Patents

Literature

376 results about "Loss minimization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

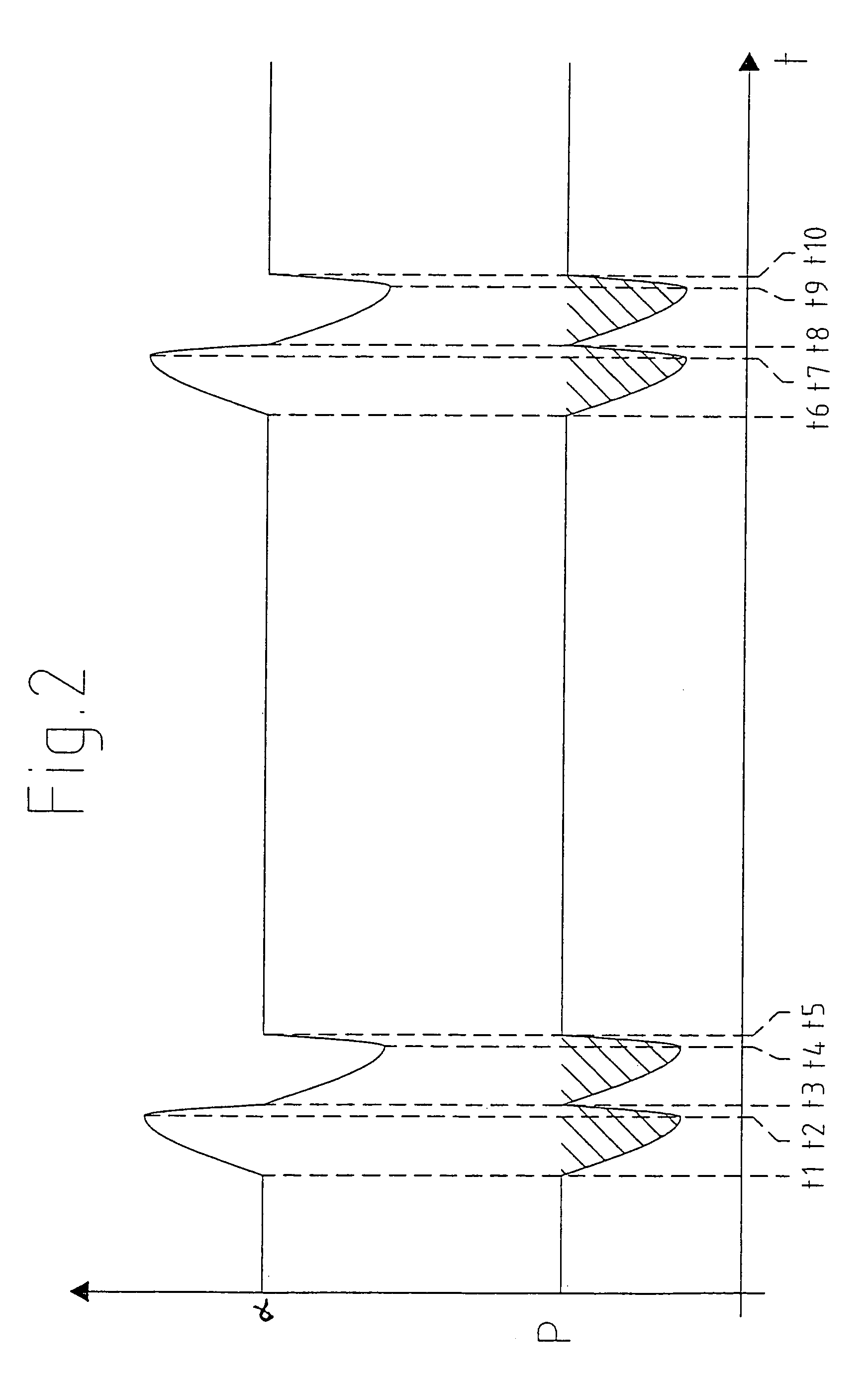

Loss minimization. the objective of the FIRM in the SHORT RUN when confronted with adverse market conditions that prevent PROFIT MAXIMIZATION. Profit maximization or loss minimization requires the firm to produce at that level of output where MARGINAL COST equals MARGINAL REVENUE.

Cost structure method including fuel economy and engine emission considerations

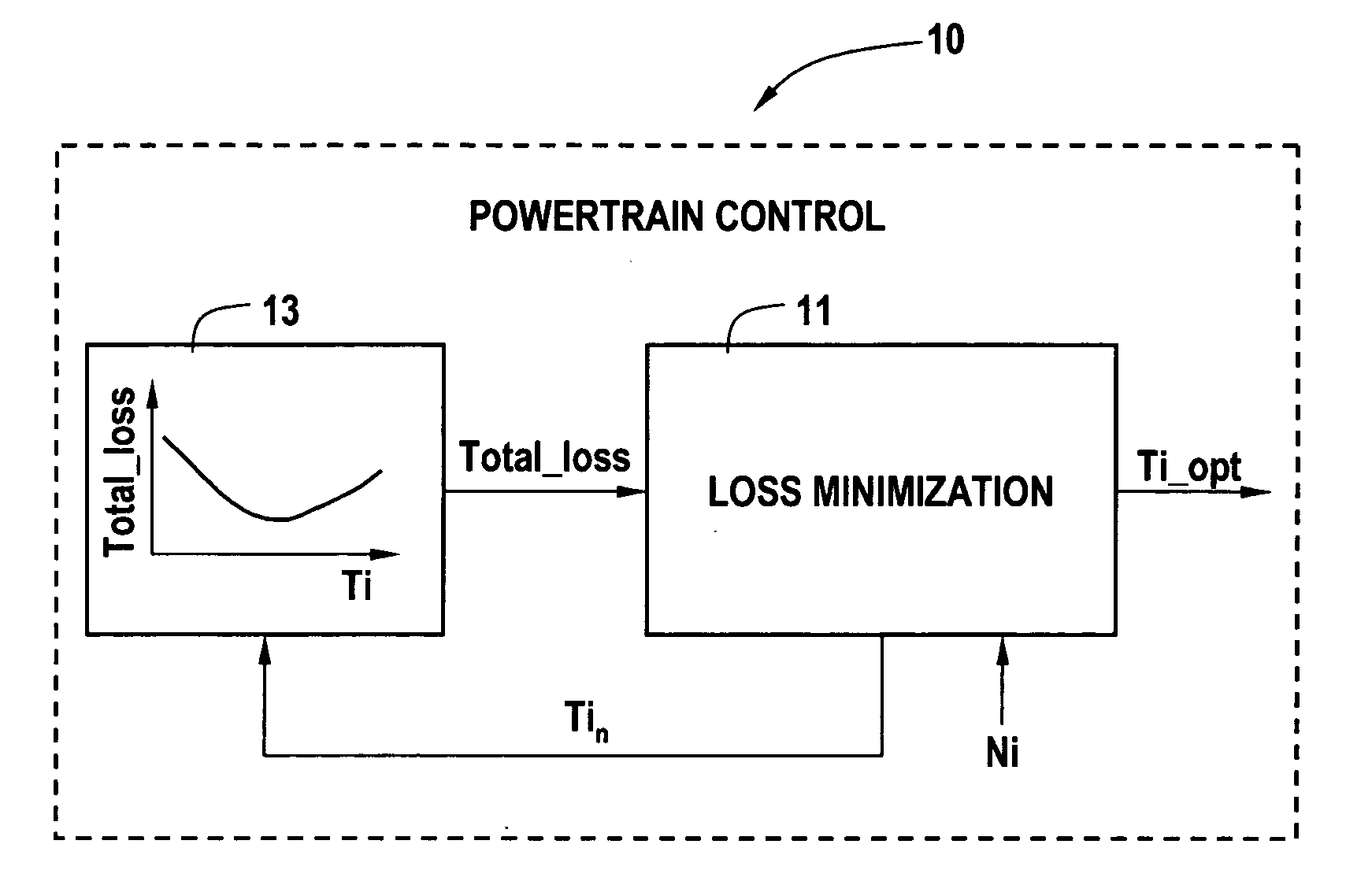

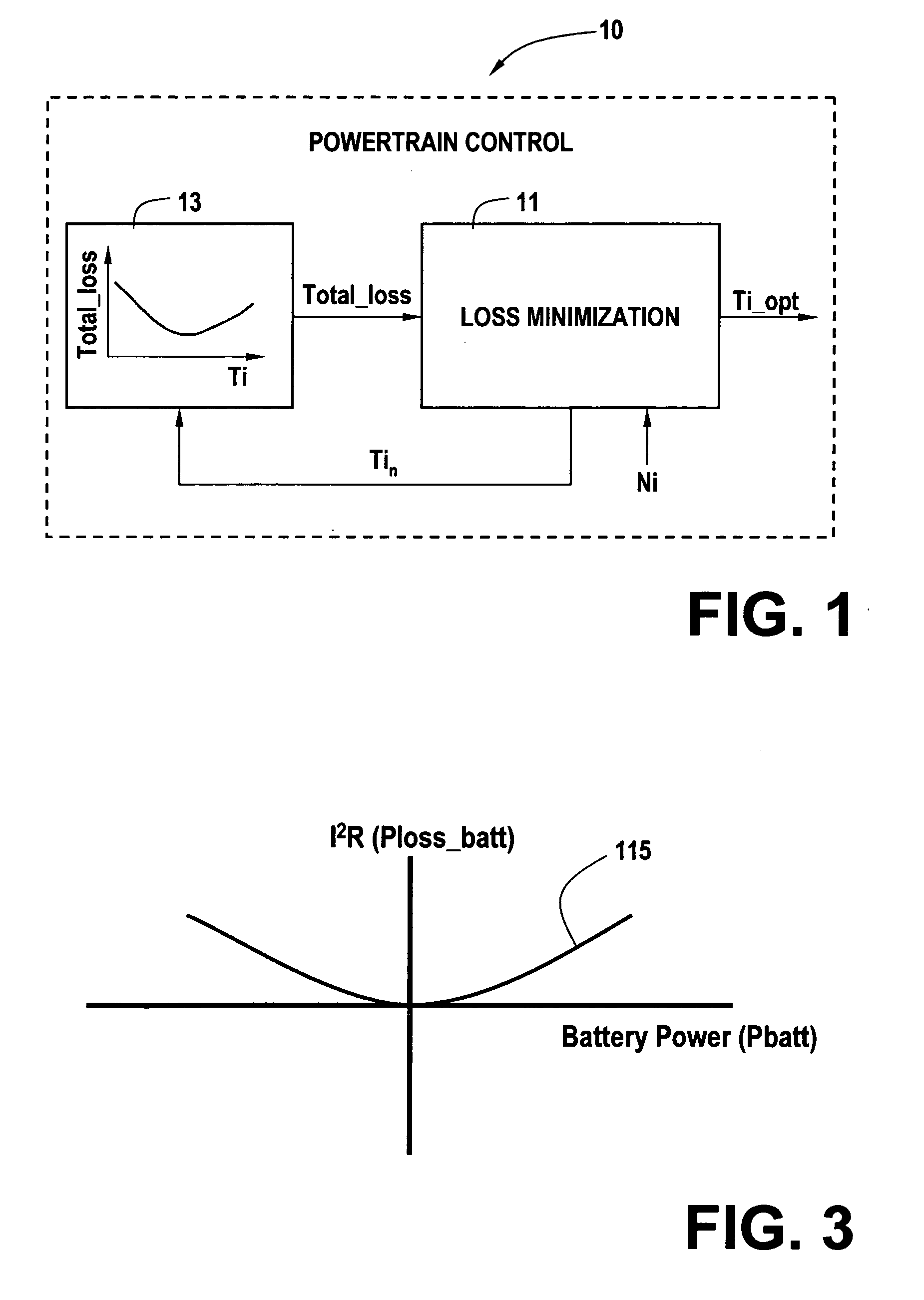

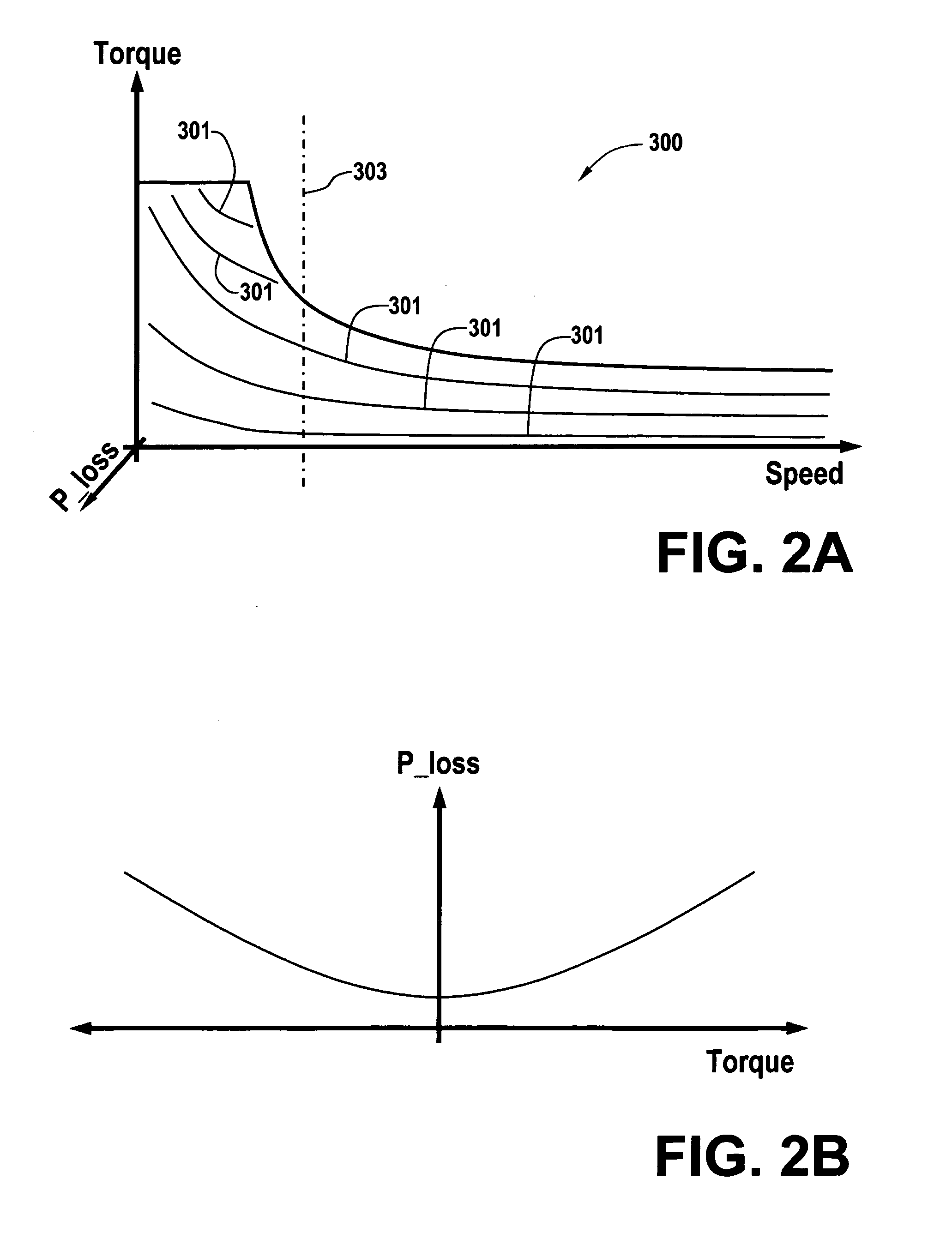

ActiveUS20070093953A1Analogue computers for vehiclesElectrical controlOperating pointPowertrain control

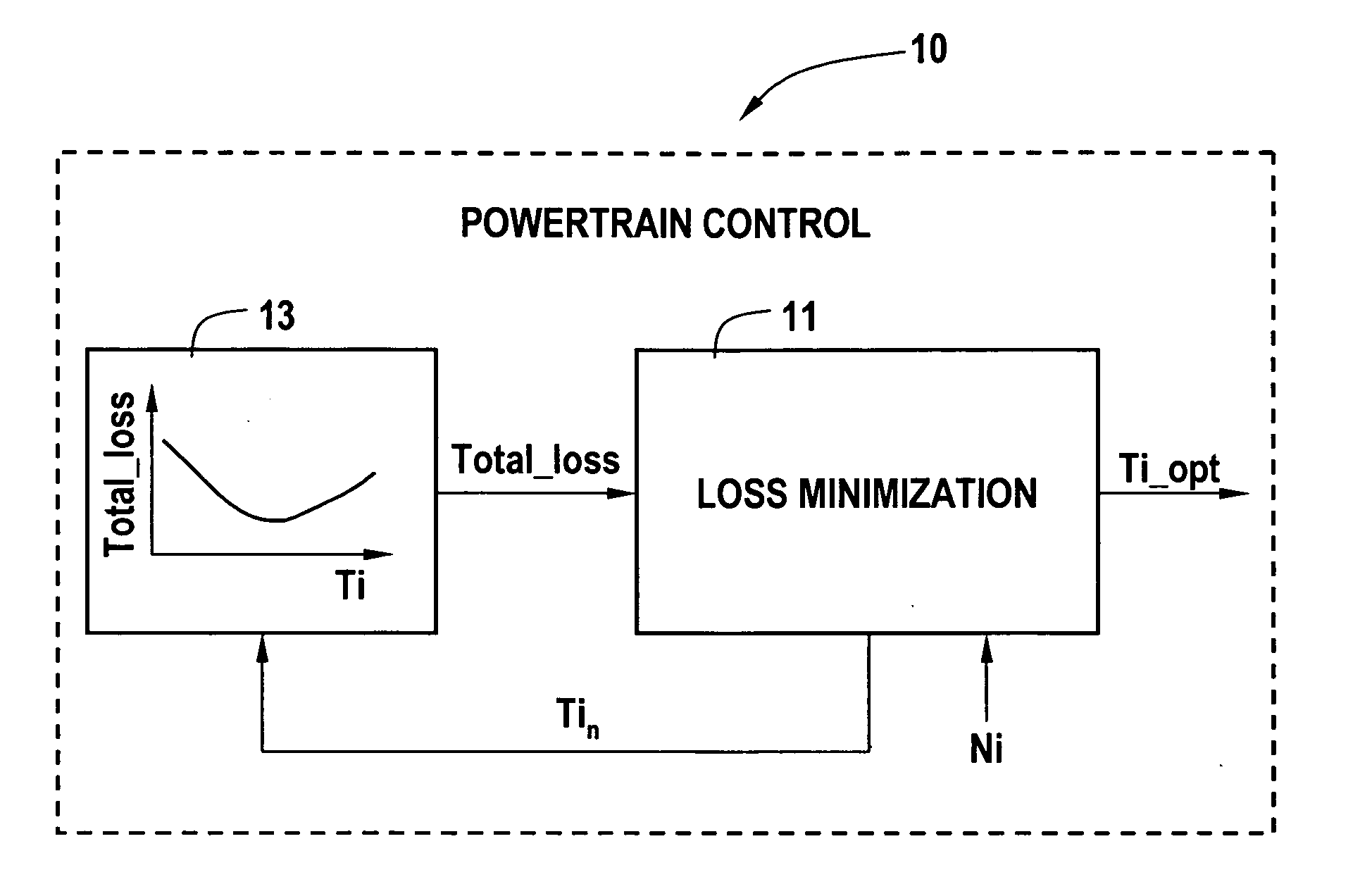

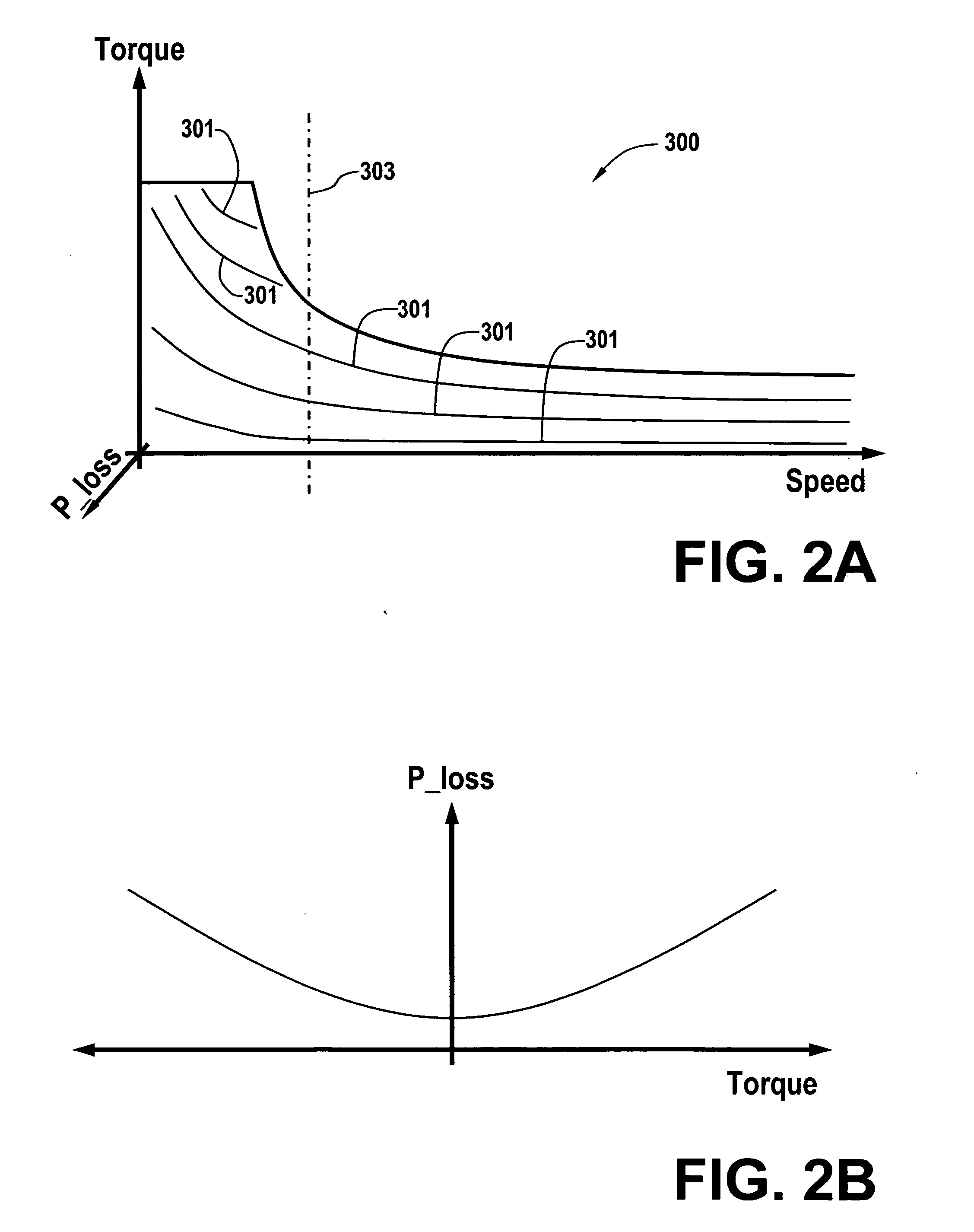

A powertrain control selects engine operating points in accordance with power loss minimization controls. Power loss contributions come from a variety of sources including engine power losses. Engine power losses are determined in accordance with engine operating metrics such as power production per unit fuel consumption and power production per unit emission production. Engine power losses are combined in accordance with assigned weighting into a single engine power loss term for use in the power loss minimization control and operating point selection.

Owner:GM GLOBAL TECH OPERATIONS LLC

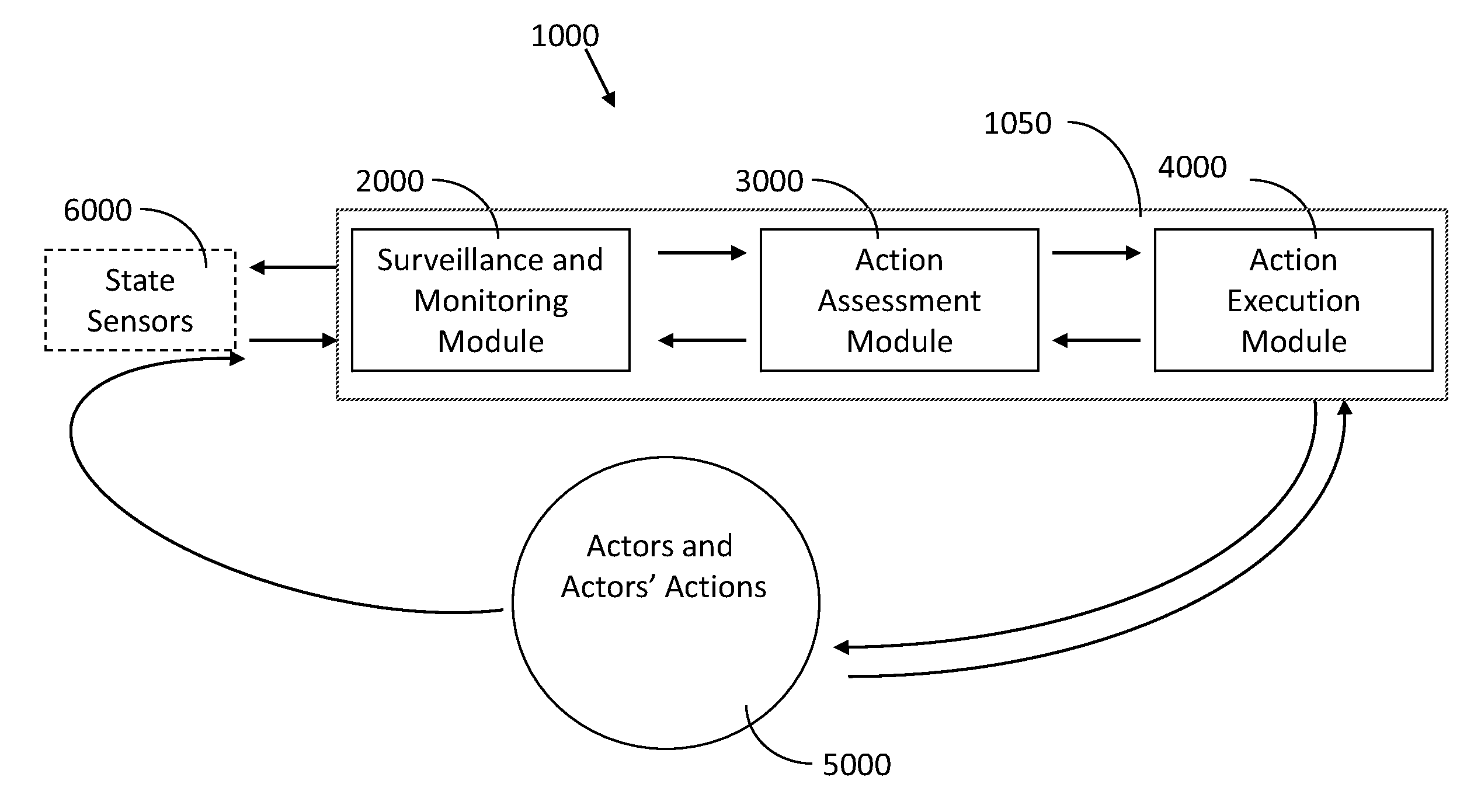

Systems and methods for comprehensive insurance loss management and loss minimization

InactiveUS20130226624A1Facilitate typeFacilitate communicationFinanceTelevision systemsMedicineLoss minimization

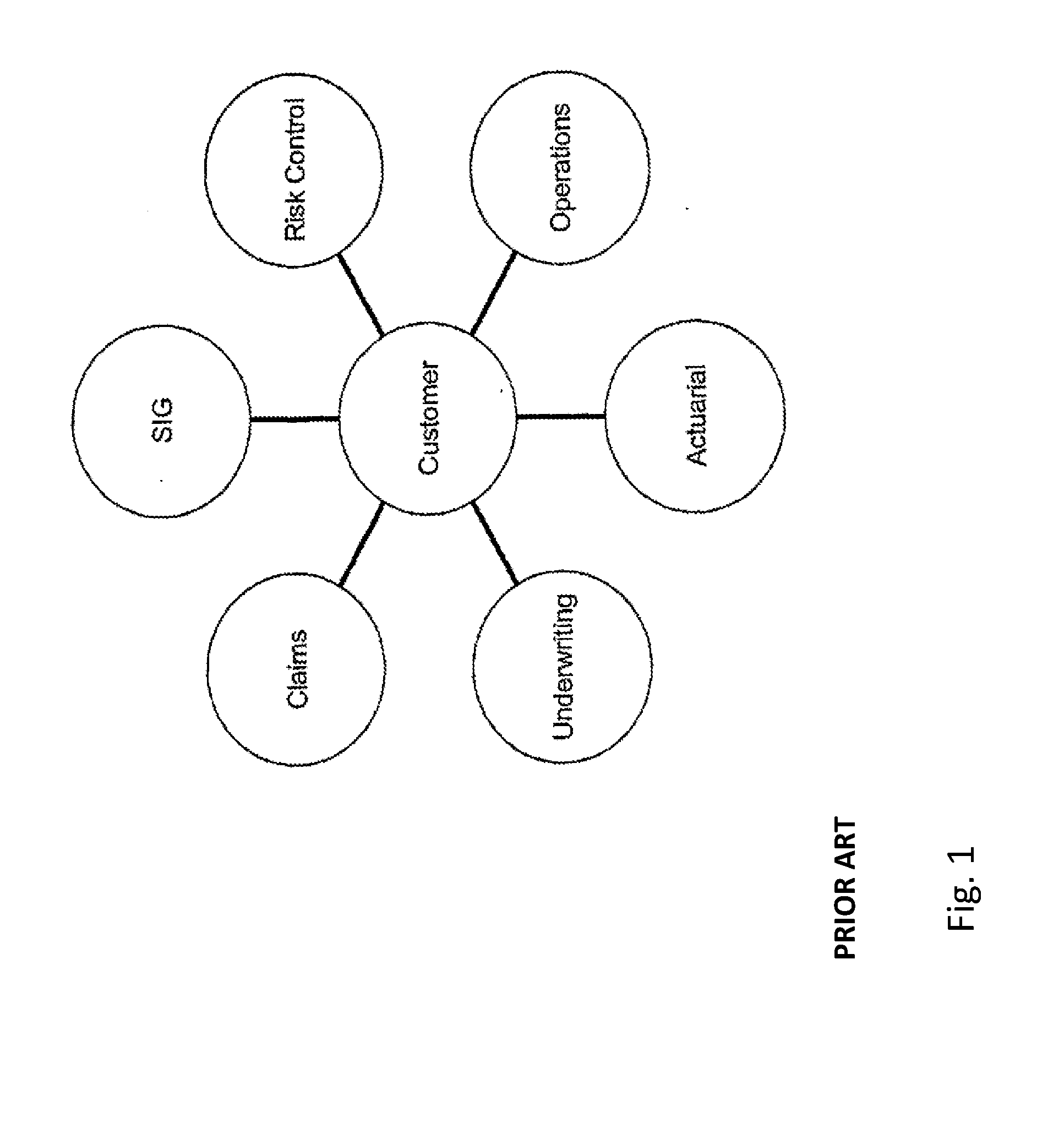

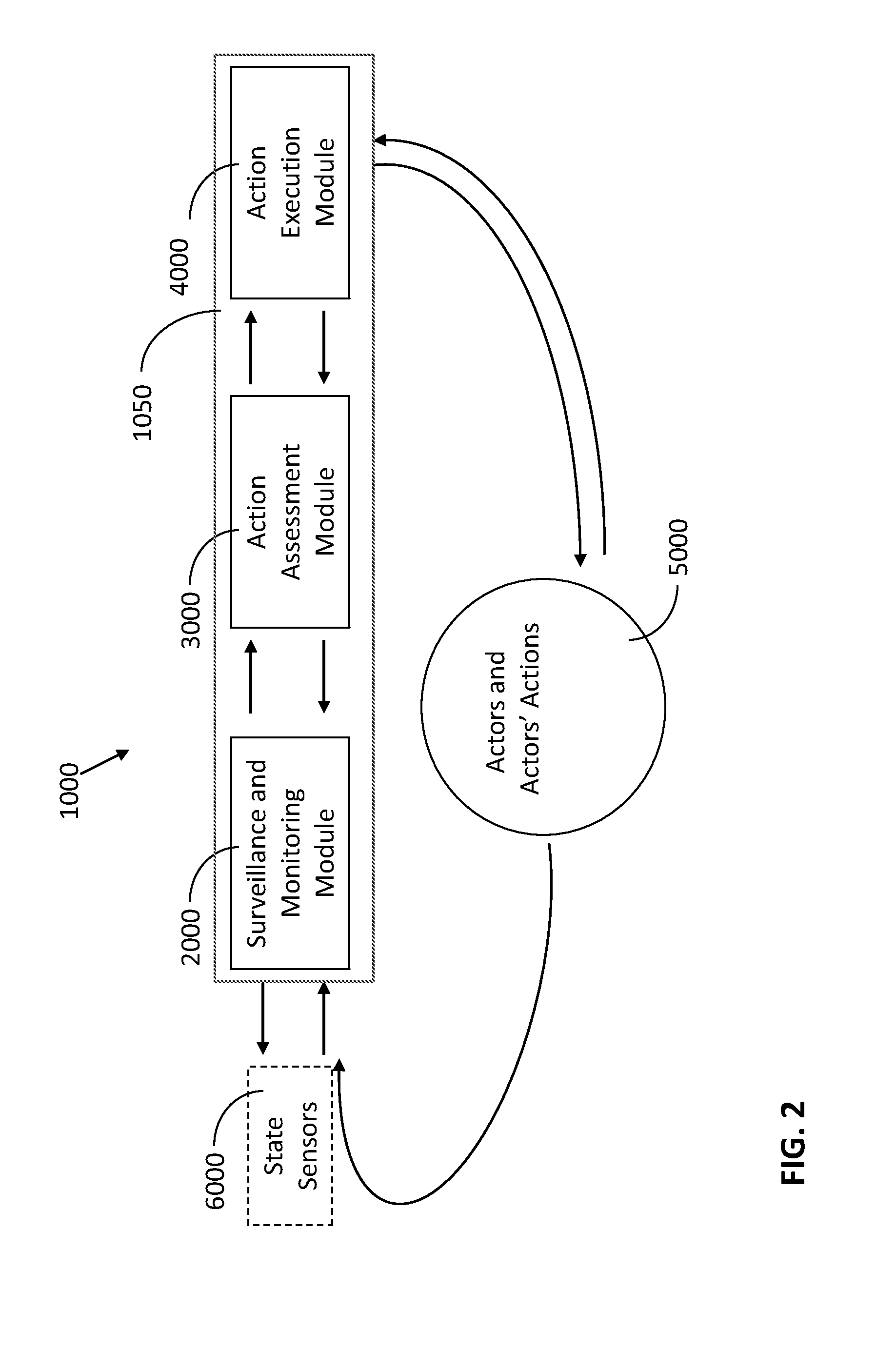

Embodiments of the present invention are generally related to a system and method for comprehensive management and minimization of insurance loss. In particular, insurance perils and insured assets are monitored, potential perils to insured assets are assessed, possible actions are determined, and selected actions are executed involving actors such as the policyholder, insurance agent, mitigation responder, and insurance appraiser. Particular embodiments address damage mitigation during peril and incident management after peril, to the policyholder and / or insured assets. Particular embodiments address the interaction between re-insurance companies and the aforementioned actors and / or insurance companies or cedants to integrate the information and resources of each respective party to provide more comprehensive and economically efficient loss mitigation.

