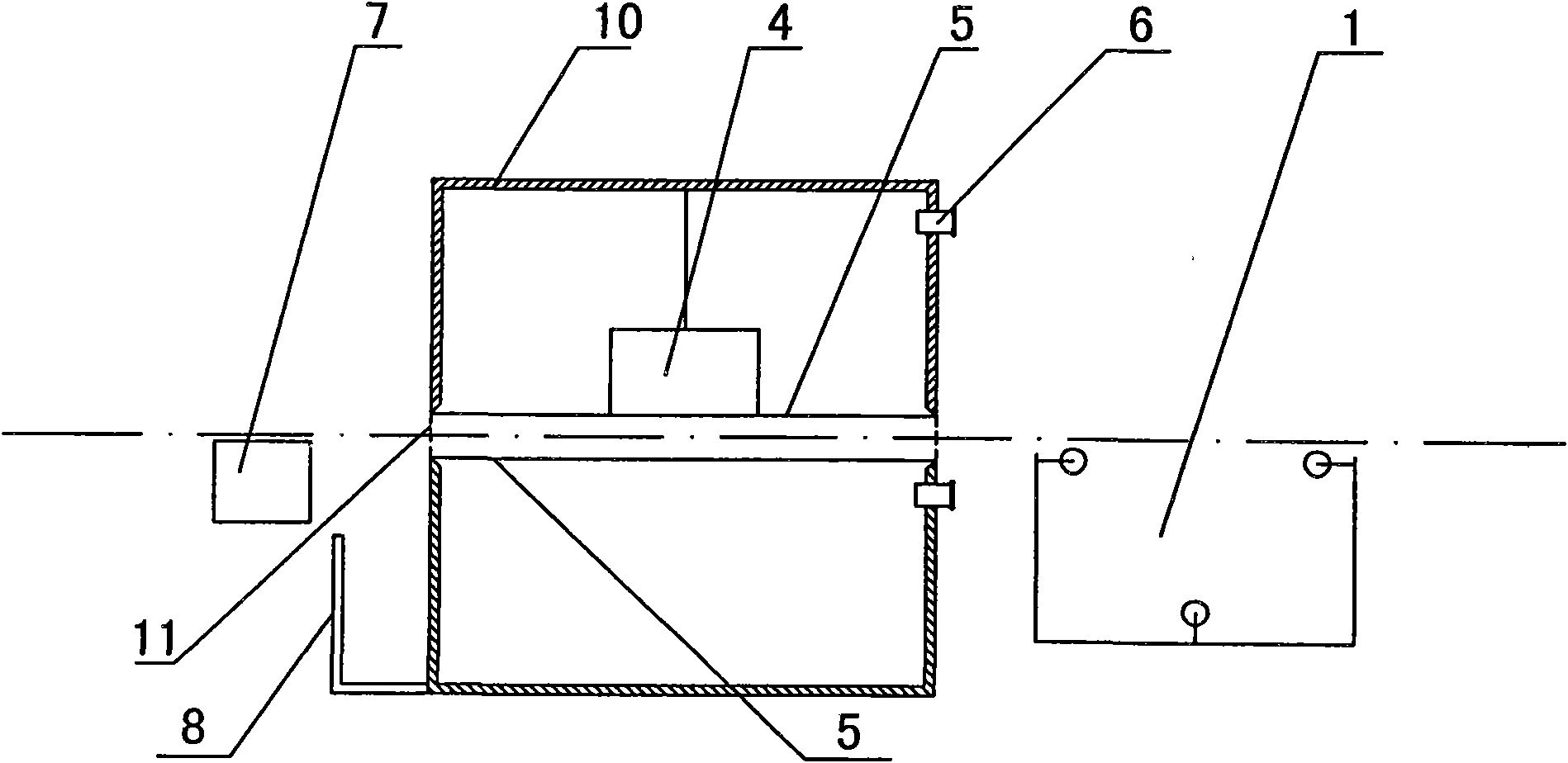

A liquid blast furnace slag granulation device comprises a gate, a granulator, a primary turntable, a water nozzle, a secondary turntable, a drive device, a center water pipe, a hopper and an exhaust pipe, wherein the gate is arranged in the middle part of the upper part of the granulator, the upper half part of the granulator is in a water cooled wall structure, the lower half part of the granulator is contracted to form the hopper, the primary turntable, the water nozzle, the secondary turntable, the drive device and a center water pipe are arranged on the center line of the interior of the granulator, the diameter of the secondary turntable is larger than that of the primary turntable, the water nozzle is located between the primary turntable and the secondary turntable, the opening direction of the water nozzle points at the upper surface of the secondary turntable, the center water pipe is arranged on the center of the turntables, the upper part of the center water pipe is connected with the water nozzle, and the lateral wall of the granulator is connected with the exhaust pipe. The liquid-state blast furnace slag is crushed and condensated into solid particles under the action of centrifugal force and water film bursting force. The invention utilizes the centrifugal force and bursting force of water flash vaporization and expansion, enhances the granulation effect, reduces power consumption and equipment investment of the granulation device, and has small water consumption and water resource saving.

Owner:云南阳光基业能源管控技术股份有限公司

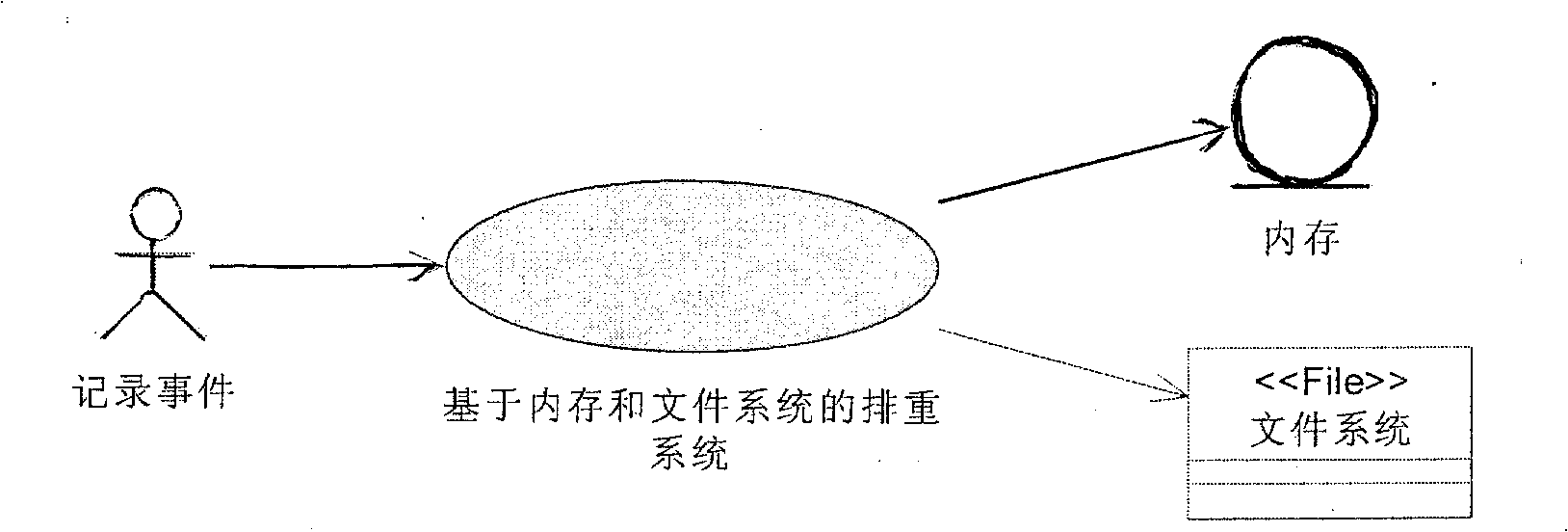

Internal memory and file system mixing rearrangement method based on HASH algorithm

InactiveCN101493835ASolve efficiency problemsSolve functionAccounting/billing servicesSpecial data processing applicationsInternal memoryFile system

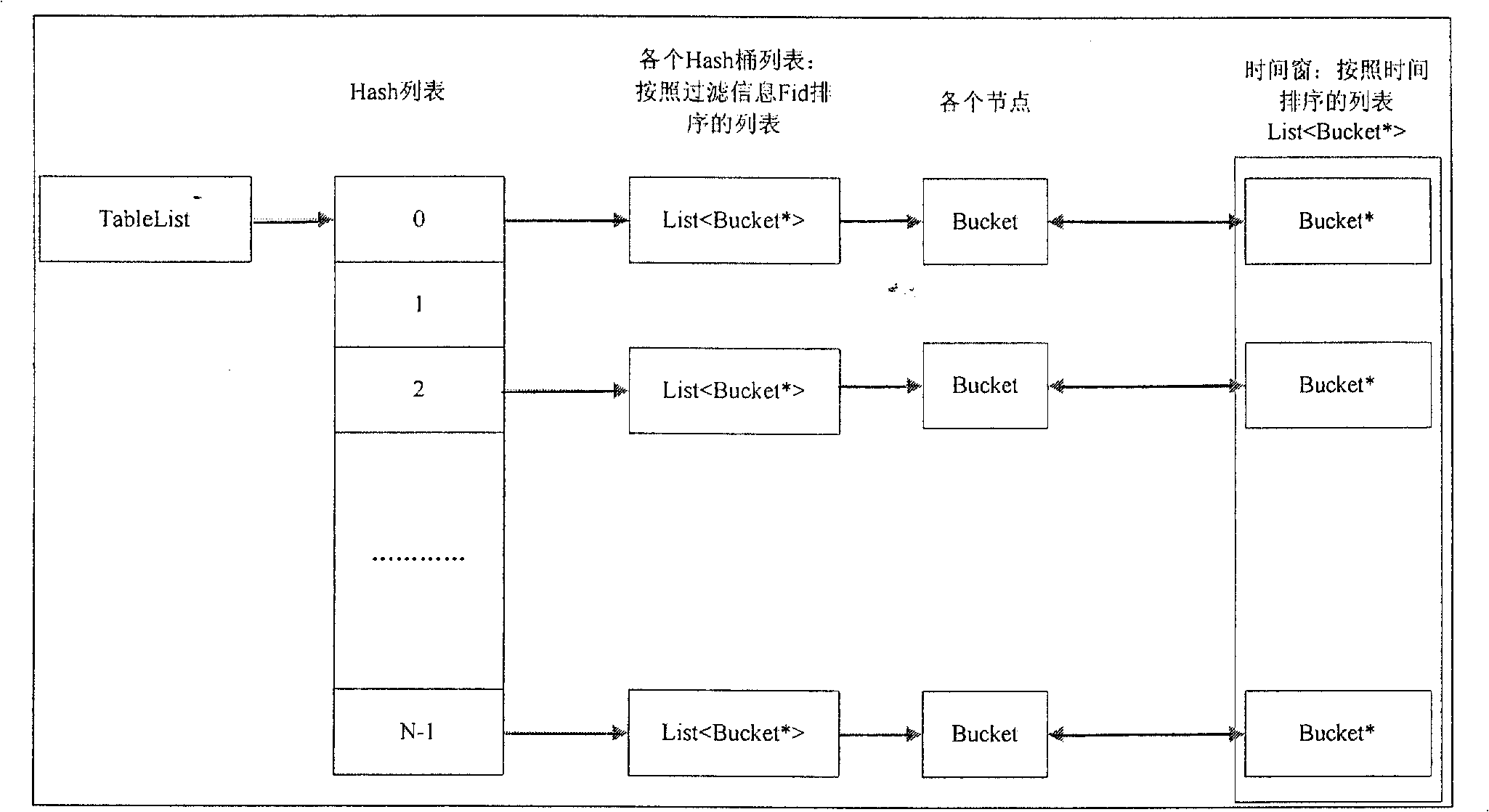

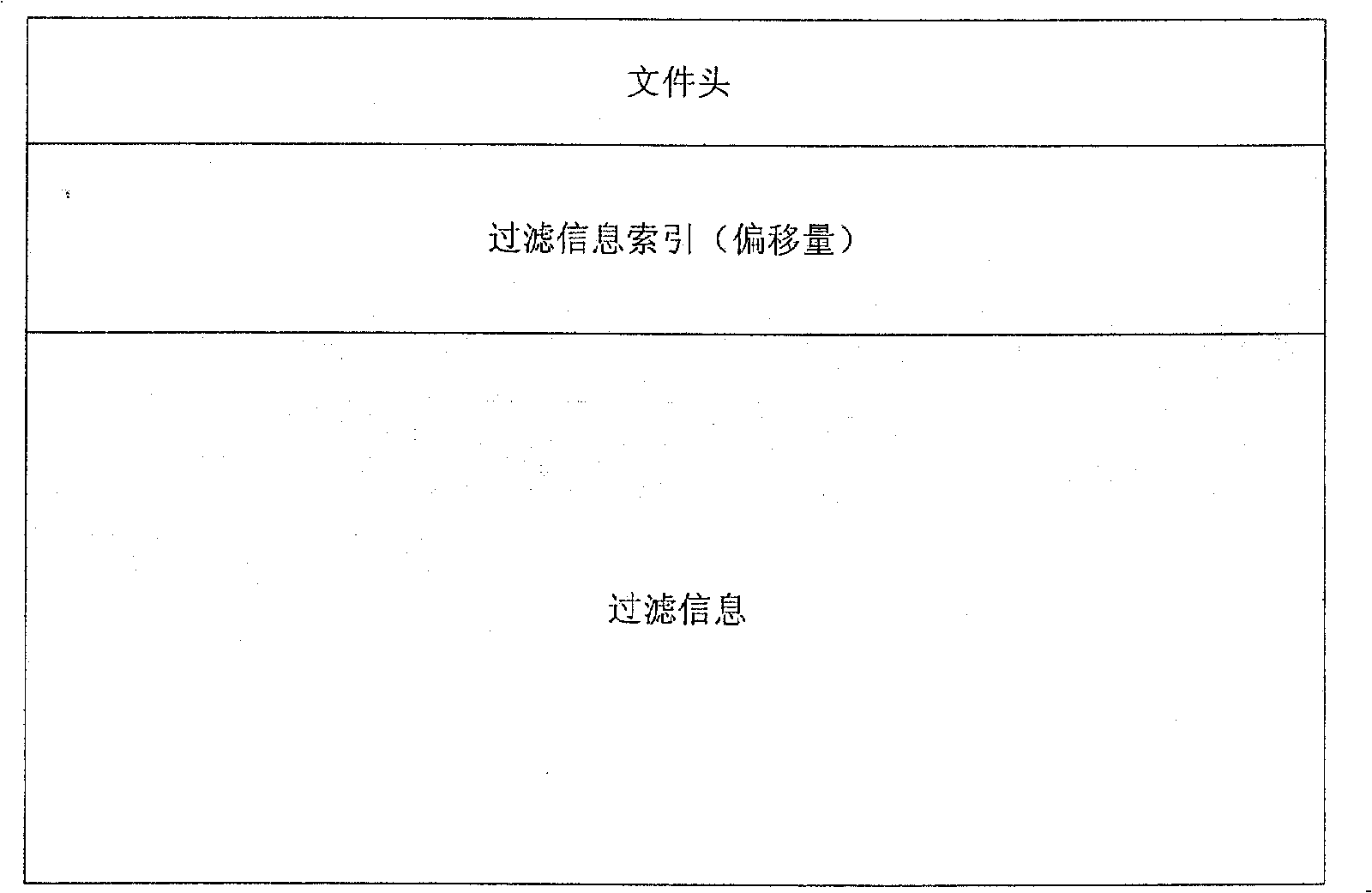

The invention relates to an implement method based on mixed tautology removal of an HASH algorithm memory and a file system, which adopts the combination of the tautology removal of the memory and the tautology removal of the file system so as to achieve a win-win result of data storage use space and processing efficiency. The implement method has the procedure that tautology removal information in a certain period of time is loaded into the memory and the tautology removal of the memory is adopted, and beyond the time the tautology removal of the document is adopted. The implement method mainly has the following steps: step 1. tautology removal configuration information (record format information, tautology removal types) is loaded into the memory; step 2. the tautology removal information in a certain period of time (configurable) is loaded into a private memory; step 3. the tautology removal of memory is performed, i.e., the tautology is removed according to the filtering information in the memory; and step 4. tautology removal of a file is performed, the tautology is removed according to the historical filtering information in the file. The storage structure of the information of the tautology removal in the memory has two characteristics of HASH lists and time window.

