Incremental absolute grating ruler-based absolute displacement detection method

A technology of absolute grating ruler and absolute displacement, which is applied in measuring devices, optical devices, instruments, etc., can solve the problems of inability to increase the allowable measurement speed, reduction of displacement measurement accuracy, physical model error, etc., to solve the contradiction between speed and accuracy. , Improve the accuracy and stability, eliminate the effect of manufacturing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

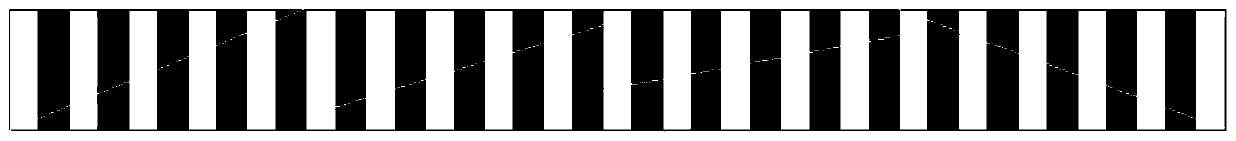

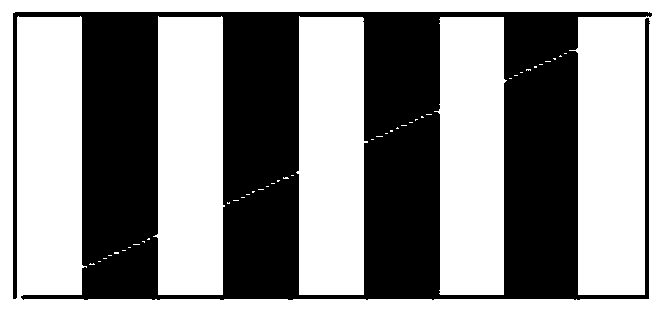

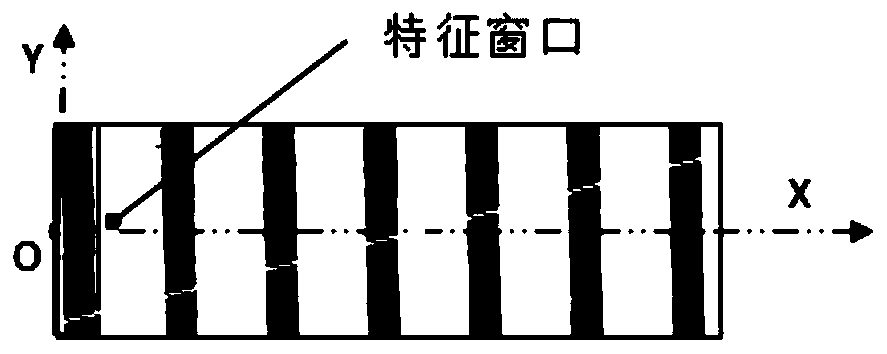

[0041] Generally, the resolution of a single grating ruler used as a displacement sensor can reach the nanometer level, but due to the limitation of the scanning frequency of signal detection, the maximum allowable speed of a single grating ruler detection is often inversely proportional to its measurement resolution. To achieve nanoscale displacement For precision measurement, the system motion speed will be limited by the grating displacement sensor measurement limit speed (generally 0.5um).

[0042] In order to solve the above problems, the present invention proposes an incremental absolute grating ruler and its displacement detection method. On the one hand, the detection accuracy is improved through the subdivision of the image pixels of the grating ruler (only relevant to the resolution of the camera, not to the resolution of the grating ruler) ; On the other hand, by downloading the weight and offset parameters of the neural network to the FPGA, a higher measurement spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com