Owner:B3 LLC

Cost structure method including fuel economy and engine emission considerations

ActiveUS20050256633A1Analogue computers for vehiclesElectrical controlOperating pointPowertrain control

A powertrain control selects engine operating points in accordance with power loss minimization controls. Power loss contributions come from a variety of sources including engine power losses. Engine power losses are determined in accordance with engine operating metrics such as power production per unit fuel consumption and power production per unit emission production. Engine power losses are combined in accordance with assigned weighting into a single engine power loss term for use in the power loss minimization control and operating point selection.

Owner:GM GLOBAL TECH OPERATIONS LLC

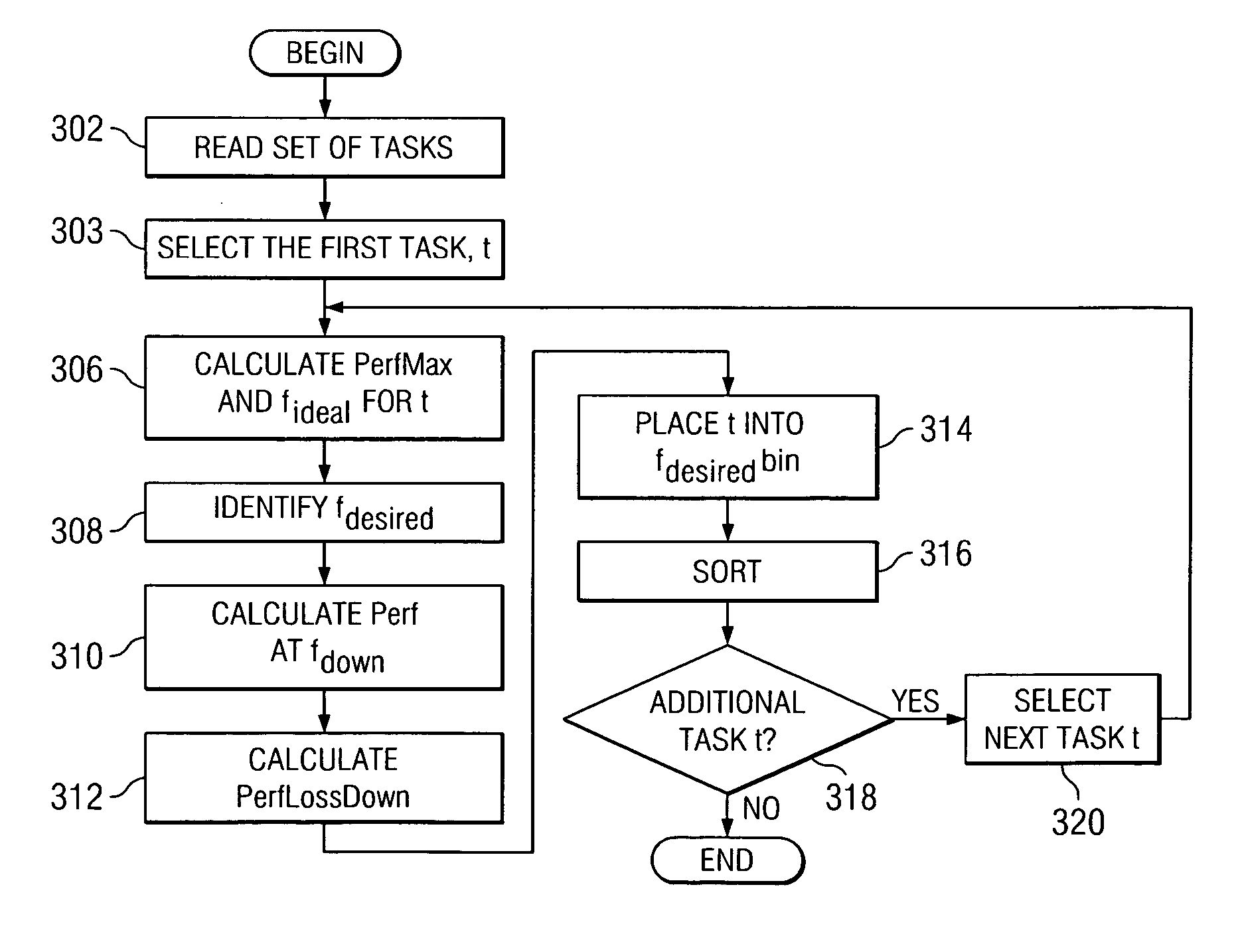

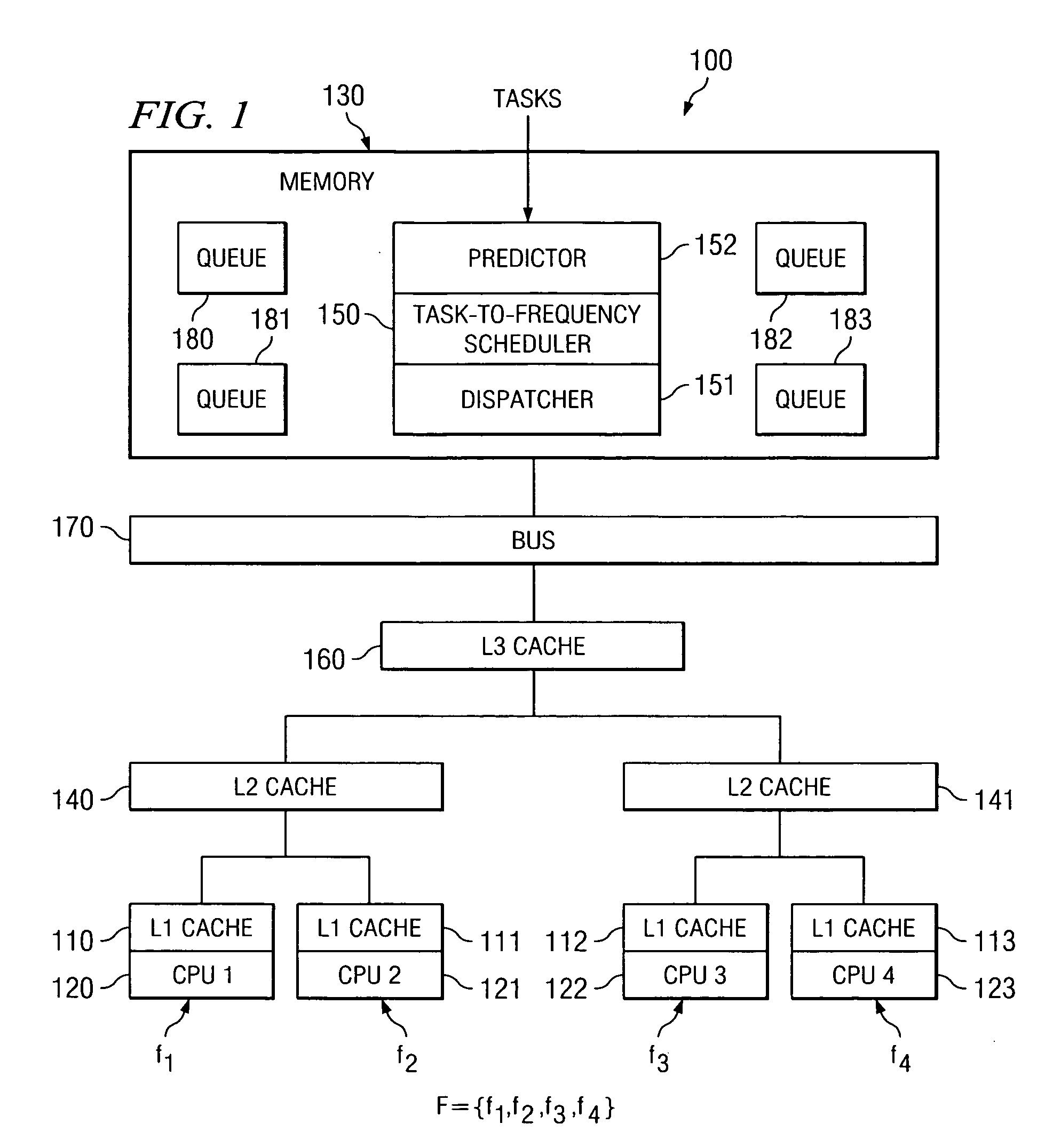

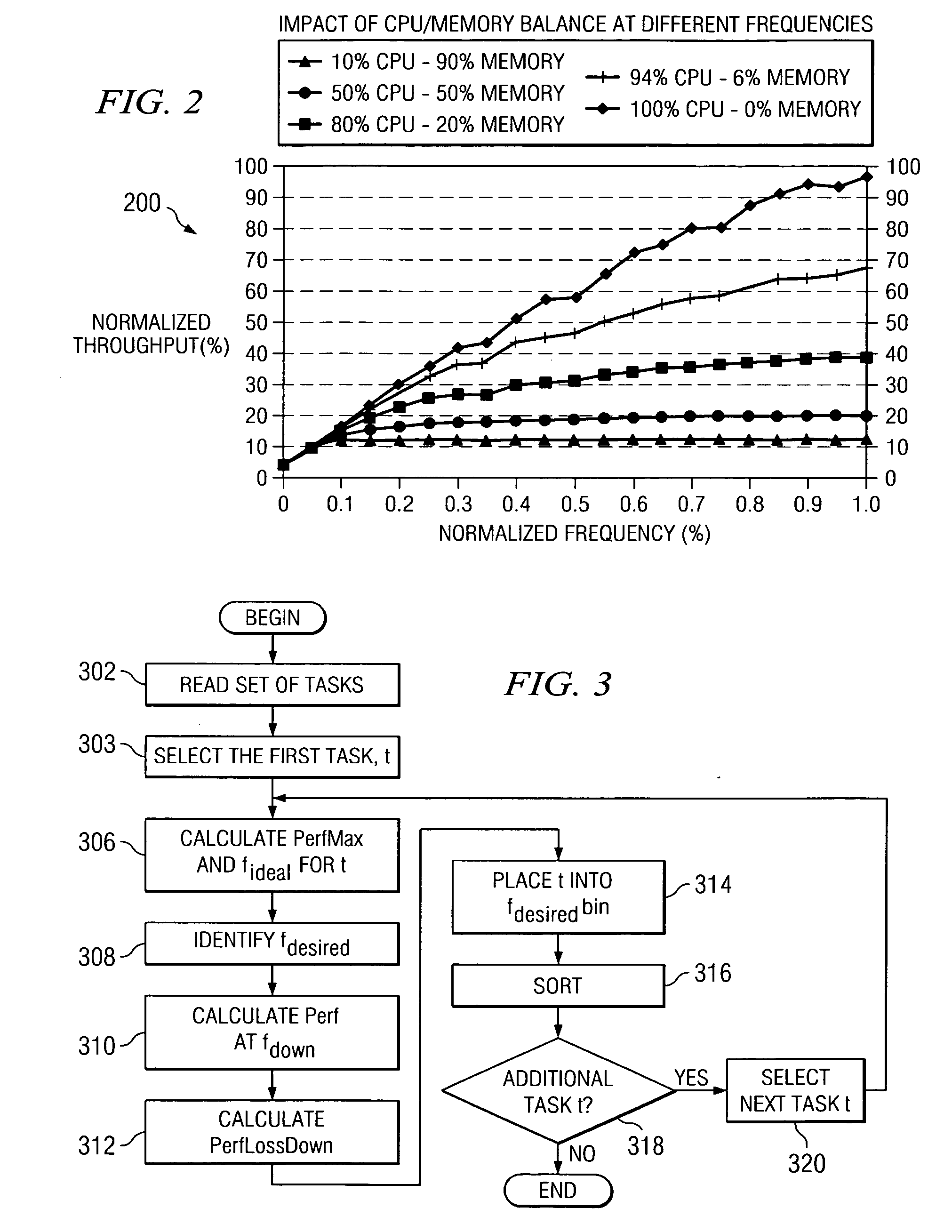

System and method for optimized task scheduling in a heterogeneous data processing system

InactiveUS20060168571A1Optimizing task throughputPerformance of was minimizedEnergy efficient ICTEnergy efficient computingData processing systemLoad Shedding

A method, computer program product, and a data processing system for optimizing task throughput in a multi-processor system. A performance metric is calculated based on performance counters measuring characteristics of a task executed at one of a plurality of processor frequencies available in the multi-processor system. The characteristics measured by the performance counters indicate activity in the processor as well as memory activity. A performance metric provides a means using measured data at one available frequency to predict performance at another processor frequency available in the multi-processing system. Performance loss minimization is used to assign a particular task to a particular frequency. Additionally, the present invention provides a mechanism for priority load balancing of tasks in a manner that minimizes cumulative performance loss incurred by execution of all tasks in the system.

Owner:IBM CORP

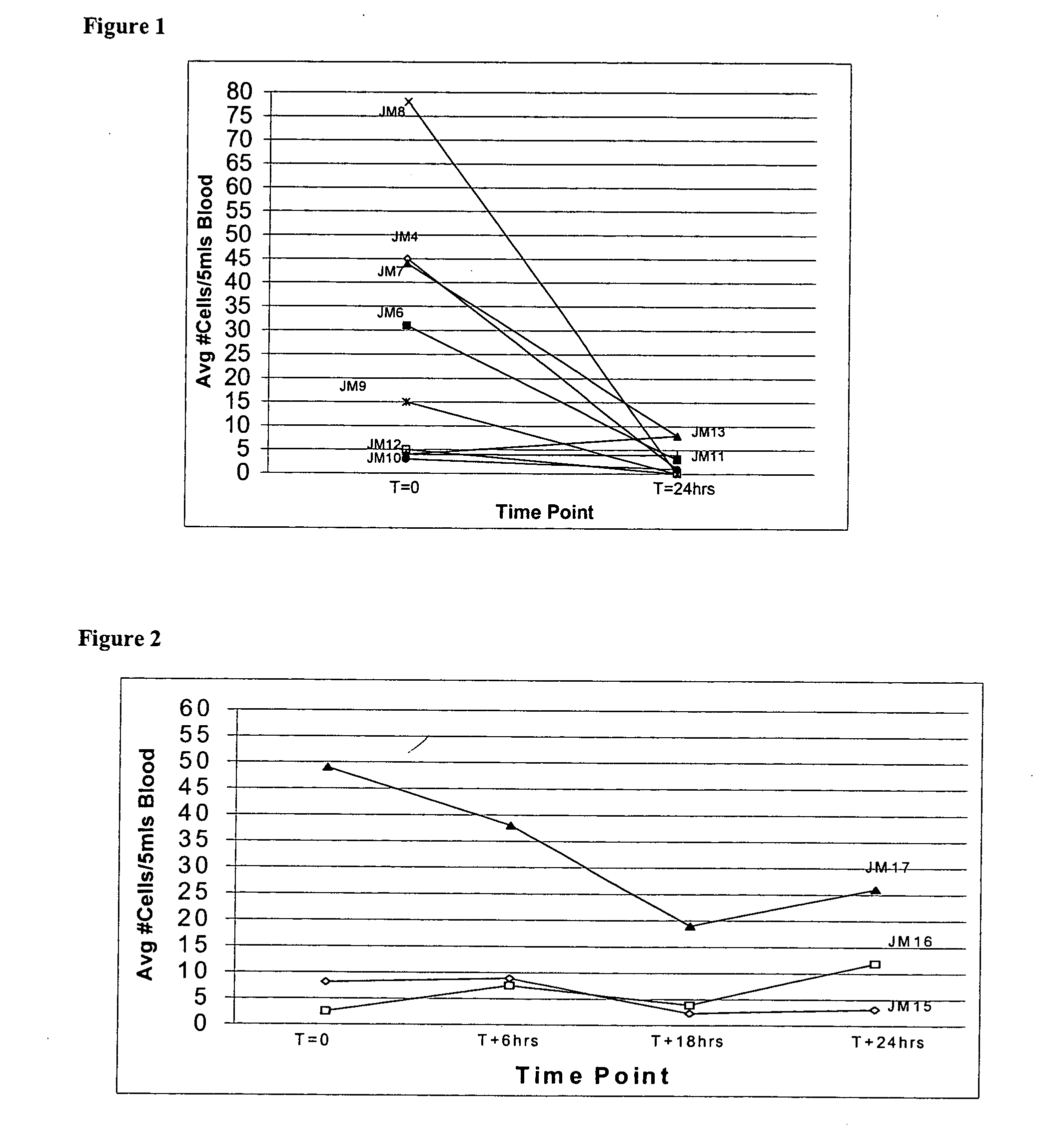

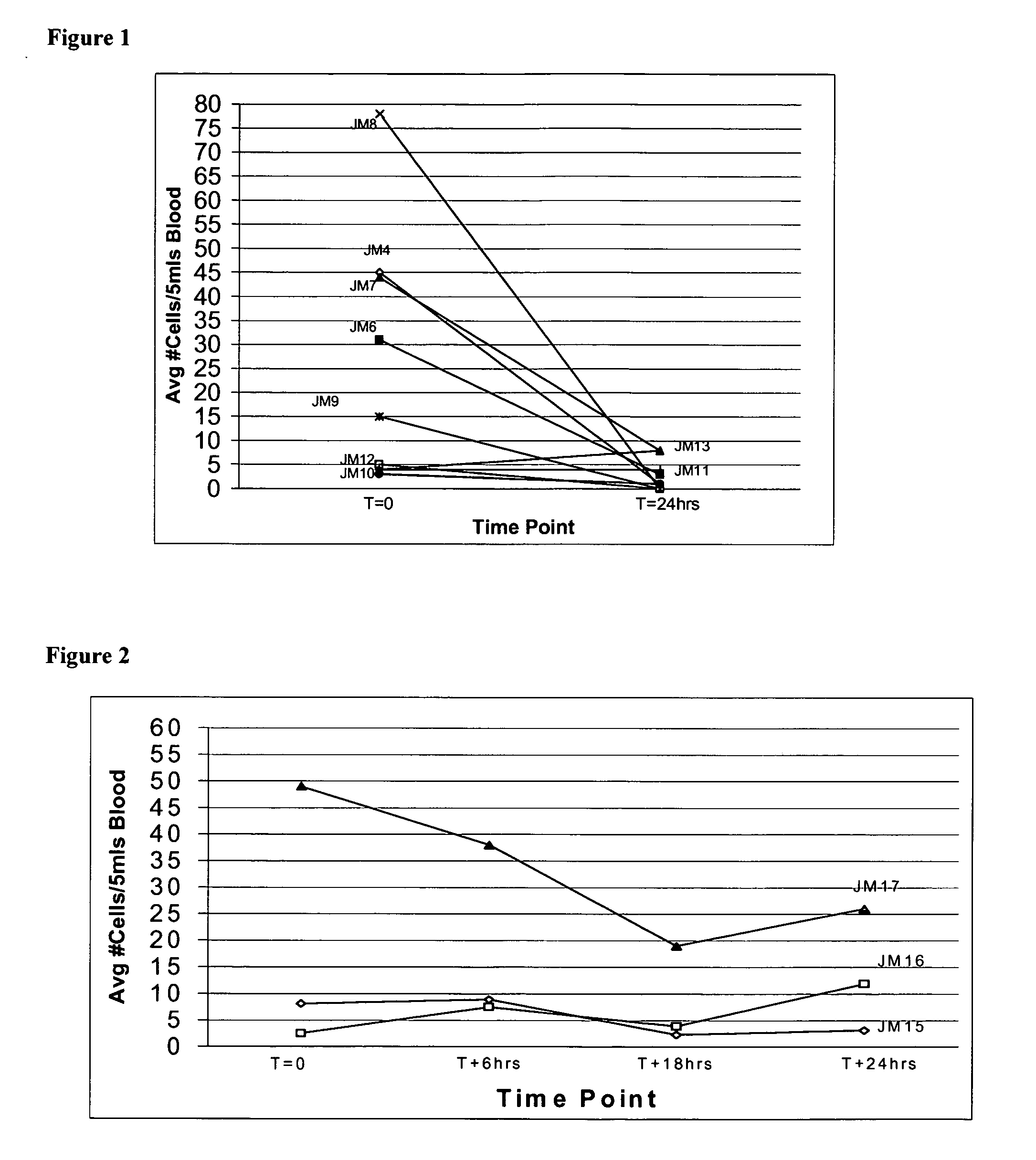

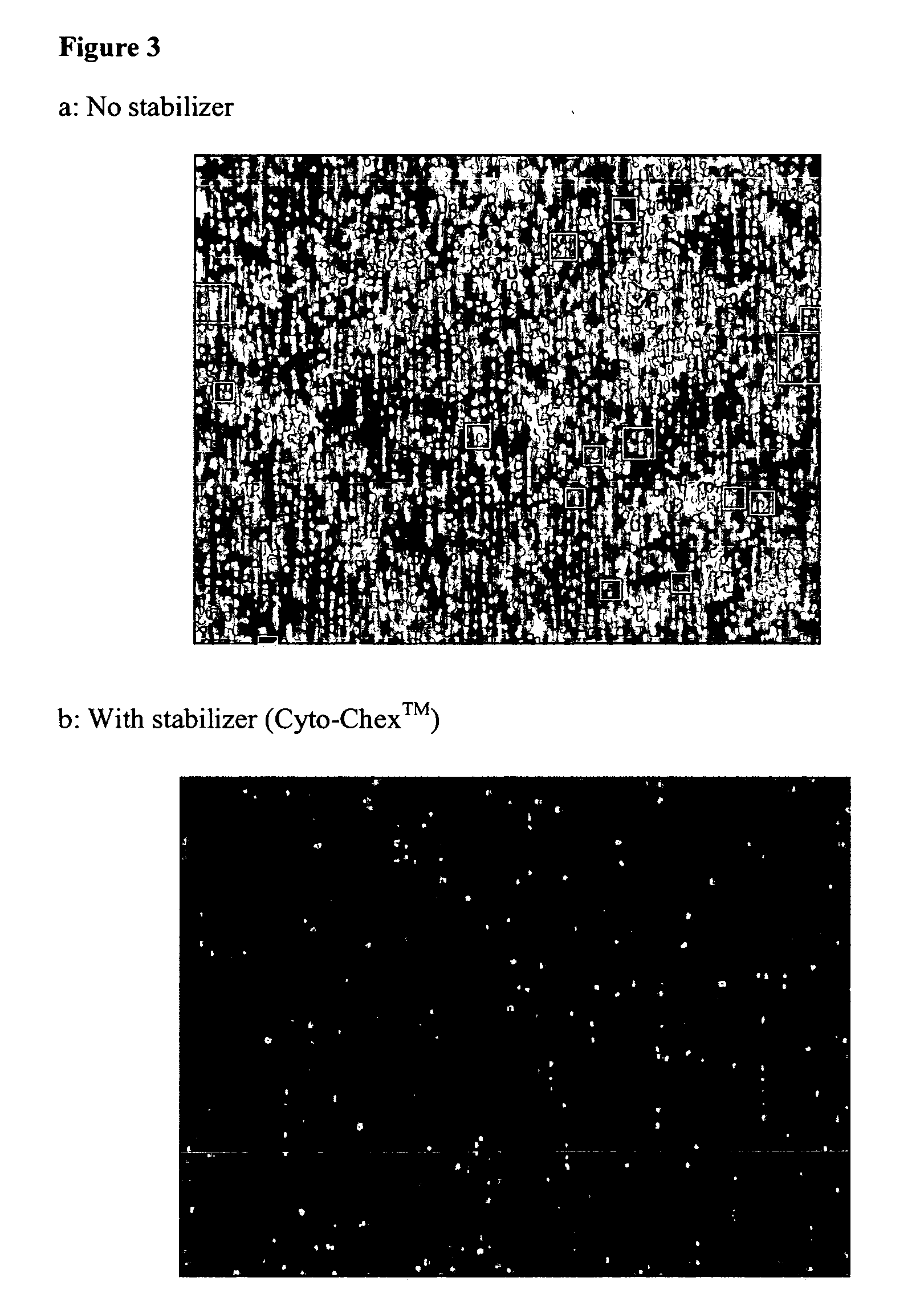

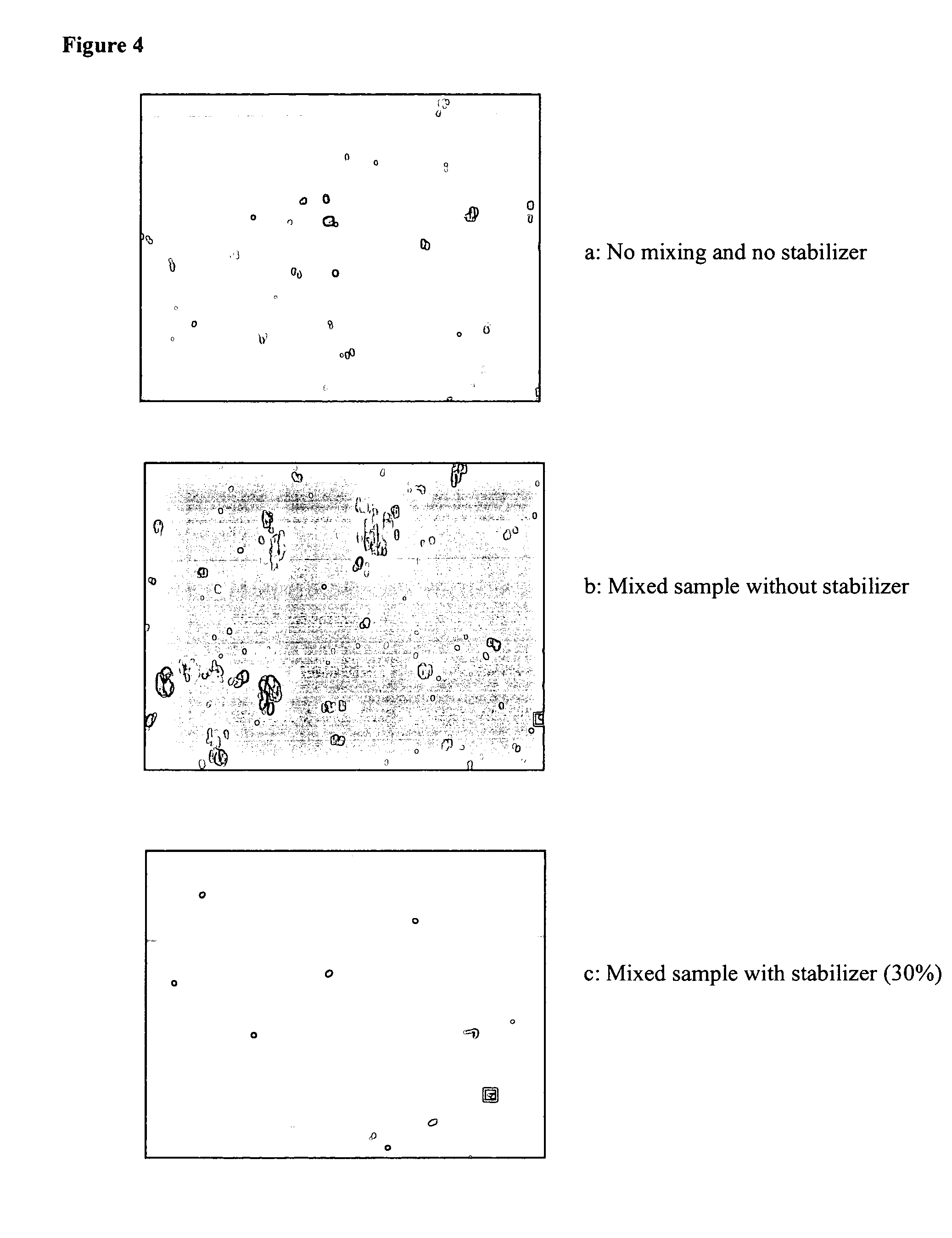

Stabilization of cells and biological specimens for analysis

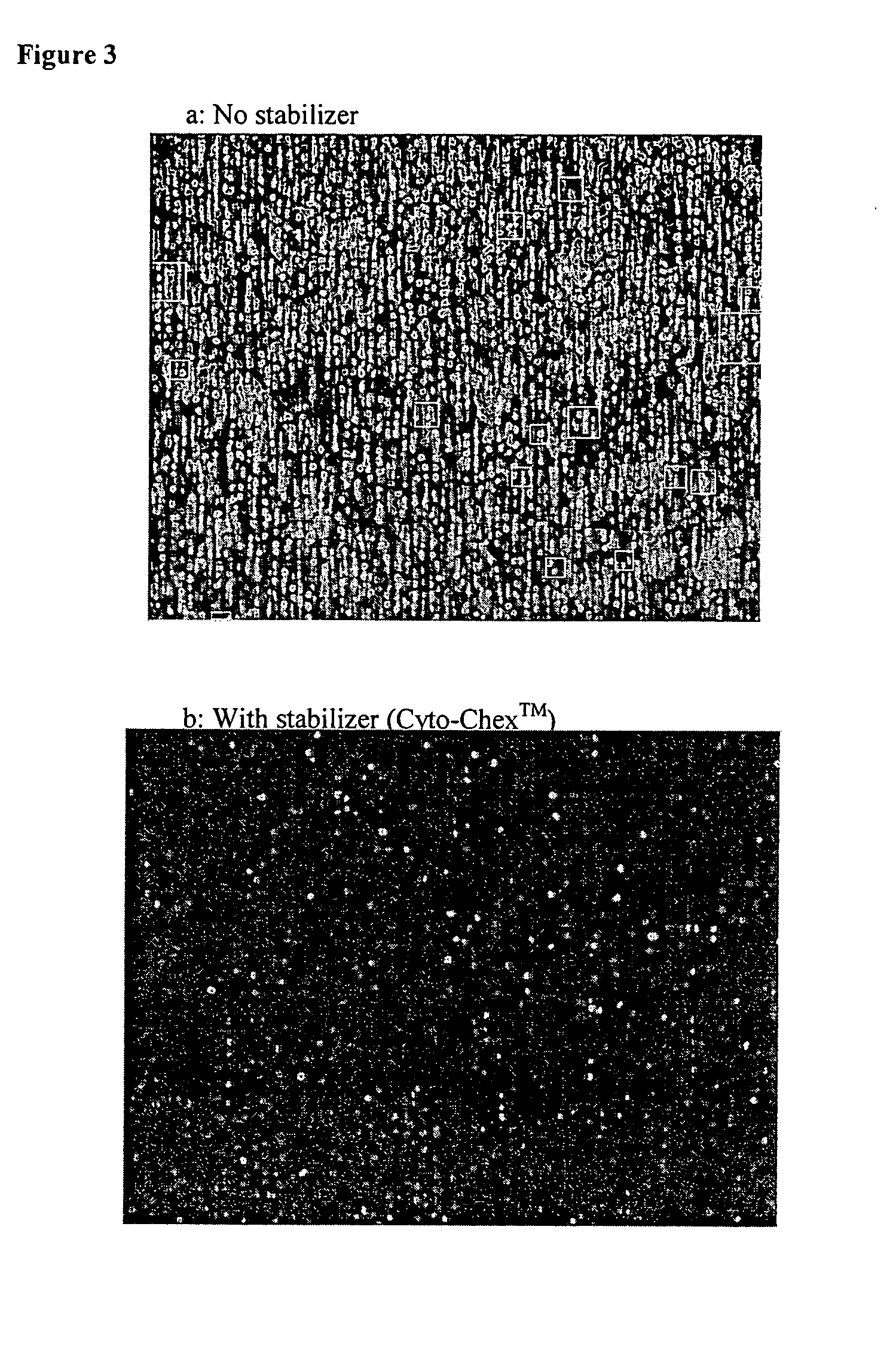

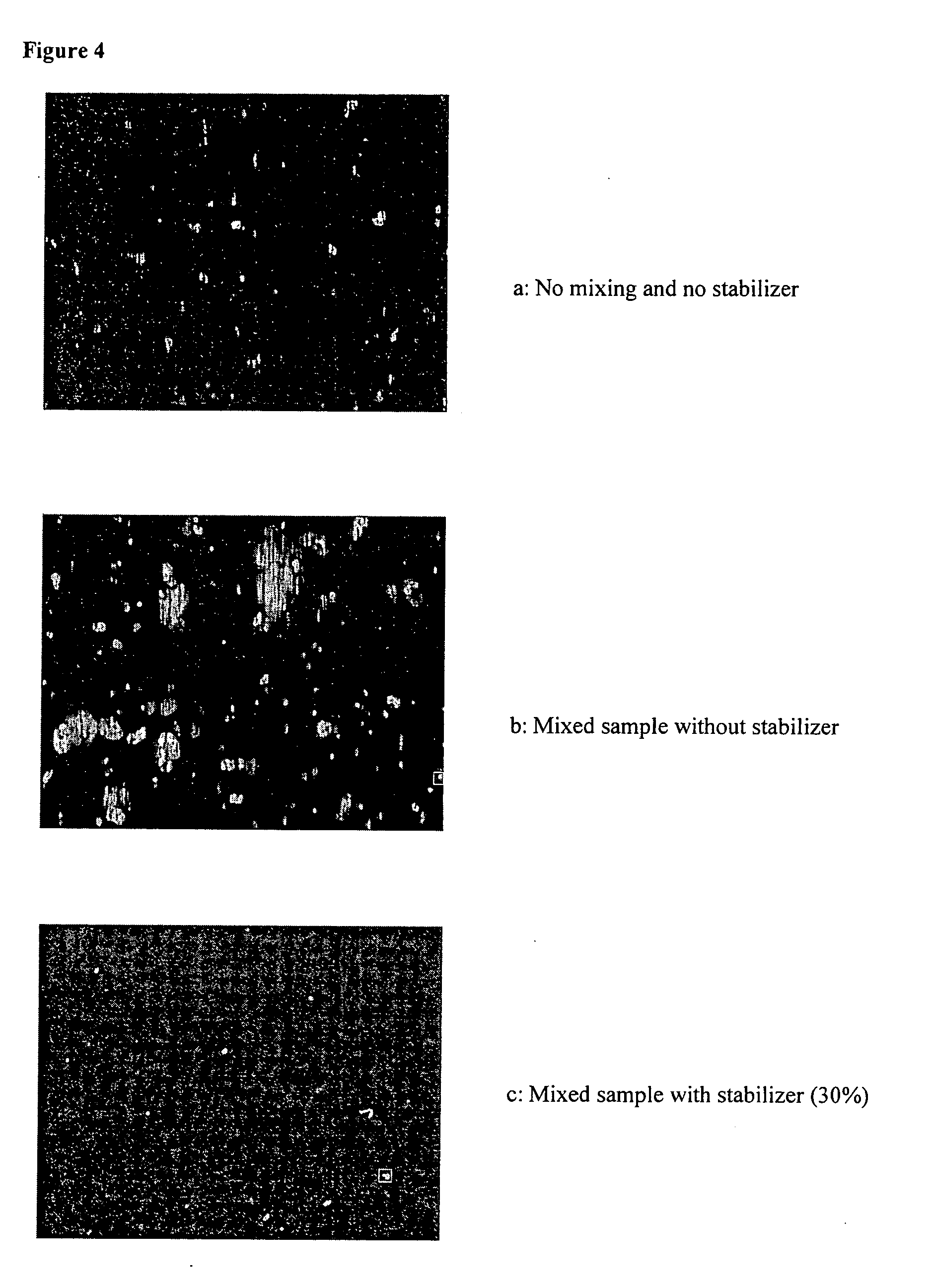

InactiveUS20050181353A1Improve stabilityMaintain qualityOrganic active ingredientsBiocideAbnormal tissue growthIn vivo

Compositions and methods for stabilizing rare cells in blood specimens, preserving the quality of blood specimens, and also serving as cell fixatives are disclosed which minimize losses of target cells (for example, circulating tumor cells) and formation of debris and aggregates from target cells, non-target cells and plasma components, thereby allowing more accurate analysis and classification of circulating tumor cells (CTC) and, ultimately, of tumor burdens in cancer patients. Stabilization of specimens is particularly desirable in protocols requiring rare cell enrichment from blood specimens drawn from cancer patients. Exposure of such specimens to potentially stressful conditions encountered, for example, in normal processing, mixing, shaking, delays due to transporting the blood, has been observed to not only diminish the number of CTC but also to generate debris and aggregates in the blood specimens that were found to interfere with accurate enumeration of target cells, if present. Stabilizers are necessary to discriminate between in vivo CTC disintegration and in vitro sample degredation.