Owner:LINKAGE SYST INTEGRATION

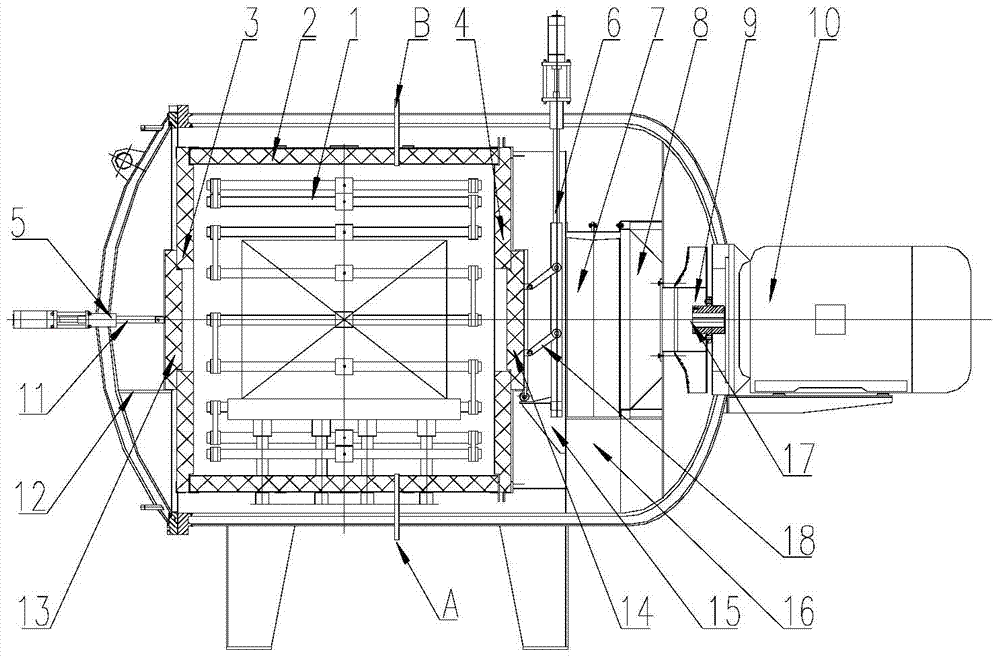

A horizontal high-pressure gas quenching-tempering-nitridation vacuum multipurpose furnace

ActiveCN104195503AAutomate program operationWith manual operation functionSolid state diffusion coatingFurnace typesTemperingEngineering

The invention discloses a horizontal high-pressure gas quenching-tempering-nitridation vacuum multipurpose furnace and relates to the field of metal vacuum thermal treatment. The furnace comprises a vacuum furnace main body, a heating chamber, a wind cooling system, a vacuum unit, a gas supplying system and an electric control system. The heating chamber comprises heating elements, a cylinder, a front cover and a back cover. The front cover and the back cover are provided with wind guiding holes. An air cylinder drives movable doors to open and close the wind guiding holes so as to guarantee circular flowing of cooling gas during tempering and gas quenching and to guarantee a closed structure of the heating chamber during nitridation. The furnace overcomes the disadvantages caused by adoption of metal nitridation tanks adopted by nitridation furnaces at present, namely slow heating and cooling speeds, low atmosphere pressure, and the like. The furnace is provided with using conditions for high-pressure high-flow-rate quenching and tempering, is simple in structure and practical, and truly achieves the using requirements on vacuum multipurpose furnaces.

Owner:北京华翔电炉技术有限责任公司

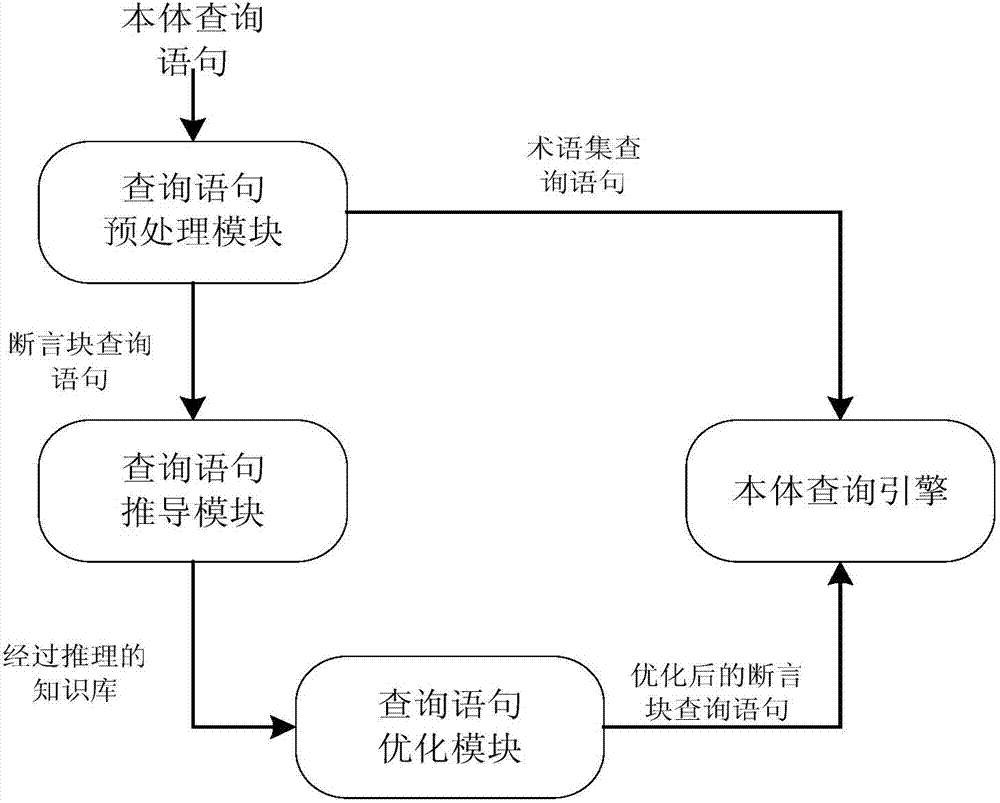

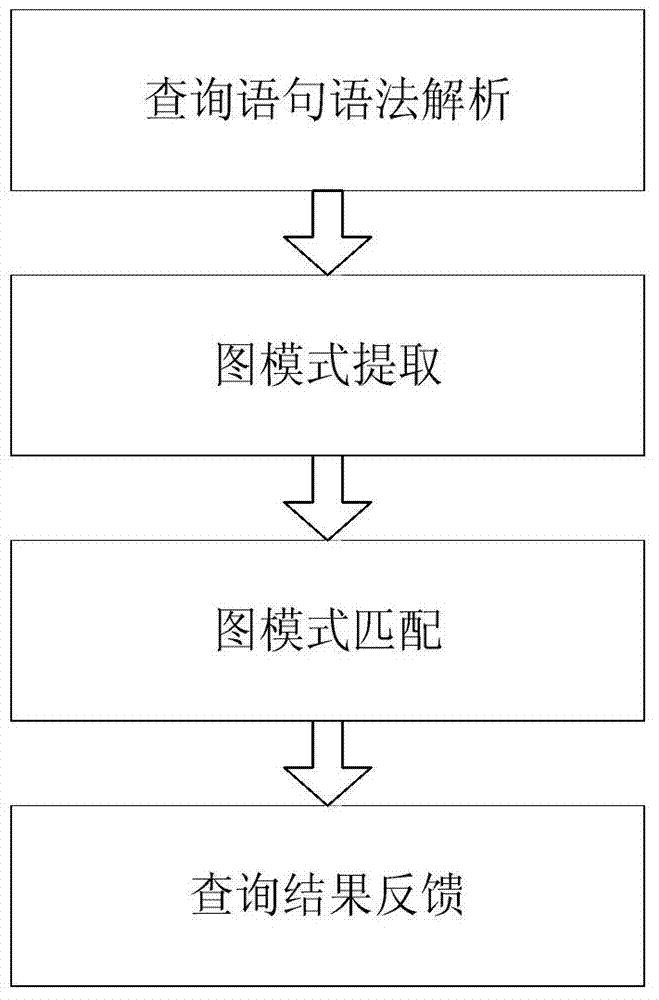

Ontology query engine optimizing system based on ontology semantic information

InactiveCN103617265AImprove query efficiencyOptimize query statementSpecial data processing applicationsQuery statementSemantic Web

An ontology query engine optimizing system based on ontology semantic information comprises a query statement preprocessing module, a query statement deducing module and a query statement optimizing module. The query statement preprocessing module is used for converting query statements into the expression form of a disjunctive normal form, classifying query variables and query atoms of the query statements, differentiating the query statements aiming at a terminology set and calling a query engine to convert the original query statements into a series of corresponding assertionbox query statements. The query statement deducing module is used for combining the query atoms of the assertionbox query statements and the terminology set in a knowledge base to form a temporary knowledge base and deducing hidden information of the newly formed knowledge base through an inference engine. The query statement optimizing module is used for optimizing the original query statements according to the deduced hidden information through related rules, searching for a result on assertionboxes, and combining the result on the assertionboxes with a result on the terminology set to obtain a final result. The ontology query engine optimizing system shortens query time and can be widely applied to an existing semantic net development tool and play a role in optimizing the query engine.

