Patents

Literature

33 results about "Scoria" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

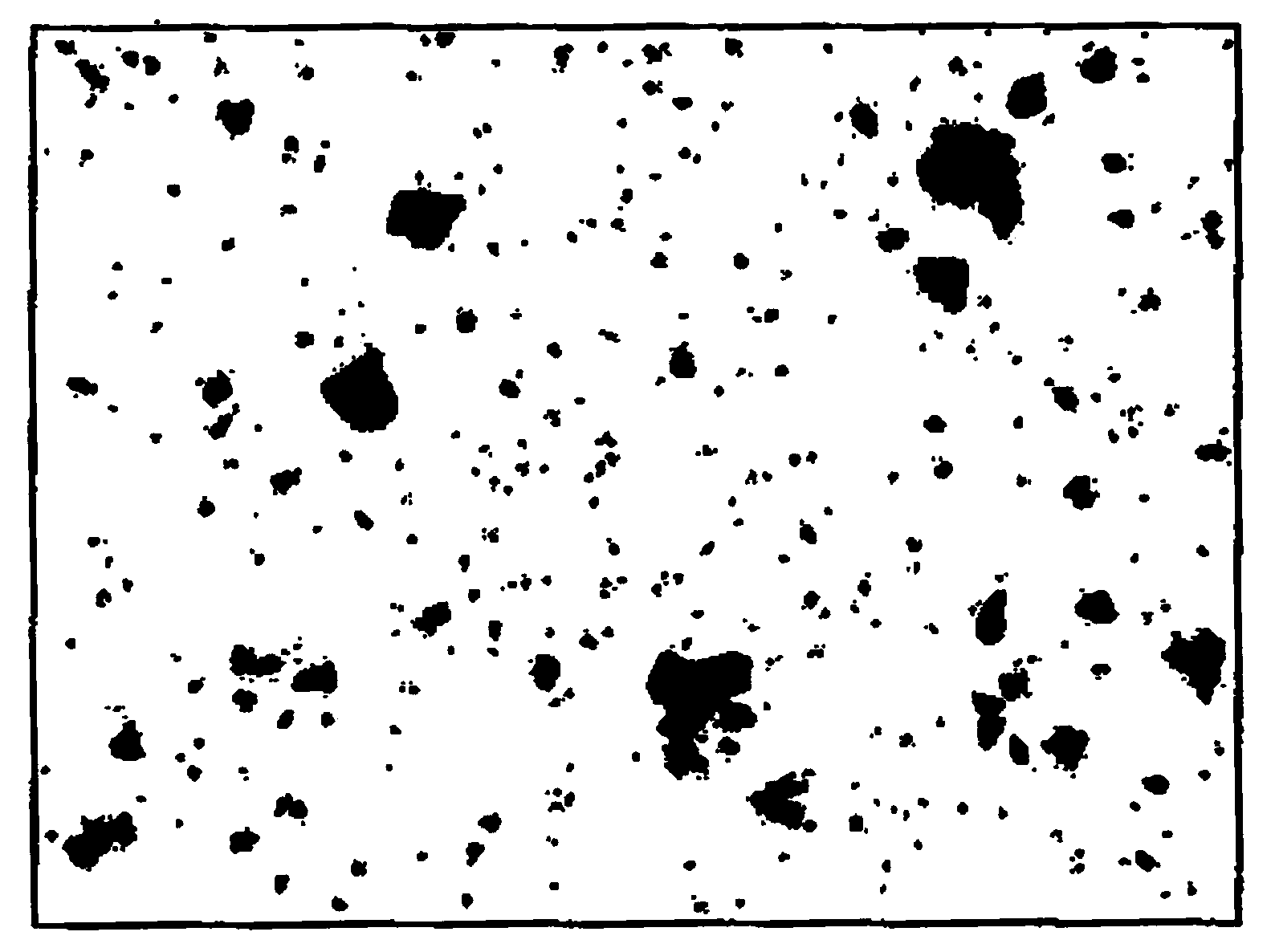

Scoria is a highly vesicular, dark colored volcanic rock that may or may not contain crystals (phenocrysts). It is typically dark in color (generally dark brown, black or purplish red), and basaltic or andesitic in composition. Scoria is relatively low in density as a result of its numerous macroscopic ellipsoidal vesicles, but in contrast to pumice, all scoria has a specific gravity greater than 1, and sinks in water. The holes or vesicles form when gases that were dissolved in the magma come out of solution as it erupts, creating bubbles in the molten rock, some of which are frozen in place as the rock cools and solidifies. Scoria may form as part of a lava flow, typically near its surface, or as fragmental ejecta (lapilli, blocks and bombs), for instance in Strombolian eruptions that form steep-sided scoria cones. Chemical analysis of scoria found in Yemen showed that it was mainly composed of volcanic glass with a few zeolites (e.g. clinoptilolite). Most scoria is composed of glassy fragments, and may contain phenocrysts. The word scoria comes from the Greek σκωρία, skōria, rust. A colloquial term for scoria is cinder.

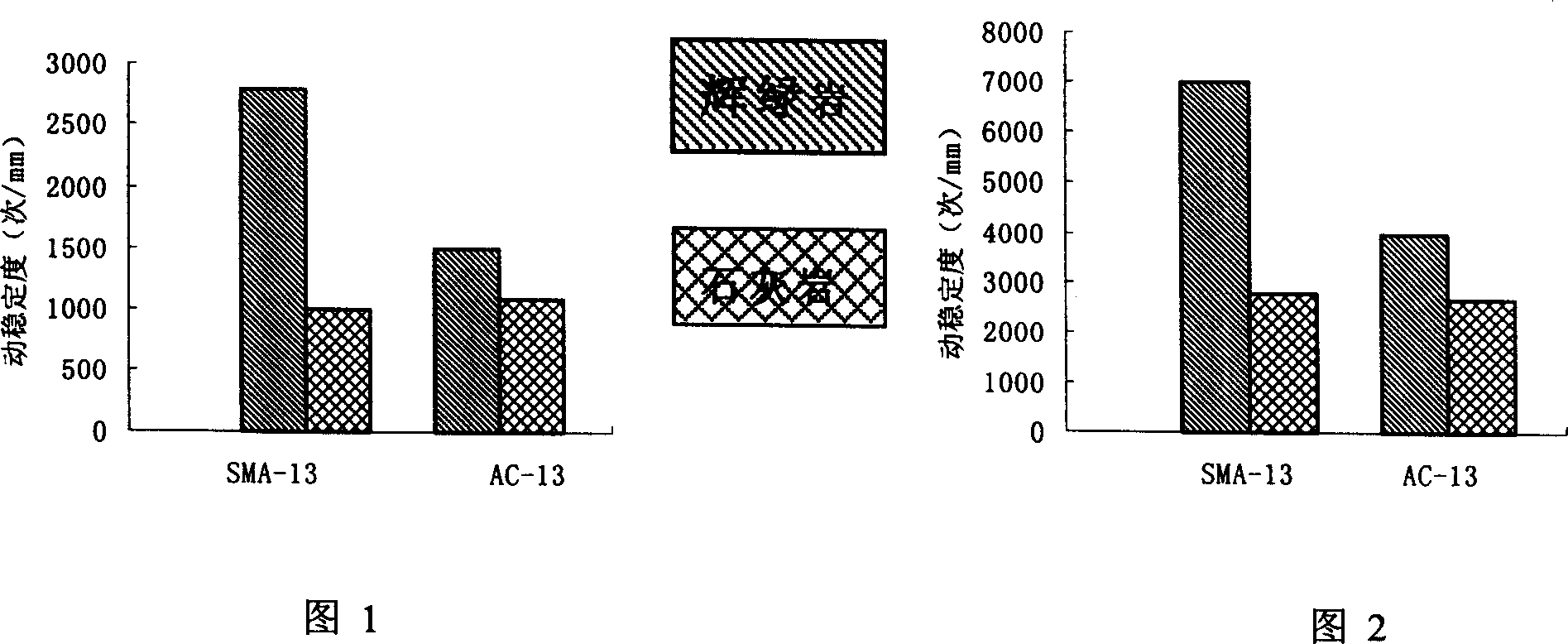

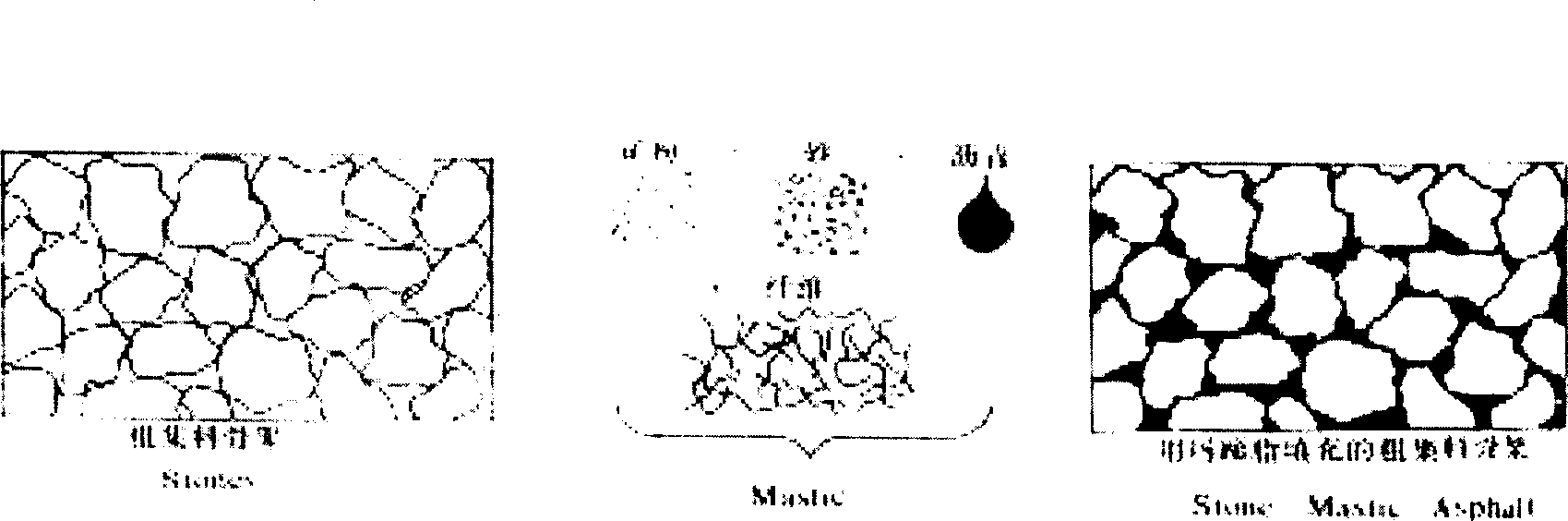

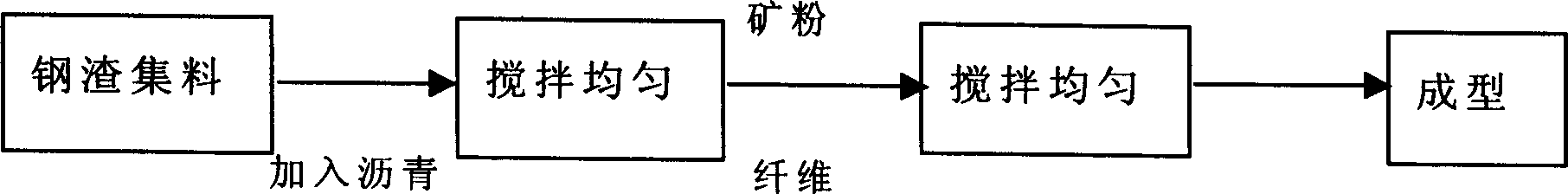

Steel scoria mastic detritus asphaltum concrete and method for preparing the same

InactiveCN1482091AImprove long-term road performanceLow costSolid waste managementCeramic shaping apparatusFiberAdhesive

Steel slag as aggregate for road engineering has not only excellent pressure resisting and wear resisting performance but also high adhesion. The asphalt concrete consists of steel slag as aggregate, mineral powder stuffing, fiber as stabilizer and asphalt as adhesive. The production process includes heating the aggregate to 170 deg.c and mixing with hot molten liquid asphalt, mixing with mineral powder, adding fiber as stabilizer, and beating the steel slag SIA asphalt mixture on two sides for 50 times each or rolling for 18 times to form. The steel slag SIA asphalt concrete has its performance indexes reaching national standard, dynamic stability up to 5846 times / mm and may be used in expressway. In addition, the use of steel slag can lower engineering cost and reduce environmental pollution.

Owner:武汉钢铁集团冶金渣有限责任公司 +1

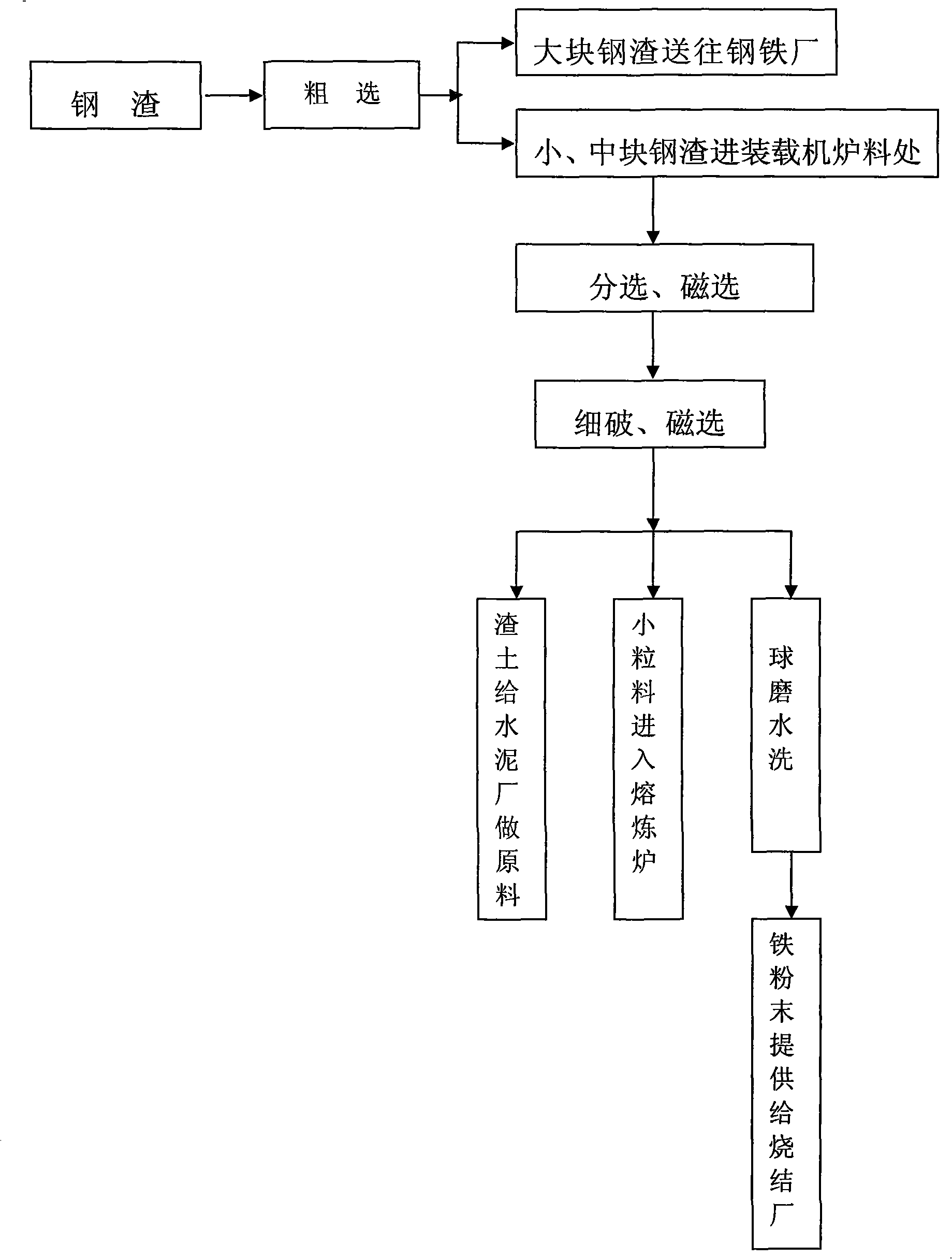

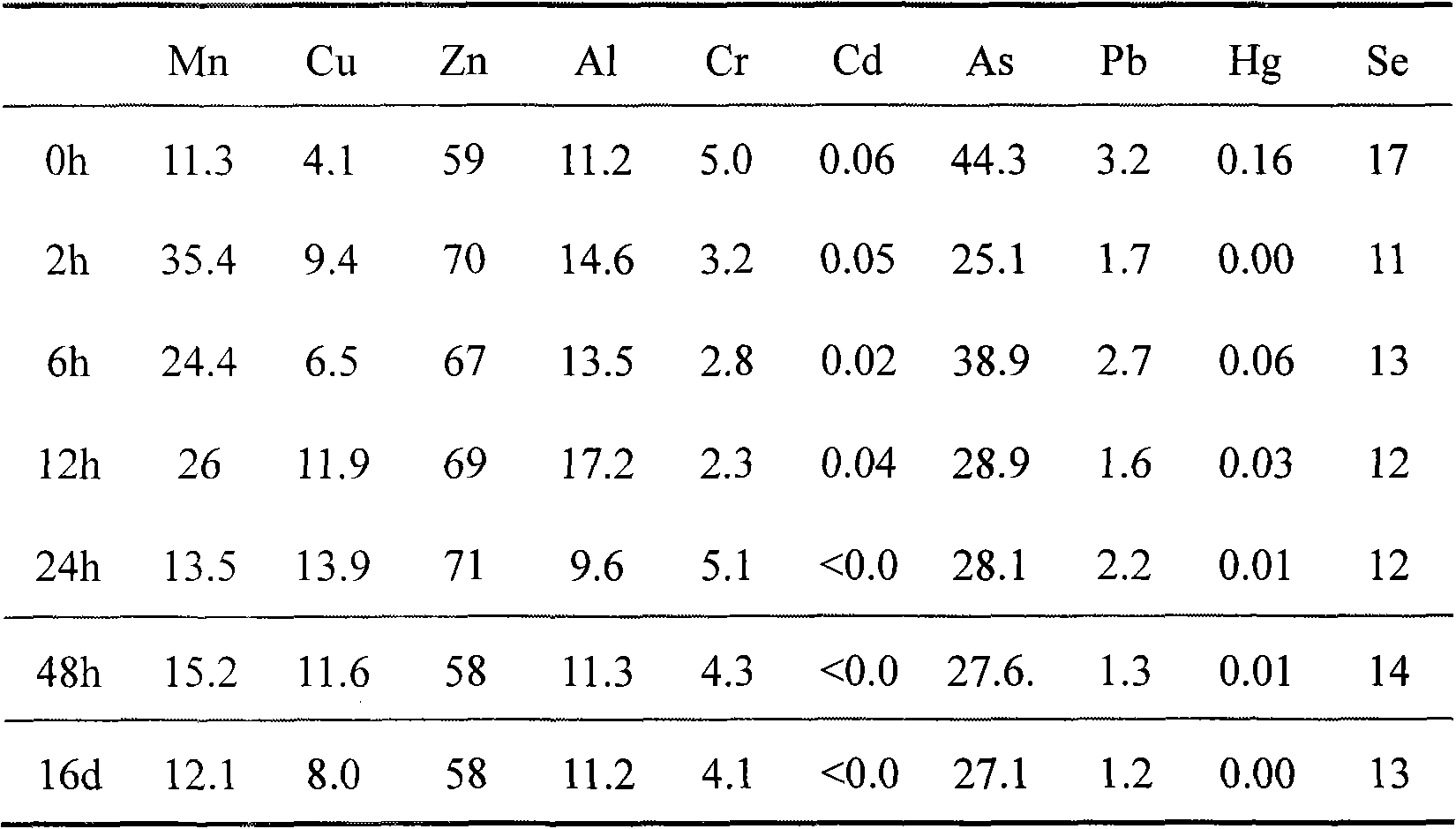

Steel scoria processing method

The invention relates to a steel-slag processing method, including the procedures of separation, magnetic separation, fine crushing, magnetic separation, ball-mill washing, etc. The slag and steel are separated by fine processing of waste steel slag, the iron content in the waste slag is lowered, the waste steel is smelted again and recovered for use. The invention can ensure high yield and high economic benefit; and is capable to remove pollution and achieve a benign cycle.

Owner:NANJING BANQIAO SLAG

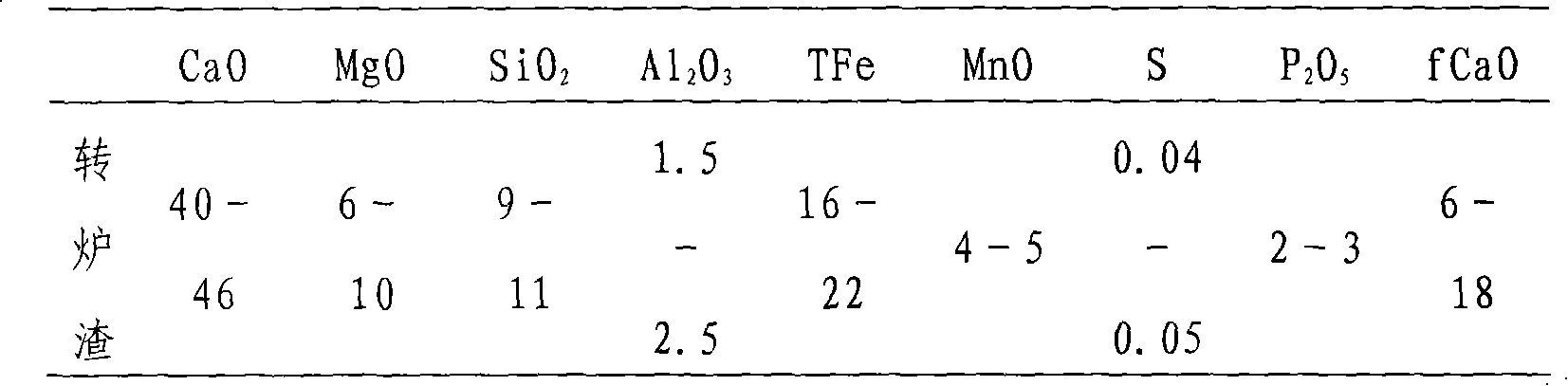

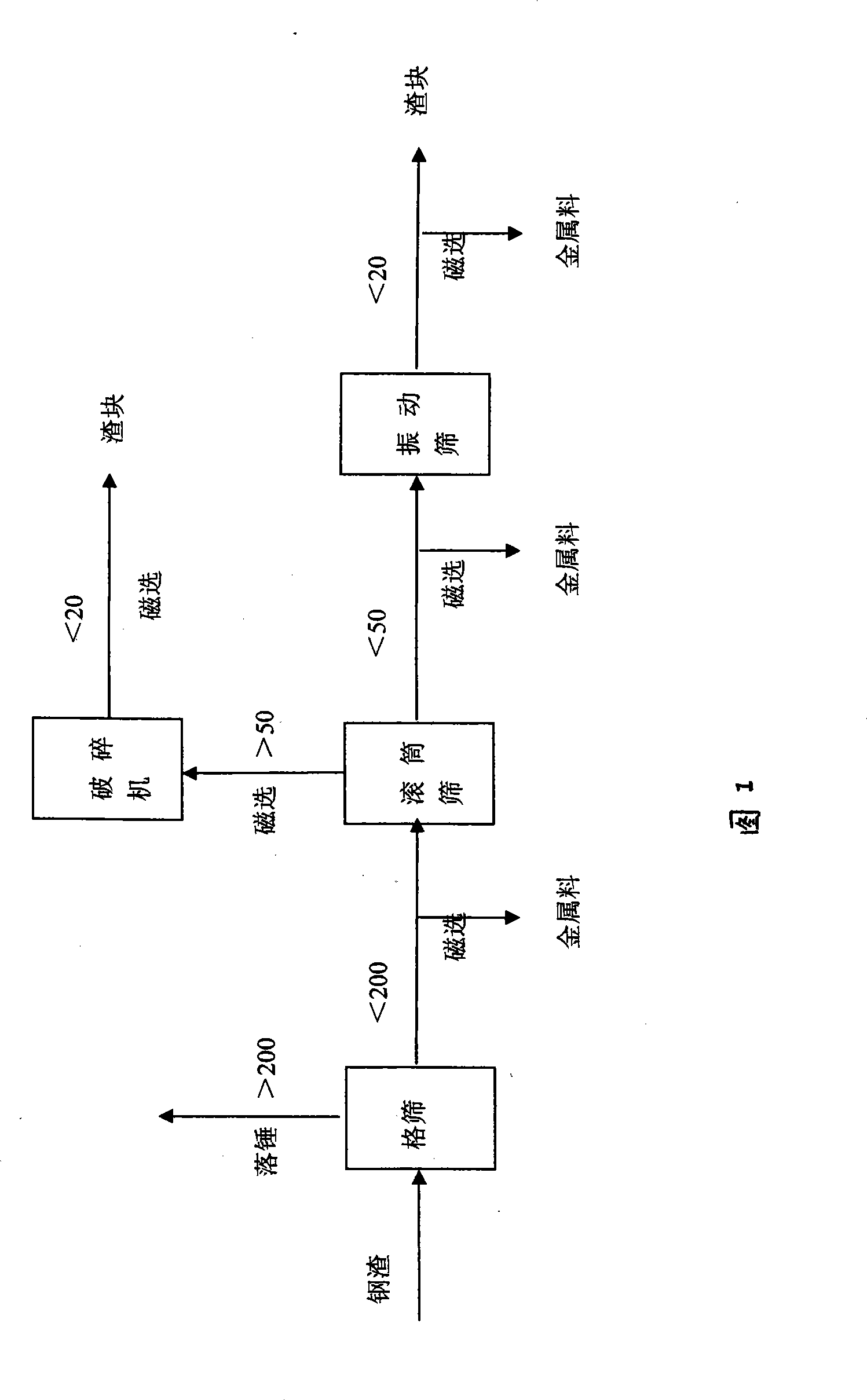

Carbonatation processing method of steel scoria

The present invention provides a method of carbonatation treatment for steel slag, and comprises the steps: in a boiling-bed reactor, under the temperature of 350 to 800 DEG C and the pressure atmosphere 0.1 to 3.6 and under the condition of 5 to 25 percent of the vapor, the steel slag with the particle diameter being less than or equal to 15 mm reacts with the carbon dioxide for two to twelve hours. The present invention adopts the one-step carbonization in the boiling bed to substitute the conventional reactions with a hydration step and then a carbonization step, thus greatly shortening the carbonization time of the steel slag; the industrial waste gas and the stack gas (the valid compositions are carbon dioxide, and containing certain vapor when the temperature of the gas is more than 100 degrees centigrade) are used as the gas source, which reduces the exhaustion of the greenhouse gas carbon dioxide and adequately uses the surplus heat, while completing the carbonization of the steel slag; moreover, the operation is flexible and convenient, and the carbonization degree of the steel slag can be controlled according to the requirements of different application areas of the steel slag.

Owner:BAOSHAN IRON & STEEL CO LTD

Cold steel scoria processing method

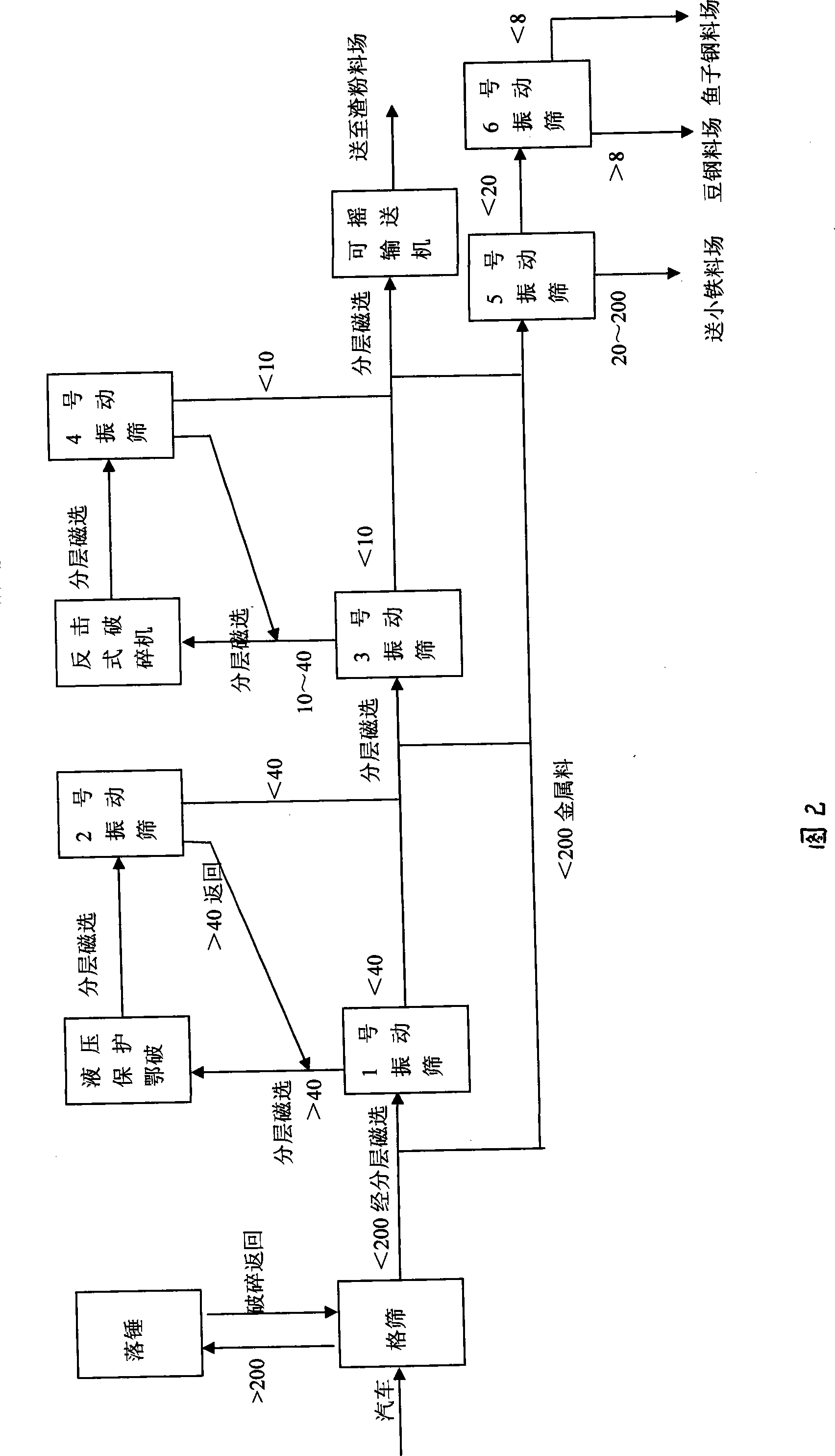

InactiveCN101249498AIncrease labor intensityImprove working environmentSievingScreeningSlagClosed loop

The invention discloses a cold steel slag processing method, which comprises the following steps of: pouring processed solidified and moistened cold steel slag into an inclinable grizzly for screening, magnetically separating iron contained in the lower layer by a head wheel permanent-magnet drum, and carrying out secondary screening by a first vibrating screen; delaminating and removing iron of larger slag blocks after screening by a belt-type iron remover and a permanent-magnet drum, crushing by a hydraulic protection crusher, screening by a second vibrating screen, returning larger slag blocks and crushing to form a one-step closed-loop circle; screening small slag blocks screened by the first vibrating screen and the second vibrating screen by a third vibrating screen; and screening the small ones by a fourth vibrating screen, and circularly crushing the large ones to form a secondary closed-loop circle, wherein the slag blocks screened by the third and the fourth vibrating screens are the final slag powder, and all of the magnetically-selected metal materials are transported to small iron material fields, bean steel material fields or roe steel material fields. By adopting double closed-loop circle process, the cold steel slag processing method has high efficiency, low labor intensity and less dust in process and can completely achieve zero discharge.

