Patents

Literature

337 results about "Carbonatation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

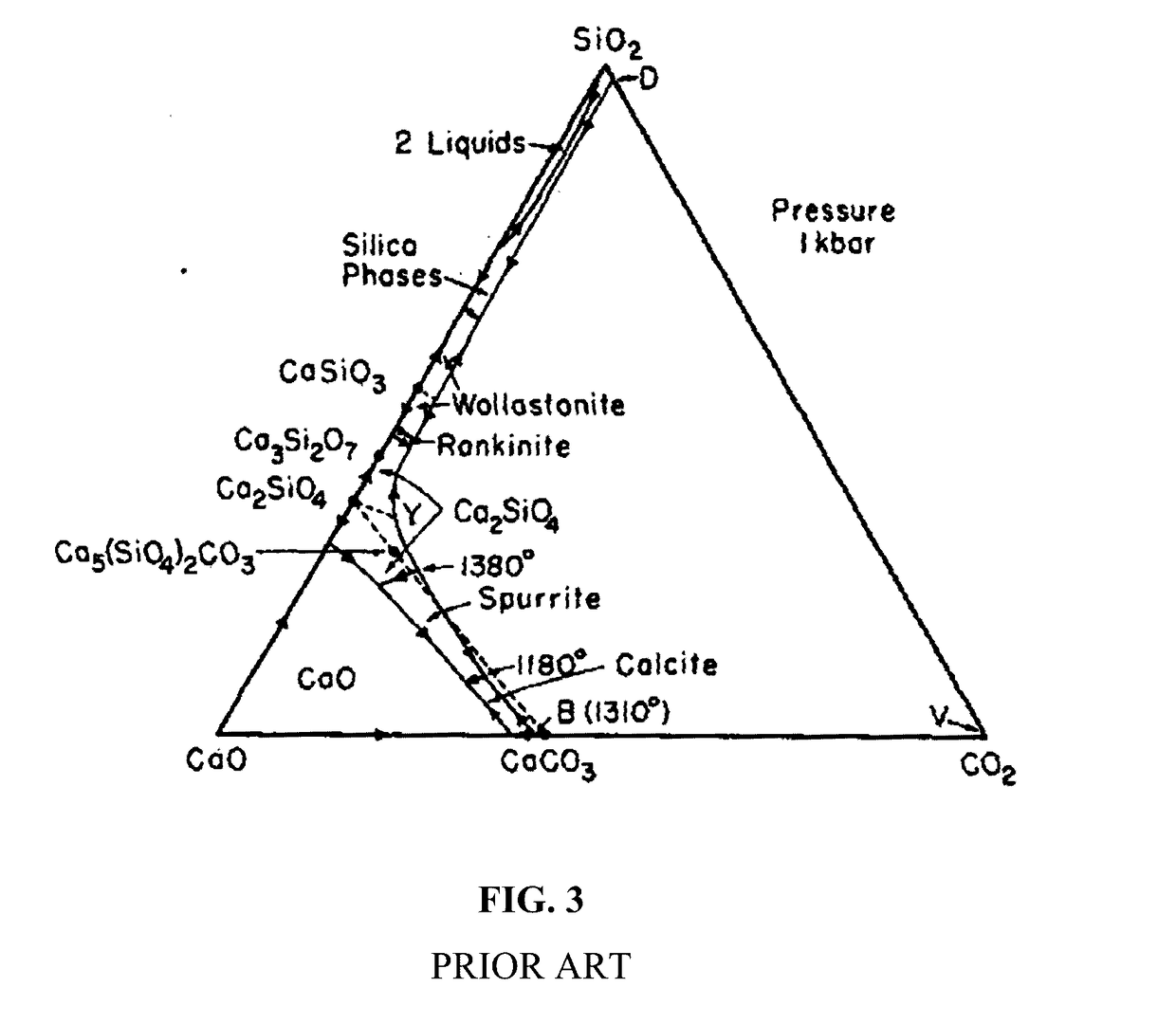

Carbonatation is a chemical reaction in which calcium hydroxide reacts with carbon dioxide and forms insoluble calcium carbonate...

Separation of carbon dioxide (CO2) from gas mixtures

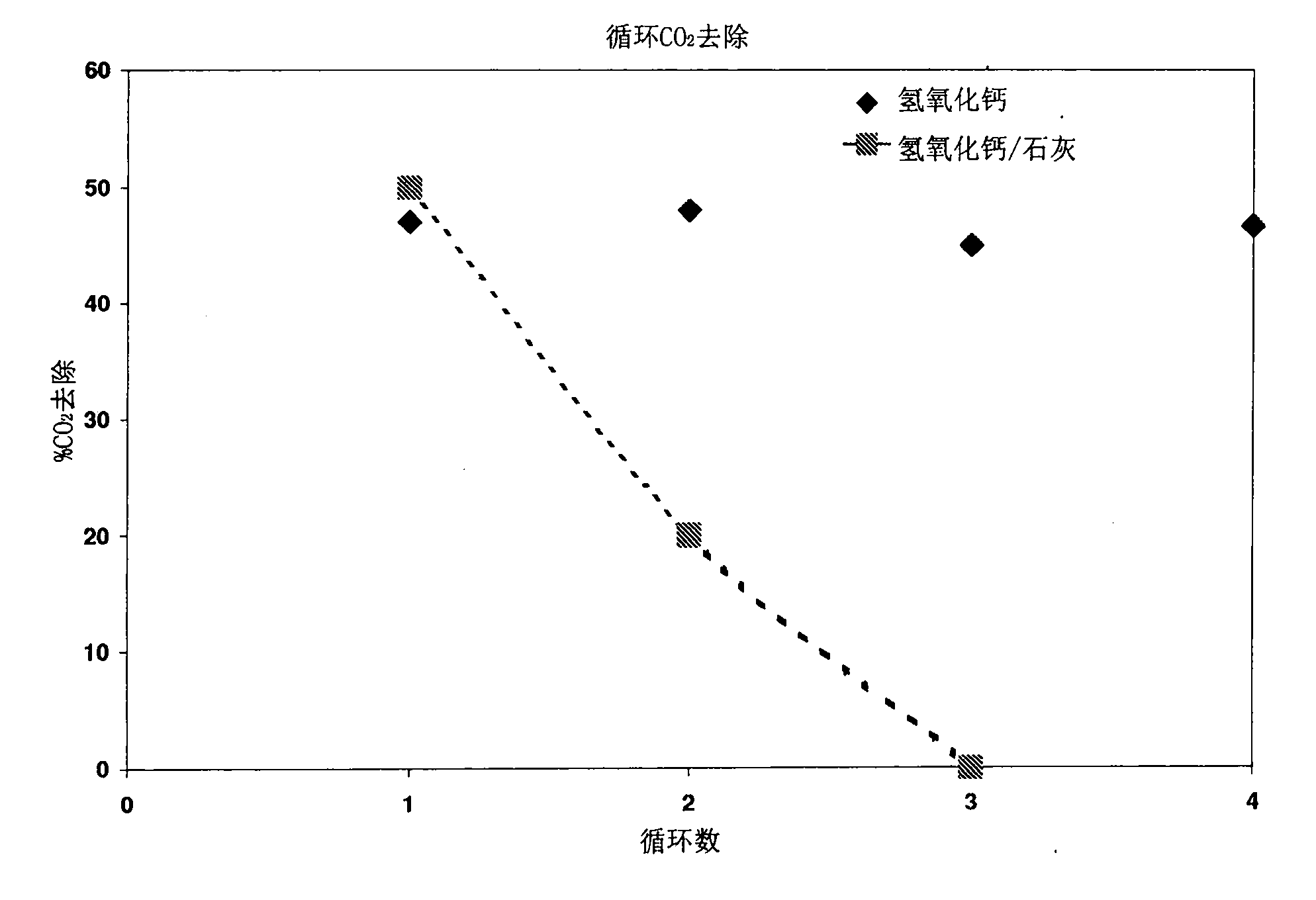

ActiveUS7618606B2Good repeatabilityMaterial nanotechnologyCombustible gas catalytic treatmentCo2 removalSorbent

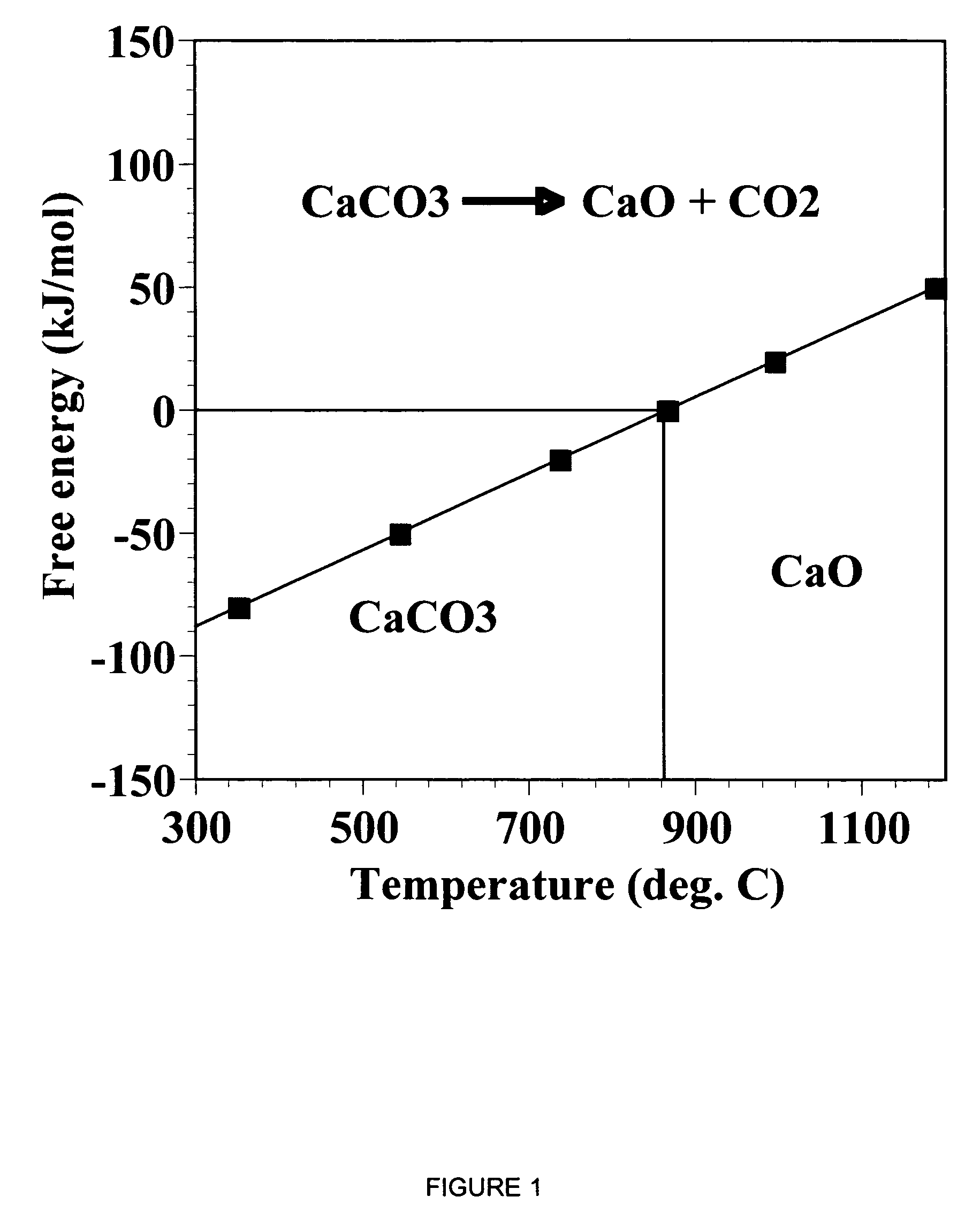

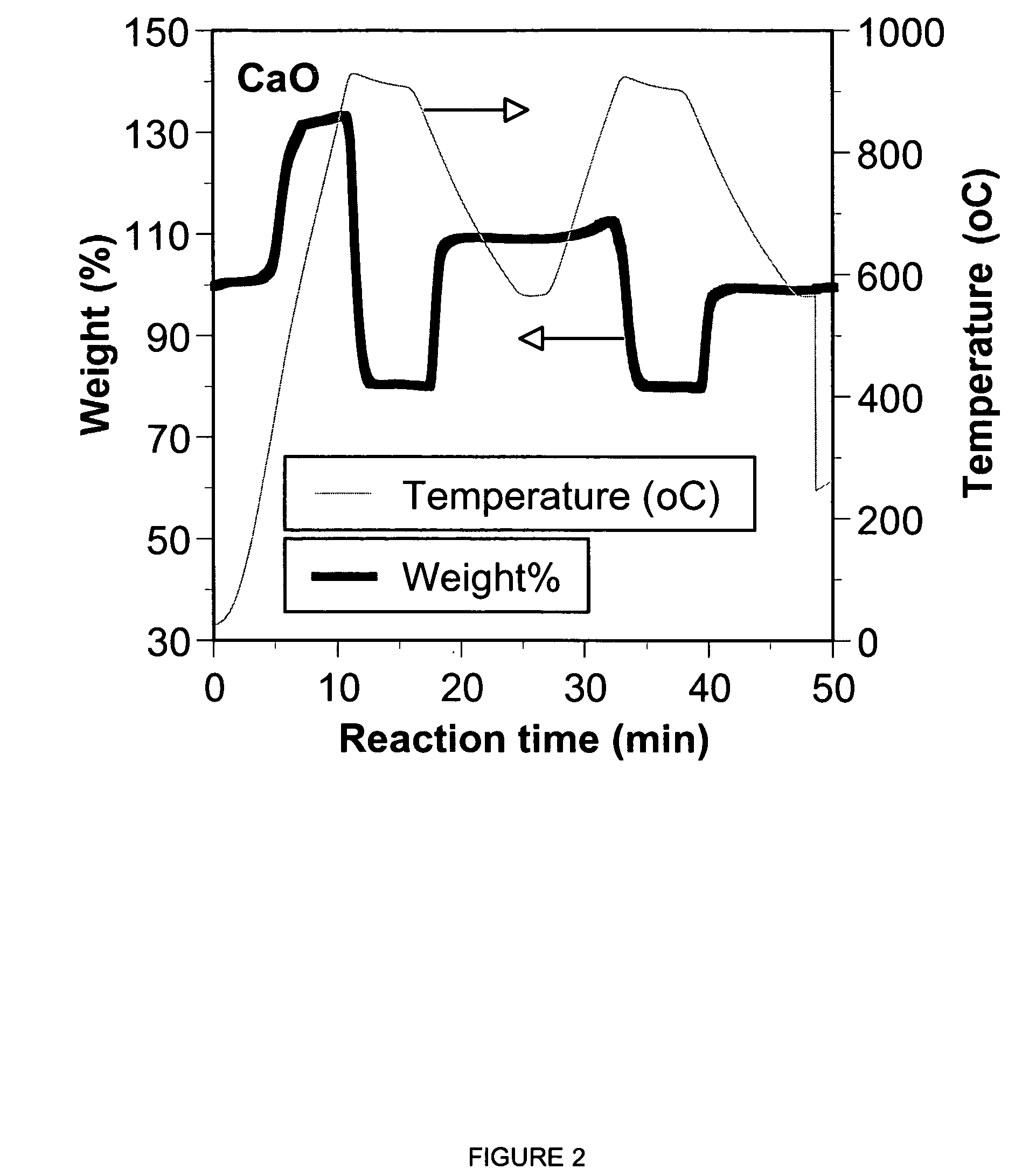

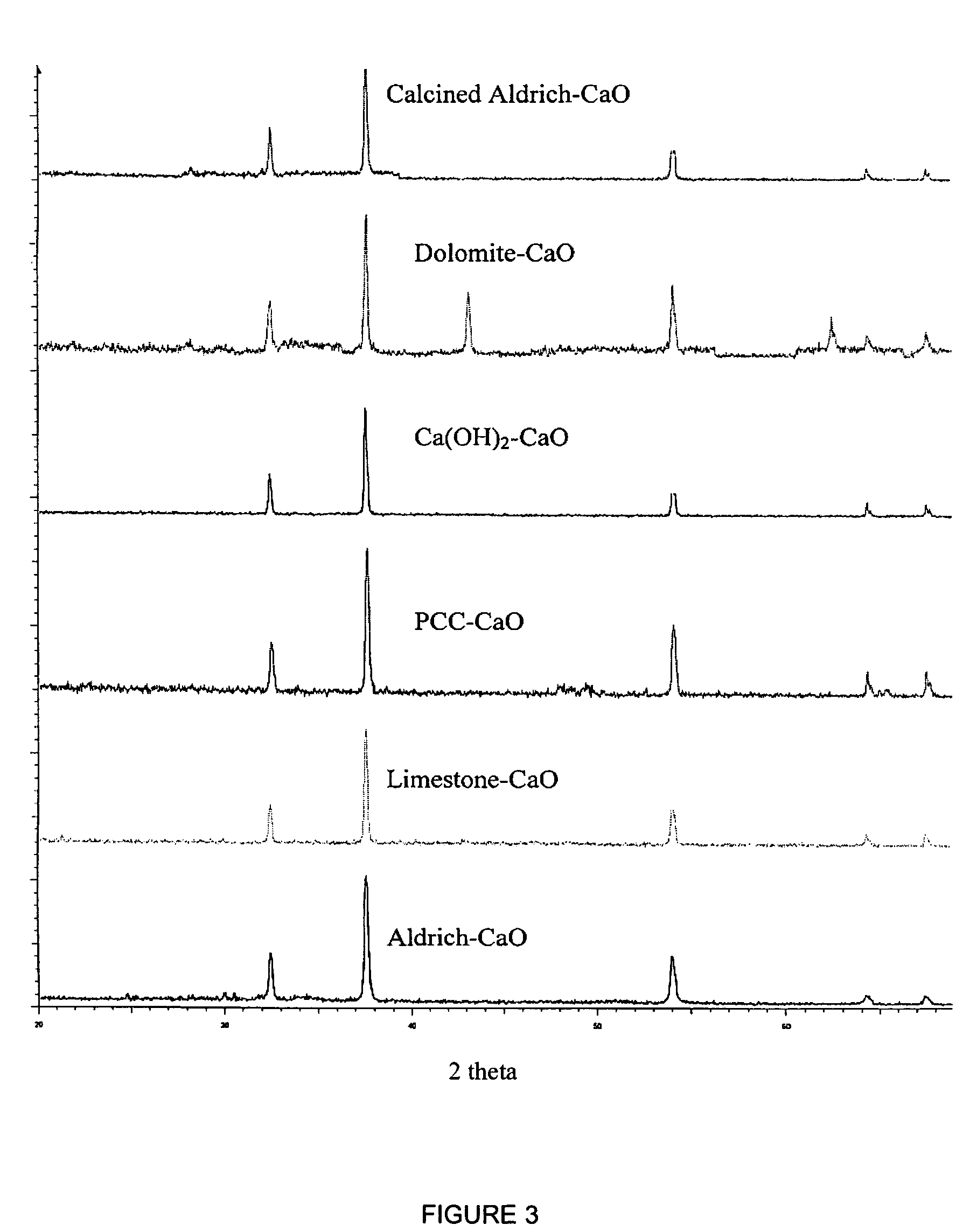

A reaction-based process has been developed for the selective removal of carbon dioxide from a multicomponent gas mixture. The proposed process effects the separation of CO2 from a mixture of gases by its reaction with metal oxides. The Calcium based Reaction Separation for CO2 process consists of contacting a CO2 laden gas with calcium oxide in a reactor such that CaO captures the CO2 by the formation of calcium carbonate. Once “spent”, CaCO3 is regenerated by its calcination leading to the formation of fresh CaO sorbent. The “regenerated” CaO is then recycled for the further capture of more CO2. This process also identifies the application of a mesoporous CaCO3 structure, that attains >90% conversion over multiple carbonation and calcination cycles. Lastly, thermal regeneration (calcination) under vacuum provided a better sorbent structure that maintained reproducible reactivity levels over multiple cycles.

Owner:THE OHIO STATES UNIV

Method for preparing high-alkali value (TBN400) synthesized calcium alkyl benzene sulfonate

ActiveCN101318915AImprove cleanlinessGood dispersionAdditivesSulfonic acid preparationTotal Base NumberAlkaline earth metal

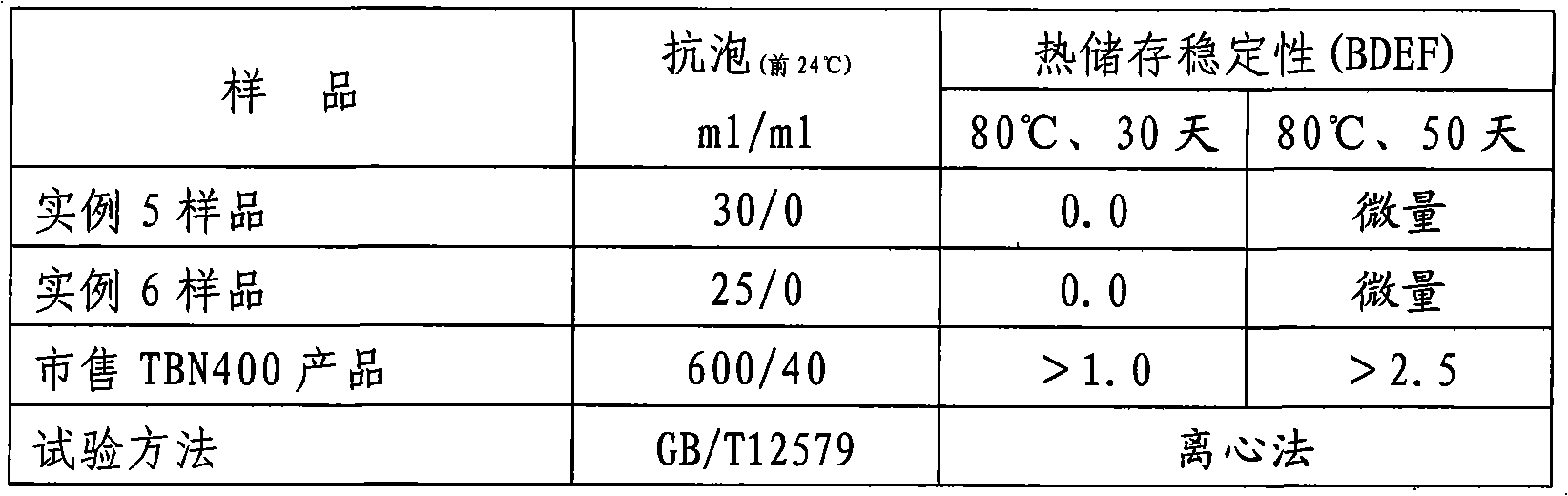

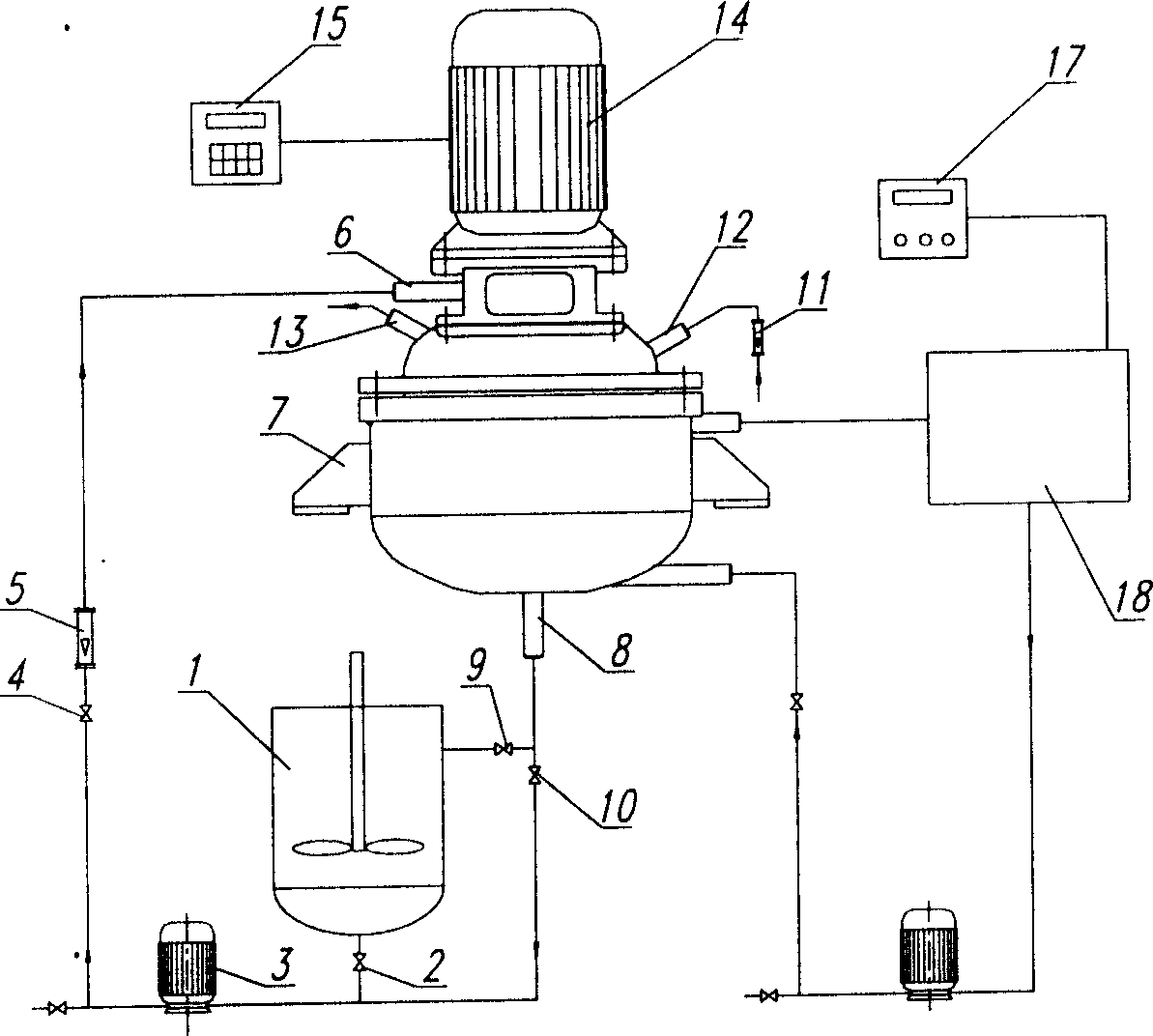

The invention provides a method for preparing high base number (TBN400) synthetic calcium alkyl-benzene sulfonate. The method comprises the following steps of: adopting a mixed acid of long-chain linear alkyl-benzene sulfonic acid and high-boiling heavy alkyl-benzene sulfonic acid, calcium oxide and / or calcium hydroxide, low-carbon alcohol, alkaline-earth metal halide or nitrate, and a mixture of alkaline-earth metal alkylphenol or alkaline-earth metal alkylphenate and polyisobutylene succinic anhydride for a neutralization reaction in the presence of a solvent and cutback oil at a temperature of between 40 and 80 DEG C; then, passing through carbon dioxide to a product of the neutralization reaction at a temperature of between 40 and 60 DEG C for a carbonation reaction; and producing high base synthetic alkyl-benzene sulfonate with a total base number (TBN) of 400mgKOH / g by adopting a process of a one-step method. The product is divided into high-base number (TBN400) synthetic alkyl-benzene sulfonate containing chlorine and high-base number (TBN400) synthetic alkyl-benzene sulfonate without the chlorine. The product produced by adopting the method with low viscosity, small turbidity, easy filtration, light color and no skin formation has the advantages of excellent high-temperature detergency, excellent anti-foaming property and excellent heat storage stability.

