Mode locking mechanism of electric plastic injection machine

An injection molding machine and mold clamping technology, which is applied in the field of mold clamping mechanisms of electric injection molding machines, can solve the problems of insufficient mold protection level, large deformation of the middle template, and high lubrication requirements, and achieve compact structure, uniform force, and easy disassembly and assembly. convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

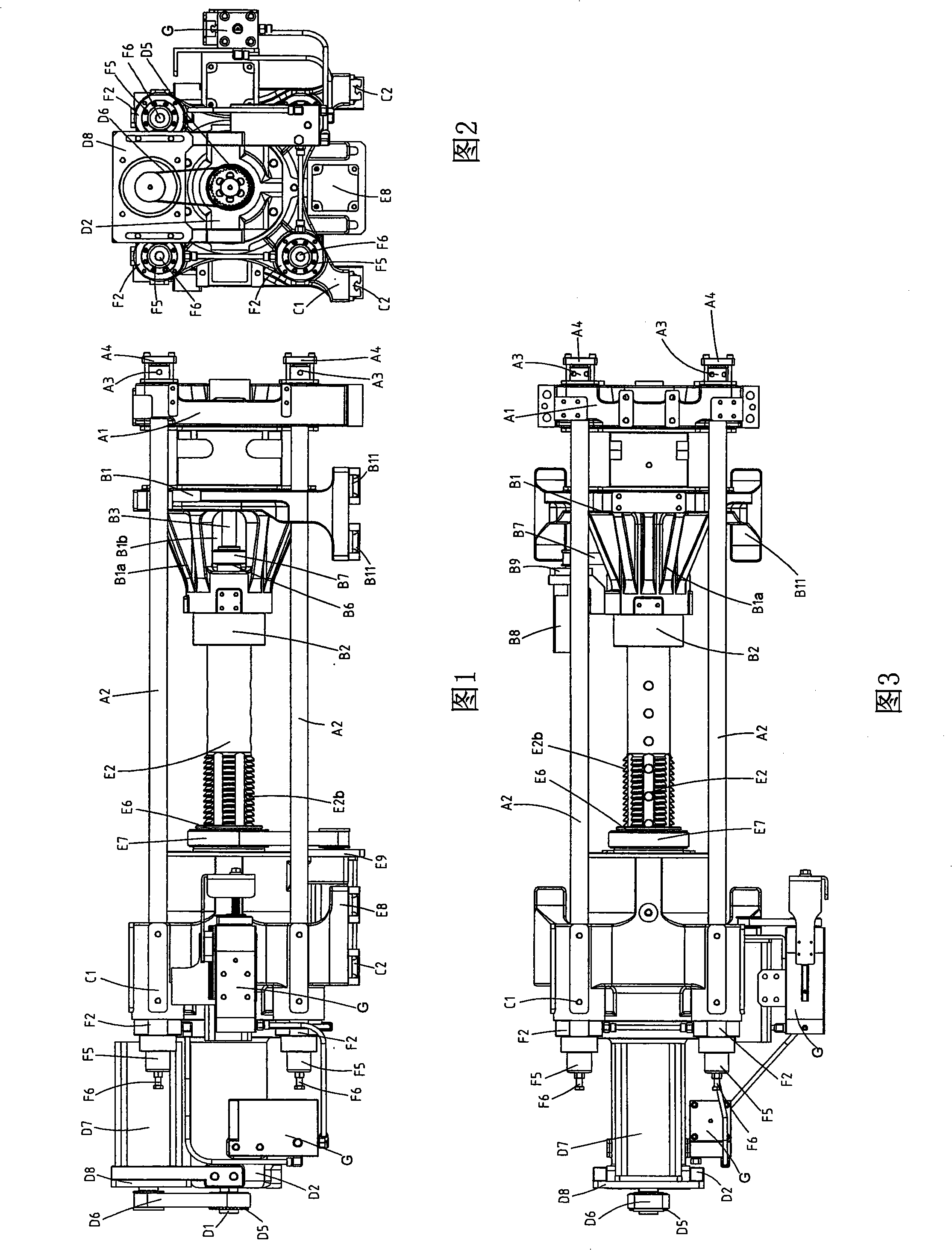

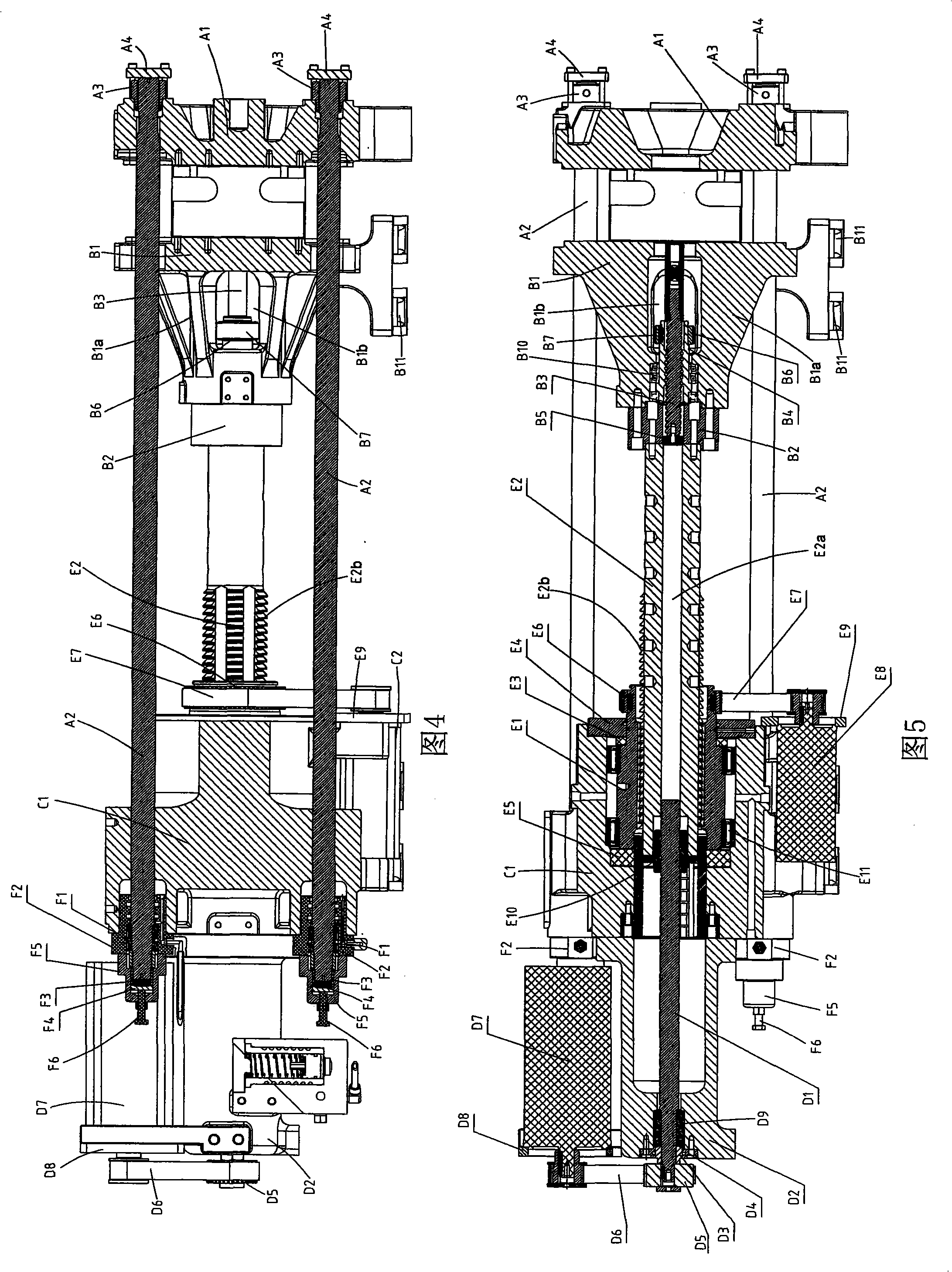

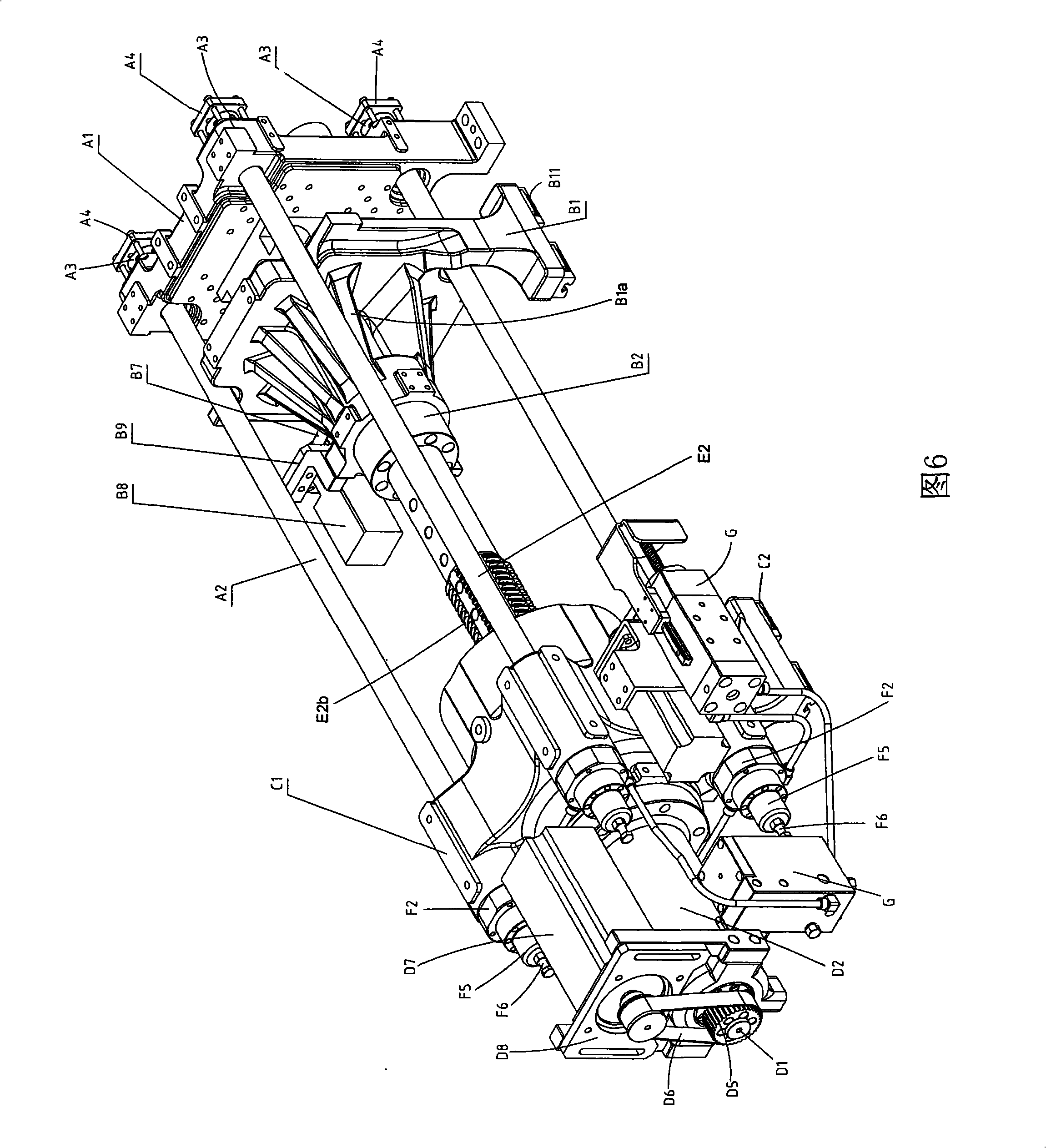

[0029] Such as Figure 1 to Figure 6As shown, the icon numbers are as follows: front template A1, tie rod A2, tie rod nut A3, tie rod gland A4, middle template B1, horn-shaped body B1a, ejection chamber B1b, inner and outer ring body B2, ejection ball screw B3, Eject the ball screw nut B4, limit block B5, eject the timing belt pulley B6, eject the timing belt B7, eject the motor B8, eject the motor fixing plate B9, the third bearing B10, the first linear guide rail B11, Rear template C1, second linear guide C2, mold moving ball screw D1, protective oil cylinder D2, mold moving ball screw nut D3, mold moving ball screw gland D4, mold moving timing belt pulley D5, mold moving timing belt D6, mold moving motor D7, mold moving motor fixing plate D8, first bearing D9, spindle nut E1, spindle E2, through hole E2a, concave-convex tooth body E2b, fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com