Owner:南京钢铁集团盛达实业有限公司

Modified steel scoria adsorbent and preparation thereof

The invention discloses a preparation method for steel slag adsorbent without secondary pollution and a synthetic method of modified steel slag used for adsorbing organic pollutants. The steel slag has extensive sources. The method has the advantages of ability to obtain adsorption material of low price, convenient application, and no secondary pollution, and also ability to use waste to control waste, to make the waste into a resource, and to improve the adsorption and removing capacity of steel slag for organic pollutant.

Owner:CHENGDU UNIV OF INFORMATION TECH

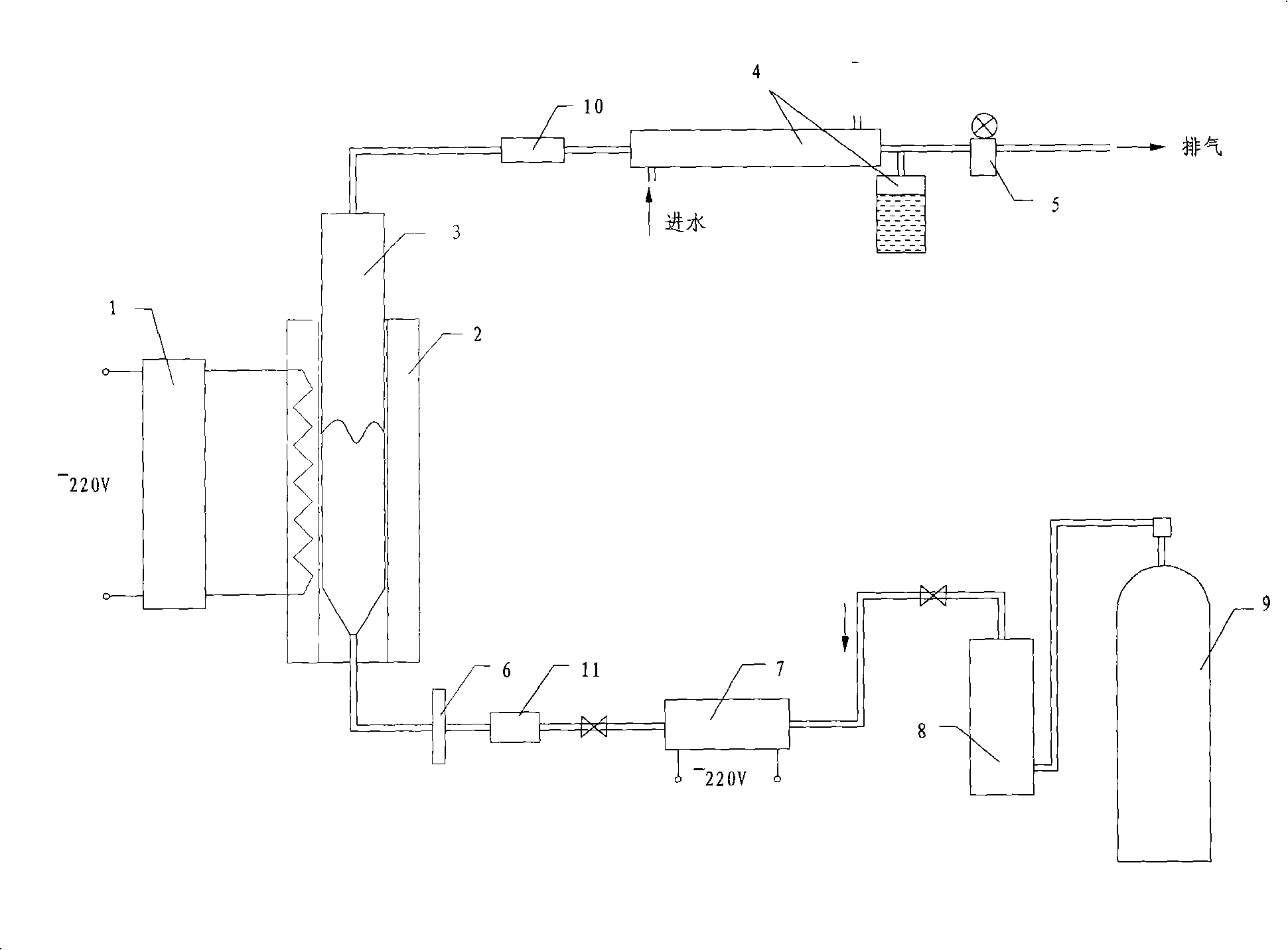

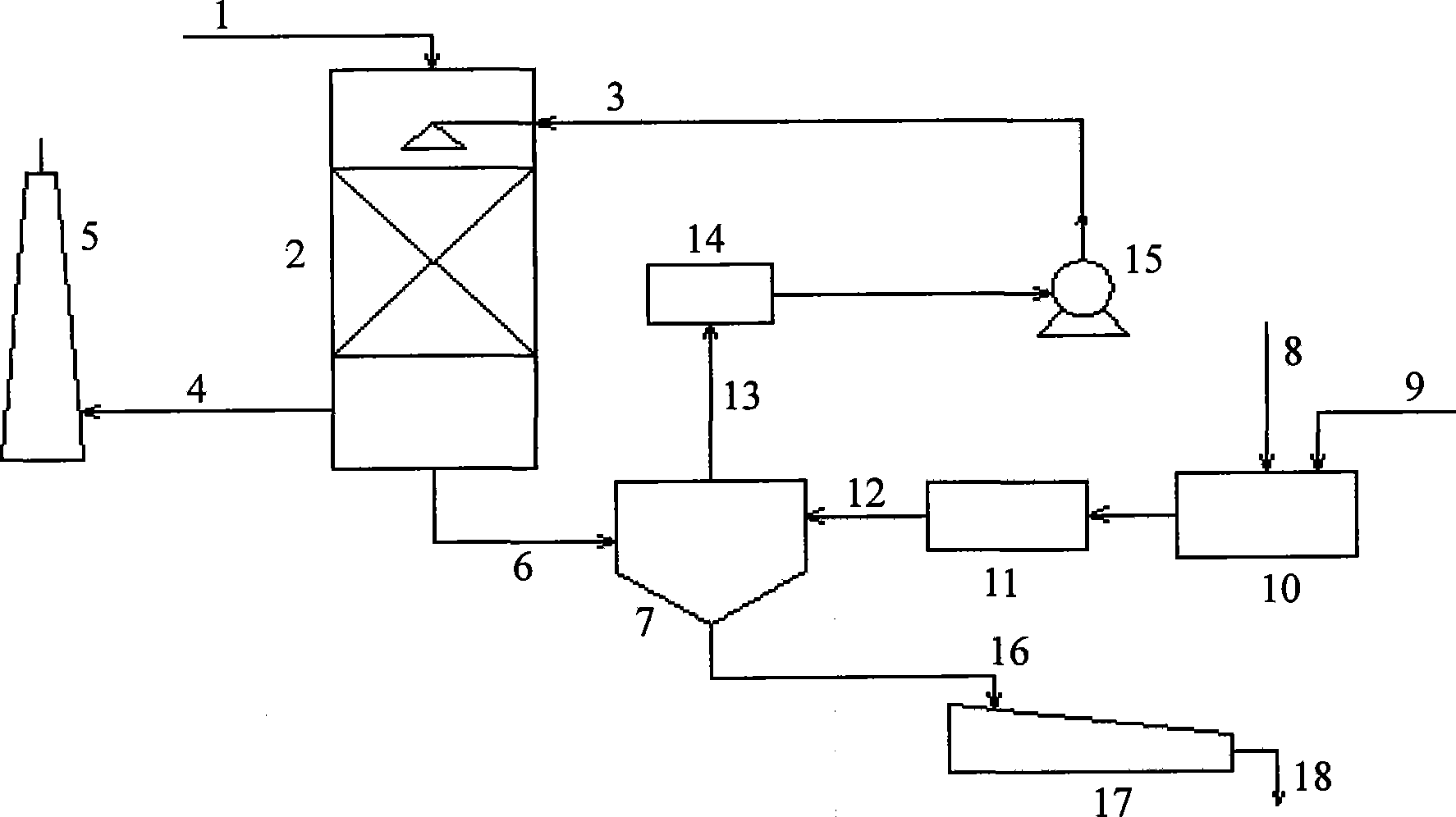

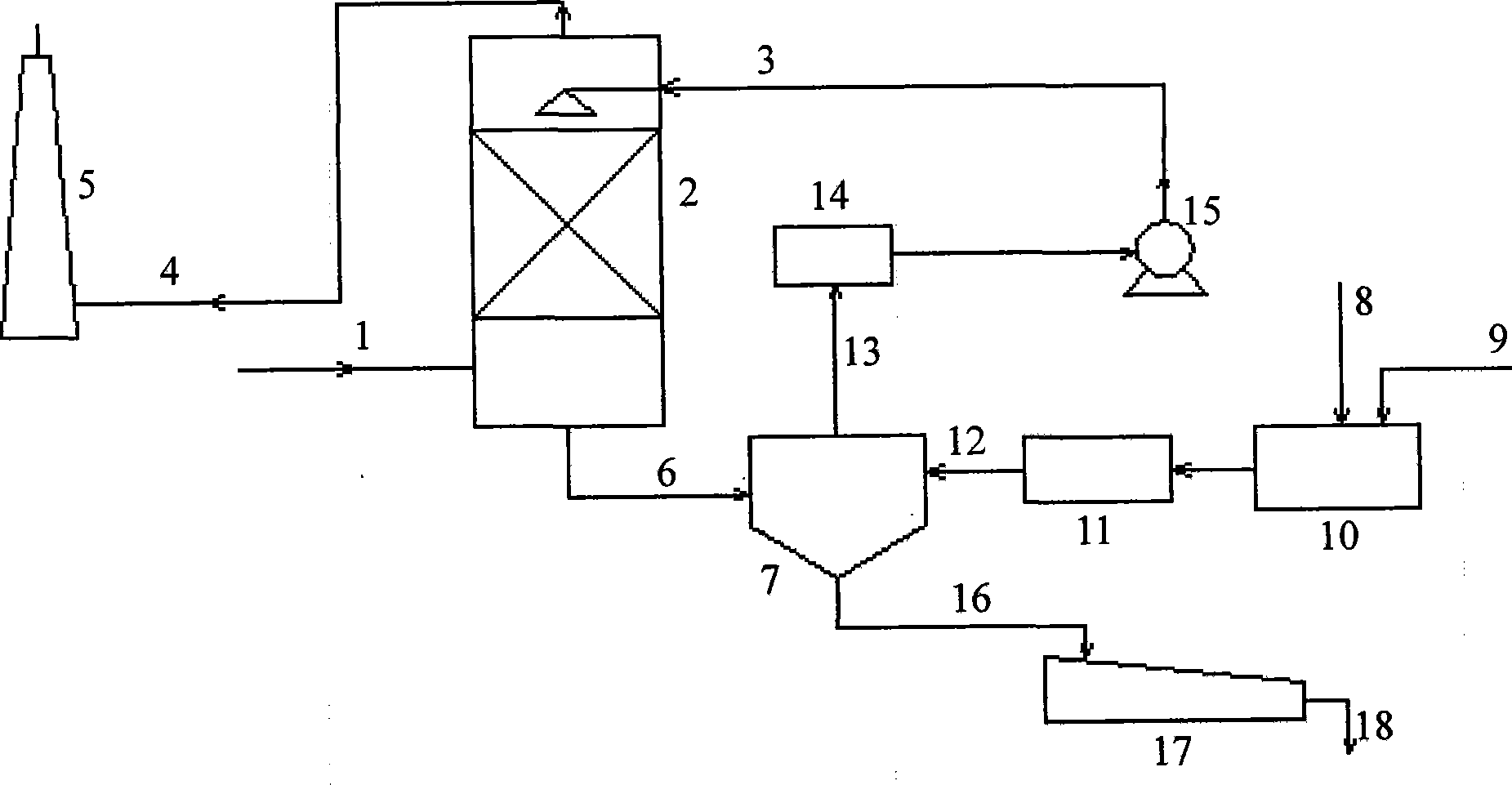

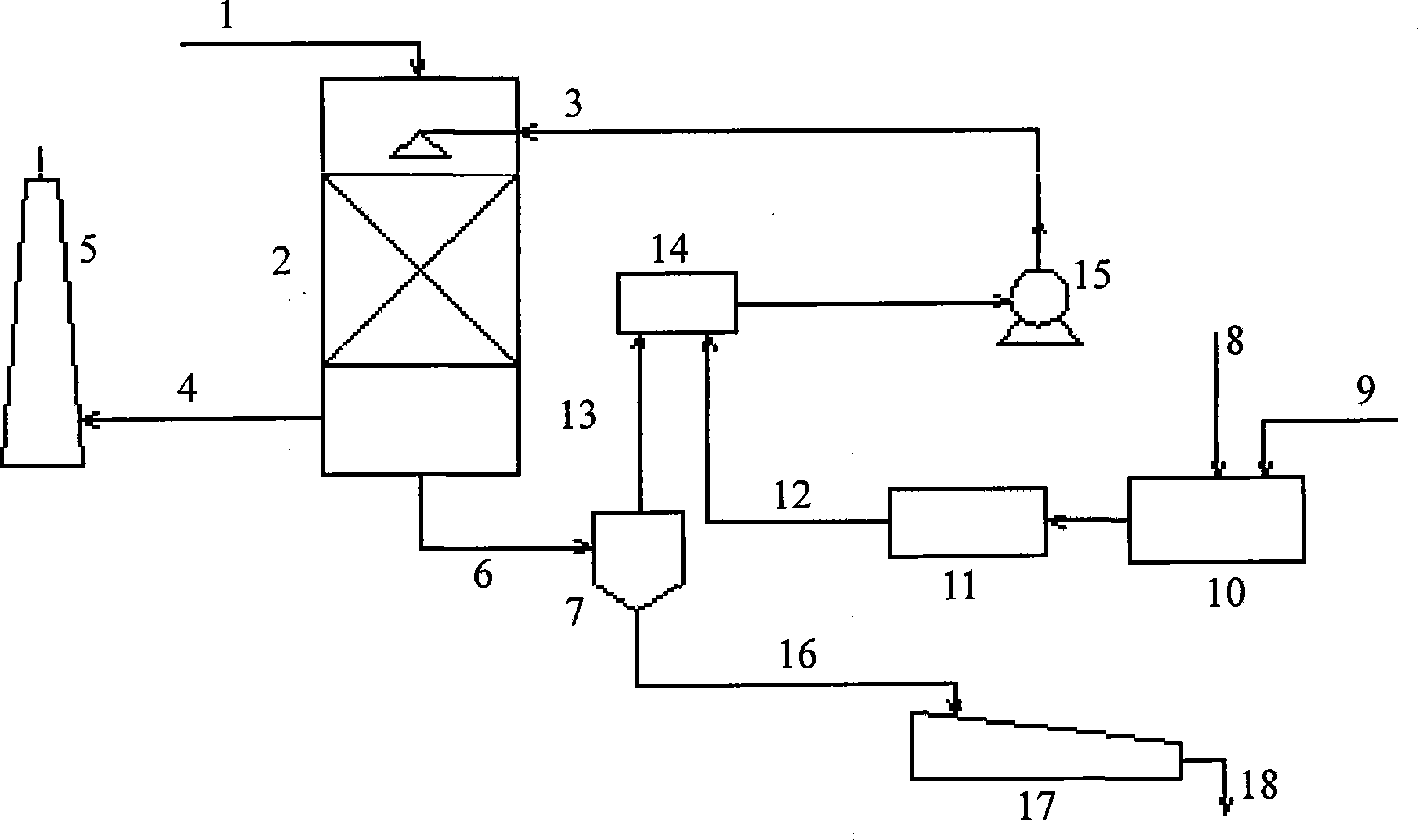

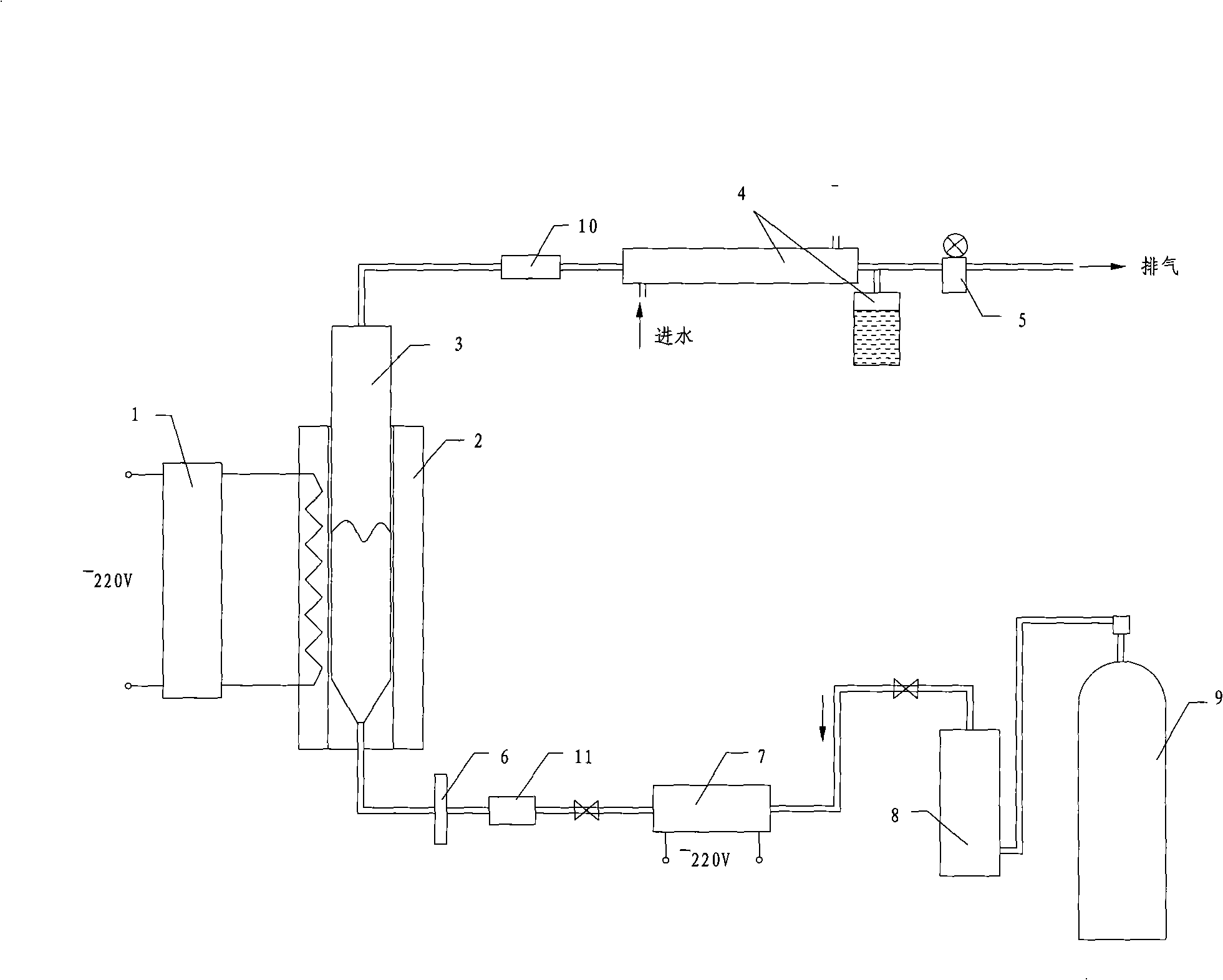

Wet-type desulfuration method for steel scoria with flue gas

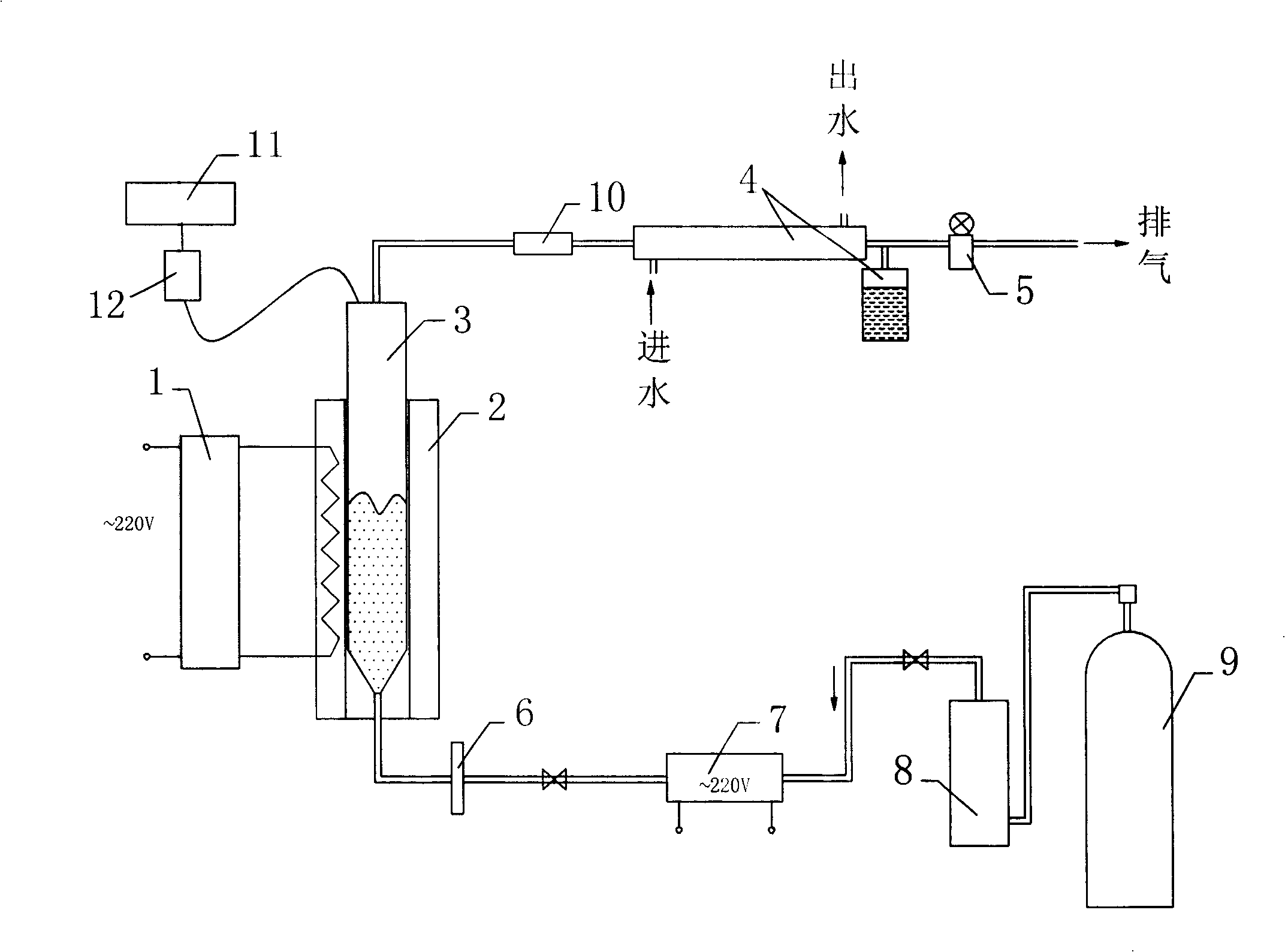

ActiveCN101428193AIncrease profitImprove dissolution rateDispersed particle separationAtmospheric airSlag

The invention discloses a method for steel slag wet-type desulphurization of flue gas. The method includes the following process: steel slag powder is subjected to hydrolysis and additional dissolution treatment; a steel slag solubilization liquid is obtained, added into a solid-liquid separator and mixed with steel slag absorption pregnant solution; after separation, the supernatant liquid after passing through a steel slag absorption liquid storage tank is pumped to an absorption tower where desulphurization occurs when the supernatant liquid is in contact with flue gas; or the steel slag solubilization liquid is added into the steel slag absorption liquid storage tank and mixed with the supernatant liquid, and then the steel slag solubilization liquid is pumped to the absorption tower where desulphurization occurs when the liquid is in contact with the flue gas; a steel slag absorption pregnant solution produced at the bottom part of the absorption tower is subjected to separation in the solid-liquid separator; precipitum is dehydrated in a hydroextractor, and plaster, a by-product, is obtained; and purified flue gas emitted from the bottom part or the top part of the absorption tower is discharged into the atmosphere. Compared with the traditional lime / limestone-plaster method, the invention has the advantages of ensuring the desulphurization degree of flue gas can be attained, and effectively preventing the absorption tower from scaling. Moreover, the equipment occupies a small area and is operated at a low cost, so that the economic benefits of waste utilization are improved.

