Carbonation calcination reaction process for CO2 capture using a highly regenerable sorbent

一种吸附剂、碳酸化的技术,应用在化学仪器和方法、分离方法、通过吸附等方向,能够解决吸附剂反应性稳定下降等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

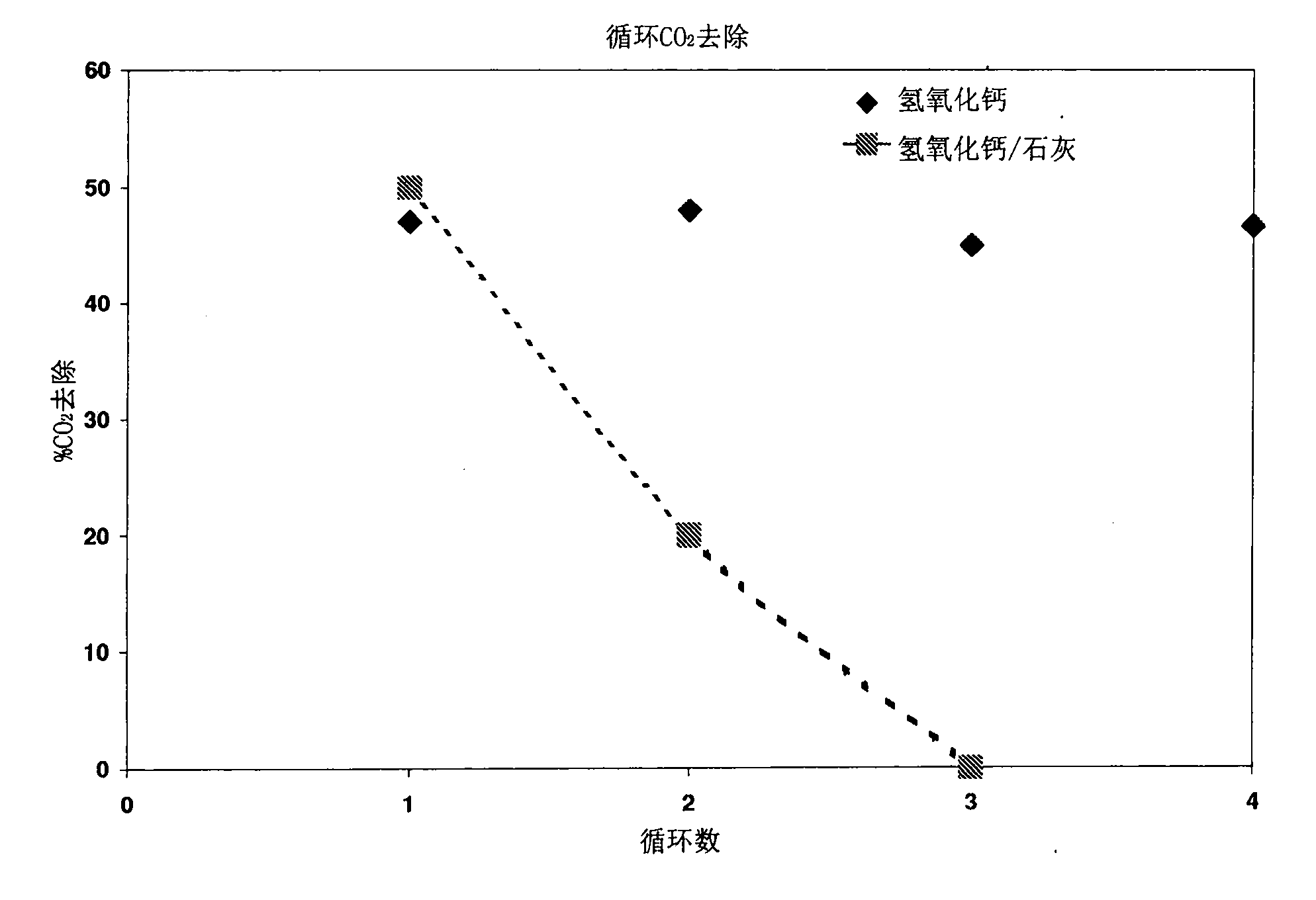

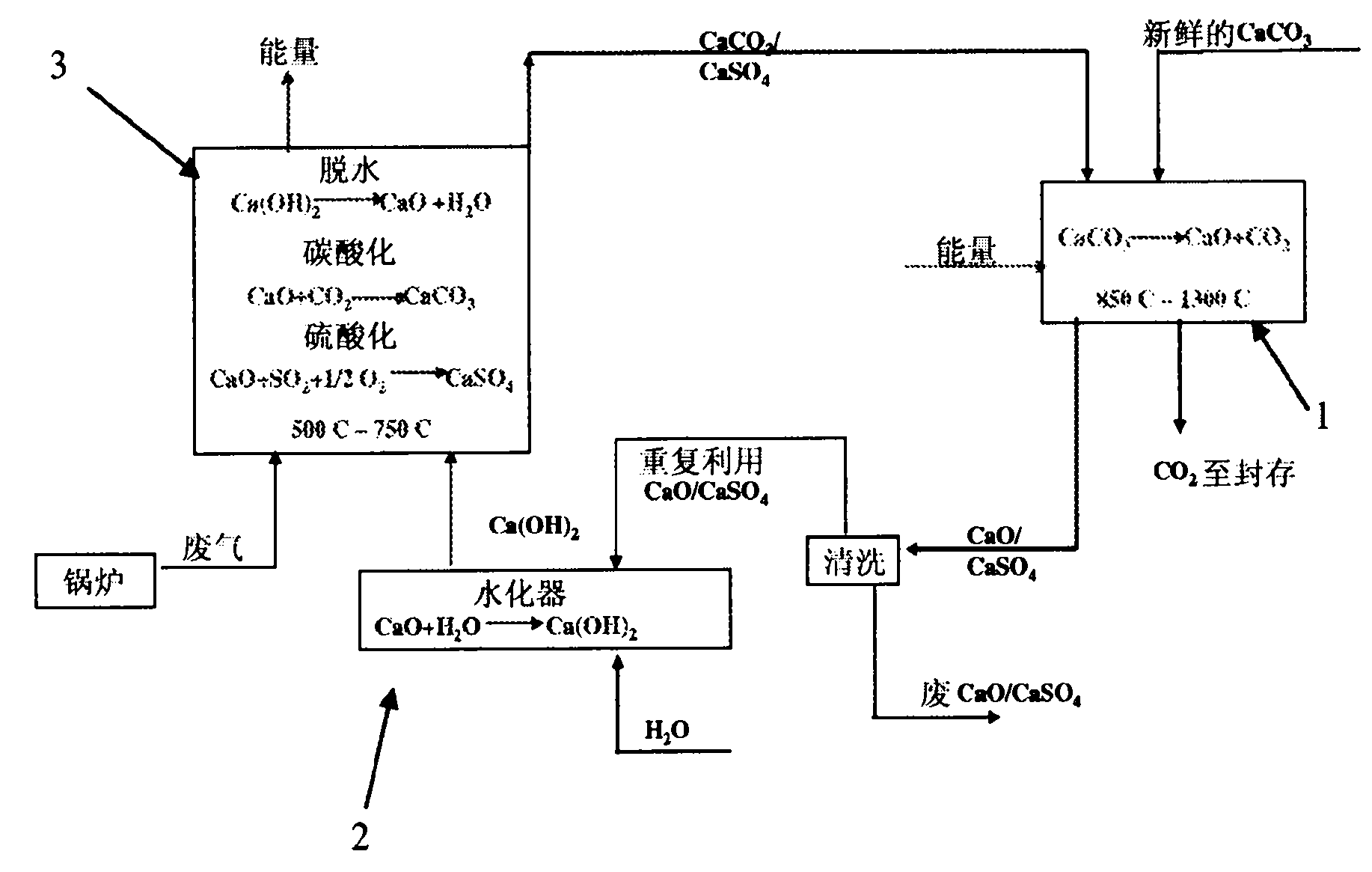

[0039] The regenerability of calcium oxide sorbent is high temperature calcium-based CO 2 The main disadvantage of the capture method. A potential solution is to hydrate the sorbent with ambient water during each cycle, which leads to a complete reactivation of the sorbent. However, due to the capture of CO 2 High-quality heat was previously required for dehydration of sorbents, and this ambient-temperature reactivation technique results in very high additional energy consumption. To this end, exemplary embodiments provide a unique method of pressure hydration for reactivating the sorbent without adding additional energy to the overall process. The pressure hydration of high calcium content oxides is performed at or above the temperature used for the dehydration reaction to enhance the quality of the heat of hydration (e.g., at about 300 psi, the hydration temperature is about 600° C.) and to allow This energy can be used for dehydration reactions. figure 1 Provides for CO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com