Owner:JINZHOU DPF TH CHEM CO LTD

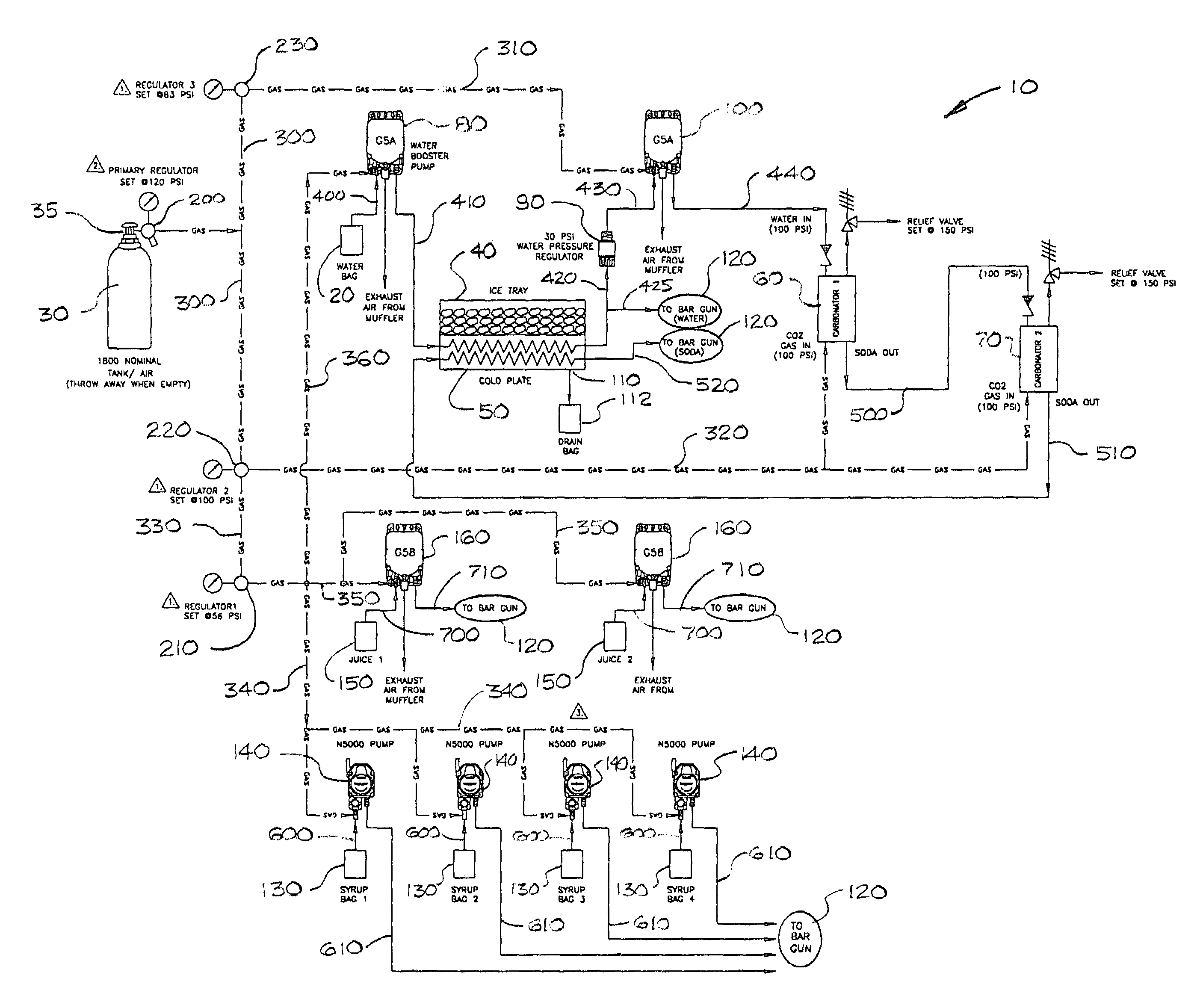

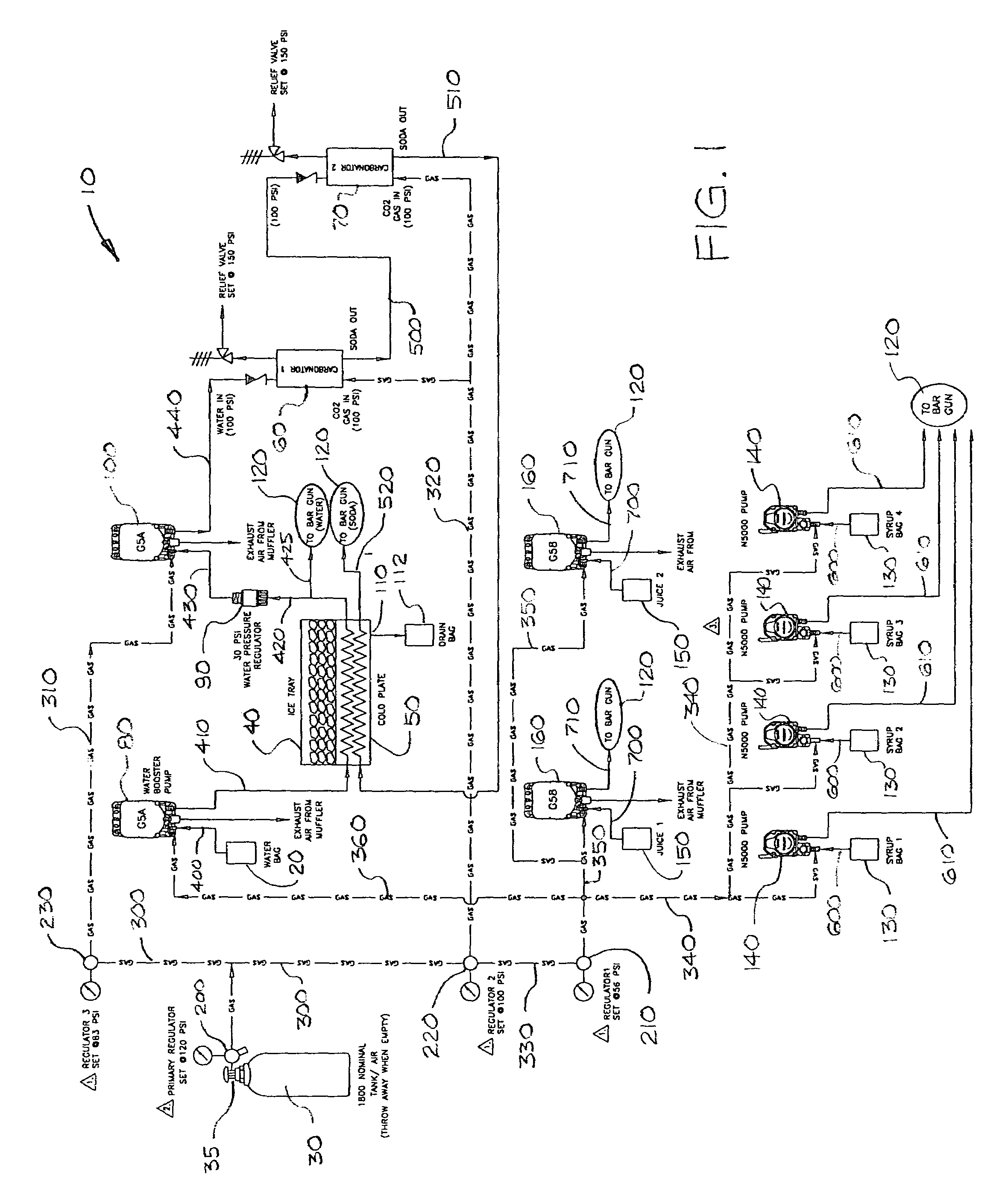

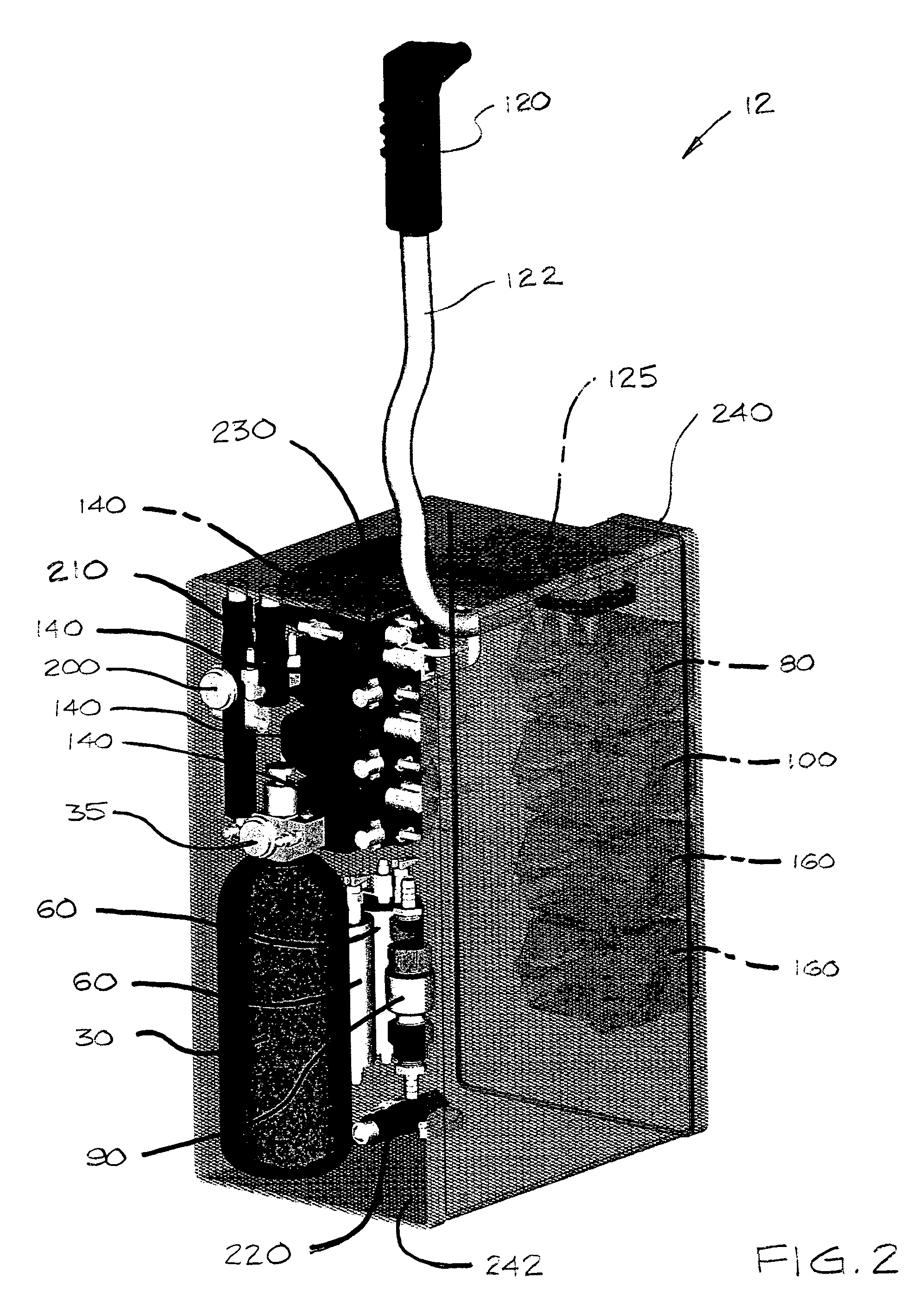

Portable beverage dispensing system

InactiveUS7267247B1Safe storageLiquid flow controllersLiquid transferring devicesCarbonationCarbon dioxide

A portable beverage dispensing system includes a supply of flat water and a supply of pressurized gaseous carbon dioxide. A first motorless carbonator is configured to receive a portion of the flat water and a portion of the carbon dioxide and to cause a portion of the carbon dioxide to dissolve in the flat water to produce partially carbonated soda. A second motorless carbonator is configured to receive a portion of the partially carbonated soda and a portion of the carbon dioxide and to cause a portion of the carbon dioxide to dissolve in the partially carbonated soda and to produce fully carbonated soda. The system also includes a dispenser for selectively dispensing the fully carbonated soda.

Owner:INNOVATIVE SYST & CYLINDERS

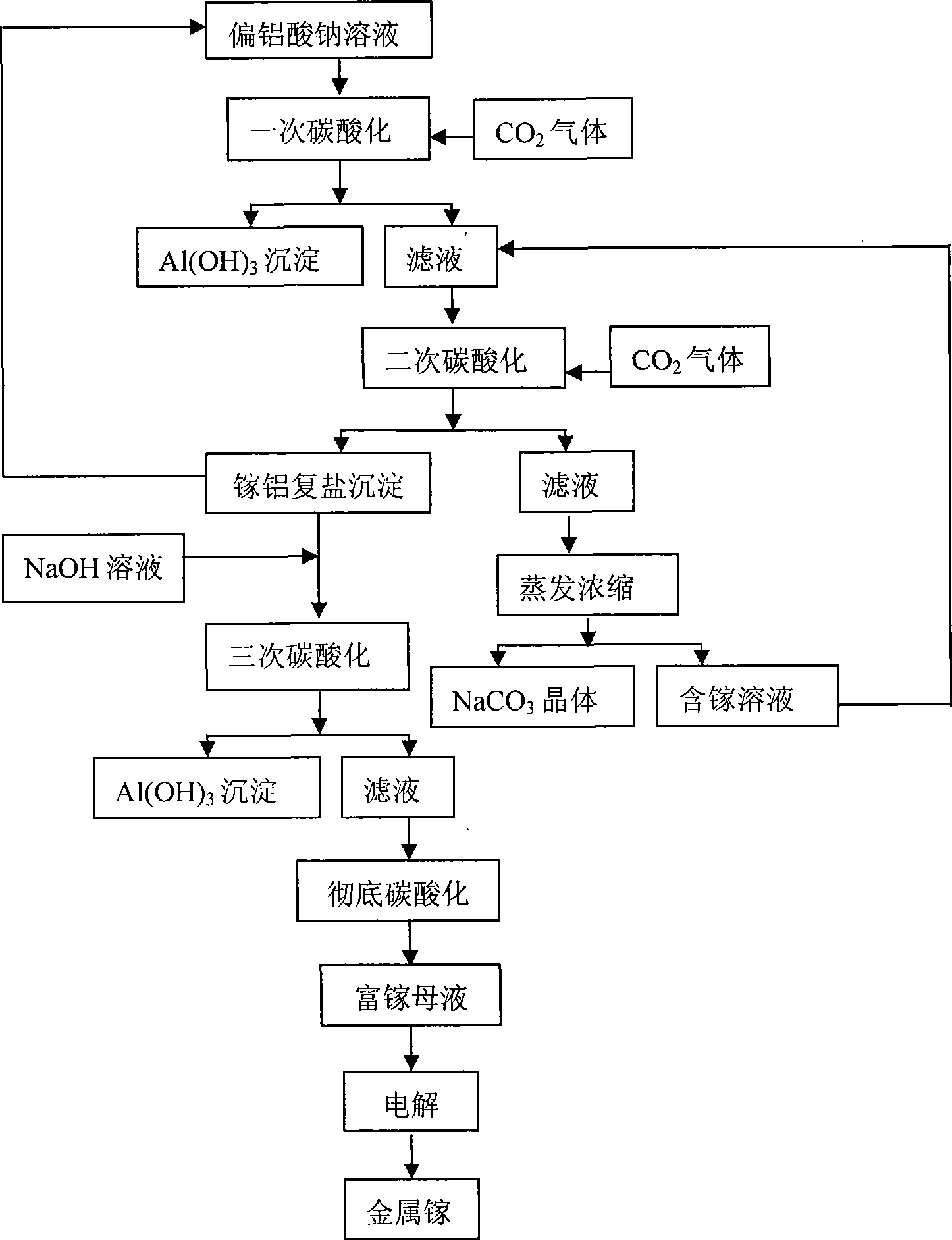

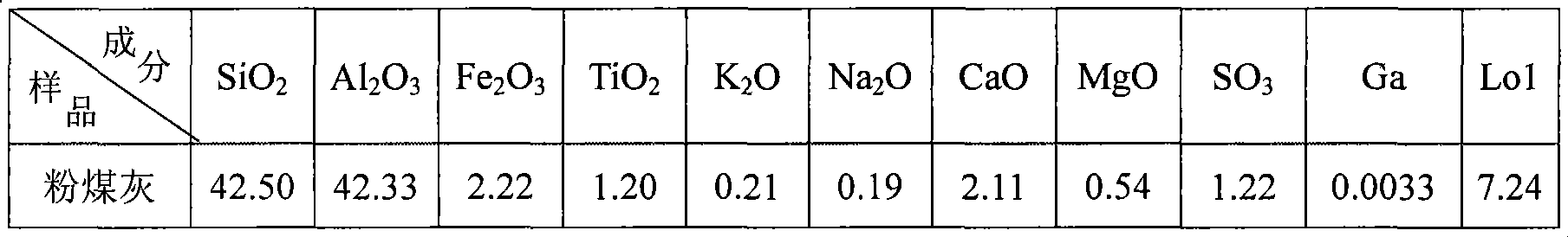

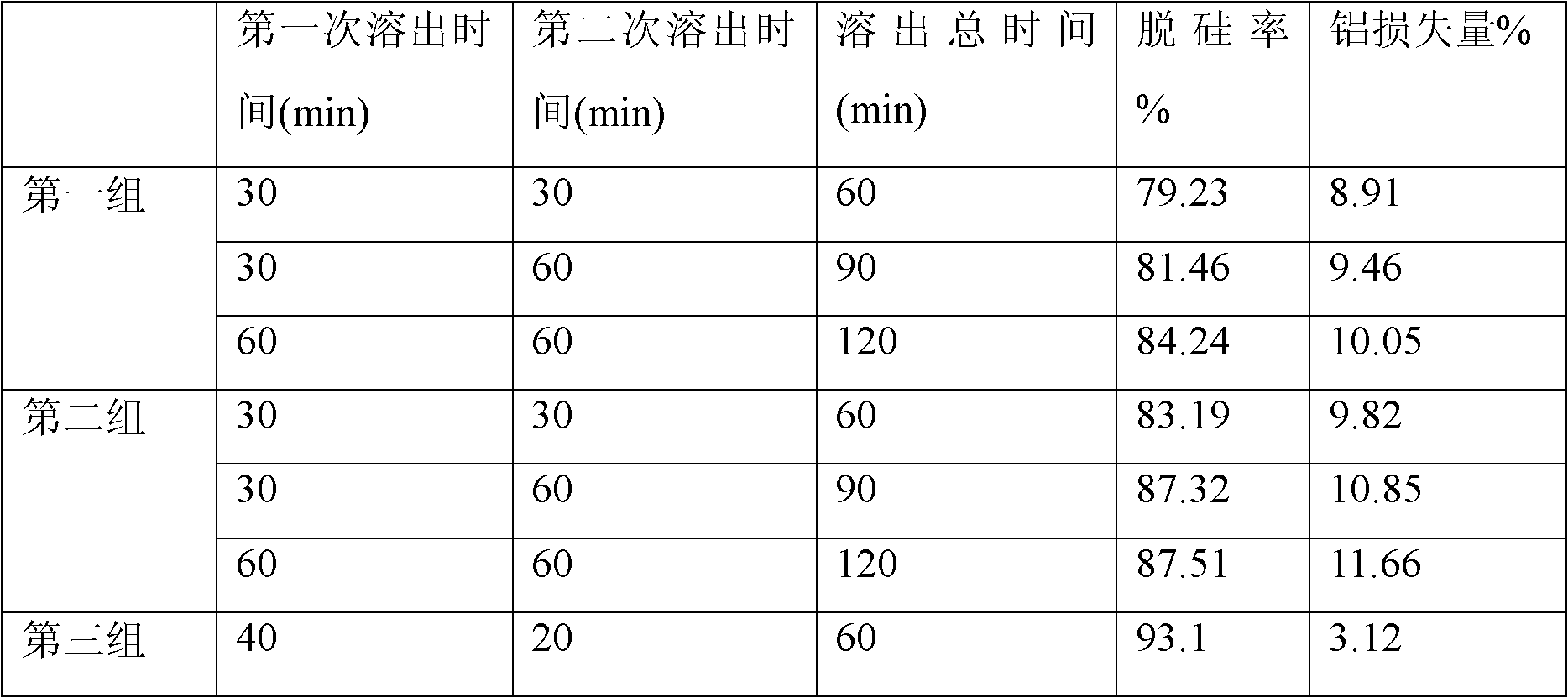

Method for extracting metal gallium from coal ash

InactiveCN101368231AEfficient use ofIn line with the concept of circular economyProcess efficiency improvementAluminateElectrolysis

The invention relates to a method for extracting metal gallium from coal powder ashes, in particular suitable for the ashes of a circulating fluidized bed. In the method, a mother liquor of sodium meta-aluminate is obtained through acid dissolving and alkali dissolving; then aluminum hydroxide is obtained simultaneously during enriching and spearing the gallium through carbon content by steps. The main steps include as follows: CO2 is led into the mother liquor of sodium meta-aluminate to carry out carbon content decomposing; the primary separation between the aluminum and the gallium is realized by primary carbonatation to filter out sodium hydroxide; secondary carbonatation is carried out on the filtrate to obtain the deposit of the complex salt of gallium and aluminum; a sodium carbonate crystal is obtained after the filtered filtrate is condensed and vaporized; the deposit of the complex salt of gallium and aluminum is dissolved in the mother liquor of sodium meta-aluminate; the processes are repeated until the proportion of gallium and aluminum in the complex salt of gallium and aluminum is larger than 1 / 340; then the complex salt of gallium and aluminum is added into the NaOH liquor and electrolyzed, thus obtaining the metal gallium with a purity larger than 99.9 percent which reaches the level of 3; simultaneously, the byproducts of the aluminum hydroxide and the sodium carbonate during the process of carbonatation by steps are obtained. The method has the advantages of simple technique, easy operation, low cost, high comprehensive benefits, and the like.