Owner:深圳市千方航实科技有限公司

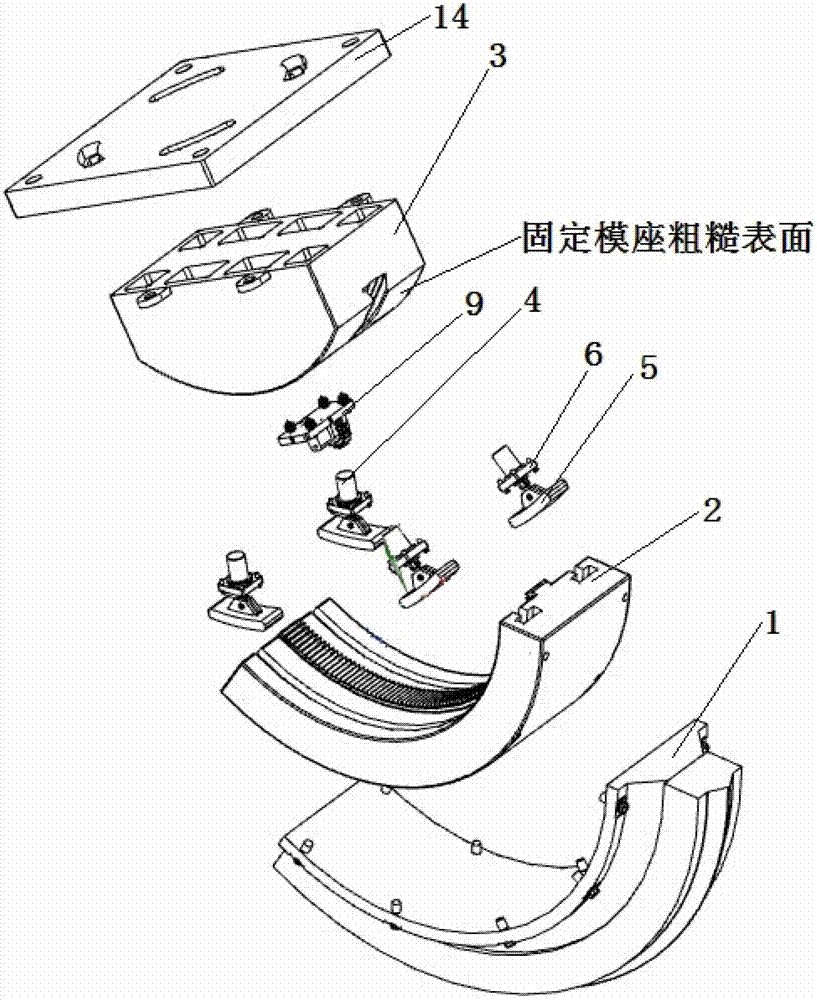

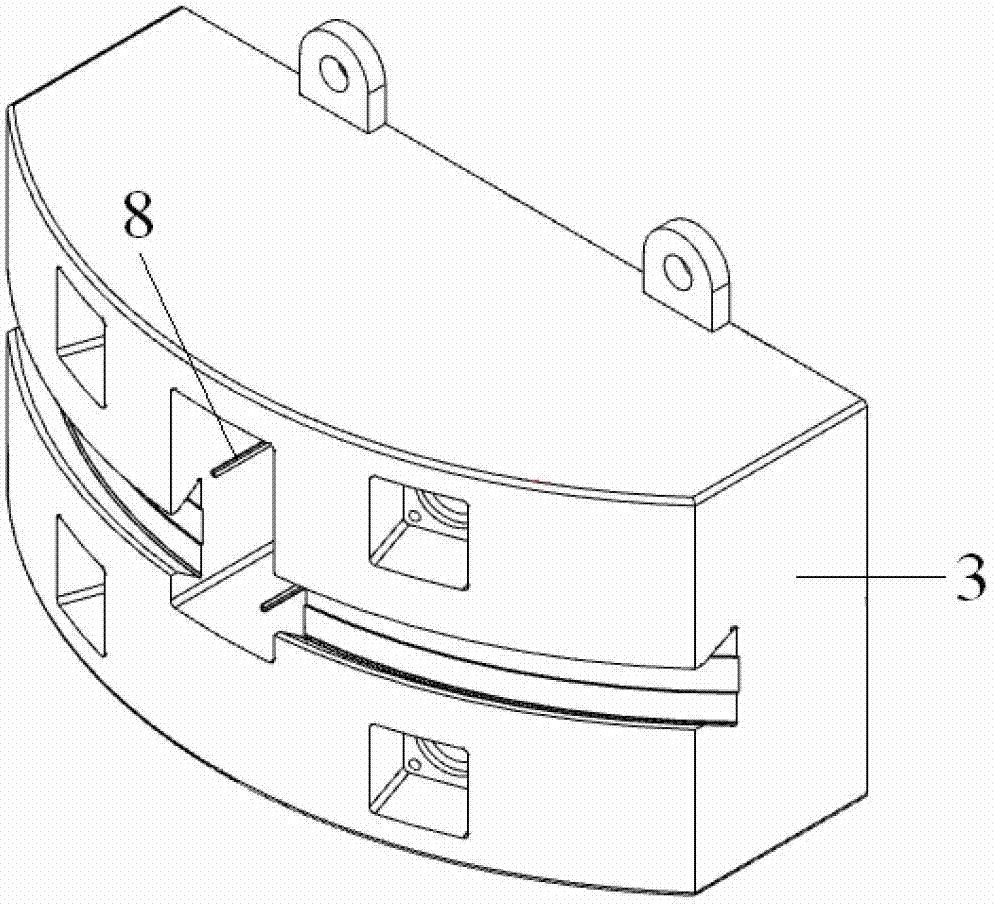

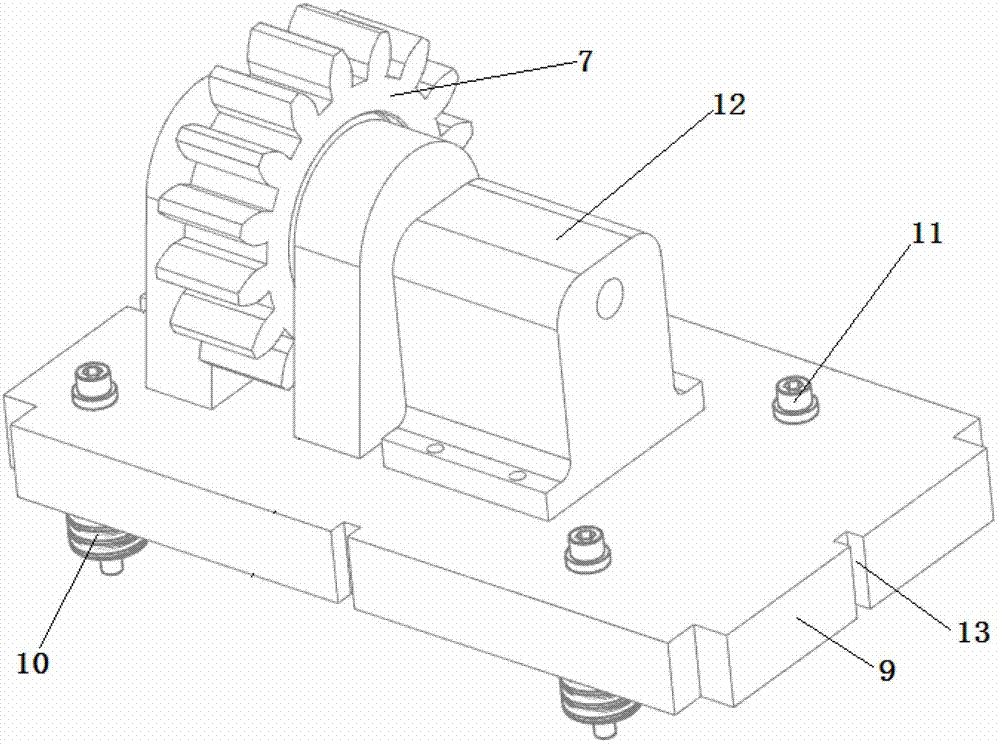

Hammer forging device for forming complicated long-axis forgings applied to radial forging machine

InactiveCN102728757AAxial dimensional accuracy controlIncrease consumptionForging hammersForging/hammering/pressing machinesHelical lineGear wheel

The invention relates to a hammer forging device for forming complicated long-axis forgings applied to a radial forging machine. The hammer forging device consists of forging units which are respectively mounted on hammers of a precise forging machine and have the same structure, wherein each forging unit consists of a fixed mold seat, a moving mold seat, a forming module and the like. Different from the existing forging method, according to the hammer forging device, the relative positions of the moving mold seats and the fixed mold seats are maintained by using compressed slide blocks, when the compressed slide blocks are opened, driving gears mounted on the fixed mold seats drive tooth rings machined at the top ends of dovetails of the moving mold seats so as to realize the circumferential feeding of the moving mold seats, and thus, variable plastic deformation zones are formed by regions among the forming modules; and blanks are clamped to make axial and rotational movement by using a clamping head of the radial forging machine, so that the blanks are progressively formed in a piecewise manner, and then, the long-axis forgings which need multiple mold parting directions and have complicated cross sectional shapes, helical line characteristics and larger sizes can be forged.

Owner:SHANGHAI JIAO TONG UNIV

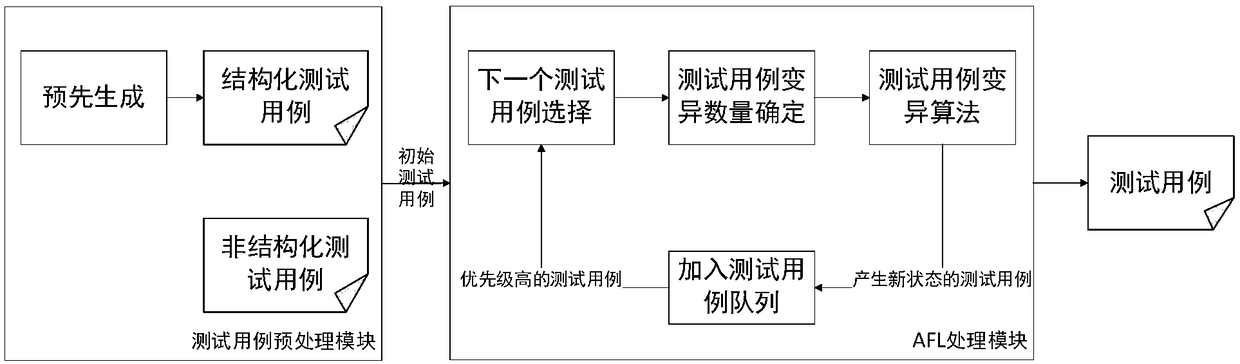

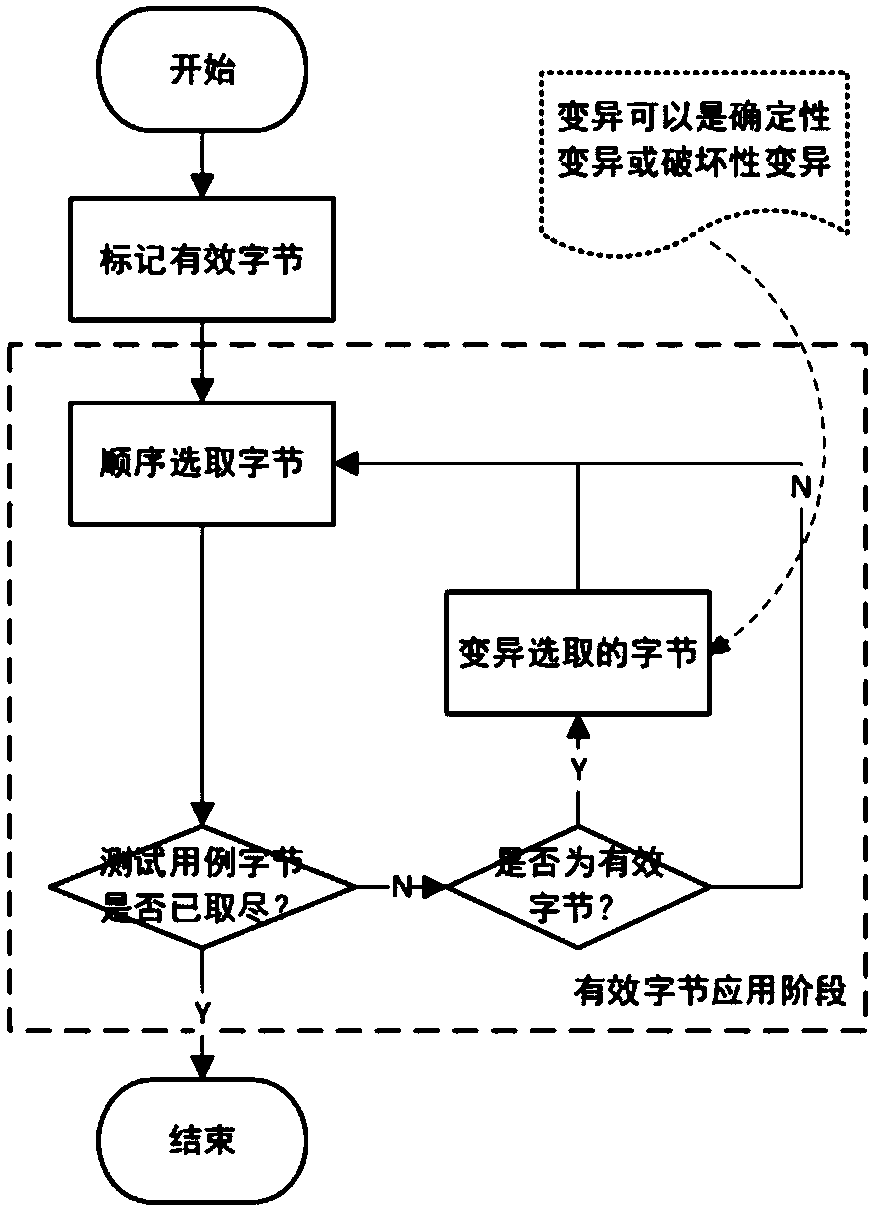

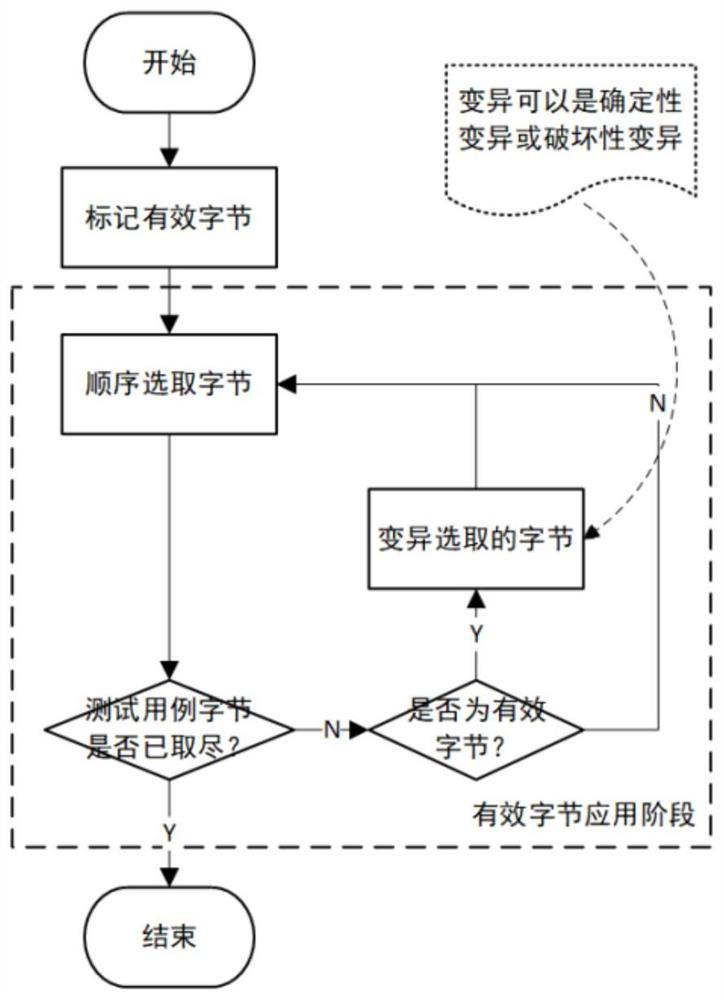

An AFL-based fuzzy test mutation method and apparatus

ActiveCN109101422AEasy accessConsumes a lotSoftware testing/debuggingSmall probabilityResource consumption

The invention discloses an AFL-based fuzzy test mutation method and an apparatus. The effective byte of a test case is determined in the deterministic mutation stage of the AFL. In the deterministic mutation stage, the mutation byte is determined according to the information of the effective byte, and all invalid bytes are not mutated; in the destructive mutation stage, the mutation is guided according to the information of the effective byte, and if the current randomly selected byte is an effective byte, the mutation is certain; otherwise, a small probability of mutation is given. The invention can improve the efficiency of the AFL, and can solve the problem of increasing resource consumption caused by the prior symbol execution and stain analysis technology.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