Owner:VERIDEX LCC

Method of purifying protein

InactiveUS20060142549A1Efficient removalSerum immunoglobulinsColony-stimulating factorActive proteinDNA Contamination

Problems to be Solved: The present invention provides a simpler and less expensive method for purifying physiologically active proteins, especially antibodies, which can ensure removal of impurities such as DNA contaminants and viruses, and which can minimize a loss of physiologically active proteins. Means for Solving the Problems: A method for removing impurities in a physiologically active protein-containing sample, which comprises the following steps: 1) allowing the physiologically active protein-containing sample to be converted into an aqueous solution of low conductivity at a pH below the isoelectric point of the physiologically active protein; and 2) removing the resulting particles.

Owner:CHUGAI PHARMA CO LTD

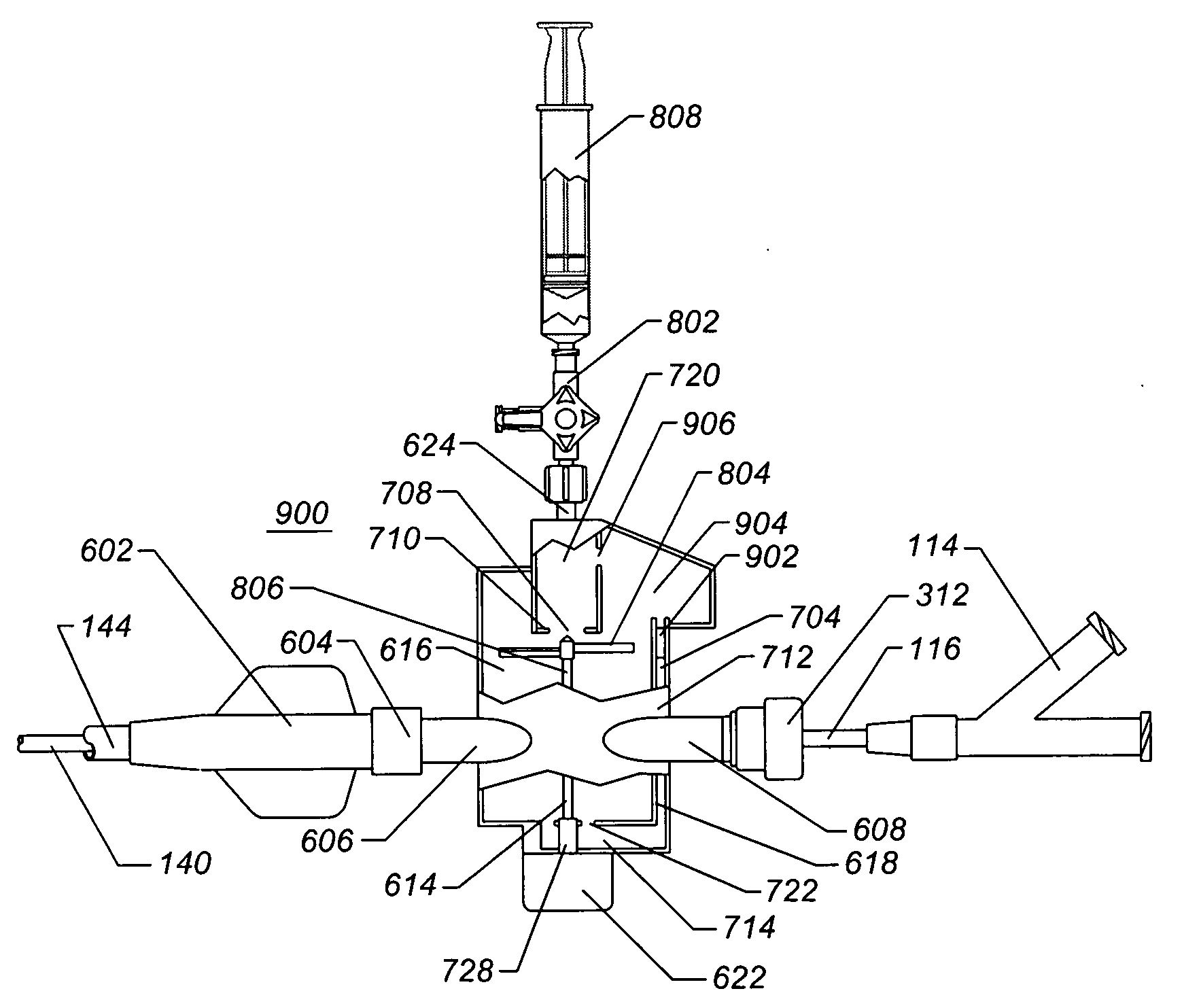

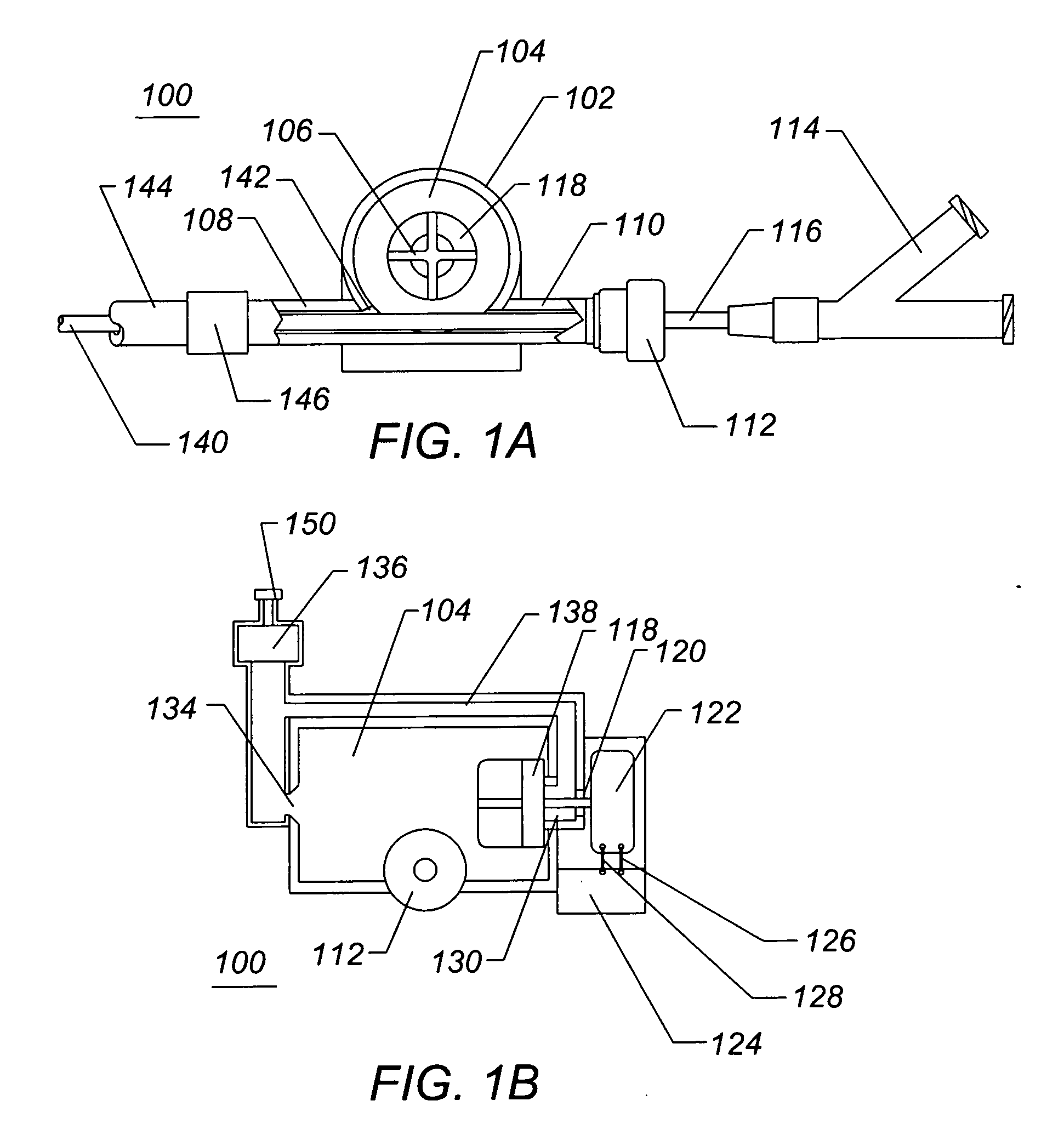

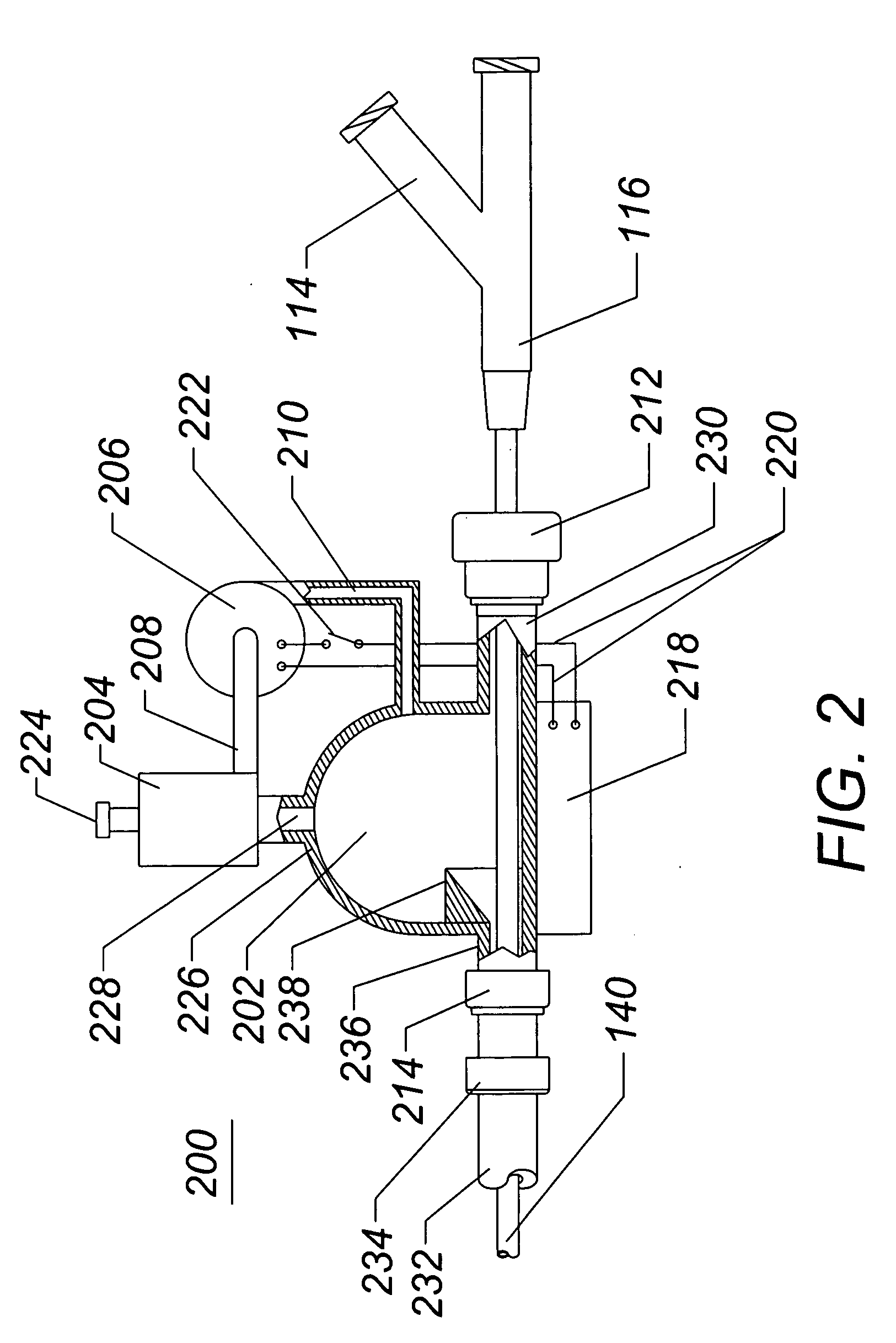

Method and apparatus for prevention of catheter air intake

InactiveUS20090163864A1Quantity minimizationEasy to removeMedical devicesIntravenous devicesEngineeringHemostasis valve

A system is disclosed for preventing air from entering a first catheter or cannula of a multi-catheter system. Air is prevented from entering the proximal end of the first catheter by an axially elongate chamber having an impeller, the chamber being affixed to the proximal end of the first catheter. The first catheter is affixed at an offset location, near the periphery of the chamber. The impeller is driven by a motor drive and imparts rotational energy to the fluid within the chamber forcing any air within the chamber to migrate to the center of the chamber by buoyancy effects. The air is removed through a port near the centerline of the chamber. Liquid removed with the air is returned to the chamber to minimize liquid loss during the procedure. Hemostasis valves or seals can be provided at the entrance and the exit of the chamber. A second catheter inserted through the chamber and into the first catheter is unable to entrain gas into the first catheter because any gas that enters the chamber is routed to the centerline of the chamber where it is removed. The first catheter can be a cannula or an introduction sheath, devices suited for endovascular access into the mammalian cardiovascular system where pressures may fall below ambient room pressure, a condition, which could encourage the possibility of air embolism to a patient. Inflow of fluid from an external pump scrubs the second catheter shaft of air bubbles attached by surface tension.

Owner:INDIAN WELLS MEDICAL

Stabilization of cells and biological specimens for analysis

InactiveUS20060194192A1Improve stabilityMaintain qualityOrganic active ingredientsDead animal preservationAbnormal tissue growthIn vivo

Owner:JANSSEN DIAGNOSTICS LLC

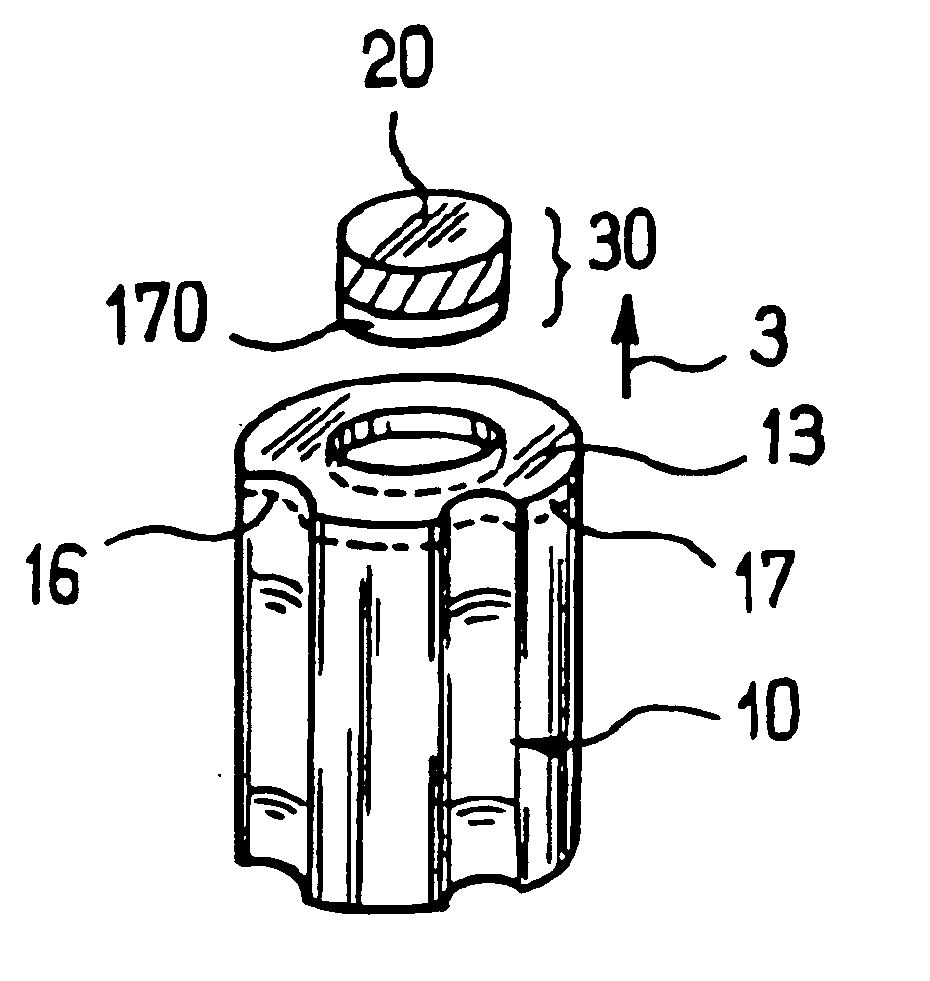

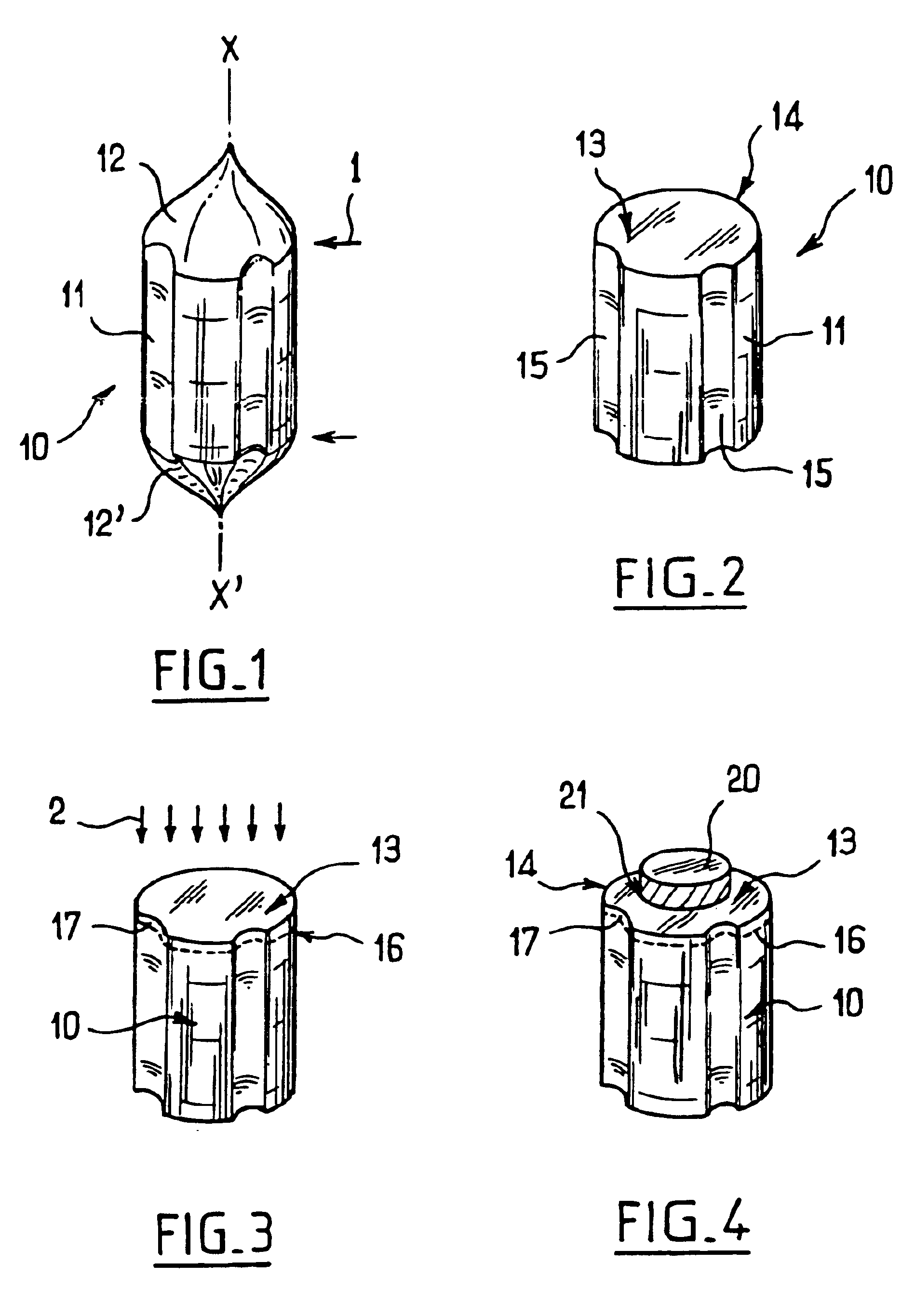

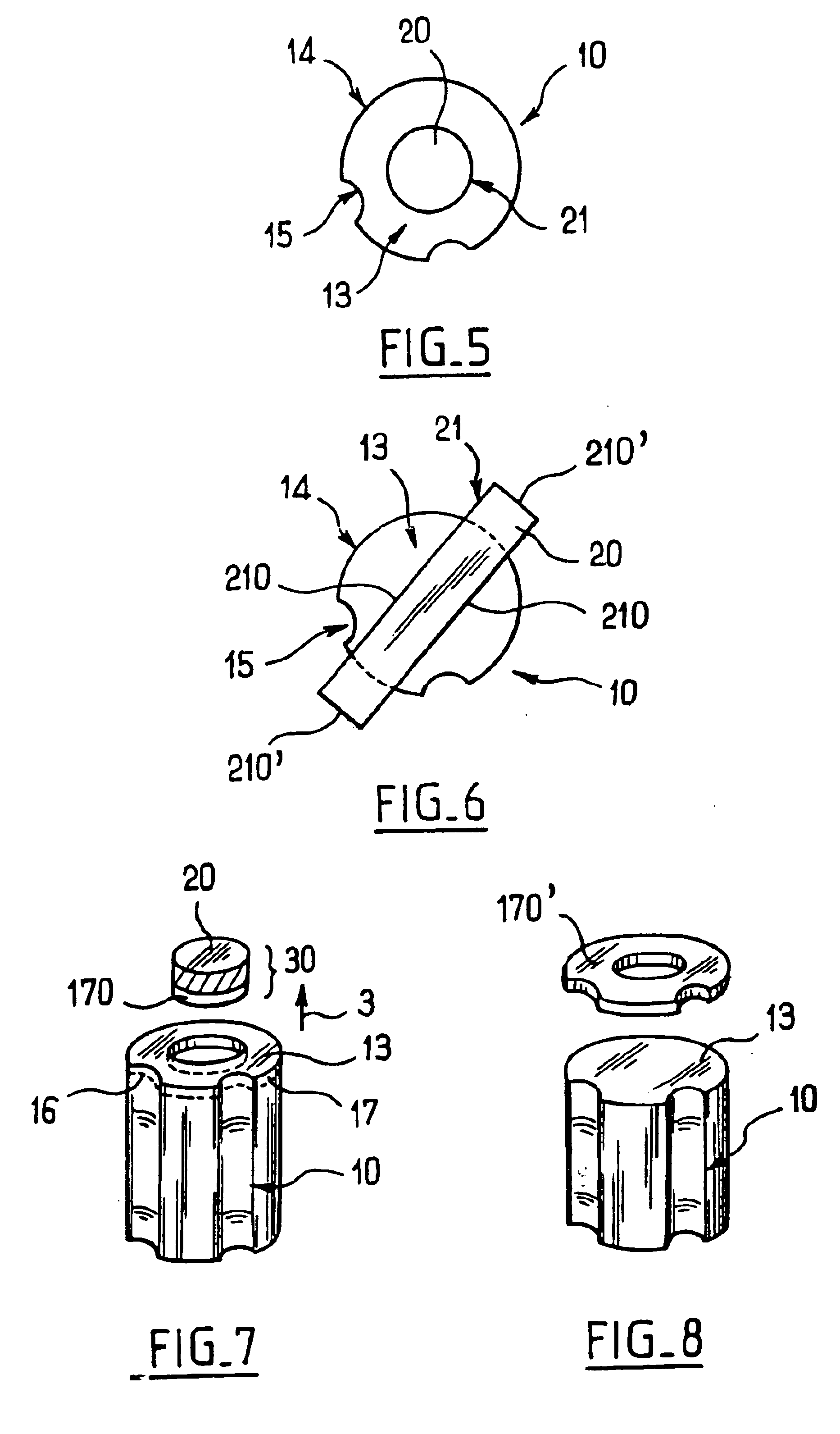

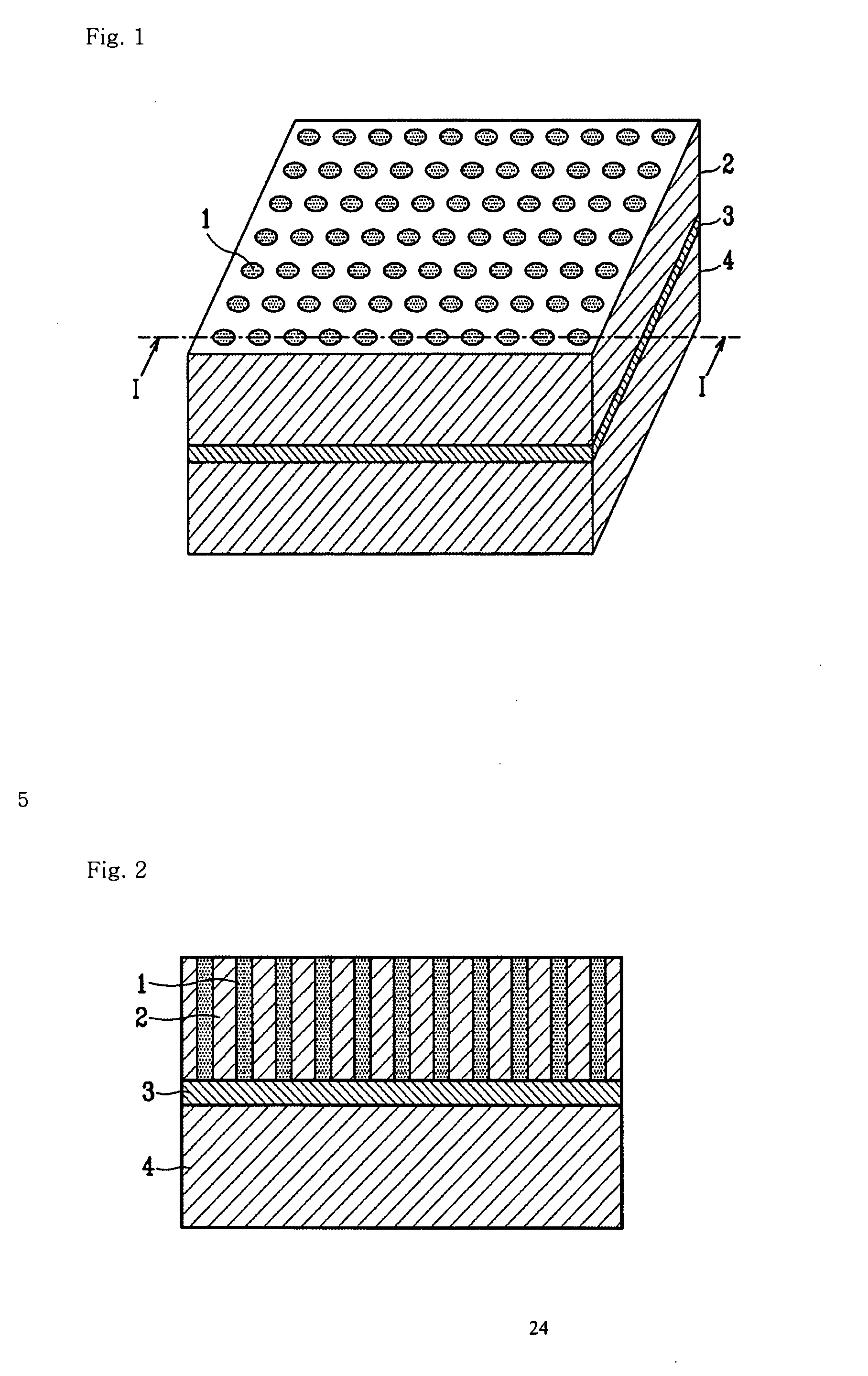

Method of fabricating substrates, in particular for optics, electronics or optoelectronics

ActiveUS6858107B2Reduce lossesDecorative surface effectsSemiconductor/solid-state device manufacturingOptoelectronicsIngot

A method of fabricating substrates while minimizing loss of starting material of an ingot, wherein a layer is transferred onto a support. The technique includes forming a flat front face on a raw ingot of material, implanting atomic species through the front face to a controlled mean implantation depth to create a zone of weakness that defines a top layer of the ingot, bonding a support to the front face of the ingot, wherein the support has a surface area that is smaller than a surface area of the front face of the ingot, and detaching from the ingot at the zone of weakness that portion of the top layer that is bonded to the support to form the substrate.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

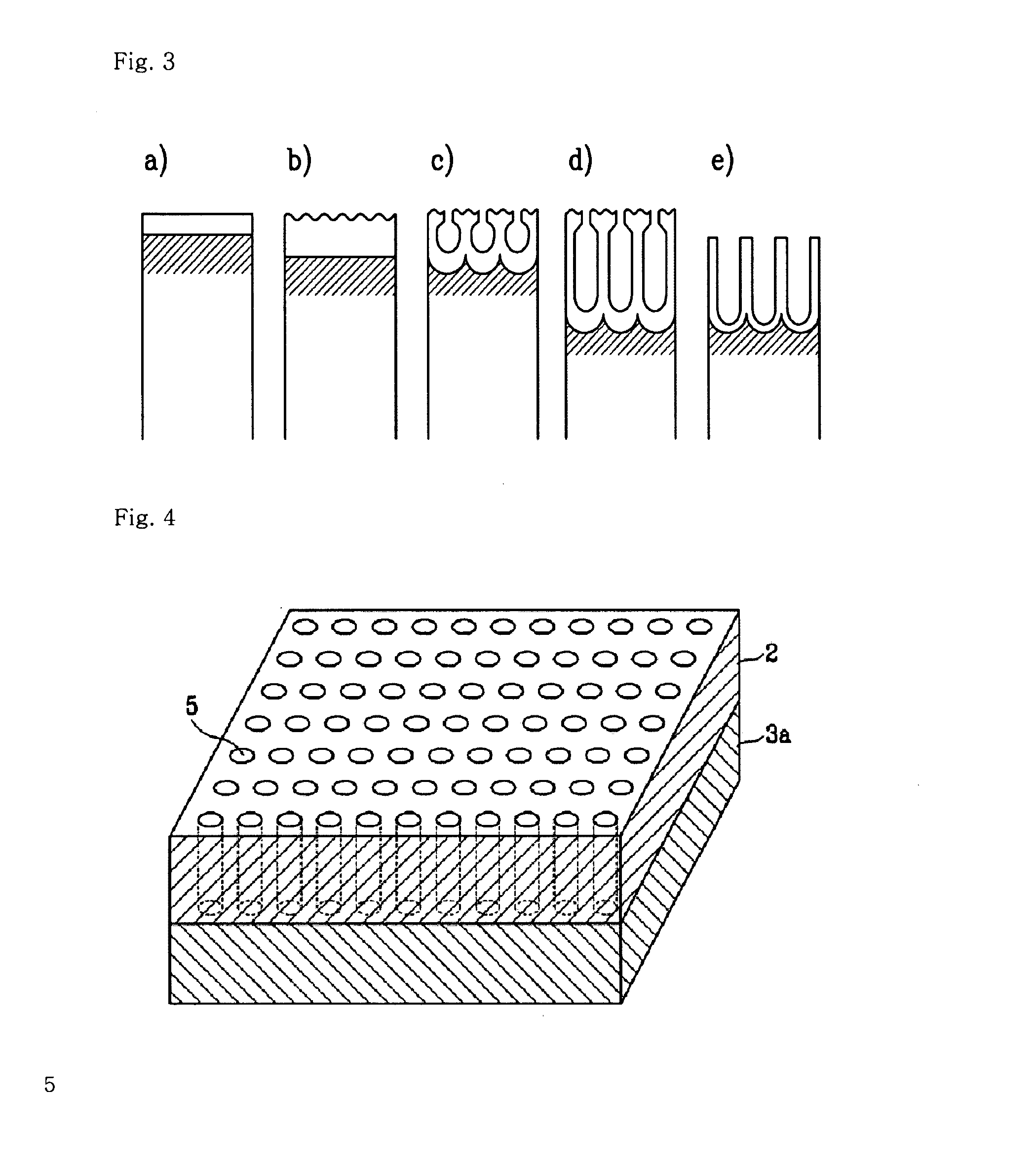

Method for preparing electrode system, electrode system prepared therefrom, and electric device comprising the same

ActiveUS20050117194A1Improve response speedRaise transfer toHybrid capacitor electrodesFinal product manufactureElectron holeSupercapacitor

Provided are a method for preparing an electrode system, an electrode system prepared therefrom, and an electric device including the same. The method includes the steps of forming a porous template having nanopores on a first electrode, wherein a diameter of the nanopores is between 5 to nm 500 nm; and forming a rod-type / tube-type second electrode inside the nanopores which are connected to the first electrode, the electrode system prepared therefrom, and an electric device including the same. With the large surface area, the electrode system of the present research improves efficiency and performance of various electric devices. The contrast and respond speed of the electrochromic device can be increased, and the number of electron-hole pairs of a solar cell is increased. The loss of electron-hole pairs is minimized, and charge storage of the supercapacitor and charge respond speed is heightened.

Owner:LG CHEM LTD

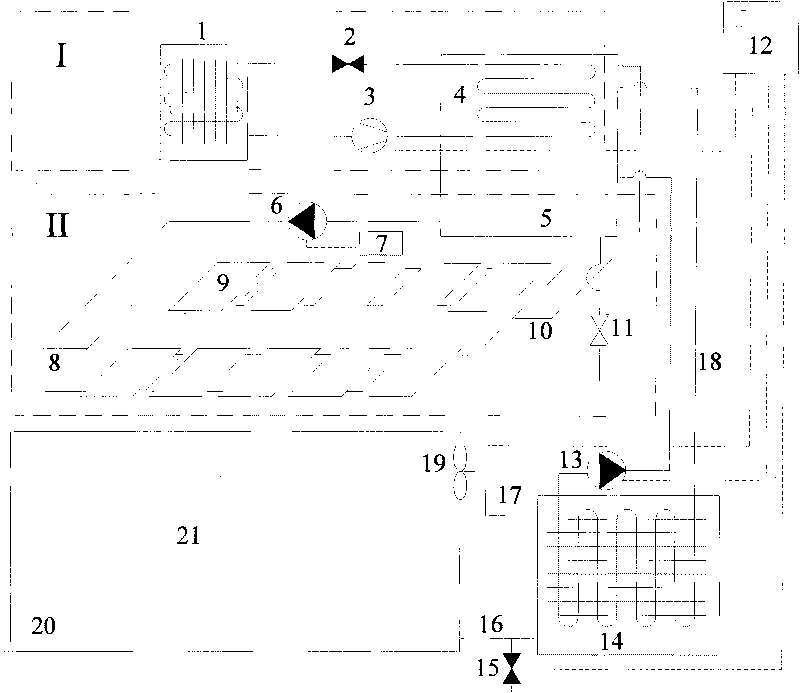

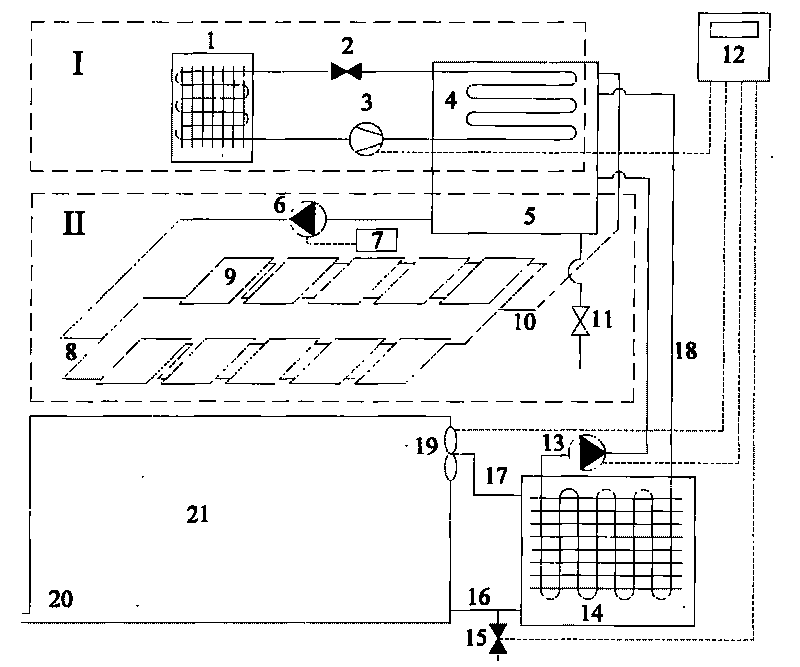

Bulk curer heat supply and ventilation system supplied by combined solar energy-air source heat pump double heat sources

InactiveCN101711599AAchieve loss reduction and value addedReduce consumptionTobacco preparationSolar heat devicesThermal energyAtmospheric air

The invention discloses a bulk curer heat supply and ventilation system supplied by combined solar energy-air source heat pump double heat sources, which consists of a solar water heating subsystem, an air source heat pump water heating subsystem, an air-water heat exchanger, a frequency conversion circulating water pump, a heat insulating hot water pipeline, a main controller, a circulating fan, an air supply pipe, a fresh air valve and a curer wet air outlet. A condenser of the air source heat pump water heating subsystem is arranged in a heat accumulating water tank; the air source heat pump water heating subsystem is coupled with the solar water heating subsystem through the heat accumulating water tank; and the air source heat pump water heating subsystem adopts a CO2 high temperature refrigerant to prepare high temperature hot water between 85 and 90DEG C. The bulk curer heat supply and ventilation system adopts the solar water heating system and the air source heat pump water heating system, which are combined to operate, to supply heat to the curer, fully utilizes the clean solar energy and low-grade heat energy in the atmosphere, has the advantages of energy conservation, environmental protection and the like, and can realize loss minimization and value addition in the process of curing tobacco leaves.

