Liquid silicone rubber base sizing material and preparation method thereof as well as organic silicon coating using sizing material and preparation method thereof

A technology of liquid silicone rubber and organic silicon coating, applied in the direction of coating, etc., can solve the problems of poor high temperature resistance of glass fiber insulating bushing, low voltage resistance of glass fiber insulating bushing, and more solvent consumption, etc., to achieve wide application Value, environmental protection, effect of less solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

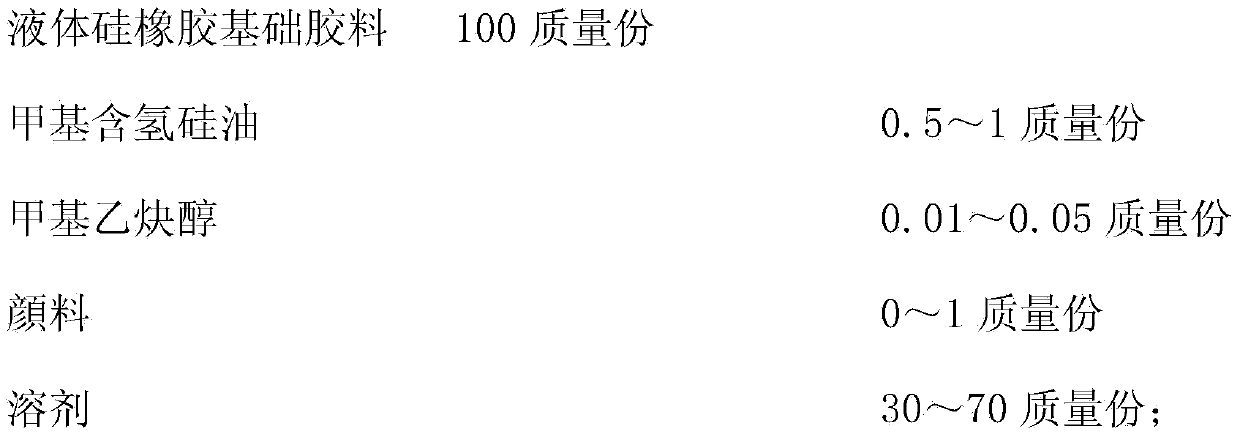

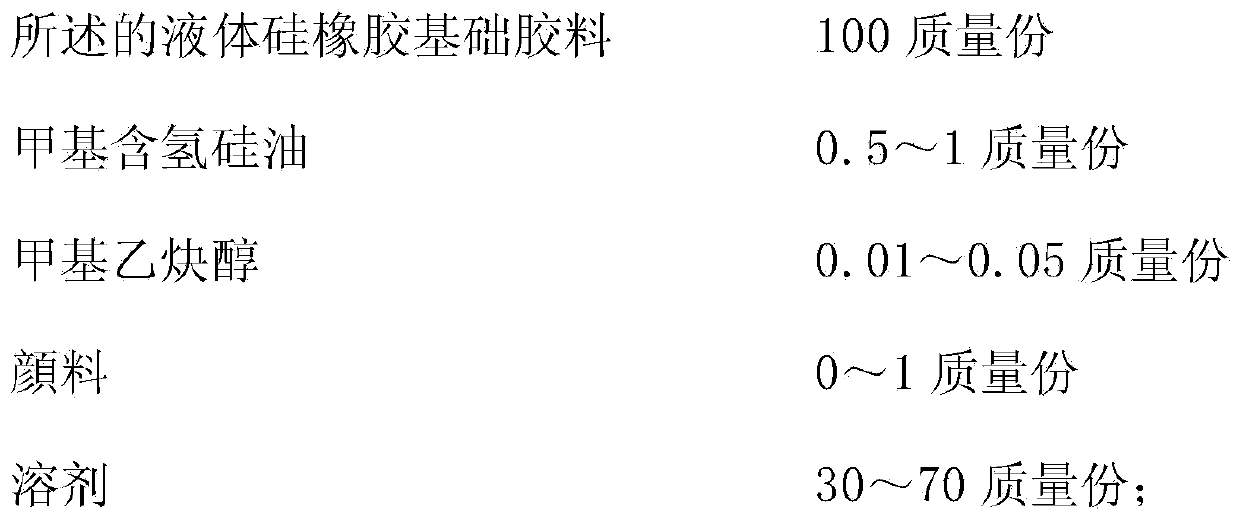

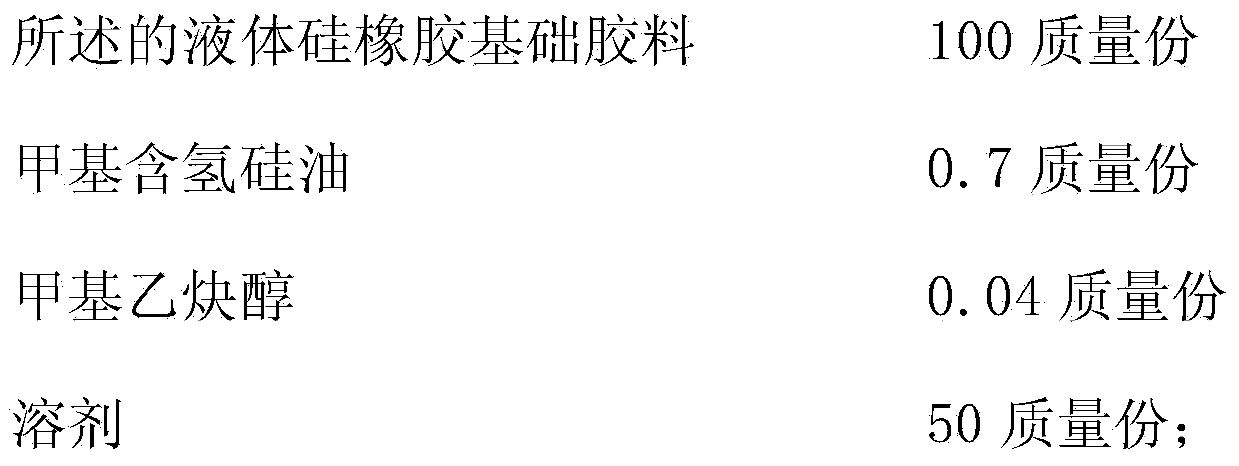

[0039] A liquid silicone rubber base compound is provided, comprising the following components in parts by mass:

[0040] 100 parts by mass of polymethylvinylsiloxane

[0041] Reinforcing filler 25 parts by mass

[0042] 25 parts by mass of hexamethyldisilazane;

[0043] Wherein, the viscosity of the polymethylvinylsiloxane at 25°C is 2000mPa.s, and the vinyl content of the polymethylvinylsiloxane is 0.8%mol / mol; The specific surface area of the reinforcing filler is 300m 2 / g.

[0044] The reinforcing filler has a specific surface area of 300m 2 / g of fumed silica or precipitated silica or a mixture of both, which can be selected according to the actual situation.

[0045] A preparation method for the liquid silicone rubber base compound described in Example 1 is provided, comprising the following steps:

[0046] (1) 100 parts by mass of polymethylvinylsiloxane with a viscosity of 2000 mPa.s and a vinyl content of 0.8% mol / mol at 25°C, 25 parts by mass of polymethyl...

Embodiment 2

[0073] A liquid silicone rubber base compound is provided, comprising the following components in parts by mass:

[0074] 100 parts by mass of polymethylvinylsiloxane