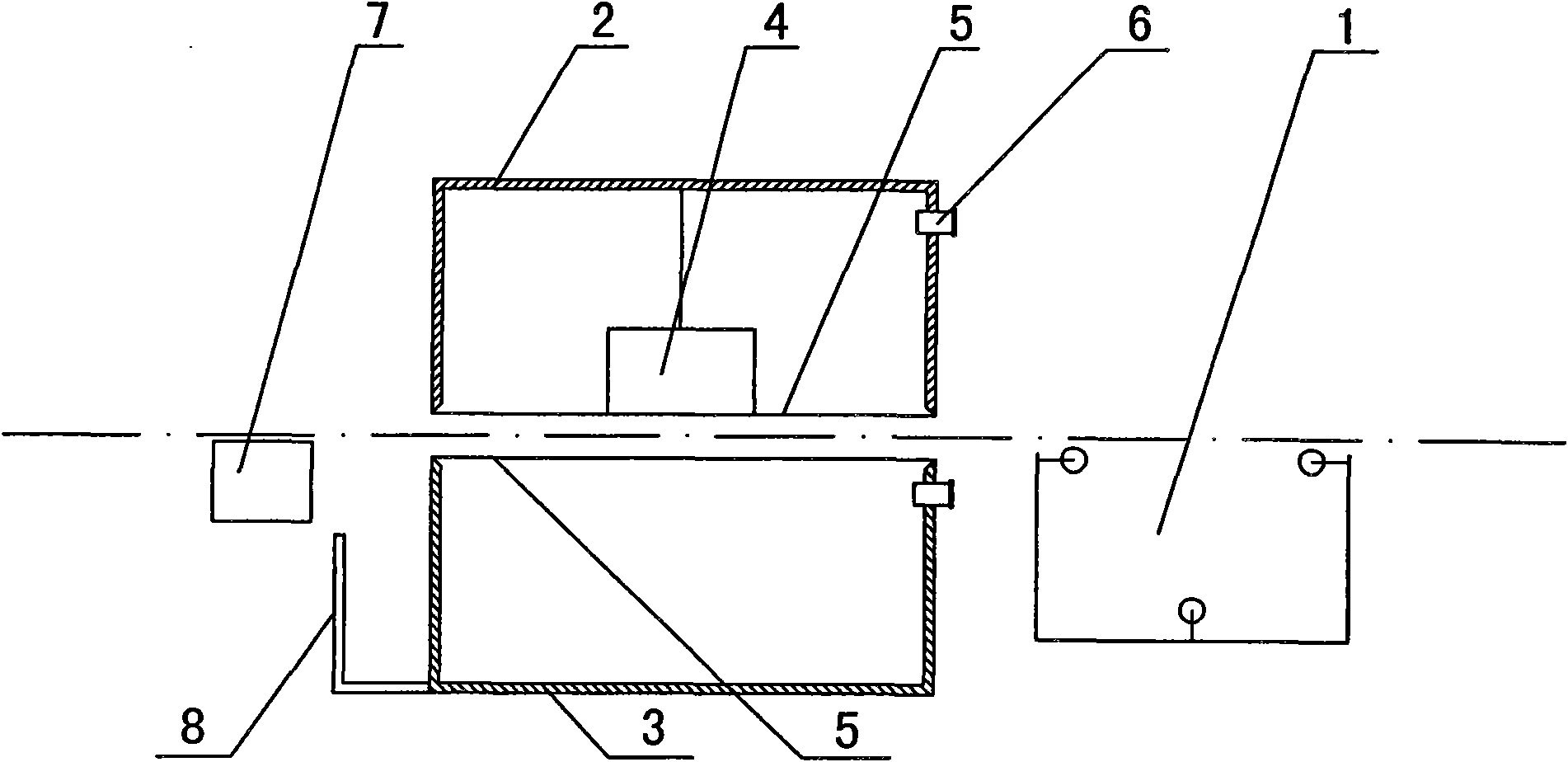

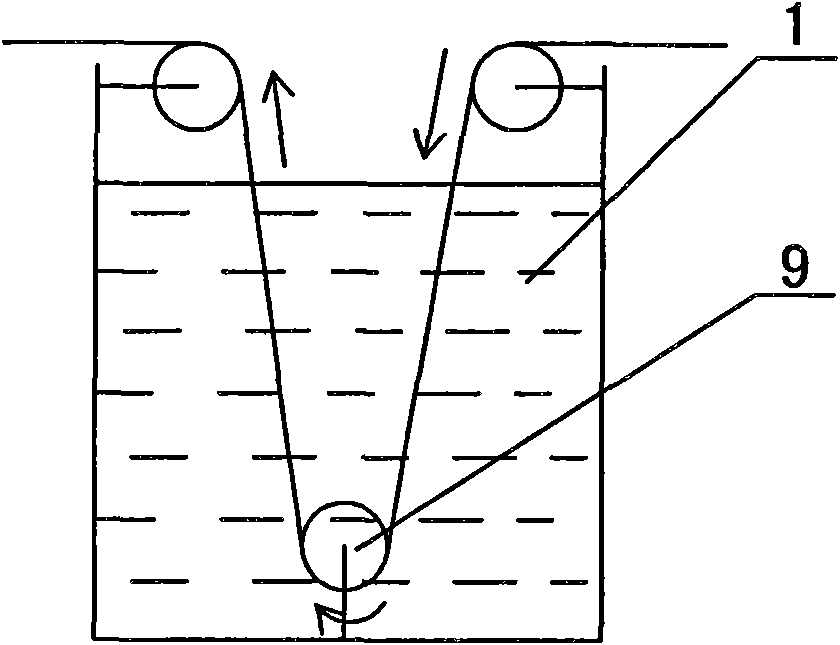

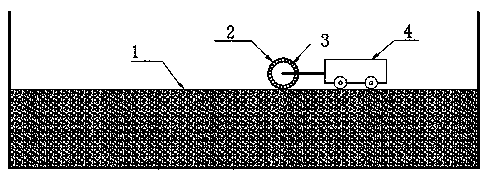

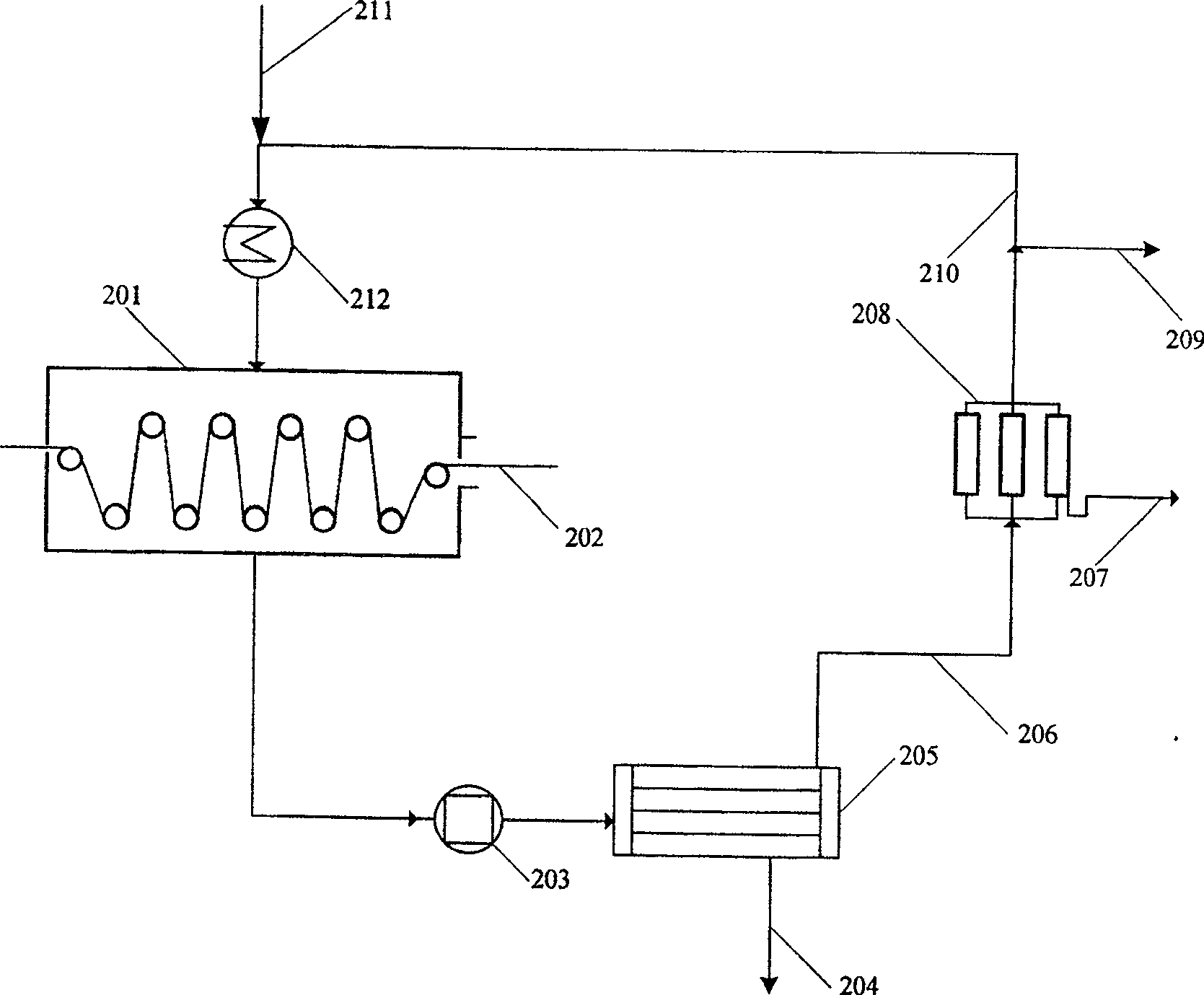

Ultrasonic wave desizing device

InactiveCN101629368AReduce dosageLittle consumptionTextile treatment containersLiquid/gas/vapor removal by suctionWater savingTransducer

The invention discloses an ultrasonic wave desizing device, comprising a water tank unit; the water tank unit consists of two semi-enclosed water tanks, namely a water tank A and a water tank B; one unenclosed side of the water tank A is enclosed by at least one layer of film, so is one unenclosed side of the water tank B; the two outmost layers of films of the two water tanks are parallel, and a gap with the distance of less than 3mm is left between the two outmost layers of films; at least one ultrasonic wave transducer is mounted in the water tank A or the water tank B and is fixed on the inner wall of the water tank; water inlets are mounted on both the water tank A and the water tank B. The invention can completely remove sizing agent attached to the textile products in the desizing technique, and the sizing agent and water can be recycled and reused, thus greatly reducing water usage and lowering processing cost with small power consumption. The invention also features energy saving, water saving, no pollution and the like.

Owner:李建华

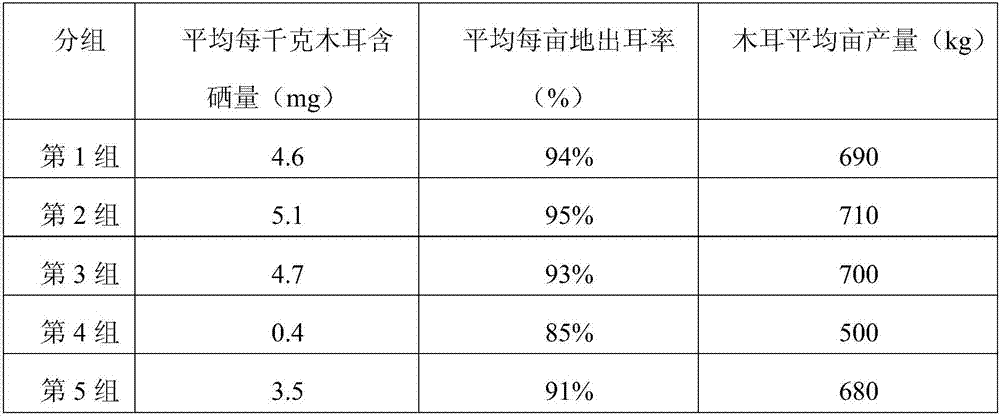

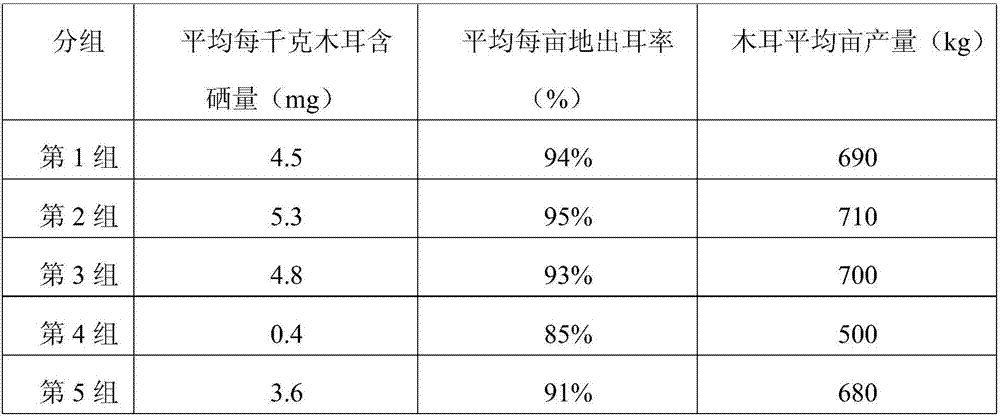

Special selenium-enriched organic fertilizer for agaric and preparation method of organic fertilizer

InactiveCN107056526ARich in nutrientsHigh activityBio-organic fraction processingAnimal corpse fertilisersAgaricAdditive ingredient

The invention discloses a special selenium-enriched organic fertilizer for agaric and relates to the field of fertilizers. The organic fertilizer specifically comprises the following raw materials: chicken manure, duck manure, pig manure, selenium-enriched corncob, wheat bran, bean dregs, humic acid, bone meal, scoria, lotus seed skin, garlic, mangosteen fruit skin, lycium ruthenicum residues, selenium-enriched waste tea leaves, overdue milk and purple sweet potatoes. A preparation method of the special selenium-enriched organic fertilizer for agaric comprises the following steps: (1) pretreating the raw materials; (2) mixing and stirring; (3) performing composting fermentation; and (4) bagging and sterilizing. The special selenium-enriched organic fertilizer for agaric disclosed by the invention is prepared from raw materials readily available and is rich in nutritional ingredients, the yield of agaric can be improved, and the harvested agaric is rich in selenium.

Owner:广西丰兄农业开发有限公司

2D simulation experiment method for flowing state of soil particles in vibrating compaction process

The invention discloses a 2D simulation experiment method for the flowing state of soil particles in the vibrating compaction process. The 2D simulation experiment method comprises the steps of: preparing a wooden box with a transparent front wall and detachably adjustable left and right walls; preparing a group of aluminum rods with different diameters; marking different colors on the end surfaces of the aluminum rods according to the different diameters; mixing the aluminum rods according to a certain proportion; wrapping the surfaces of the aluminum rods by using gauze and fine sand to simulate an internal friction angle; simulating cohesive force by using butter or slow-drying weak-viscosity glue; manufacturing a small loading device; paving the aluminum rods in a paper box; measuring and calculating the porosity before the experiment; starting a compaction experiment; measuring and calculating the porosity after the compaction; comparing the front and rear porosities; determining the compaction effect; observing a picture obtained by a high-speed camera; and analyzing a microscopic motion mechanism. The method can conveniently and detailedly simulate the flowing state of the soil particles in the vibrating compaction process, provides convenience for explaining the vibrating compaction mechanism from a microscopic angle, and provides a visual and effective experimental means for researching the relation between microscopic motion and macroscopic parameters in the vibrating compaction process.

Owner:SOUTHEAST UNIV

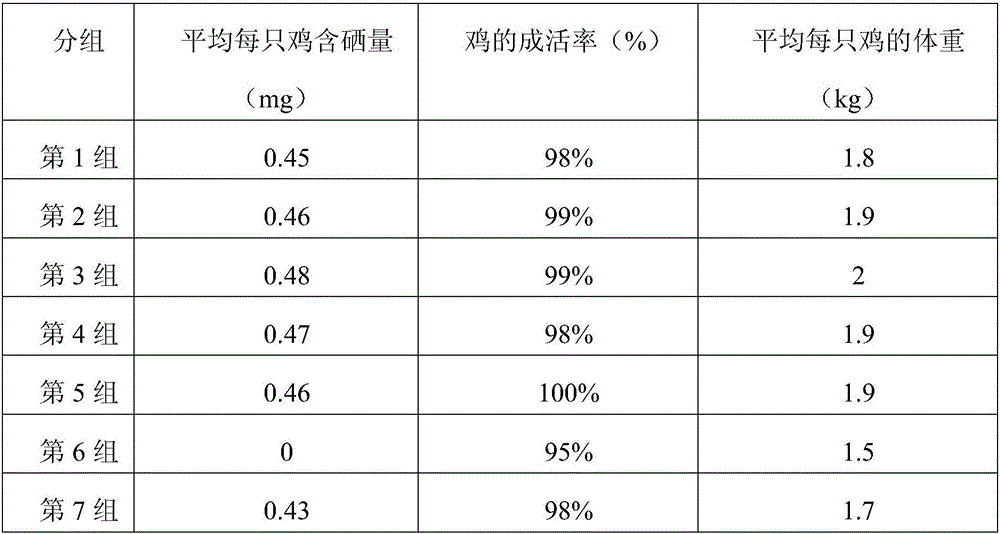

Selenium-rich chicken feed and preparation method thereof

InactiveCN106819572AGreat tasteImprove meat qualityAnimal feeding stuffAccessory food factorsBiotechnologyFodder

A selenium-rich chicken feed belongs to the field of feeds and is composed of the following raw materials: rice bran, corn, haw, cordate houttuynia, Chinese yam, carrot, grape pomace, purple sweet potato, lycium ruthenicum slag, garlic, dried orange peel, Chinese sauerkraut, rotten vegetable leaves, domestic fungus and distillers' grains. The method for preparing the selenium-rich chicken feed comprises the following steps: (1) fetching rice bran, corn, haw, Chinese yam, carrot, purple sweet potato, garlic and dried orange peel and respectively crushing; (2) fetching cordate houttuynia, grape pomace, lycium ruthenicum slag, Chinese sauerkraut, rotten vegetable leaves, domestic fungus and distillers' grains and carrying out composting fermentation; and (3) uniformly mixing all the raw materials, granulating, and drying. Chicken bred with the selenium-rich chicken feed is rich in selenium and is healthy and safe.