Owner:KUNMING UNIV OF SCI & TECH

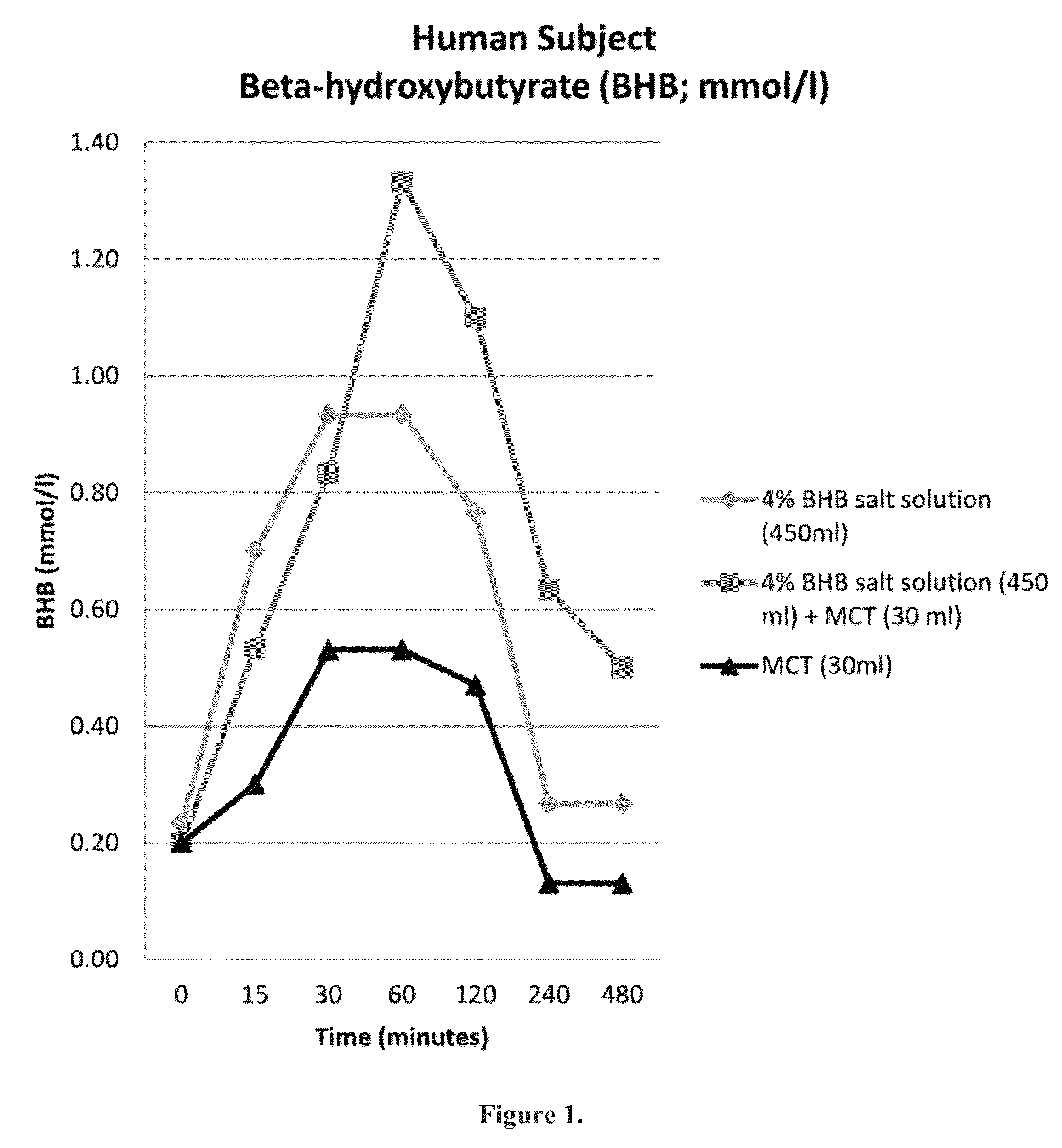

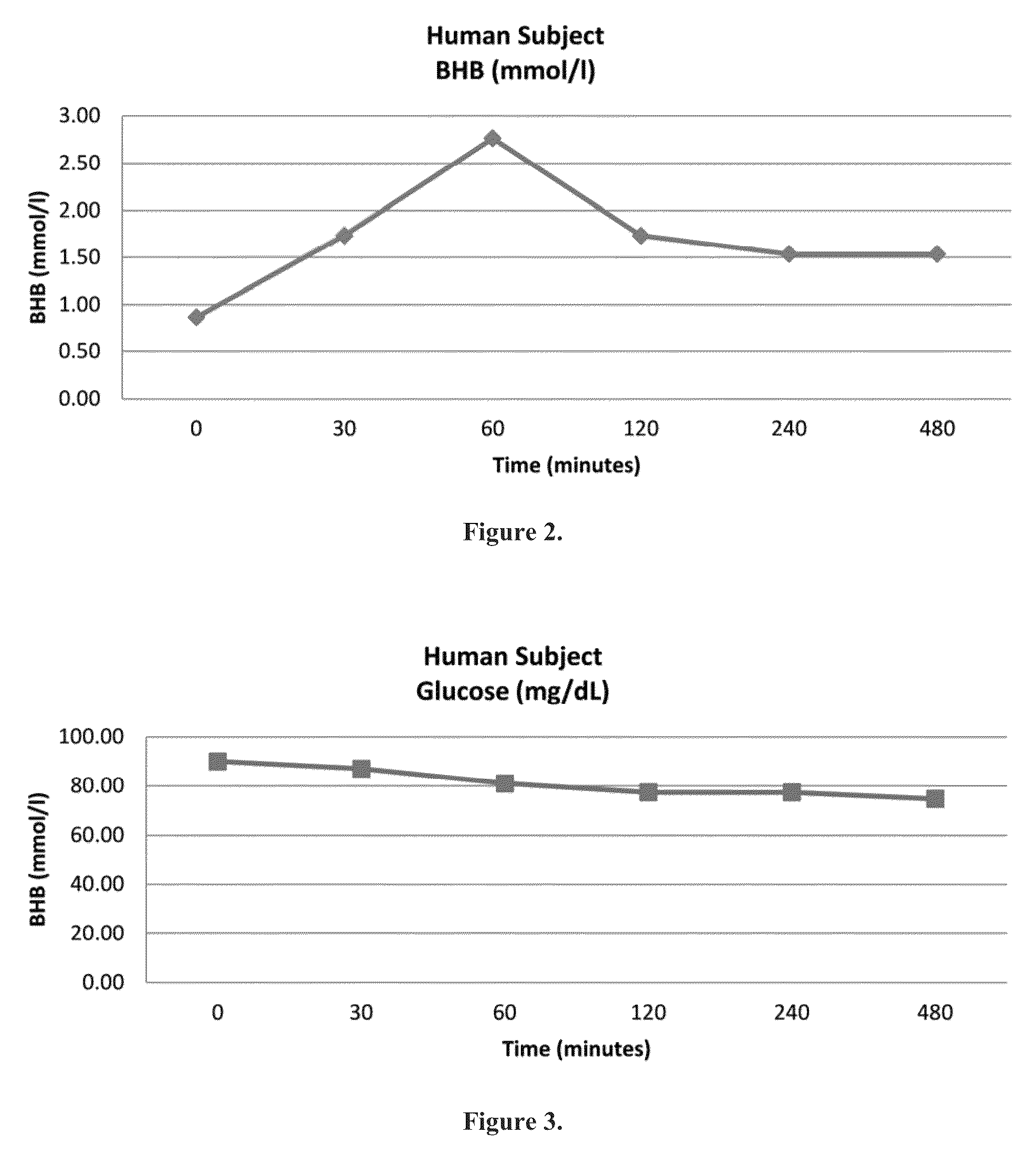

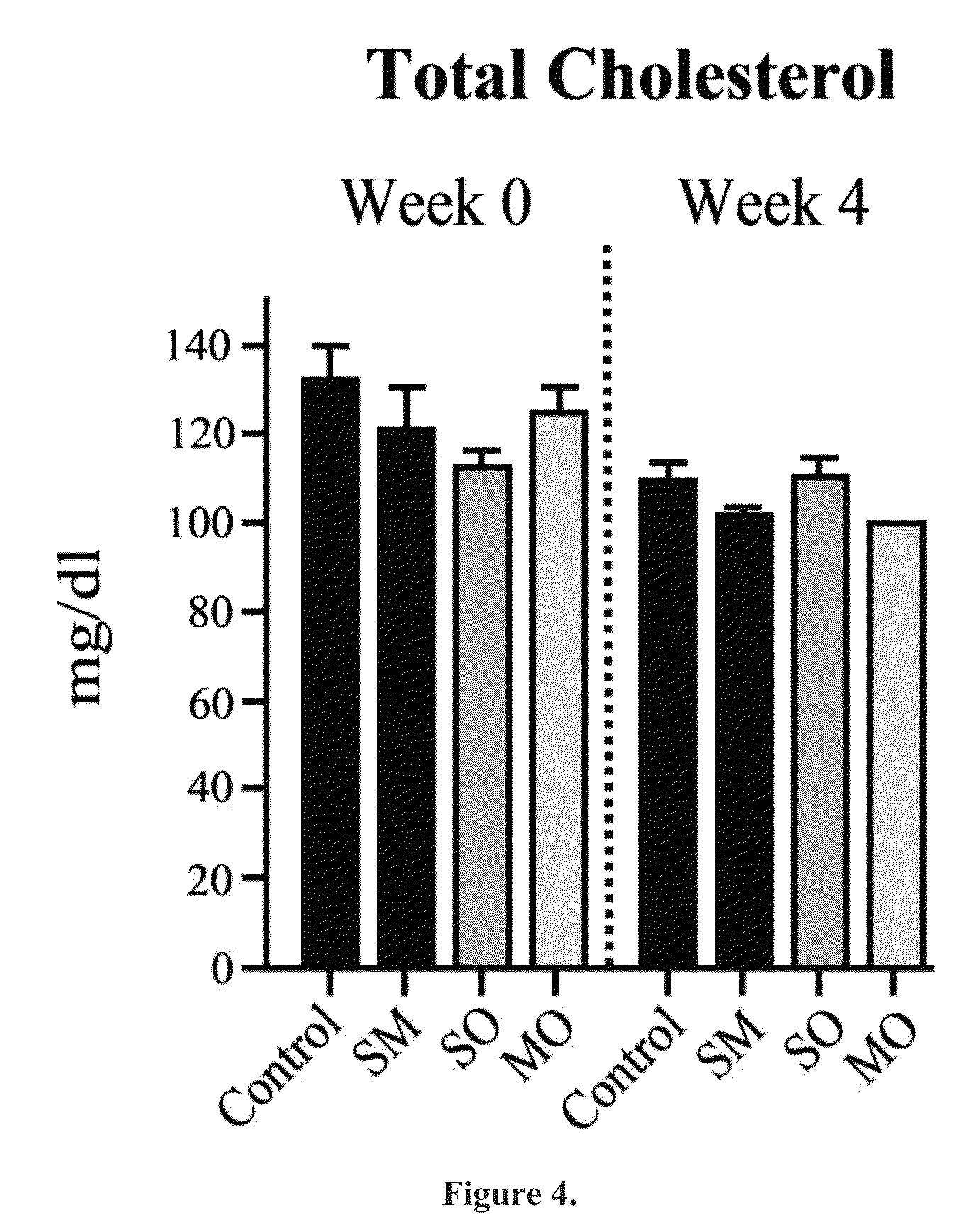

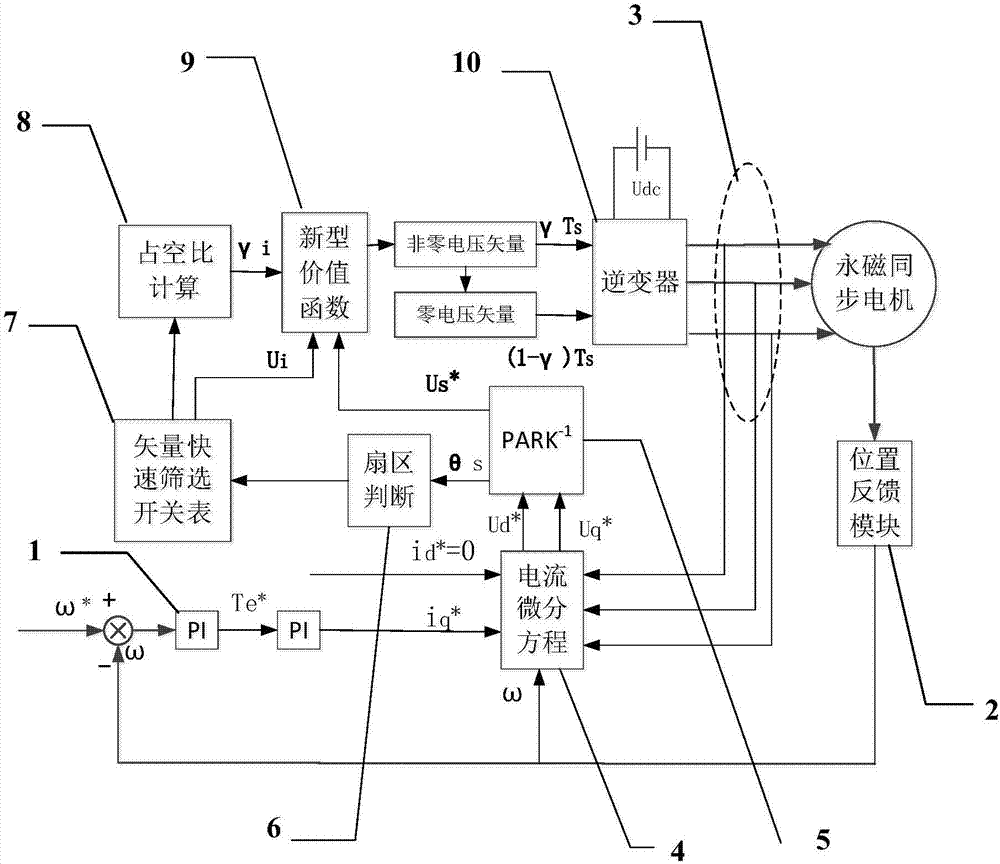

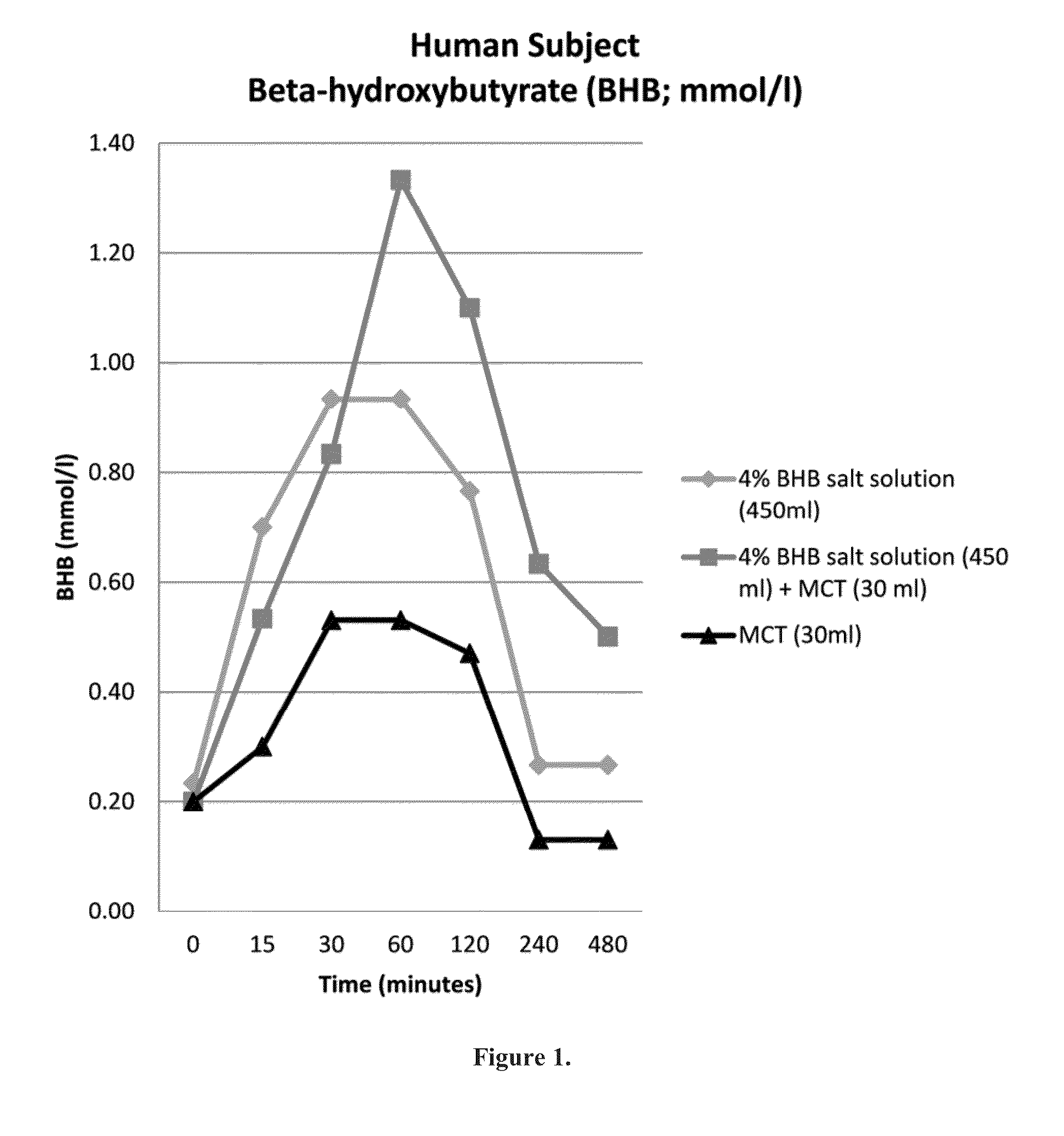

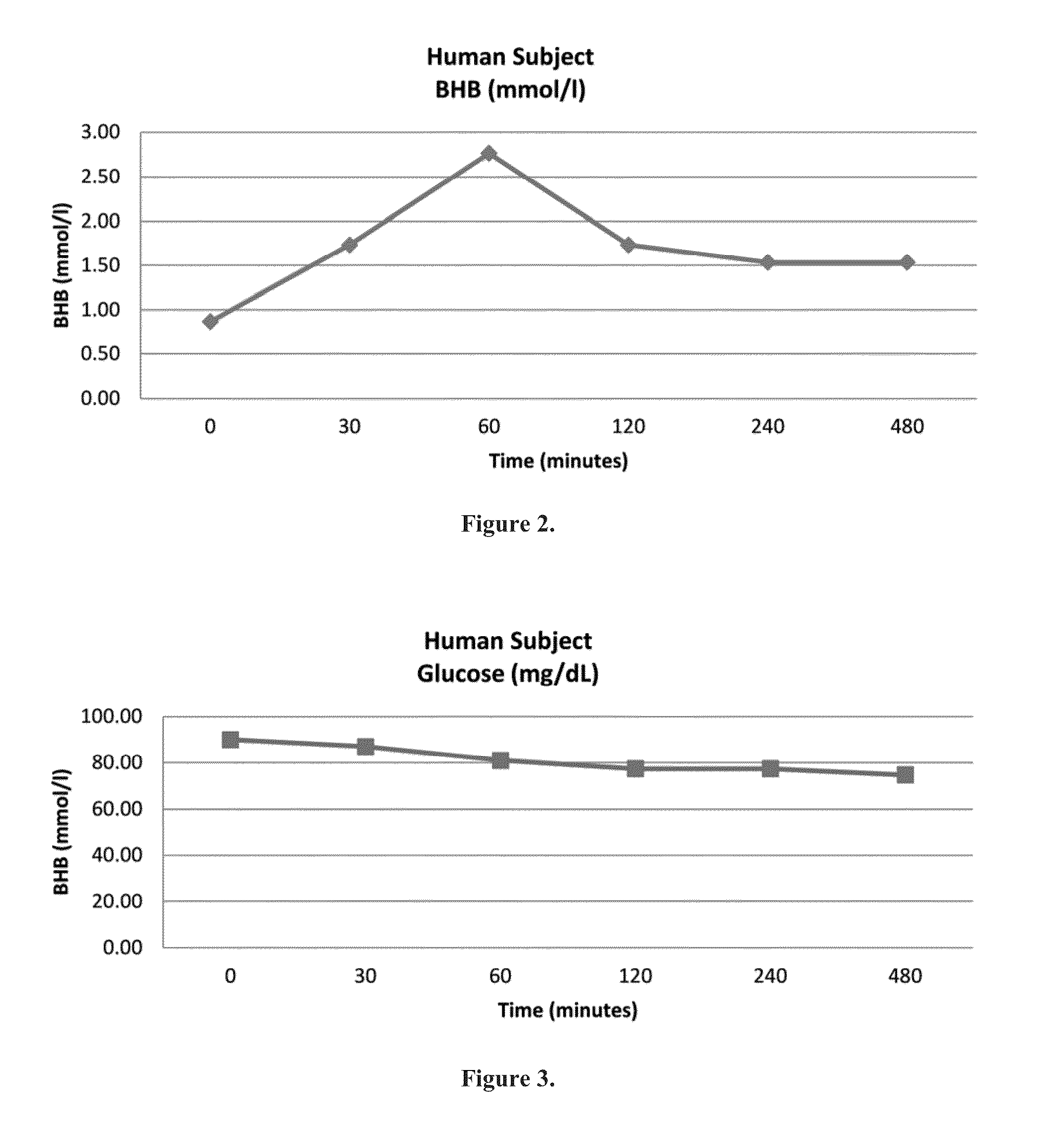

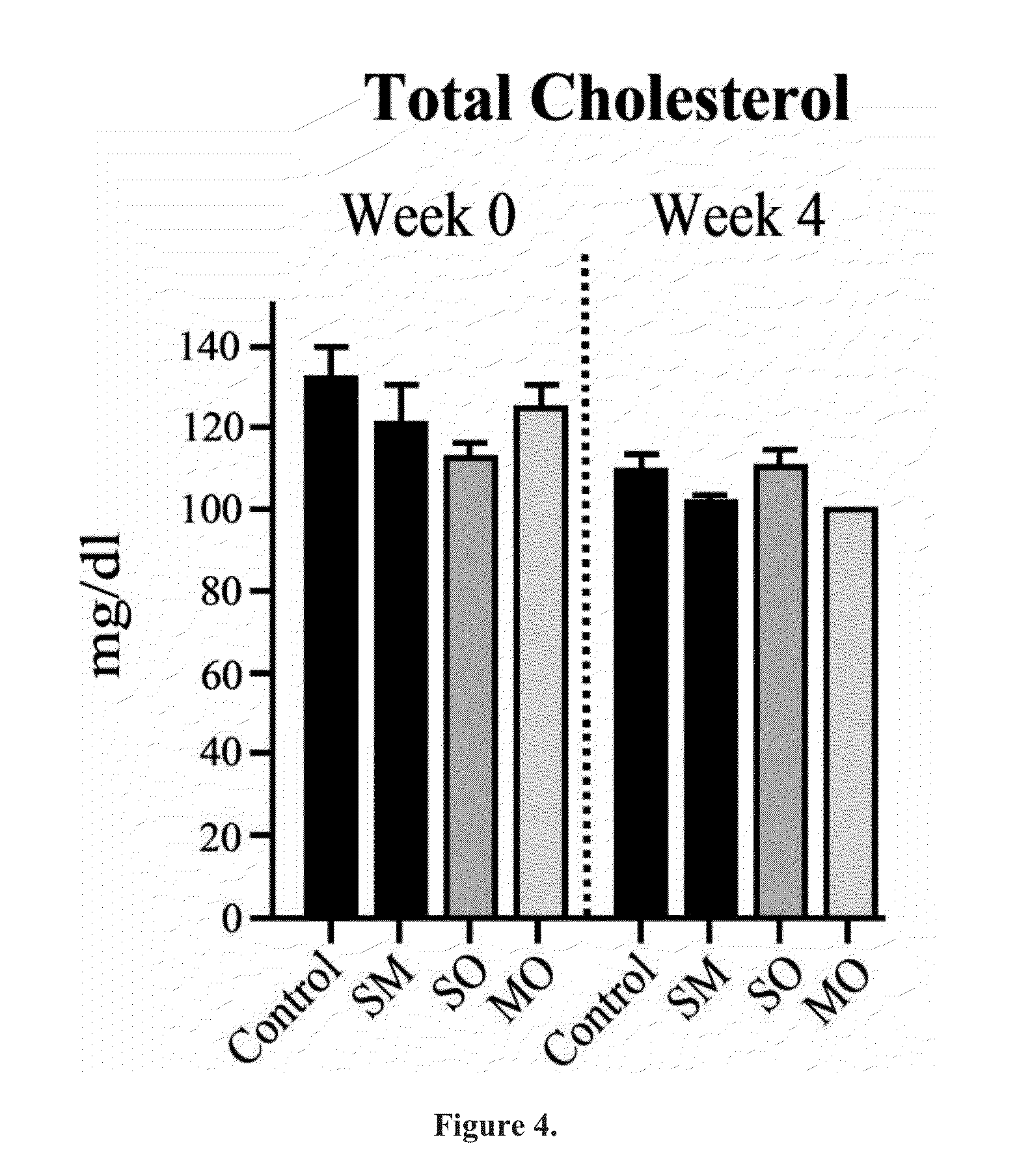

Compositions and methods for producing elevated and sustained ketosis

ActiveUS9138420B2Rapid and sustained elevationImprove the level ofHydroxy compound active ingredientsMetabolism disorderSignificant elevationKetogenic diet

Beta-hydroxybutyrate mineral salts in combination with medium chain fatty acids or an ester thereof such as medium chain triglycerides were used to induce ketosis, achieving blood ketone levels of (2-7 mmol / L), with or without dietary restriction. The combination results in substantial improvements in metabolic biomarkers related to insulin resistance, diabetes, weight loss, and physical performance in a short period of time. Further, use of these supplements to achieve ketosis yields a significant elevation of blood ketones and reduction of blood glucose levels. Use of these substances does not adversely affect lipid profiles. By initiating rapid ketosis and accelerating the rate of ketoadaptation, this invention is useful for the avoidance of glucose withdrawal symptoms commonly experienced by individuals initiating a ketogenic diet, and minimizes the loss of lean body mass during dietary restriction.

Owner:UNIV OF SOUTH FLORIDA

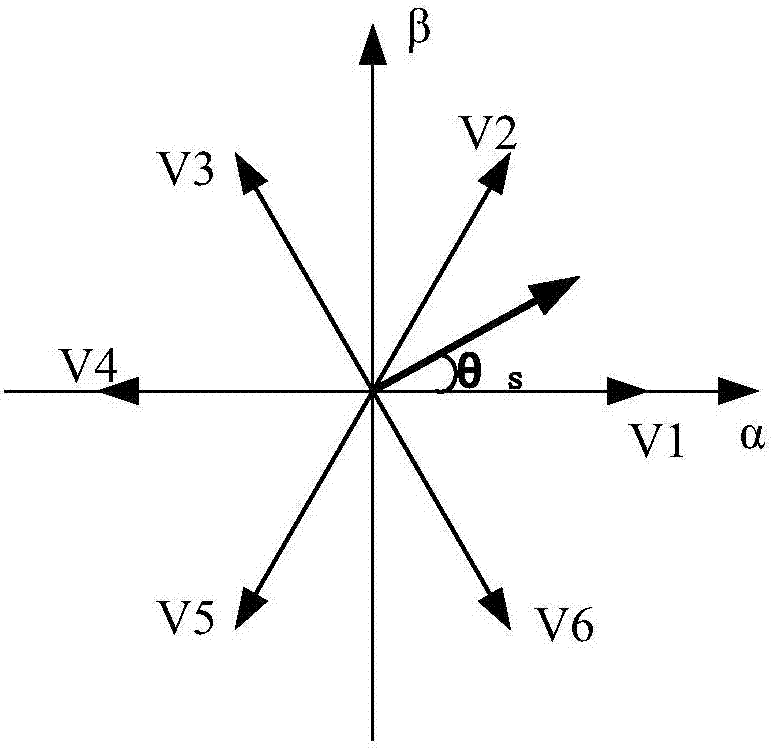

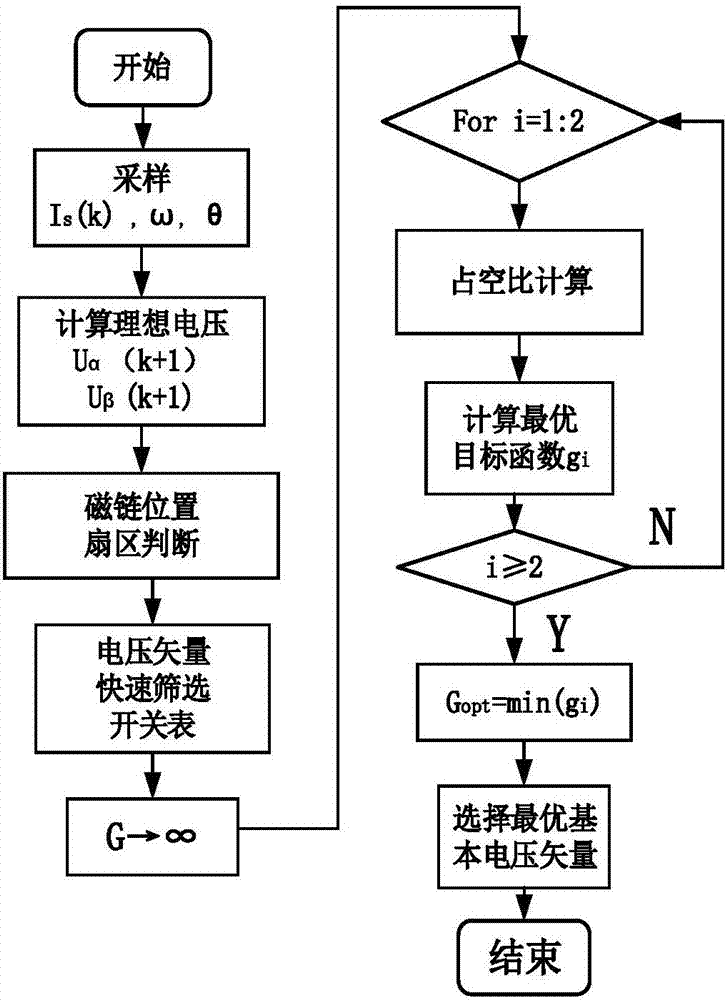

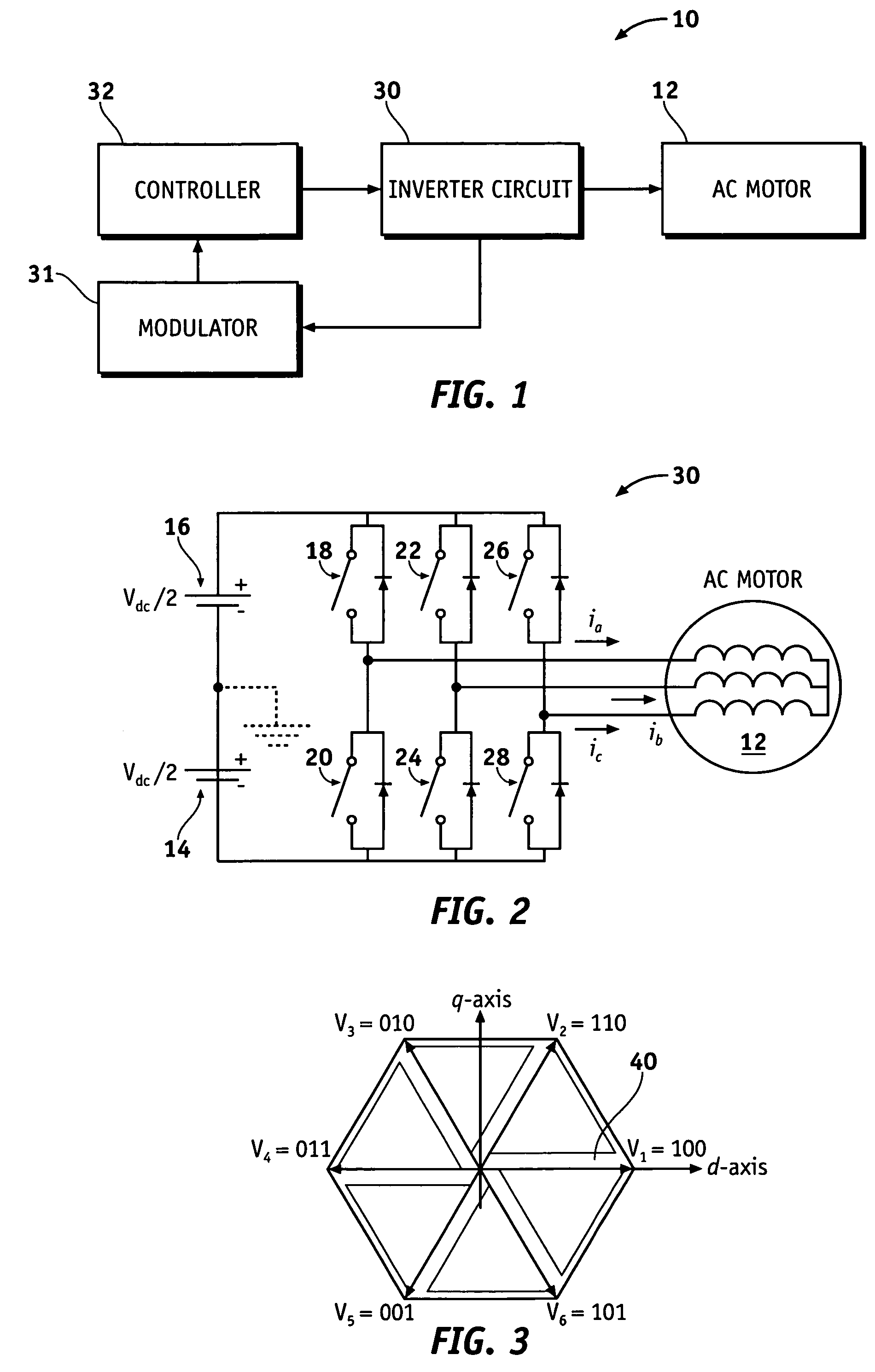

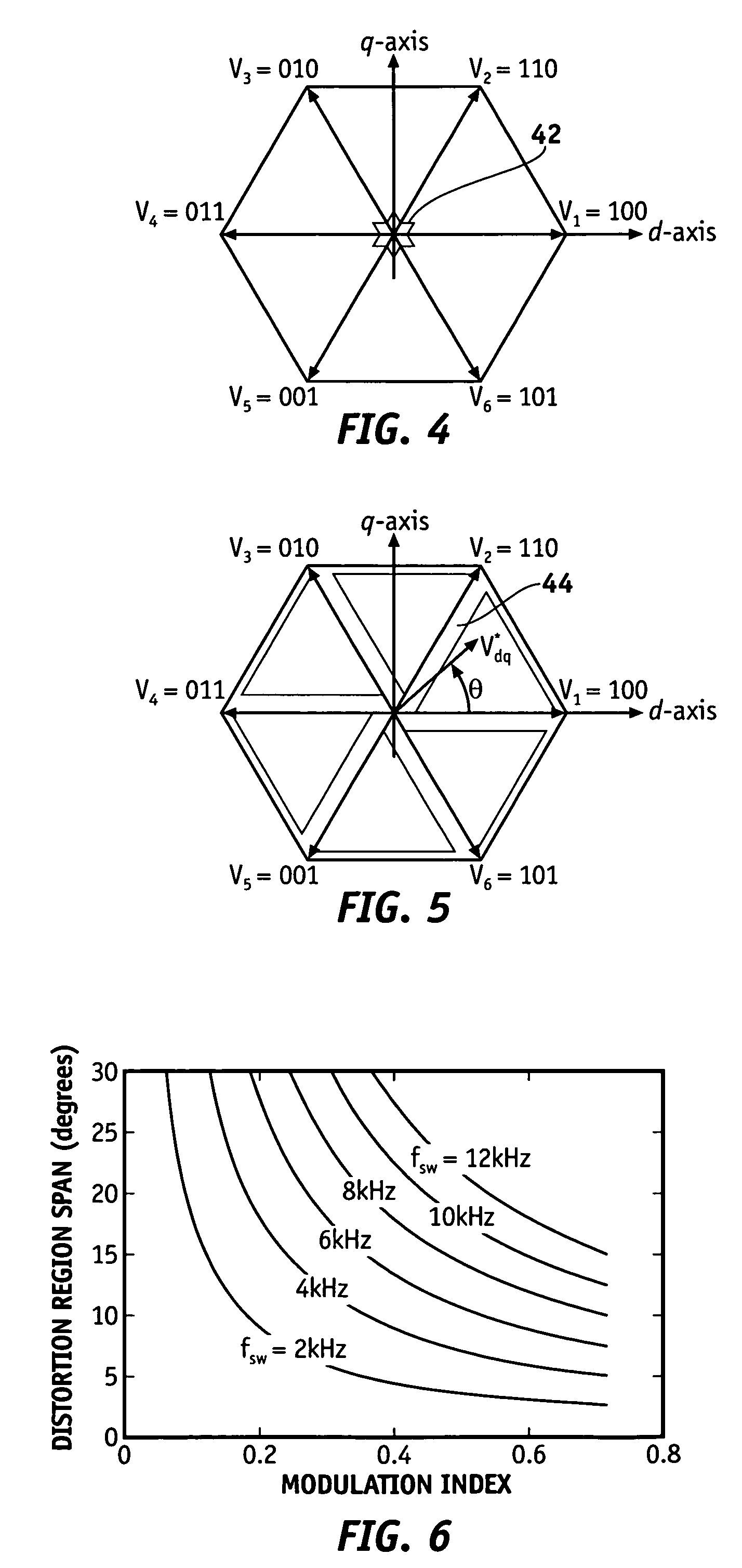

Vector screening and duty cycle combined motor model prediction control system and method