Owner:JILIN UNIV

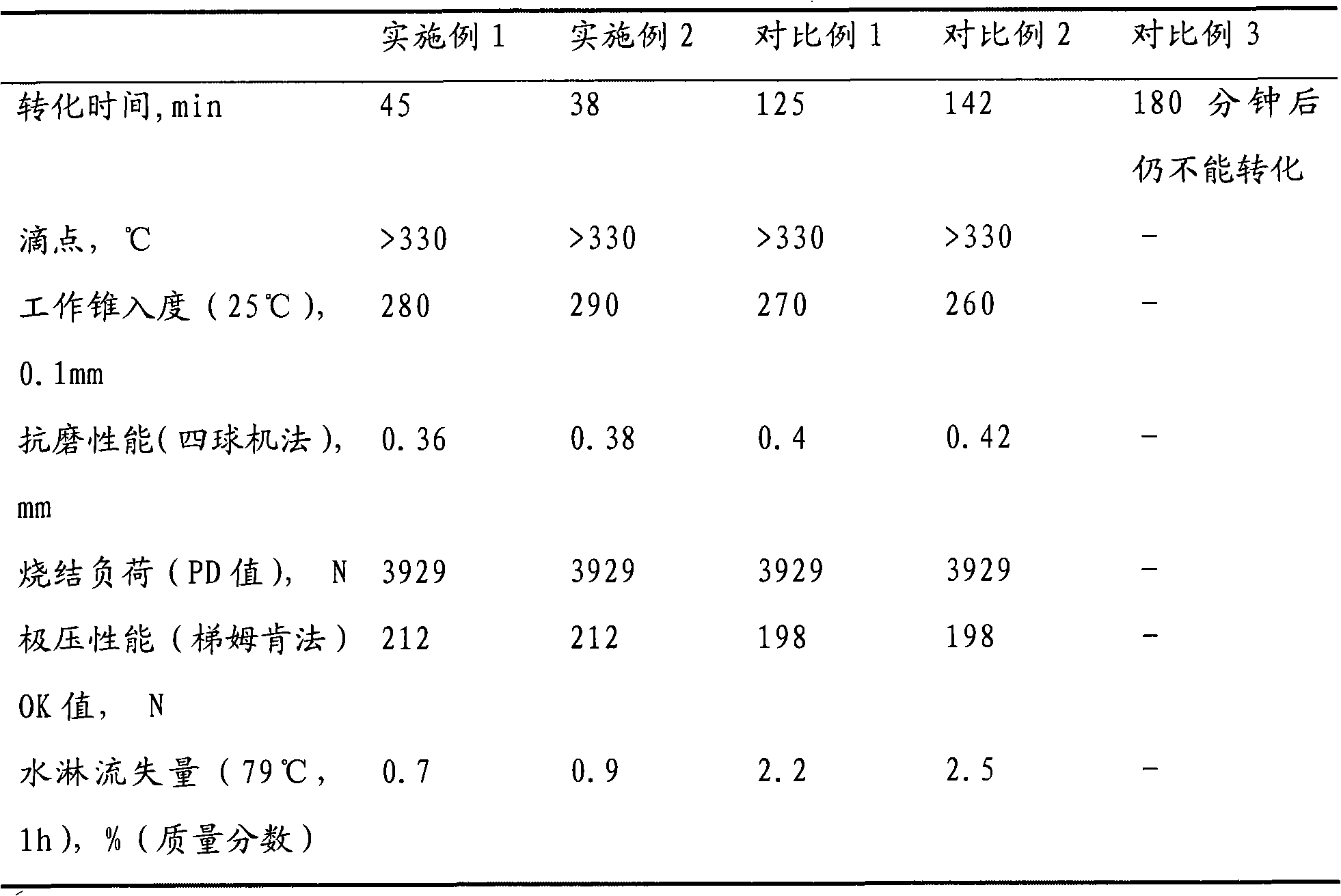

Method for preparing calcium sulfonate with high base number

The invention relates to a method for preparing calcium sulfonate with high base number. In the method, alkyl benzene sulfonic acid and / or petroleum sulfonic acid serve as raw materials, low molecular alcohol serves as accelerating agent, calcium oxide and / or calcium hydroxide serve as calcifying agent; firstly, neutralization reaction is carried out to generate calcium sulfonate; then carbonation reaction is carried out for twice, post-treating agent is added for reaction; finally, alcohol, water, solvent and solid residue are removed to obtain the calcium sulfonate with high base number. The product of the invention is especially suitable for preparing lubricating grease, can shorten conversion time of calcium sulfonate crystal form, improve high-temperature bproperty and anti-moisture performance of the lubricating grease and satisfy the demands of high-performance lubricating grease.

Owner:CHINA PETROLEUM & CHEM CORP +1

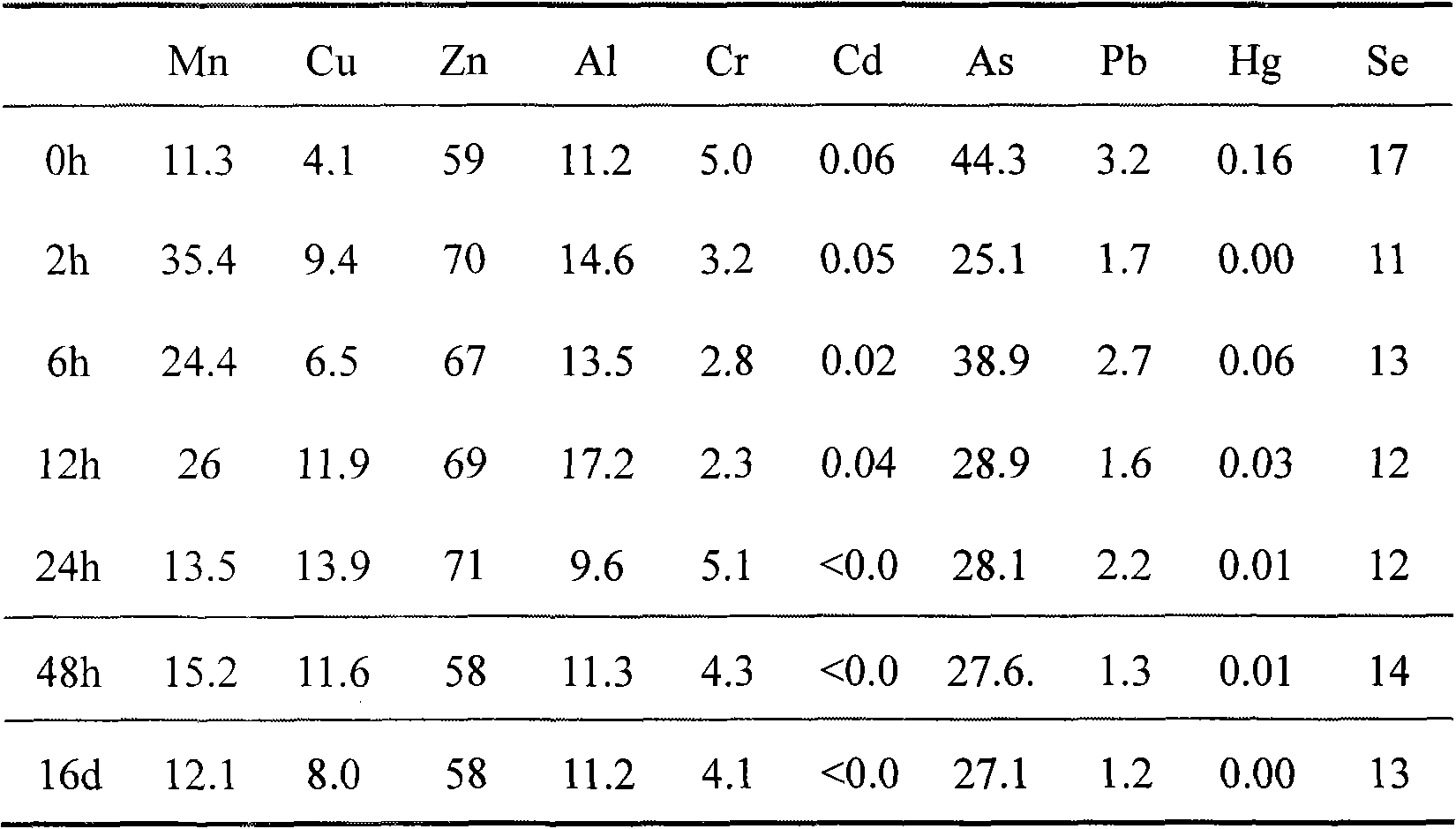

Carbonated steel slag aggregate and preparation method thereof

The invention discloses a carbonated steel slag aggregate and a preparation method thereof. The method comprises the following steps: sieving steel slag subjected to iron separation, taking particles with size between 0.5-25 mm particle for high pressure water flushing, and naturally drying the particles; immersing the dried steel slag particles in a mixed solution of 20-300 g / L caustic soda and 60-300 g / L sodium carbonate for 24 h, and maintaining the temperature at 20-60 DEG C; draining the soaked steel slag particles, immediately placing the particles in a sealed carbonation reactor, and introducing CO2 gas with purity over 99.9% for curing at the temperature of 70-90 DEG C for 0.5 h, and with the CO2 gas pressure at 0.2-0.5 MPa; cooling the steel slag particles subjected to carbonation treatment under natural conditions to room temperature, so as to obtain the carbonated steel slag aggregate. The steel slag aggregate treated by the method has compact surface structure to reduce water for concrete mixing; free magnesium oxide and free calcium oxide are conversed into carbonate precipitation to eliminate the hidden trouble of adverse stability; CO2 can be stored stably; the amount of natural aggregate is reduced to save nonrenewable resources; and the method has easily available raw materials and simple process.

Owner:UNIV OF JINAN

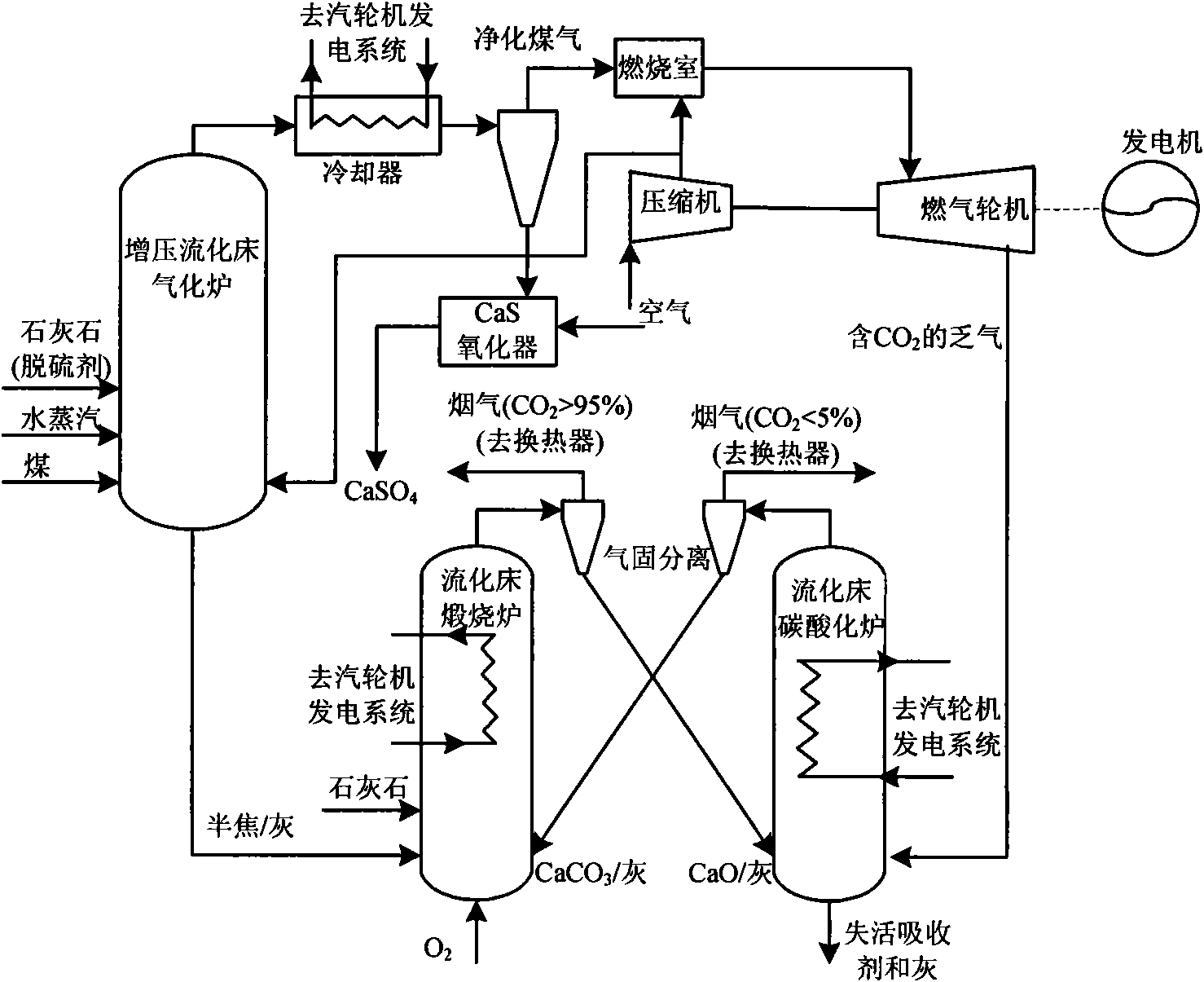

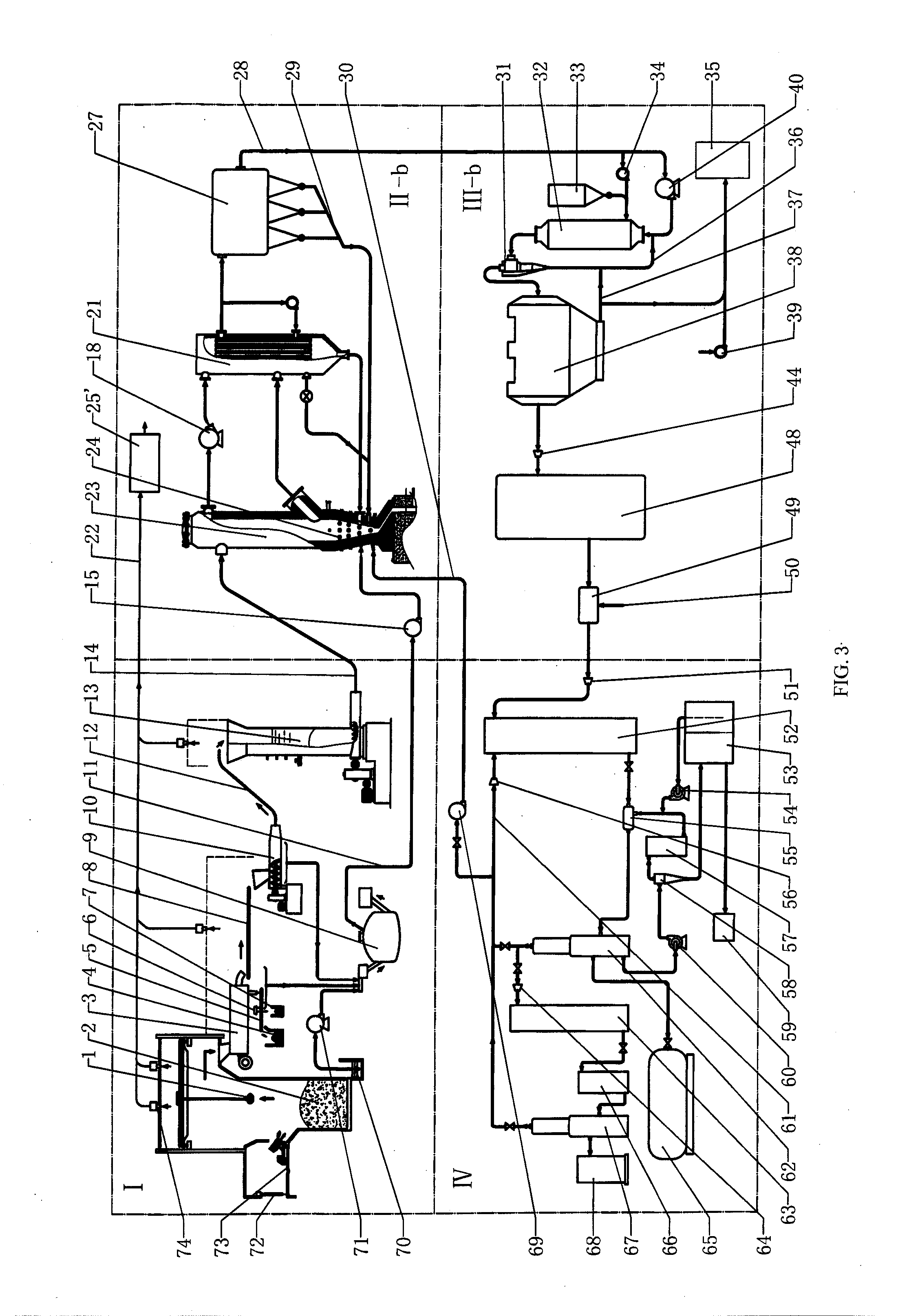

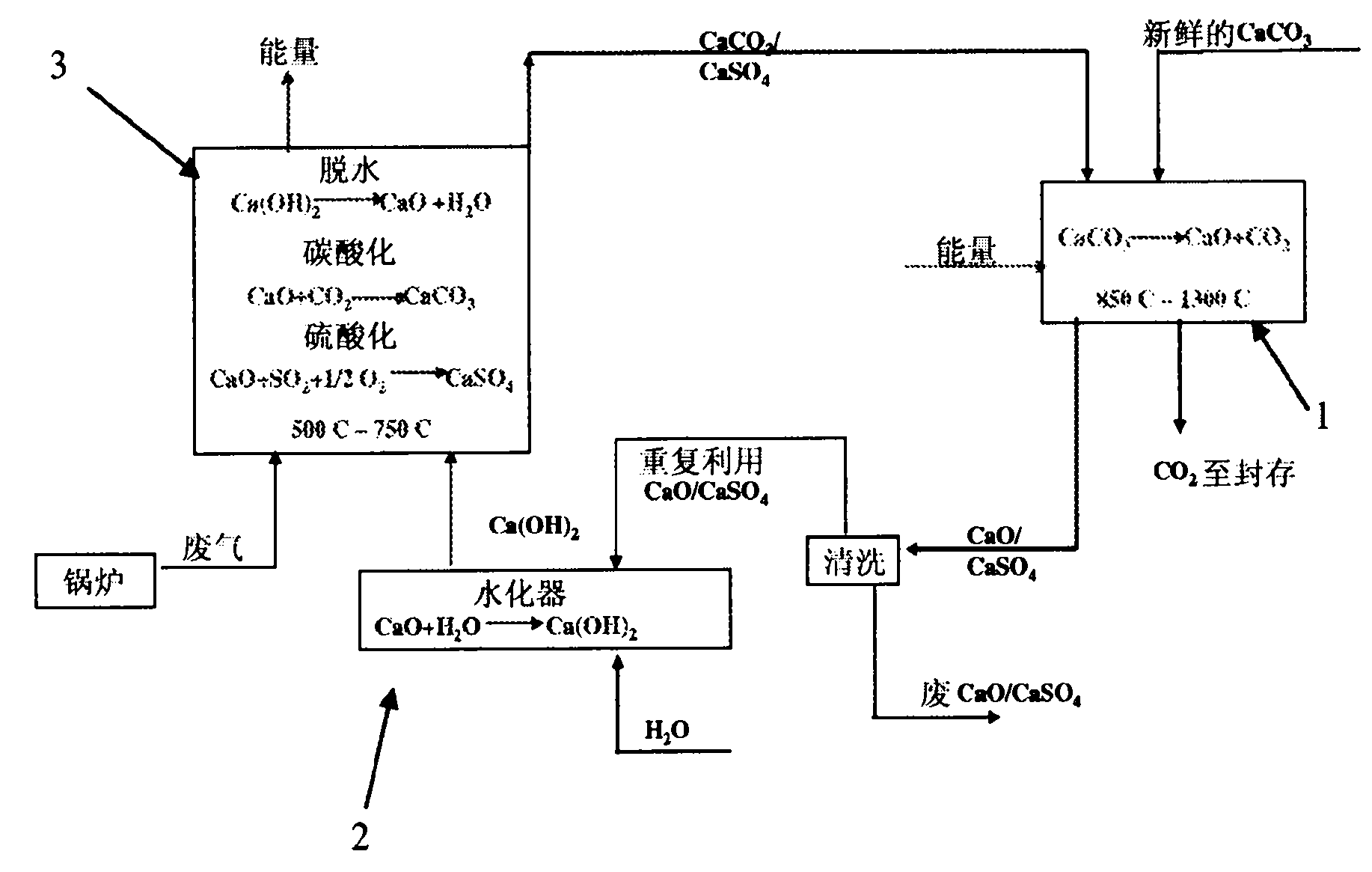

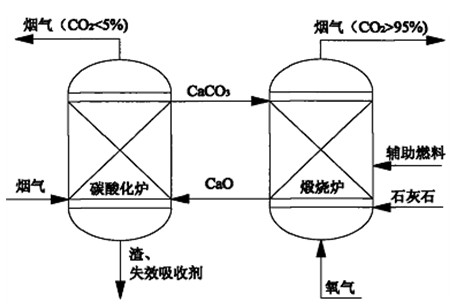

Method for catching carbon dioxide by pressurized fluidized bed combustion combined recycle generating system

InactiveCN101539037AReasonable realization of graded conversionRaise the inlet temperatureGas turbine plantsSteam engine plantsEngineeringCarbonatation

The invention relates to a method for catching carbon dioxide by a pressurized fluidized bed combustion combined recycle generating system, which is a method for catching the carbon dioxide by using CaO generated by calcining limestone or dolomite aiming at a gasification / semi-coking pressurized fluidized combustion combined recycle generating system of a coal pressurized part, coal enters into a pressurized fluidized bed gasification furnace using air as gasifying agent so as to be gasified to generate coal gas and semicoke, the coal gas is combusted after being purified to produce high-temperature fuel to enter a combustion turbine for applying work and generating electricity. Exhaust gas containing CO2 enters into a carbonatation furnace and a calciner double fluidized system, CO2 in the exhaust gas is catched by using circulation carbonatation / calcining reaction of CaO. Steam produced by a coal gas cooler and the double fluidized bed system enters into the turbine system for applying work and generating electricity, therefore, a fuel gas / steam combined recycle generating system catching CO2 is formed. The system has high generating efficiency and low energy consumption, and can realize near-zero exhaust of a plurality of pollutants of SO2, CO2 and the like.