Owner:江苏乐尔环境科技股份有限公司

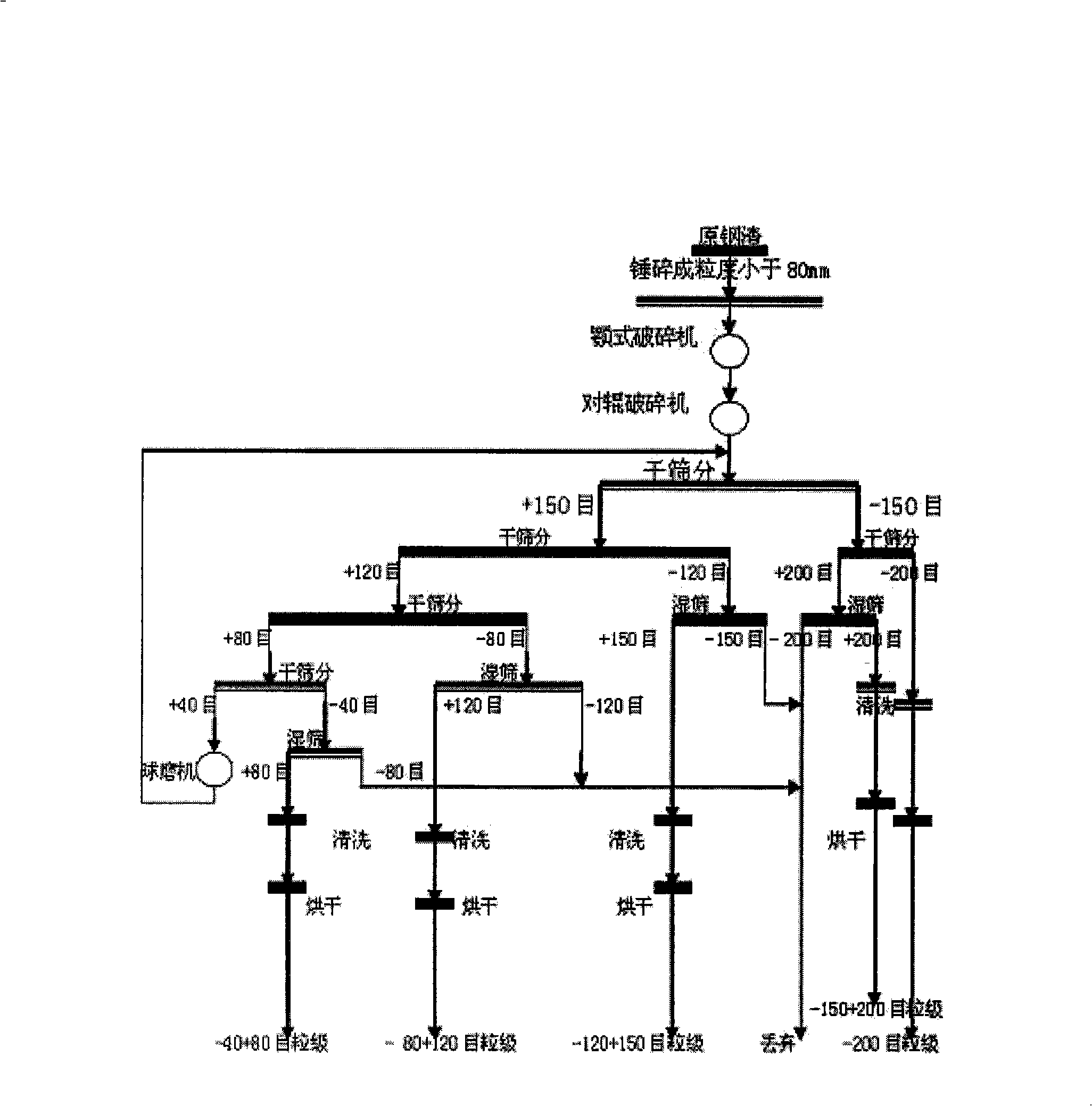

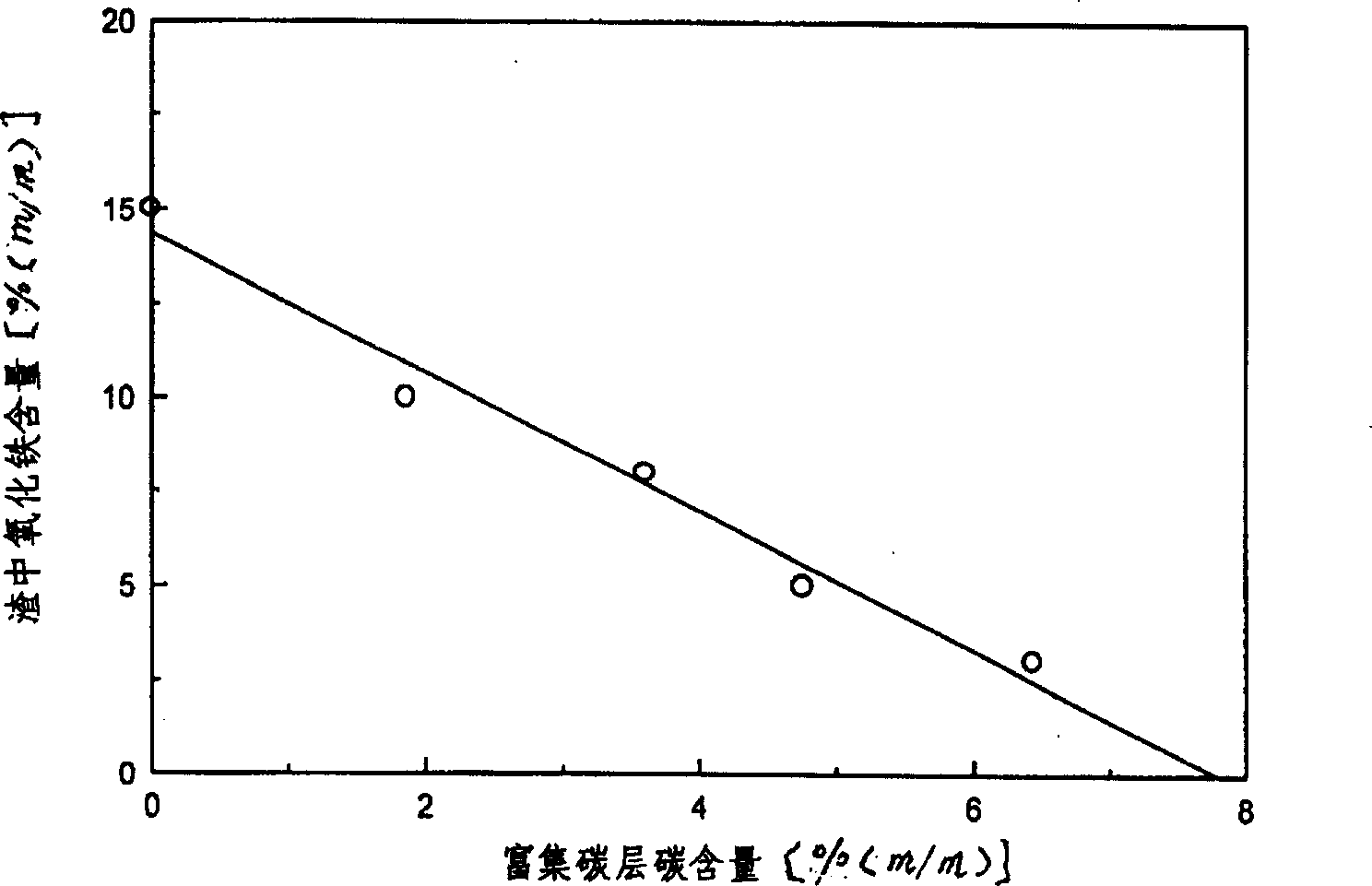

Purification technique of steel scoria magnetic separation product

The invention discloses a purification technique of steel slag magnetic separation products, which comprises the following steps: (1) the steel slag magnetic separation product is put into a ball mill and water is added, (2) full grinding is processed, the product is discharged from the exhaust end of the ball mill naturally and divided into up-screen product and below-screen product through a cylinder screen, (3) the up-screen product is divided into block iron and tailings by magnetic pulley, the block iron is dried by dryer to make water content below 2%, (4) the product below screen is divided into overflow and sand-returning by a classifier, and the overflow grade of the classifier is controlled by the size of the spray water, which controls the sand-returning grade of the classifier, and (5) the sand-returning is conveyed into the fine powder feed chute through belt, the classifier overflow is conveyed to the thickener through a pump, and the underflow of the thickener is filtered by the filter and conveyed into the tail powder feed chute. The purification technique of steel slag magnetic separation products has the advantages of no non-magnetic and weakly magnetic material loss, full and complete recovery, raising the content of iron of luppen from 60% to 65% to above 90%, raising the grade of the magnetic separation powder from 40% to 50% to above 60%, raising the content of iron of steel slag product completely, and raising the comprehensive utilization ratio of the steel slag.

Owner:鞍钢绿色资源科技有限公司 +1

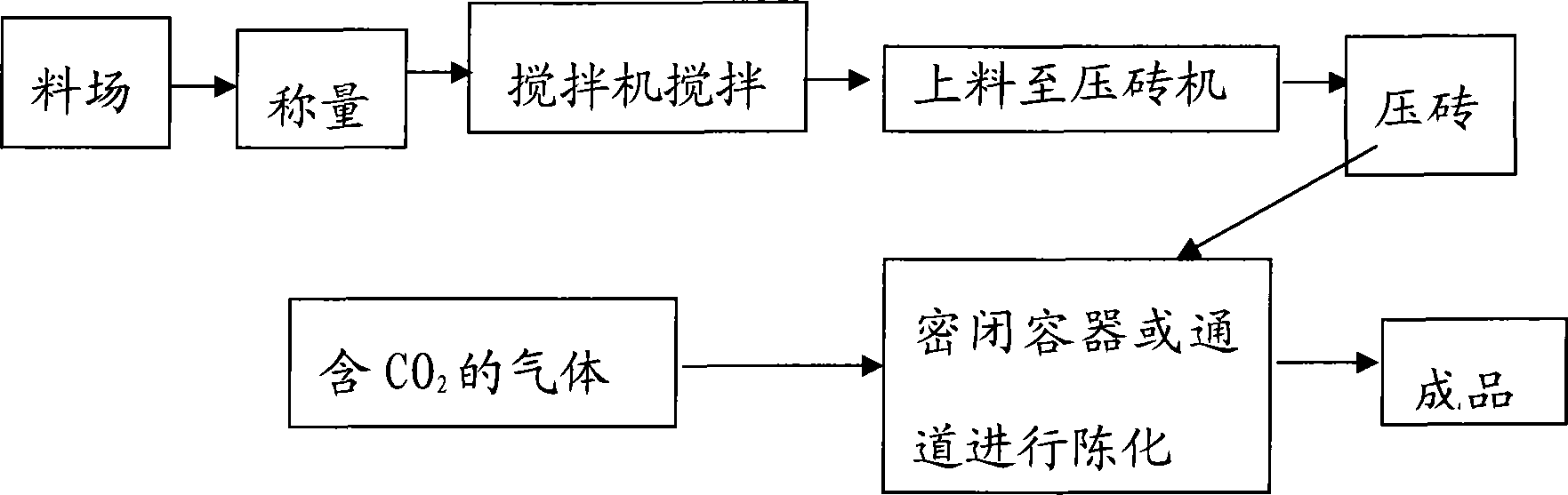

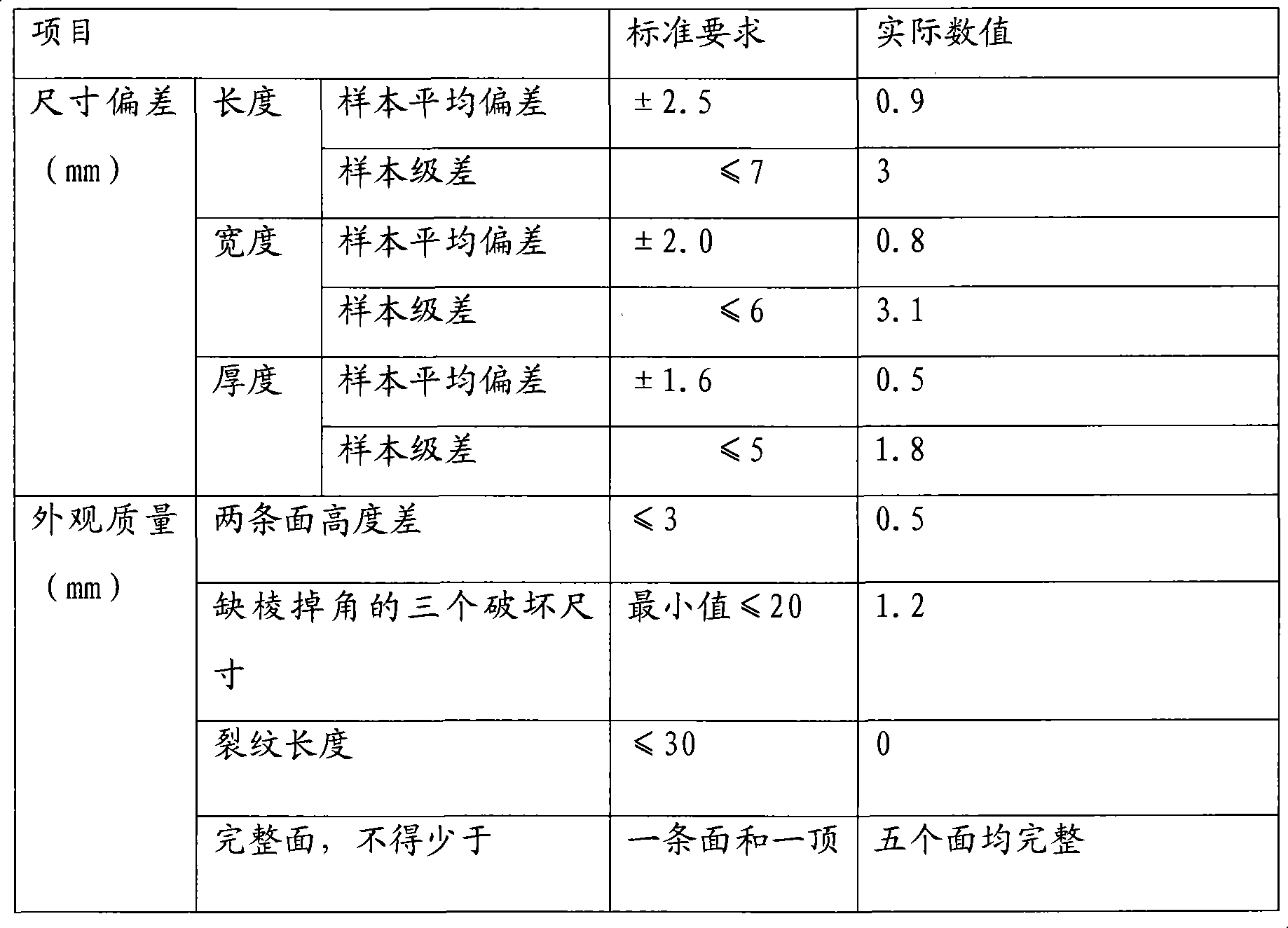

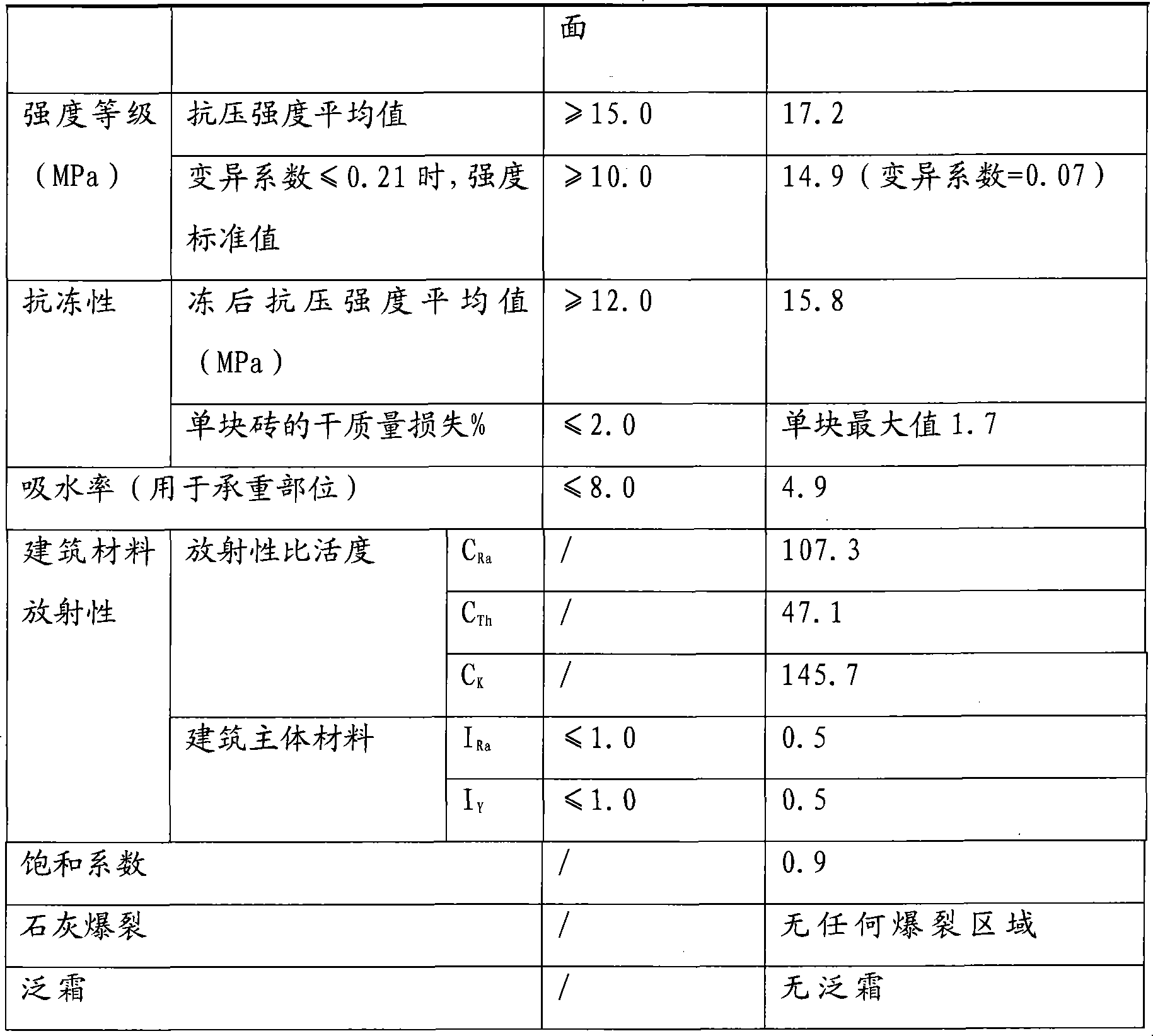

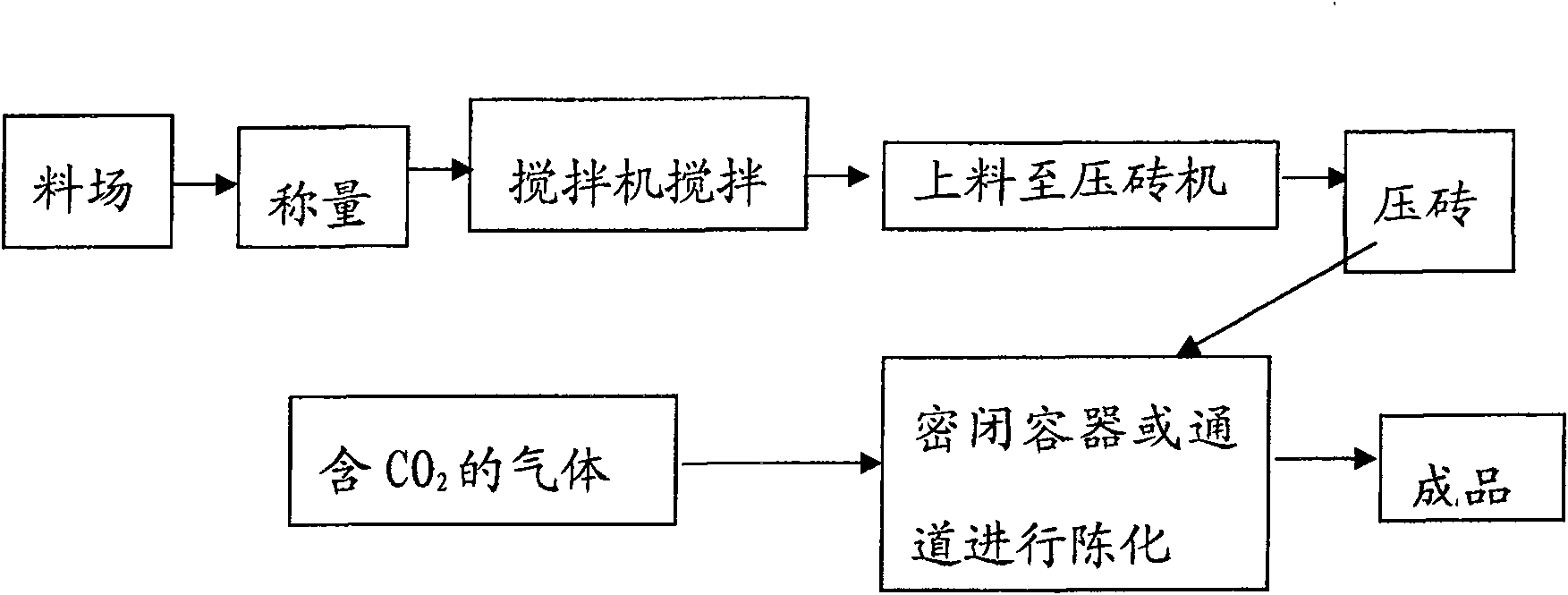

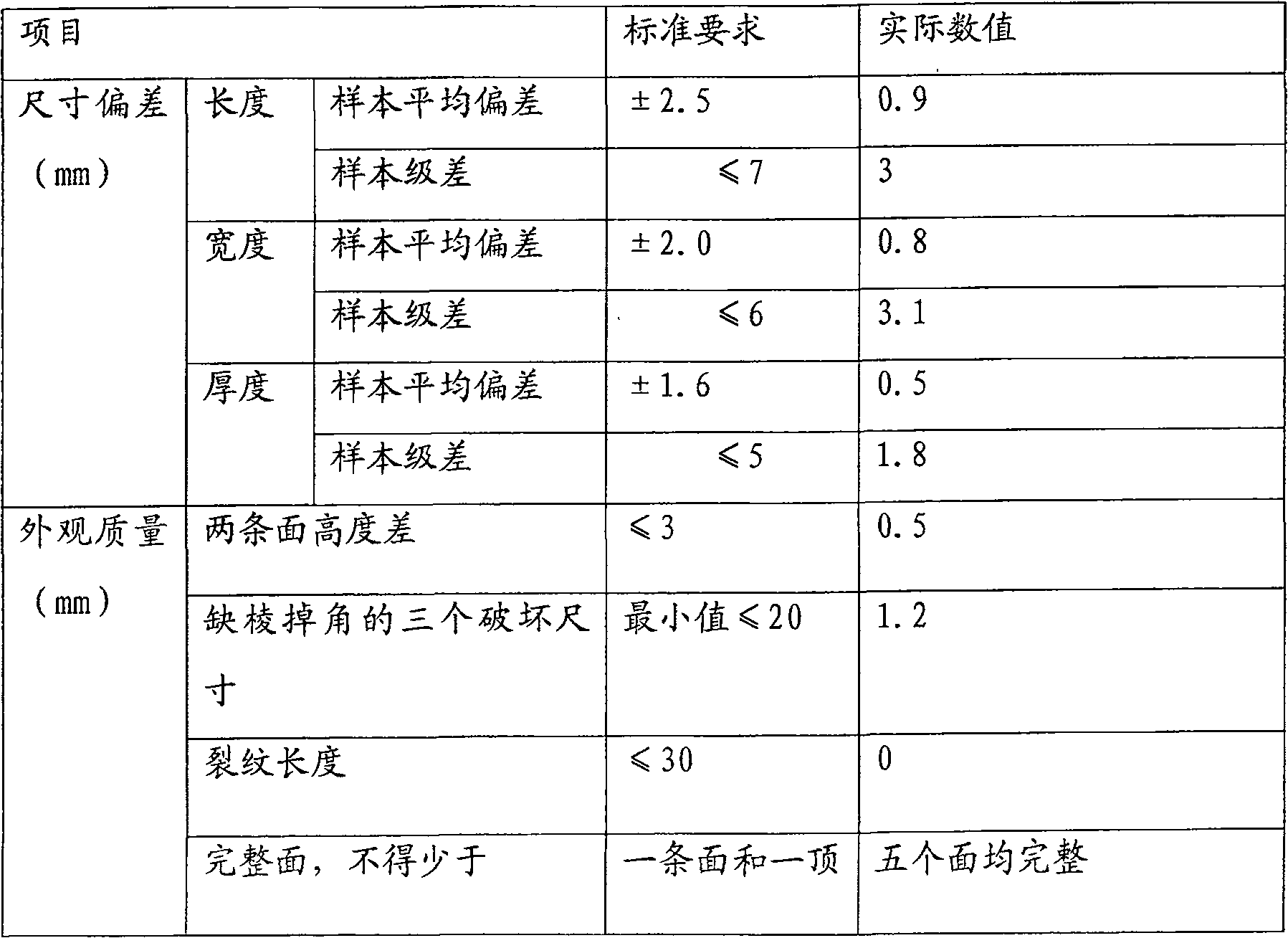

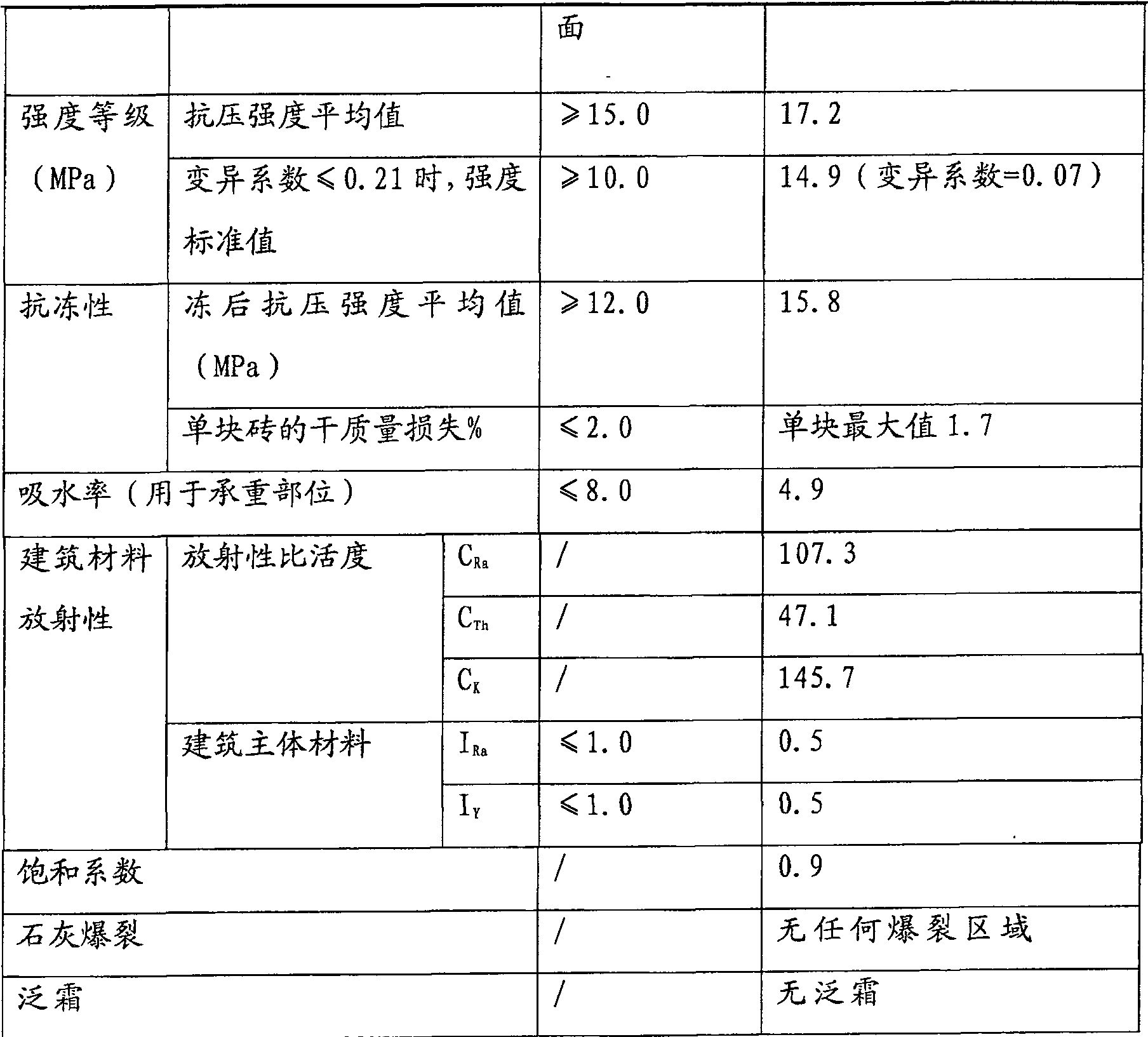

Process for producing steel scoria unburned brick

The invention discloses a making method of steel slag non-burnt brick, which belongs to steel slag reclamation field; wherein, the technical proposal resolves the problems of the prior steel slag non-burnt brick of requiring maintenance time, requiring pressure in the process of aging, high equipment cost, requiring handling and other multiple operation steps, large amount of labor, and high cost of man power and material resources. The making method of steel slag non-burnt brick is characterized in that (1) at least two materials from steel slag sand, steel slag powder, blast furnace slag and lime are weighed and fed into the blender, (2) water is added and the materials are stirred evenly, (3) the materials are fed into the brick molding press to press and form, (4) the formed brick is processed aging at the atmospheric pressure directly, (5) the industrial exhaust gas comprising CO2 is injected in the process of aging, and (6) the finished steel slag non-burnt brick is acquired as the process of aging is completed. The making method of steel slag non-burnt brick has the advantages that maintenance time is unnecessary, the pressure in the process of aging is unnecessary, requirement of equipment is low, the waste gas residual heat is utilized directly, and the cost is low.

Owner:济南鲁新新型建材股份有限公司

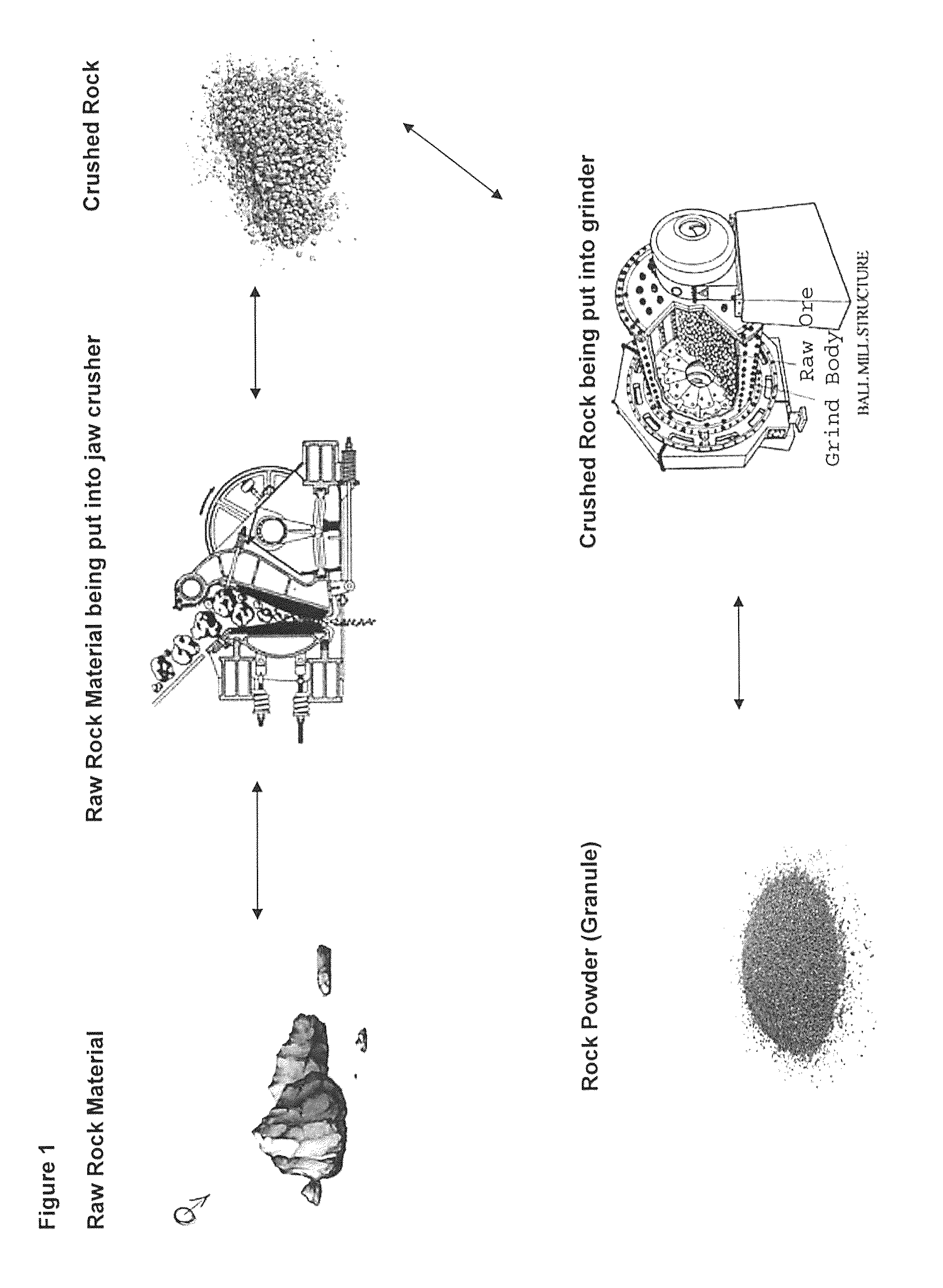

Simulated lunar soil for engineering and its preparation process

InactiveCN102288472AGuaranteed preparationMeet the requirements of the preparation cycle (complete the preparation of 700 tons of simulated lunar soil within three months)Preparing sample for investigationLunar soilVolcano

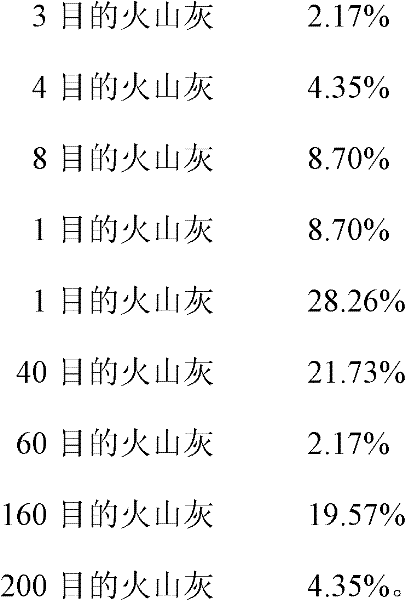

The invention discloses a simulated lunar soil for engineering and a preparation process thereof. Cinerite in Jinchuan District, Huinan County, Jilin Province is selected as the raw material of the simulated lunar soil; the simulated lunar soil is prepared from nine types of cinerite of 3 meshes, 4 meshes, 8 meshes, 10 meshes, 18 meshes, 40 meshes, 60 meshes, 160 meshes and 200 meshes according to respective weight percentages. The preparation process of the simulated lunar soil comprises the steps of raw material selection, scoria air-drying, scoria coarse crushing and drying, scoria pulverization and finished product preparation. The simulated lunar soil prepared through the preparation process of the invention meets the requirements of the simulated lunar soil for engineering in both preparation cycle and control indexes.