Owner:广西丰兄农业开发有限公司

Culture method of selenium-rich edible fungus

InactiveCN106966778AKeep looseHigh activityBio-organic fraction processingAnimal corpse fertilisersAgaricBiotechnology

Relating to the technical field of edible fungus cultivation, the invention provides a culture method of selenium-rich edible fungus. The method includes the steps of: (1) blending: taking chicken manure, duck manure, pig manure, selenium-rich cob, wheat bran, bean dregs, humic acid, bone meal, volcanic cinder, lotus seed skin, garlic, mangosteen skin, Lycium ruthenicum residue, selenium-rich waste tea, expired milk and purple sweet potato, conducting fermentation to prepare a culture material, adjusting the moisture content of the culture material to 60-70%, and adjusting the pH value of the culture material to 5.3-6.3; (2) bagging; (3) sterilization; (4) inoculation; (5) mycelium culture; (6) fungus yield management; and (7) harvesting. The culture method of selenium-rich edible fungus provided by the invention can produce selenium-rich edible fungus with high yield.

Owner:广西丰兄农业开发有限公司

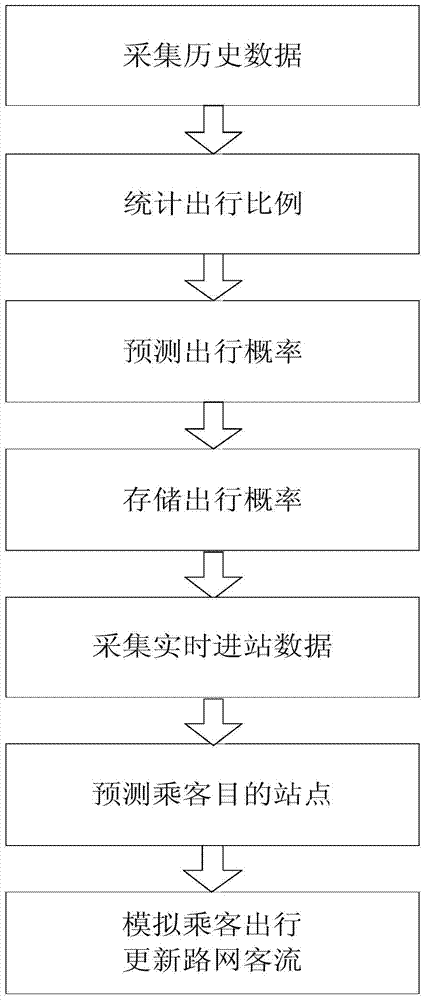

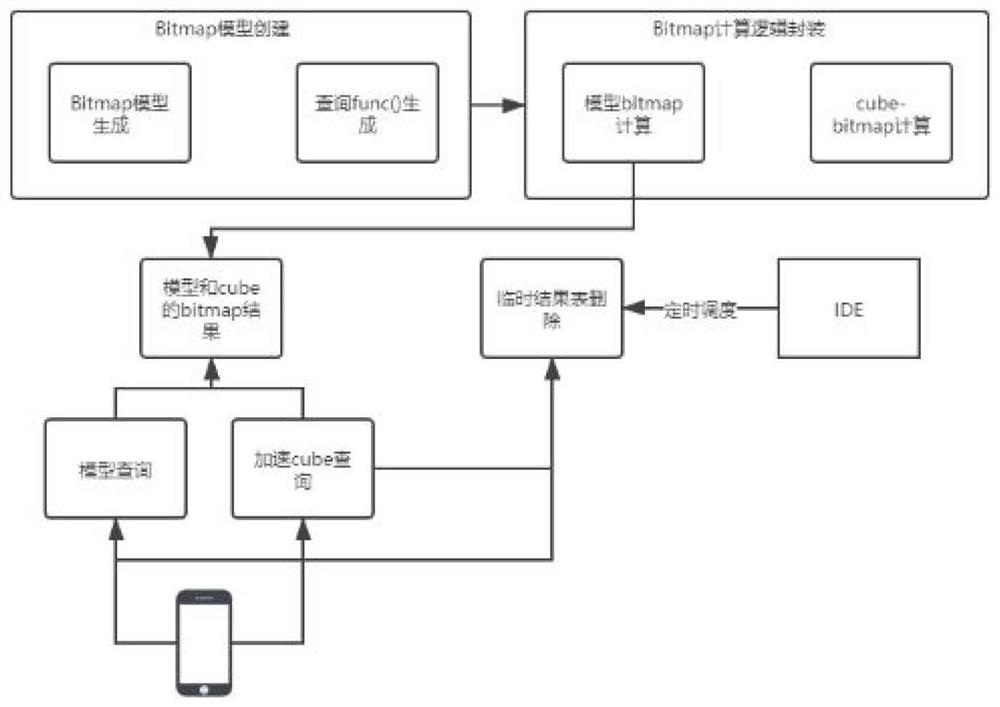

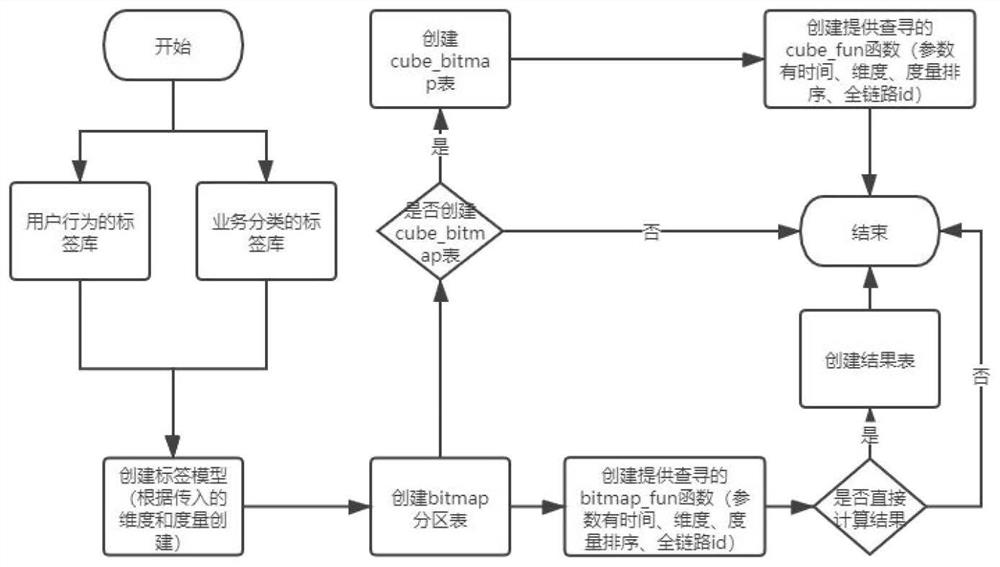

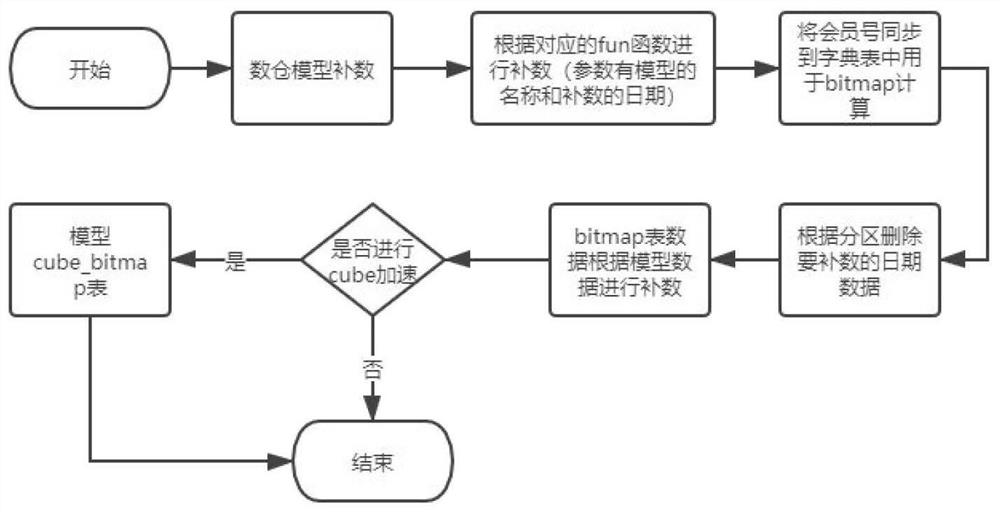

RoaringBitmap-based massive user efficient circling method and RoaringBitmap-based massive user efficient circling device

PendingCN112540972AAvoid demandImprove query efficiencyDatabase distribution/replicationSpecial data processing applicationsData synchronizationData warehouse

The invention discloses a RoaringBitmap-based massive user efficient circling method and device, and the method comprises the steps: establishing a label library of user behaviors and a label libraryof business classification according to user behavior data, building a data model according to the label libraries, establishing a bitmap partition table according to the data model, and storing userhistorical data; and finally, calculating a result through a custom function, synchronizing the data in the data warehouse into the data model, then supplementing the data in the bitmap partition table from the data model according to a rule, and finally performing cube acceleration on the bitmap partition table according to needs to generate a cube_bitmap table; and according to the dimension selected by the user, selecting to directly look up the result table or distinguish the accelerated cube query from the bitmap partition table through the storage process query. According to the method and the device, the information to be counted can be accurately and efficiently circled and selected from a large number of users.

Owner:CHINA UNITECHS

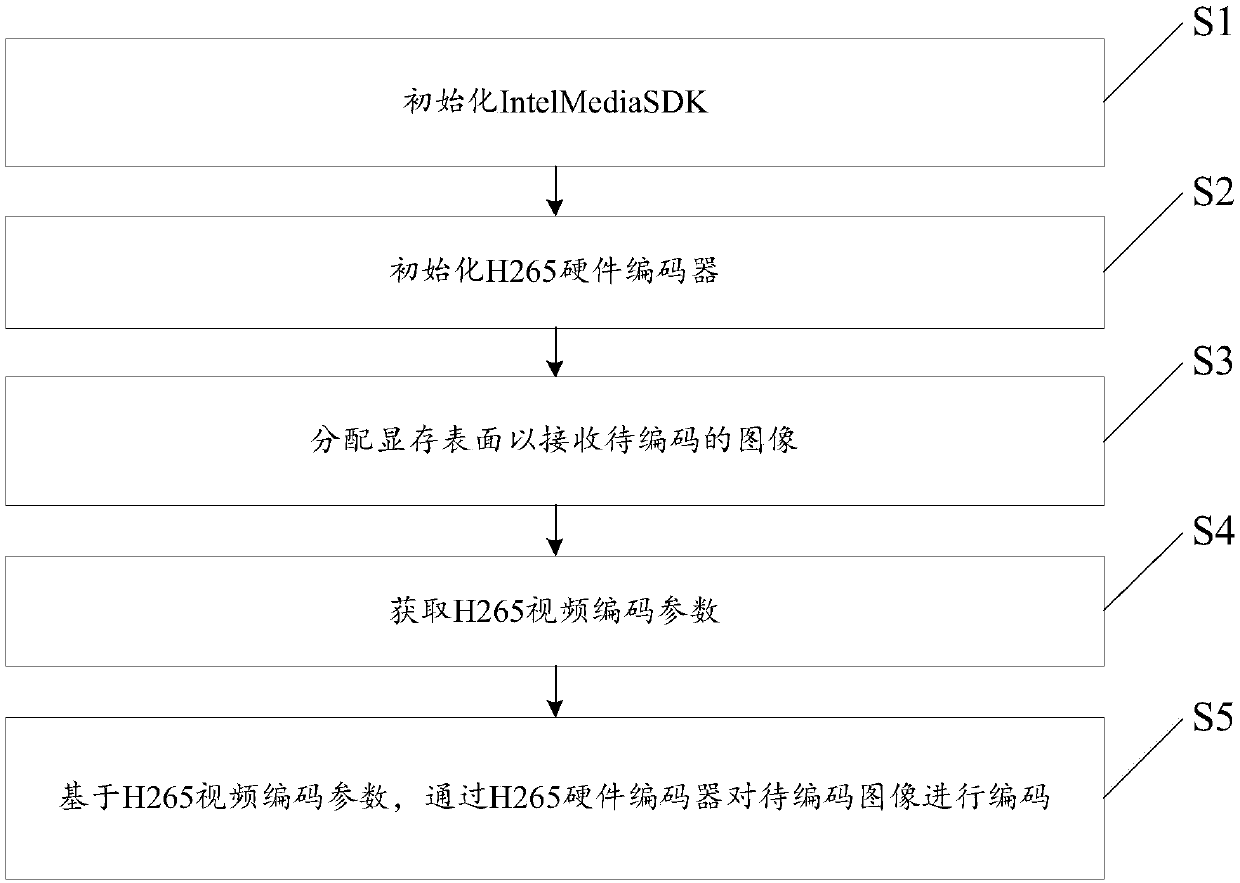

H265 hardware coding method based on Intel SkyLake integrated display card and live broadcast platform

InactiveCN110022478AImprove smooth performanceReduce consumptionDigital video signal modificationSelective content distributionVideo memoryImage resolution

The invention discloses an H265 hardware coding method based on an Intel SkyLake integrated display card and a live broadcast terminal. The method comprises the following steps: initializing an IntelMedia SDK; initializing an H265 hardware encoder; allocating a video memory surface to receive an image to be encoded; obtaining H265 video coding parameters; and encoding the image to be encoded through the H265 hardware encoder based on the H265 video encoding parameter. Thus, under the condition of the same video resolution, code rate and frame rate, the volume of the coded video is reduced byabout 30% compared with H264, and due to hardware coding, the CPU consumption of a user computer is not large, so that the CPU consumption of the user is also reduced, and the coding fluency is improved.

