Method for preparing sodium carbonate by supplementing CO2 to flue gas

A technology of flue gas and CO2, which is applied in the direction of chemical instruments and methods, carbonate preparations, alkali metal compounds, etc., can solve the problems of equipment investment and power consumption reduction and shortage, and achieve equipment investment and power consumption reduction, high efficiency Recycling, good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

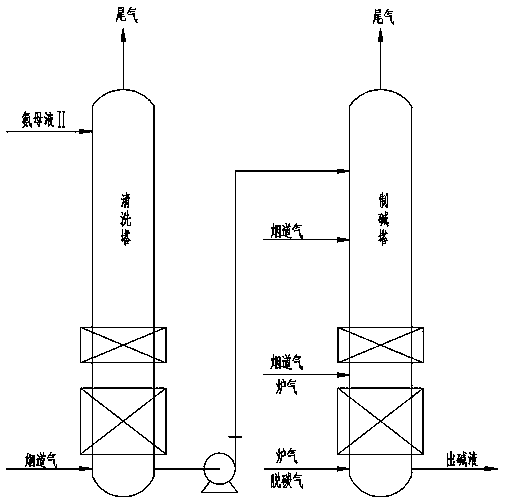

[0029] A certain engineering project uses natural gas and brine as raw materials to produce soda ash and ammonium chloride by the combined soda method. There is a problem of insufficient carbon dioxide. The flue gas of the coal-fired boiler is used to supplement carbon dioxide in the engineering design. The carbonization tower adopts the cleaning tower and alkali-making tower group mode. The carbonization tower is a continuous liquid-phase high-efficiency sieve plate carbonation tower. (Both the cleaning tower and the soda-making tower have a high-efficiency sieve plate structure). After cooling down, the temperature is about 40°C, the carbon dioxide content in the flue gas is 12%-13%, and the sulfur content is less than 50ppm. After being pressurized to 0.3MPa and 0.1MPa by the compressor, it enters the bottom of the cleaning tower and the soda making tower respectively. The upper segment, containing high concentrations of CO 2 The decarbonized gas and furnace gas enter the b...

Embodiment 2

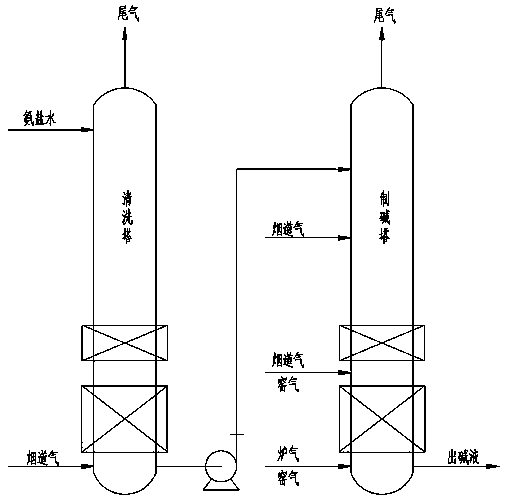

[0031] In a certain project, the ammonia-soda method is used to produce soda ash, and a part of calcium carbide waste residue is used to replace lime milk to decompose ammonium chloride. There is a problem of insufficient carbon dioxide. In the engineering design, the flue gas of coal-fired boilers is used to supplement carbon dioxide. The carbonization tower adopts the cleaning tower and soda tower group mode. The carbonization tower is a continuous liquid phase high-efficiency sieve plate carbonation tower. After the flue gas is dedusted, desulfurized, and cooled, the temperature is reduced to about 40 ° C. The carbon dioxide in the flue gas The sulfur content is 10%-12%, and the sulfur content is less than 50ppm. It is pressurized to 0.3MPa and 0.1MPa by the compressor, and enters the bottom of the cleaning tower and the middle and upper sections of the soda making tower respectively, containing high concentrations of CO 2 The kiln gas and furnace gas enter the bottom and mi...

Embodiment 3

[0033] In a certain project, the ammonia-soda method was used to produce soda ash, and there was a problem of insufficient carbon dioxide. The flue gas was used to supplement carbon dioxide in the engineering design. After the flue gas is dedusted, desulfurized, and cooled, the temperature is reduced to about 30°C, the carbon dioxide content in the flue gas is 12%-15%, and the sulfur content is less than 50ppm. It is pressurized to 0.35MPa by the compressor and enters the middle and upper sections of the carbonization tower. Contains a high concentration of CO 2 The kiln gas and furnace gas enter the bottom and middle of the carbonization tower to complete the carbonization reaction, and the CO in the tail gas of the carbonization tower 2 The content is less than 5%. The conversion rate of sodium in the liquid taken out of the carbonization tower can reach 73%-75%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com