Owner:JILIN UNIV

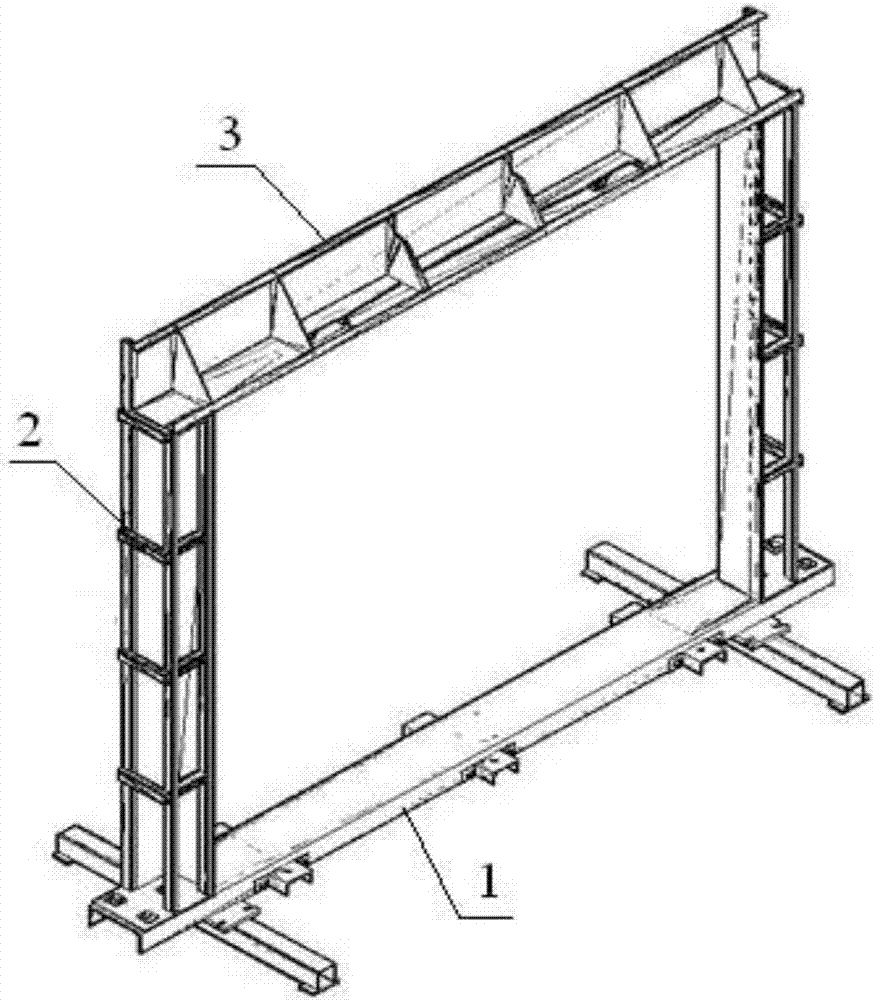

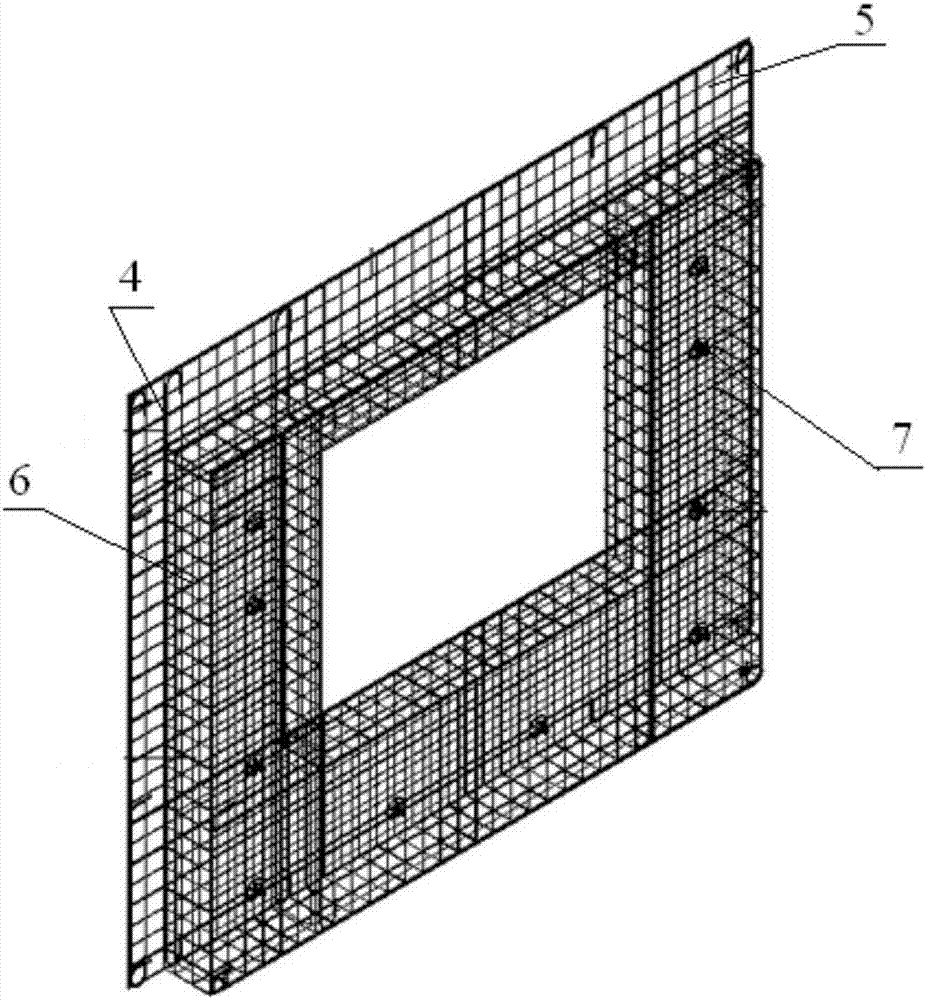

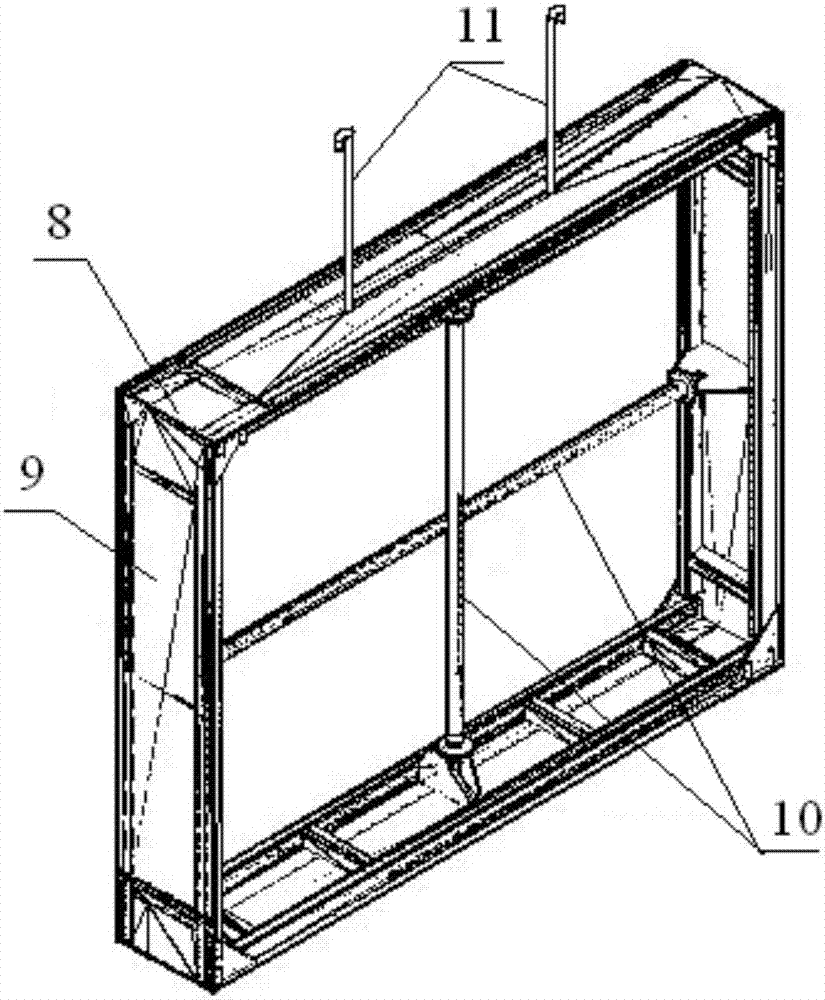

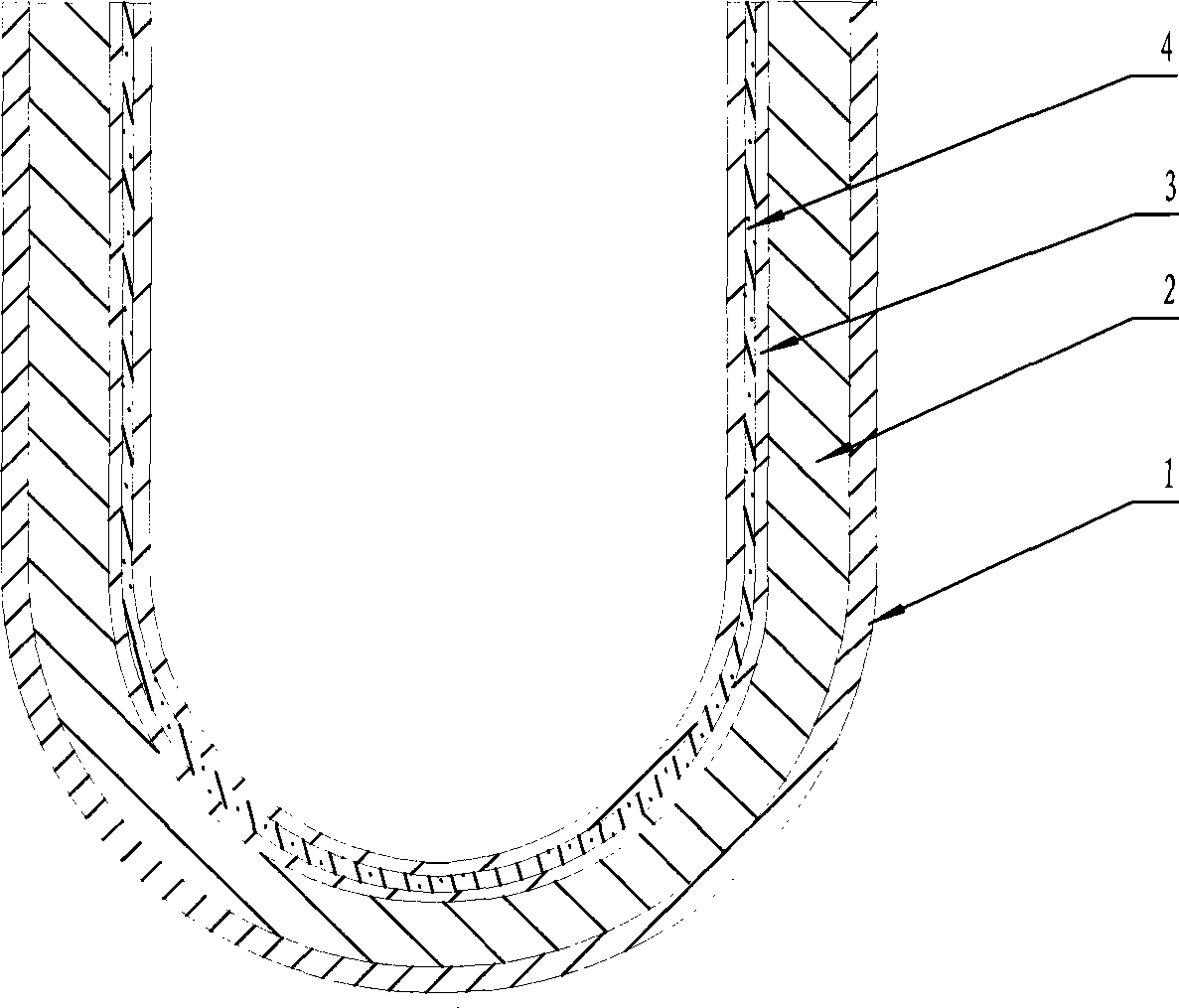

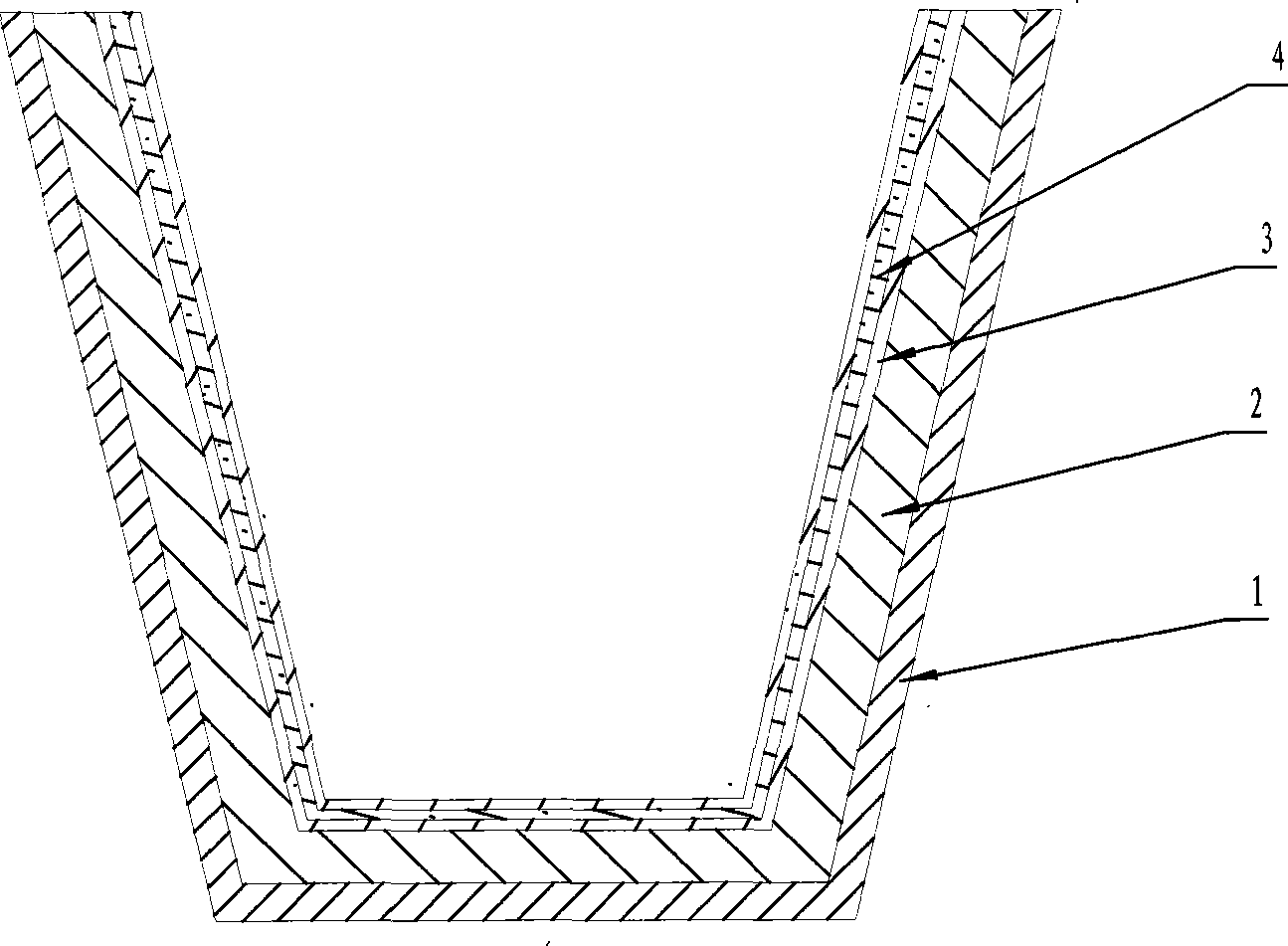

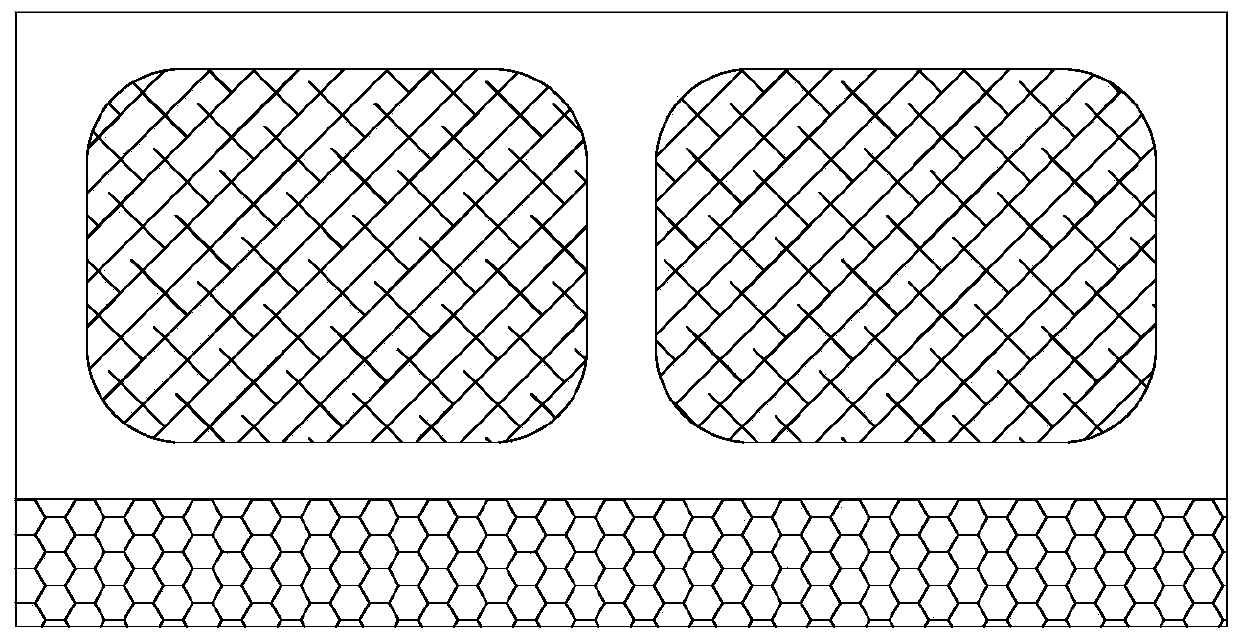

Vertical manufacture method for scoria concrete sandwich thermal insulation external wall panel

InactiveCN106926359AWith heat storage functionLow apparent densityMould separation apparatusCeramicwareThermal insulationArchitectural engineering

The invention discloses a vertical manufacture method for a scoria concrete sandwich thermal insulation external wall panel. The vertical manufacture method comprises the following steps: step 1, formulation of a production technological process; step 2, production preparation; step 3, installation of a mold table; step 4, installation of a wall panel inner core; step 5, installation of a window inner mold and a door inner mold; step 6, installation of an inner leaf mold and an outer leaf mold; step 7, casting of protective layer concrete; step 8, maintaining and demolding; and step 9, end product delivery. The vertical manufacture method has the following beneficial effects: a power trowel, a flattening machine and a mold roll-over machine are omitted, so that the area of a production site is saved, the construction is convenient and fast, factory production and assembly construction are realized, the degree of industrialization is high, lots of social labor force is saved, and the social efficiency is improved. The construction speed is high, the building period is short and the construction cost is remarkably lowered.

Owner:吉林省新生建筑工程有限公司

Application of carbonatation revolving furnace steel scoria in accelerating carbonic anhydride absorption of ocean

The present invention provides an application of carbonated converter steel dregs in absorption of carbon dioxide by oceans. In the application, the steel scrap in steel enterprises is processed by carbonation, which means industrial waste gas or flue gas is filled into the carbonation device of the converter steel under the conditions of the temperature of 350 to 800 DEG C, the atmospheric pressure of 0.1 to 3.6 and the water vapor of 5 to 25 percent; the reaction lasts 2 to 5 hours; then the converter steel dregs after the treatment of carbonation is thrown into the ocean (in the shape of particles or brick blocks). After being improved through carbonation, the converter steel dregs are used for promoting the ocean to absorb carbon dioxide. Thus the application not only reduces the discharge of greenhouse gasses in the steel industry, but also exerts positive influence on the improvement of the marine ecosystem and the absorption of carbon dioxide by the ocean. At the same time, the application also broadens the field of utilizing the resources of converter steel dregs.

Owner:BAOSHAN IRON & STEEL CO LTD

Application of carbonatation steel scoria in wastewater treatment

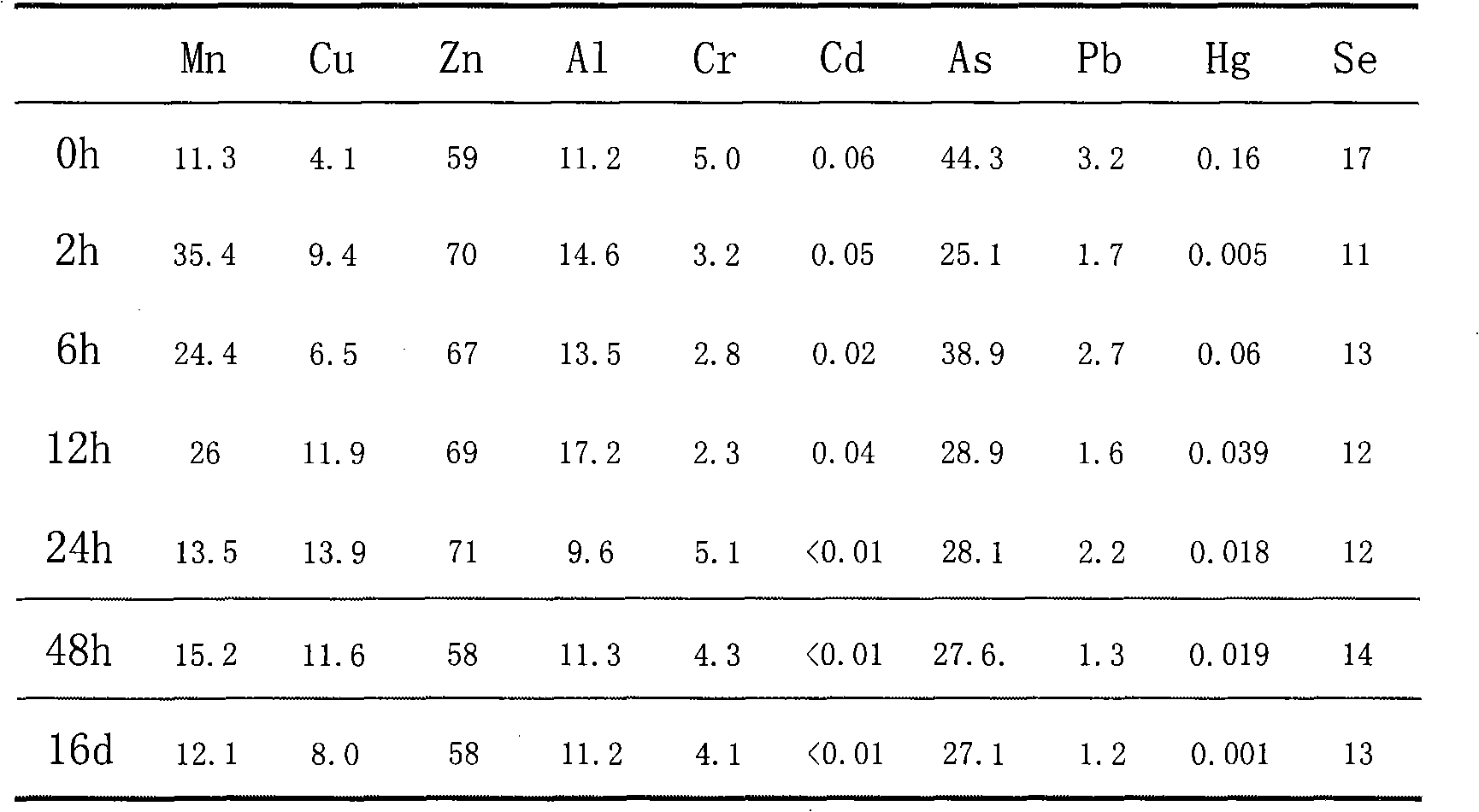

InactiveCN101269875AEmission reductionLow costTreatment using aerobic processesSolid waste disposalIron saltsSlag

The invention provides the application of carbonatation steel slag in the wastewater treatment. Under the condition that the temperature is 350-800 DEG C, the atmospheric pressure is 0.1-3.6, and the content of vapor is 5-25 percent, industrial waste gas or flue gas is led to a converter steel slag carbonatation device, the waste steel slag is carbonated, and then the carbonated steel slag is sieved to grains with the grain diameter being 5-10 mm by a screen grader. The carbonatation processing adopts the flue gas discharged by an iron and steel plant to be used as a carbon dioxide source, so the emission of greenhouse gases is reduced. The carbonated steel slag is used for the wastewater treatment, saves the medicine cost of adding iron salt and the equipment cost, creates a new path for the comprehensive utilization of the steel slag, and realizes the purposes of treating the water by the waste and reusing the sources.

Owner:BAOSHAN IRON & STEEL CO LTD

Ladle

The invention relates to a foundry ladle and belongs to the field of steel smelting. The foundry ladle is characterized in that a layer of a refractory material is coated on a firebrick. The firebrick consists of the following materials by weight percentage: 20 to 50 percent of refractory cement and 55 to 85 percent of a casting material. Paint is coated on the refractory material; and the paint is counted according to weight percentage: the ratio of ceruse to phosphor sheet to black clay is equal to 1 : 1-2 : 1-2. As the refractory material is coated on the firebrick, when the firebrick in the foundry ladle is fully stuck with scoria, the foundry ladle is cooled; the scoria adhered to the refractory material is poured out; the firebrick is coated with the refractory material and can be continuously used; if a layer of the paint is coated on the refractory material, the effect is better; and if a layer of the refractory material is coated on the paint, the effect is better. The foundry ladle reduces production cost and energy consumption and prolongs the service life.