Owner:SOUTHEAST UNIV

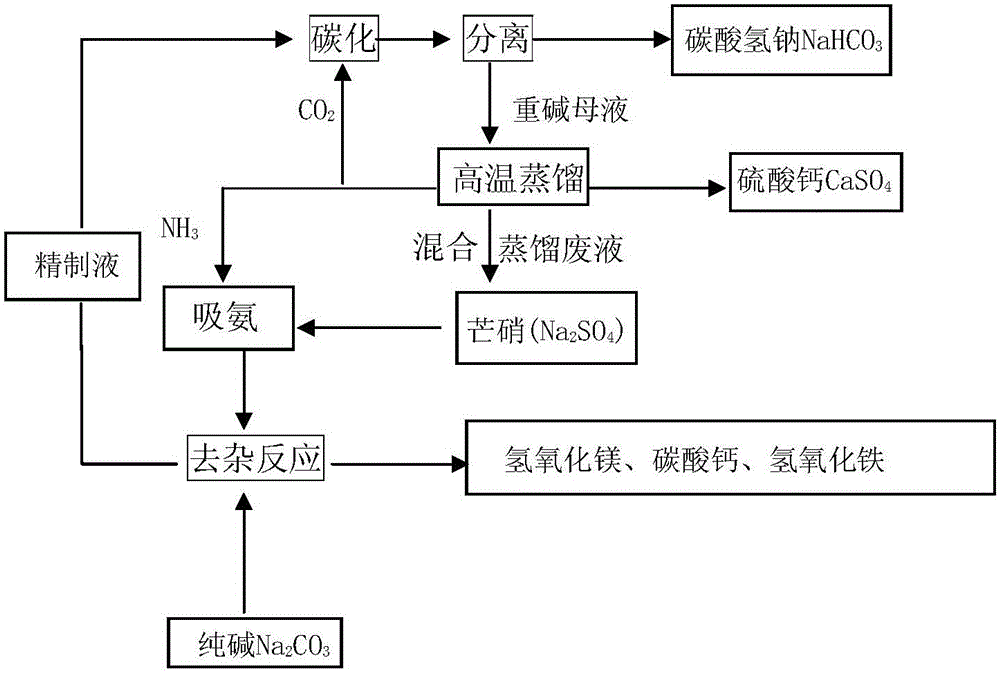

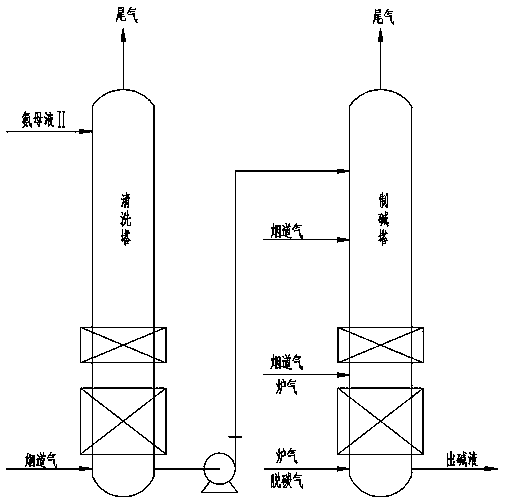

Technology for producing sodium bicarbonate from mirabilite

InactiveCN105712382AIncrease profitEmission reductionCalcium/strontium/barium sulfatesCarbonate preparationSodium bicarbonateDistillation

A technology for producing sodium bicarbonate from mirabilite comprises steps as follows: mirabilite and distillation waste liquor mixed liquor is used as a raw material, sodium carbonate is added to the solution after absorption of ammonia, magnesium, iron and calcium ions in the solution are removed after the solution is subjected to a precipitation reaction at 15-50 DEG C, and a refined solution is obtained; carbon dioxide is added to the refined solution for carbonatation, and sodium bicarbonate solids and heavy alkali mother liquor are obtained through separation after the refined solution is subjected to a replacement reaction at 15-50 DEG C; lime is added to the heavy alkali mother liquor, and ammonia gas, carbon dioxide, calcium sulfate and distillation waste liquor are obtained after distillation reaction at 15-120 DEG C; ammonia gas and carbon dioxide are recovered to ammonia absorption and carbonatation procedures respectively; the distillation waste liquor and mirabilite in Step A are mixed to be recycled. The technology has the characteristics that mirabilite is directly utilized, ammonia is recycled, the comprehensive utilization rate of distillation waste liquor waste is high, the production cost is low, the waste residue discharge is low, the technology is environment-friendly, and the like.

Owner:CHINA LIGHT IND INT ENG CO LTD

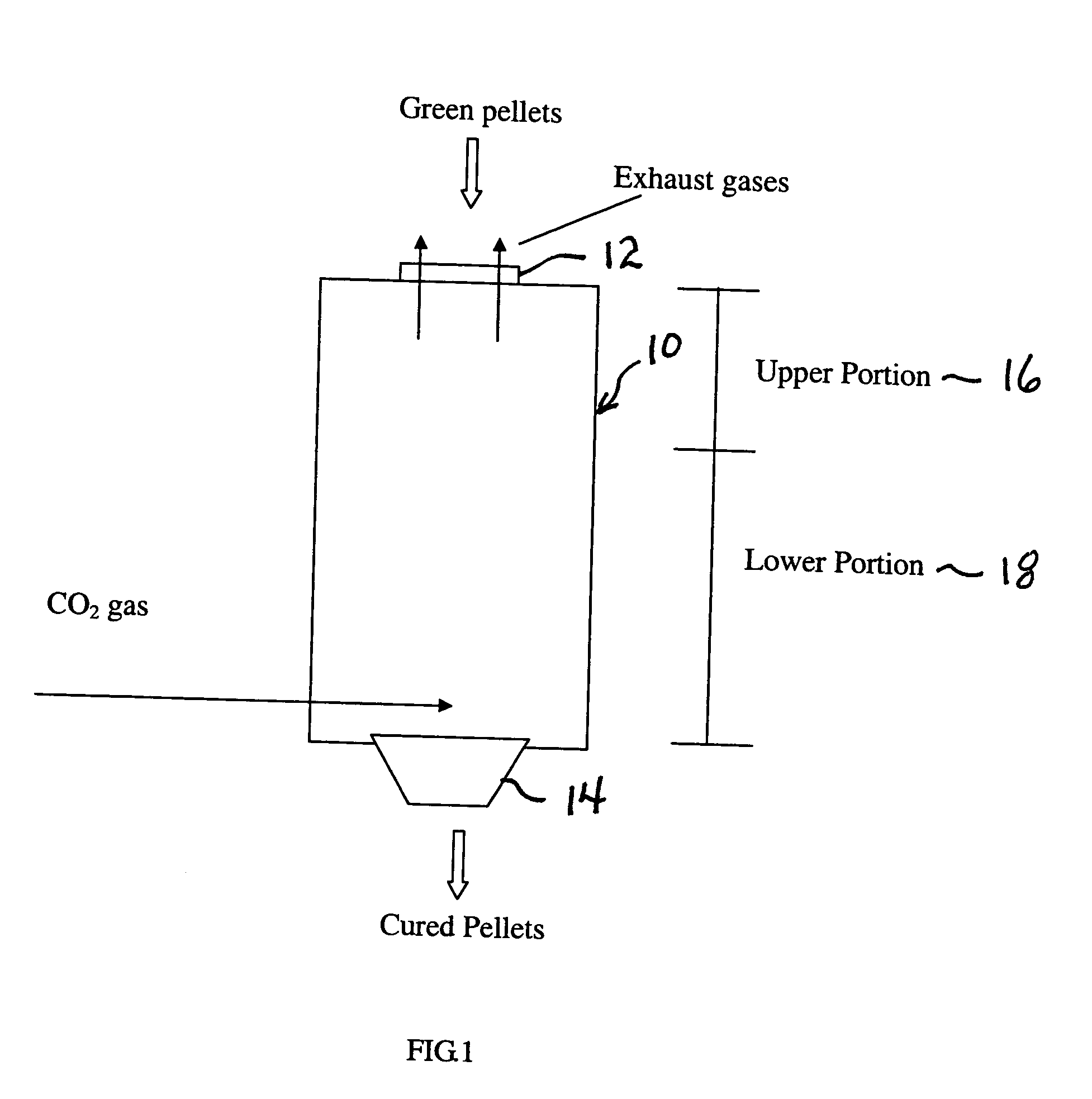

Self-reducing, cold-bonded pellets

ActiveUS20050061207A1Lower production costHigh flexibilityCeramic shaping apparatusCarbon dioxidePortland cement

Self-reducing, cold-bonded pellets and a method for their production for smelting a great variety of steels, including blast furnace iron-making, non-blast furnace iron-making, and all sorts of steelmaking in steel smelting furnaces, etc. The self-reducing, cold-bonded pellets comprise iron ore concentrate, carbonaceous reducing agent, and finely divided Portland cement clinker with special requirements as binder. The components are combined together to form a mixture. Pellets are produced when the mixture is placed into a balling disc or rotating drum and water is added. Pellets with predetermined size normally ranging from about 8-16 mm are obtained by using roller screens. The pellets are then continuously placed into a curing device. Inside the curing device, the pellets will then be hydrated and carbonated by using hot gases containing carbon dioxide with a temperature range of about 100-300° C. Thereafter, after drying, the dried pellets are discharged from the curing device and will be ready for use.

Owner:HANQING LIU

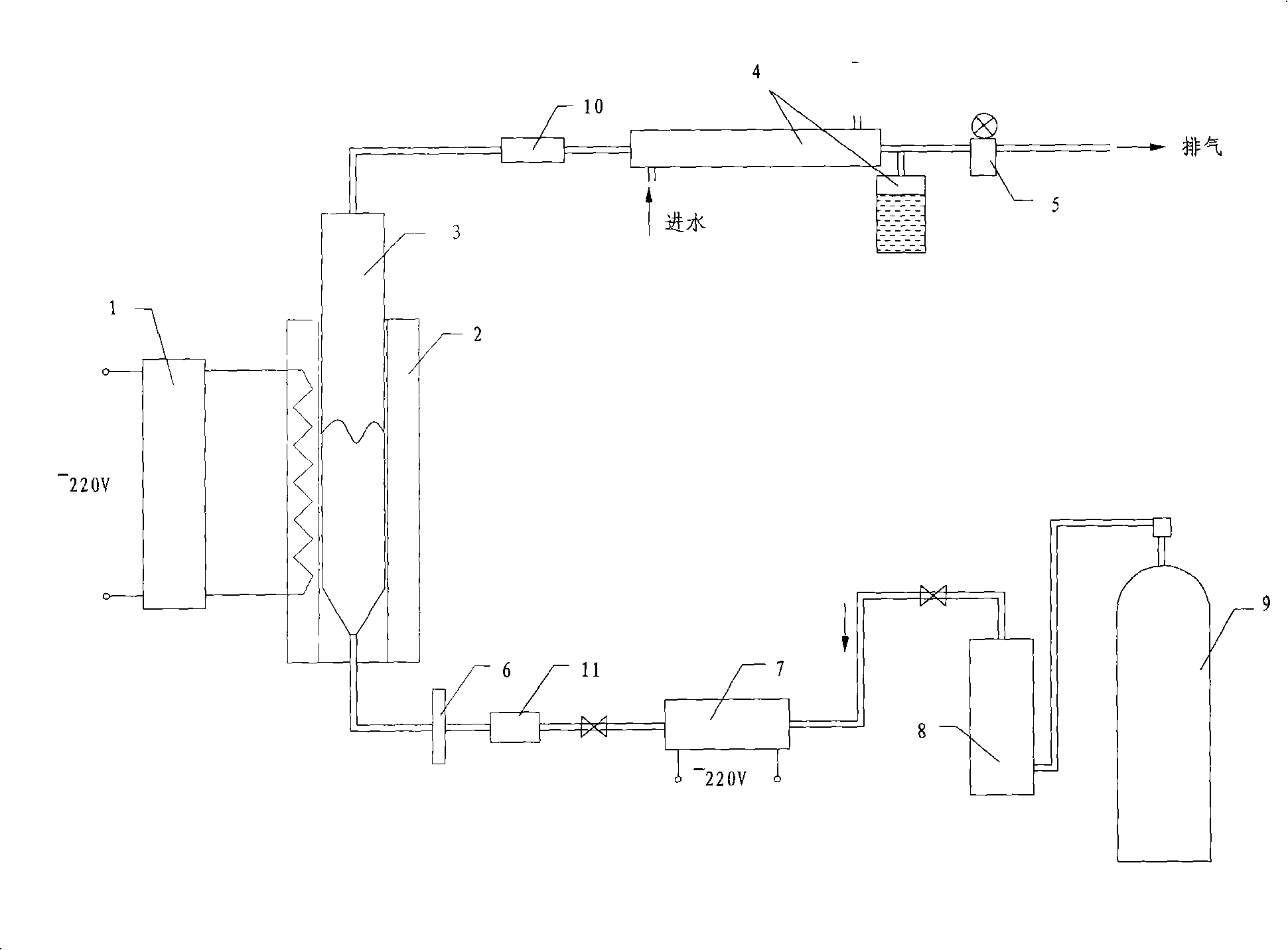

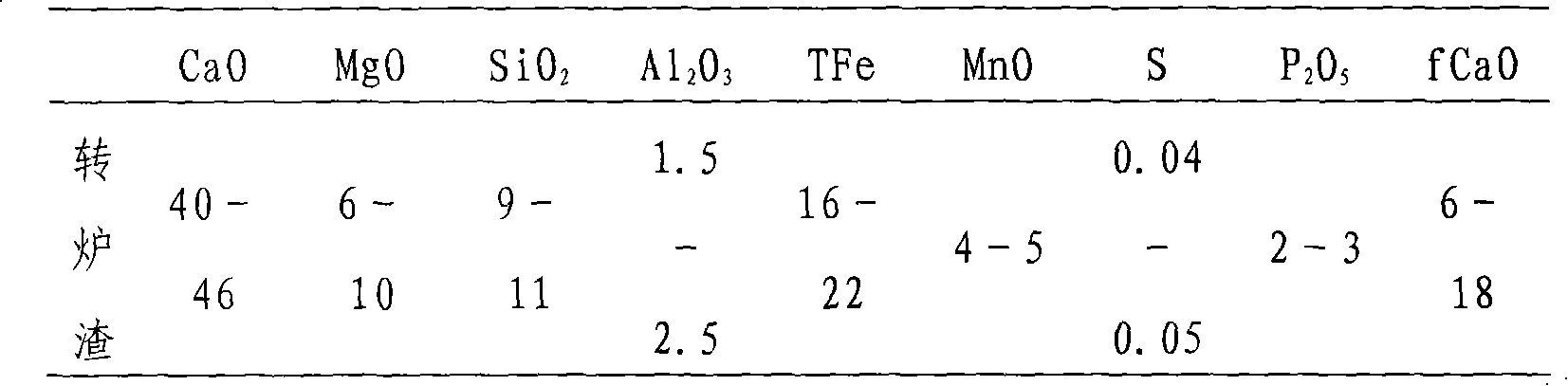

Carbonatation processing method of steel scoria

The present invention provides a method of carbonatation treatment for steel slag, and comprises the steps: in a boiling-bed reactor, under the temperature of 350 to 800 DEG C and the pressure atmosphere 0.1 to 3.6 and under the condition of 5 to 25 percent of the vapor, the steel slag with the particle diameter being less than or equal to 15 mm reacts with the carbon dioxide for two to twelve hours. The present invention adopts the one-step carbonization in the boiling bed to substitute the conventional reactions with a hydration step and then a carbonization step, thus greatly shortening the carbonization time of the steel slag; the industrial waste gas and the stack gas (the valid compositions are carbon dioxide, and containing certain vapor when the temperature of the gas is more than 100 degrees centigrade) are used as the gas source, which reduces the exhaustion of the greenhouse gas carbon dioxide and adequately uses the surplus heat, while completing the carbonization of the steel slag; moreover, the operation is flexible and convenient, and the carbonization degree of the steel slag can be controlled according to the requirements of different application areas of the steel slag.

Owner:BAOSHAN IRON & STEEL CO LTD

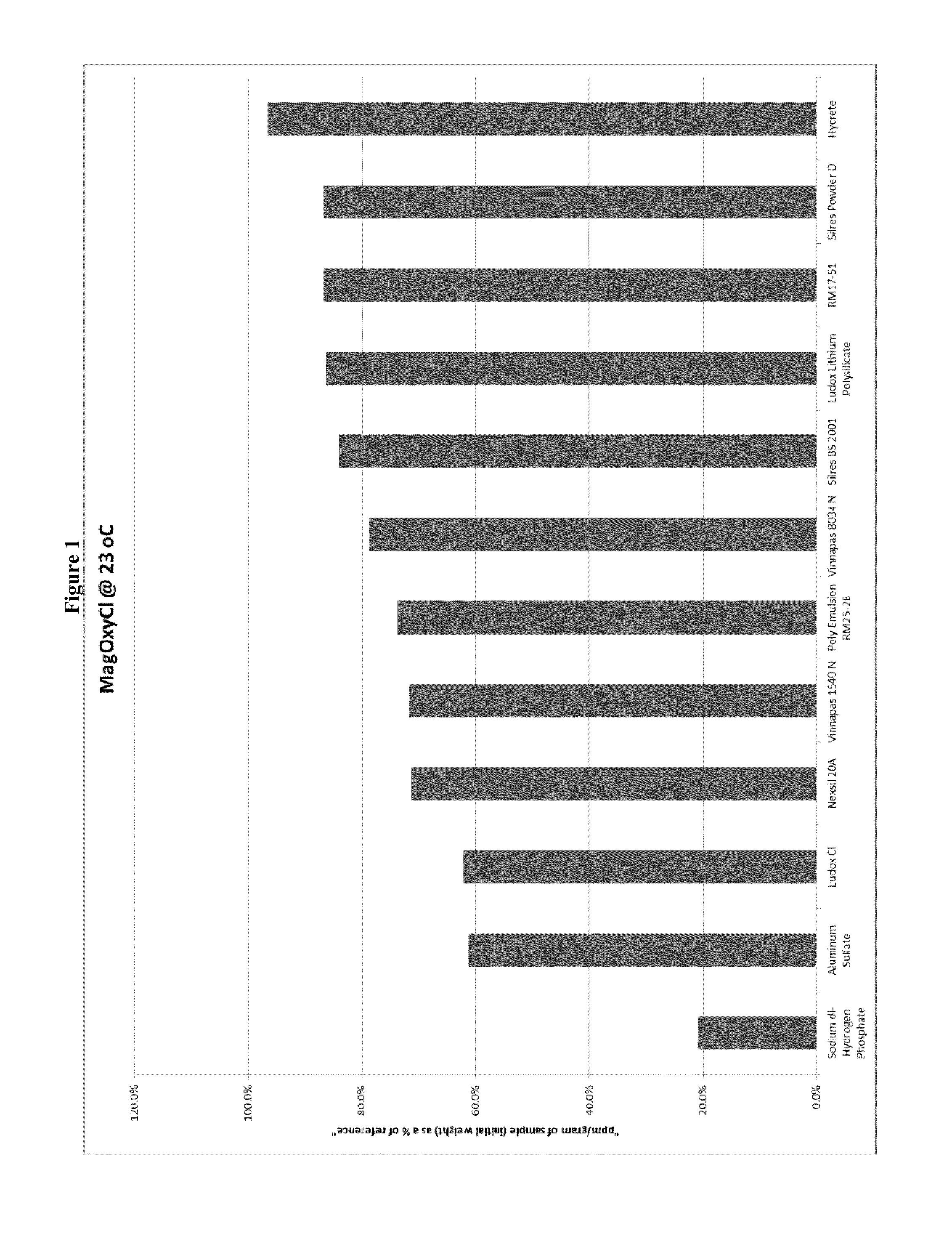

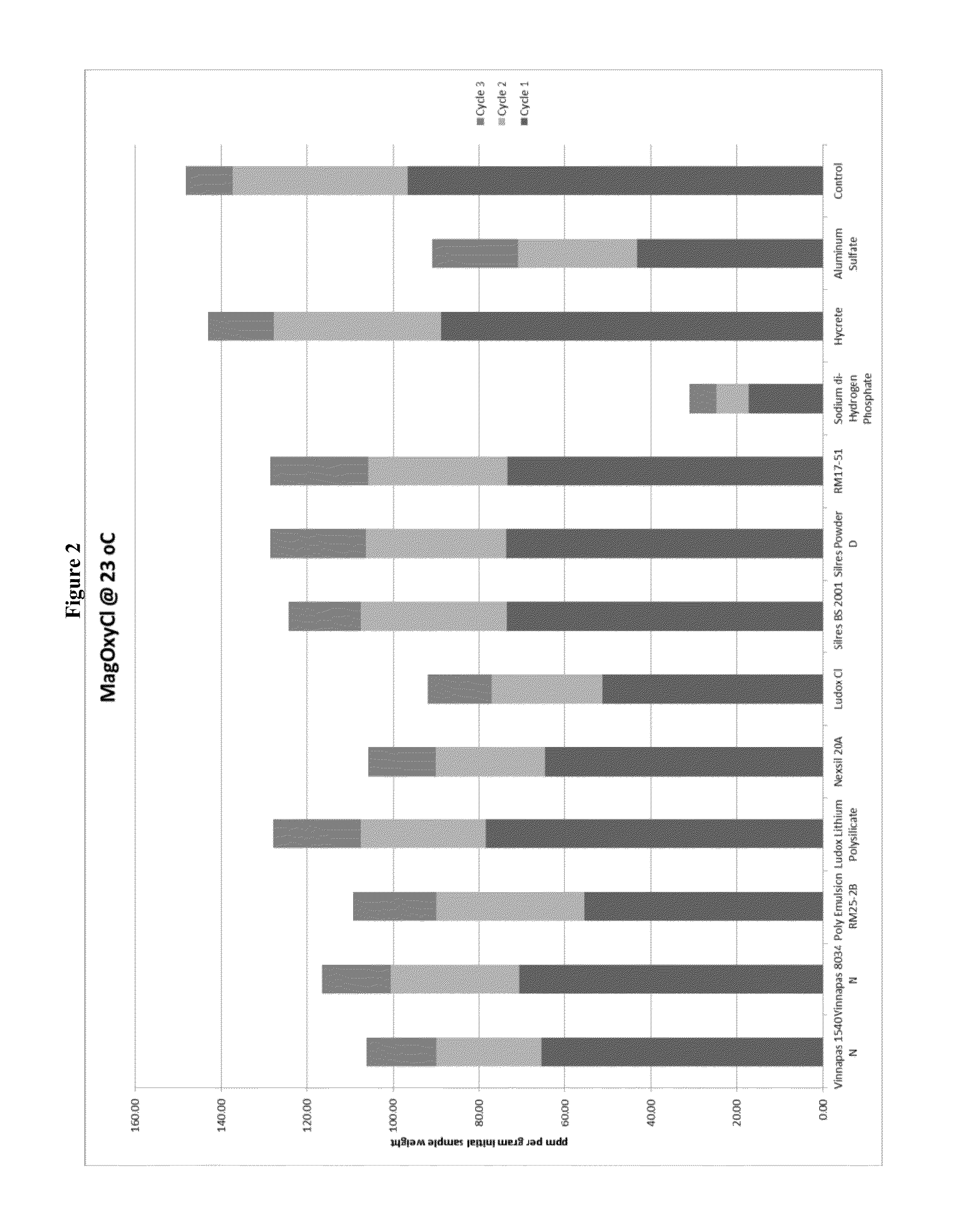

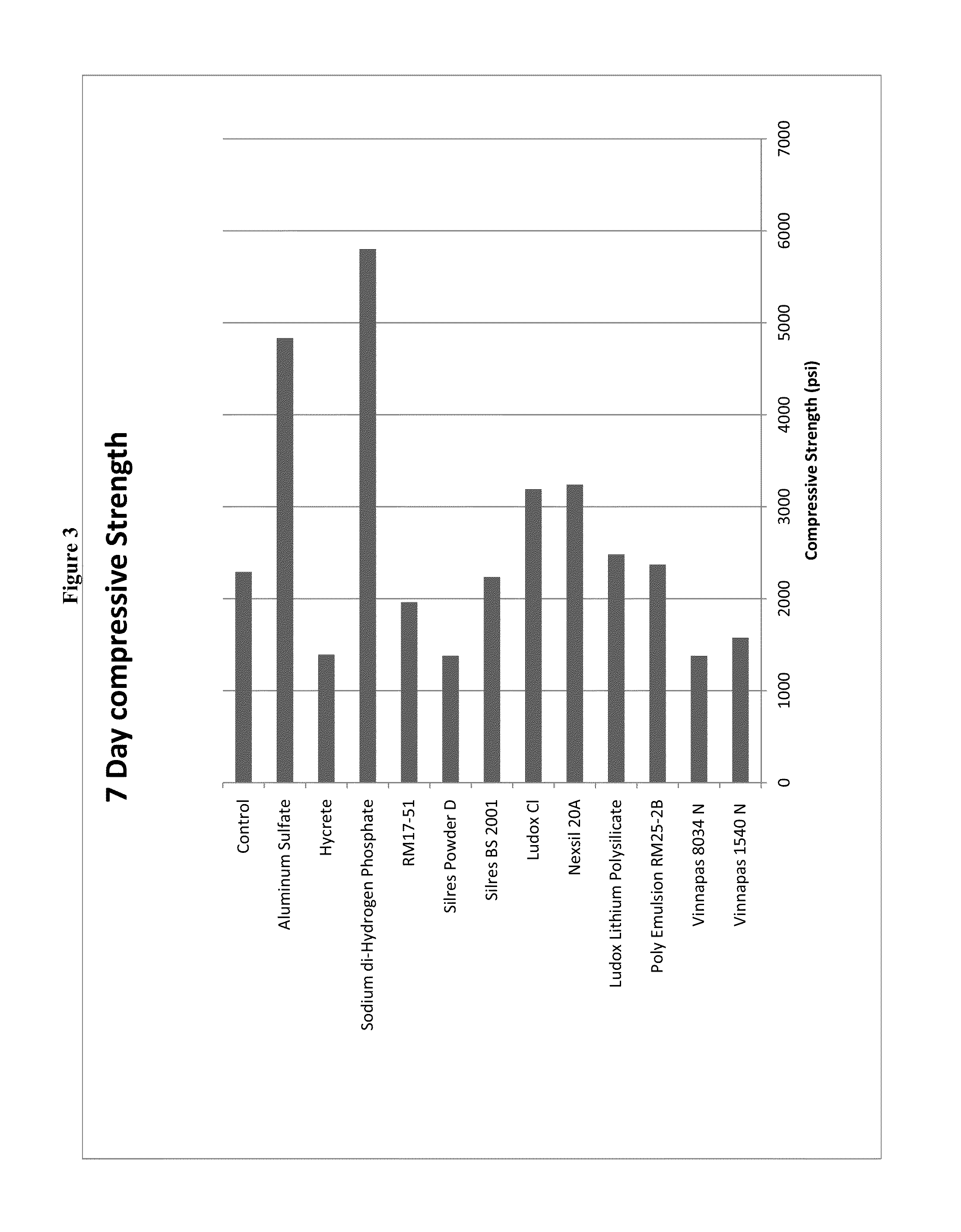

Method and compositions for improving performance properties of magnesium oxychloride cements

ActiveUS20130263759A1Improve water resistanceEarly water resistanceSolid waste managementMonomagnesium phosphatePhosphate

Despite the excellent properties associated with Magnesium OxyChloride (Sorel) based cements and Magnesium OxySulfate based cements, water and corrosion resistance has been limiting factors for achieving greater commercial applications. Such issues can be addressed by incorporating various alkali metal phosphates, such as Magnesium mono- or dihydrogen phosphate (MgHPO4 or MgH2PO4) with alkali metal fatty acids; such as Magnesium Stearate; and metal or alkali metal sulfates such as Aluminum Sulfate or Magnesium Sulfate. Water resistance is further enhanced by either pre-carbonating the mix water or the liquid magnesium chloride phase of the cements, or by adding a carbonate into the powder phase. Accelerated cure of this system has also been obtained by using various inorganic metal oxides. Additionally, improved corrosion resistance is achieved through the use of certain phosphates, zeolites, nitrites and other novel additives.

