A horizontal high-pressure gas quenching-tempering-nitridation vacuum multipurpose furnace

A high-pressure gas, quenching and tempering technology, applied in the direction of quenching device, furnace, furnace type, etc., can solve the problems of unsatisfactory ventilation structure, unfavorable diffusion process, affecting nitriding speed and quality, etc., and achieves favorable adsorption and interface reaction. , The process control is simple, the effect of preventing oxidation of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

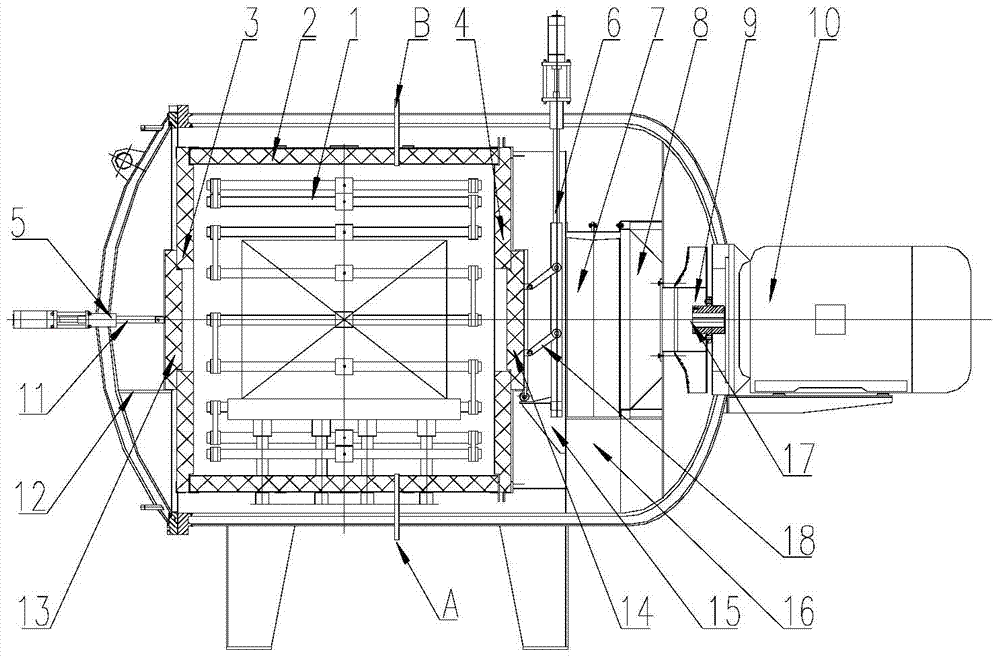

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0019] The invention includes a vacuum furnace main body, a heating chamber, an air-cooling system, a vacuum unit, a gas supply system, and an electrical control system. Aiming at the disadvantages of the traditional nitriding furnace using a nitriding tank structure, such as slow heating and cooling speeds, the nitrogen chemical The parts are placed directly in the heating chamber.

[0020] The heating chamber includes a heating element (1), a cylinder body (2), a front cover (3), and a rear cover (4). The heating element (1) is formed into a cylindrical shape by 18 graphite rods through a connecting plate, and the wiring The form is triangular, and the heat shield of the cylinder body (2) includes composite hard felt, graphite soft felt, ceramic fiber felt and stainless steel guard plate. The front cover (3) and the rear cover (4) are composed of heat insulation la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com