Owner:柳亚军

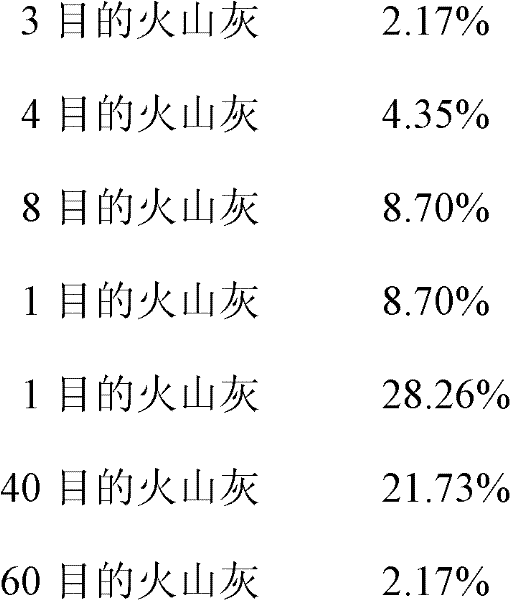

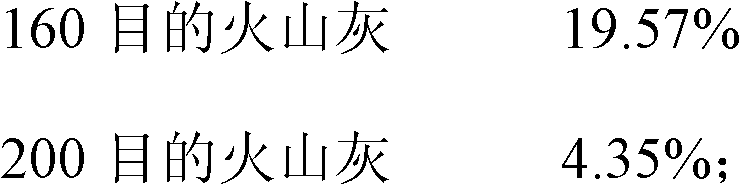

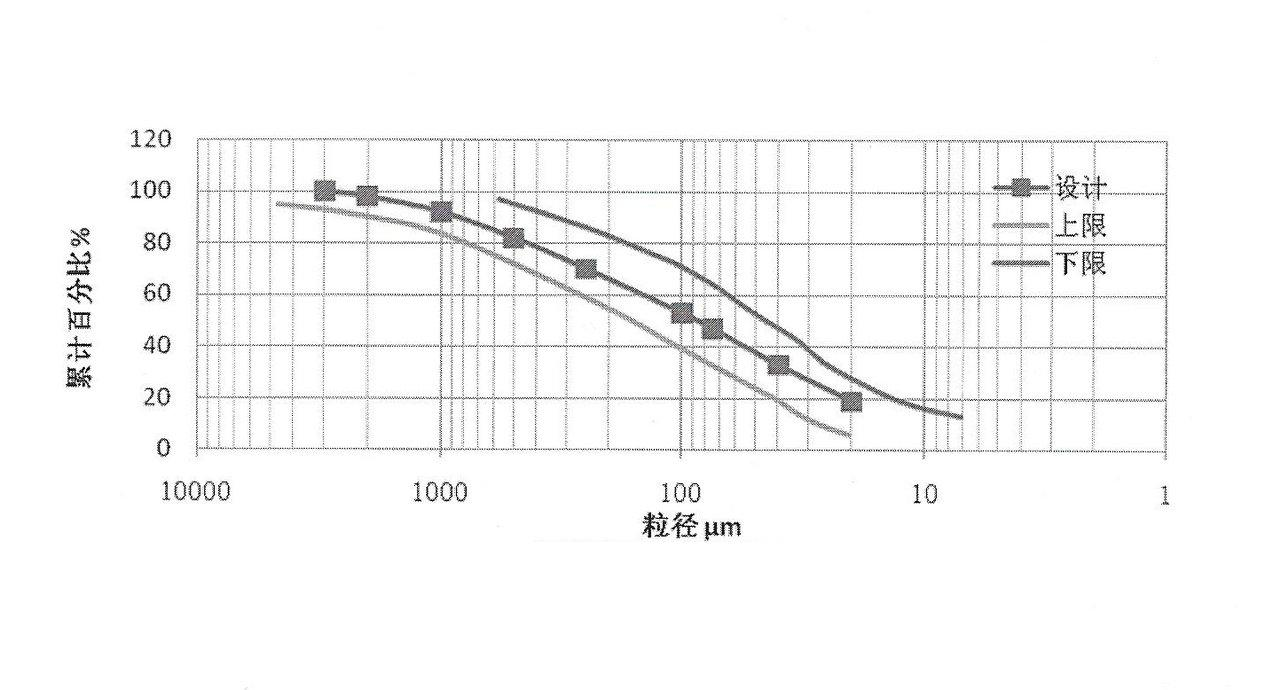

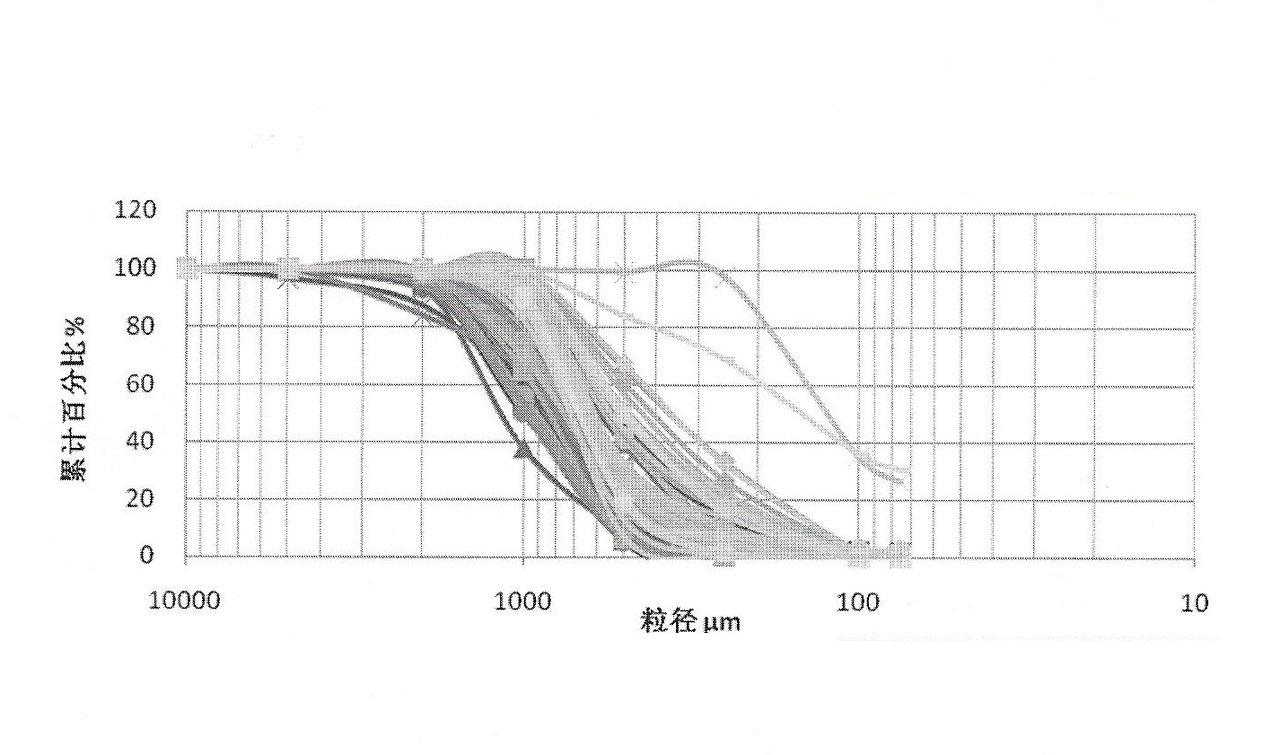

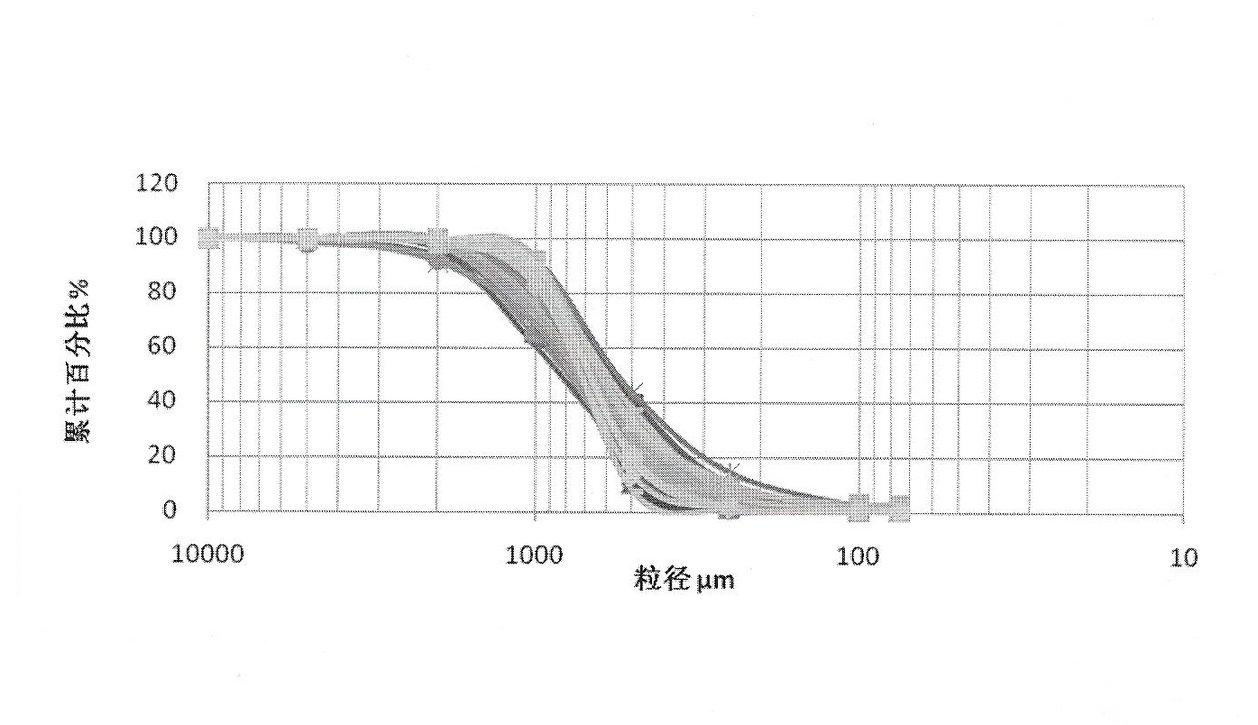

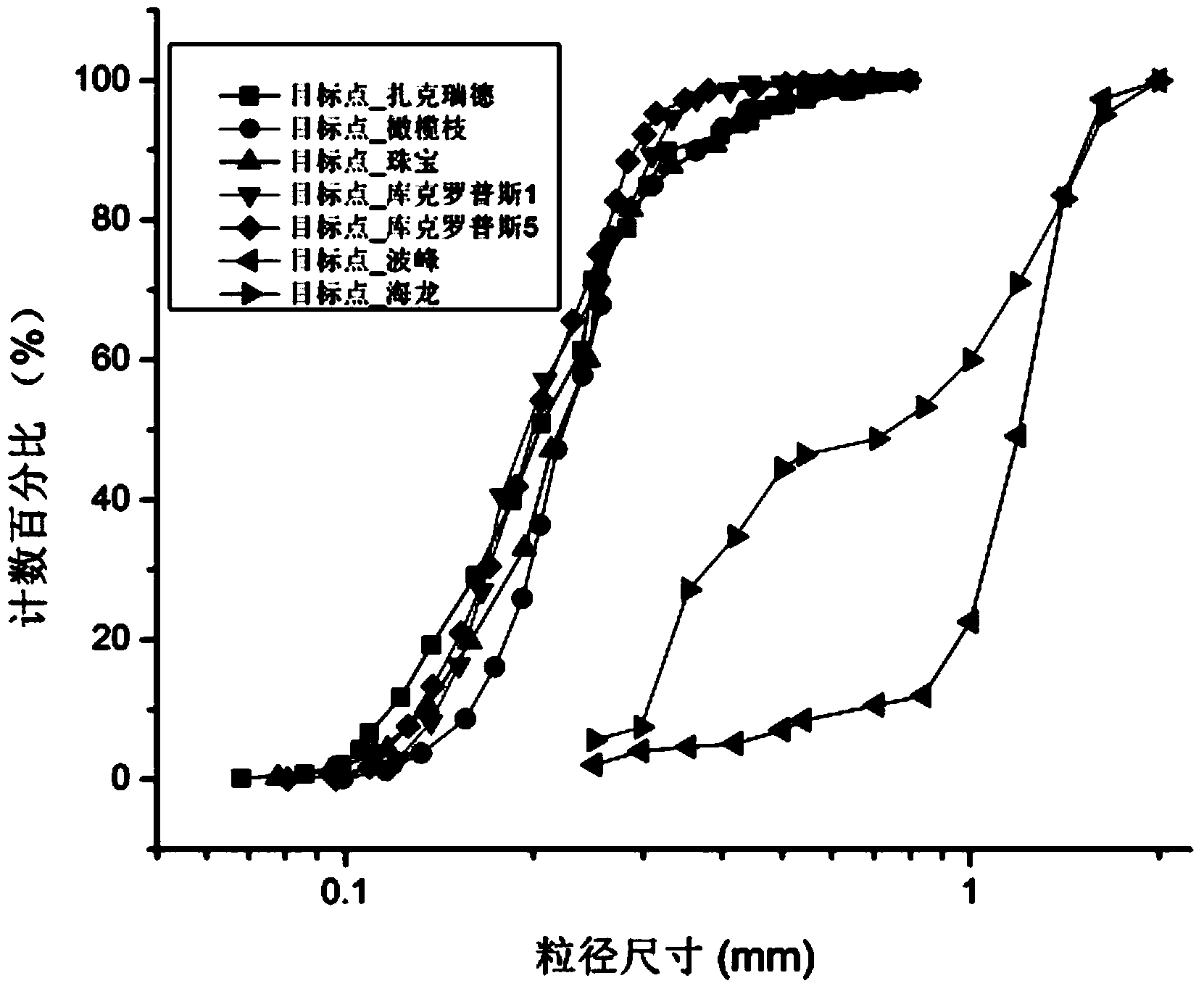

Formula design and adjustment method of lunar regolith simulant for engineering

InactiveCN102313573ARealize large-scale productionIn line with the processing statusMeasurement devicesMethod selectionMechanical property

The invention discloses a formula design and adjustment method of a lunar regolith simulant for engineering, in the method, butte black clay scoria in Jinchuan Town, Huinan Country is selected as a raw material for preparing the lunar regolith simulant; median value particle size (D50), effective particle size (D10), particle size (D30) with 30% of sifted weight, control particle size (D60), coefficient of non-uniformity (Cu) and coefficient of curvature (Cc) are selected for controlling mechanical properties of the lunar regolith simulant; the median value particle size D50 is more than 48 mu m and less than 300 mu m, the design particle size distribution is in the range of a particle size distribution curve of lunar regolith as far as possible, and the shape of the particle size distribution curve can be in line with the natural law by regulating the Cu and the CC; the raw material in 10 different mesh sizes can be obtained after crushing the scoria, pulverizing and sorting, the particle size distribution of the raw material after sorting is taken as a coefficient matrix, the design particle size distribution is taken as an object matrix, and a formula matrix of the lunar regolith simulant can be obtained by solving linear equations; when the design particle size distribution of the lunar regolith simulant and the particle size distribution of the raw material change, re-adjustment and calculation are performed so as to enable the mechanical properties of the prepared lunar regolith simulant to be close to those of real lunar regolith.

Owner:JILIN UNIV

Method for extracting fine iron powder from steel scoria

InactiveCN101138762AImprove performanceReduce volumeGas current separationMagnetic separationNatural resourceIron powder

The present invention relates to a method to extract refined iron powder from steel slag. The method comprises the steel slag pretreatment, the pneumatic pre-selection of iron substances and removal of non-iron substances, the magnetic selection and separation, and other steps to get the iron powder with the iron content above 40 weight percent, and the fine steel slag powder with the iron content below 1 weight percent. The method is simple and convenient, fully presents the characteristic of the circular economy, realizes the full use of natural resources and is provided with the good economic benefits.

Owner:冀更新

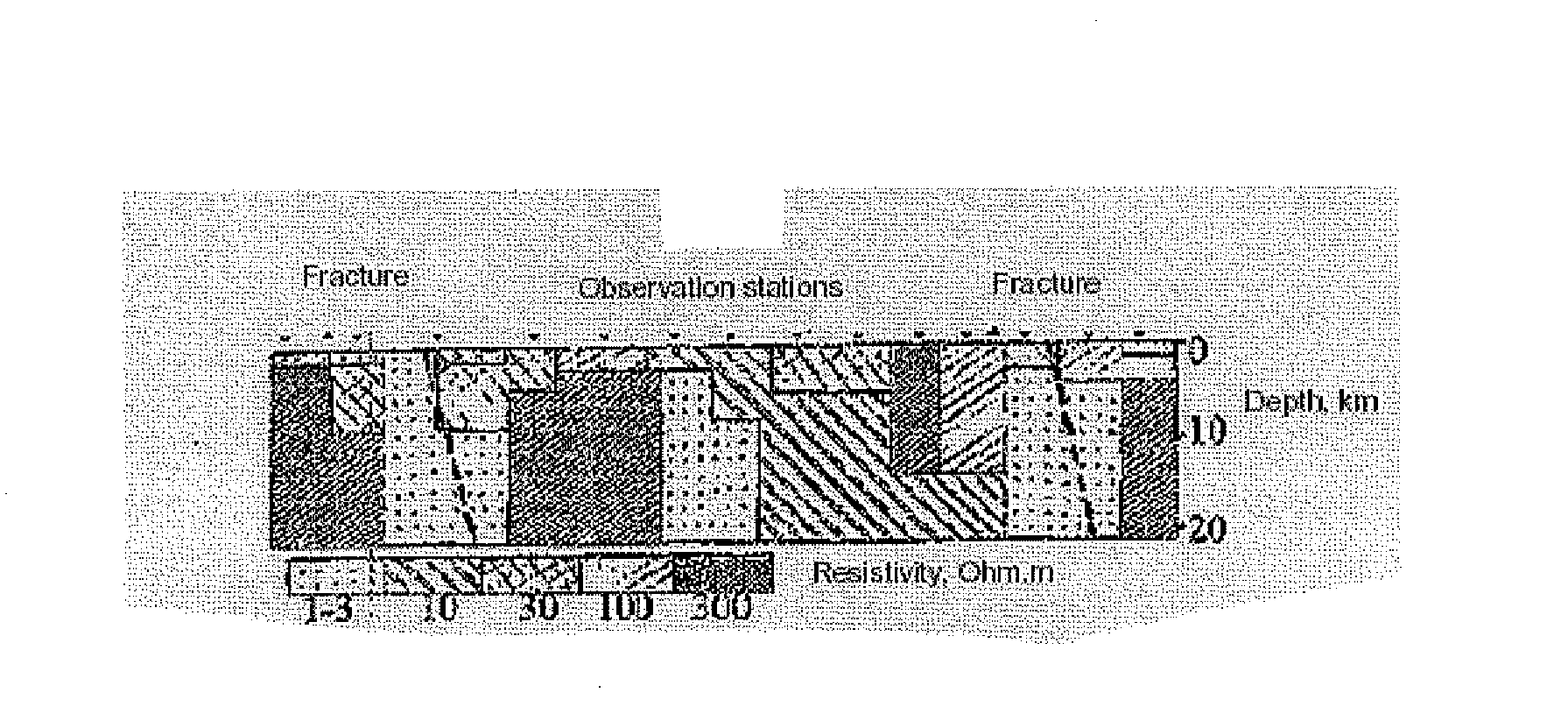

Method for detecting an occurrence zone of a mantle diapir finger location

InactiveUS20070213937A1Shorten the timeImprove reliabilityDispersed particle separationProspecting/detection of underground/near-surface gasesSilanesMining industry