Owner:PREMIER MAGNESIA

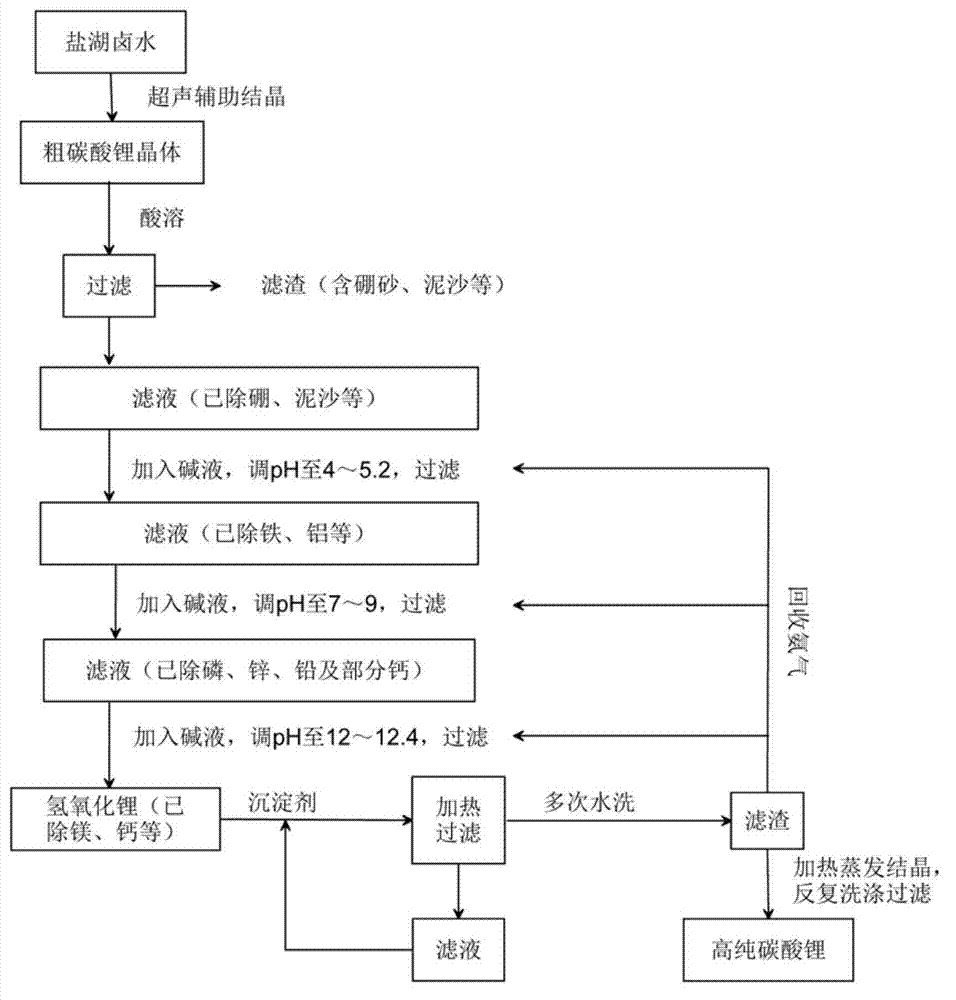

Method for preparing high-purity lithium carbonate from salt lake brine

ActiveCN102963914AHigh recovery rateReduce manufacturing costLithium carbonates/bicarbonatesLithium carbonateEnvironmental engineering

The invention discloses a method for preparing high-purity lithium carbonate from salt lake brine. The method comprises the following basic processes in sequence: concentrating the salt lake brine to quickly separate crude lithium carbonate; gradually alkalizing at different grades; precisely controlling the precipitating point; and carbonating to obtain high-purity lithium carbonate, wherein if the metal ion is completely precipitated, the prepared lithium carbonate has the purity up to 99.9% and can be directly applied to the production of lithium batteries; and the recovery rate of Li<+> is also up to about 80%. The method is simple in technology and process, lower in cost, and easy for industrial production; few chemical agents are used in the technology; especially, new metal ion impurity cannot be introduced while ammonia water serves as the alkali liquor; and the technological process is carried out in closed loop, so that ammonia exhausted in firing can be immediately recovered and then returned to the production line to be continuously utilized, except for the precipitated slag, and substances are not discharged to the outside any more, and as a result, no disadvantage influence is brought to the outside environment.

Owner:TIBET JINHAO INVESTMENT +1

Method for clean production of titanium dioxide by using sodium hydroxide

ActiveCN101172648AObvious superiorityLow reaction temperaturePigmenting treatmentTitanium dioxideSeparation technologyTitanium nitride

The invention belongs to the preparation of inorganic metallic compound and the processing filed of mineral resource, in particular to a preparation method for titanium dioxide (titanium pigment) through high titanium slag and sodium hydroxide without pollution. The invention is characterized in that the high titanium slag is taken as the raw material; the high titanium slag and the sodium hydroxide having temperature range from 350 DEG C to 550DEG C are reacted to prepare a medium product; the medium product is then washed through water(or carbonatation), acid solubled, reduced, hydrolyzed and burned to prepare anatase or rutile titanium dioxide. The alkali circulation, the acid circulation and the separation technology of the invention greatly reduce the production energy consumption, simplify the production process, reduce the device investment, and increase the technology maneuverability, thereby providing an effective method for the comprehensive use of titanium resource and the preparation of titanium dioxide(titanium pigment).

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

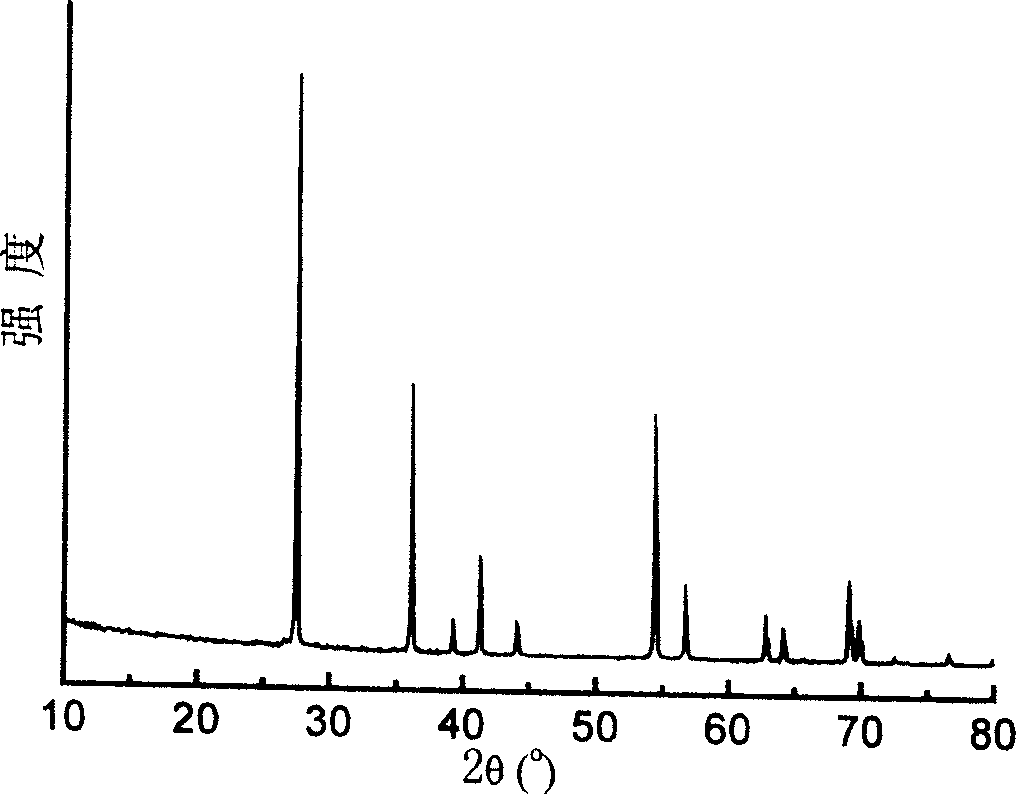

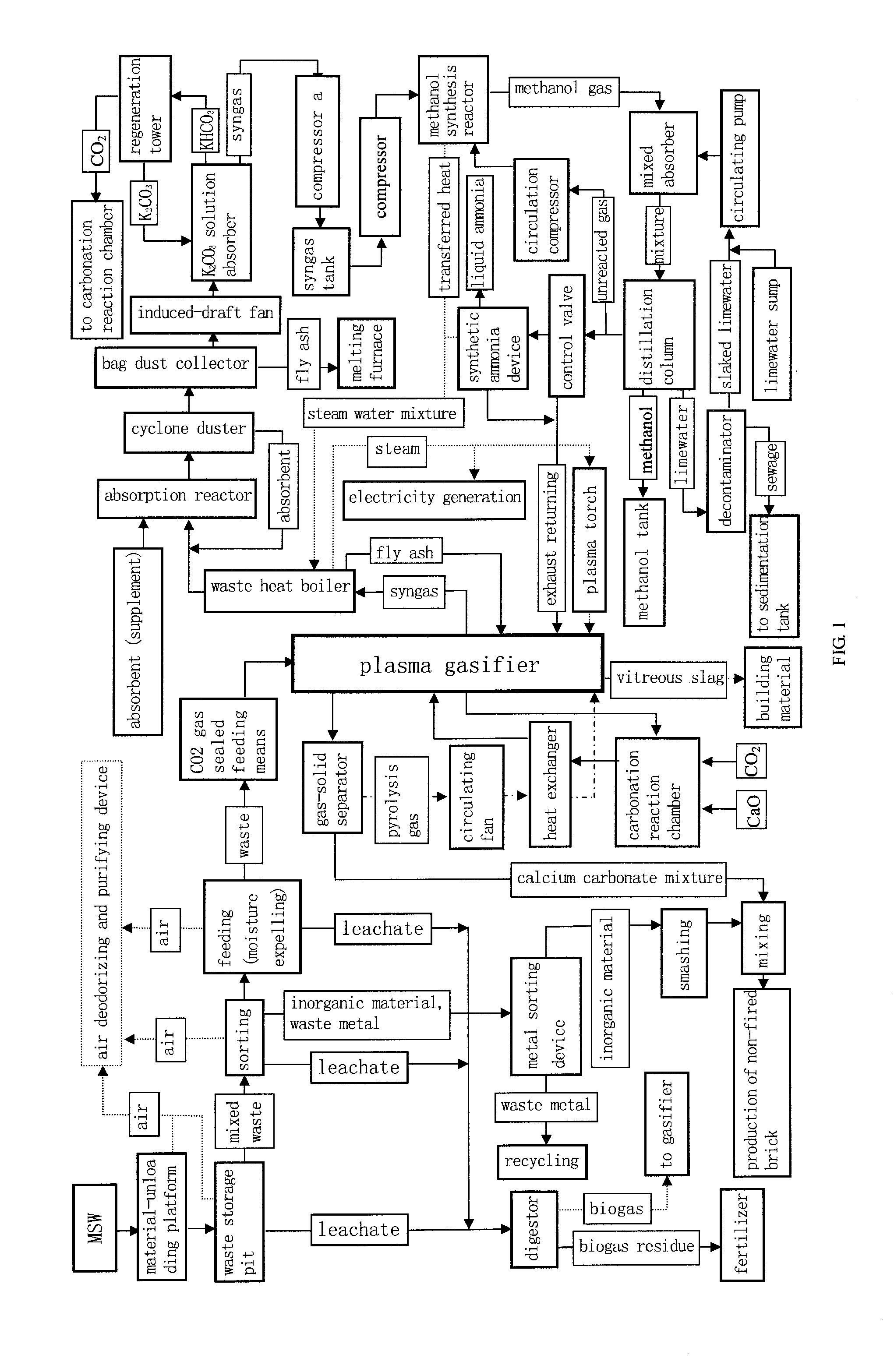

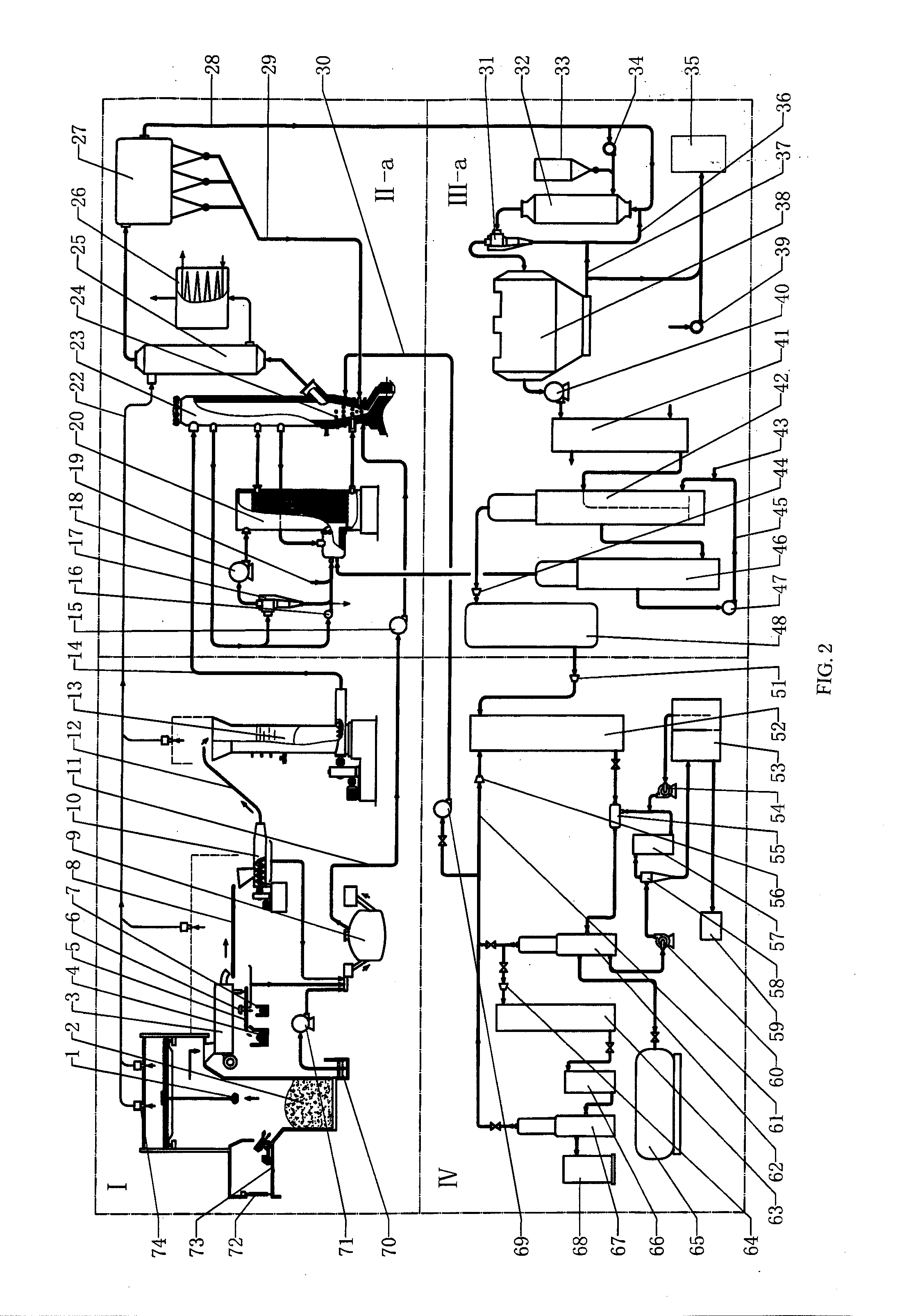

Method, system and equipment for gasification-liquefaction disposal of municipal solid waste

InactiveUS20130012605A1Zero emissionAvoid dioxin contaminationBio-organic fraction processingPreparation by oxidation reactionsHeat energyCarbonatation

A gasification-liquefaction disposal method, system and equipment for MSW are disclosed. The method involves the MSW pretreatment of dehydrating and separating, thus reducing water and inorganic substance content of the waste. Then, the MSW is introduced into a plasma gasifier (23) by a carbon dioxide air-sealed feeding device (13) and gasified therein to obtain hydrogen-rich syngas. The hydrogen-rich syngas is then cooled, deacidified, dedusted and separated to obtain carbon dioxide. Then, the hydrogen-rich syngas is catalyzed to produce methanol product in a methanol synthesis reactor (52). The separated carbon dioxide is sent back to a carbonation reaction chamber (2007) of a gasification system to perform carbonation reaction with calcium oxide, thereby releasing heat to provide assistant heat energy for gasification and avoiding greenhouse gas from being discharged into environment. Exhaust gas is returned to the plasma gasifier (23) for remelting treatment, thus forming a closed-loop circulation production system and realizing the disposal of the MSW with zero discharge and no pollution, thereby avoiding dioxin pollution and converting the MSW to chemical raw materials and fuel needed by mankind The method, system and equipment are suitable for harmless and recycling disposal of MSW, industrial high polymer waste, composting waste and waste in waste sorting sites.

