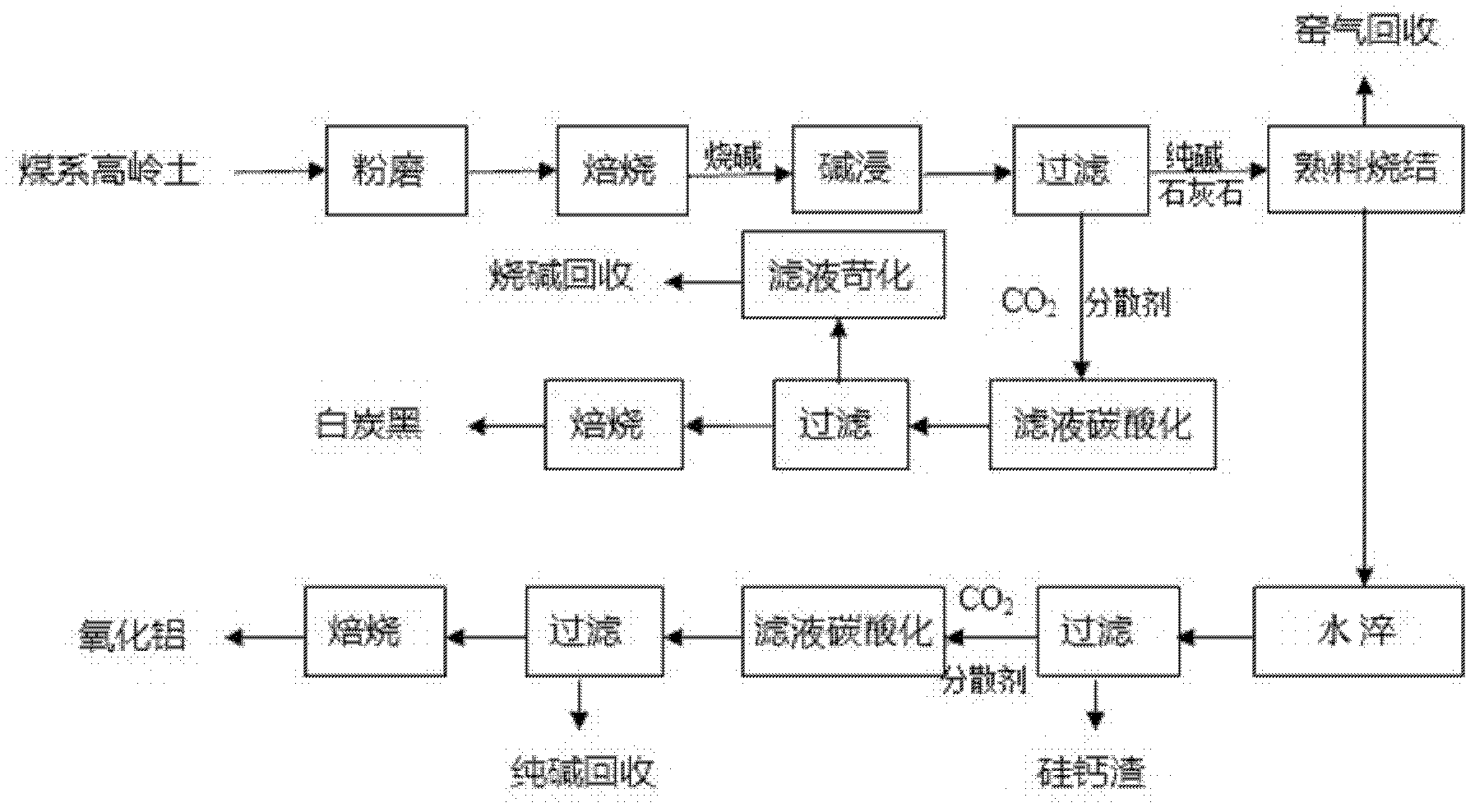

Method for preparing ultrafine alumina and coproducing and white carbon black by utilizing coal series kaolin

A technology of ultra-fine alumina and white carbon black, applied in the direction of alumina/aluminum hydroxide, silicon oxide, silicon dioxide, etc., can solve the problem of low comprehensive utilization of high energy consumption resources, non-recyclable by-products, comprehensive utilization of resources Low-level problems, to achieve the effect of high comprehensive utilization rate, high product added value, and uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Alumina, silica, and loss on ignition account for 40.08%, 37.65%, and 17.32% of the coal-based kaolin used in this example, respectively.