ActiveCN106936356AAvoid control performance impactReduce the burden onTorque ripple controlAC motor controlVoltage vectorPosition angle

The invention discloses a vector screening and duty cycle combined motor model prediction control system and method. The method comprises the steps that a reference voltage vector is acquired according to the idea of no-beat control; the sector of the reference voltage vector is judged through the position angle of the reference voltage vector, and at the same time two effective non-zero voltage vectors are quickly selected; the comparison between the reference voltage vector and two quickly selected effective non-zero voltage vectors is used as a value function; a new value function is provided, and a duty cycle control method is used to calculate the action time of the non-zero voltage vectors; and based on the principle of switching loss minimization, the appropriate zero voltage vector is selected according to the non-zero voltage vectors, and the action time of the zero voltage vector is calculated. The switching state and action time of the non-zero voltage vectors and the switching state and action time of the zero voltage vector are applied on an inverter in turn. The inverter converts the switching state into voltage and outputs the voltage to a permanent magnet synchronous motor to drive a motor to run.

Owner:SOUTHEAST UNIV

Compositions and methods for producing elevated and sustained ketosis

ActiveUS20140350105A1Rapid and sustained elevationImprove metabolic healthBiocideHydroxy compound active ingredientsKetoneSignificant elevation

Beta-hydroxybutyrate mineral salts in combination with medium chain fatty acids or an ester thereof such as medium chain triglycerides were used to induce ketosis, achieving blood ketone levels of (2-7 mmol / L), with or without dietary restriction. The combination results in substantial improvements in metabolic biomarkers related to insulin resistance, diabetes, weight loss, and physical performance in a short period of time. Further, use of these supplements to achieve ketosis yields a significant elevation of blood ketones and reduction of blood glucose levels. Use of these substances does not adversely affect lipid profiles. By initiating rapid ketosis and accelerating the rate of ketoadaptation, this invention is useful for the avoidance of glucose withdrawal symptoms commonly experienced by individuals initiating a ketogenic diet, and minimizes the loss of lean body mass during dietary restriction.

Owner:UNIV OF SOUTH FLORIDA

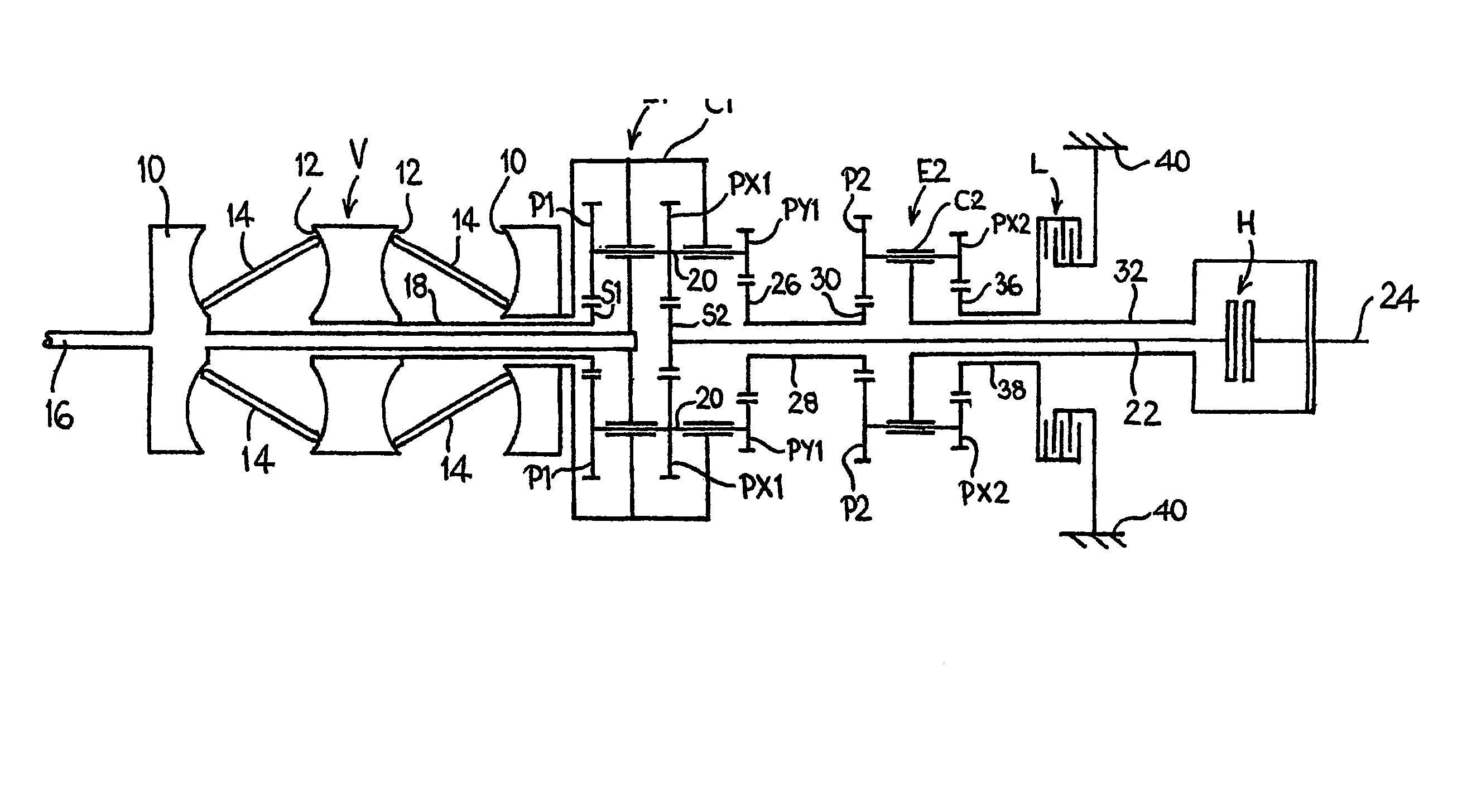

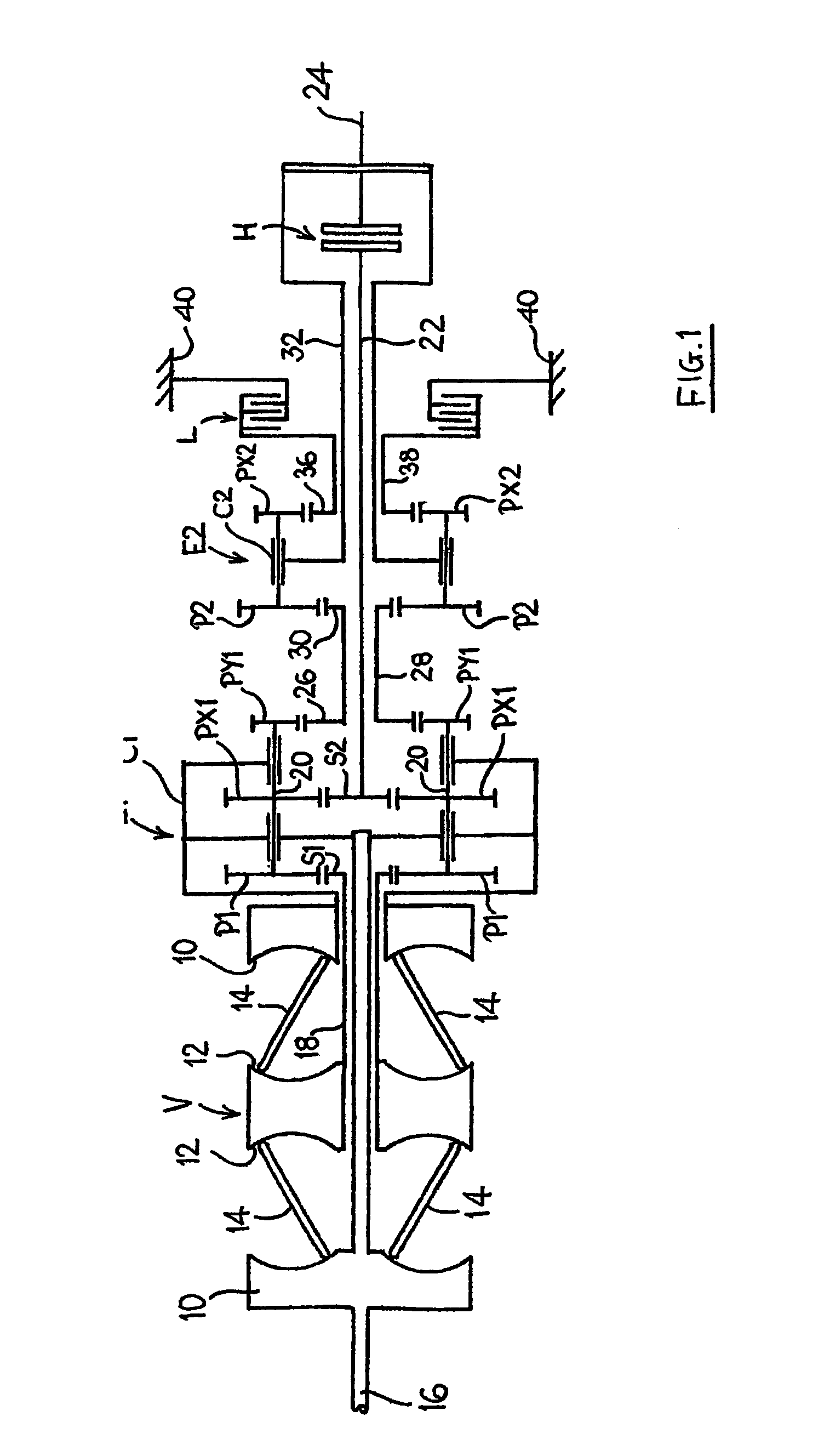

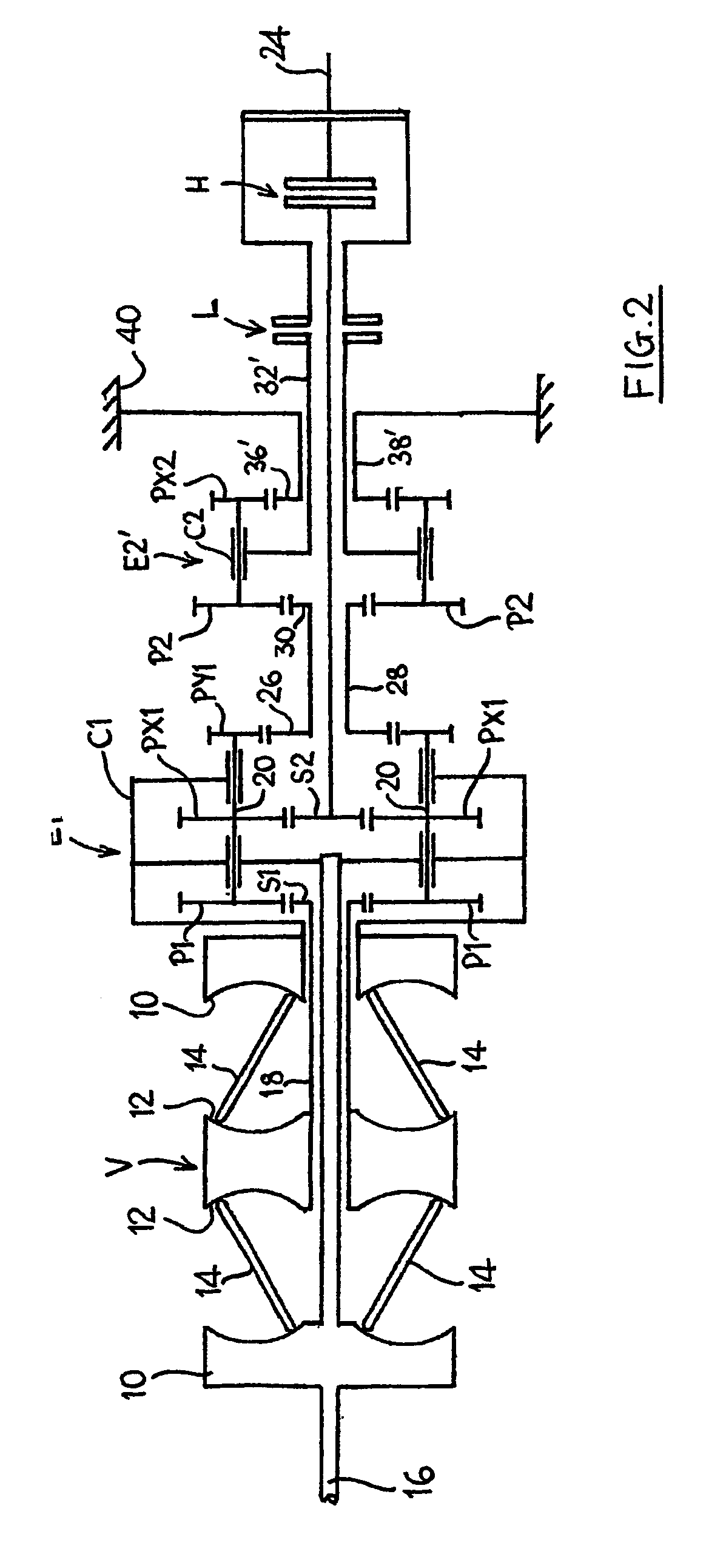

Continuously variable ratio transmission system

A multi-regime continuously variable ratio transmission system has coaxial system input and output shafts (16, 24), a continously variable ratio transmission unit (V) connected coaxially to the system input shaft (16) and having a coaxial variator output shaft (18) and a mixing epicyclic gear train (E1) having an input sun gear (S1) drivably connected to the variator ouput shaft (18), a planet carrier (C1) drivably connected to the system input shaft (16) and a planet gear (P1) mounted on the planet carrier ((C1). The planet gear (P1) drives a first intermediate output shaft (22) arranged coaxially with the system input shaft (16) and selectively connectable to the system output shaft via a first clutch (H) in high-regime operation of the transmission. The planet gear (P1) also provides the input for a second epicyclic gear train (E2) having an output (C2) which is selectively connectable to the system output shaft via a braking element (L) for low-regime operation of the transmission. The arrangement minimises the number of gear meshes, thereby minimising transmission losses and the absence of an annulus in the mixing epicyclic gear train (E1) allows more freedom in the choice of gear sizes, thereby permitting reduced gear speeds.

Owner:TOROTRAK (DEV) LTD

Methods and compositions for extinguishing fires using aqueous gelled fluids

The present invention relates to improved methods of extinguishing fires or retarding fire propagation by forming a crosslinked water gel which is then applied to the fire or area to be protected. By forming a semi-solid crosslinked gel water can be conveyed over large distances while minimizing losses due to misting, thus making fire fighting from great distances possible and improving the efficiency of aerial drops. The crosslinked gel also has a particularly good adhesiveness and cohesiveness, giving it the ability to form one continuous blanket on the ground thereby smothering the fire and preventing re-ignition. The combination of these properties makes the crosslinked gel ideal for applications such as control and extinguishing of forest fires. In addition, the composition may include additional active ingredients such as herbicide, pesticide, fungicide fertilizer, or the like for soil remediation after the fire is extinguished.

Owner:TAYLOR ROBERT STEWART

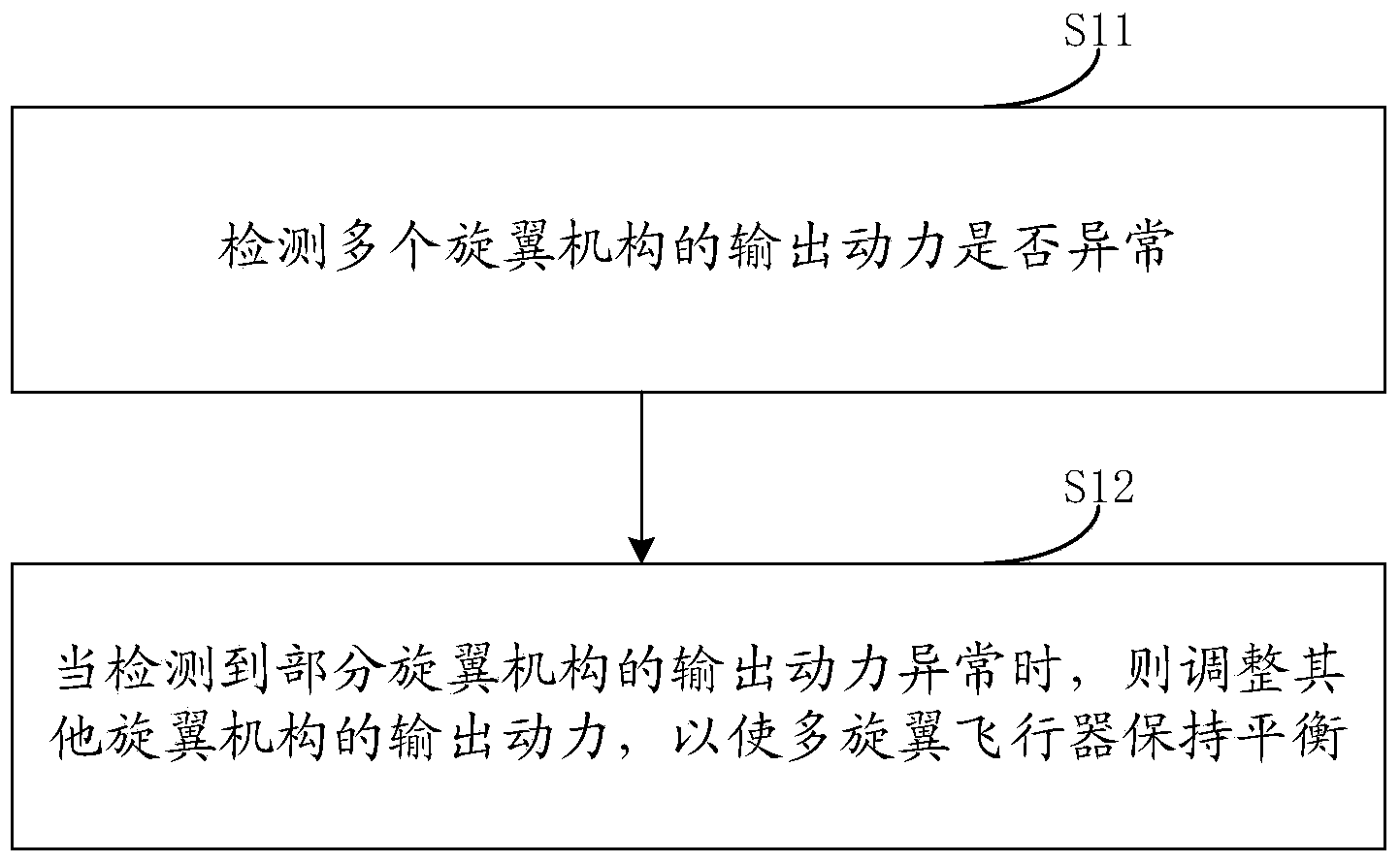

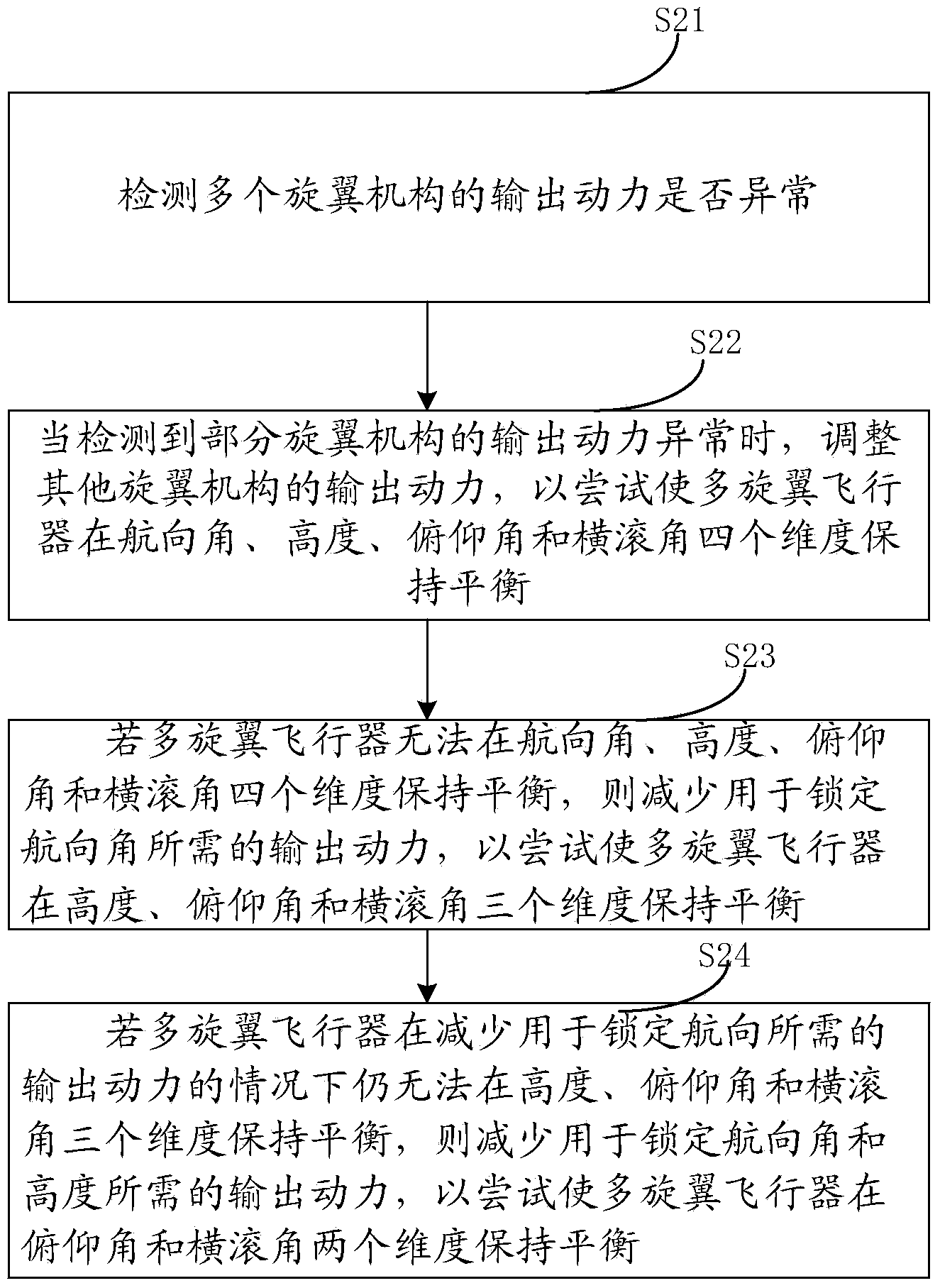

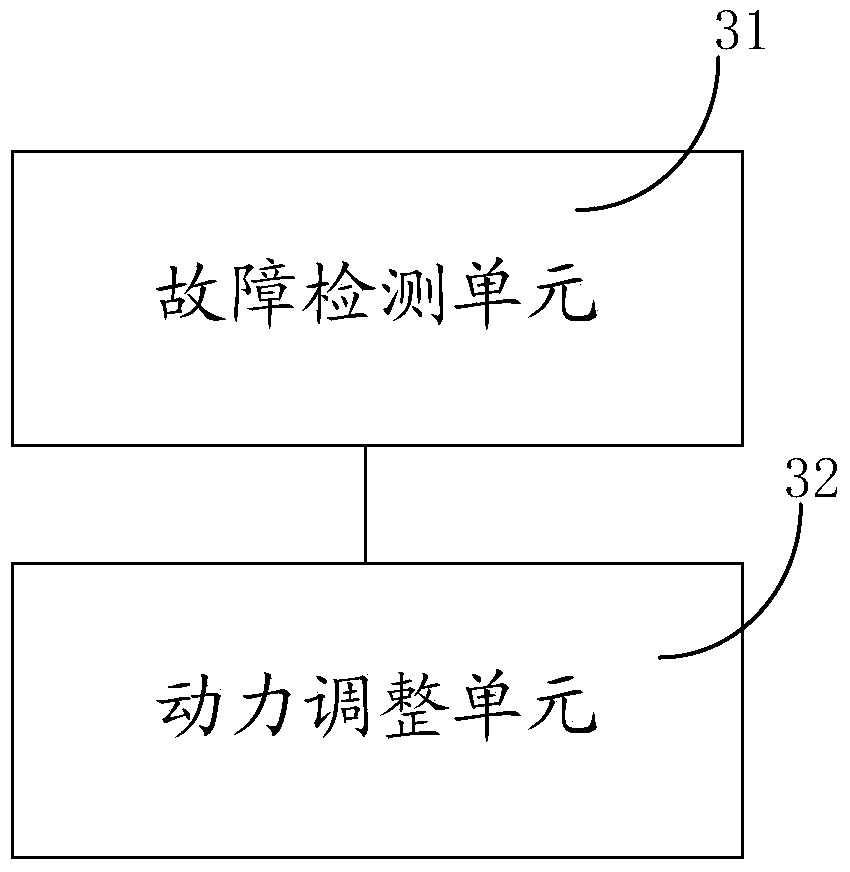

Flight control method and system for multiple-rotor-wing aircraft

The invention discloses a flight control method for a multiple-rotor-wing aircraft. The multiple-rotor-wing aircraft comprises multiple rotor wing mechanisms; the multiple rotor wing mechanisms provide power for the multiple-rotor-wing aircraft. The flight control method comprises the following steps: detecting whether the output power of the multiple rotor wing mechanisms is abnormal or not; if detecting that the output power of partial rotor wing mechanisms is abnormal, adjusting the output power of other rotor wing mechanisms, so as to enable the multiple-rotor-wing aircraft to keep balanced. The invention further discloses a flight control system for the multiple-rotor-wing aircraft. Through the above mode, additional power can be saved to stabilize the attitude, therefore, that the multiple-rotor-wing aircraft lands in a loss minimization manner is ensured, and the damage of the parts of the aircraft and damage to vehicles and people on the ground, which are caused by direct crash of the aircraft are avoided.