Owner:WUHAN DOUYU NETWORK TECH CO LTD

System for desulfurizing and denitrating active coke flue gas, and process method

ActiveCN102430318BIntegrated purification effect is obviousImprove utilization efficiencyDispersed particle separationSulfurDesorption

Owner:SHANGHAI CLEAR ENVIRONMENTAL PROTECTION SCI & TECH

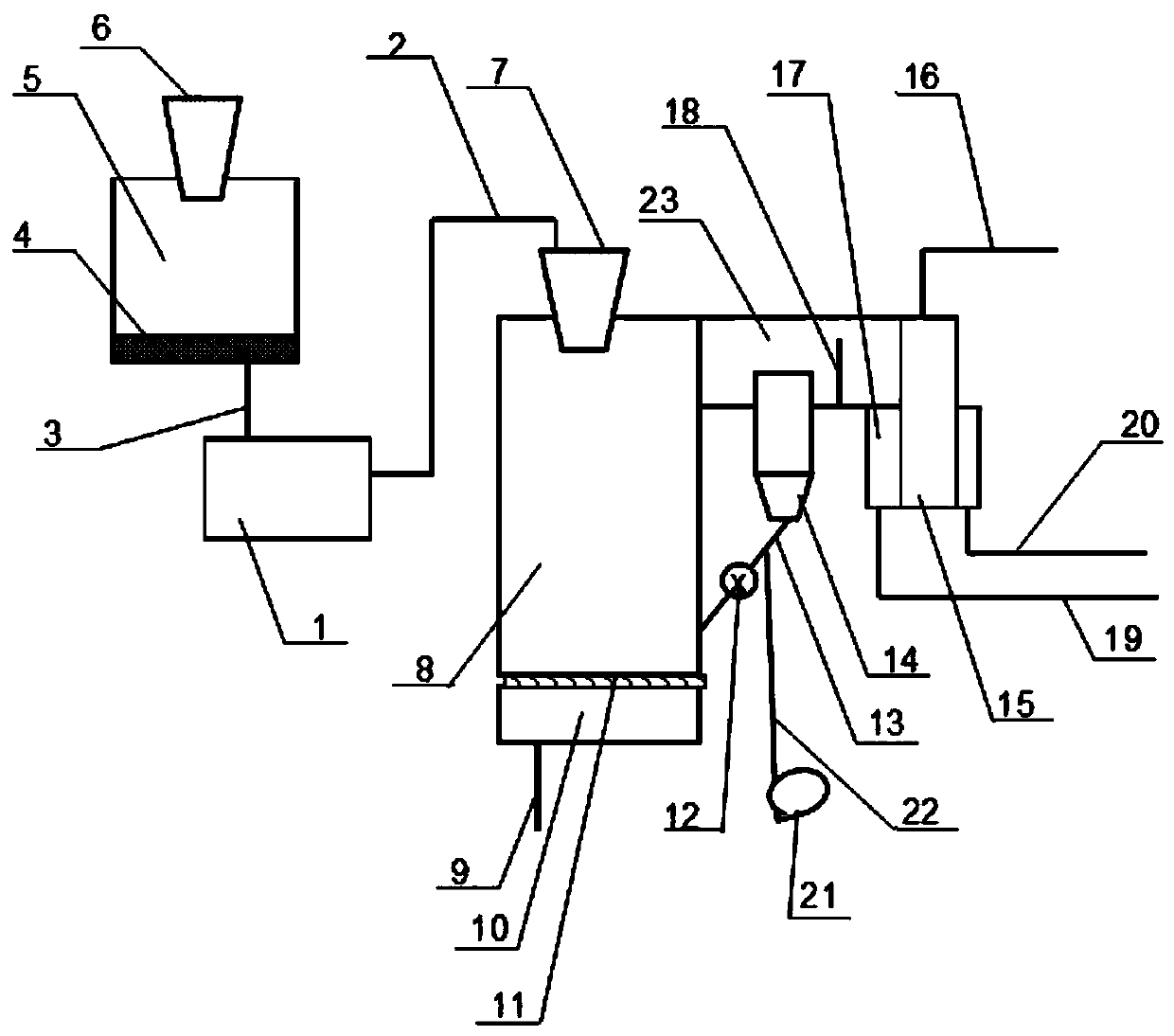

Device and method for producing hydrogen by gasifying plastic biomass

InactiveCN110804465AUniform particle sizeImprove melting efficiencyChemical industryGasification processes detailsThermodynamicsNew energy

The invention discloses a device and a method for producing hydrogen by gasifying plastic biomass, and belongs to the technical field of chemical engineering and new energy utilization. The device comprises a mixing system and a cooling separation system, the mixing system comprises a melting part and a gasification part, the melting part comprises a melting chamber, the bottom of the melting chamber is provided with a feeding port, the gasification part comprises a fluidization chamber and an atomizer mounted at the top of the fluidization chamber, and the melting chamber is connected with the atomizer through a swing pump; the cooling separation system comprises a separation box and a cooling water jacket mounted outside the separation box; and a separator is connected to a pipeline between the fluidization chamber and the separation box. Waste plastic is melted and mixed with biomass particles to be atomized, then the mixture is fed into the fluidization chamber to prepare the hydrogen, and the hydrogen is purified after being cooled and separated. The device is energy-saving, environment-friendly, high in hydrogen production efficiency, low in power consumption and energy consumption and high in practicability.

Owner:张俊霞

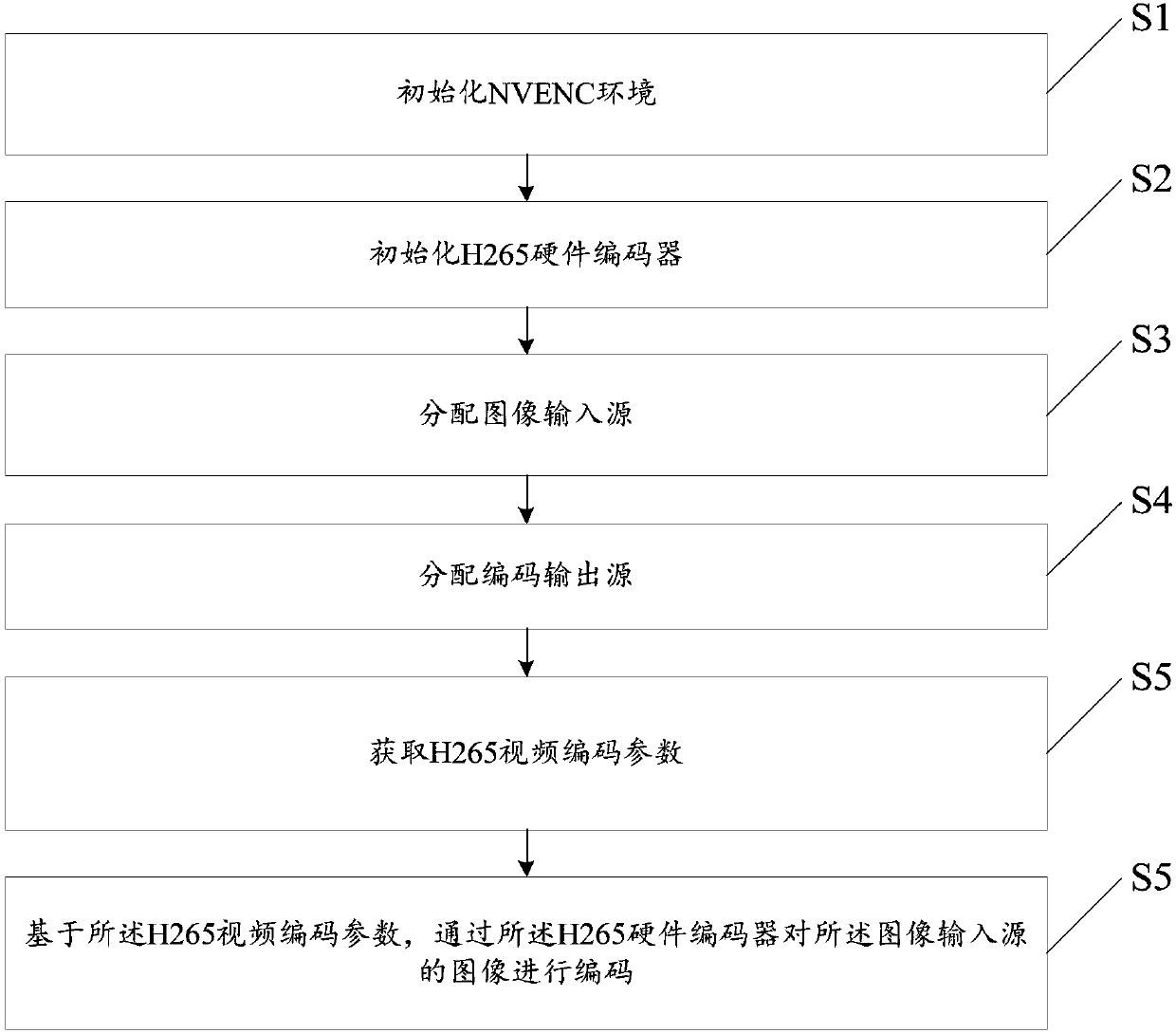

H265 hardware coding method based on Nvidia Maxwell2 display card and live broadcast platform

InactiveCN110022479AReduce consumptionConsumes a lotDigital video signal modificationComputer hardwareVideo encoding

The invention discloses an H265 hardware coding method based on an Nvidia Maxwell2 display card and a live broadcast terminal. The method comprises the following steps: initializing an NVENC environment; initializing an H265 hardware encoder; allocating an image input source; allocating a coding output source; obtaining H265 video coding parameters; and encoding the image of the image input sourcethrough the H265 hardware encoder based on the H265 video encoding parameter. Thus, under the condition of the same video resolution, code rate and frame rate, the volume of the coded video is reduced by about 30% compared with H264, and due to hardware coding, the CPU consumption of a user computer is not large, so that the CPU consumption of the user is also reduced, and the coding fluency is improved.

Owner:WUHAN DOUYU NETWORK TECH CO LTD

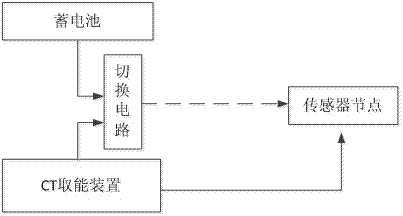

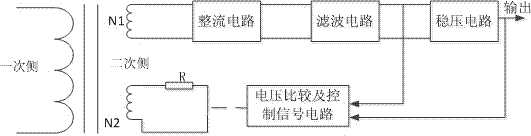

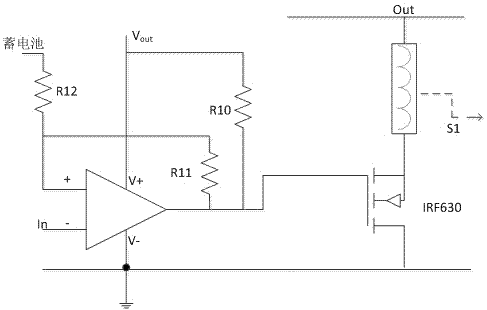

Hybrid power supply device oriented to power grid wireless sensor network node

InactiveCN103904772AShorten the timeLittle consumptionPower network operation systems integrationDc-dc conversionLine sensorPower grid

The invention discloses a hybrid power supply device oriented to a power grid wireless sensor network node. The hybrid power supply device comprises a storage battery, a CT energy taking device and a switching circuit; the output end of the storage battery is connected with the input end of the switching circuit, the output end of the CT energy taking device is connected with the input end of the switching circuit and the sensor node, and the output end of the switching circuit is connected with the sensor node. When the circuit works normally, the CT energy taking device supplies power to the node; when the circuit has a fault or has no load, the storage battery supplies energy to the node. As the node is monitored, fault time of the circuit will be short, power supply time of the storage battery is relatively short, consumption is low, the storage battery is not replaced for a long time, and therefore the requirement for energy consumption of the node can be completely met by adopting combination of the two power supply modes.

Owner:GUANGDONG UNIV OF TECH

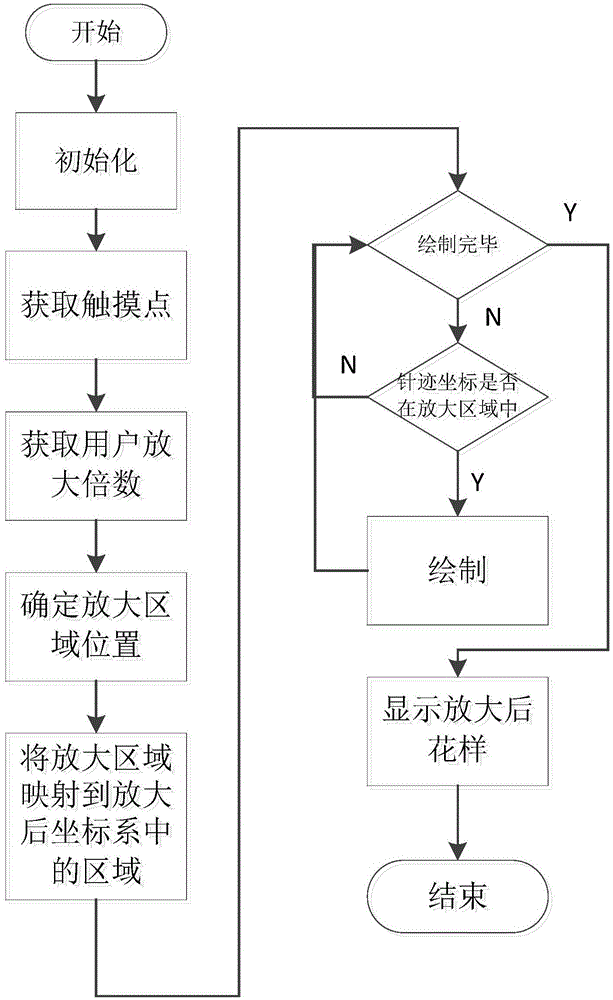

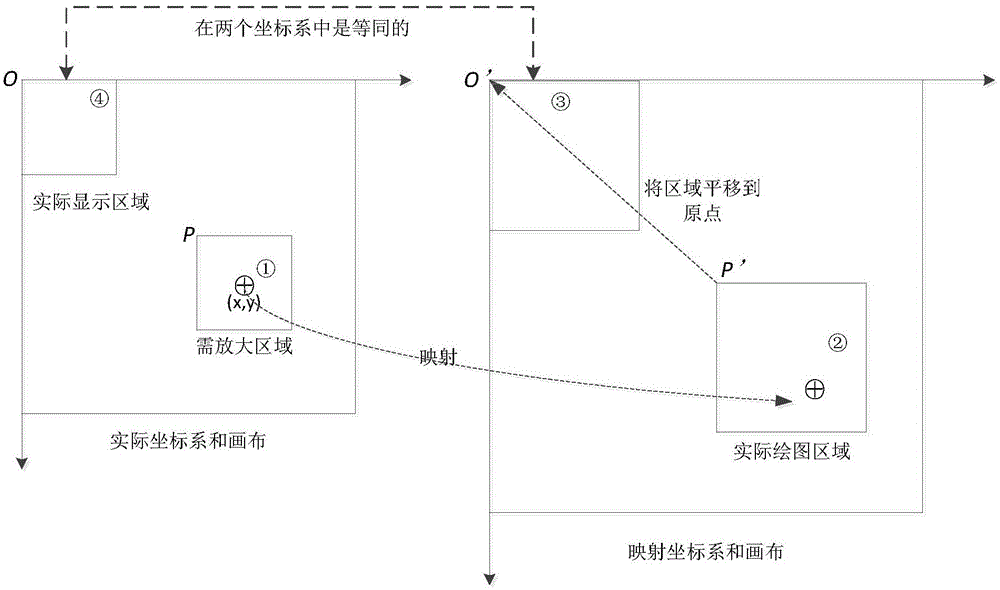

Processing method for displaying local patterns in computerized embroidery machine

InactiveCN105155153AAccurate displayConsumes a lotAutomatic machinesComputer graphics (images)Local pattern

The invention discloses a processing method for displaying local patterns in a computerized embroidery machine. The processing method includes the steps of generating and displaying embroidery pattern previews via a first coordinate system according to pattern files; acquiring coordinates of a user's touch point on the first coordinate system; according to the coordinates of the touch point and the size of a set touch area, determining a touch area; according to a coordinate position of the touch area in the first coordinate system, extracting related data from the pattern files for decoding; and setting a second coordinate system parallel to the first coordinate system. Pattern stitches obtained by decoding, located in the touch area in the first coordinate system, are converted to the second coordinate system and are magnified according to a set magnifying times; according to the set magnifying times and the size of the touch area, a magnifying window is set on a display screen; the magnified stitches in the second coordinate system are used as local pattern stiches for displaying in the magnifying window. The method allows real stitches of local patterns to be displayed vividly and accurately, with consuming low memory of a mainframe.