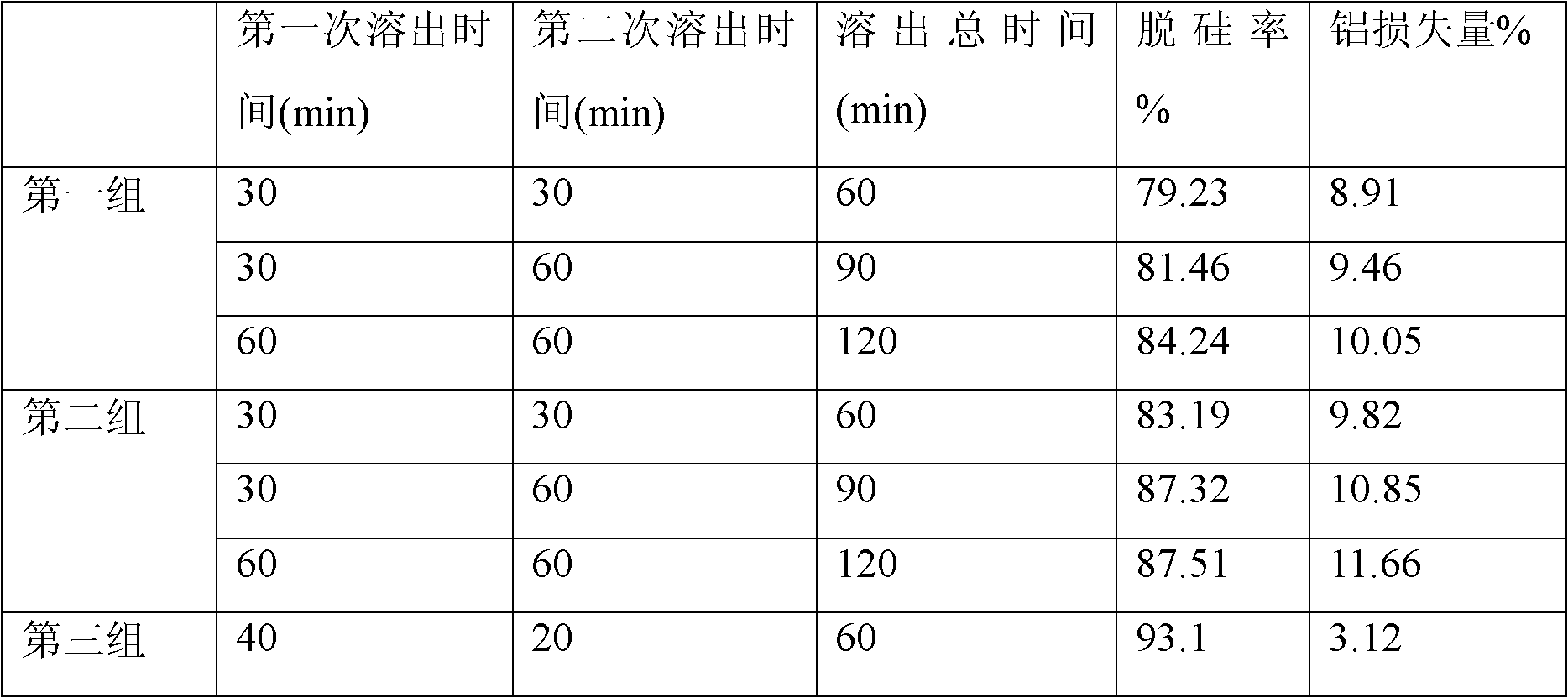

[0048] Weigh 50 grams of coal-series kaolin, crush the coal-series kaolin into powder, and then roast and activate it. After the roasted powder is cooled naturally, it is placed in a leacher, and the mass fraction is 25% dilute caustic soda in Reaction at 80°C for 30 minutes, the total amount of caustic soda is based on Na 2 O: SiO 2 =1.0 molar ratio calculation, after the reaction is completed, filter to obtain sodium silicate solution and alkali leaching residue. Add sodium hexametaphosphate to the sodium silicate solution, the quality of sodium hexametaphosphate is 0.5% of the quality of the sodium silicate solution, feed carbon dioxide gas for carbonation treatment, when the pH of the solution is 4, the carbonation reaction ends, filter , to obtain the ortho silicic acid precipitation filter cake and desiliconization solution,...

Embodiment 2

[0053] In the coal series kaolin used in this example, alumina, silica, and loss on ignition accounted for 37.36%, 42.79%, and 15.60%, respectively.

[0054] Weigh 50 grams of coal-series kaolin, crush the coal-series kaolin into powder, and then roast and activate it. After the roasted powder is cooled naturally, it is placed in a leacher, and the mass fraction is 5% dilute caustic soda in React at 100°C for 90 minutes, and the total amount of caustic soda is based on Na 2 O: SiO 2 =1.2 molar ratio calculation, after the reaction is completed, filter to obtain sodium silicate solution and alkali leaching residue. Add polyethylene glycol as a dispersant to the sodium silicate solution, the quality of polyethylene glycol is 5% of the mass of the sodium silicate solution, carbon dioxide gas is passed into it for carbonation treatment, and the carbonation reaction ends when the pH of the solution is 7 , filtered to obtain ortho silicic acid precipitation filter cake and desilic...

Embodiment 3

[0059] Alumina, silica, and loss on ignition accounted for 40.08%, 37.65%, and 17.32% of the coal-based kaolin used in this example, respectively.

[0060] Weigh 50 grams of coal-series kaolin, crush the coal-series kaolin into 200-mesh powder, and then calcinate at 960°C for 60 minutes to activate the roasting. The roasted powder is naturally cooled and placed in a leaching device , react with a mass fraction of 15% caustic soda solution at 95°C for 60 minutes, and the total amount of caustic soda is based on Na 2 O: SiO 2 =1.2 molar ratio calculation, after the reaction, SiO 2 The detachment rate is 86.33%. After filtration, sodium silicate solution and alkali leaching residue are obtained. Add composite dispersant in sodium silicate liquid, the amount of composite dispersant is 1% of the quality of sodium silicate solution, composite dispersant is made up of sodium hexametaphosphate and polyethylene glycol by the mass ratio of 1: 1, then 80 Carbon dioxide gas with a conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com