Owner:SHANGHAI FEILAI INFORMATION TECH CO LTD

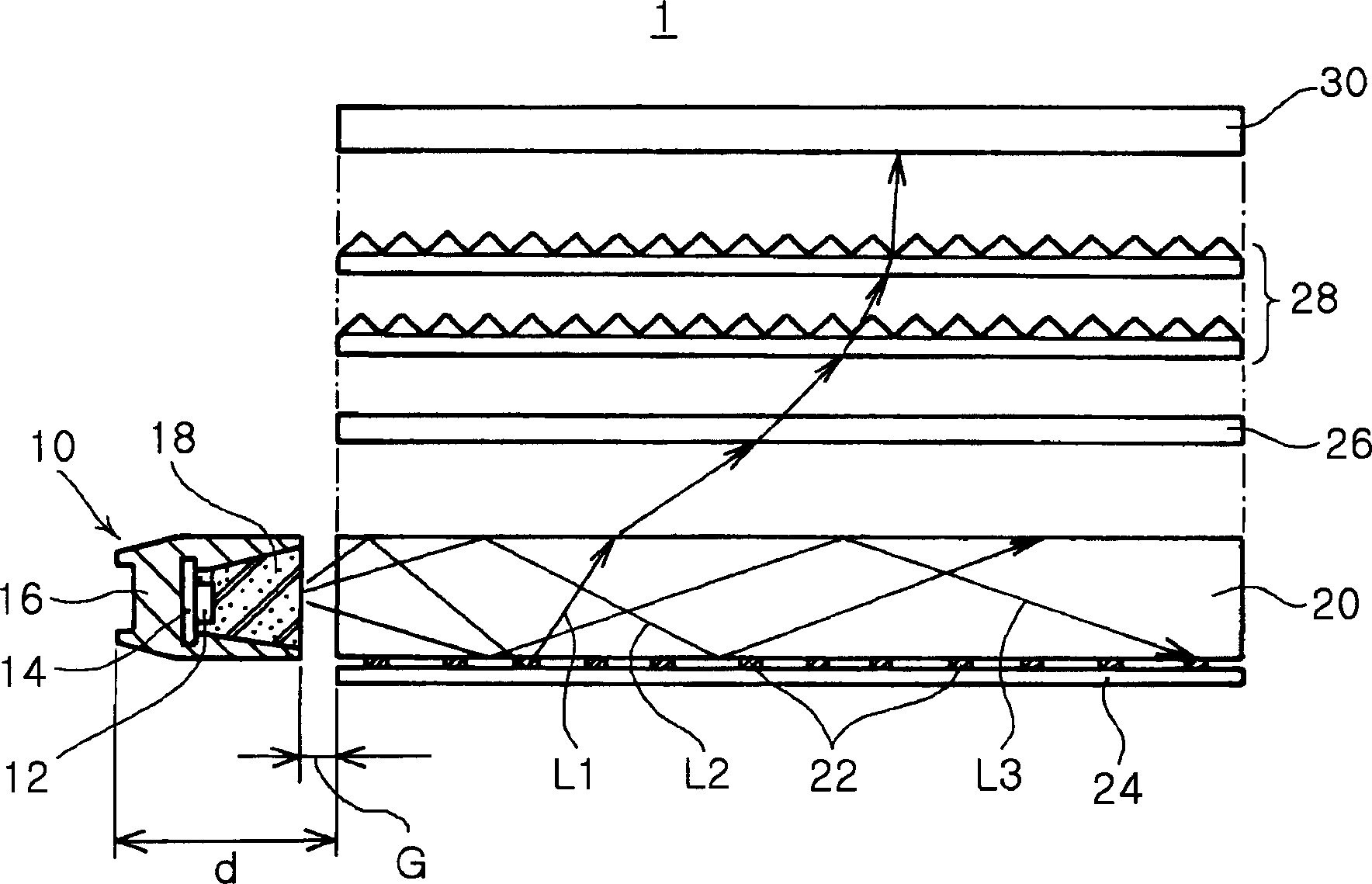

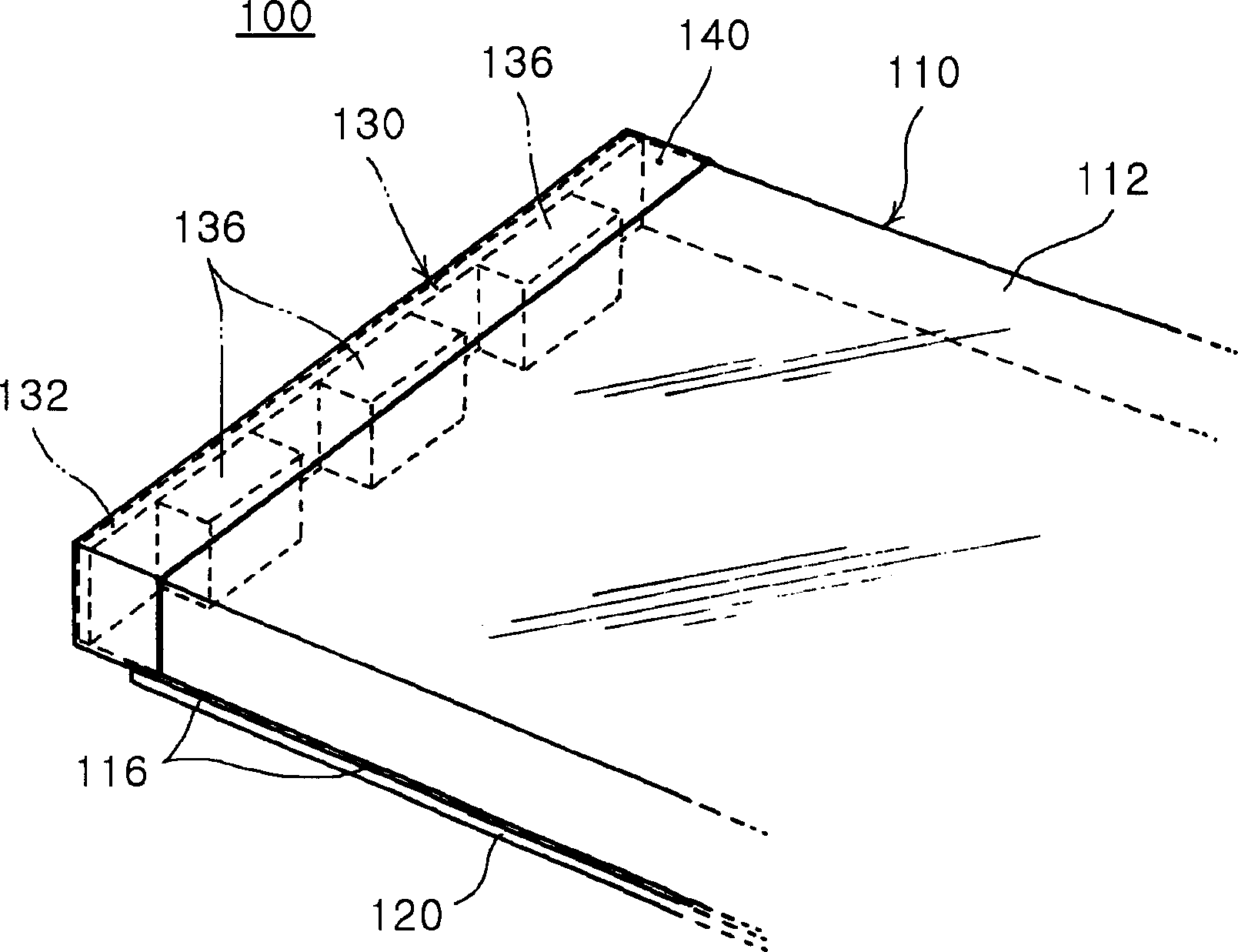

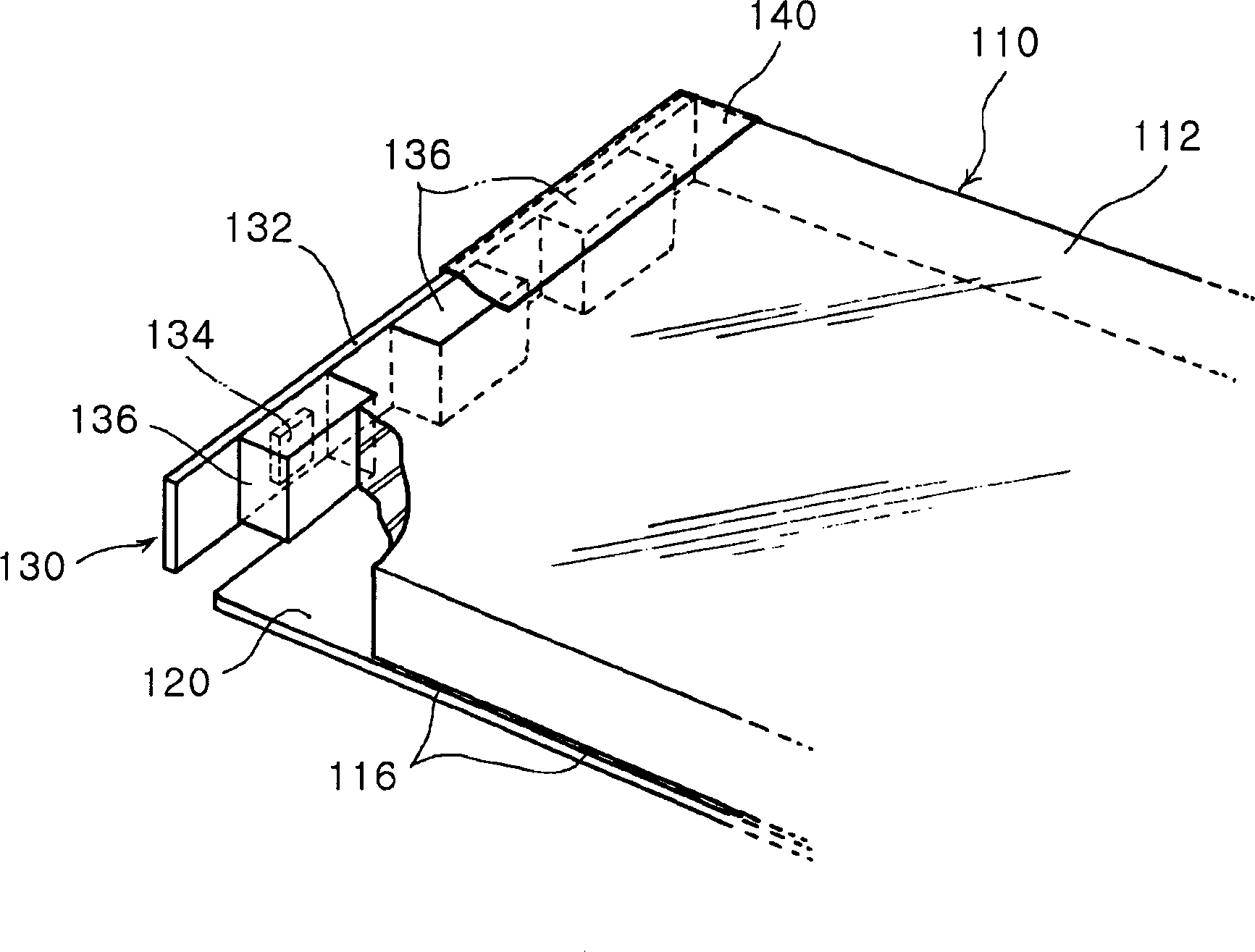

Light source-guide structure of backlight apparatus and backlight apparatus having the same

InactiveCN1892361ALoss minimizationIncrease horizontal beam angleOptical light guidesNon-linear opticsBeam angleLight guide

The present invention relates to a light source-guide structure having an LED as a light source and a backlight apparatus having the same. The light source-guide structure includes a light guide plate with grooves formed in a peripheral side thereof and a light source having a transparent package fitted into the groove of the light guide plate with an LED chip inside the transparent package. The structure also includes a wiring substrate for seating the LED chip and reflecting the light from the LED chip to the light guide plate and a reflection layer attached on upper surfaces of the light source and the light guide plate. With the light source inserted into the light guide plate, the loss of light is minimized while the horizontal beam angle of light from the LED is increased, minimizing the peripheral area.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

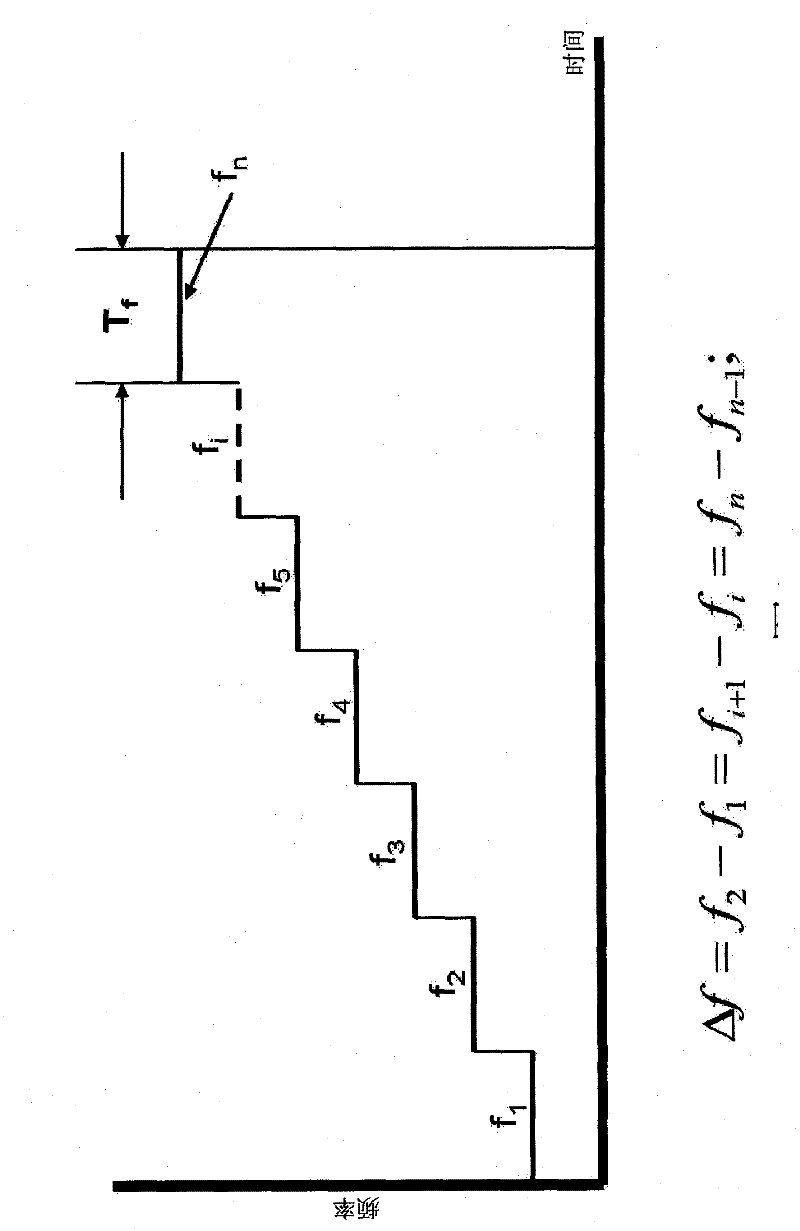

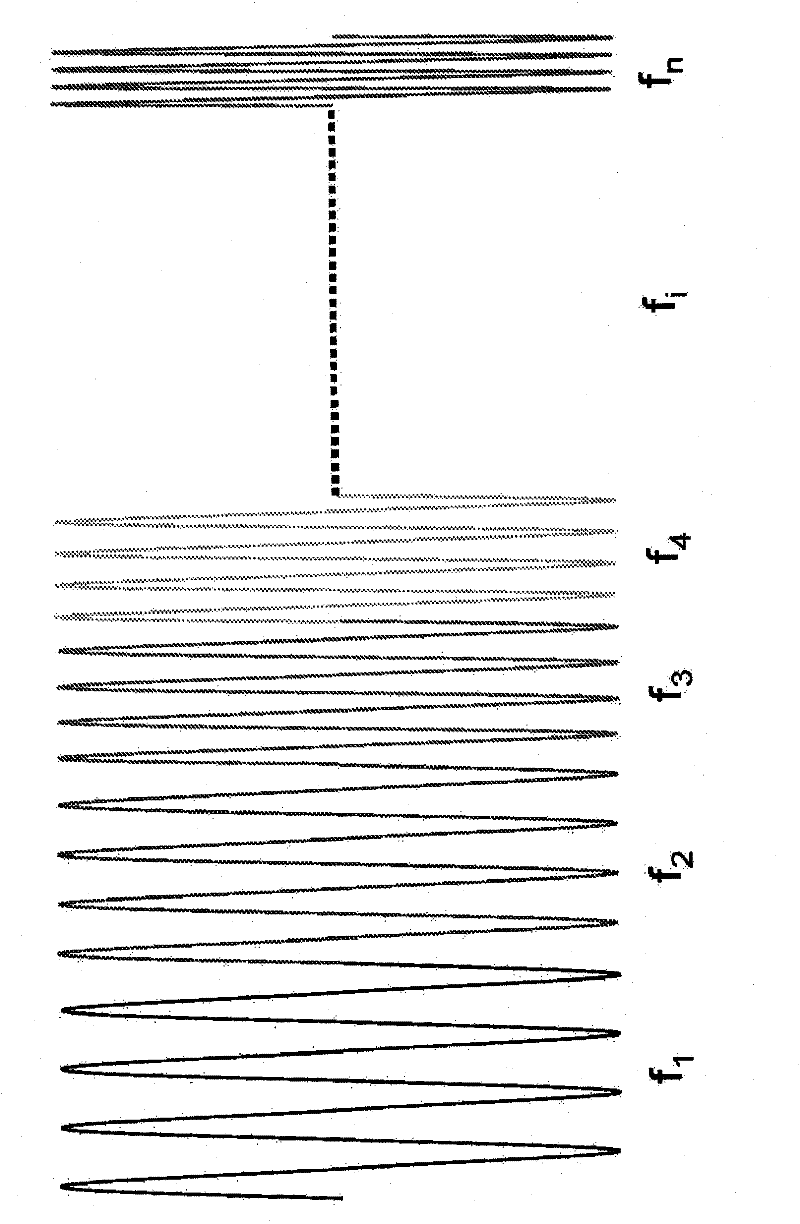

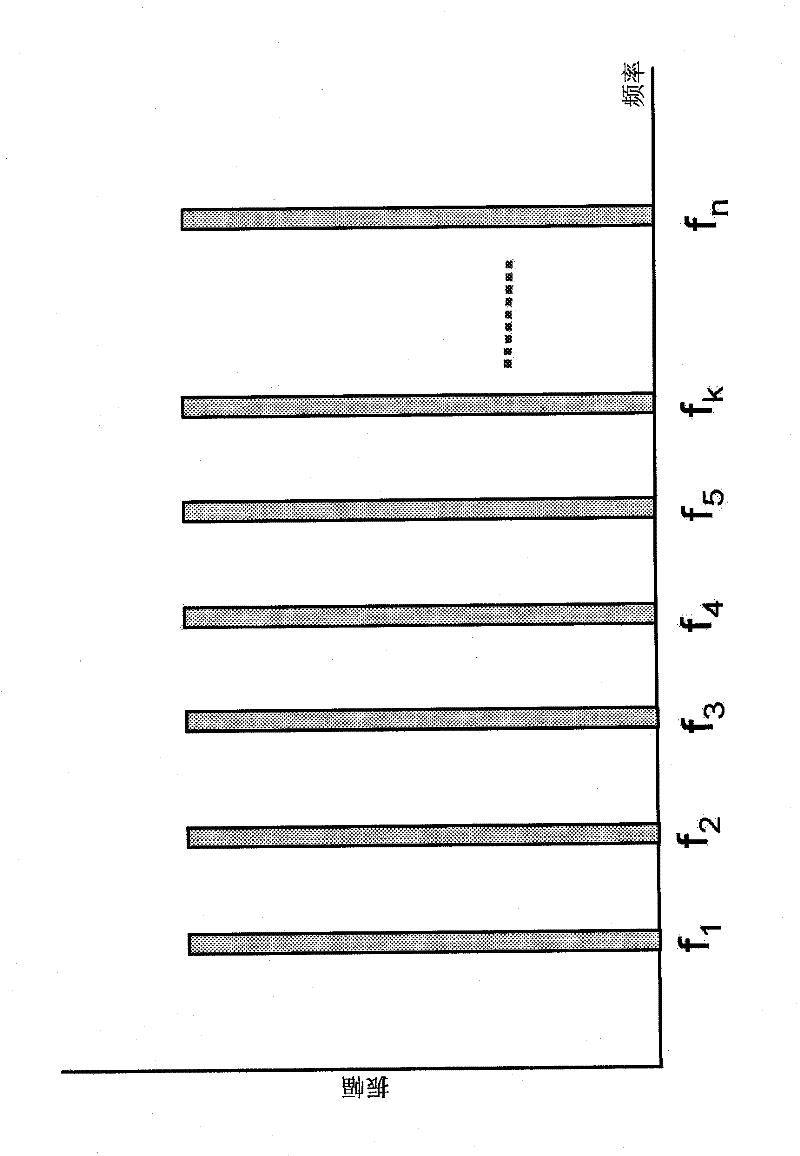

Methods and system for multi-path mitigation in tracking objects using reduced attenuation RF technology

ActiveCN102203634AImprove accuracyBeacon systems using radio wavesRoad vehicles traffic controlDigital signal processingLow frequency band

A method and system for a long range Radio Frequency (RF)-based identification, tracking and locating of objects. The method and system use a narrow bandwidth ranging signal(s), including VHF of lower frequency bands, which minimizes propagation loss and loss of accuracy of the RF locating signals. The method and system includes narrow bandwidth ranging signal multi-path mitigations processor, which further improves the track-locate accuracy. The signal is sent from a Master Unit(s) to a Tag. The signal traveling time is recorded and the distance between the Master(s) and the Tag is calculated. The method and system allow achieving a longer distance of the RF narrow bandwidth ranging signal penetration and an increased accuracy by using VHF bands in conjunction with the narrow bandwidth ranging signal multi-path mitigations processor. The techniques of Digital Signal Processing and Software-Defined Radio are used. The actual waveforms transmitted and received by the radios are defined by the software. The roles of the Master Unit(s) and the Tag can be reversed.

Owner:英维斯塔克有限公司

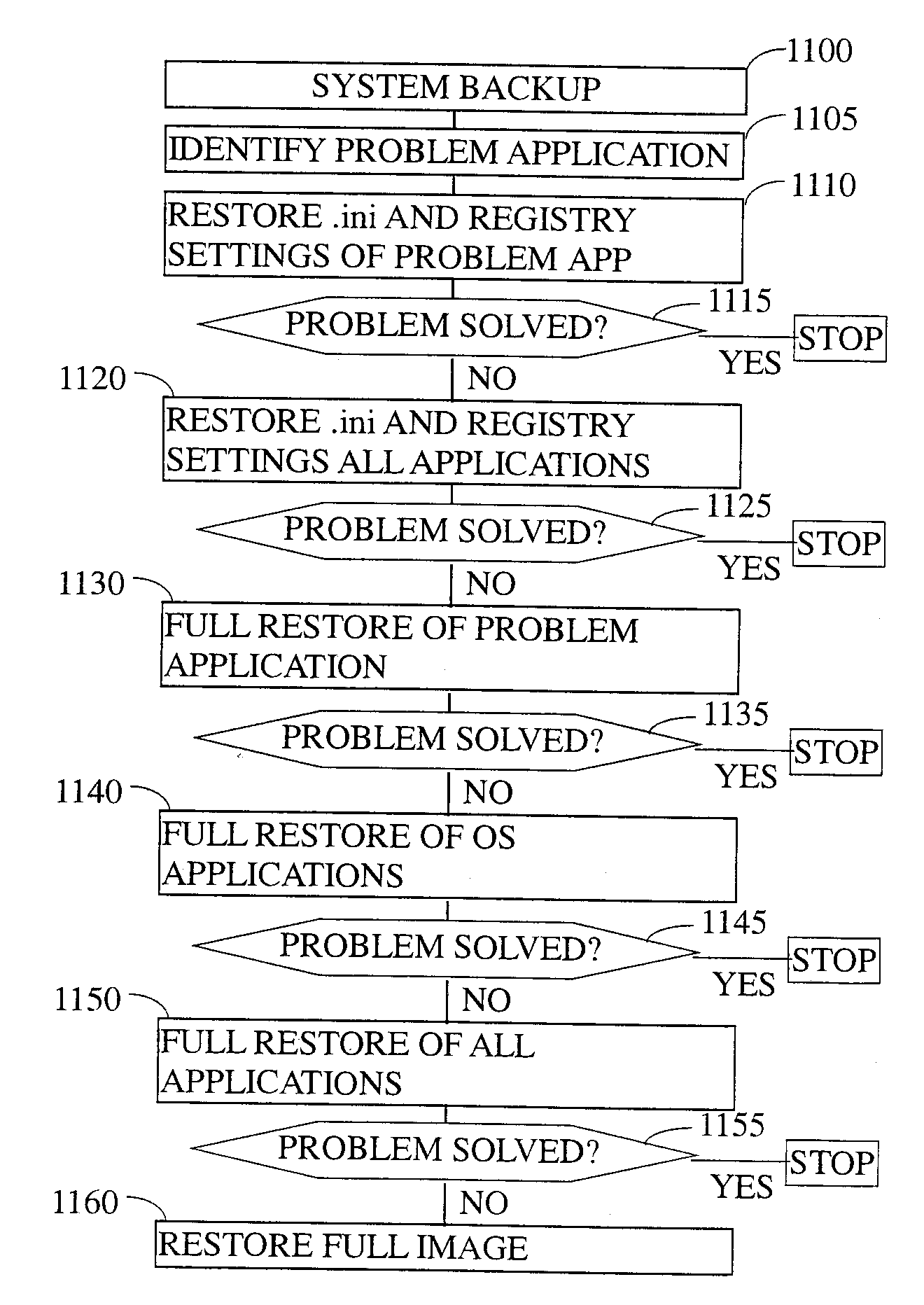

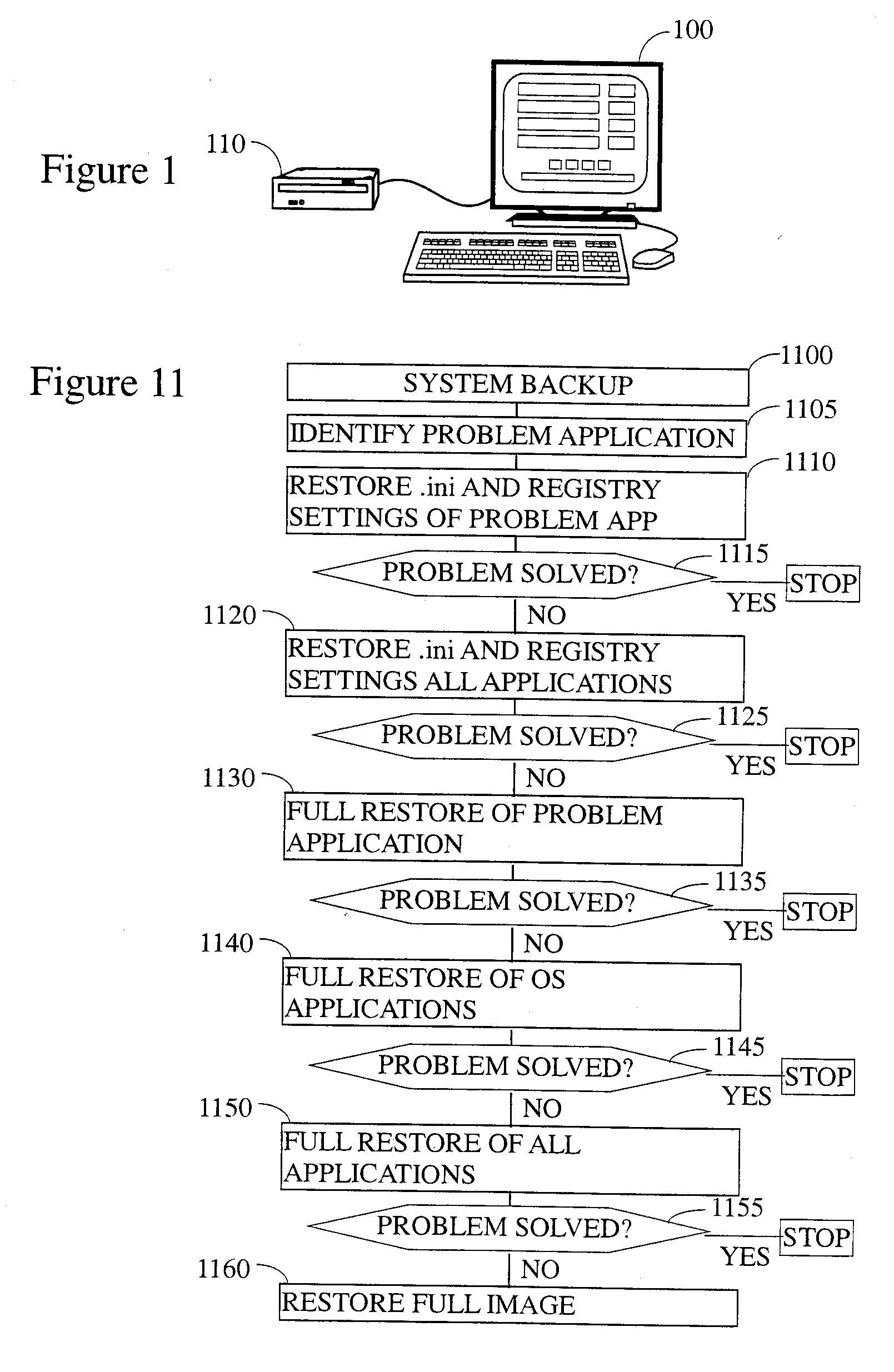

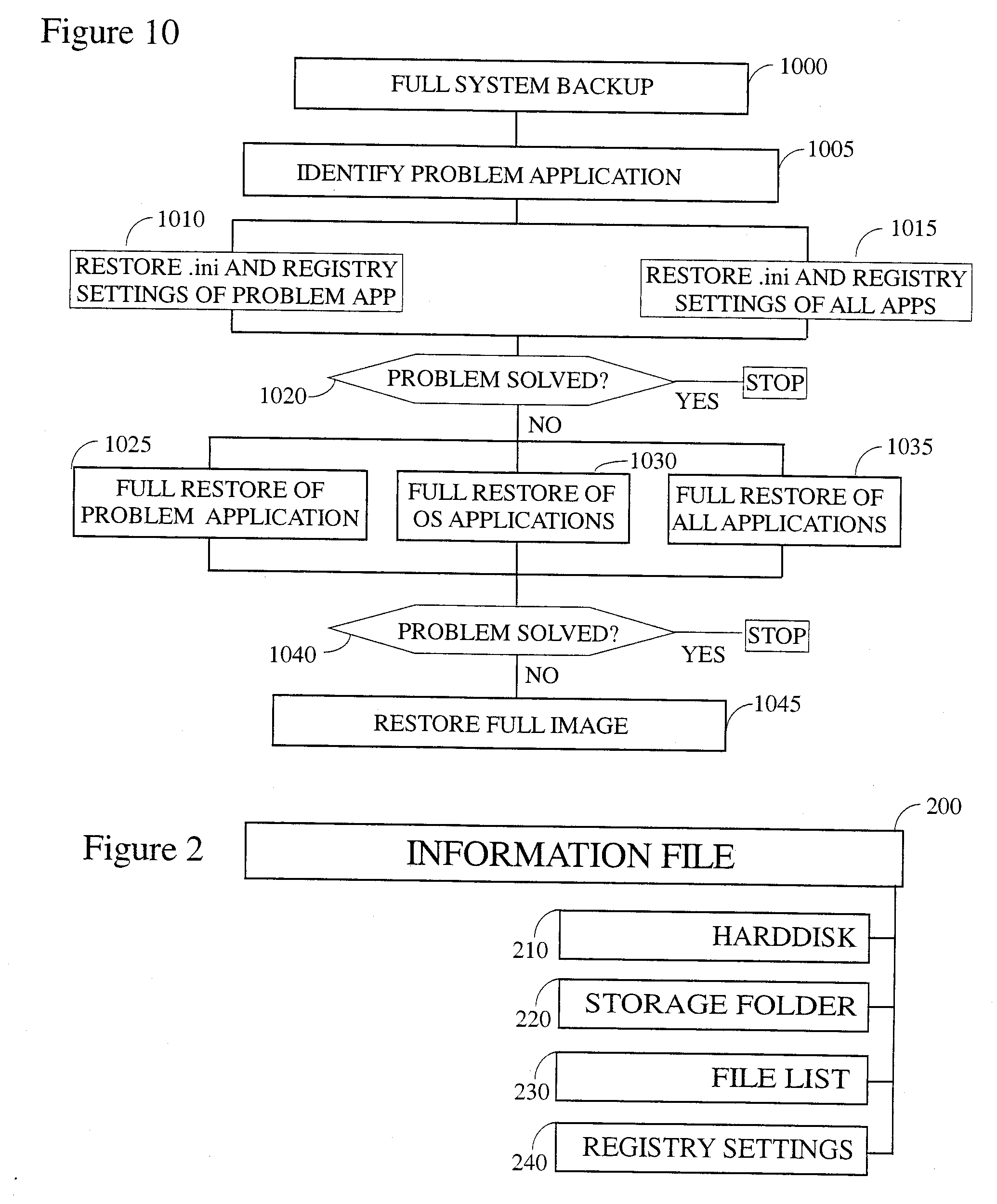

Application-specific intelligent backup and restore system

ActiveUS20080109495A1Reduce amountMaintain securityDigital data processing detailsError detection/correctionPaper documentDocument preparation

There is provided herein an application-oriented backup and restore system, which leads the user through a plurality of different selectable steps to repair specific application errors / problems. The preferred embodiment minimizes the loss of user productivity and because of its easy and accessible layout and presentation it may eliminate the need for tech-support to repair the problem. The average user can initiate the steps, wherein the restore steps are explicitly directed to secure the safe storage of user created documents and files.

Owner:SIMPLITEC

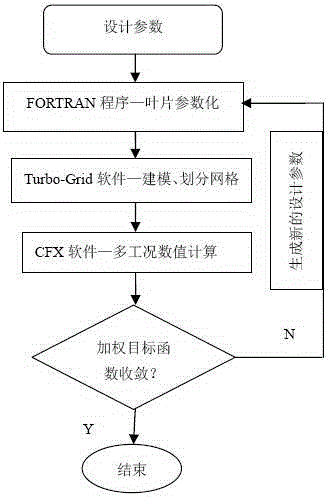

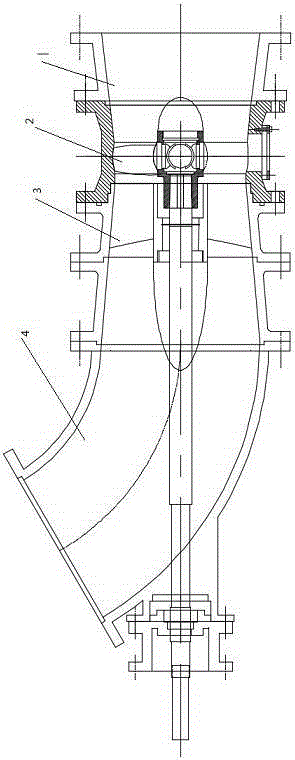

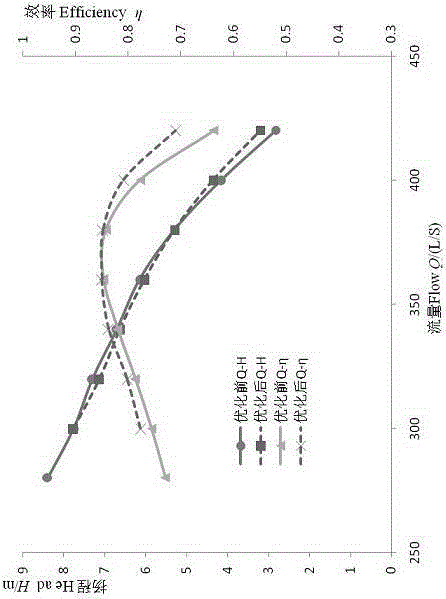

Axial flow pump impeller all-operating-condition design method

ActiveCN105179303AImprove efficiencyWide efficiency curvePump componentsPumpsAxial-flow pumpImpeller

An axial flow pump impeller all-operating-condition design method comprises the following steps that 1, parametric modeling of an axial flow pump impeller is performed, namely 2k design parameters including k wing section cascade solidities and wing placement angle values of the axial flow pump impeller are selected; 2, all-operating-condition optimal design is performed: firstly, conventional design parameters of the impeller are dertemined, then numerical calculation is conducted on the design conditions of the axial flow pump impeller and various losses in a pump are comprehensively analyzed to preliminarily design the axial flow pump impeller having better hydraulic performance under the design conditions in a total-loss minimization mode; secondly, guide blades, a water guide cone and water inlet and outlet flowing channels of the impeller are designed; thirdly, the optimal all-operating-condition weighted average effciency of the pump device is regarded as a target, a lift is regarded as a constraint condition, and a seqential quadratic programming method of a gradient optimum algorithm is adopted to constantly change the design parameters of the axial flow pump impeller and perform iterative numerical calculation of the pump device. The axial flow pump impeller all-operating-condition design method adopts CFD numerical calculation, the design accuray is high, and optimization results are reliable.