Owner:SHENZHEN SOLARPEX TECH

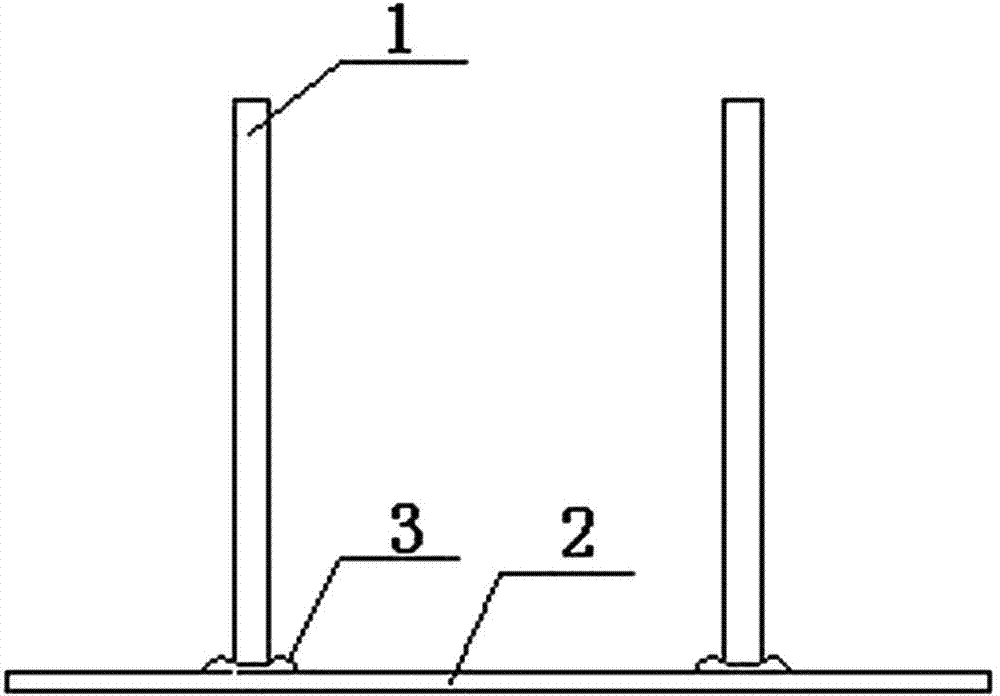

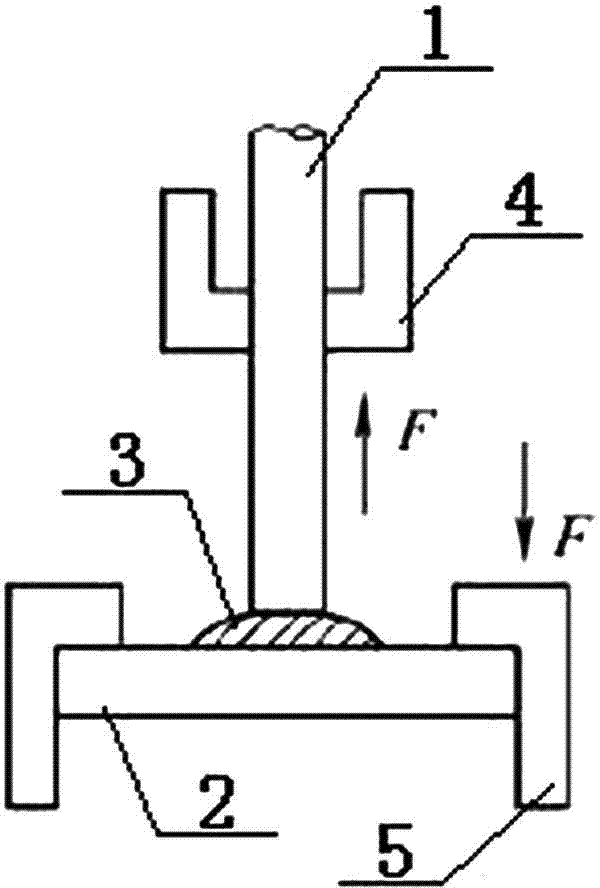

Submerged arc welding processing method of curtain wall buried element

ActiveCN104772555AEasy to operateQuality assuranceWelding/cutting auxillary devicesAuxillary welding devicesOperabilityDrill

The invention discloses a submerged arc welding processing method of a curtain wall buried element. The method comprises the following steps including welding tooling manufacturing, anchor bar clamp installation, marking of points to be welded, welding seam size control, anchor bar clamping and installing, welding point alignment, welding flux filling, welding preparation, welding, welding flux recovery and the like. A simple pressure submerged arc welding equipment manufactured by matching a modified woodworking bench drill with an ordinary electric welding machine is used for welding the curtain wall buried element, the modified equipment electric welding machine and the woodworking bench drill can be utilized in the subsequent engineering, the primary investment cost is not high, the used welding fluxes are cheap, and the consumption is not great; the operability is high, and the quality is guaranteed; the process is simple, the mastering is easy, and the technical requirements on operators is not too high; the welding efficiency is high, the construction speed is high, and the welding time of each anchor bar is within 30s under the skilled condition.

Owner:葛斌斌 +2

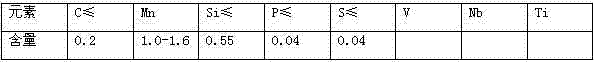

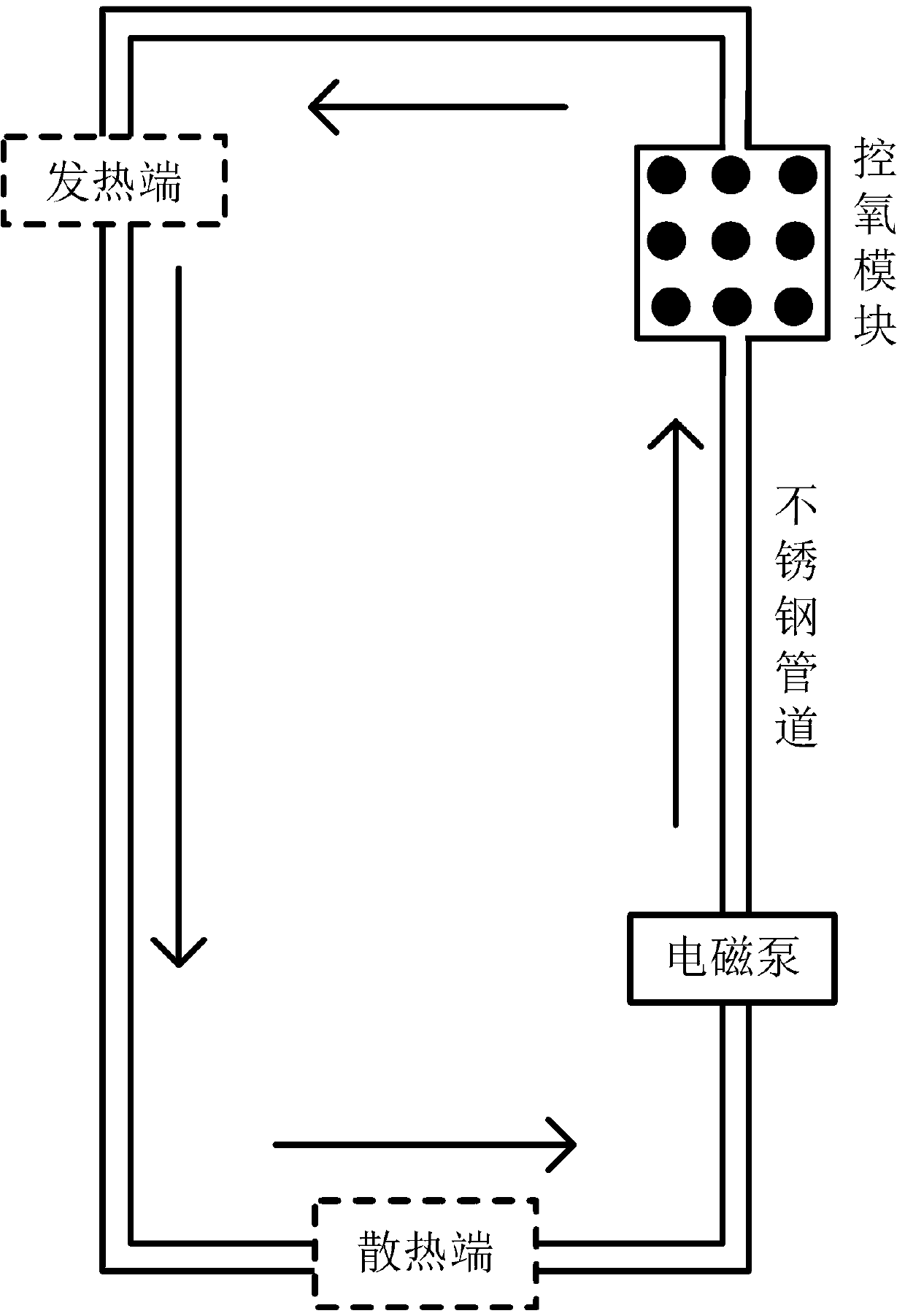

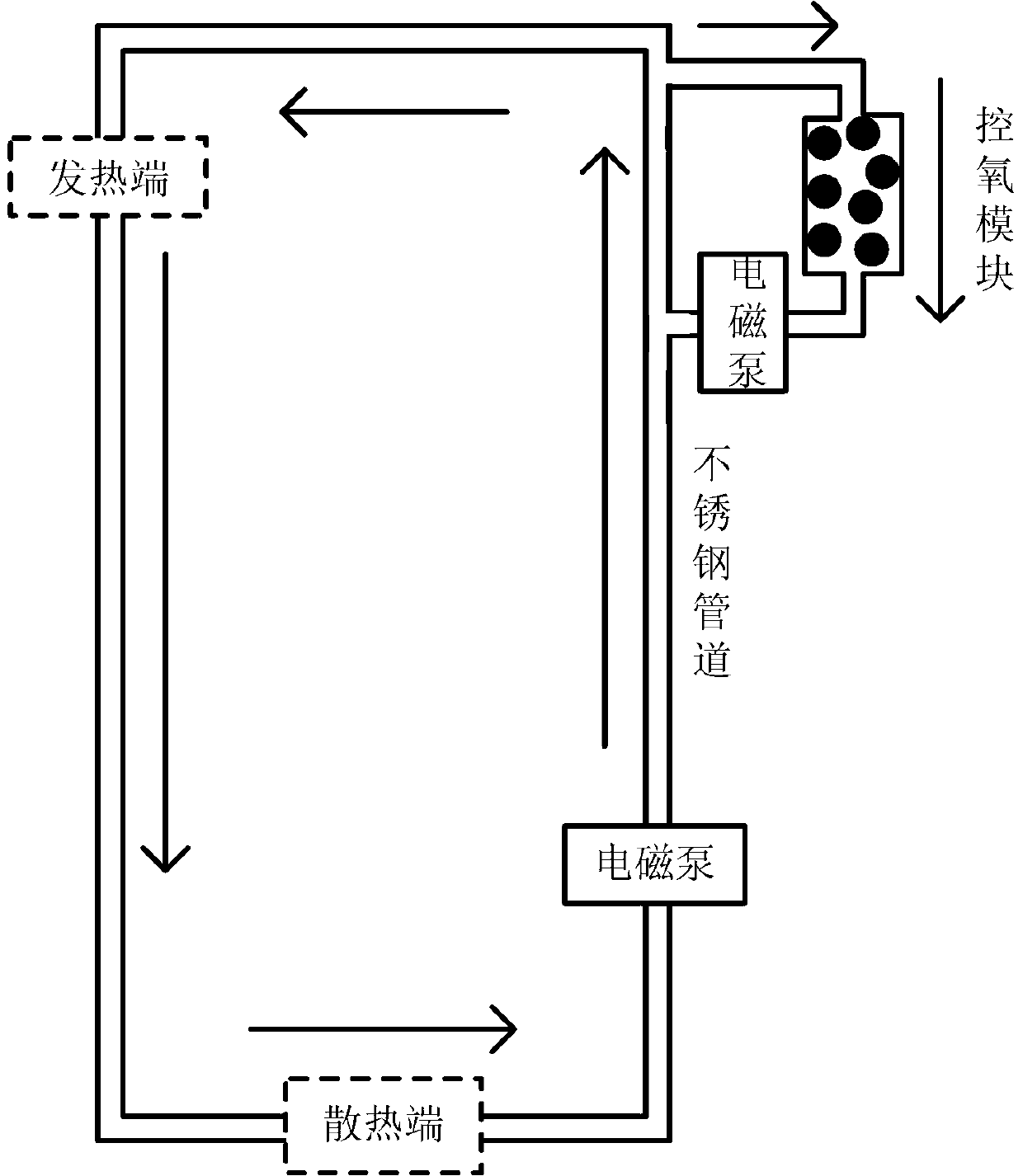

Oxygen-control type pipeline-corrosion-resistant liquid metal for 40-80 DEG c of electronic chip and process thereof.

InactiveCN110343926AStrongly corrosiveReduce corrosion rateMetallic material coating processesLiquid metalOxygen

The invention discloses an oxygen-control type pipeline-corrosion-resistant liquid metal for 40-80 DEG c of an electronic chip and a process thereof. The alloy comprises the following components in percentage, by weight, the alloy composition is 0.2-0.5wt% of Hf, 0.4-1.0wt% of Co, 4.0-8.0wt% of Bi, 2.0-5.0wt% of Zn, 5.0-10.0wt.% of In,1.0-2.0wt.% of Cd, 5.0-8.0wt.% of Pb, and the balance of gallium; wherein the oxide composition for controlling the oxygen activity is pbo: 30.0-40.0wt% of PbO, 2.0-4.0wt% of CuO,10.0-20.0wt% of AgO, 4.0-6.0wt% of CdO, 5.0-8.0wt% of NiO, and the balance of Fe2O3.Through controlling the oxygen activity by adopting an oxygen control module, the stable compact oxidation film can be effectively generated on the surface of the stainless steel pipeline to inhibitcorrosion of the liquid metal to the pipeline material, the method has the characteristics that the process is simple, the implementation cost is low, the heat dissipation is efficient, the service life of the heat dissipation component is prolonged, and the service life of the heat dissipation component is obvious.