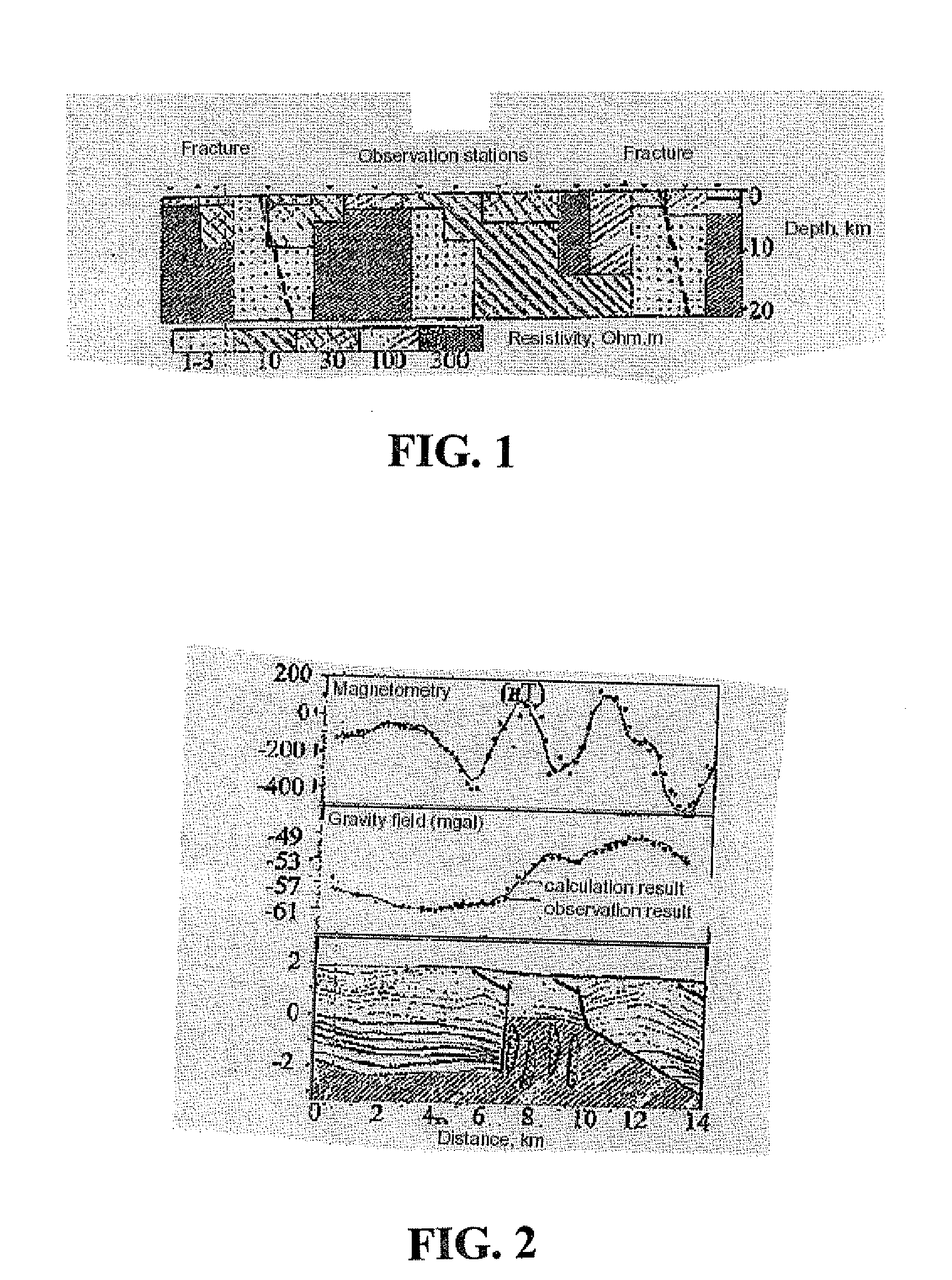

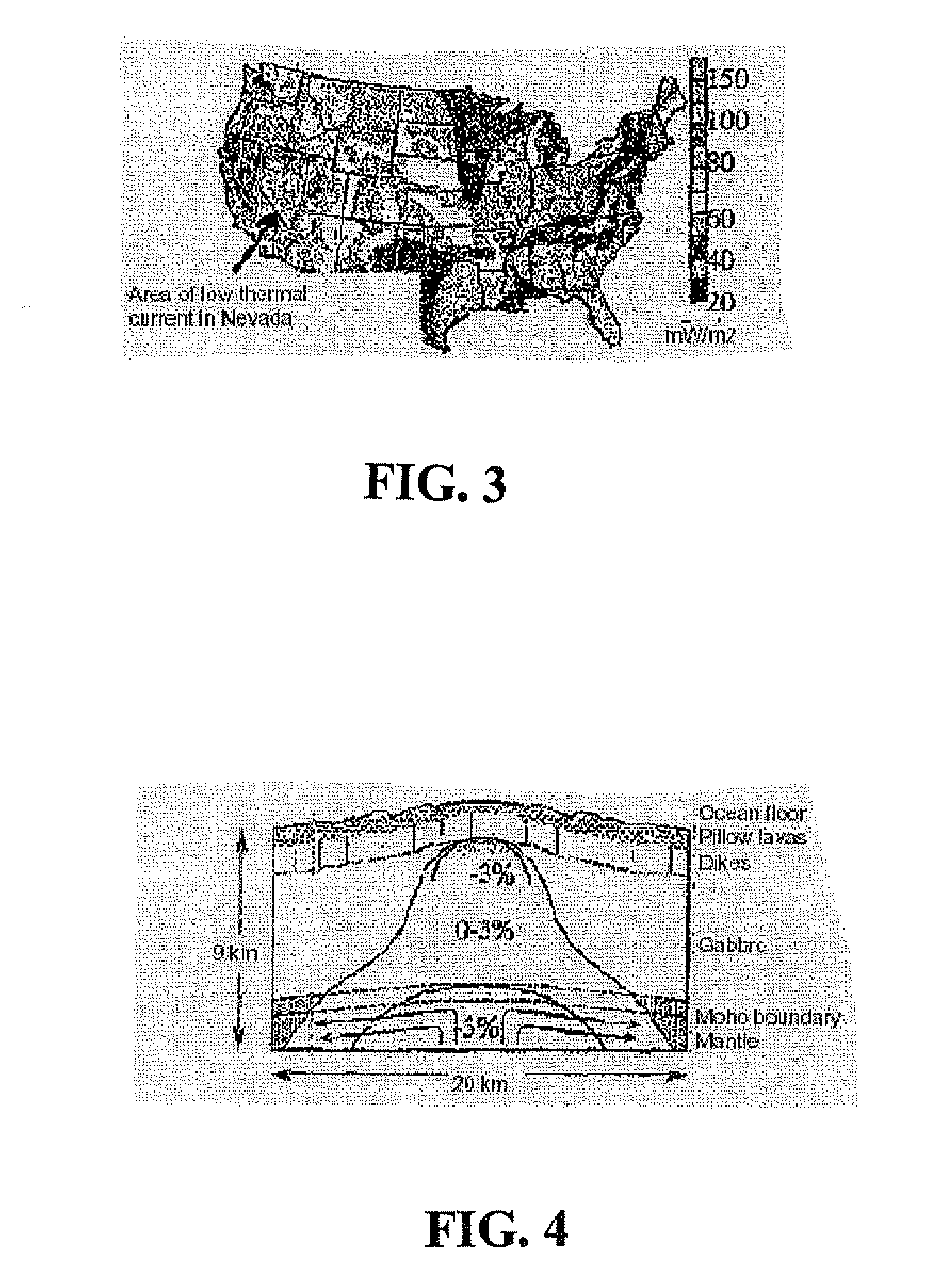

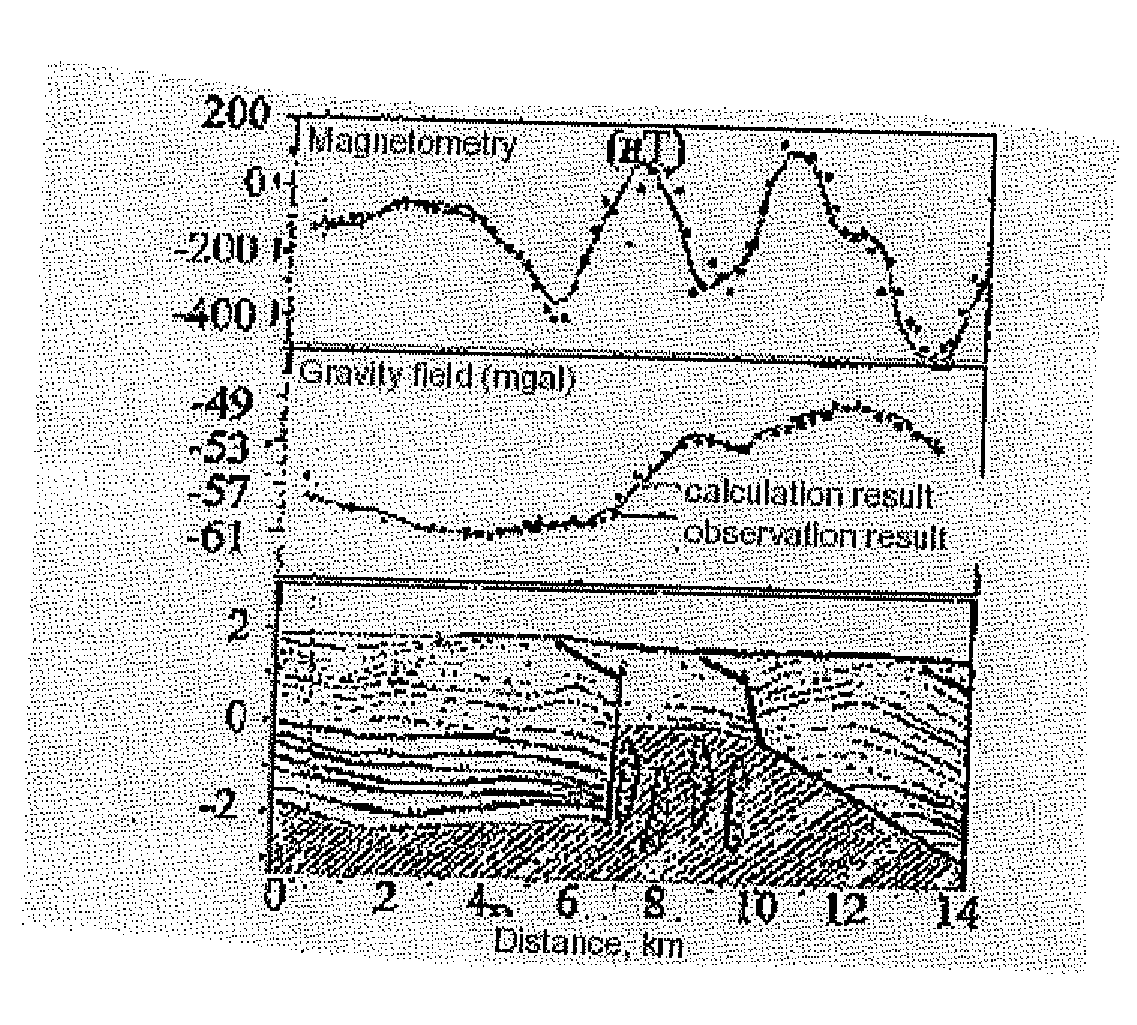

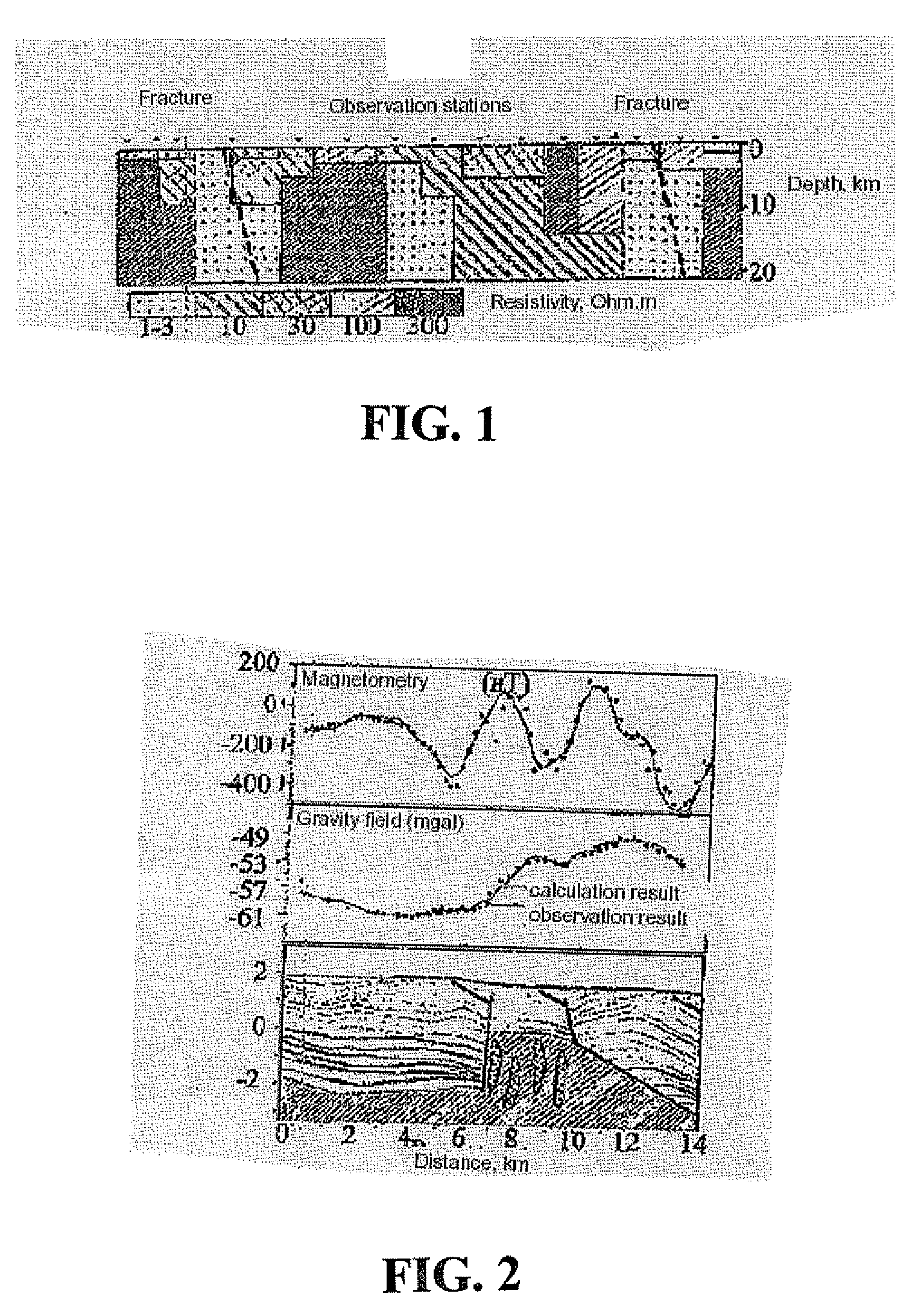

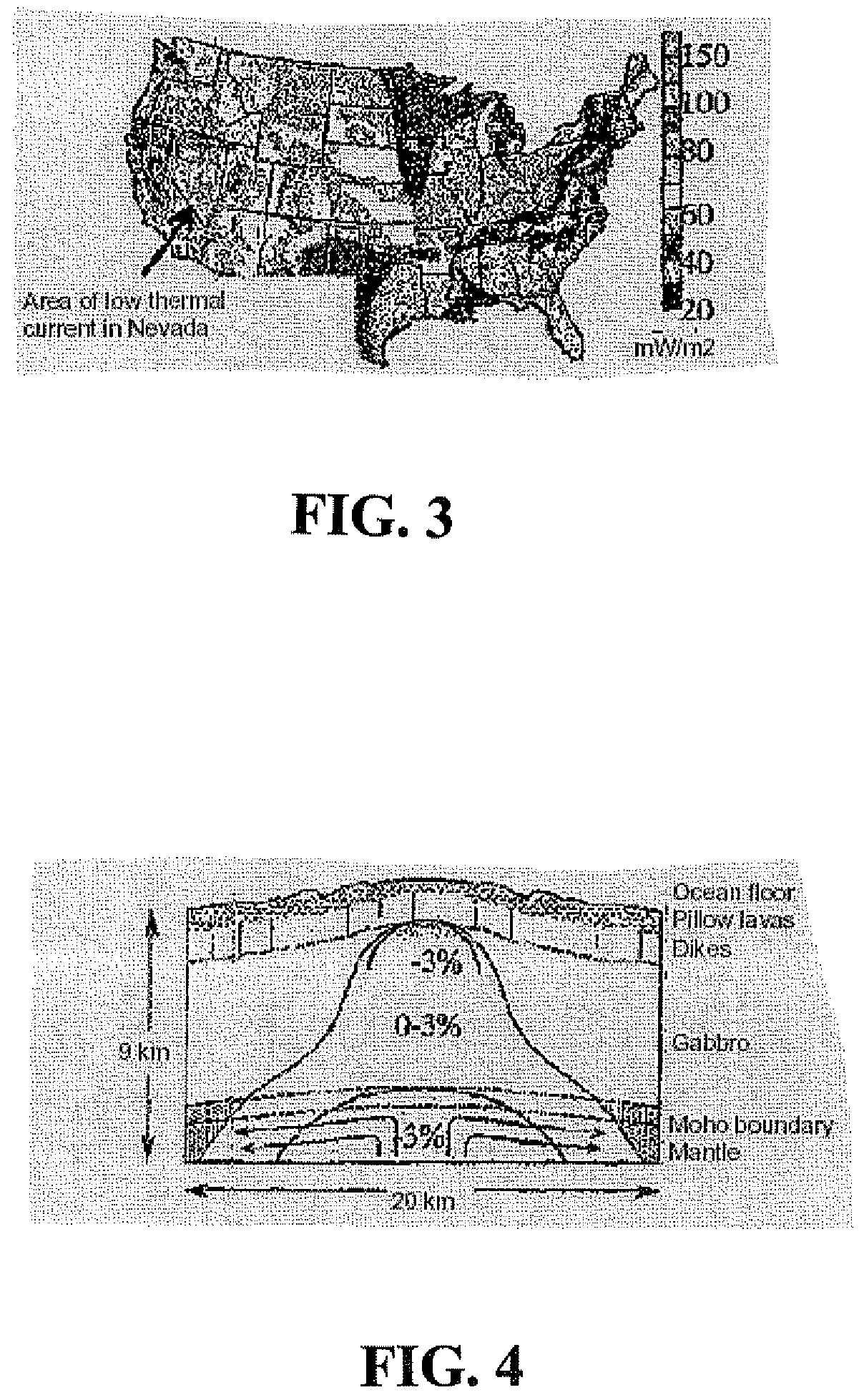

The invention covers the mining industry. Detection method of the occurrence zone of the mantle substance diapir finger consisting in that that geological observation are carried out in riftzones banked up by diapirs of the abnormal mantle and places of location of the mantle substance finger in the earth's crust are determined. Based on the presence of influence traces of silanes streams upon the rock and / or presence of separate ridges having the length up to 200 km by the width of up to 20 km and / or based on the blast traces of silanes and / or presence of scoria cones, differing by that that the correspondence of 3He / 4He from gases sampled from sources of 10−5 order is additionally determined for determination of silicides at the small depth as physical parameters for the location of the mantle substance diapir finger in the earth's crust. The presence of high semiconductor conductivity, locality and activity of magnetic anomalies and anomalies of gravity field is additionally established. The occurrence depth of silicides is determined by magnetotelluric sounding and / or seismic reflection and refraction methods.

Owner:LARIN VLADIMIR NIKOLAEVICH +1

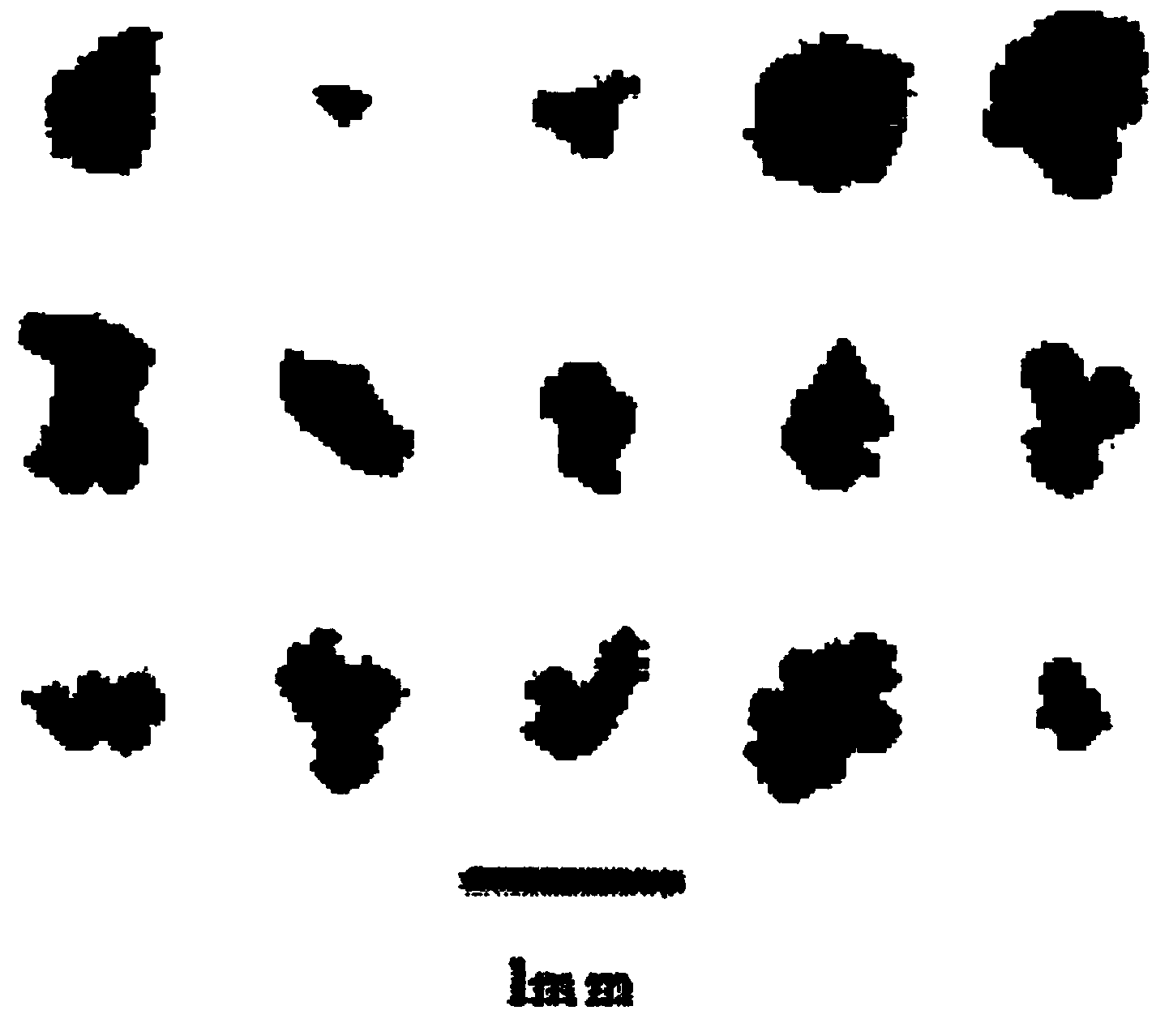

Engineering simulative Mars soil for ground tests of touring device

InactiveCN104297007AIncrease the internal friction angleStructural/machines measurementVolcanic ashMaterials science

The invention discloses engineering simulative Mars soil for ground tests of a touring device. The Mars soil is formed by mixing scoria powder of the Jingyu Shuangshan volcano and ilmenite powder, wherein the weight percentage of the scoria powder of the Jingyu Shuangshan volcano is 96%, and the weight percentage of the ilmenite powder is 4%. The particle morphology of the simulative Mars soil is similar to that of Mars soil. The spectral change curve of volcanic ash of the Jilin Jingyu Shuangshan volcano is similar to that of Olympus-Amazonis. The volcanic ash of the Jilin Jingyu Shuangshan volcano is red which is closest to the color of weathered materials on the surface of Mars. The engineering simulative Mars soil guarantees that the ground tests are carried out smoothly and various tests are reliable, and enables Mars exploration plans to be smoothly carried out.

Owner:JILIN UNIV

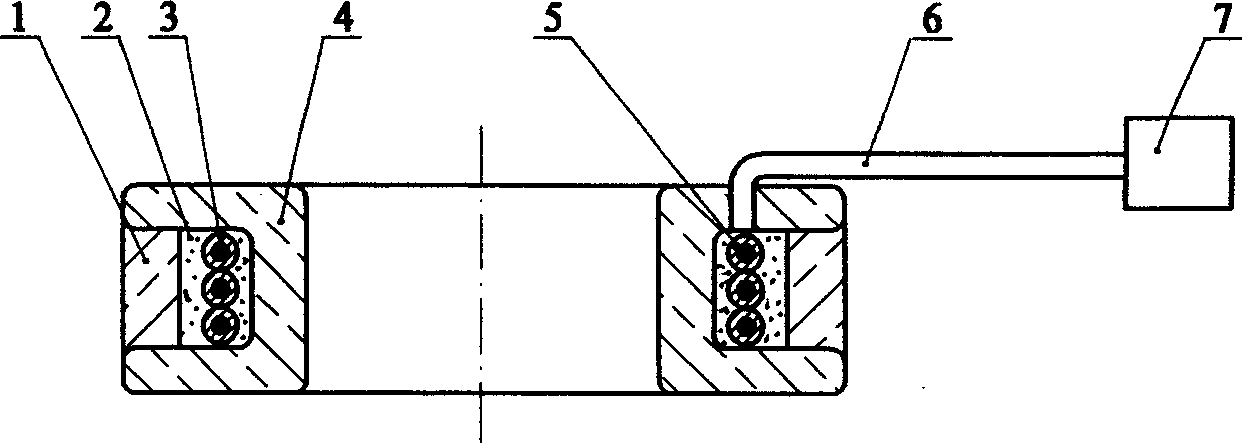

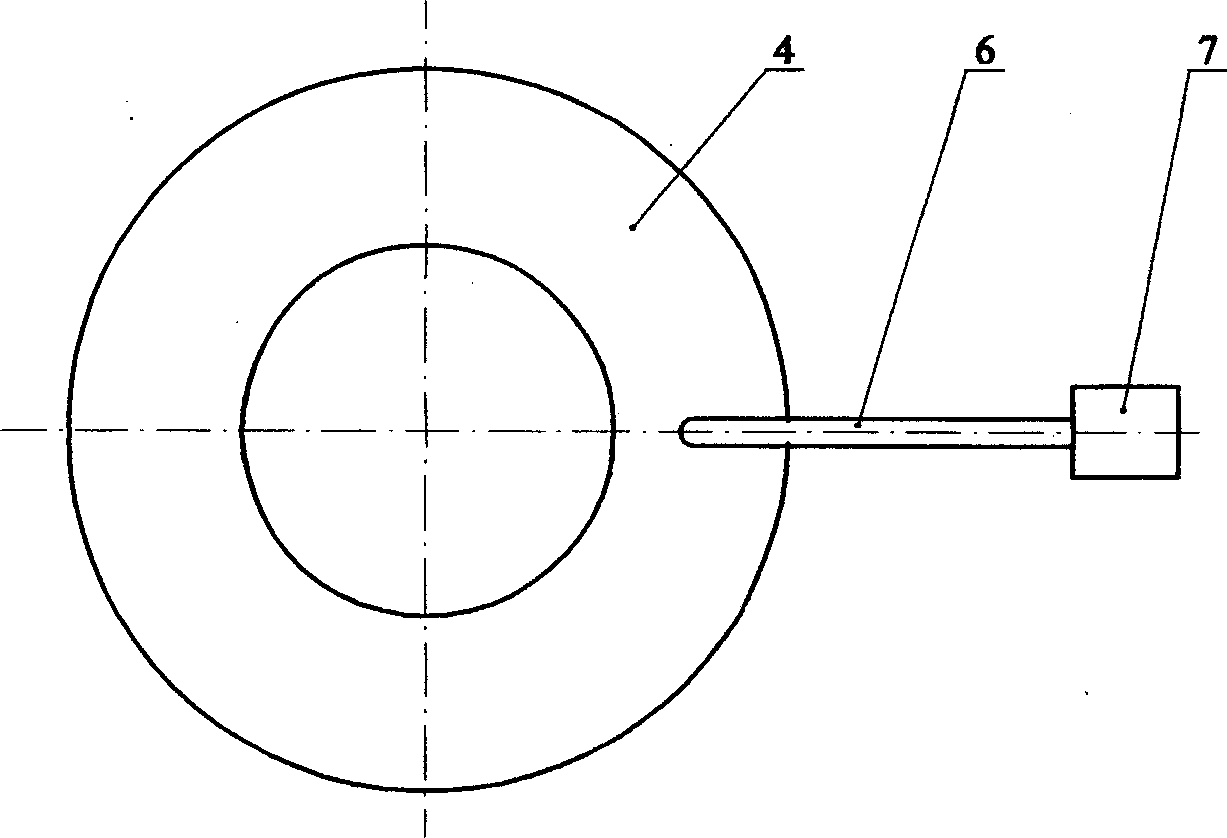

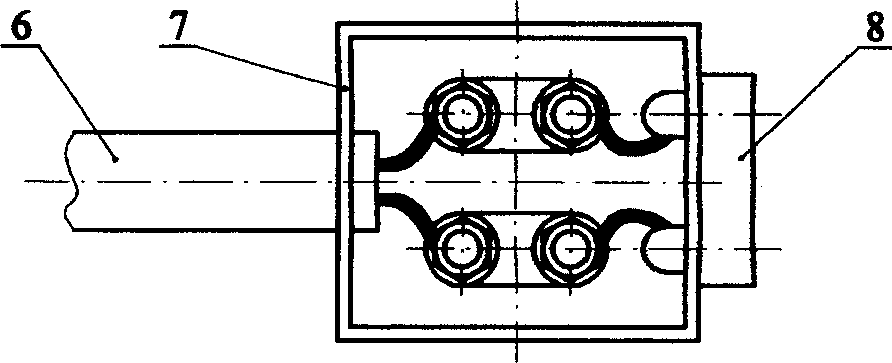

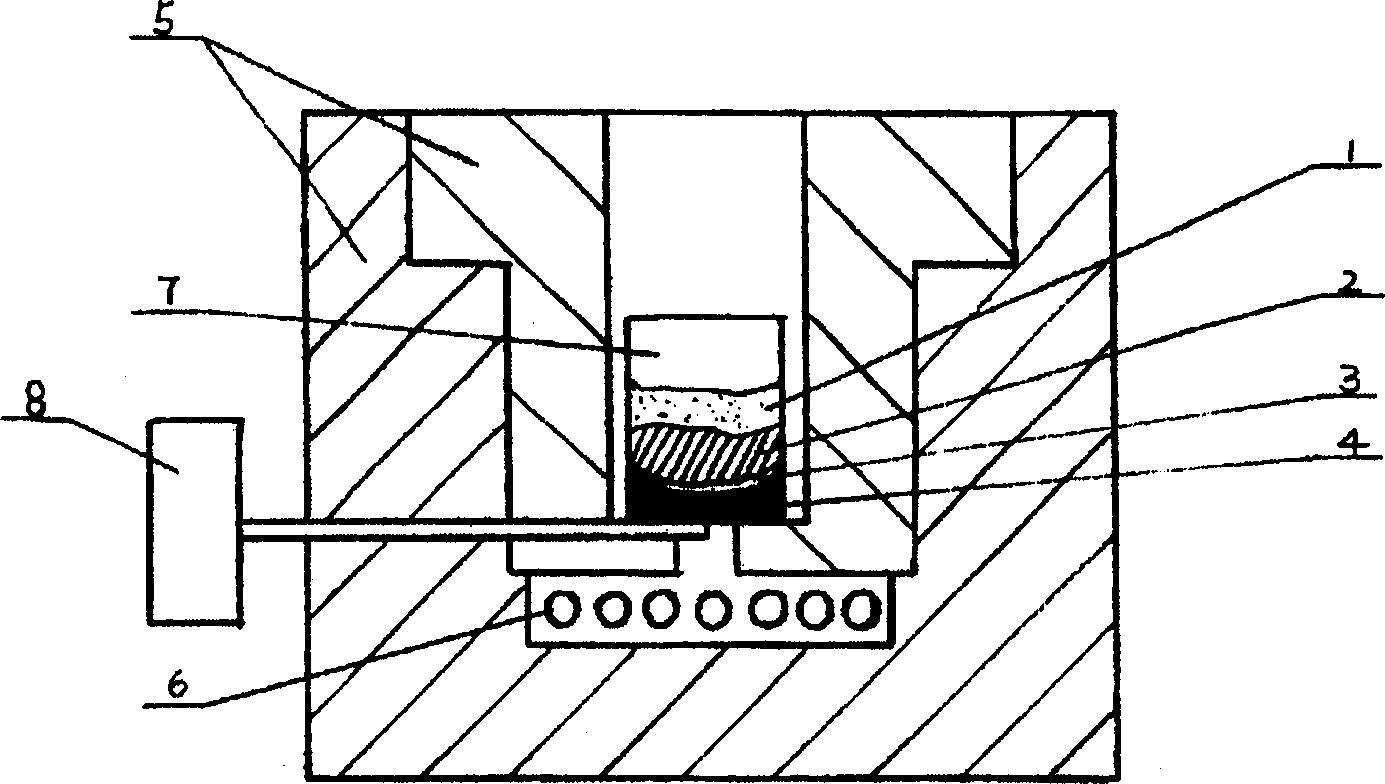

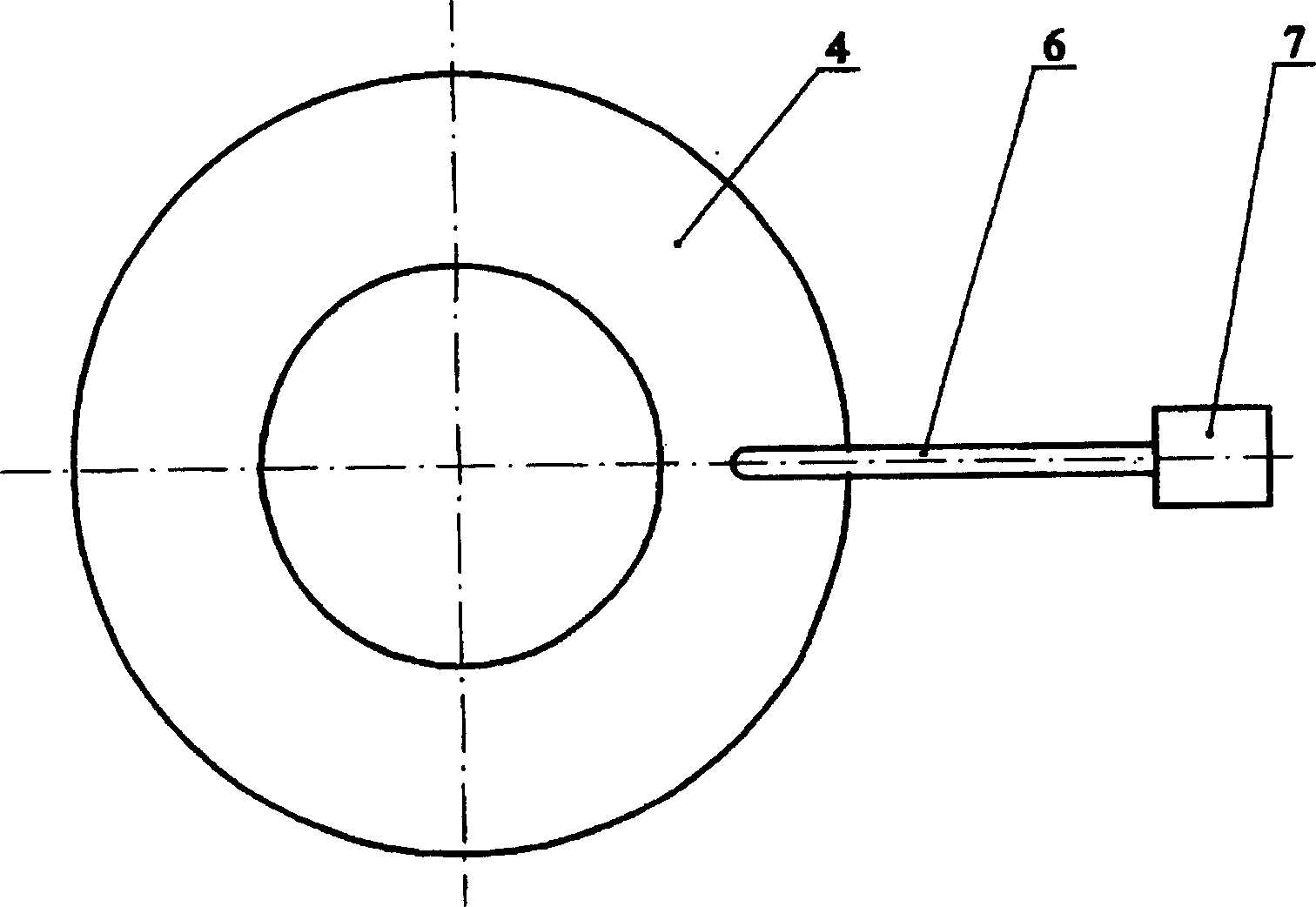

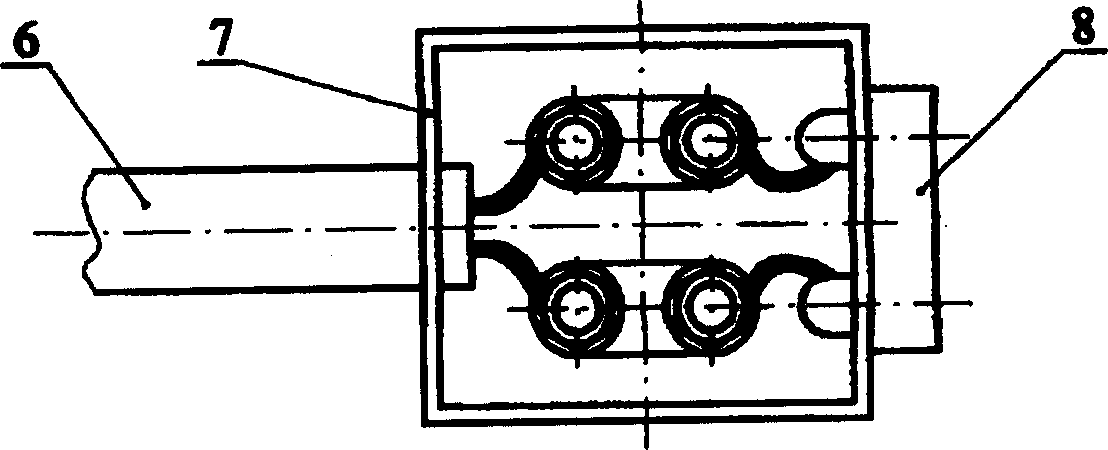

Sensor for obtaining scoria flow-out signal during steel ladle casting

InactiveCN1349095ASimple structure requirementsSimplify cost inputMaterial impedanceMaterial magnetic variablesConductor CoilMolten slag

The invention discloses a sensor for capturing the flowing out of molten slag in casting steal from steel ladle. The process of manufacturing the sensor is as follows. There are spiral shaped windingwrapped in insulating magnetic tube on channel of circular ring frame with I bar shape. Heat insulating material is filled around said windings, and fire clay is filled in the channel. After drying and shaping the semi-finished product, the high temperature cable with double core is welded to windings and the other end of cable is connected to the linker box on the shell of the steel container. The invented sensor only contains one spiral shaped winding and minimum two lead out wires so it possesses features of simple structure and lower cost. The sensor also can be used in metallurgy industry.

Owner:ZHEJIANG UNIV

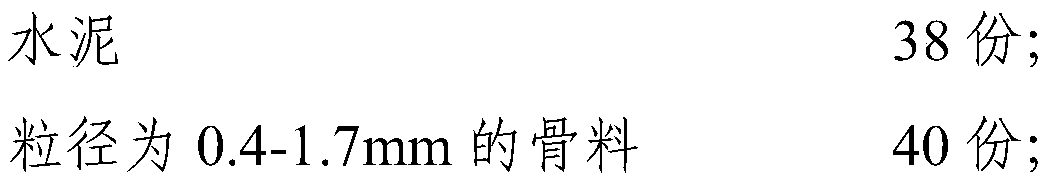

Method for forming counterweight block of elevator with waste steel scoria

The invention discloses a method for forming elevator counterweight blocks by waste steel slag, which uses the waste steel slag with the iron content of 30 percent to 40 percent, iron plates with the thickness of 0.78mm to 0.82mm and cement as raw materials. The method comprises the following processes: 1. preparing a metal shell of the counterweight block; 2. processing the waste steel slag: the waste steel slag is crushed and passes through a powdering machine to lead particle diameters to be less than 3mm; 3. mixing materials: the raw materials are weighed according to the following weight radio: the waste steel slag: 90 percent to 94 percent, the cement: 6 percent to 10 percent, water: 5 percent to 6 percent, the mixture material is prepared after being mixed evenly and fully by a mixer; 4. molding: the mixture material is transmitted to a pressure machine by a transmission belt to be pressed into needed modules automatically, and then the needed modules are transmitted to an iron plate container made by the step 1 by the transmission belt; 5. maintaining: the modules are maintained for 6 to 8 days, and an upper cover is covered and welded after the counterweight block is hardened completely, and then the finished product is obtained. The method for forming the elevator counterweight blocks by the waste steel slag has the advantages that the waste can be turned into useful materials, thus conforming to the national requirements of building a resource-conserving society.