Owner:YANGZHOU UNIV

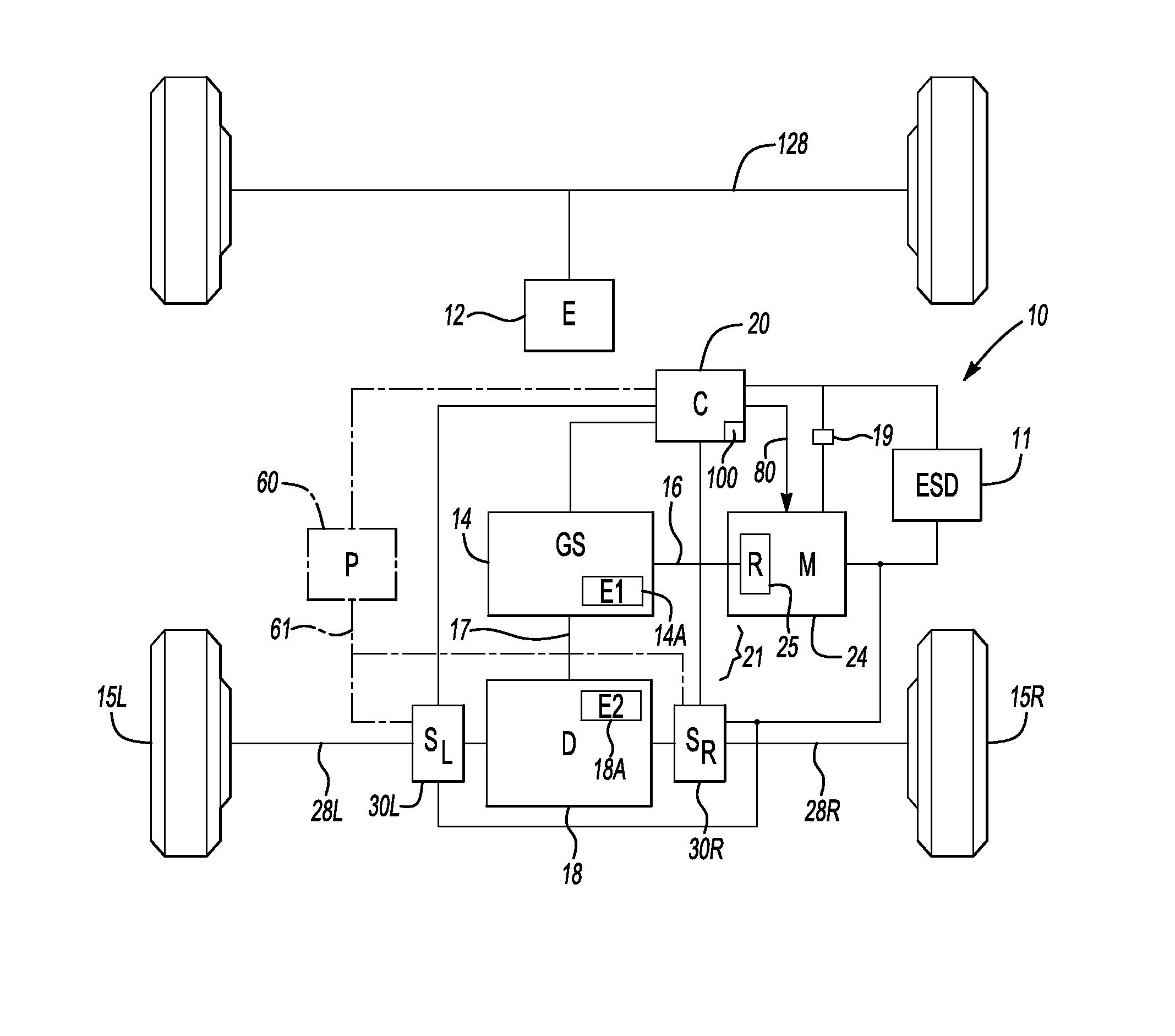

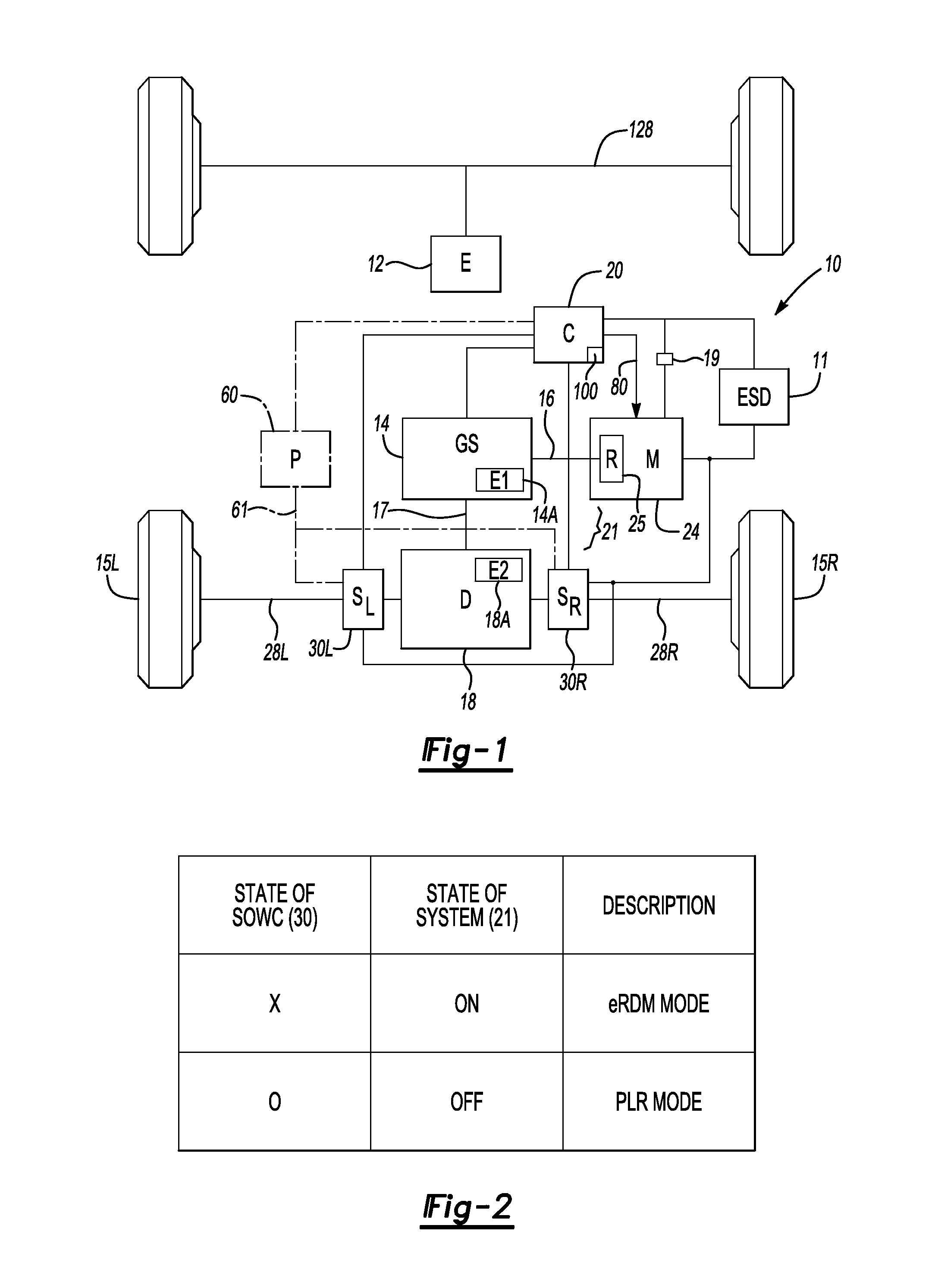

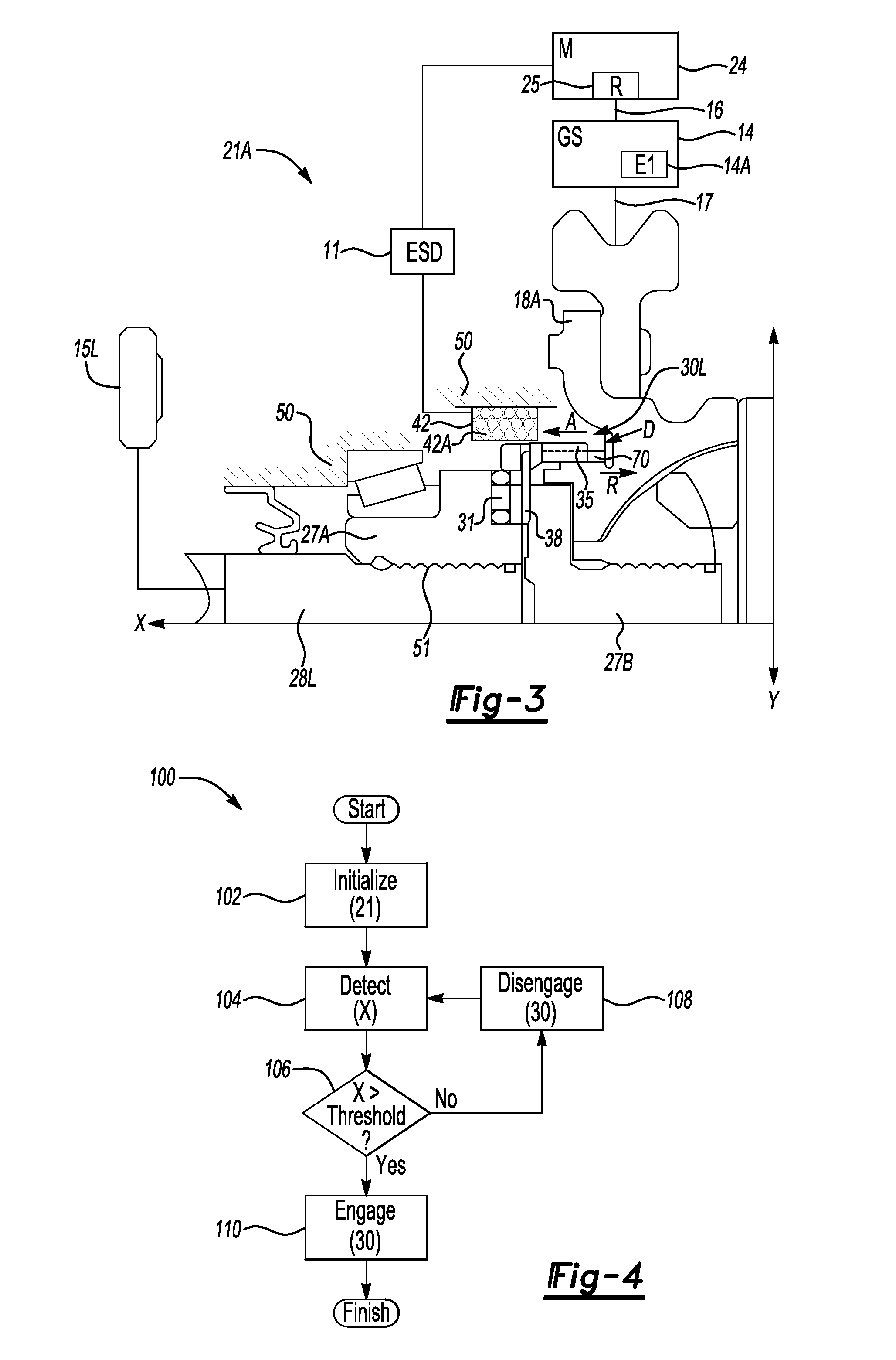

Electric drive system with a selectable one-way clutch

ActiveUS8011464B2Prevent rotationMinimizing parasitic spin lossDigital data processing detailsElectric propulsion mountingDrive motorEngineering

A vehicle has a motor and axles which are selectively rotatable by the motor, a reduction gear set, a differential transferring torque from the motor to the axles, and selectable one-way clutch (SOWC) assemblies. The SOWC assemblies are connected to a different one of the axles, and are engaged to transfer torque to the drive axles whenever the motor is energized. The SOWC assemblies are disengaged when the motor is de-energized to prevent rotation of the rotor and various elements of the reduction gear set and differential. A method minimizes parasitic spin losses in an electric rear drive motor (eRDM) system. The method includes engaging a pair of SOWC assemblies when the motor is on to transfer torque from the motor to the axles, and disengaging the SOWC assemblies when the motor is off to prevent rotation of a rotor and of elements of the reduction gear set and differential.

Owner:GM GLOBAL TECH OPERATIONS LLC

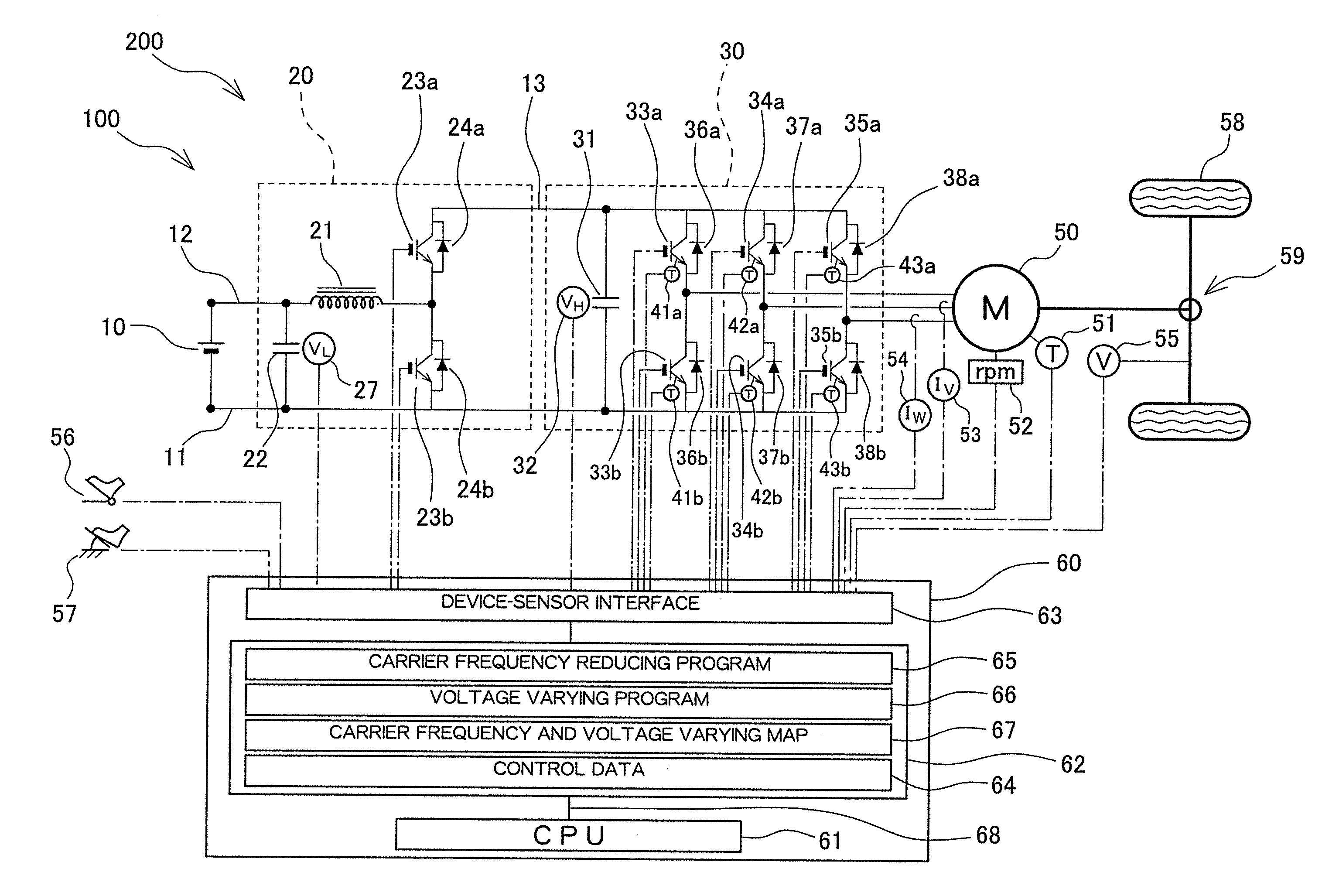

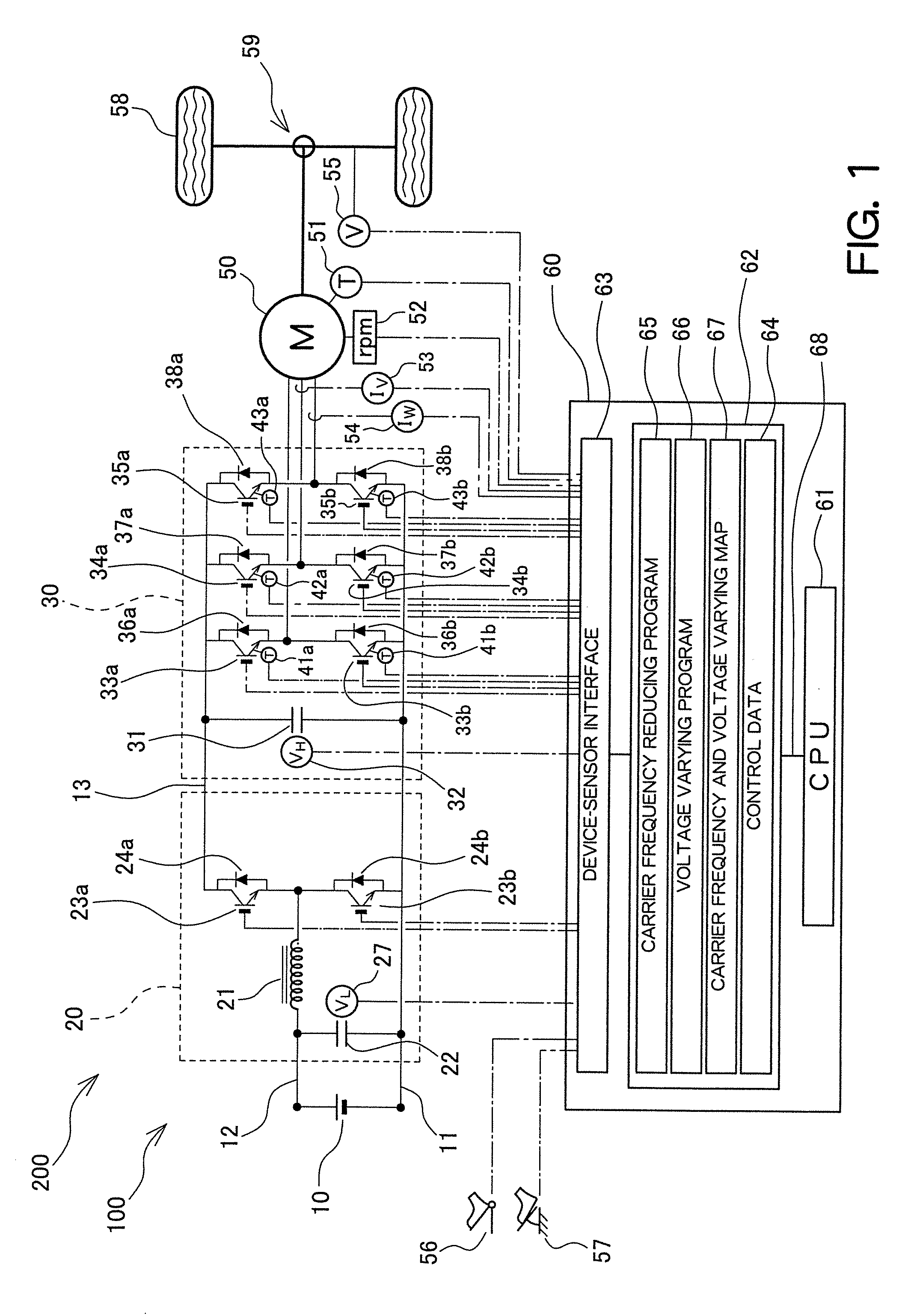

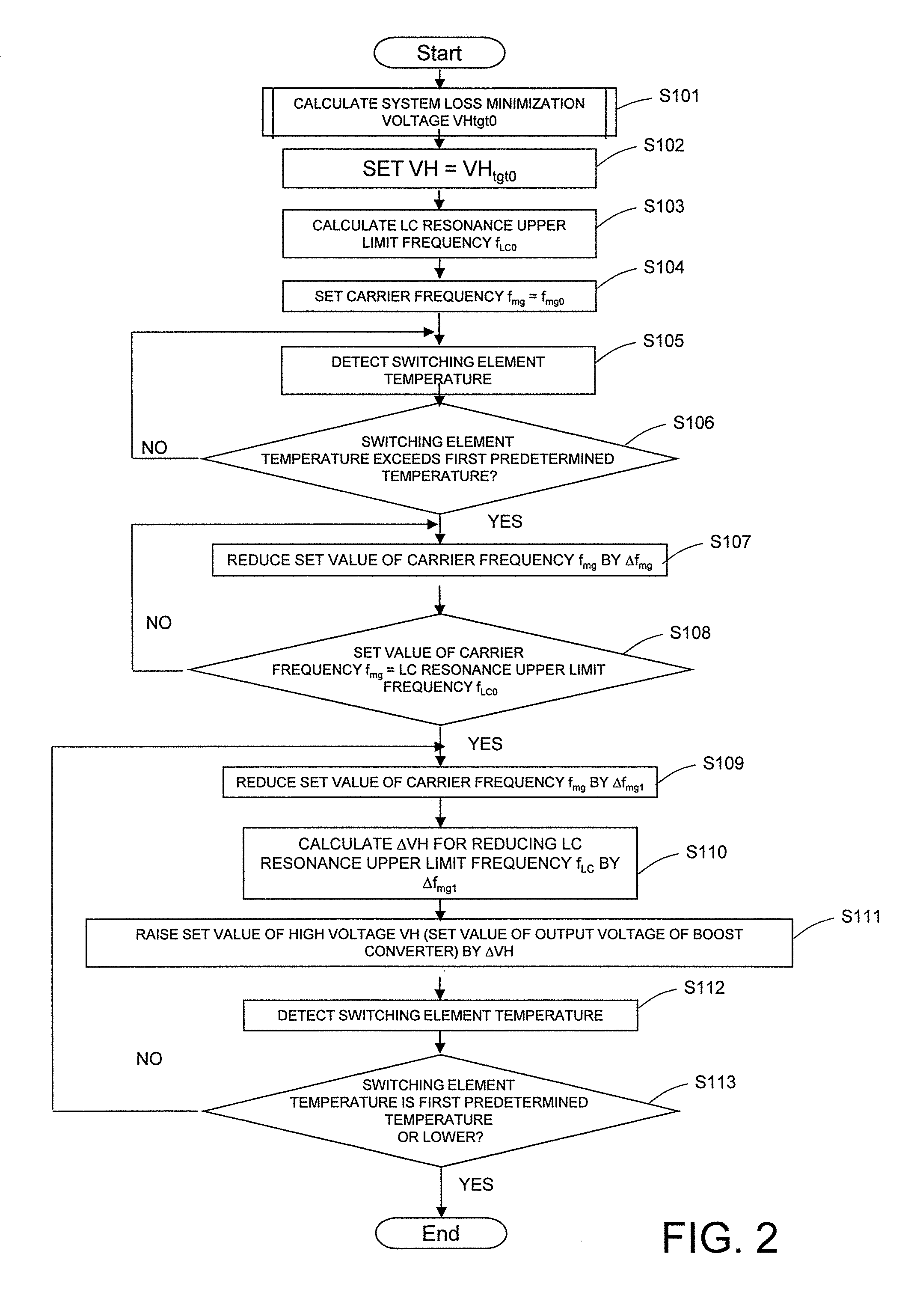

Power controller

InactiveUS20150108929A1Inhibit deteriorationRise in temperature of electronicSpeed controllerMotor/generator/converter stoppersPower inverterPower controller

A power controller includes a boost converter, an inverter, and a control unit controlling the output voltage of the boost converter and the carrier frequency of the inverter. The control unit includes a carrier frequency reducing program which reduces the carrier frequency to an LC resonance upper limit frequency while maintaining a set value of the output voltage of the boost converter at a system loss minimization voltage at the time of reduction of the carrier frequency from the set frequency, and a voltage varying program which changes the carrier frequency to a first varied frequency calculated based on a first predetermined temperature or lower and the temperatures of the respective switching elements, and changes the set value of the output voltage of the boost converter to a voltage at which the LC resonance upper limit frequency becomes the first varied frequency.

Owner:TOYOTA JIDOSHA KK

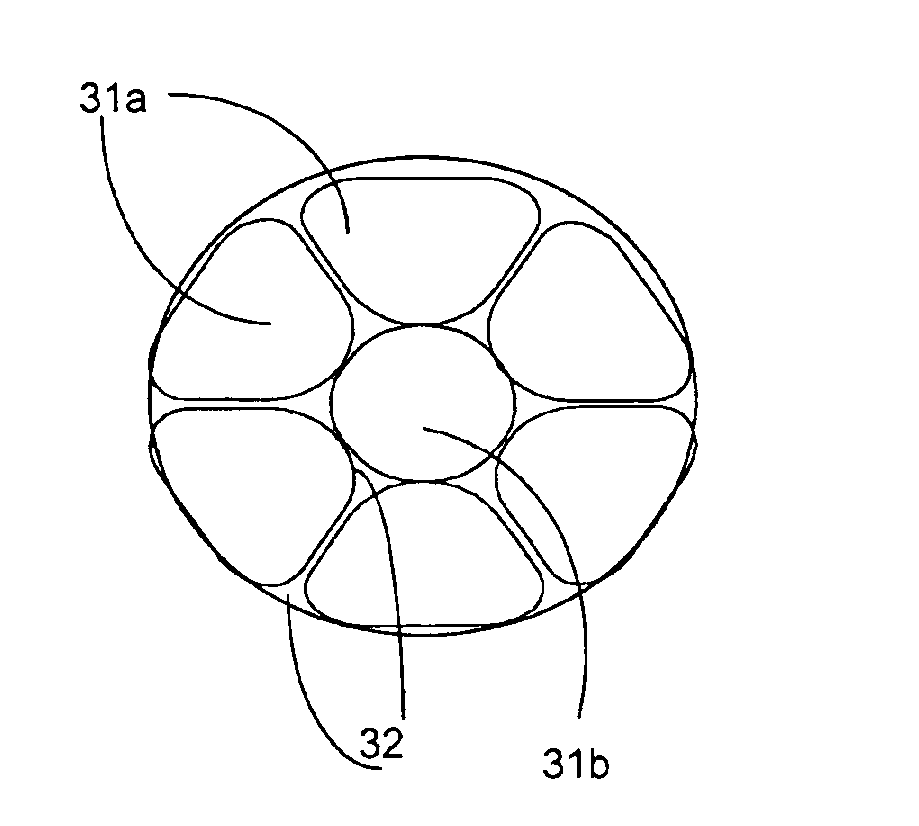

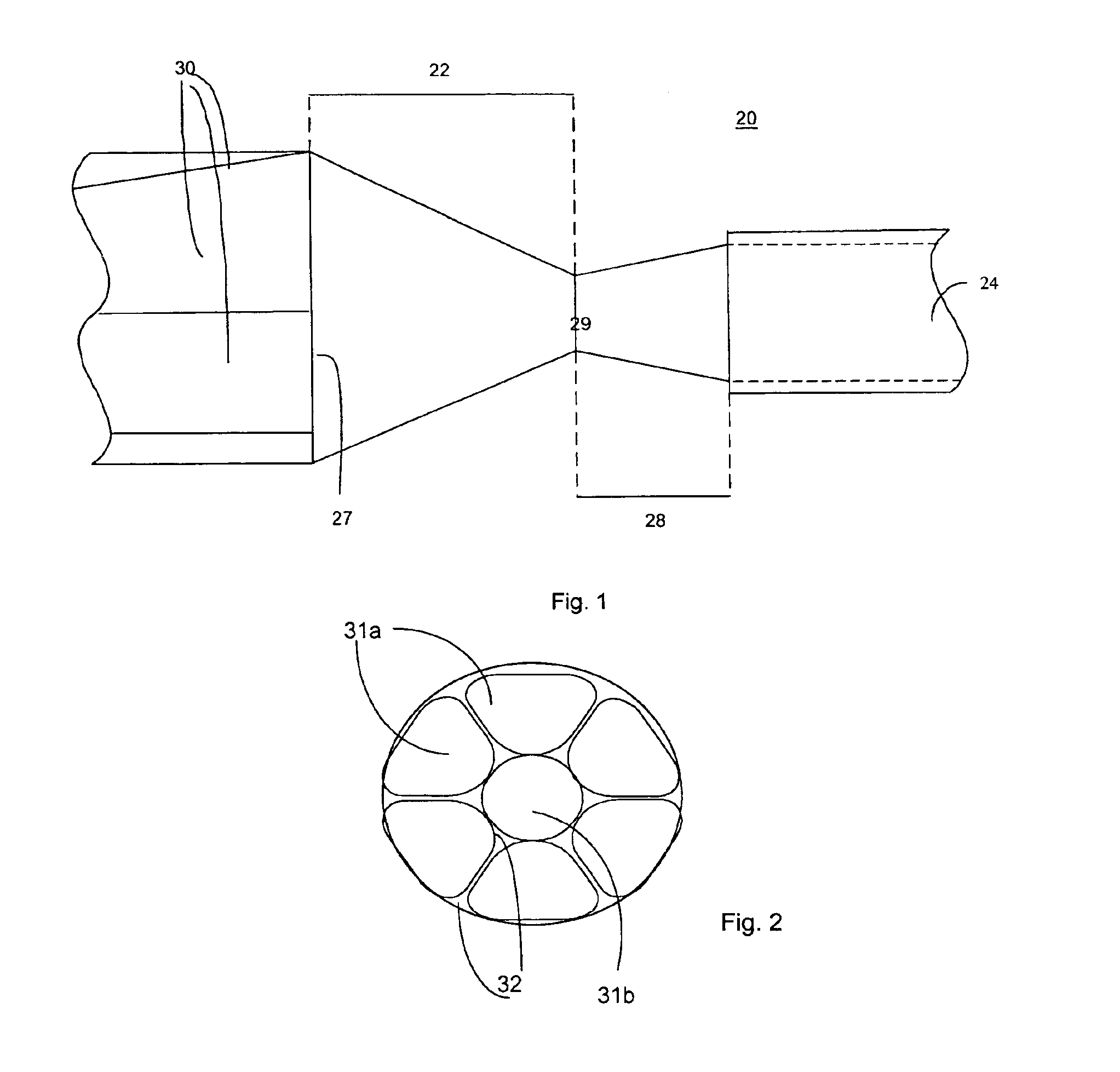

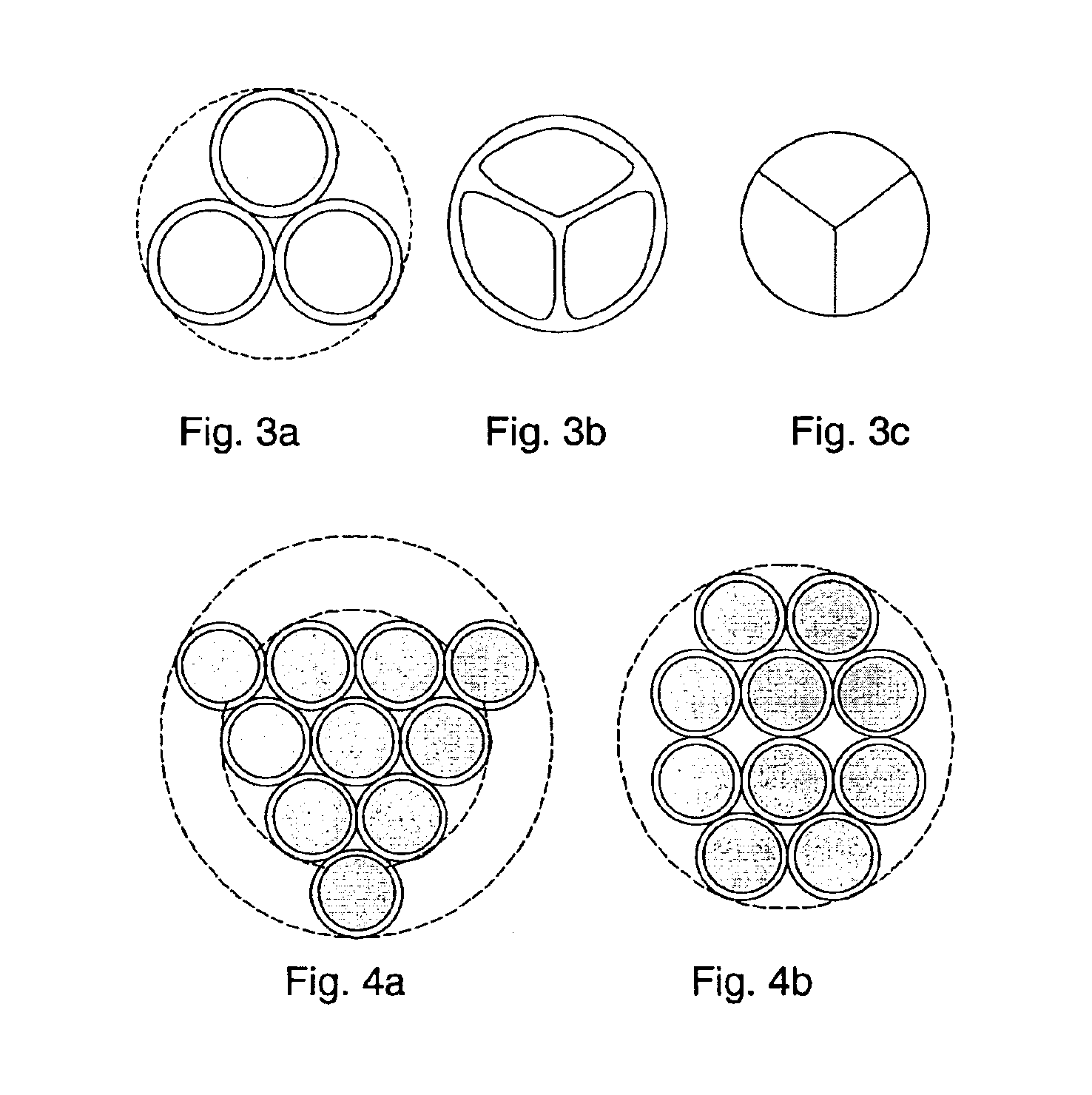

Mode multiplexing optical coupling device

InactiveUS6990278B2Enhanced couplingReduced insertion lossCoupling light guidesBundled fibre light guideMultiplexingFiber bundle

An efficient tapered optical fiber bundle along with the method of manufacturing is presented. The tapered fiber bundle is fully fused to an induced shape with no interstitial space between fibers. To minimize fiber deformation and hence the tapered bundle's loss, the individual fibers are minimally deformed by positioning them in a fixture with predetermined geometry prior to fusion. The bundle could be optionally reshaped after fusion. The tapered bundle could then be used in its original form as a star coupler, or it could be cleaved and coupled to a multimode fiber, a multi-clad fiber, a cladding-pumped fiber, or an optical system to form an optical device. The resulting optical device has improved efficiency and lower loss compared with prior art devices.

Owner:COHERENT INC

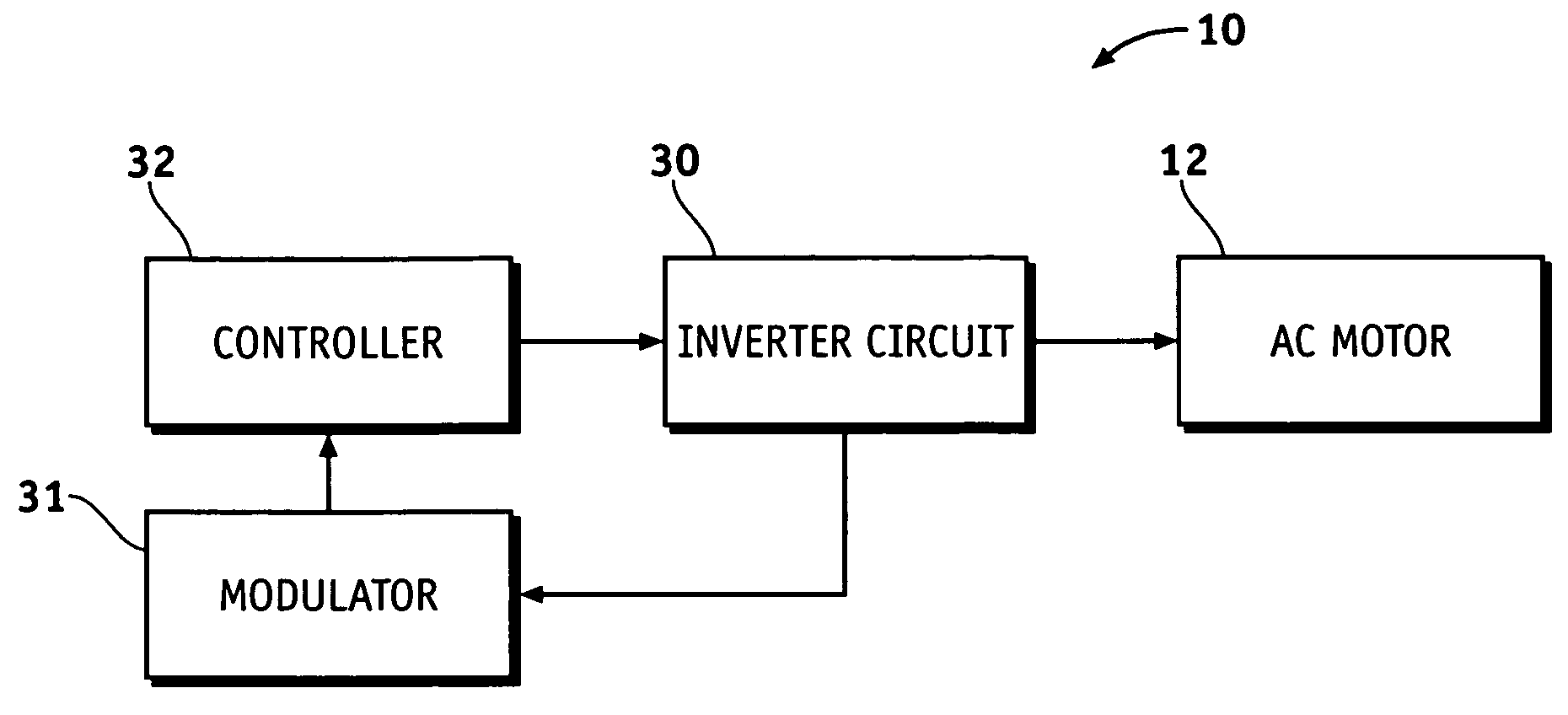

Method and apparatus for PWM control of voltage source inverter

ActiveUS7307401B2Minimize limitationDC motor speed/torque controlAC motor controlSwitching cycleVoltage source inverter

PWM methods and apparatus are provided for loss minimized control of AC motors taking into consideration inverter non-linear limitations. The method comprises providing a voltage to the AC motor based on a switching cycle, adding a duty cycle of a zero vector to each phase leg of the switching cycle when a duty cycle of a first phase leg of the switching cycle is less than a minimum duty cycle, and subtracting the duty cycle of the zero vector from each phase leg of the switching cycle when a second duty cycle of a second phase leg is greater than a maximum duty cycle. The minimum duty cycle and maximum duty cycle indicate distortion regions.