Owner:QUZHOU CITY GUANGYUAN DOMESTIC GARBAGE LIQUEFY TECH INST

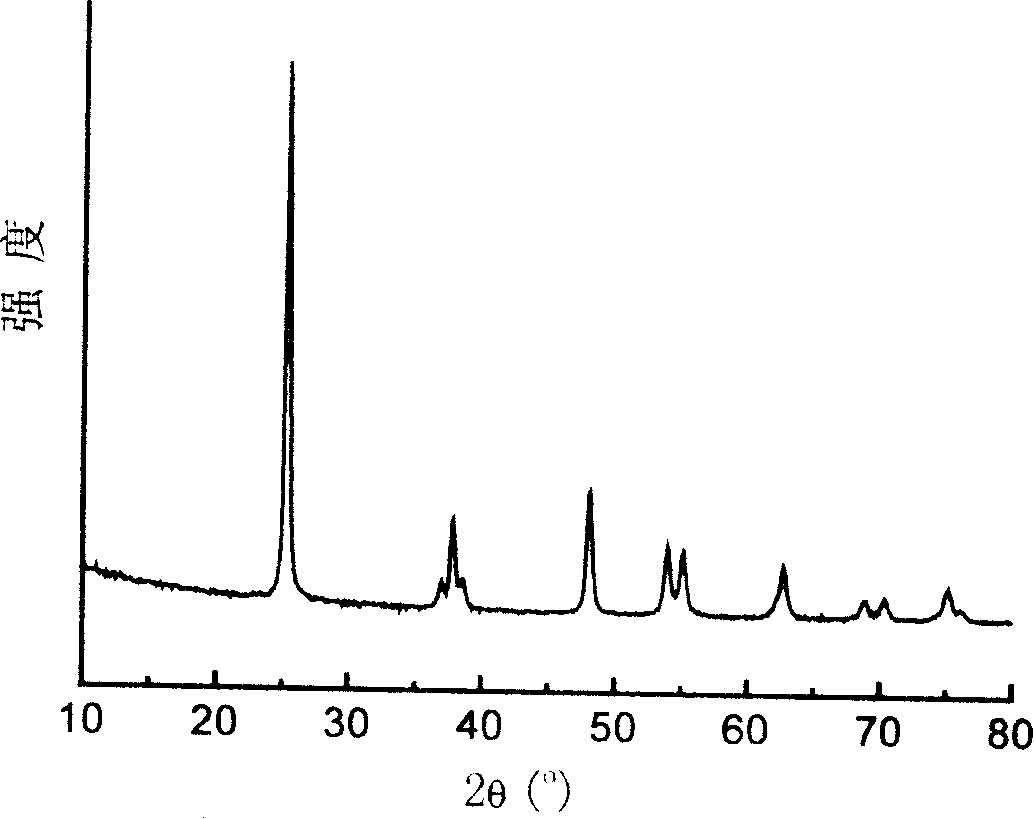

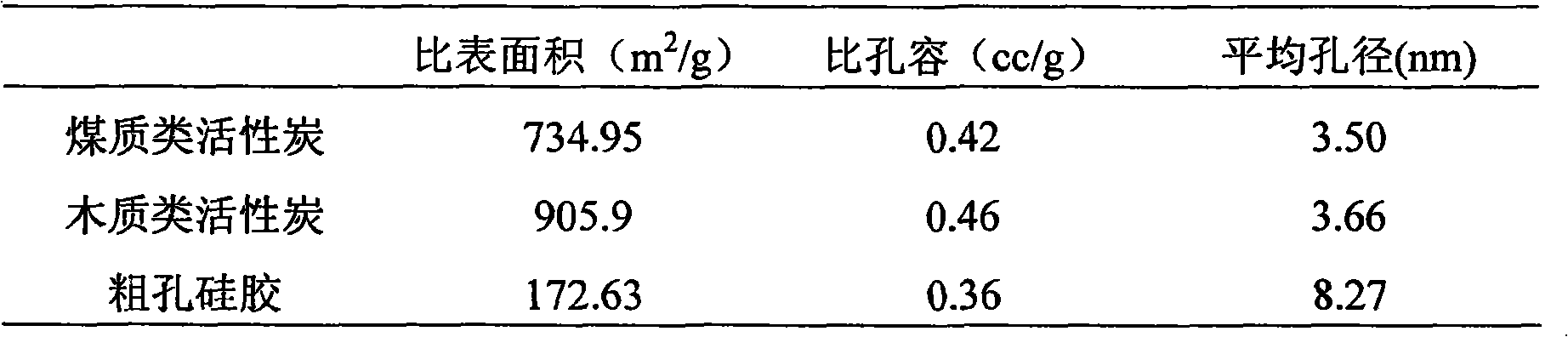

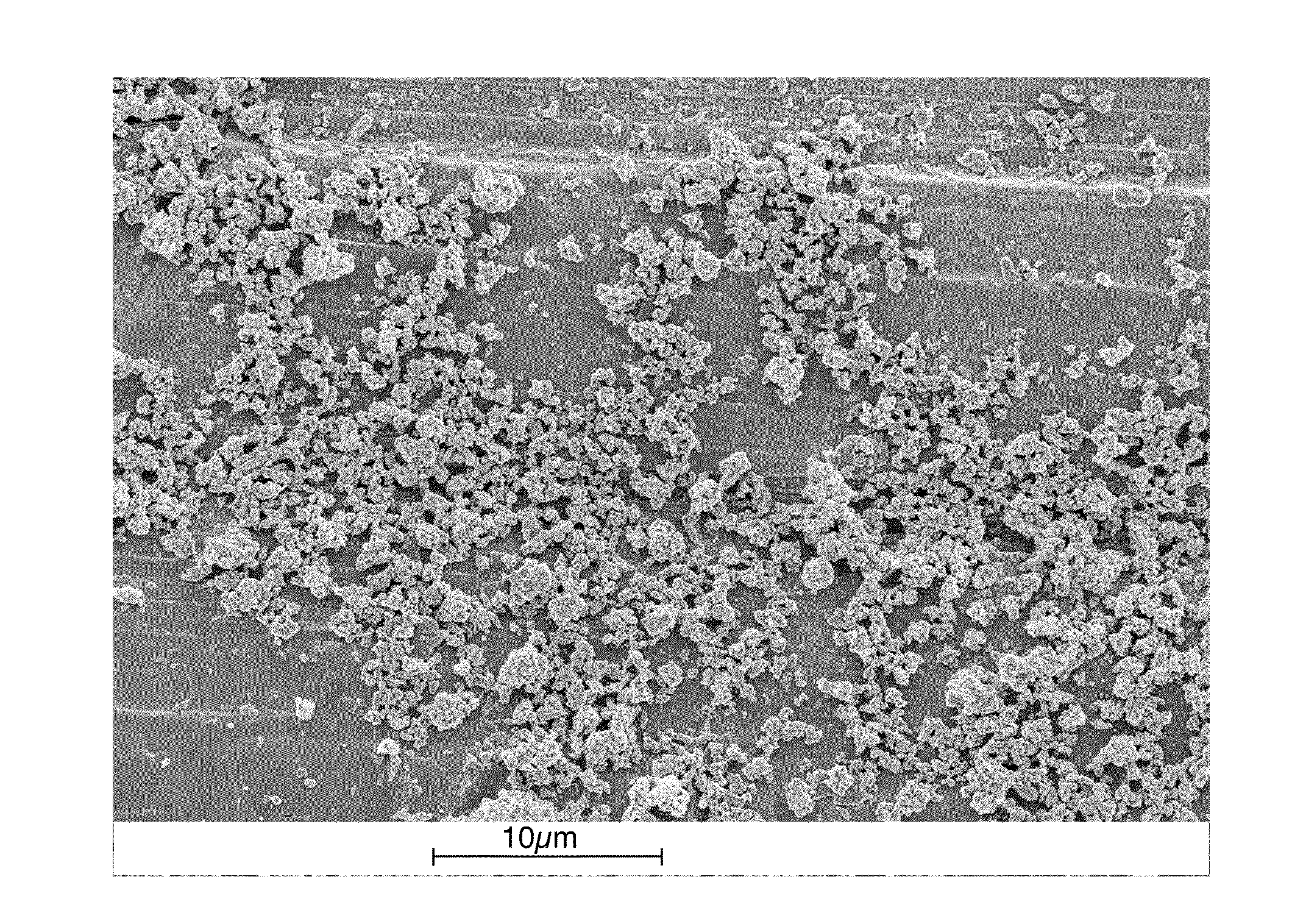

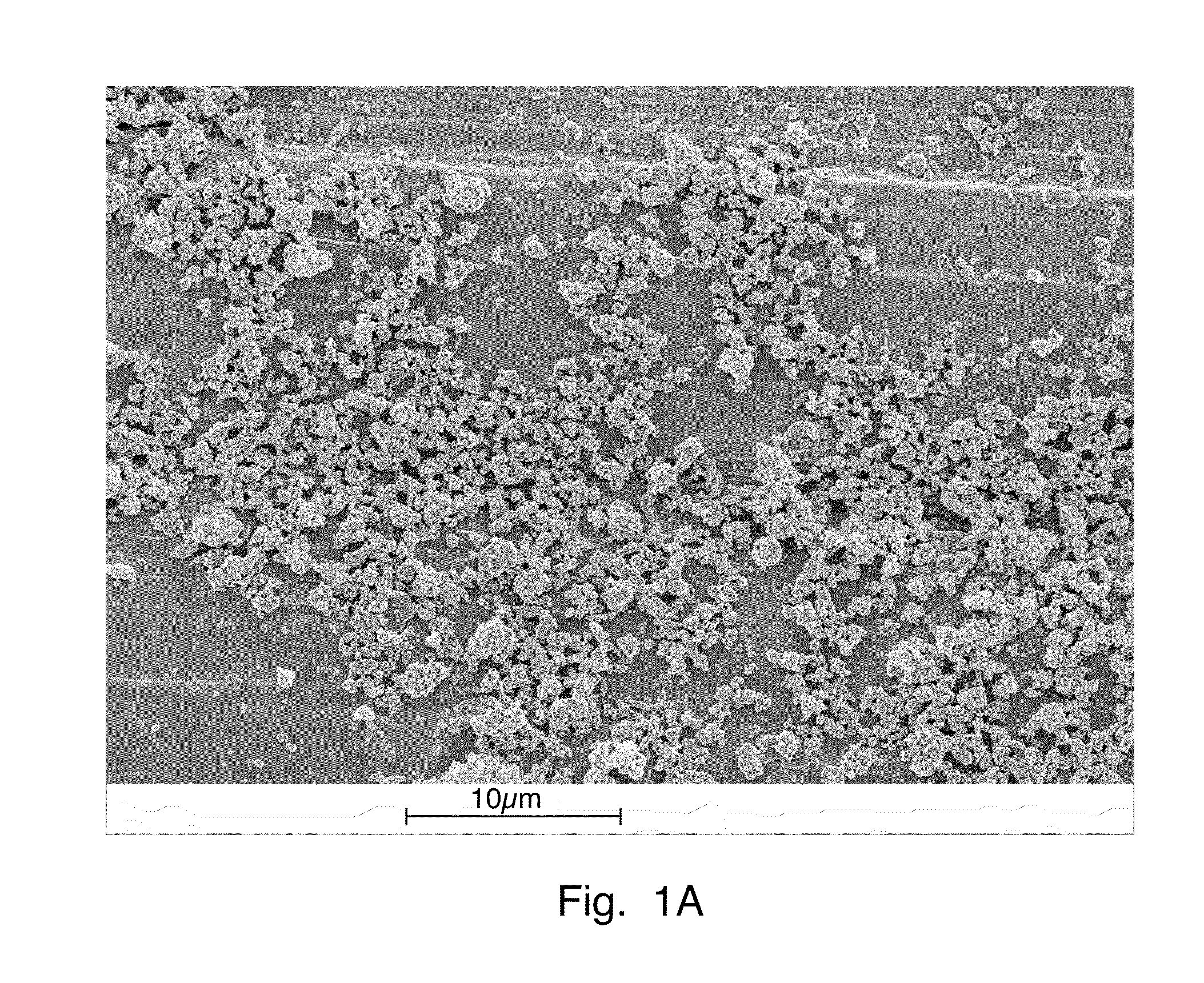

High-activity kalium group solid absorbing agent for removing CO2 in flue gas and preparation method thereof

InactiveCN101269316AIncrease reaction rateImprove conversion rateOther chemical processesDispersed particle separationHexagonal crystal systemPotassium

The invention provides a highly active potassium base solid absorbent for CO2 in the process of removing flue gas and a preparation method thereof. The solid absorbent takes hexagonal crystal system potassium carbonate as the active component, coal activated carbon or wood activated carbon or silochrom as a carrier; and the solid absorbent is made by a method of impregnation. The materials required by the absorbent is chemical medicine and carrier which are cheap and easy to be obtained; the preparation of the absorbent has simple process and low cost, the carbonatation temperature ranges from 60 DEG C to 80 DEG C, while the regeneration temperature ranges from 100 DEG C to 200 DEG C, and the absorbent belongs to a low-temperature absorbent. Under the temperature, the absorbent is not easy to lose activity, and can maintain a higher transformation ratio after multiple circulations. The highly active potassium base solid absorbent for CO2 in the process of removing flue gas and the preparation method provide a key technology for the application of the technique about removing the CO2 by a dry method for an alkali metal base absorbent and has a wide application prospect.

Owner:SOUTHEAST UNIV

Pigment particle composition, its method of manufacture and its use

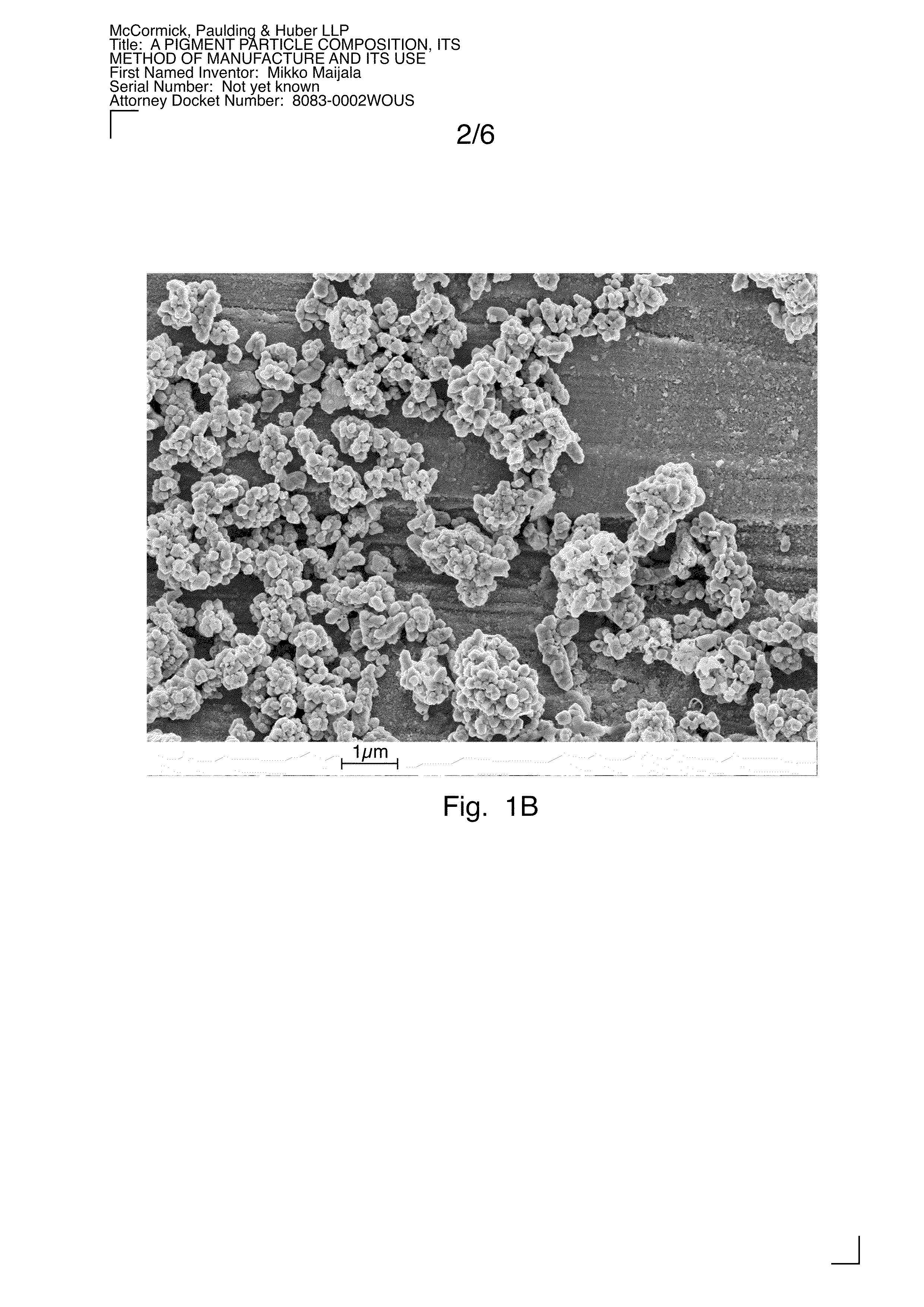

ActiveUS20110011305A1Retention quality is often poorLarge particle sizeCalcium/strontium/barium carbonatesMaterial nanotechnologyCalcium hydroxideSlurry

A pigment particle composition which comprises calcium carbonate particles and pigment particles, its method of manufacture and its use. According to the present invention, the calcium carbonate particles are carbonated so that they bind to each other, in which case calcium carbonate structures are generated, which comprise pigment particles and which form essentially opaque and stable pigment-calcium carbonate aggregates. It is possible to manufacture the composition by atomizing calcium hydroxide-bearing pigment slurry into a carbon dioxide-bearing gas, in which case the calcium hydroxide is carbonated in order to precipitate the calcium hydroxide particles to be attached to each other and the carbonation is continued until essentially all of the calcium hydroxide has been converted into calcium carbonate. The composition is suitable for use, among others, in paints, coating materials, fillers, polymers and printing inks.

Owner:FP PIGMENTS

Method for preparing lithium carbonate and ternary precursor by recycling waste ternary lithium battery

ActiveCN112374511ACannot be recycled effectivelyImprove leaching rateWaste accumulators reclaimingNickel compoundsMetallic lithiumManganese

The invention discloses a method for preparing lithium carbonate and a ternary precursor by recycling a waste ternary lithium battery, and belongs to the field of solid waste recycling. Graphite and abinder carried in black powder obtained after pretreatment of a waste ternary battery are adopted as reducing agents, and the structure of the ternary material is destroyed through self-reduction phase inversion; lithium carbonate is converted into lithium bicarbonate which is easy to leach with water by adopting a carbonation water leaching method, so as to realize the preferential leaching of lithium; and sulfuric acid leaching is directly performed on the material subjected to lithium extraction without adding a reducing agent to obtain a nickel-cobalt-manganese solution. Copper, iron, calcium and other impurities in the solution are deeply removed through an impurity removal procedure, the content of aluminum and magnesium in the solution is controlled, then nickel, cobalt and manganese in the solution are extracted into an organic phase through synchronous extraction, a nickel sulfate solution, a cobalt sulfate solution and a manganese sulfate solution are obtained after reverseextraction is conducted through sulfuric acid, and a high-quality ternary positive electrode material precursor can be prepared after the metal proportion is adjusted. The method provided by the invention has the advantages of high recovery rate of valuable metals including lithium, nickel, cobalt and manganese, short flow, good product quality, economy and environment-friendliness.

Owner:UNIV OF SCI & TECH BEIJING

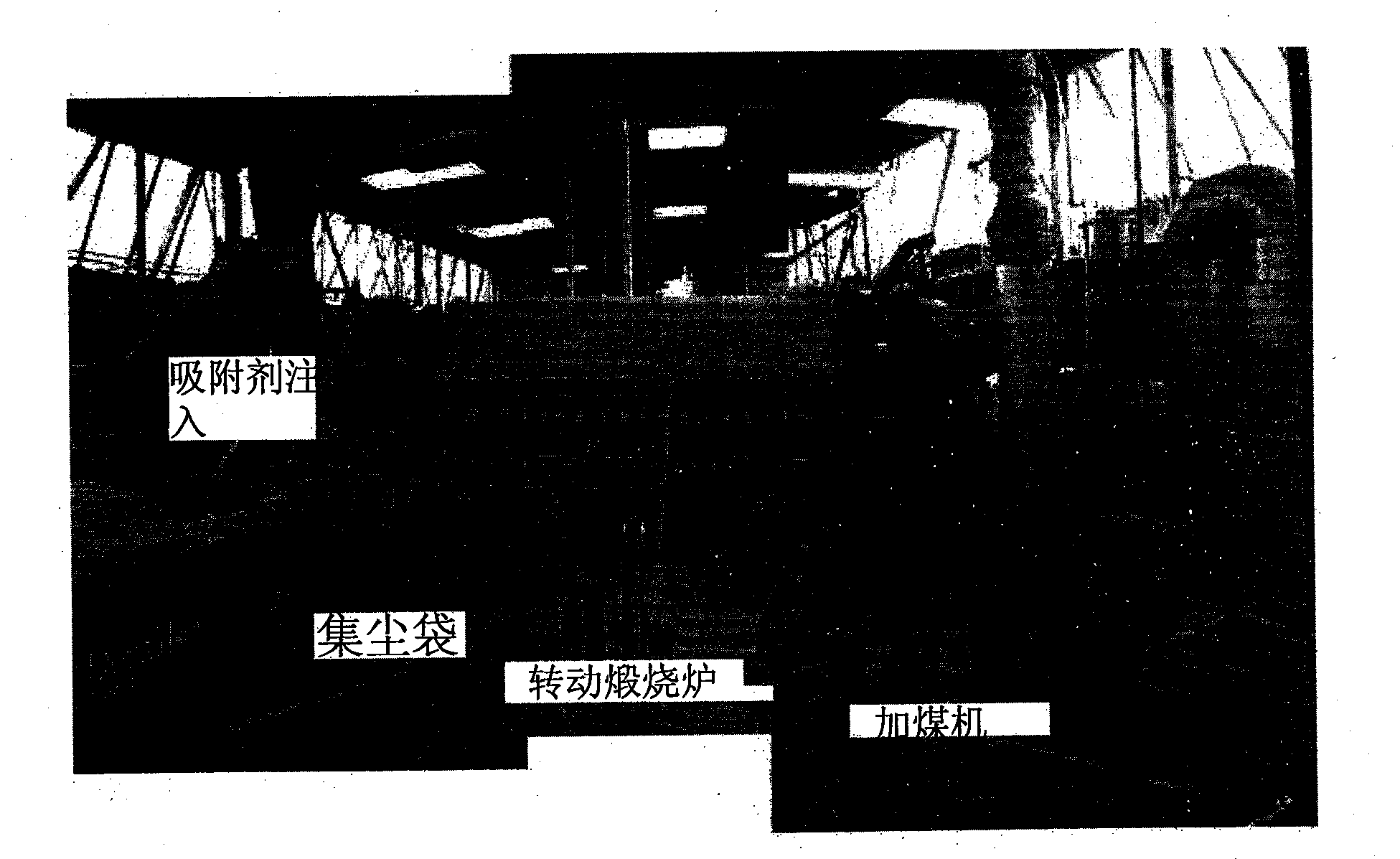

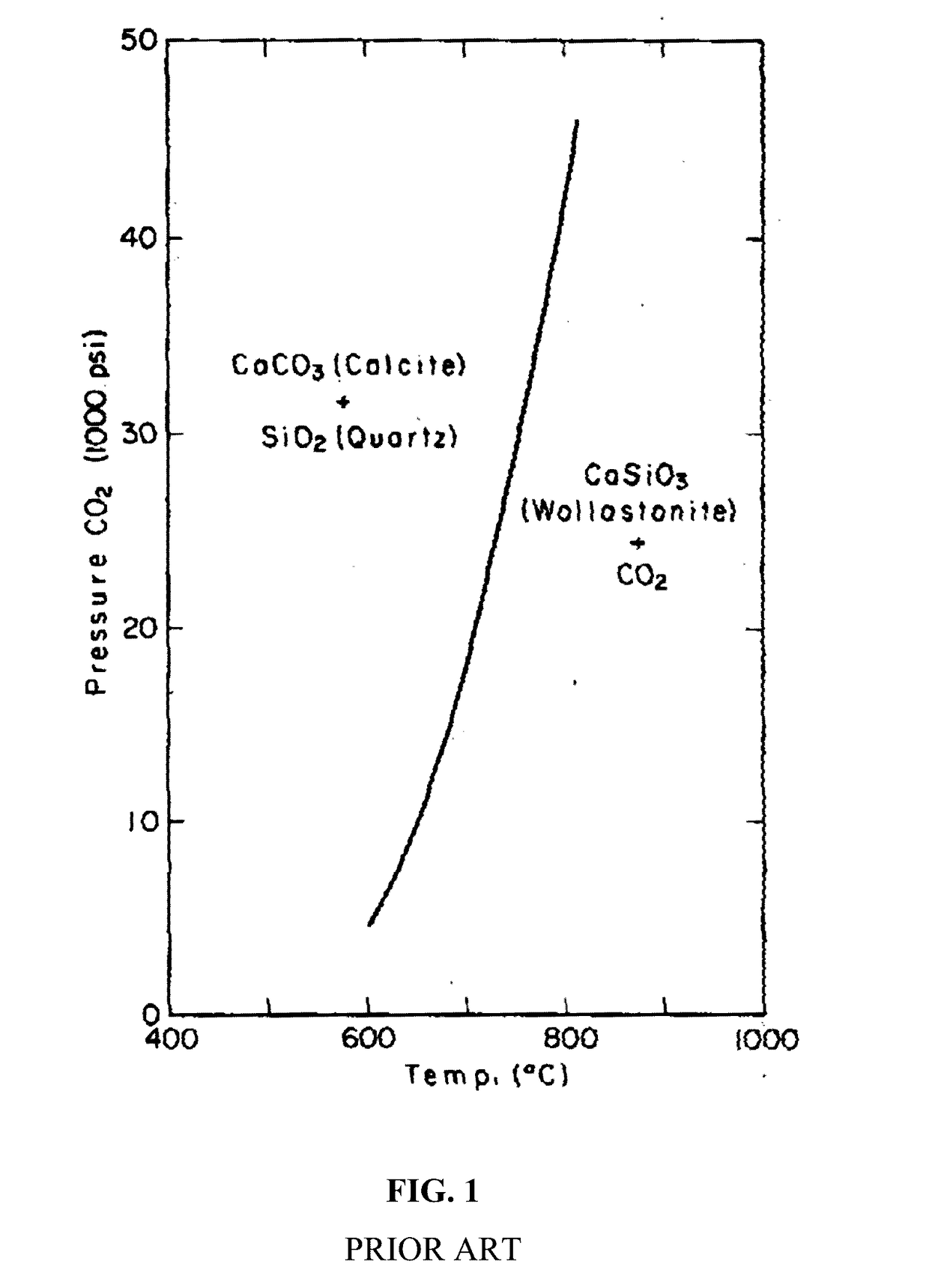

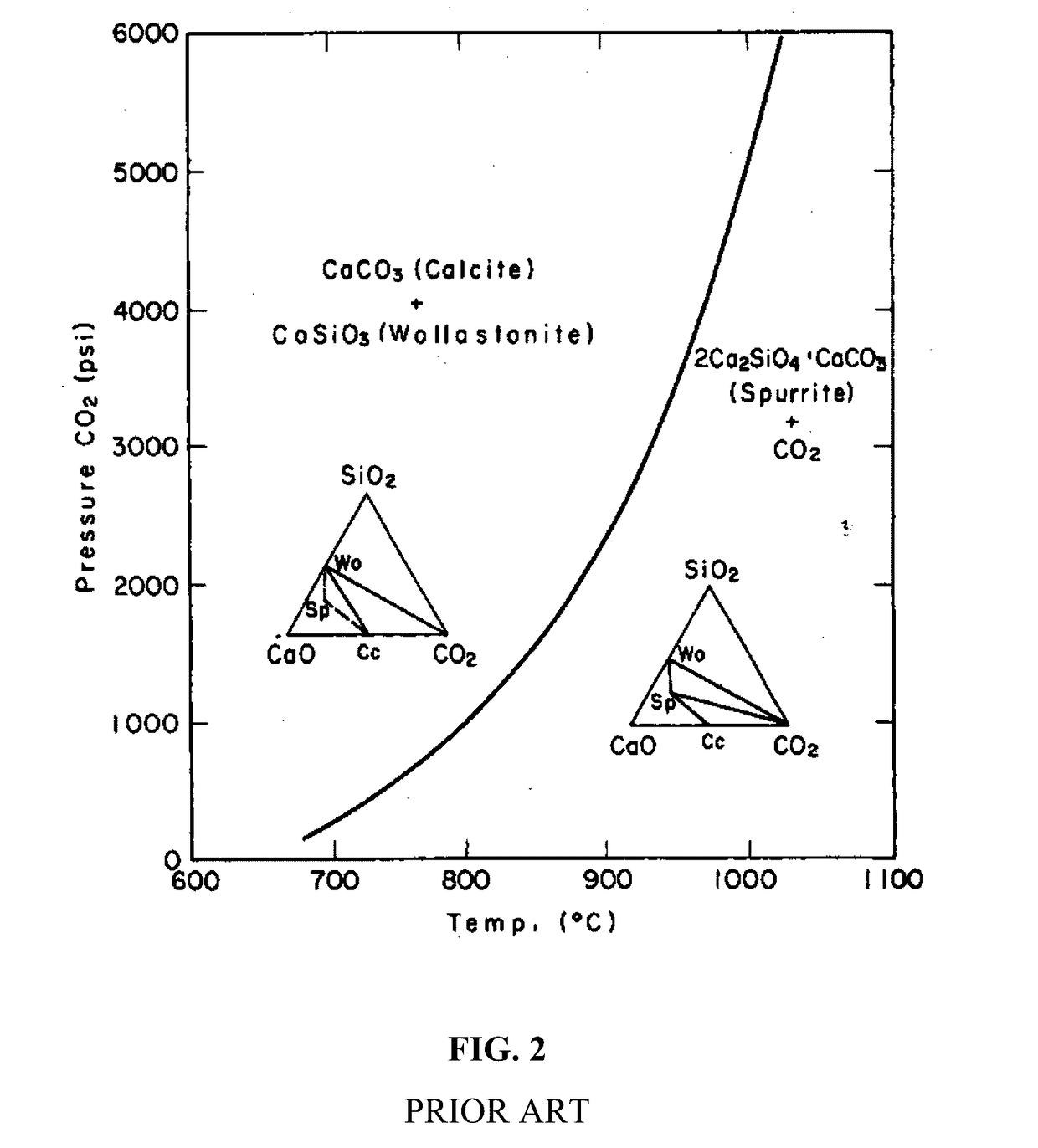

Carbonation calcination reaction process for CO2 capture using a highly regenerable sorbent

A process for the efficient capture of CO2 and sulfur from combustion flue gas streams and gasification based fuel gas mixtures using regenerable and recyclable calcium based sorbents. The regeneration of the calcium sorbent is accomplished by hydrating the sorbent at high temperatures of about 600 DEG C and a pressure higher than 6 bars to lower the parasitic energy consumption.