Owner:叶春华

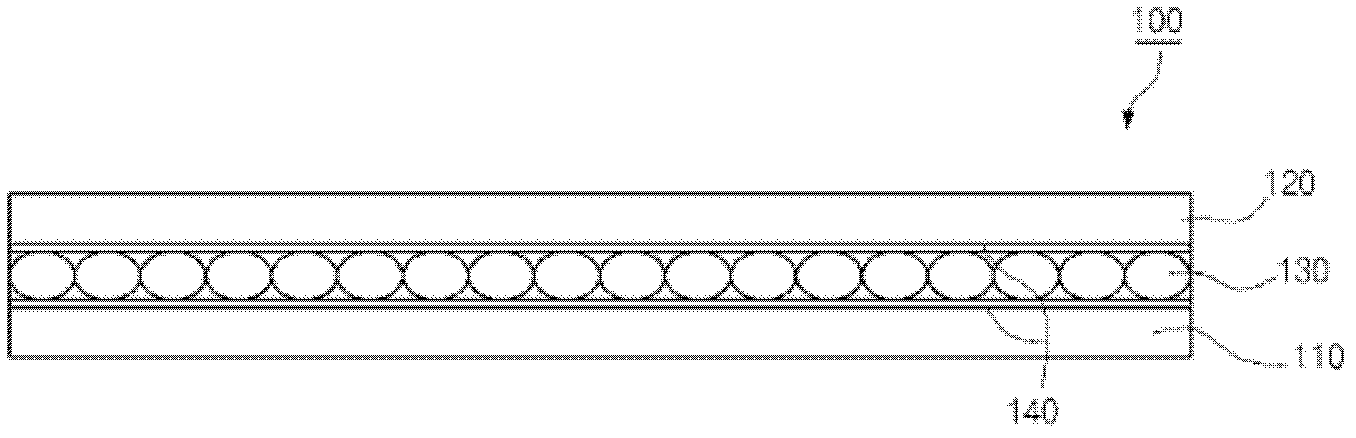

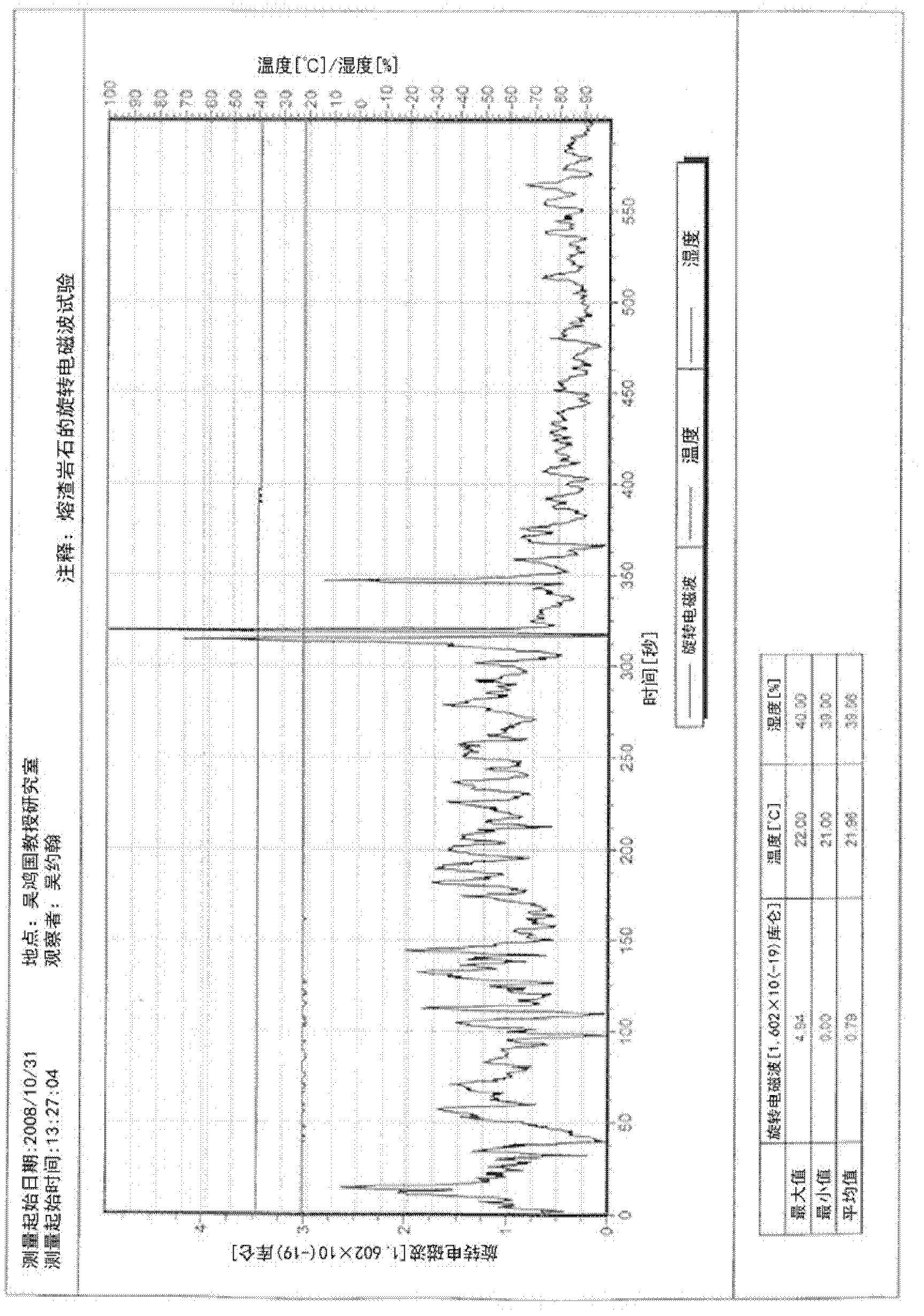

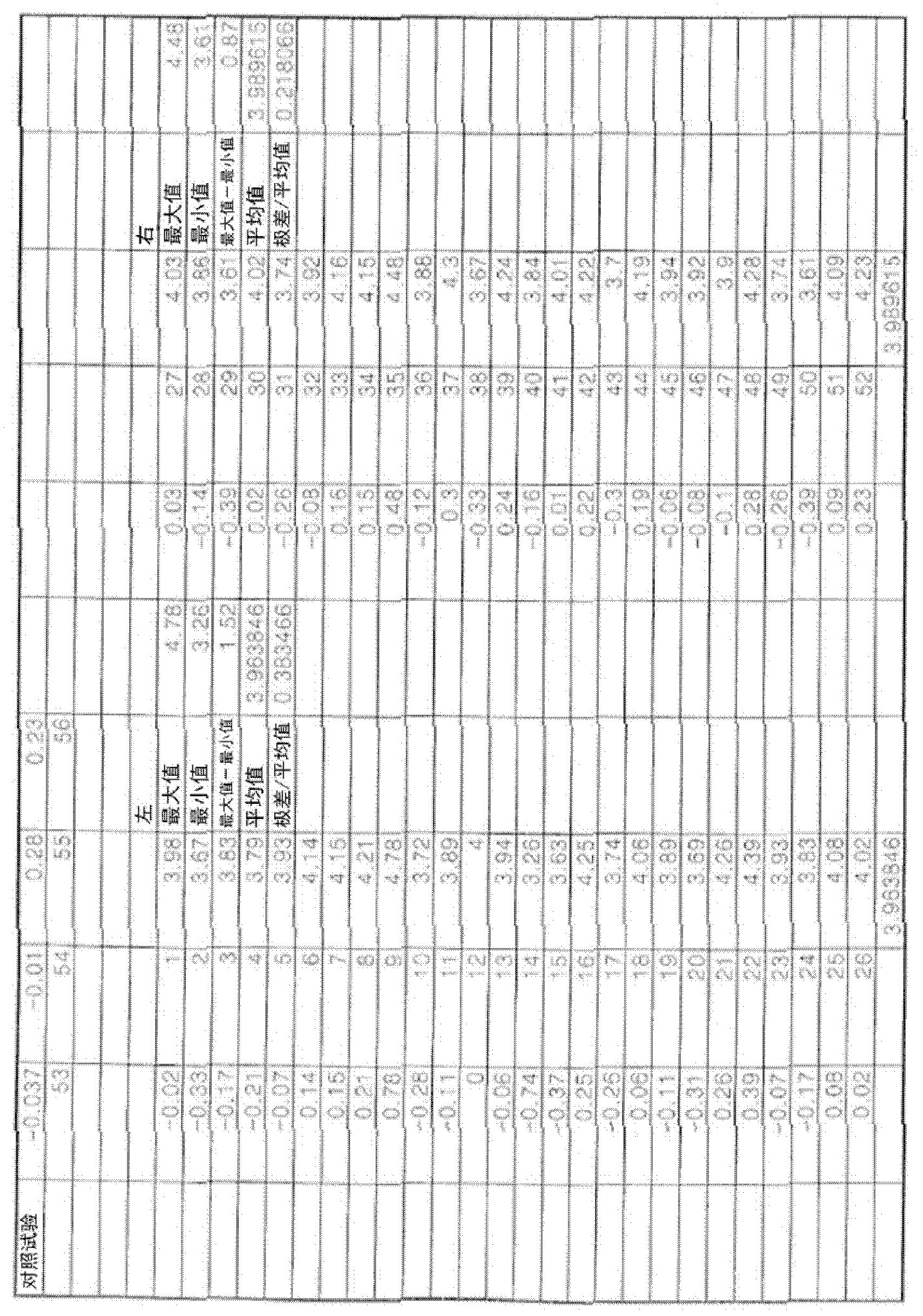

Fabric and fabric product provided with scoria molded body, and method for adhering scoria

InactiveCN102482810APromote public healthAvoid cloggingPhysical treatmentSynthetic resin layered productsHuman bodyFar infrared

The present invention relates to fabric and a fabric product provided with a scoria molded body which brings a scoria molded body containing scoria powder into contact with the human body to activate the function of the human body, thereby promoting public health, and a method for adhering scoria. The fabric provided with the scoria molded body according to the present invention is characterized in that the fabric has a scoria molded body placed between a first fabric and a second fabric, and the scoria molded body is formed by mixing scoria powder containing silicon dioxide and titanium dioxide with water, molding and solidifying the mixture, and has 90% or more of far infrared ray radiation characteristics and rotating electromagnetic wave characteristics. In addition, the fabric of the present invention can be applied to fabric products that could come in contact with the human body, for example, a brassiere or briefs. Therefore, a user can be easily provided with far infrared ray radiation characteristics and rotating electromagnetic wave characteristics through a scoria component by bringing the scoria molded body of the present invention in contact with the human body.

Owner:白禹铉 +1

Mineral paper

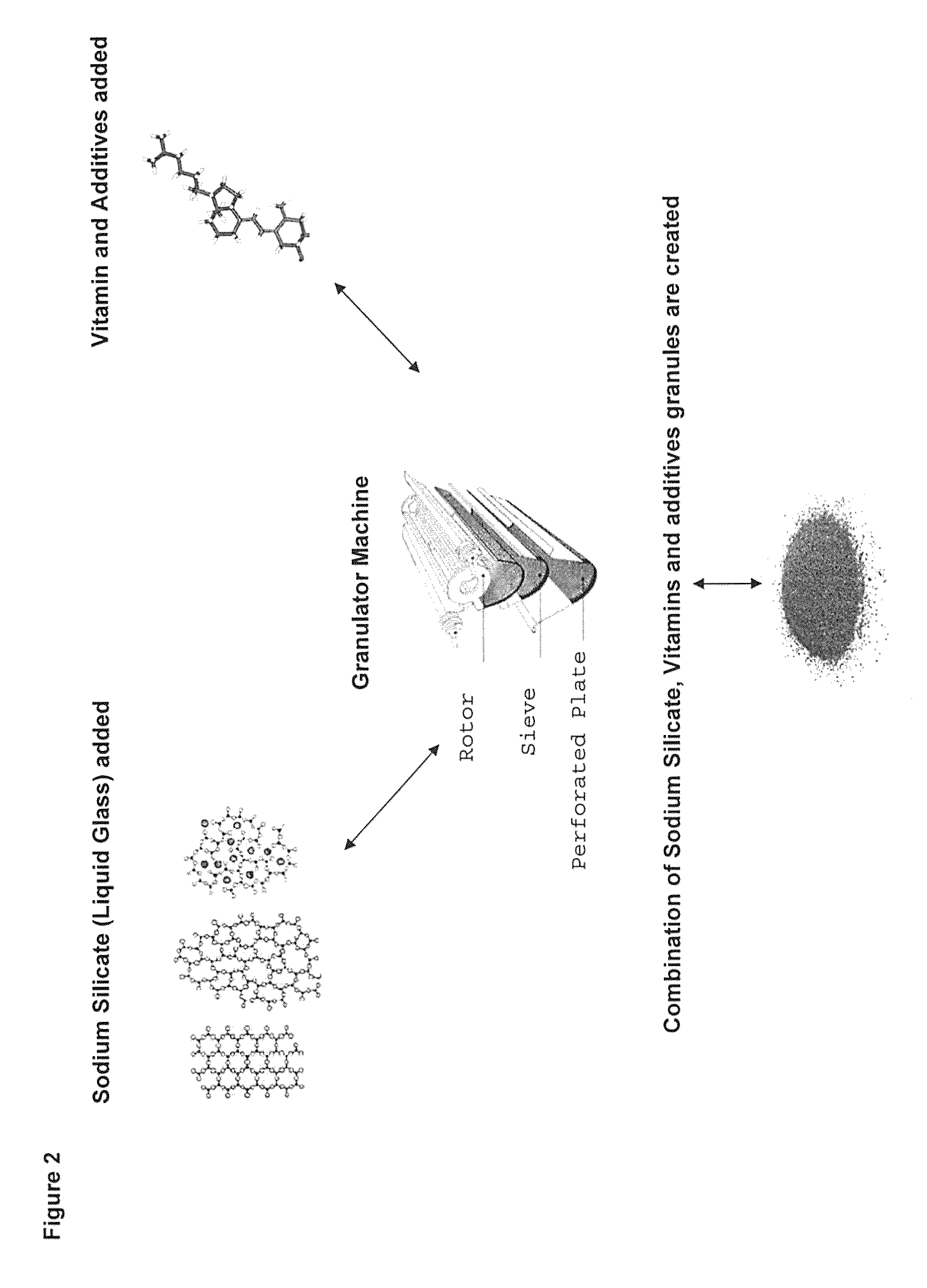

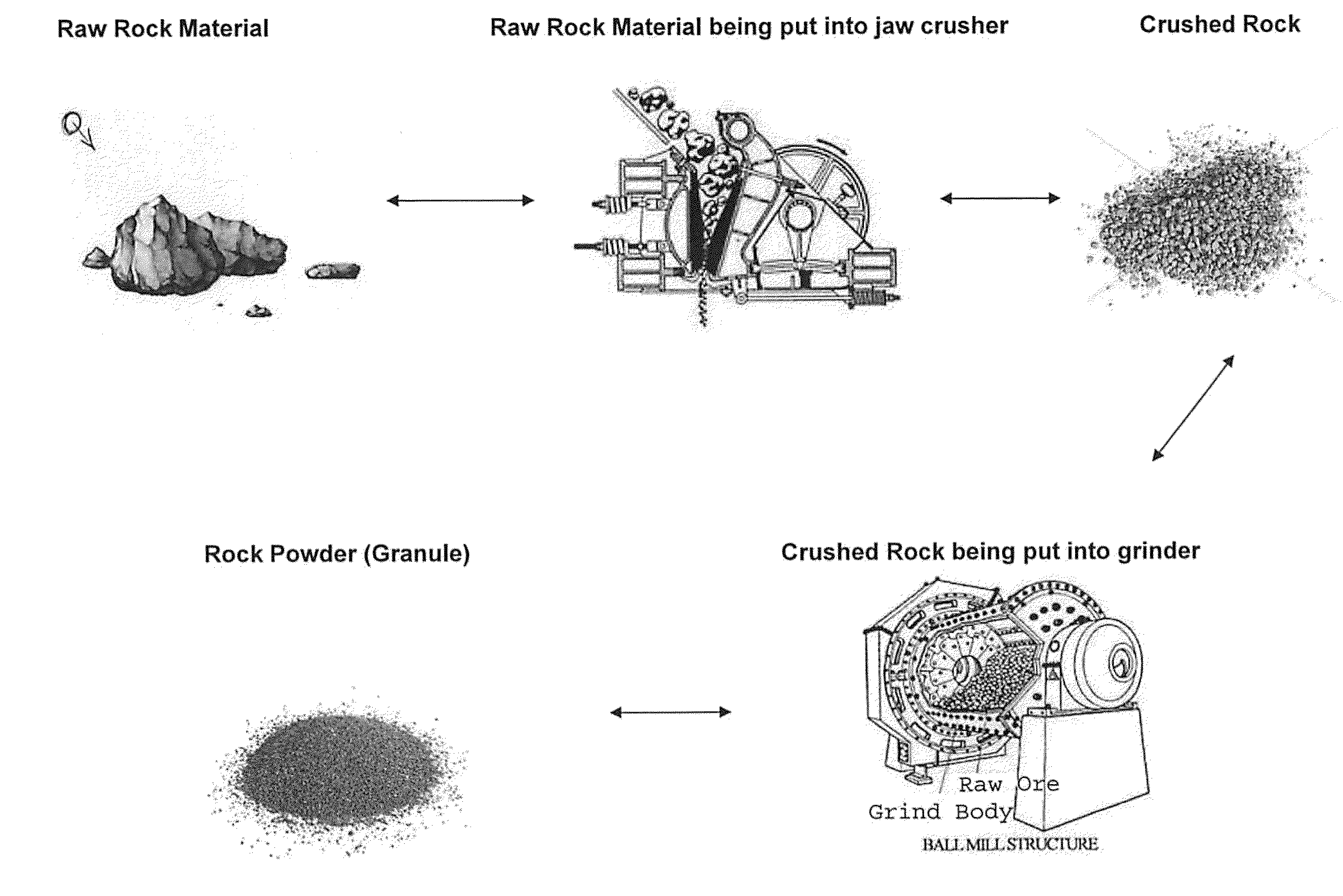

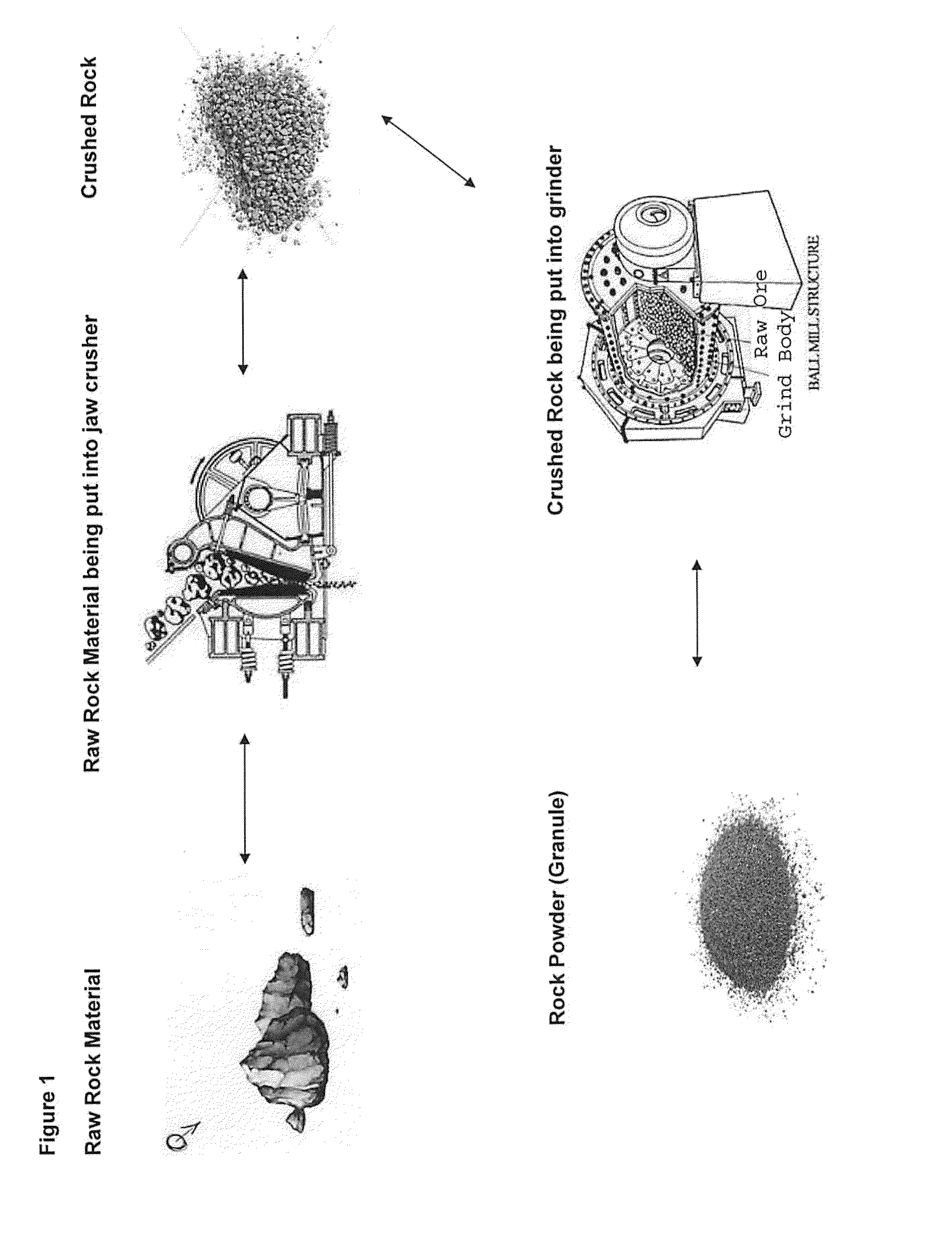

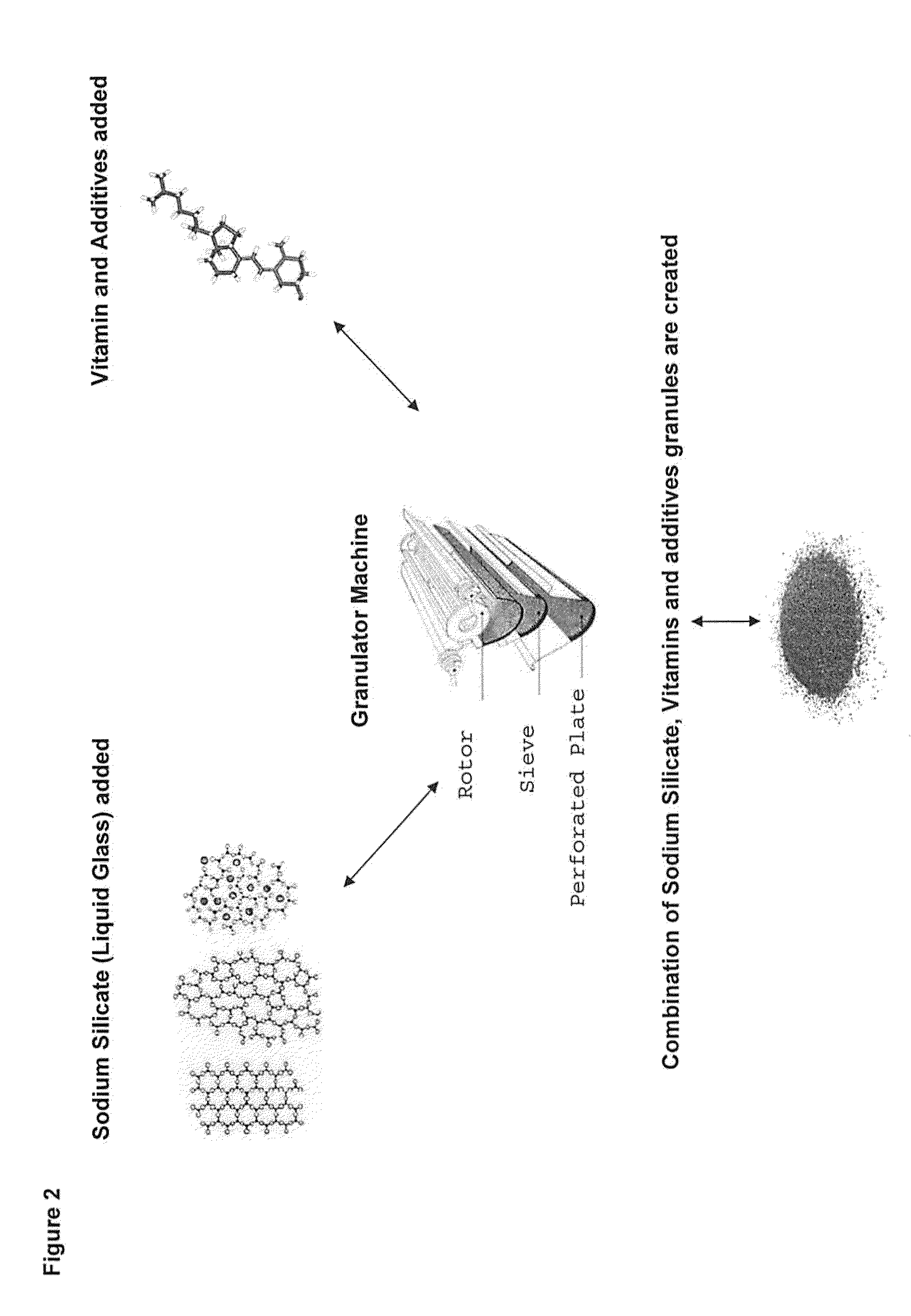

A process to manufacture a paper derived from minerals includes the steps of preparing a mineral preparation that includes 50% to 70% of total dry weight of rocks that have been crushed and ground into a powdery substance; combining the mineral preparation with a sodium silicate solution of total dry weight of 30% to 50%; and adding additives having a weight of 2% to 5% of a total dry weight. The powdery substance may have granules of about 0.05 mm to 0.08 mm in diameter and can be mixed with vitamin powder. The igneous rocks can be selected from the set of: dolostone, basalt, granite, gabbro, andesite, diorite, obsidian, pegmatite, peridotite, pumice, rylolite, and scoria. Sedimentary rocks can be selected from the set of: limestone, sandstone, conglomerate, shale, siltstone, brecca, gypsum, chert, travertine, flint, iron ore, rock salt, and oil shale.

Owner:NEW MILLENIUM

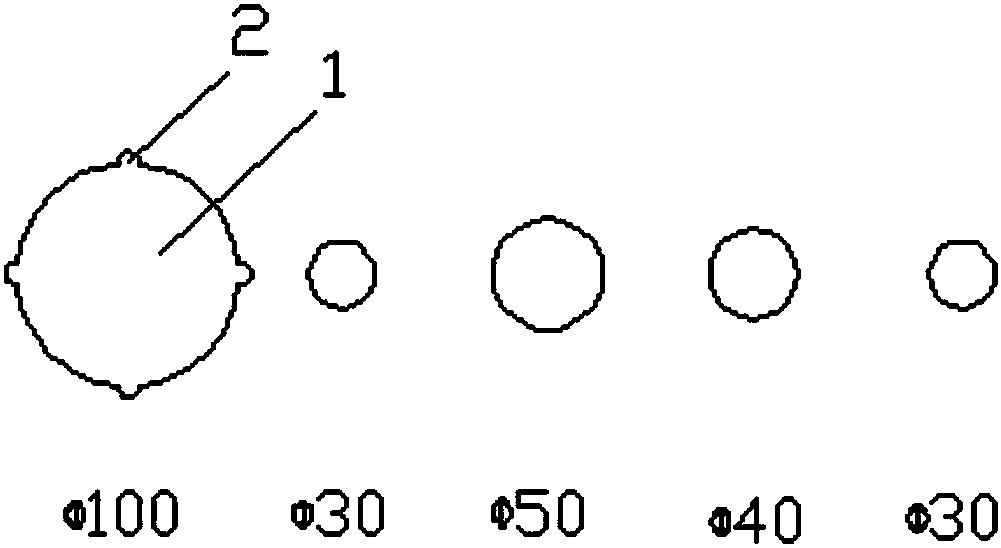

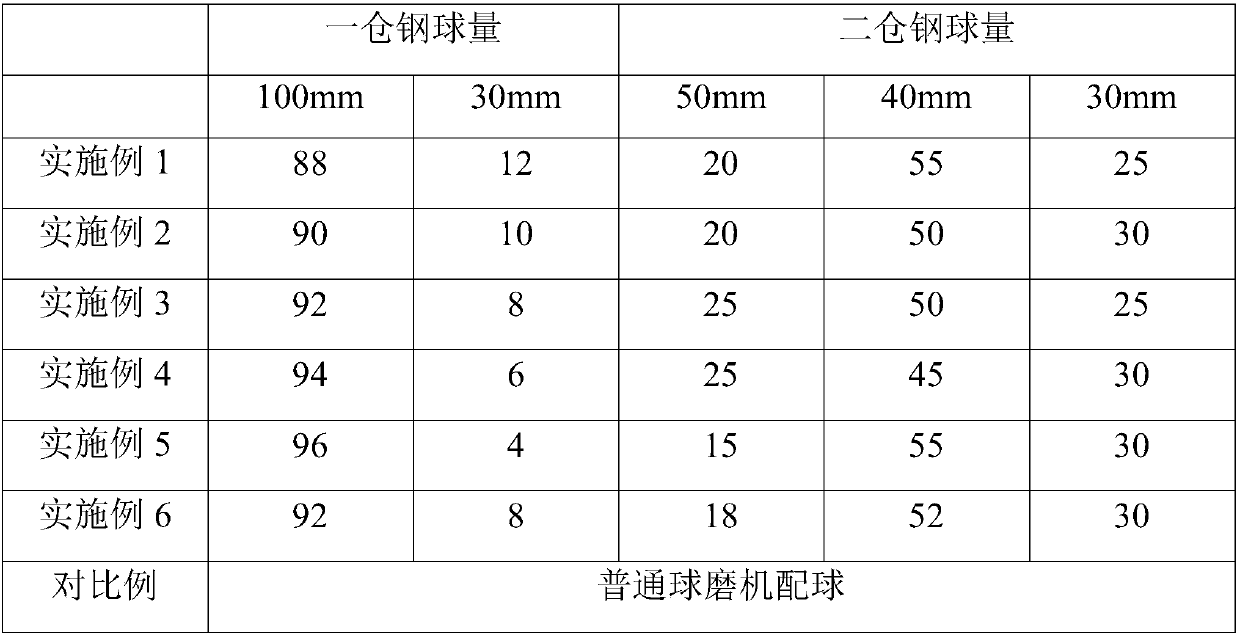

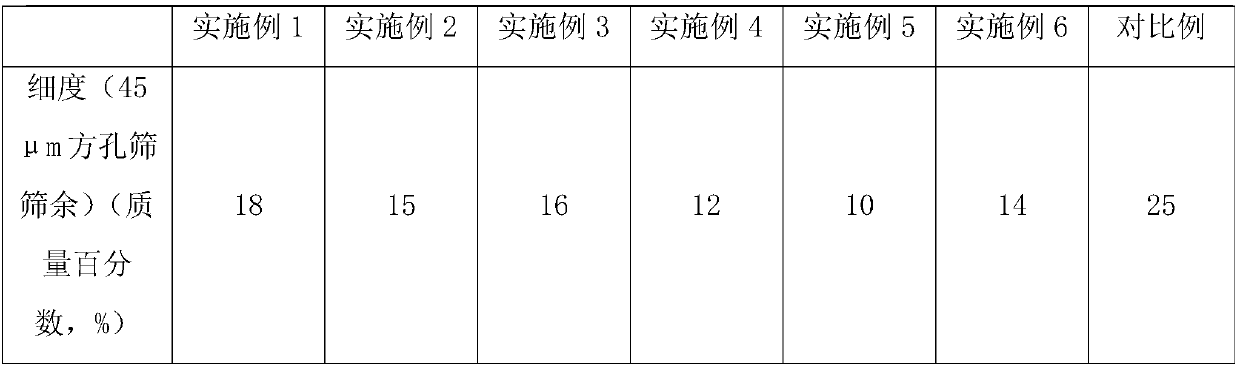

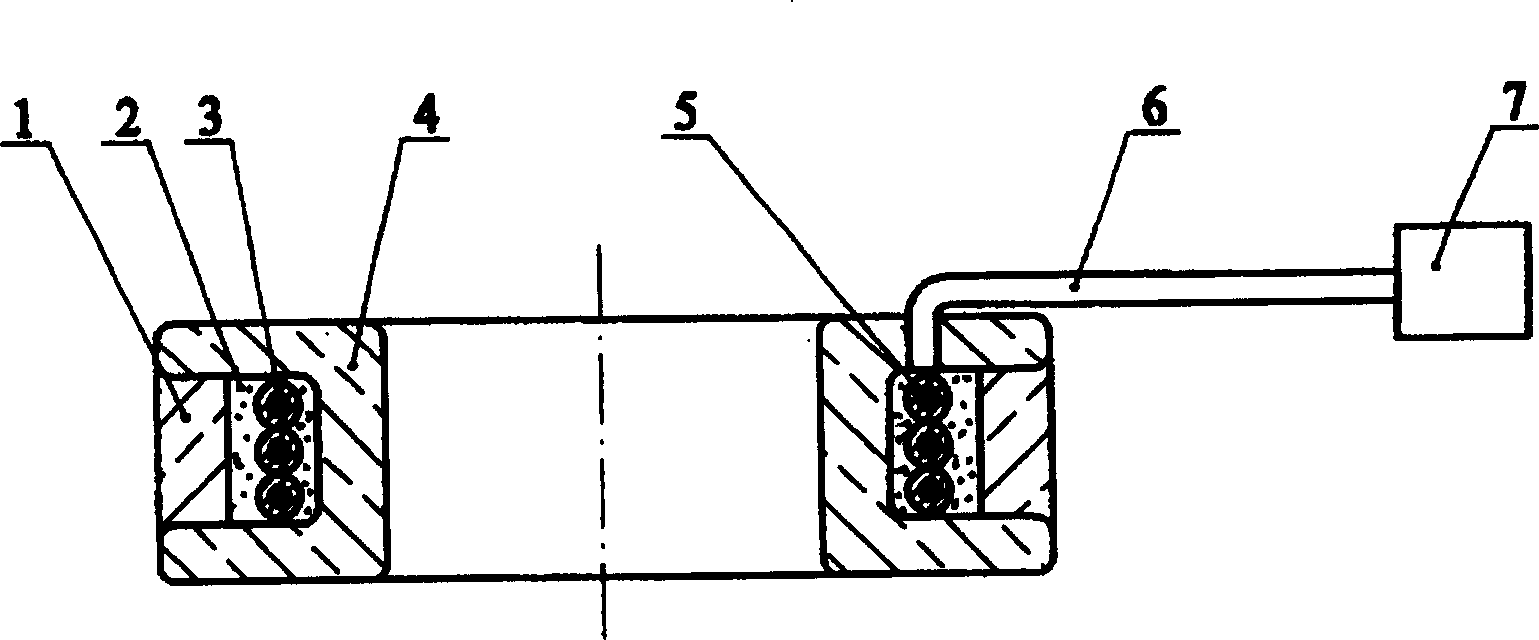

Special accessory balls for grinding of natural scoria

The invention discloses special accessory balls for grinding of natural scoria. The special accessory balls for grinding are applied to a two-bin grinding machine. The steel balls contained in one bininclude, by weight percentage, 87-97% of the irregular-shaped steel balls with the diameter of 100 mm, and 3-13% of the steel balls with the diameter of 30 mm. The steel balls contained in the otherbin include, by weight percentage,10-30% of the steel balls with the diameter of 50 mm, 35-55% of the steel balls with the diameter of 40 mm, and 20-35% of the steel balls with the diameter of 30 mm.The irregular-shaped steel balls are composed of common steel balls and protrusions attached on the common steel balls. Through the reasonable steel ball proportion and irregular-shaped steel ball structure, low-energy grinding of natural scoria is realized, and ground natural scoria powder has the effect of good quality.