Owner:深圳市兴荣晟物业管理有限公司

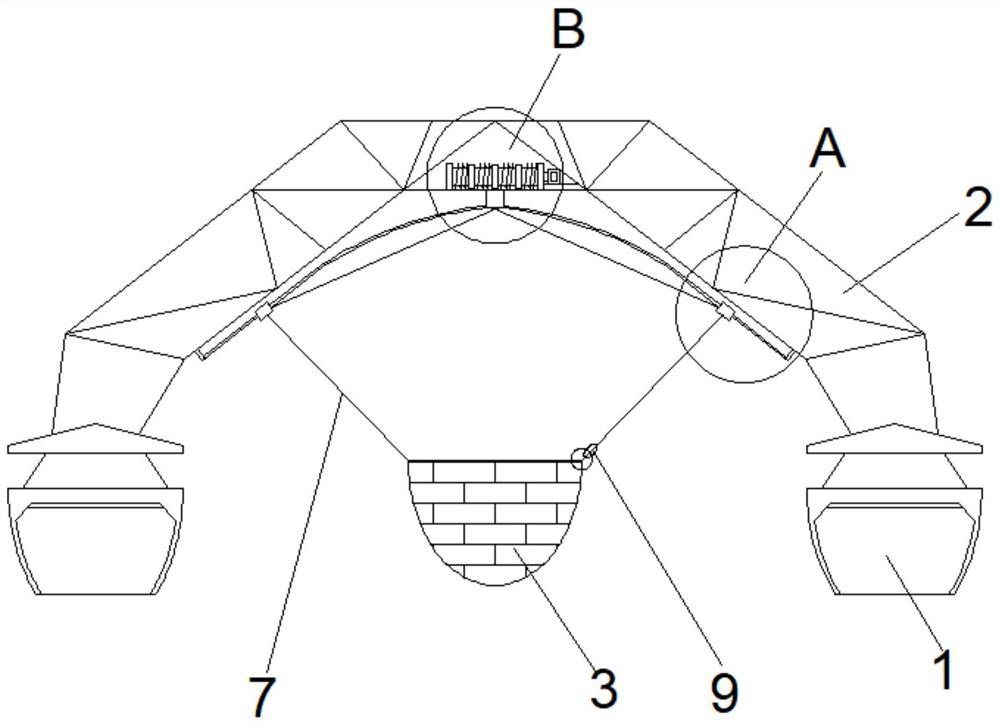

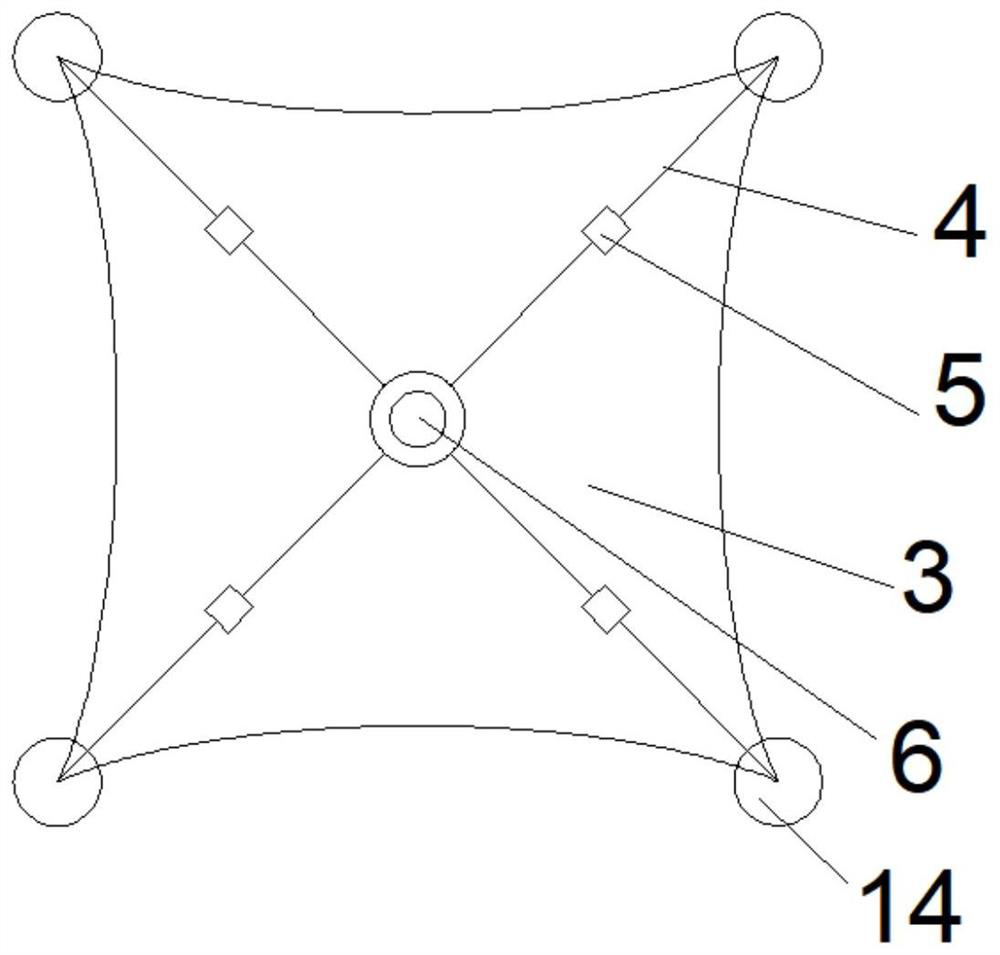

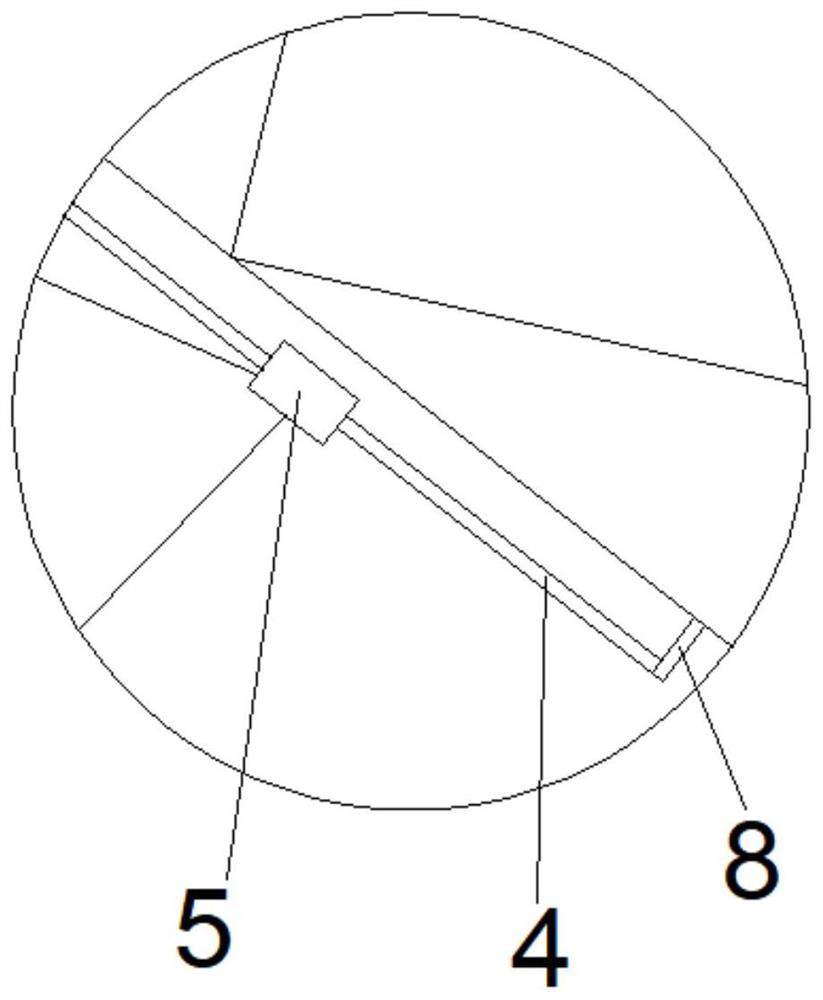

Mesh foldable garbage salvage catamaran

ActiveCN112829886BMove at a constant speedEasy and stable fishingWater cleaningHydrodynamic/hydrostatic featuresElectric machineStructural engineering

Owner:ZHEJIANG OCEAN UNIV

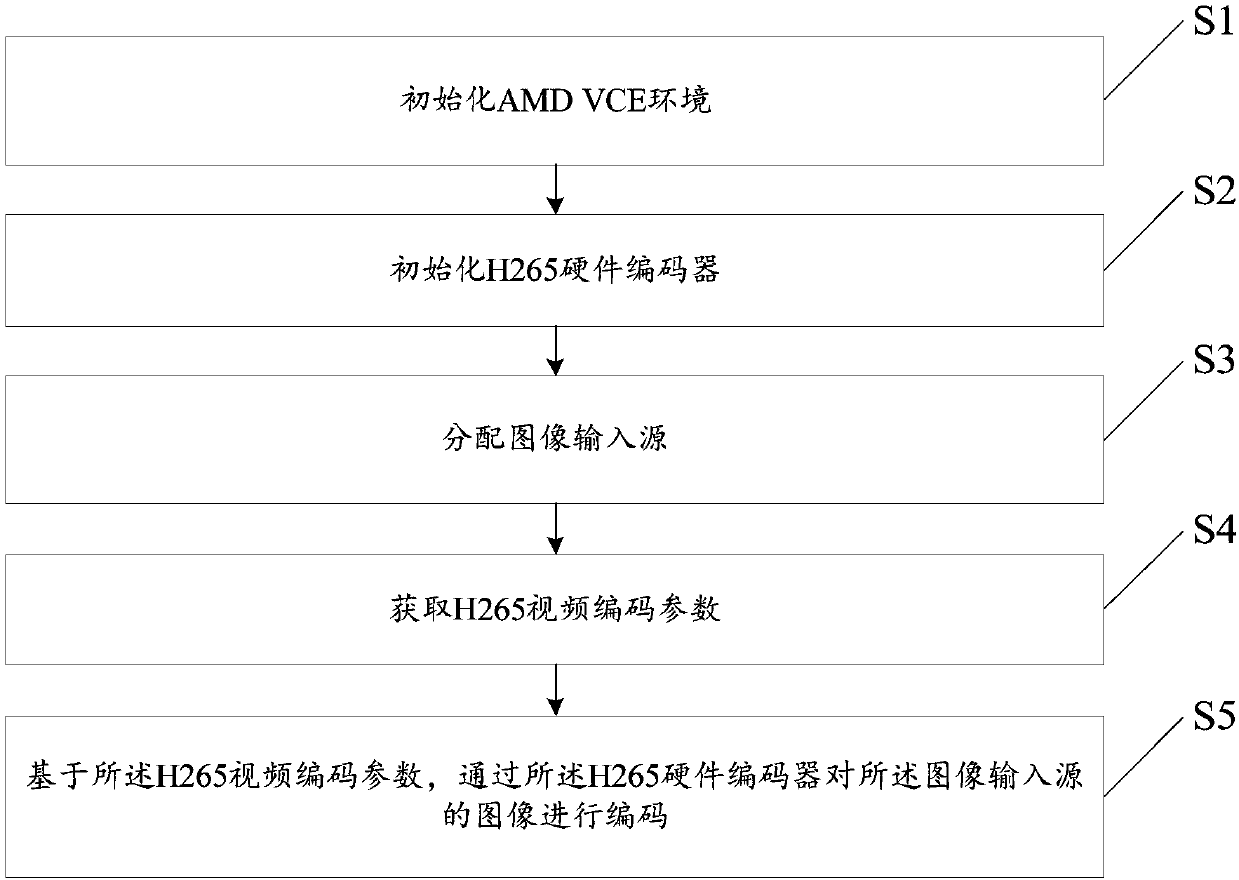

H265 hardware coding method based on AMD display card and live broadcast platform

ActiveCN110022480AImprove smooth performanceVideo size reductionDigital video signal modificationTransmissionGraphic cardVideo encoding

The invention discloses an H265 hardware coding method based on an AMD display card and a live broadcast terminal. The method comprises the steps of initializing an AMD VCE environment; initializing an H265 hardware encoder; allocating an image input source; allocating a coding output source; obtaining H265 video coding parameters; and encoding the image of the image input source through the H265hardware encoder based on the H265 video encoding parameter. Thus, under the condition of the same video resolution, code rate and frame rate, the volume of the coded video is reduced by about 30% compared with H264, and due to hardware coding, the CPU consumption of a user computer is not large, so that the CPU consumption of the user is also reduced, and the coding fluency is improved.

Owner:WUHAN DOUYU NETWORK TECH CO LTD

Afl-based fuzz testing mutation method and device

ActiveCN109101422BEasy accessLittle consumptionSoftware testing/debuggingAlgorithmResource consumption

The invention discloses an AFL-based fuzzy test variation method and device, in which valid bytes of a test case are determined in the deterministic variation stage of AFL; in the deterministic variation stage, the mutated bytes are determined according to the information of the effective bytes, Do not mutate all invalid bytes; in the destructive mutation stage, guide the mutation according to the information of the valid bytes, if the currently randomly selected byte is a valid byte, it must be mutated; otherwise, give a small probability of mutation. Using the invention can improve the efficiency of AFL, and can solve the problem of increased resource consumption caused by the existing symbol execution and taint analysis technology.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Disc type turbine agitator for reaction vessel

InactiveCN105688779AConsumes a lotImprove stirring efficiencyMixer accessoriesChemical/physical/physico-chemical stationary reactorsCircular discEmulsion

The invention discloses a disc type turbine agitator for a reaction vessel. The disc type turbine agitator comprises a shaft, a shaft sleeve, a disc and a group of blades, wherein the shaft passes through the center of the disc and is fixed through shaft sleeve, and the group of blades are uniformly distributed along the circumference of the disc and are bent. The disc type turbine agitator is low in energy consumption and high in agitation efficiency; liquid flow direction formed by agitation pervades the whole reaction vessel, so stable and agitated eddy flow is formed; thus, the disc type turbine agitator is applicable to emulsion, fluid suspension, etc.

Owner:NANJING ZHONGTENG CHEM

Extraction and desiccation method in preparing process of polyvinyl fibre with super high molecular weight

ActiveCN100494523CSafe to useLow boiling pointArtificial filament washing/dryingMonocomponent polyolefin artificial filamentFiberPolymer science

The invention relates to extracting and drying methods in the process for preparing uhmwpe fiber, belonging to the field for polymers preparing technology. The method comprises that the uhmwpe powder, assistant and solvent is solidified by extruding after they are mixed in uniformity and solved sufficiently; the solvent is eliminated in extracting process and the extraction agent is eliminated by drying technology; the final product is formed by heat drawing. It is characterized in that because dichloromethane is used as the extraction agent, there is good safety, low boiling point and it is eliminated easily. Because countercurrent extraction operation is adopted in the extracting process and there is no ultrasonic wave, it is provided with low drying temperature, simple technology, high intensity of fiber product, high modulus and low oil percentage of fiber.

Owner:安徽威亚新材料技术有限公司

Electronic chip 80-120 degree oxygen control type pipeline corrosion resistance liquid metal and process thereof

InactiveCN110306090AQuick responseIncrease consumptionSemiconductor/solid-state device detailsSolid-state devicesLiquid metalOxygen

The invention discloses electronic chip 80-120 degree oxygen control type pipeline corrosion resistance liquid metal and a process thereof. According to the weight percentage, an alloy comprises 0.2%-0.4% of Ag, 0.1%-0.3% of Ni, 4.0%-6.0% of Sb, 8.0%-10.0% of Zn, 15.0%-20.0% of In, 3.0%-5.0% of Bi, 1.0%-3.0% of Pb and the balance gallium; and oxide for controlling the oxygen activity comprises 10.0%-20.0% of PbO, 4.0%-8.0% of SnO2, 1.0%-2.0% of TaO, 5.0%-8.0% of MnO2, 2.0%-4.0% of CoO and the balance Fe2O3. The liquid metal is packaged in the pipeline, an oxygen control module is adopted for controlling the oxygen activity, a stable and dense oxide film can be effectively formed on the surface of the stainless steel pipeline, and the corrosion of the liquid metal to pipeline materials is inhibited. The liquid metal has the advantages that the technology process is simple, the implementation cost is low, the heat dissipation is efficient, and the service life of a heat dissipation component is obviously improved.

Owner:深圳市兴荣晟物业管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com