Owner:THE OHIO STATE UNIV RES FOUND

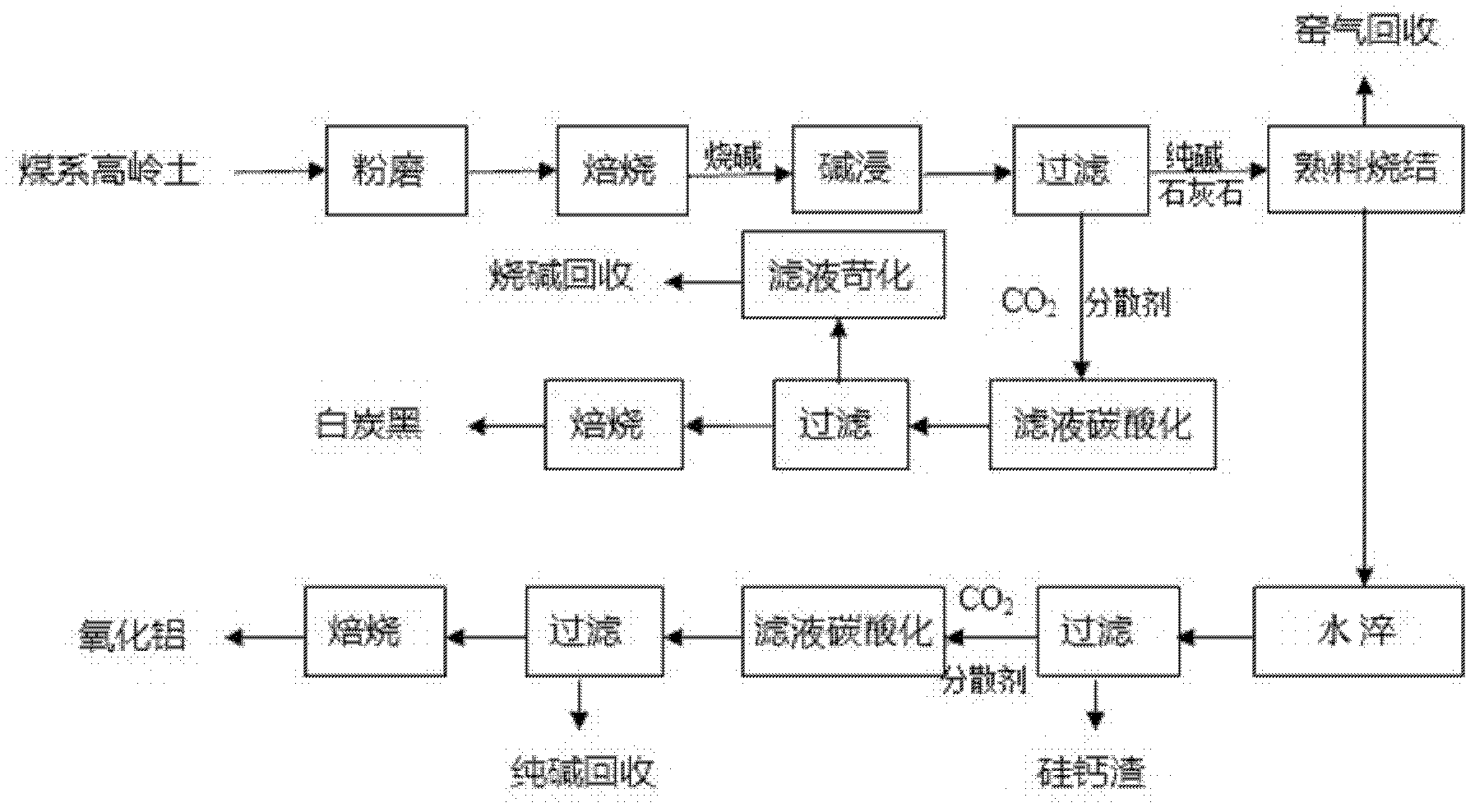

Method for preparing ultrafine alumina and coproducing and white carbon black by utilizing coal series kaolin

InactiveCN103121700ALower requirementReduce energy consumptionSilicaEnergy inputAdditional valuesSodium silicate

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Steam-assisted production of metal silicate cements, compositions and methods thereof

The invention provides a novel, steam-assisted production methodology and associated compositions and methods of use in the manufacture of carbonatable or non-carbonatable metal silicate or metal silicate hydrate (e.g., calcium silicate or calcium silicate hydrate) compositions. These metal silicate compositions and related phases are suitable for use hydraulic, partially hydraulic or non-hydraulic cement that sets and hardens by a hydration process, a carbonation process or a combination thereof, and may be applied in a variety of concrete components in the infrastructure, construction, pavement and landscaping industries.

Owner:SOLIDIA TECH

Method for preparing lube oil detergent of calcium nitrate in high base number

A high-basicity calcium sulfonate as the cleaner of lubricant oil is prepared from sulfonate, organic solvent, methanol, and calcium hydroxide through circulating their mixture in the filler layer of supergravitational rotating bed for high-speed neutralizing, carbonating and phase-converting, vacuum distilling for resultant liquid for removing alcohol and water, diluting, centrifugal separation of dregs, and removing solvent.

Owner:KARAMAY JINSHAN PETROCHEMICAL LTD CO +1

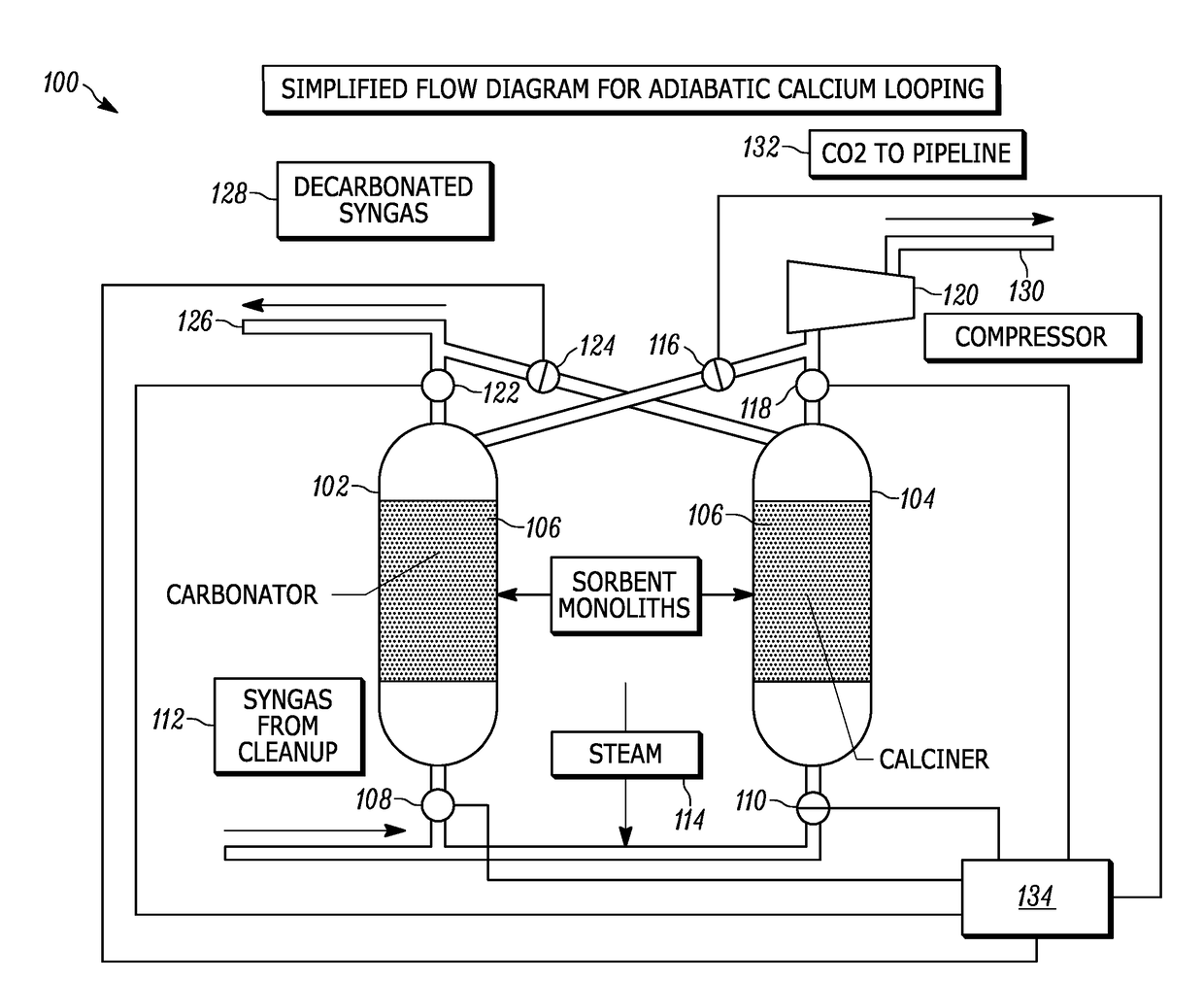

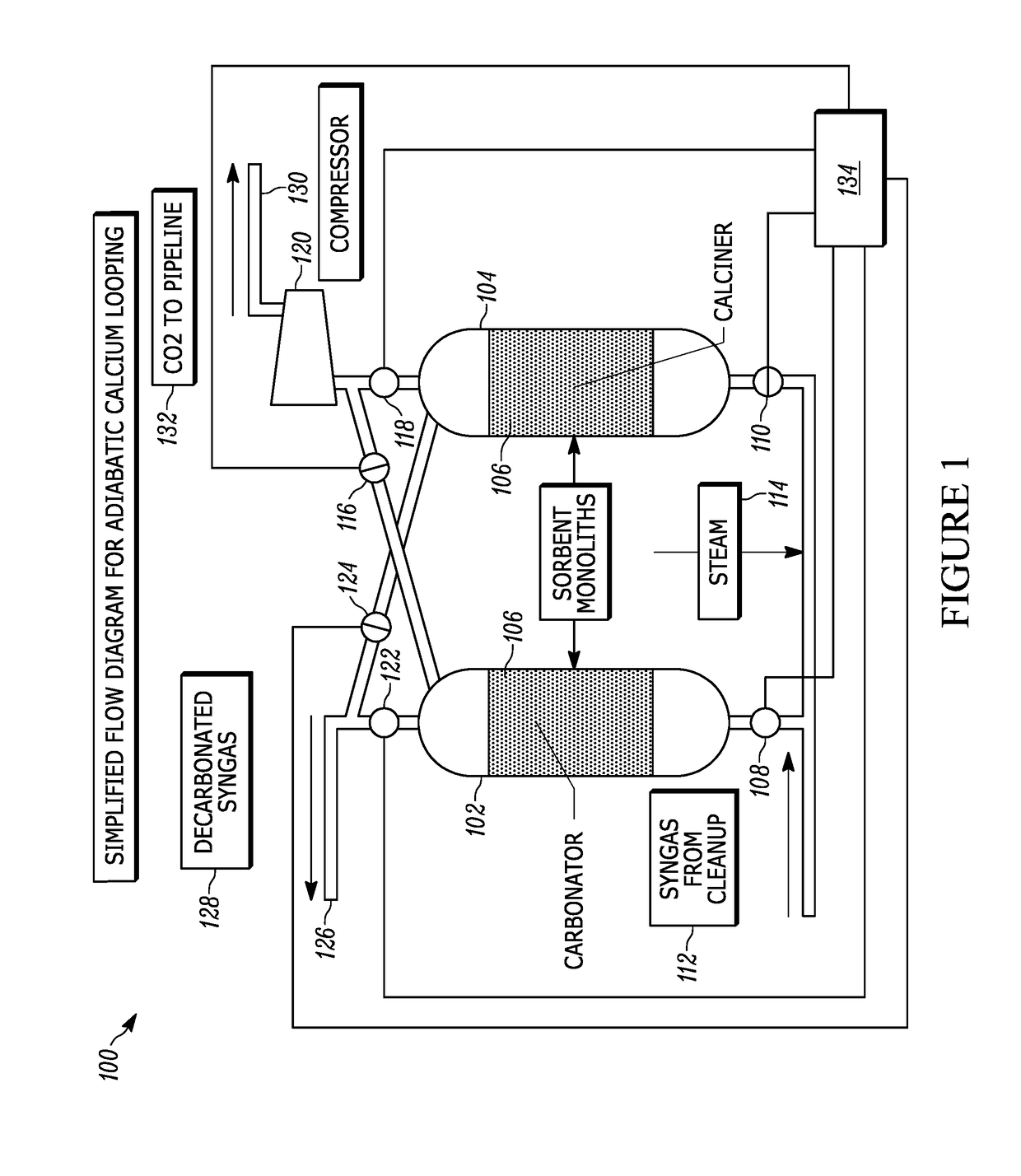

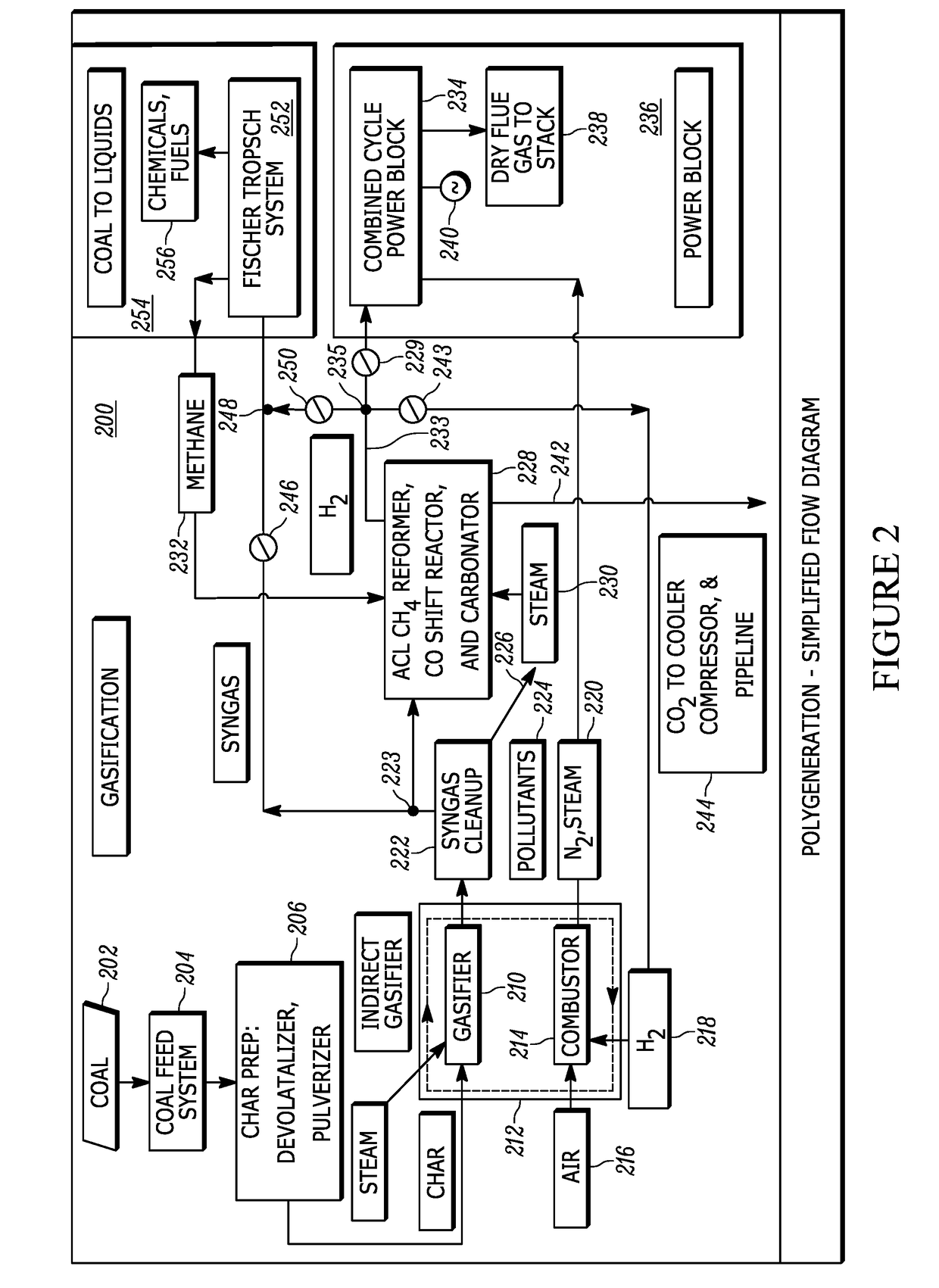

Method and Apparatus for Adiabatic Calcium Looping

A method and apparatus for decarbonizing gases using pressure swing in a first and second pressure vessel that each comprise a fixed bed sorbent. Syngas and steam are received in the first pressure vessel. A carbonation reaction is performed in the first pressure vessel that reacts carbonaceous species in the received syngas with the received steam to produce carbon dioxide and hydrogen. Decarbonated syngas is exhausted from first pressure vessel. A calcination reaction is performed in the second pressure vessel to produce carbon dioxide. A vacuum is provided to the second pressure vessel that causes carbon dioxide to exhaust from the second pressurized vessel at a pressure that substantially follows the decomposition pressure line.

Owner:WORMSER ENERGY SOLUTIONS

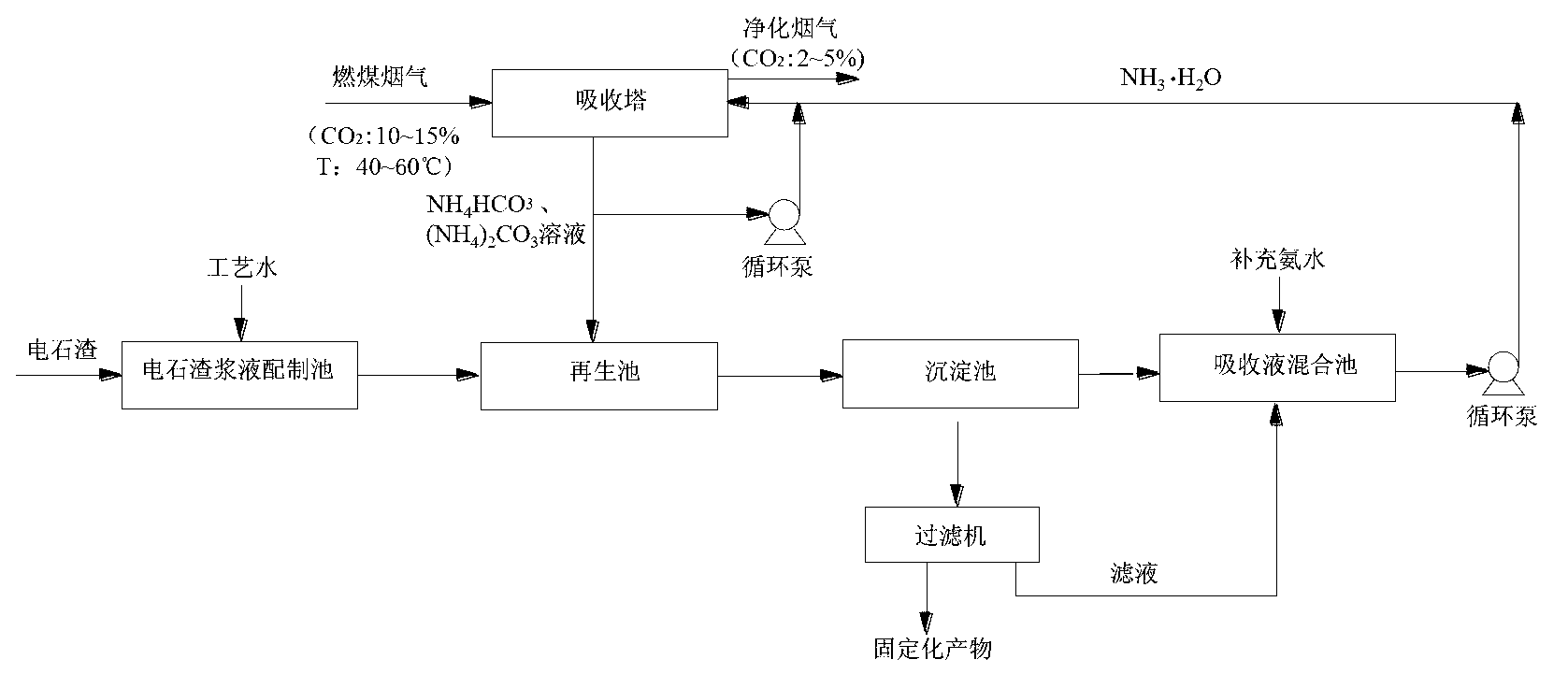

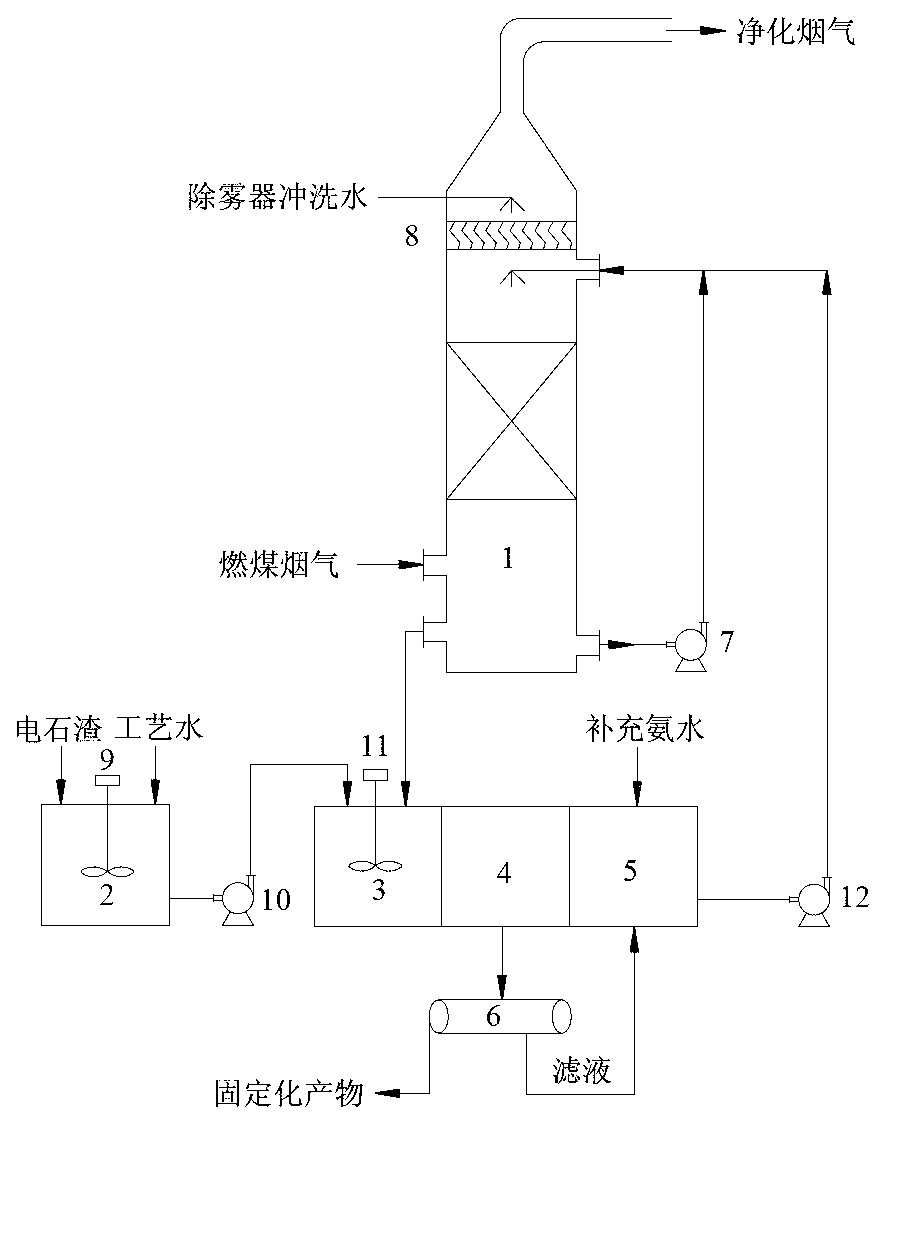

Ammonia circulation-based method and device for carbonating fixation of CO2 in coal-fired flue gas