Owner:CHINA ROAD & BRIDGE +1

Process for producing steel scoria unburned brick

The invention discloses a making method of steel slag non-burnt brick, which belongs to steel slag reclamation field; wherein, the technical proposal resolves the problems of the prior steel slag non-burnt brick of requiring maintenance time, requiring pressure in the process of aging, high equipment cost, requiring handling and other multiple operation steps, large amount of labor, and high cost of man power and material resources. The making method of steel slag non-burnt brick is characterized in that (1) at least two materials from steel slag sand, steel slag powder, blast furnace slag and lime are weighed and fed into the blender, (2) water is added and the materials are stirred evenly, (3) the materials are fed into the brick molding press to press and form, (4) the formed brick is processed aging at the atmospheric pressure directly, (5) the industrial exhaust gas comprising CO2 is injected in the process of aging, and (6) the finished steel slag non-burnt brick is acquired as the process of aging is completed. The making method of steel slag non-burnt brick has the advantages that maintenance time is unnecessary, the pressure in the process of aging is unnecessary, requirement of equipment is low, the waste gas residual heat is utilized directly, and the cost is low.

Owner:济南鲁新新型建材股份有限公司

Method for detecting an occurrence zone of a mantle diapir finger location

InactiveUS7403858B2Improve reliabilityDispersed particle separationProspecting/detection of underground/near-surface gasesSilanesMining industry

The invention covers the mining industry. Detection method of the occurrence zone of the mantle substance diapir finger consisting in that that geological observation are carried out in riftzones banked up by diapirs of the abnormal mantle and places of location of the mantle substance finger in the earth's crust are determined. Based on the presence of influence traces of silanes streams upon the rock and / or presence of separate ridges having the length up to 200 km by the width of up to 20 km and / or based on the blast traces of silanes and / or presence of scoria cones, differing by that that the correspondence of 3He / 4He from gases sampled from sources of 10−5 order is additionally determined for determination of silicides at the small depth as physical parameters for the location of the mantle substance diapir finger in the earth's crust. The presence of high semiconductor conductivity, locality and activity of magnetic anomalies and anomalies of gravity field is additionally established. The occurrence depth of silicides is determined by magnetotelluric sounding and / or seismic reflection and refraction methods.

Owner:LARIN VLADIMIR NIKOLAEVICH +1

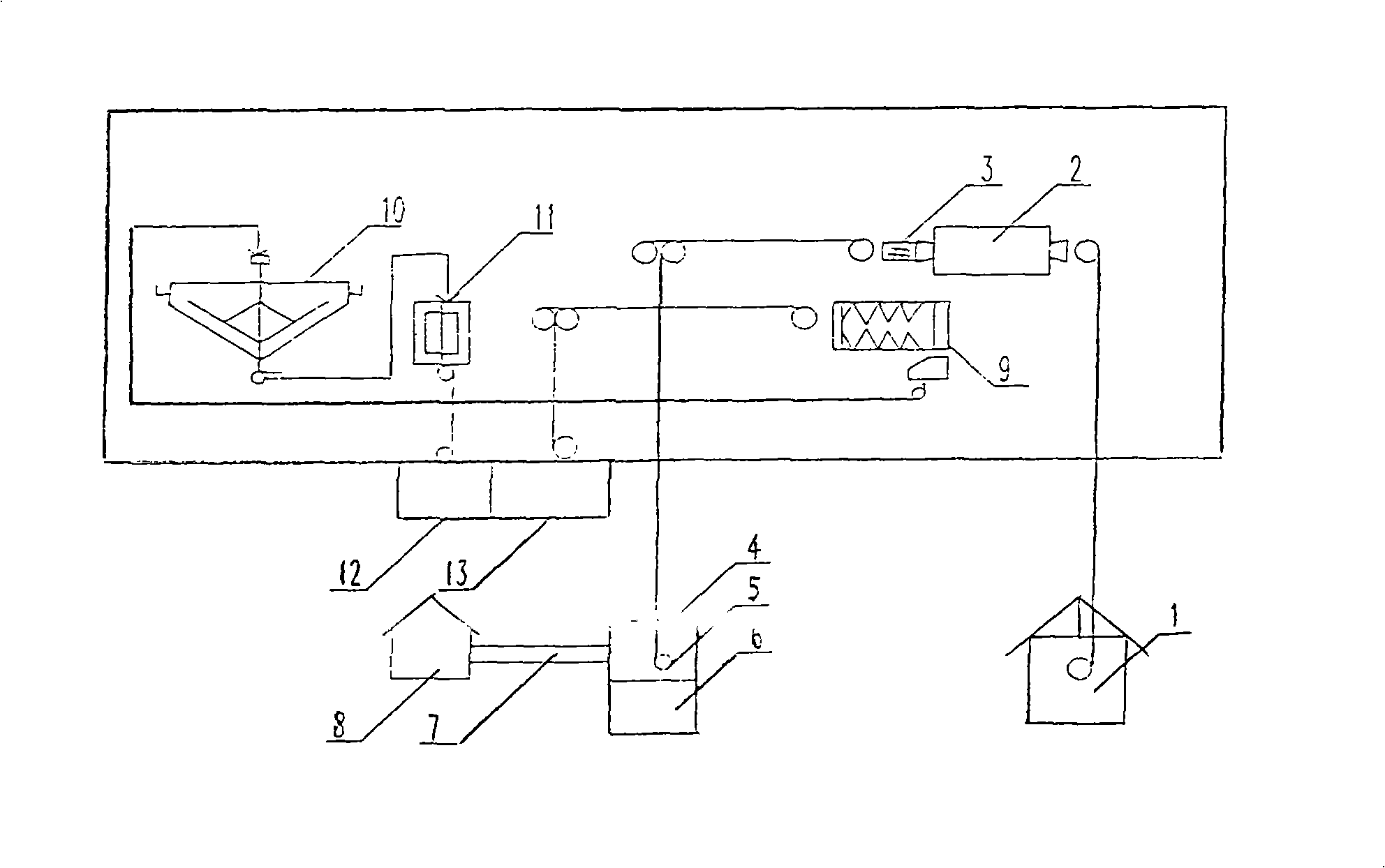

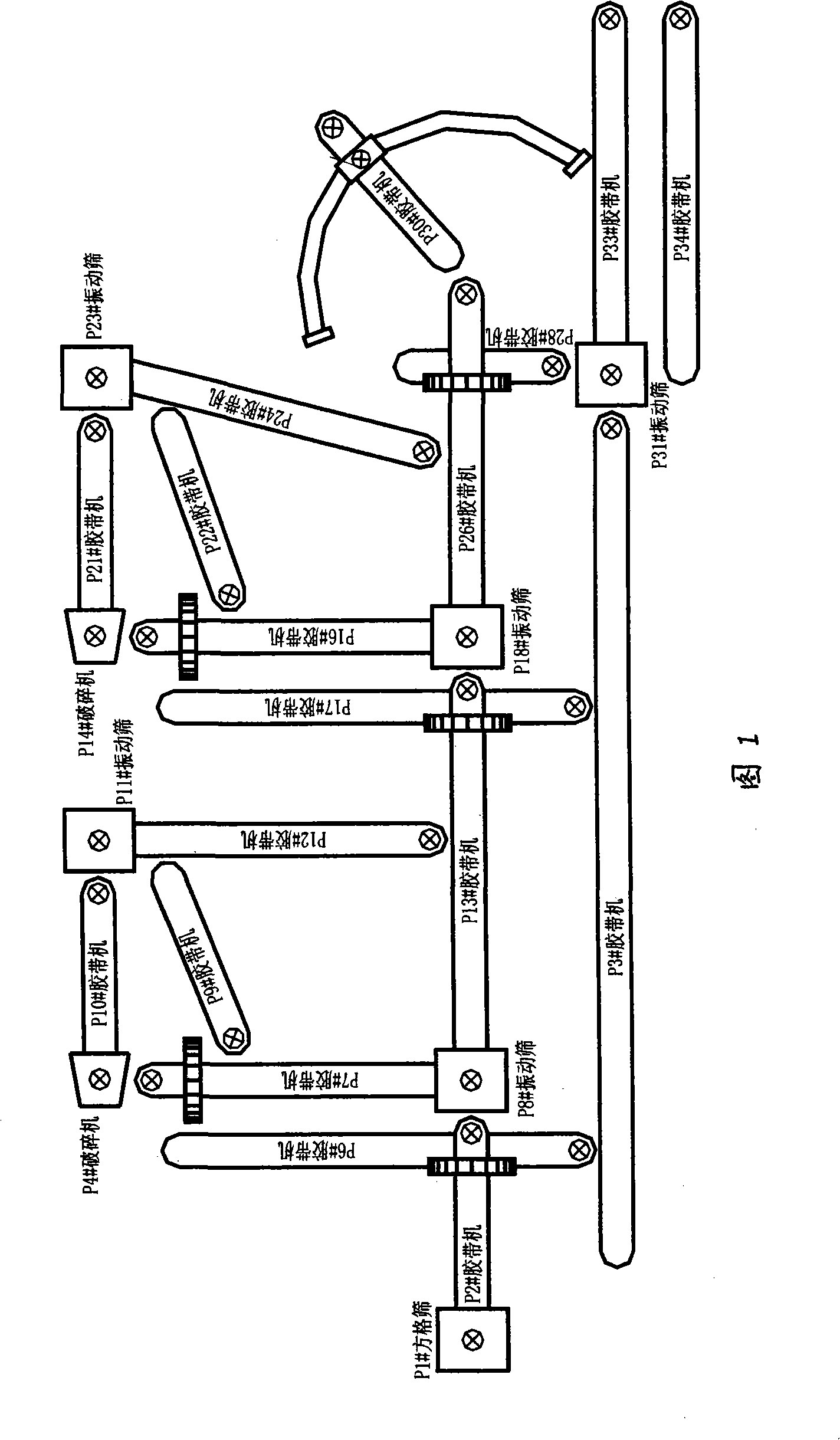

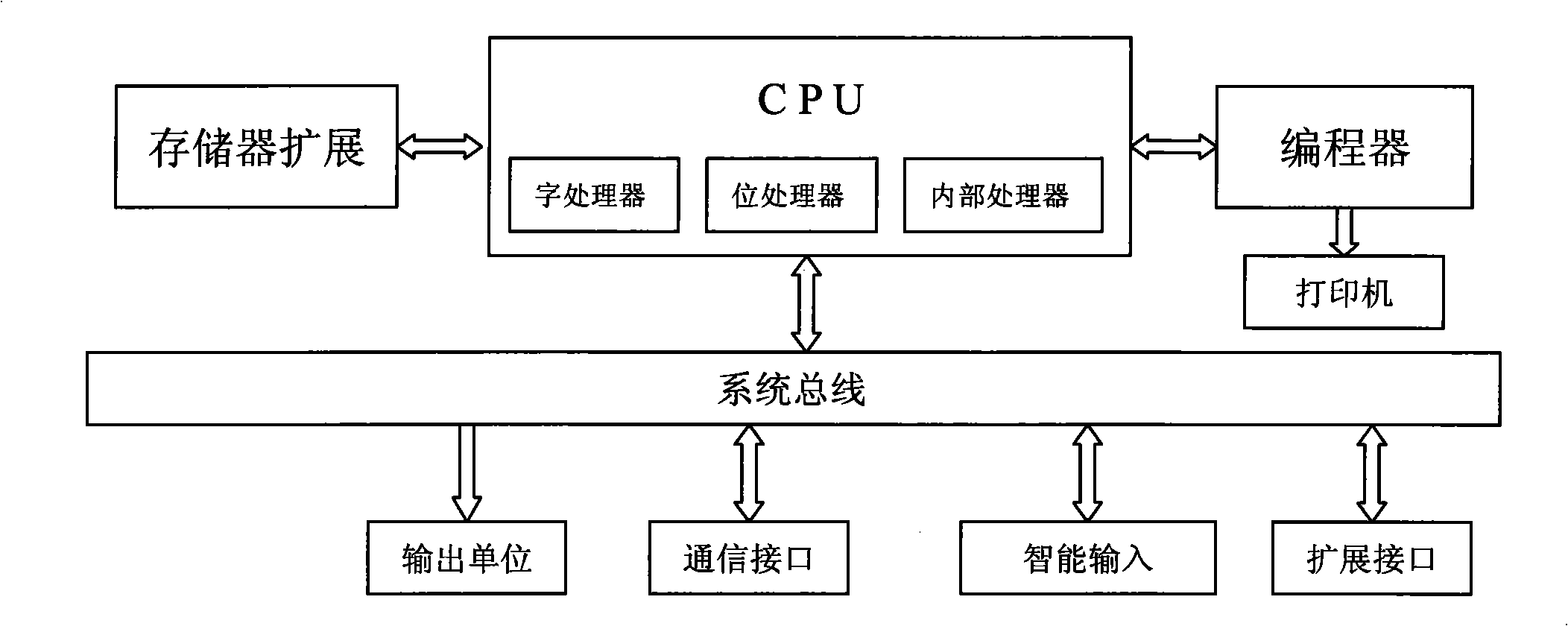

Control method for processing cold steel scoria

InactiveCN101256393ALow costReduce maintenance workloadSolid waste disposalSolid separationProduction lineSlag

The invention discloses a control method for cold steel slag processing, in which signals are inputted to a processor through an intelligent input interface. Firstly, two crushers are started, and operating equipments are sequentially started at regular intervals; a production line is interlockingly started in two steps, so that the fluctuation of a powder network is minimized; when the production line is stopped, the equipments are sequentially stopped in reverse steps. According to the invention, local material stacking is avoided; and the load is low, thus to reduce equipment loss.

Owner:南京钢铁集团盛达实业有限公司

Scoria-imitation decoration sheet, scoria-imitation veneering decoration building block and processing method of building block

InactiveCN110394880AUnique decorative effectRealistic decorative effectDischarging arrangementCovering/liningsFoaming agentMixed materials

The invention provides a scoria-imitation decoration sheet, a scoria-imitation veneering decoration building block and a processing method of the building block. The building block comprises a commonconcrete building block body with a cavity and the scoria-imitation decoration sheet attached to the outer side face of the common concrete building block body, the inside of the cavity of the commonconcrete building block body is filled with a heat preservation filling material, and the scoria-imitation decoration sheet is of a natural-scoria-imitation sheet structure which is prepared by adopting a chemical foaming-maintenance technology, wherein irregular air holes are formed in the scoria-imitation decoration sheet; raw materials of the scoria-imitation decoration sheet comprise cement, aggregate, an active mixed material, a foaming agent and an air entraining agent. The processing method comprises the steps that firstly, the inside of the cavity of the common concrete building blockbody is filled with the heat preservation filling material, and then cement mortar is used for attaching the scoria-imitation decoration sheet to the outer side face of the scoria-imitation decorationsheet. According to the scoria-imitation decoration sheet, the chemical foaming-maintenance technology is used for preparing the scoria-imitation decoration sheet, and by adjusting the sizes of the air holes and distribution of hole diameters, after the scoria-imitation decoration sheet is pasted to the surface of the building block, the surface of the building block has a unique and vivid natural scoria decoration effect; the finished product is high in density and strength and excellent in heat preservation performance and has a wide market prospect.

Owner:CHINA BUILDING MATERIALS ACAD

Mineral Paper

A process to manufacture a paper derived from minerals includes the steps of preparing a mineral preparation that includes 50% to 70% of total dry weight of rocks that have been crushed and ground into a powdery substance; combining the mineral preparation with a sodium silicate solution of total dry weight of 30% to 50%; and adding additives having a weight of 2% to 5% of a total dry weight. The powdery substance may have granules of about 0.05 mm to 0.08 mm in diameter and can be mixed with vitamin powder. The igneous rocks can be selected from the set of: dolostone, basalt, granite, gabbro, andesite, diorite, obsidian, pegmatite, peridotite, pumice, rylolite, and scoria. Sedimentary rocks can be selected from the set of: limestone, sandstone, conglomerate, shale, siltstone, brecca, gypsum, chert, travertine, flint, iron ore, rock salt, and oil shale.

Owner:NEW MILLENIUM

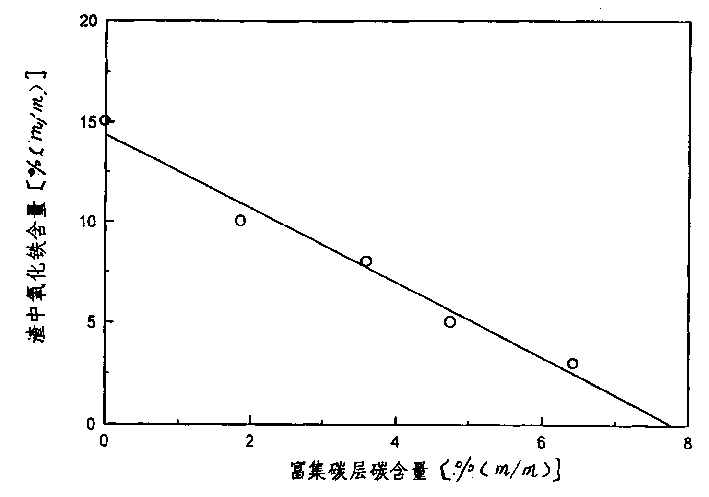

Protective scoria for continuous casting of ultralow carbon steel

The present invention relates to the treatment of molten ferroalloy and continuous casting of metal. The protective scoria for continuous casting has the chemical components in mass percengate of: Na2O 6-10, F- 7-10, Al2O3 2-8, MgO 2-5, one or two of FeO, Fe3O4 and Fe2O3 3.1-15, C 1.0-1.5, and the rest being CaO and SiO2 in the CaO / SiO2 ratio of 0.70-0.89. It is hollow grains in size of 0.7-1.08 mm. When it is used in continuous casting of ultralow carbon steel, it results in very low carbon increment.

Owner:CENT IRON & STEEL RES INST +1

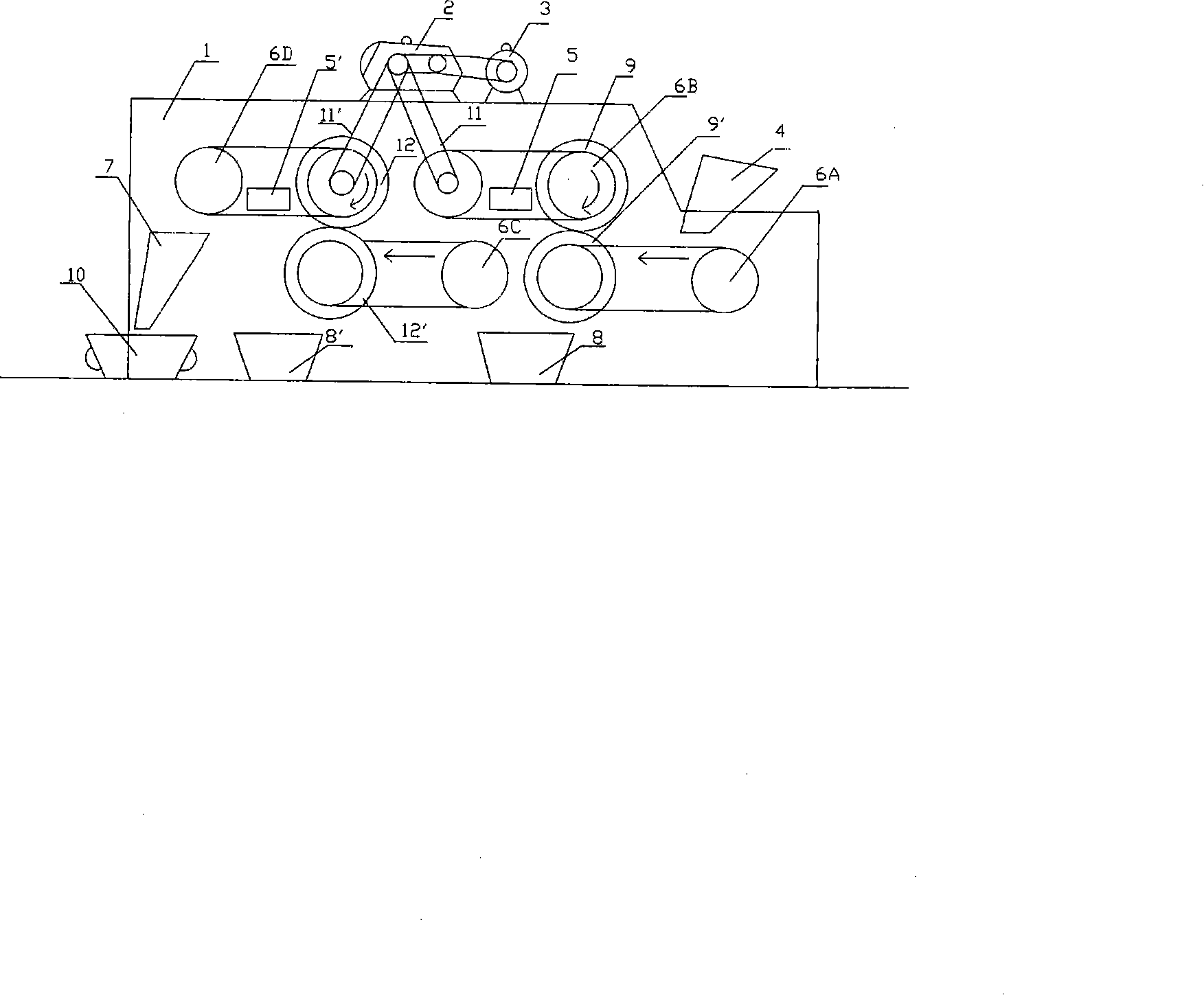

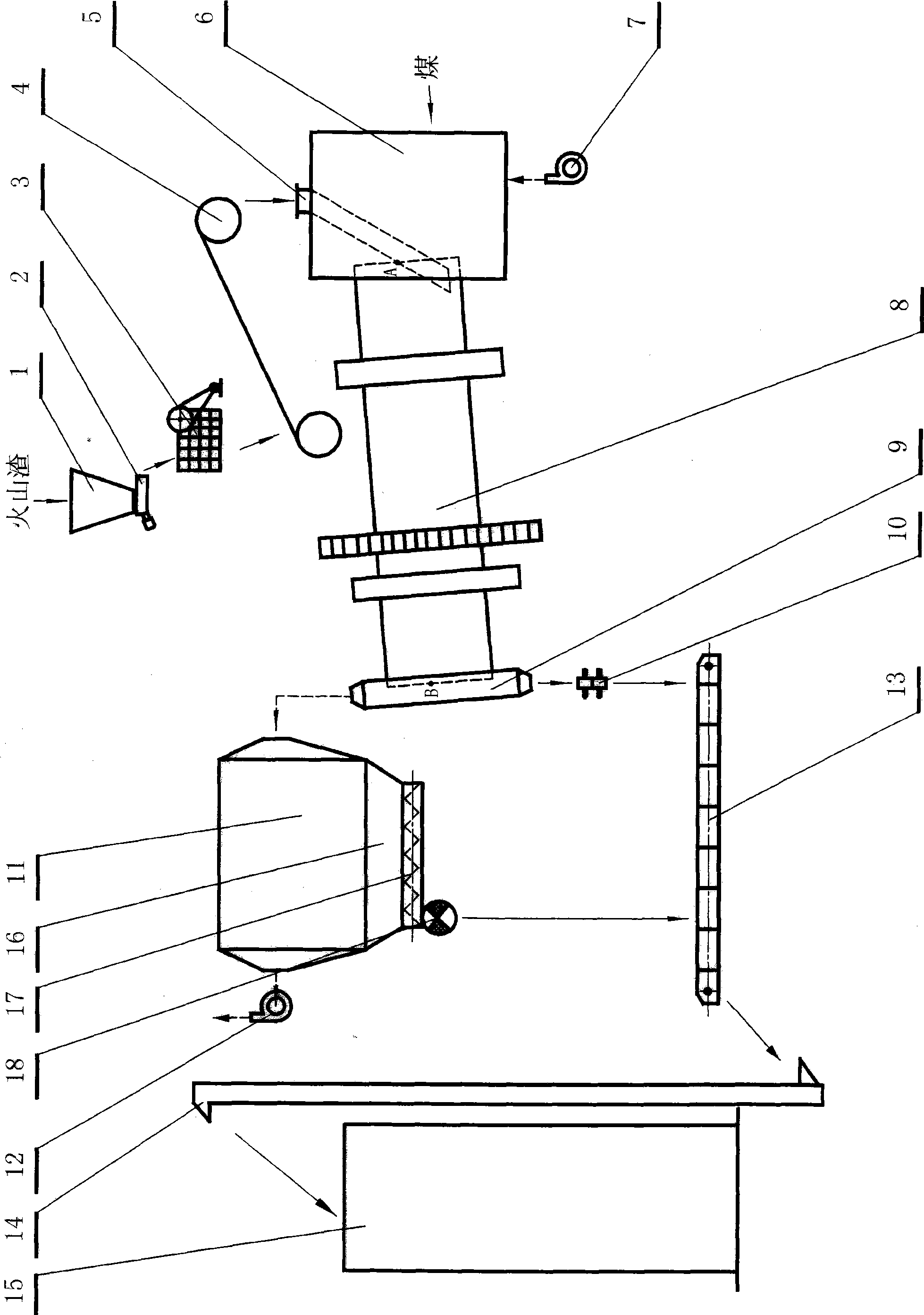

Processing method of natural scoria activity

InactiveCN101386479AChange internal structureSimple stand-alone structureCement productionTemperature controlEngineering

The invention discloses a method for stimulating the activity of natural volcanic cinders. The method realizes heat processing of volcanic cinders through the steps of crushing, delivery, heating and dust collection. A feeding device, a crushing device and a conveying device are arranged before a feed inlet of a rotary treatment machine so as to ensure regular grains of volcanic cinders are feed in the rotary treatment machine constantly and uniformly. An air heating furnace which uses coal as fuel is arranged at the feed inlet of the rotary treatment machine, the heat generated during coal burning is drawn in the rotary treatment machine by a fan arranged at rear side of the rotary treatment machine so the volcanic cinders are heated. The inside of the rotary treatment machine is provided with a raise plate to throw the volcanic cinders on a cross section of the rotary treatment machine uniformly to heat the volcanic cinders evenly and constantly, so the stimulation of the activity of the volcanic cinders is realized and the optimal stimulation of the activity of the volcanic cinders can be realized through temperature control. The volcanic cinders discharged from a discharge end of the rotary treatment machine are delivered to a storage cylinder by a conveyer. The dust containing gas generated in the rotary treatment machine is filtered by a bag dust catcher and discharged into the air. The method has the characteristics of high heat exchange rate, high heat transmission speed, simple operation, convenient maintenance, high operation factor, long service life and high activity of the treated volcanic cinders and can achieve the highest utilization rate of volcanic cinder resources.

Owner:JIANGSU PENGFEI GROUP

Sensor for obtaining scoria flow-out signal during steel ladle casting

InactiveCN1128354CSimple structure requirementsSimplify cost inputMaterial impedanceMaterial magnetic variablesConductor CoilMolten slag

The invention discloses a sensor for capturing the flowing out of molten slag in casting steal from steel ladle. The process of manufacturing the sensor is as follows. There are spiral shaped winding wrapped in insulating magnetic tube on channel of circular ring frame with I bar shape. Heat insulating material is filled around said windings, and fire clay is filled in the channel. After drying and shaping the semi-finished product, the high temperature cable with double core is welded to windings and the other end of cable is connected to the linker box on the shell of the steel container. The invented sensor only contains one spiral shaped winding and minimum two lead out wires so it possesses features of simple structure and lower cost. The sensor also can be used in metallurgy industry.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com