Modified steel scoria adsorbent and preparation thereof

An adsorbent, steel slag technology, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as poor organic wastewater effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

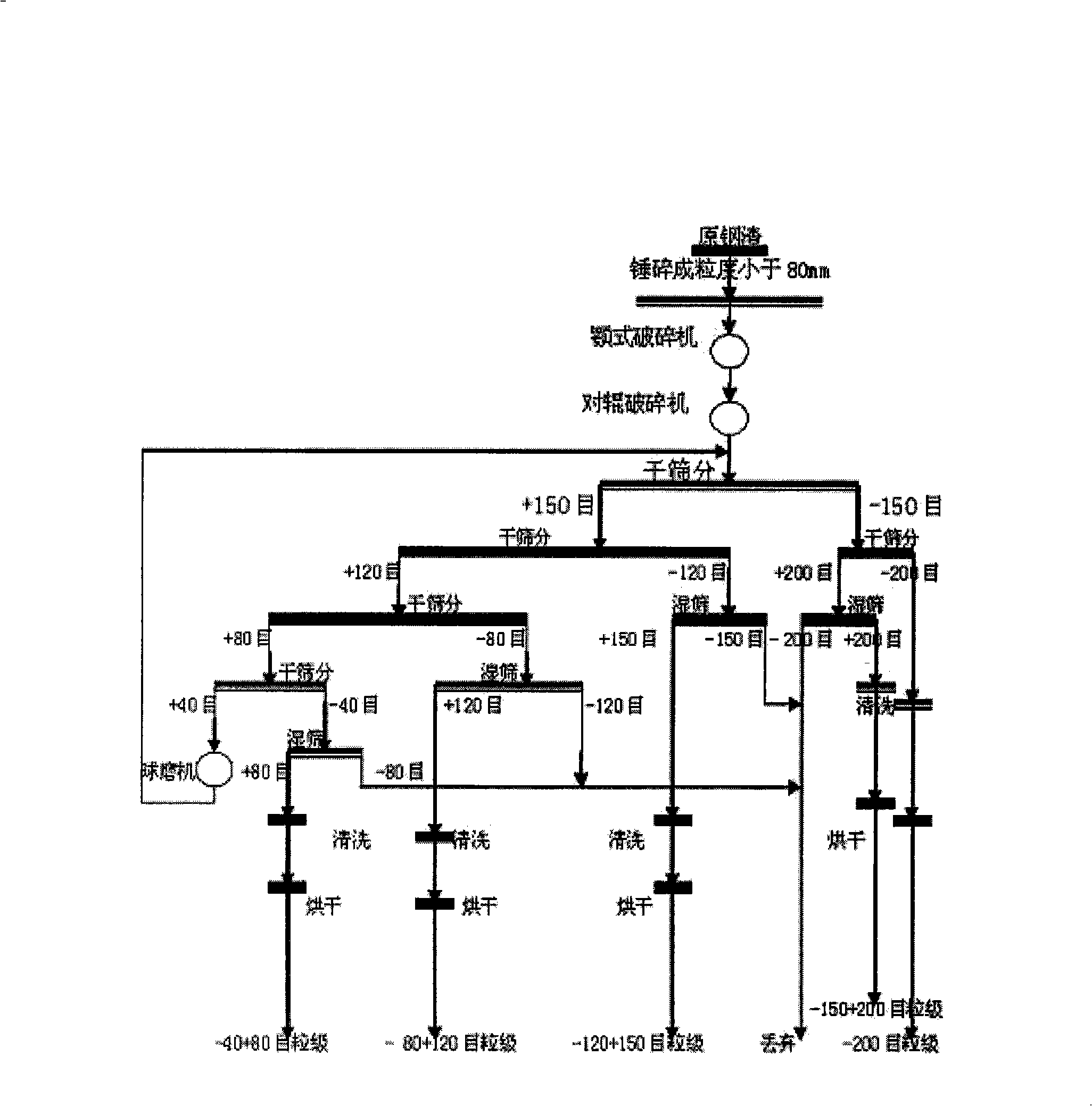

[0015] Referring to the attached "flow chart of preparation of harmless steel slag adsorbent", the open hearth steel slag is crushed by jaw crusher, and steel slag of various particle sizes is obtained by dry or wet screening and classification. Add the obtained steel slags of different particle sizes into hydrochloric acid with a concentration of 1mol / L, shake for 2 hours, filter, and rinse repeatedly with distilled water until the filtrate is neutral.

[0016] Then, take 10g of the prepared steel slag and add it into cetyltrimethylammonium bromide (CTMAB) with a modifier concentration of 2%, vibrate at 50°C for 2 hours, filter, rinse with distilled water until the filtrate is medium The modified steel slag is then dried at 100°C.

[0017] Finally, the prepared modified steel slag was irradiated with 800W microwave for 5 minutes to obtain activated modified steel slag.

Embodiment 2

[0019] Referring to the attached "Flowchart for Preparation of Harmless Steel Slag Adsorbent", the converter steel slag is crushed by a roller crusher, and steel slag of various particle sizes is obtained by dry or wet screening and classification. Add the obtained steel slags with different particle sizes into sulfuric acid with a concentration of 0.5 mol / L, vibrate for 2 hours, filter, and rinse repeatedly with distilled water until the filtrate is neutral.

[0020] Then, take 10g of the prepared steel slag and add it into dodecyltrimethylammonium bromide (DTMA) with a modifier concentration of 4%, vibrate at 50°C for 2 hours, filter, rinse with distilled water until the filtrate is medium The modified steel slag is then dried at 100°C.

[0021] Finally, the prepared modified steel slag was irradiated with 800W microwave for 5 minutes to obtain activated modified steel slag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com