Disc type turbine agitator for reaction vessel

A turbine agitator and disc type technology, applied in the field of reaction kettles, can solve the problems of uneven mixing, uneven stirring, single stirring direction, etc., and achieve the effects of high stirring efficiency, uniform mixing and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

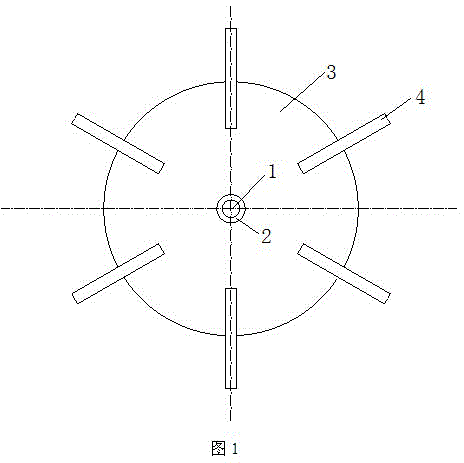

[0012] Example: A disc turbine agitator for reactors such as figure 1 As shown, it includes a shaft 1, a shaft sleeve 2, a disc 3 and six paddles 4, the diameter of the disc 3 is 350 mm, the shaft 1 passes through the center of the disc 3 and is fixed by the shaft sleeve 2, and the six paddles 4 are 60° is evenly welded to the circle of the disc 3, and the paddle 4 is bent in a wave shape; the curved paddle 4 can drive the entire reactor to form a wide and stable swirling flow at a relatively low speed.

[0013] The direction of the swirling flow formed in the reactor of this embodiment is clockwise at the upper part of the paddle 4, and counterclockwise at the lower part of the paddle 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com