A steering gear isolation bypass valve group

A technology for isolating bypass and valve group, which is used in mechanical equipment, servo motor components, fluid pressure actuating devices, etc., and can solve the problems of limited flow capacity of spool valve, high precision requirements of spool valve, and difficult to overcome hydraulic control force. , to achieve strong adaptability, solve large leakage of slide valve, and achieve good rudder stabilization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

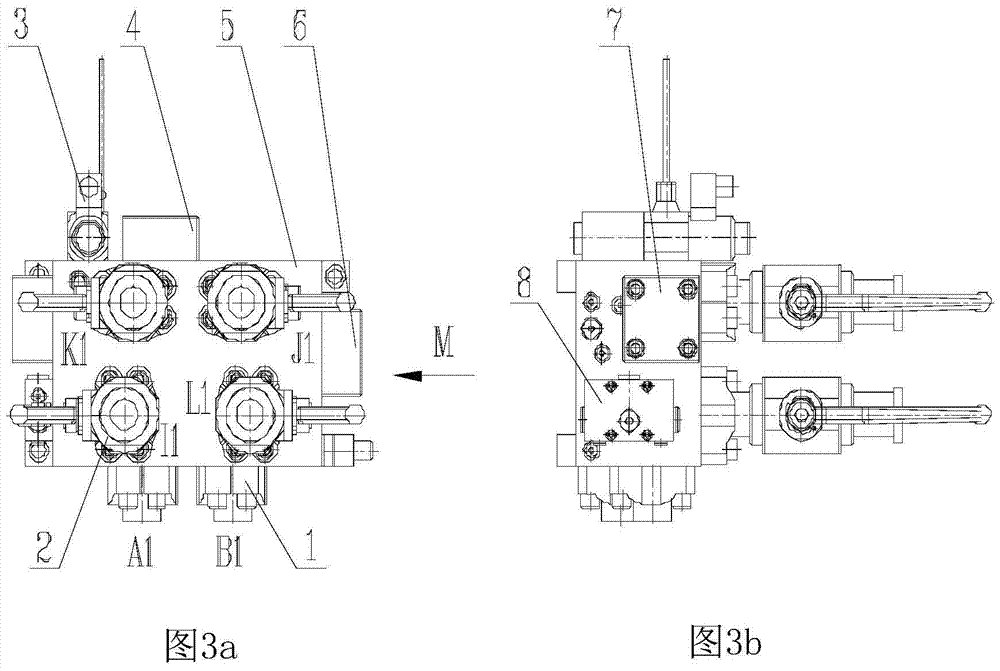

[0038] The present invention will now be described in further detail with reference to the drawings.

[0039] The structure of the steering gear isolation bypass valve group of the present invention is shown in Fig. 3, including: flange 1, ball valve 2, electromagnetic reversing valve 3, first cartridge valve 4, main valve body 5, and second cartridge valve 6. The third cartridge valve 7, the one-way valve assembly 8.

[0040] The main valve body 5 is used to install various parts, and there are valve fitting holes and hydraulic oil circulation holes inside;

[0041] There are two flanges 1, which are installed on the bottom surface of the main valve body 1 by screws to provide interfaces A1 and B1 for connecting with the main oil pump;