InactiveCN103007721ARealize comprehensive utilizationFixed applicationDispersed particle separationAir quality improvementHigh concentrationSlag

The invention discloses an ammonia circulation-based method and device for carbonating fixation of CO2 in coal-fired flue gas. The method comprises the following steps that ammonia water is sprayed for absorbing CO2 in the coal-fired flue gas, part of absorption liquid generated in reaction is recycled for use, the rest of the absorption liquid flows into a regeneration pool through tower bottom so as to be reacted with added carbide slag slurry to be converted into calcium carbonate and ammonia water, after sediment through a sedimentation basin, supernatant liquor which is rich in ammonia flows into an absorption liquid mixed pool, and then a proper amount of ammonia water is added into the absorption liquid mixed pool so as to be sent to a CO2 absorption tower through a pump for reuse, after filtration of calcium carbonate sediment in the sediment pool, calcium carbonate is recycled, and the filtrate is sent to the absorption liquid mixed pool for reuse. According to the method, CO2 in the coal-fired flue gas is directly converted into calcium carbonate under normal temperature and pressure by taking ammonia water as an absorbent and taking carbide slag as a regenerant. Compared with the technology that CO2 of high concentration is obtained by ordinary ammonia water absorption and regeneration and carbonation seal is performed, the method has obvious technical economy advantages.

Owner:SOUTHEAST UNIV

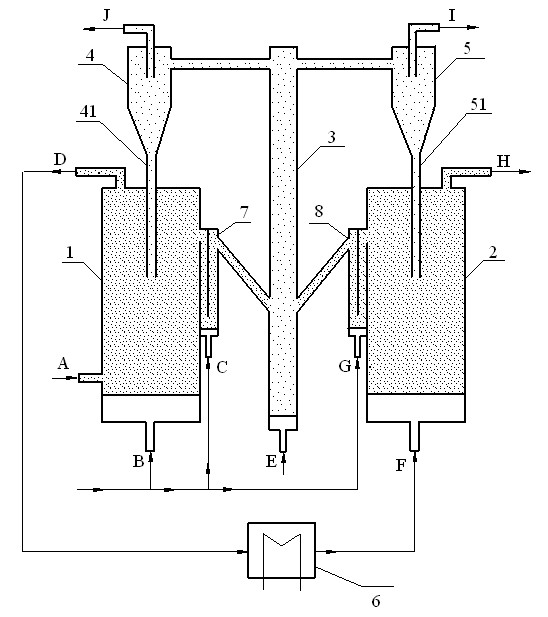

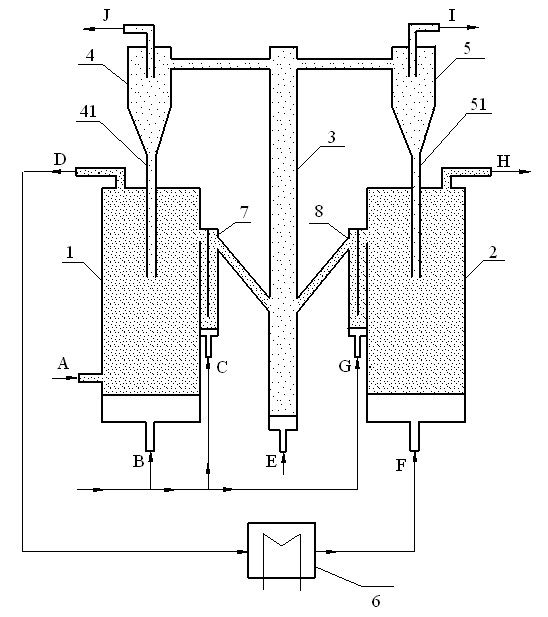

Device and method for producing hydrogen through coal gasification

InactiveCN102585911AReduce qualityEfficient captureGas purification with selectively adsorptive solidsGranular/pulverulent flues gasificationSorbentCarbonatation

The invention discloses a device and a method for producing hydrogen through coal gasification. The device comprises a gasification reactor (1), an adsorption reactor (2) arranged opposite to the gasification reactor (1), a calcination reactor (3) arranged between the gasification reactor (1) and the adsorption reactor (2), a gasification cyclone separator (4), an adsorption cyclone separator (5), an external heat exchanger (6), a gasification isolator (7) and an adsorption isolator (8). A high temperature synthetic gas inlet of the external heat exchanger (6) is connected with a high temperature synthetic gas outlet (D) of the gasification reactor (1). The method for producing the hydrogen through coal gasification comprises the following steps of: performing pyrolysis gasification reaction of coal particles; performing carbonation reaction on calcium-based adsorber particles; and performing calcinations reaction on calcium carbonate particles. By the device and the method, the coal particles are gasified to form high-quality hydrogen rich gas, and carbon dioxide is effectively captured.

Owner:SOUTHEAST UNIV

Vanadium extraction method of high-calcium and high-phosphor vanadium slag clinker

InactiveCN104532009AAchieving selective leachingReduce pollutionProcess efficiency improvementPregnant leach solutionSlag

The invention provides a vanadium extraction method of a high-calcium and high-phosphor vanadium slag clinker. The method comprises the following steps: crushing, grinding and screening the high-calcium and high-phosphor vanadium slag clinker with greater than 7wt% of CaO and greater than 0.6wt% of P2O5 until the particle size is 0.050-0.154mm, wherein the mass ratio of CaO to V2O5 is greater than 0.7, then carrying out carbonation leaching in a Na2O3 solution with a concentration of 3-20wt% or a NaHCO3 solution with a concentration of 4-25wt%, wherein a solid-liquid ratio is 1:1mL / g-1:15mL / g, the leaching temperature is 50-99 DEG C, the leaching time is 30-120 minutes and the stirring rate is higher than 150 revolutions per minute during leaching; carrying out solid-liquid separation to obtain a vanadium-containing leaching liquid; and then preparing a vanadium product by using the existing mature process of precipitating vanadium and deaminizing. According to the method, the leaching operation process is simple; a leaching agent is low in cost; a high vanadium leaching rate can be achieved; the leaching of phosphor in the vanadium slag clinker can be avoided; and the effective vanadium extraction of the high-calcium and high-phosphor vanadium slag clinker can be implemented.

Owner:UNIV OF SCI & TECH BEIJING

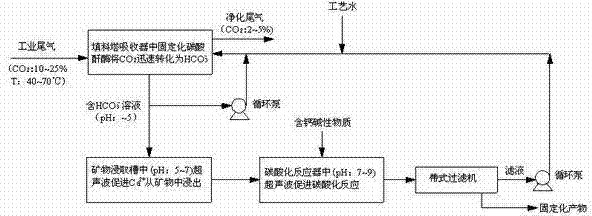

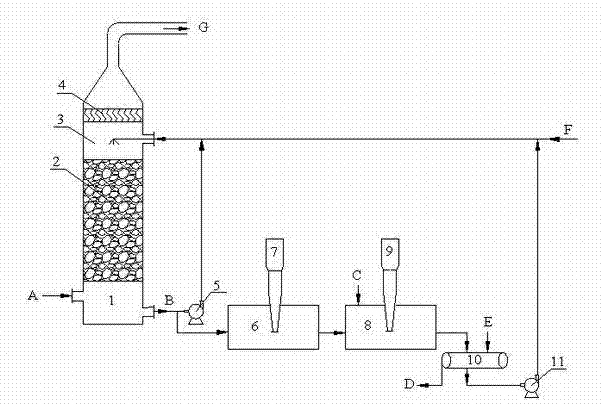

Method and device for immobilizing CO2 by enhancing mineral carbonation

InactiveCN102343199AFast catalytic reaction ratePromotes hydrationDispersed particle separationUltrasound - actionSlurry

The invention discloses a method and device for immobilizing CO2 in industrial tail gas by enhancing mineral carbonation. The device comprises a packed column absorber, a mineral leaching tank, a carbonation reactor and a belt type filter. The method comprises the steps of: enabling the industrial tail gas containing CO2 to enter the packed column absorber filled with immobilization carbonic anhydrase, rapidly transforming the CO2 into HCO3<-> under the catalysis action of the carbonic anhydrase; with a weak acidic solution containing the HCO3<-> as a mineral leaching agent, effectively leaching calcium ions from minerals in the mineral leaching tank under the action of ultrasonic waves to form a slurry enriching Ca<2+>; introducing the slurry enriching Ca<2+> into the carbonation reactor, adding a calcium-containing alkali material, regulating the pH of the slurry to be 7-9 to ensure that the HCO3<-> is transformed into CO3<2->, and generating a carbonation reaction with the Ca<2+> leached from the minerals to generate CaCO3. The invention can promote the CO2 to be rapidly transformed into the HCO3<->, can promote the calcium ions to be leached from the minerals and the carbonation reaction, and further realizes that the CO2 in the industrial tail gas is immobilized through direct carbonation under normal pressure.

Owner:SOUTHEAST UNIV

Method for extracting aniline and sodium carbonate and potassium carbonate from mixed alkaline residue in bipseudoindoxyl production

InactiveCN101323577AImprove protectionSimple extraction methodAmino compound purification/separationCarbonate preparationWater vaporSludge

The invention discloses a method for extracting aniline, sodium carbonate and potassium carbonate from mixed caustic sludge in the production of indigo, which relates to a comprehensive treatment technology in the production of indigo. The adopted technical proposal is that the mixed caustic sludge forms aniline vapor and water vapor after calcination, water is on the upper layer and aniline is on the lower layer by natural settling after condensation, aniline is drawn out and put into a reaction kettle to produce sodium sulfanilate, dry mixed alkali produced is dissolved with water and filtrated, and CO2 is introduced for carbonatation treatment so as to produce potassium carbonate and sodium carbonate which are separated out after concentration, and finally the potassium carbonate and the sodium carbonate are dried, calcinated, naturally cooled and packaged. The method of the invention is characterized by simple extraction method, easy purchase of equipment, low cost, realization of cyclic economy, thus being beneficial to 'recycle and reclamation' and environmental protection. The method of the invention is applicable to the comprehensive treatment of indigo production industry.

Owner:重庆达华砼外加剂科技发展有限公司

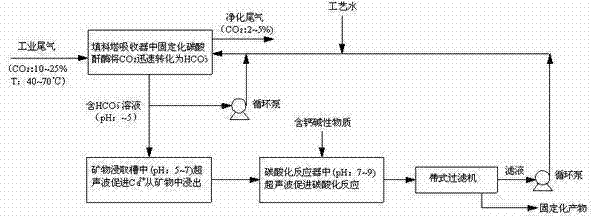

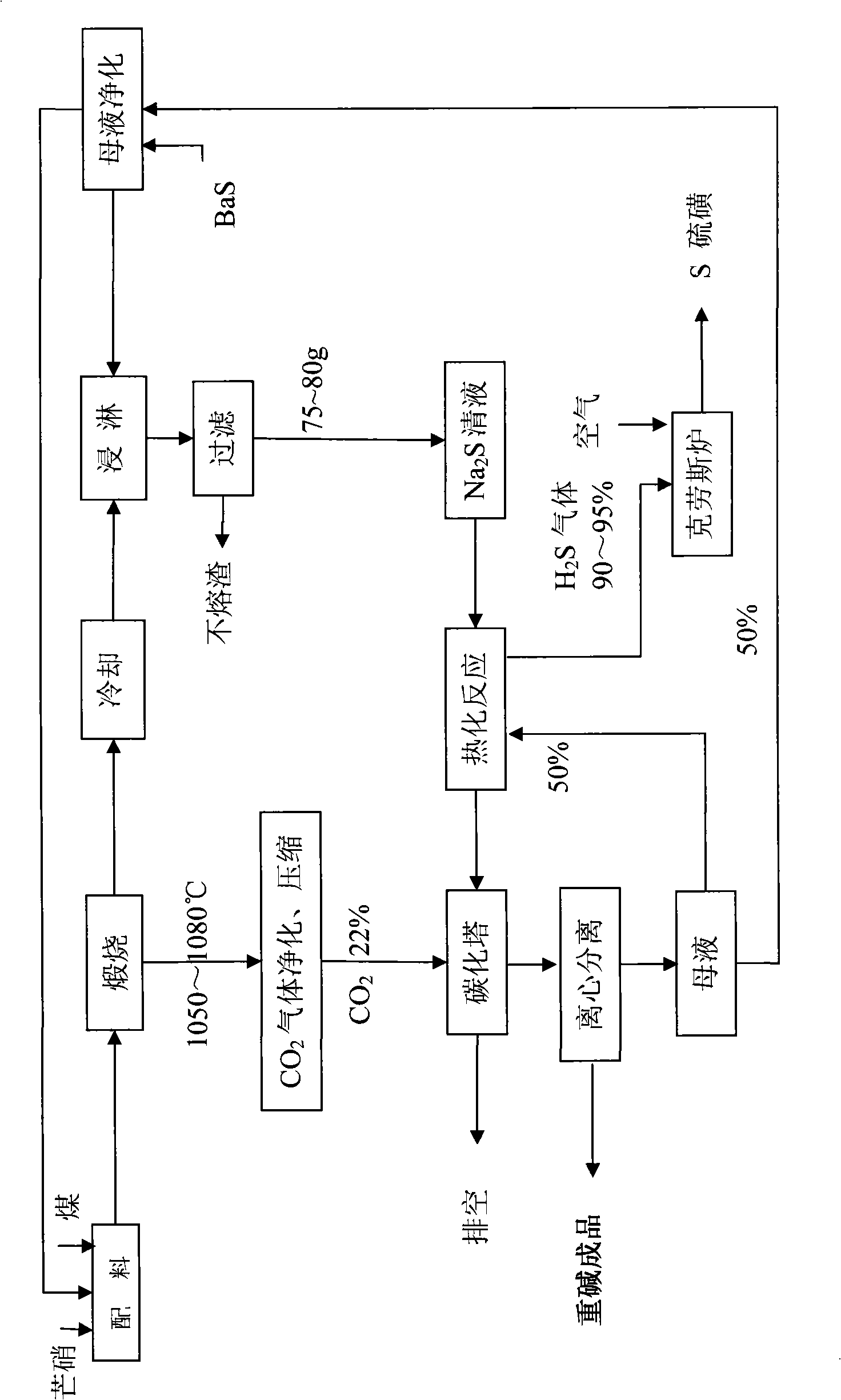

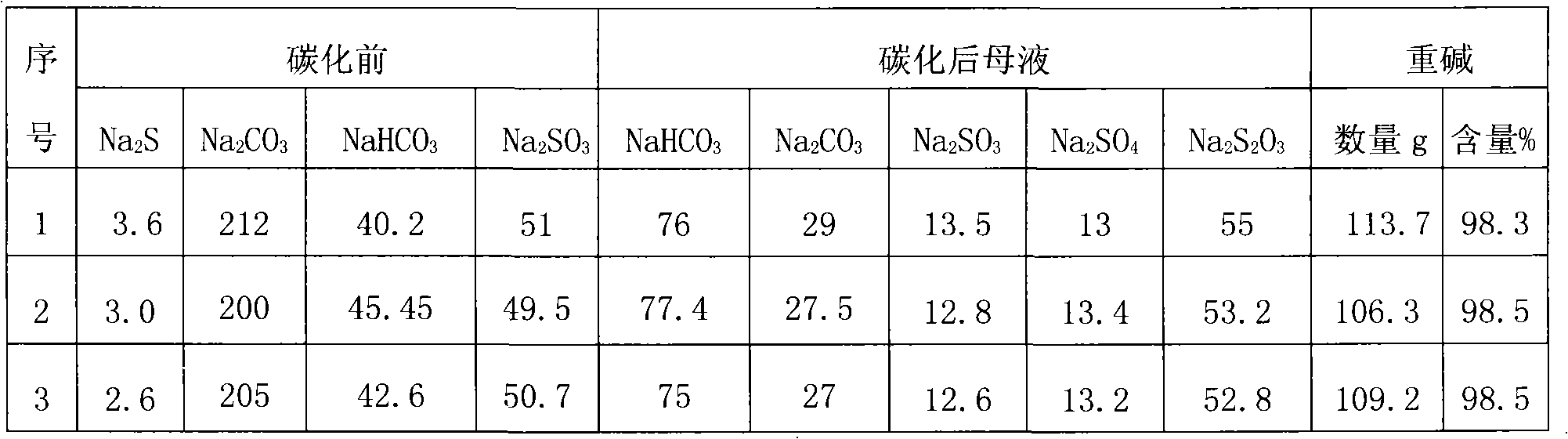

Method for producing sodium bicarbonate and sulfur from mirabilite by wet process

InactiveCN101264904AAchieving zero emissionsAchieve recyclingBicarbonate preparationSulfur preparation/purificationSodium bicarbonateCarbonization

The invention discloses a method for clean method for producing sodium bicarbonate and sulphur by means of Glauber salt wet method for reducing the emission of CO2 and avoiding the discharge of wastewater, which comprises the following steps: A, sodium sulphide preparing process, B, hot carbonatation process, C, sulphur preparing process, D, cold carbonization process, and E, mother liquor purifying. Glauber salt coal is reduced and calcined into sodium sulphide, and the sodium sulphide solution is heated and carbonized into a mixed solution with the soda as the main component by use of sodium bicarbonate, then the mixed solution is cold-carbonated by CO2 to separate out NaHCO3 crystal, which is dried to finally obtain the soda in conformity with relevant standard. The production method has the advantages of simple process, environmental friendliness, no pollution, full circulation of the mother liquor, and no wastewater discharged.

Owner:GANSU JINSHI CHEM

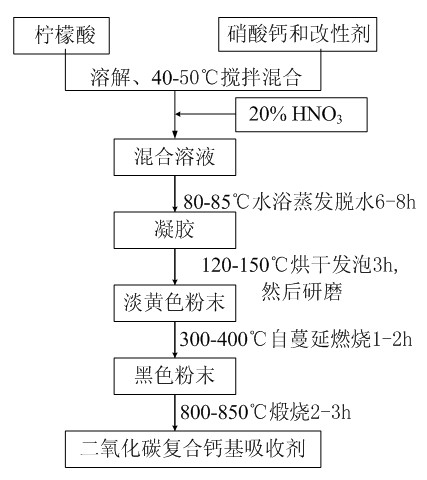

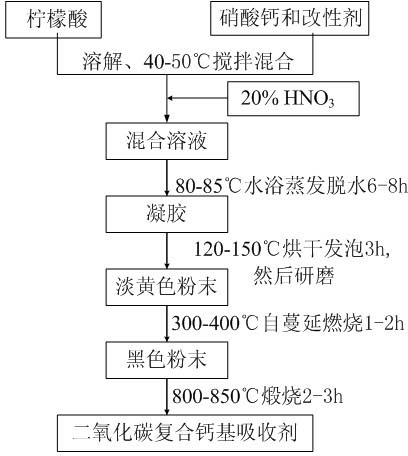

Preparation method of carbon dioxide composite calcium-base absorbent

InactiveCN102658010AHigh mechanical strengthImprove wear resistanceDispersed particle separationAir quality improvementAir atmosphereCo2 absorption

The invention discloses a preparation method of a carbon dioxide composite calcium-base absorbent. Citric acid and nitrate are used as raw materials to prepare the composite calcium-base absorbent doped with other metal oxides by a sol-gel process. The preparation method comprises the following steps: by using calcium nitrate as the main raw material, other metal nitrates as a modifier and citric acid as a complexing agent, carrying out solution mixing, dehydrating by evaporation to obtain a gel, drying and carrying out heat treatment on the gel, and calcining at 800 DEG C in an air atmosphere for 3 hours, thereby obtaining the carbon dioxide composite calcium-base absorbent. The carbon dioxide composite calcium-base absorbent prepared by the method disclosed by the invention has high carbon dioxide absorption capacity and stable reaction activity, and has high CO2 capture rate in multiple-circulating calcining / carbonating reaction process; and the carbon dioxide composite calcium-base absorbent has favorable properties in the aspects of CO2 capture efficiency, mechanical strength, caking resistance and the like in the circulating calcining / carbonating process.

Owner:SOUTHEAST UNIV

Method for preparing sodium carbonate by supplementing CO2 to flue gas

ActiveCN103588226AReduce investmentReduce power consumptionCarbonate preparationFlue gasCarbonization

The invention discloses a method for preparing sodium carbonate by supplementing CO2 to flue gas. The method comprises the following steps: carrying out de-dusting, desulfurizing and cooling on CO2-containing flue gas, increasing the pressure to be 0.05-0.35 MPa, directly filling the flue gas into the middle and the upper part of a sodium carbonate preparation carbonizing tower, producing a carbonation reaction, enabling a reaction product to continue to pass through the lower section of the carbonizing tower to finish the carbonation reaction with high-concentration CO2-containing gas to obtain sodium hydrogen carbonate, and calcining sodium hydrogen carbonate to obtain sodium carbonate. According to the method, during sodium carbonate production, the problem of CO2 deficiency is successfully solved, the equipment investment and the power consumption are greatly reduced, the CO2 emission is reduced, the utilization rate of sodium chloride is high, both the energy consumption and the cost are low, and the economic feasibility is high.

Owner:CHINA CHENGDA ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com