[0075] 35 parts by mass of reinforcing filler

[0076] 35 parts by mass of hexamethyldisilazane;

[0077] Wherein, the viscosity of the polymethylvinylsiloxane at 25°C is 9000mPa.s, and the vinyl content of the polymethylvinylsiloxane is 0.5%mol / mol; The specific surface area of the reinforcing filler is 380m 2 / g.

[0078] The reinforcing filler has a specific surface area of 380m 2 / g of fumed silica or precipitated silica or a mixture of both, which can be selected according to the actual situation.

[0079] A preparation method for the liquid silicone rubber base compound described in Example 2 is provided, comprising the following specific steps:

[0080] (1) 100 parts by mass of polymethylvinylsiloxane with a viscosity of 9000mPa.s and a vinyl content of 0.5%mol / mol at 25°C, 35 parts by mass of ...

Embodiment 3

[0108] A liquid silicone rubber base compound is provided, comprising the following components in parts by mass:

[0109] 100 parts by mass of polymethylvinylsiloxane

[0110] Reinforcing filler 20 parts by mass

[0111] 5 parts by mass of hexamethyldisilazane;

[0112] Wherein, the viscosity of the polymethylvinylsiloxane at 25°C is 200mPa.s, and the vinyl content of the polymethylvinylsiloxane is 0.05%mol / mol; The specific surface area of the reinforcing filler is 150m 2 / g.

[0113] The reinforcing filler has a specific surface area of 150m 2 / g of fumed silica or precipitated silica or a mixture of both, which can be selected according to the actual situation.

[0114] A preparation method for the liquid silicone rubber base compound described in Example 3 is provided, comprising the following specific steps:

[0115](1) 100 parts by mass of polymethylvinylsiloxane with a viscosity of 200 mPa.s and a vinyl content of 0.05% mol / mol at 25° C., 20 parts by mass with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com