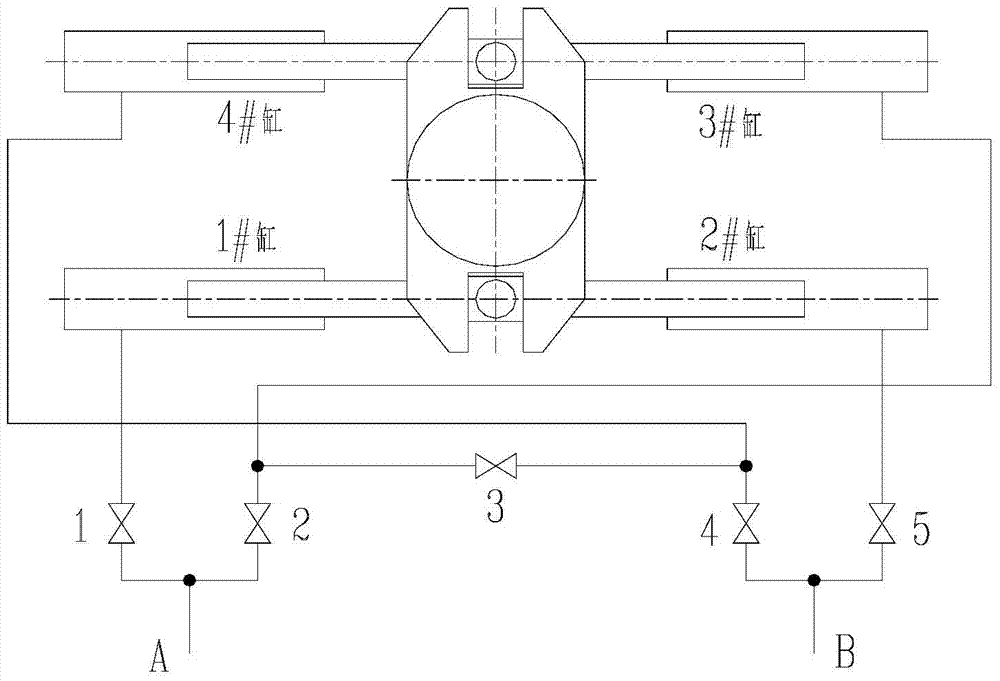

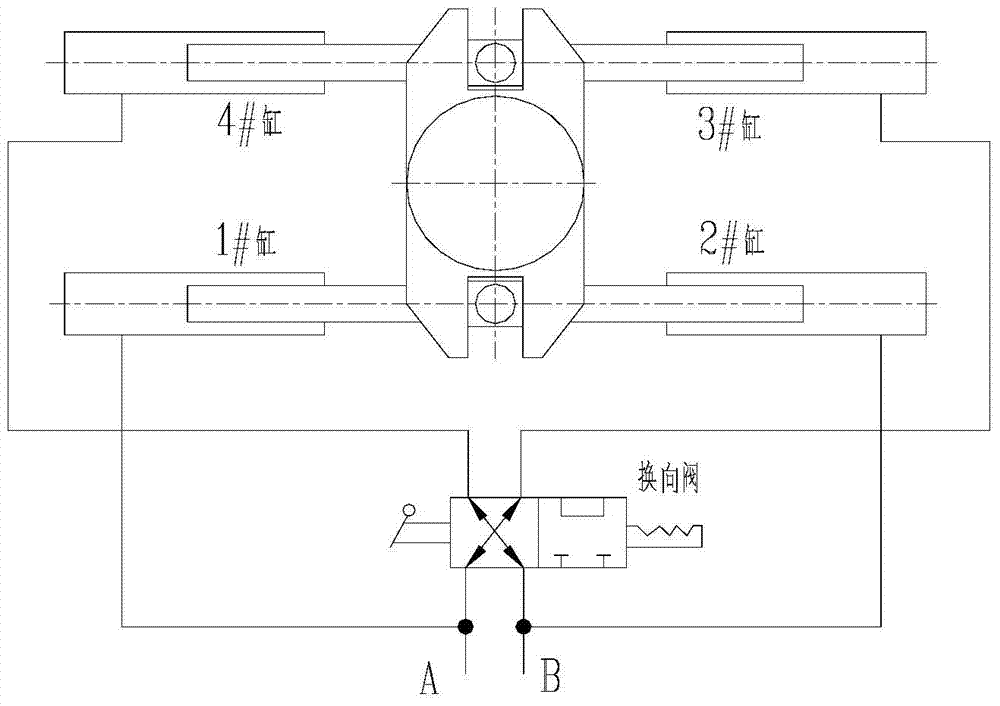

[0042] There are four ball valves 2, which are fixed on the main valve body 5 by screws, and provide ports I1, K1, L1, and J1 for connecting with the rudder steering mechanism. The A1 port of the valve group communicates with I1 and K1 ports, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com