Owner:GM GLOBAL TECH OPERATIONS LLC

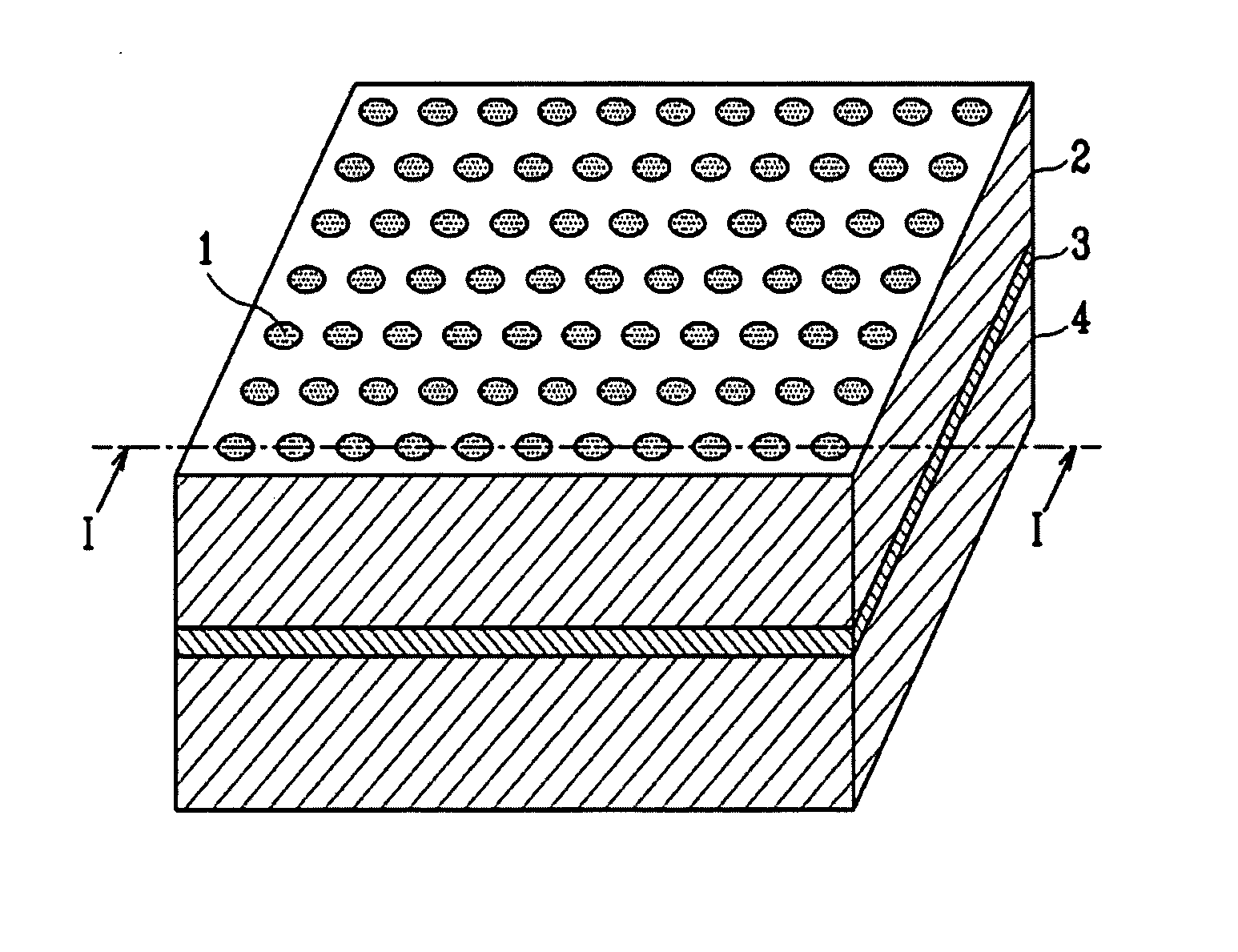

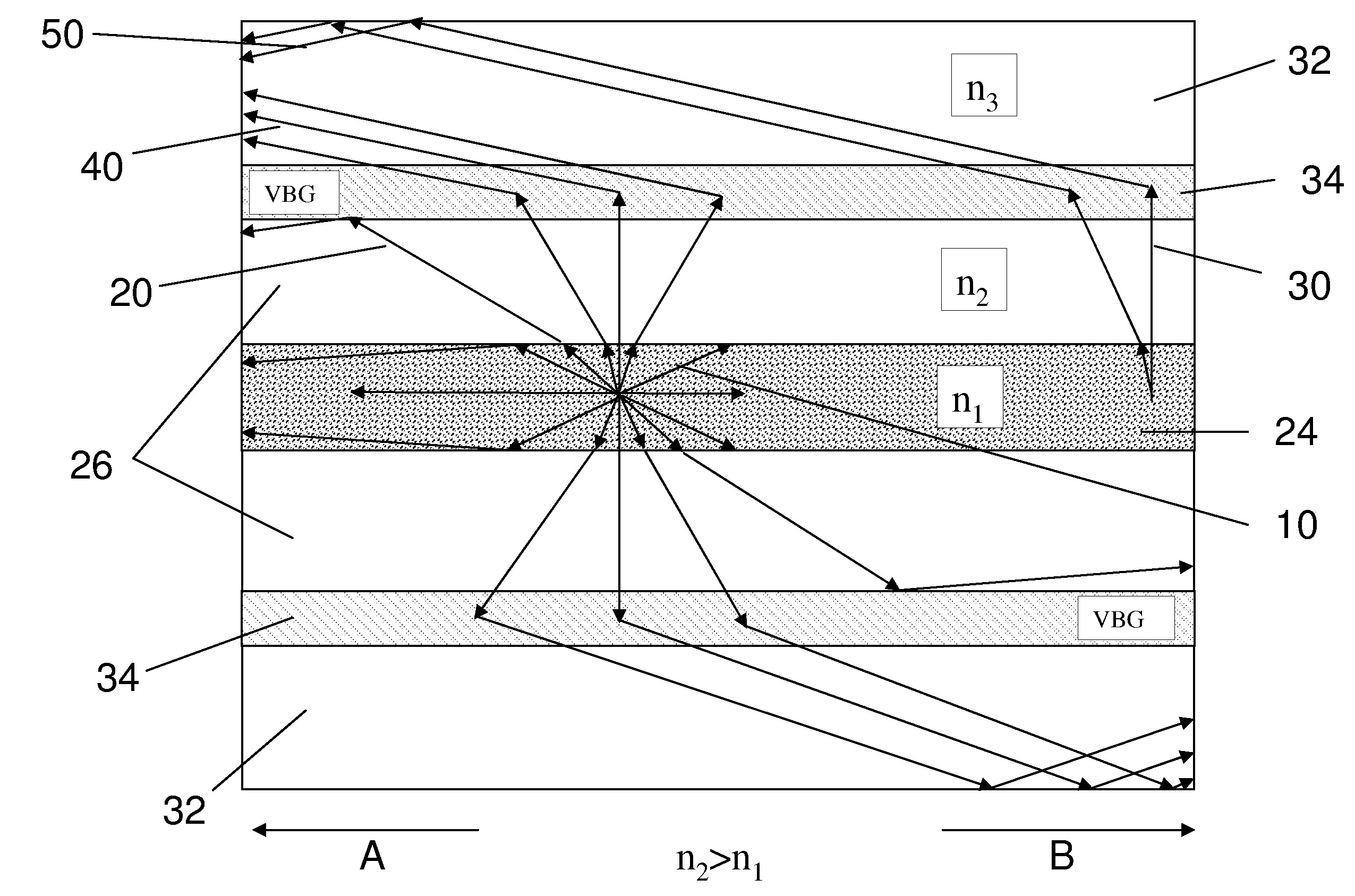

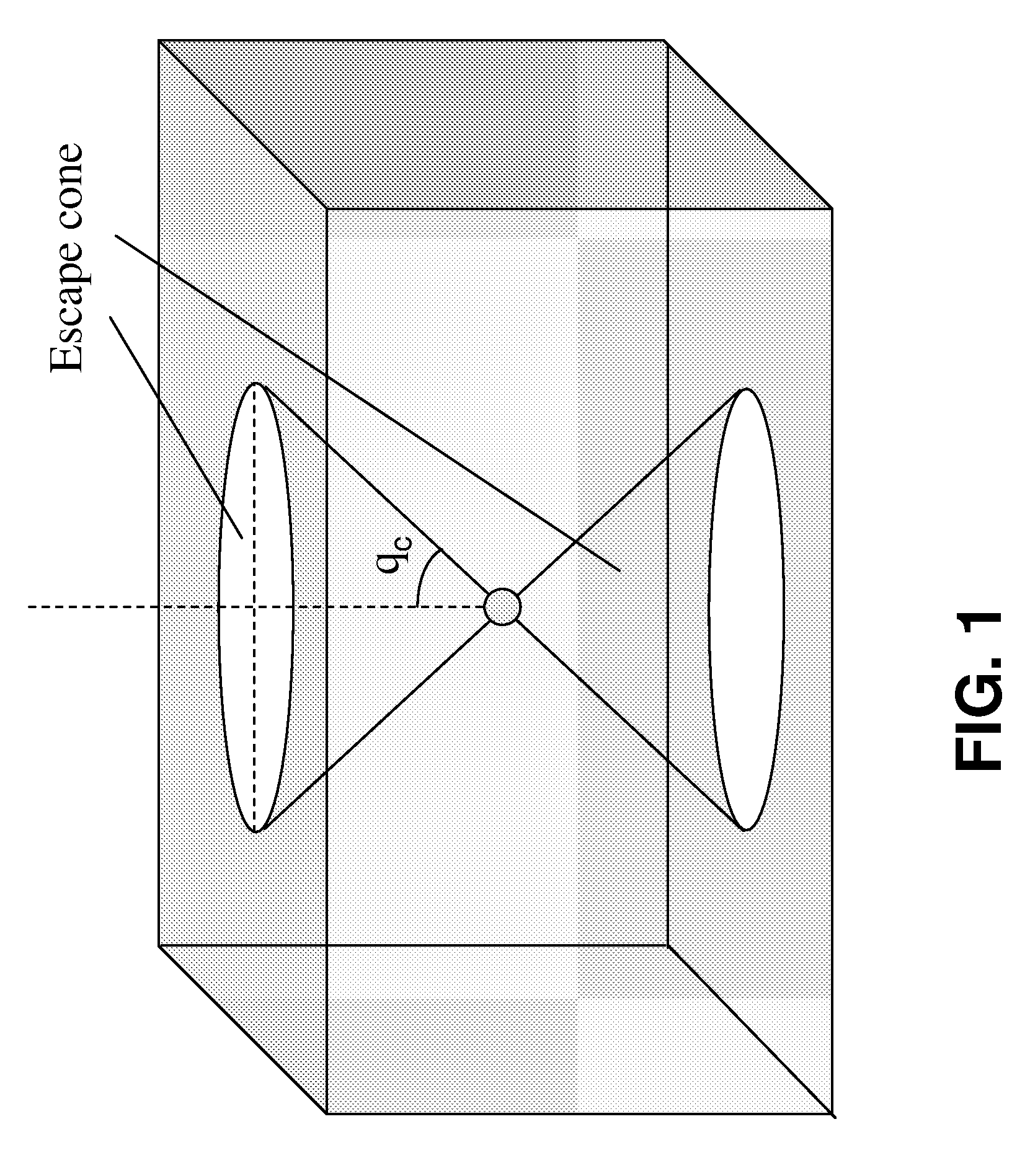

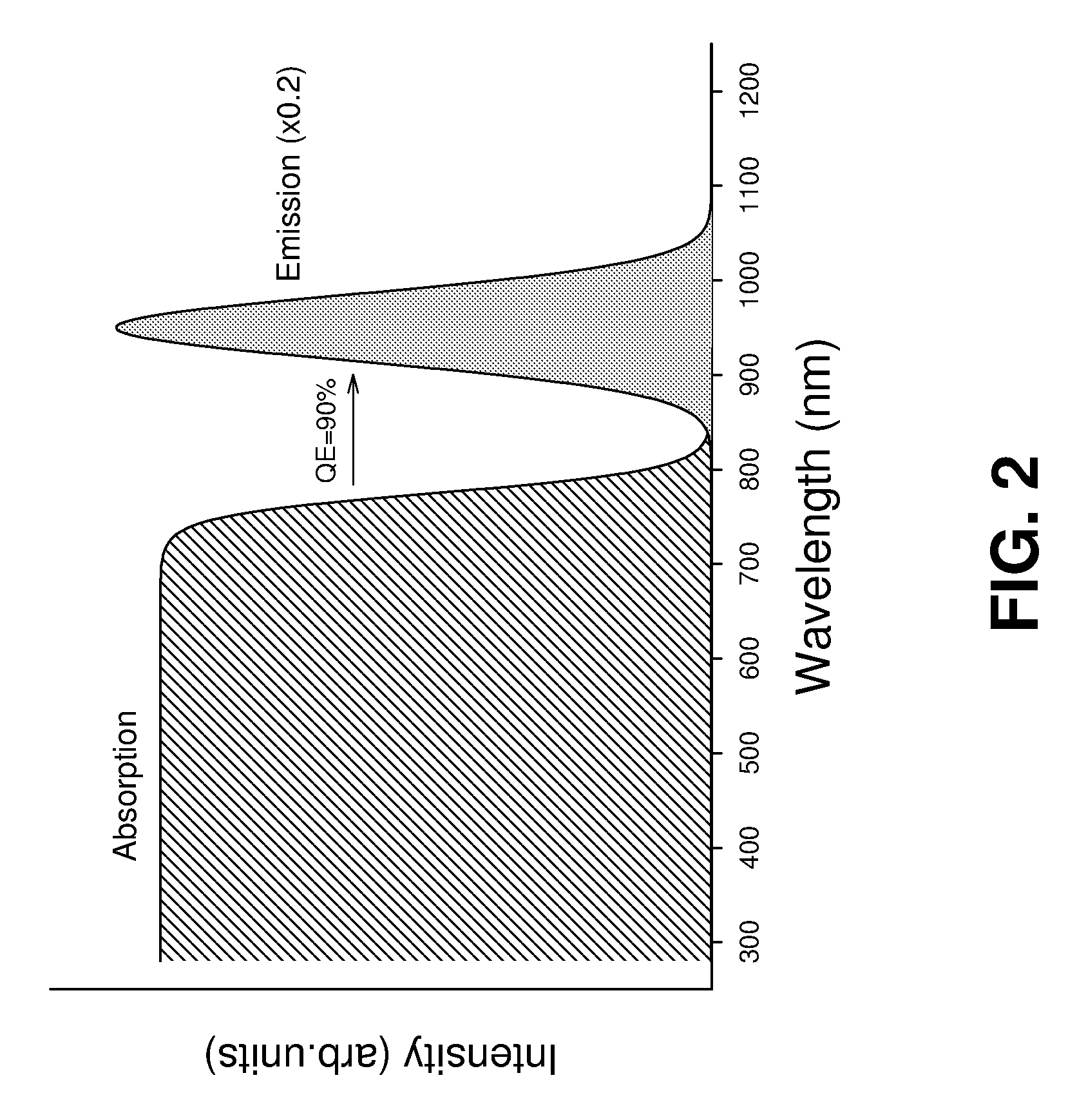

Methods and apparatuses for waveguiding luminescence generated in a scattering medium

InactiveUS20090110356A1Improve luminescent concentrator performanceMinimizing critical-angle lossOptical waveguide light guidePhotovoltaic energy generationRefractive indexWaveguide

The present invention is directed to a luminescent waveguide device, and methods of making thereof, that may be used to convert solar energy into electricity. In particular, the present invention relates to extracting and waveguiding luminescence generated in a scattering medium so as to improve luminescent concentrator performance. By stacking one or a pair of transparent plates of refractive index slightly smaller than that of luminescent plate but still larger than that of air, a much greater fraction of re-emitted light by the embedded luminescent particles can be extracted so that the detrimental effect of particle scattering can be minimized. Additionally, by additionally using a high-efficiency diffractive optic component in the structure to redirect the re-emitted photons with angles falling into the escape zone to much larger angles so these otherwise outgoing photons can be waveguided by total internal reflection. These improvements minimize the critical-angle loss and increase the output light intensity at the ends of the waveguide.

Owner:E CUBE ENERGY TECH CO LTD

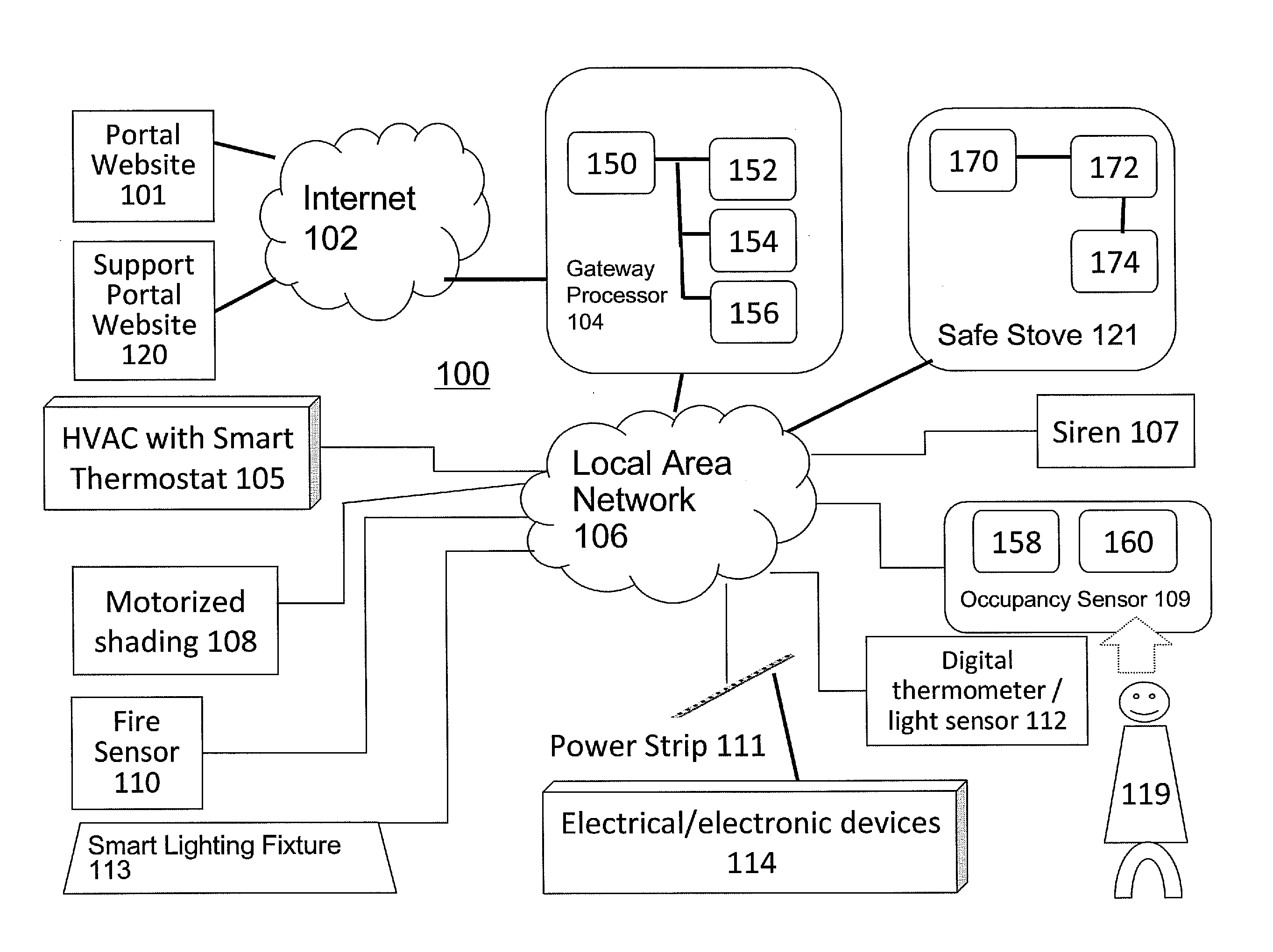

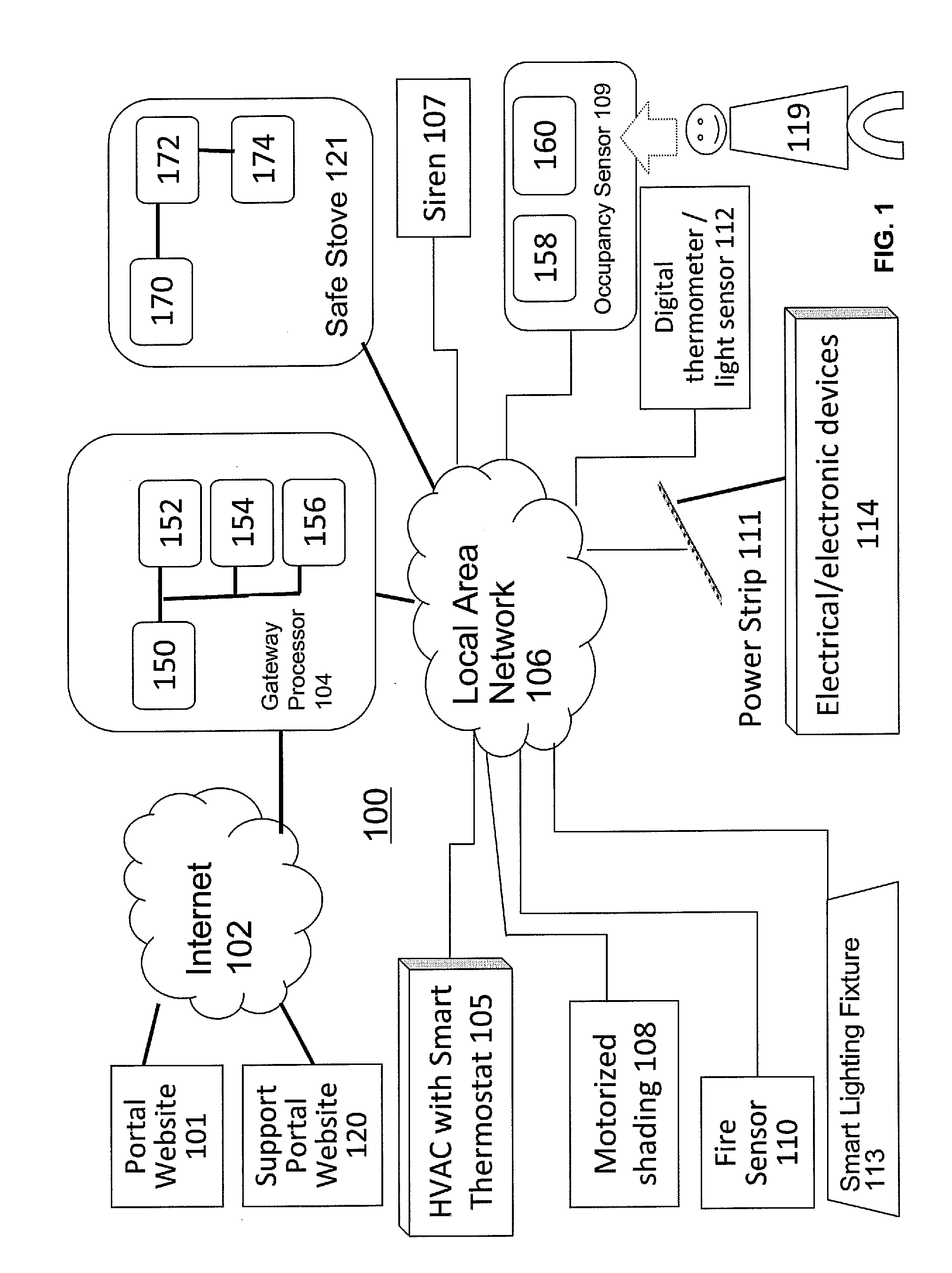

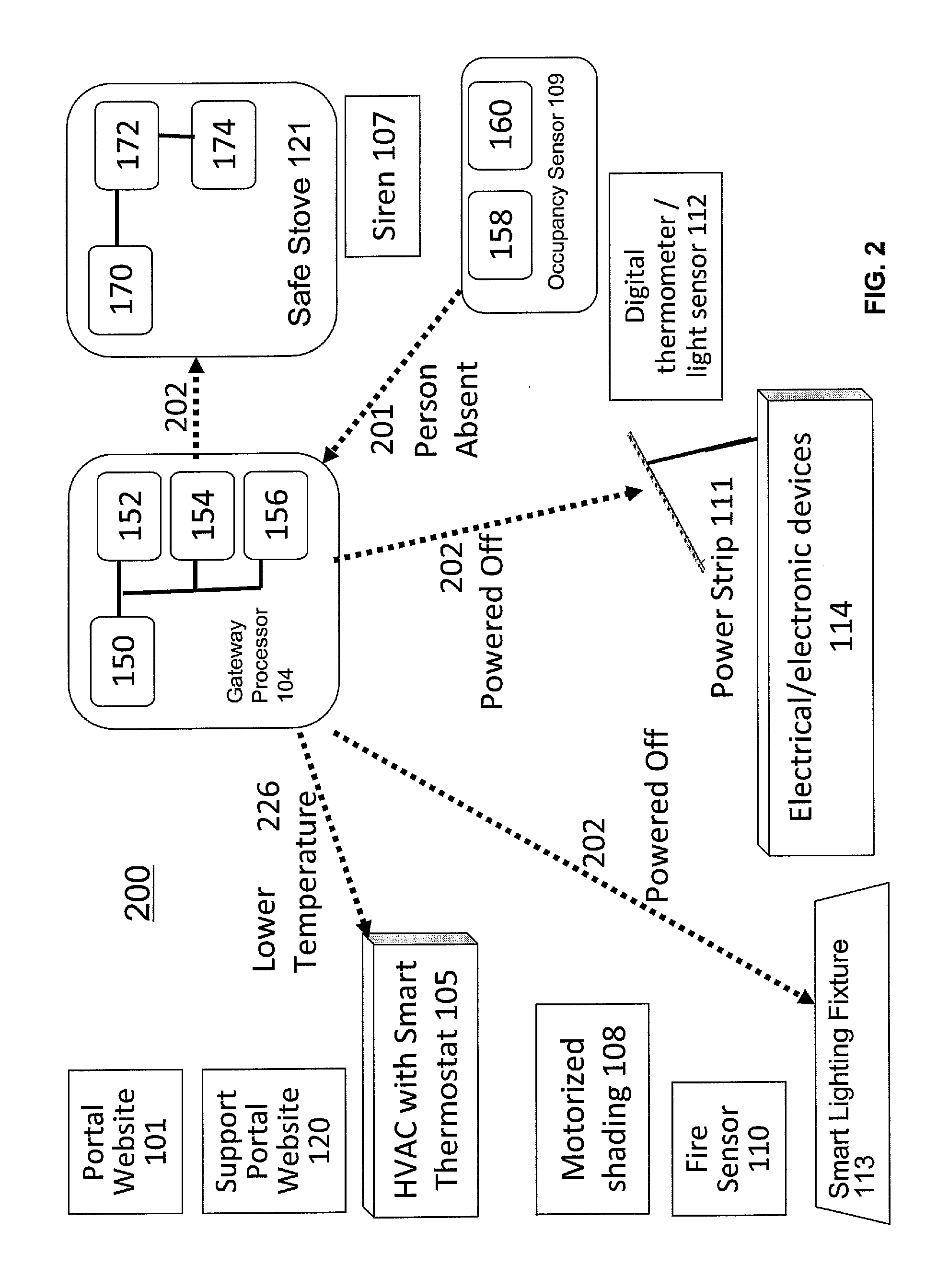

Systems, devices and methods of energy management, property security and fire hazard prevention

InactiveUS20110238234A1Reduce lossesReduce detectionLevel controlCircuit arrangementsEngineeringComputer software

Systems and devices for and methods of energy management, property security and fire hazard prevention are provided. The systems, devices and methods are able to be centralized, computerized, and expandable. The devices and systems are capable of automatically reducing energy consumptions and minimizing losses of property caused by fire, theft, and vandalism using monitoring sensors (e.g., occupancy sensors) and computer software and equipments.

Owner:CHEN DAVID H C

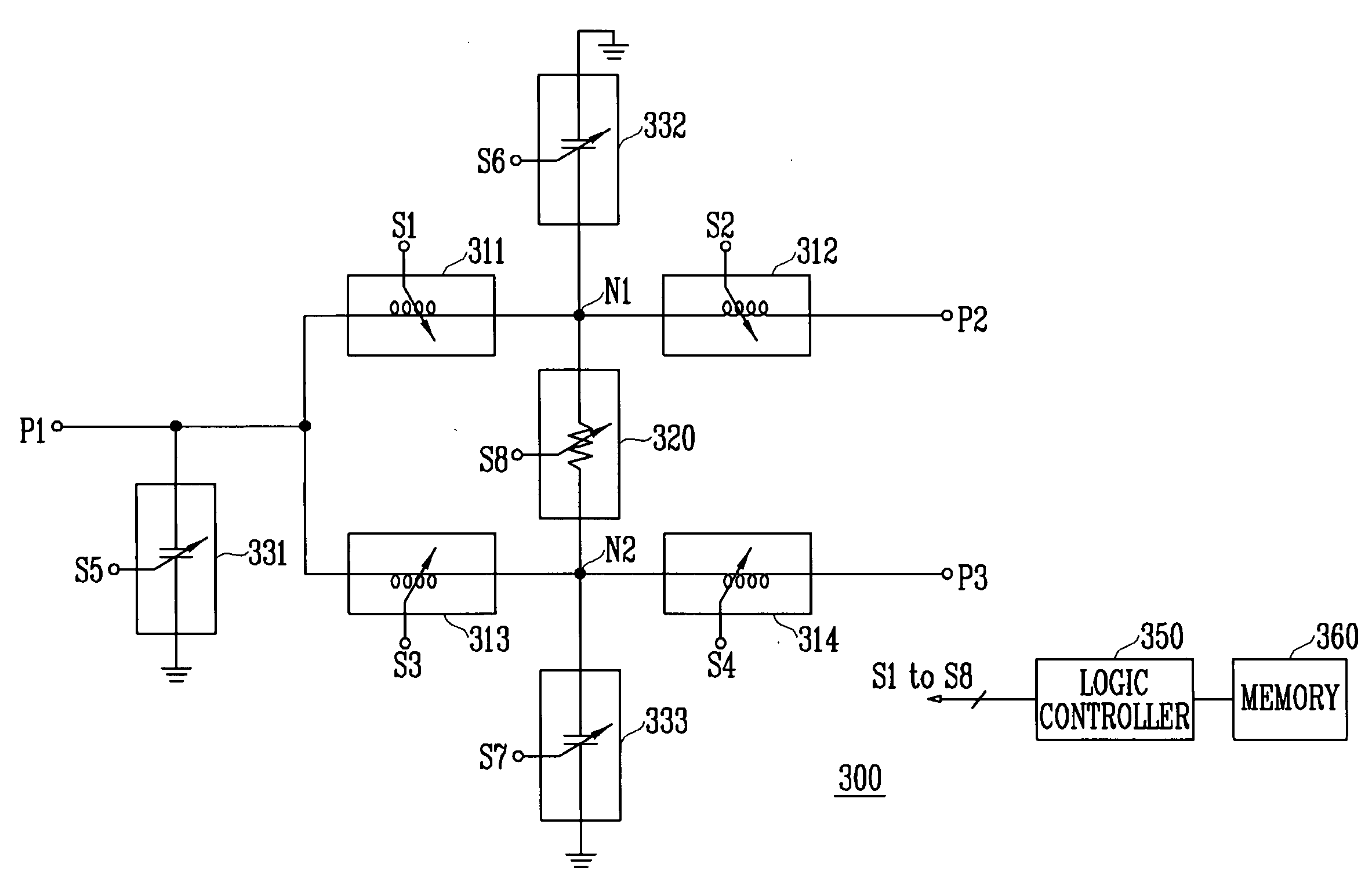

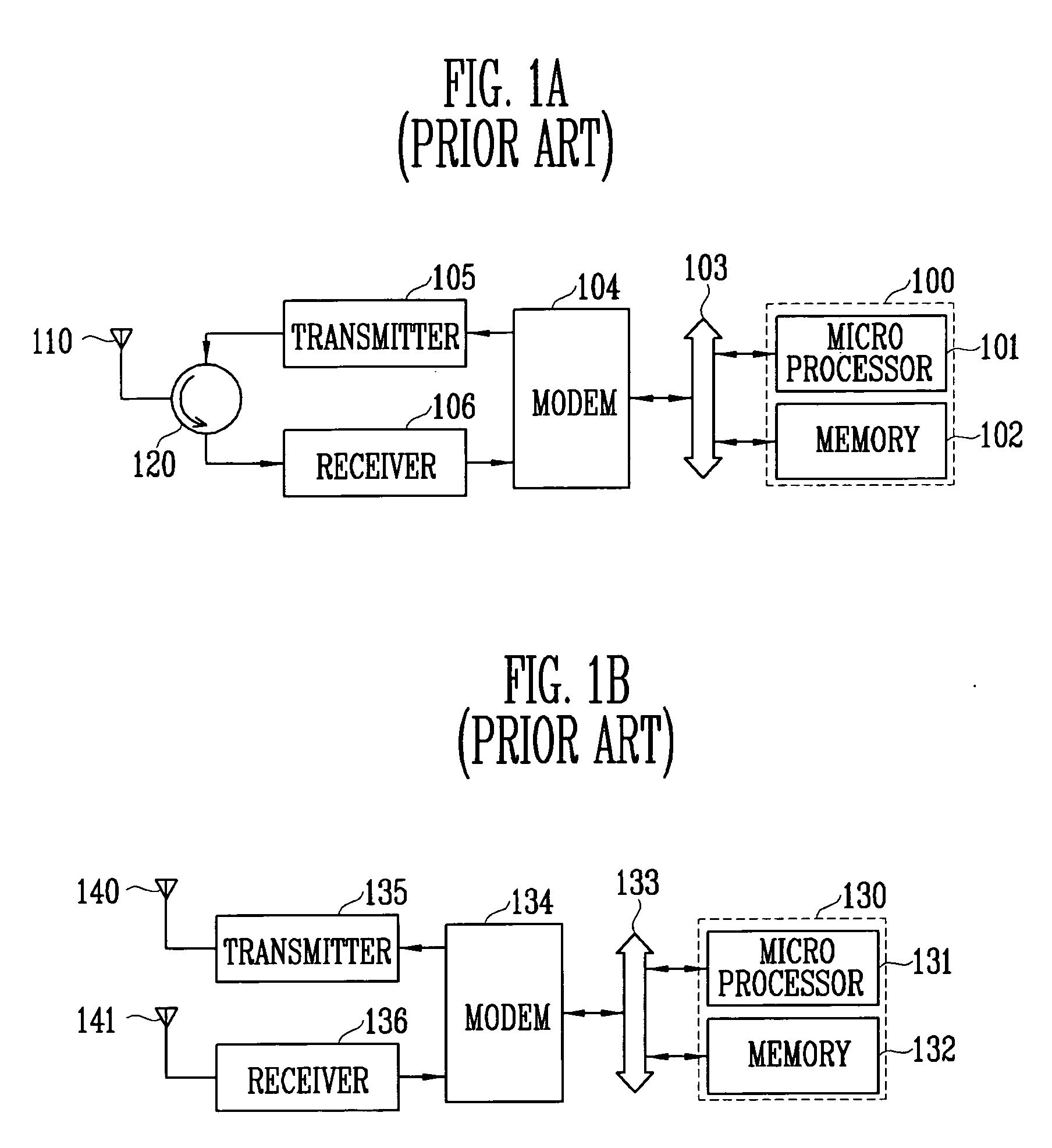

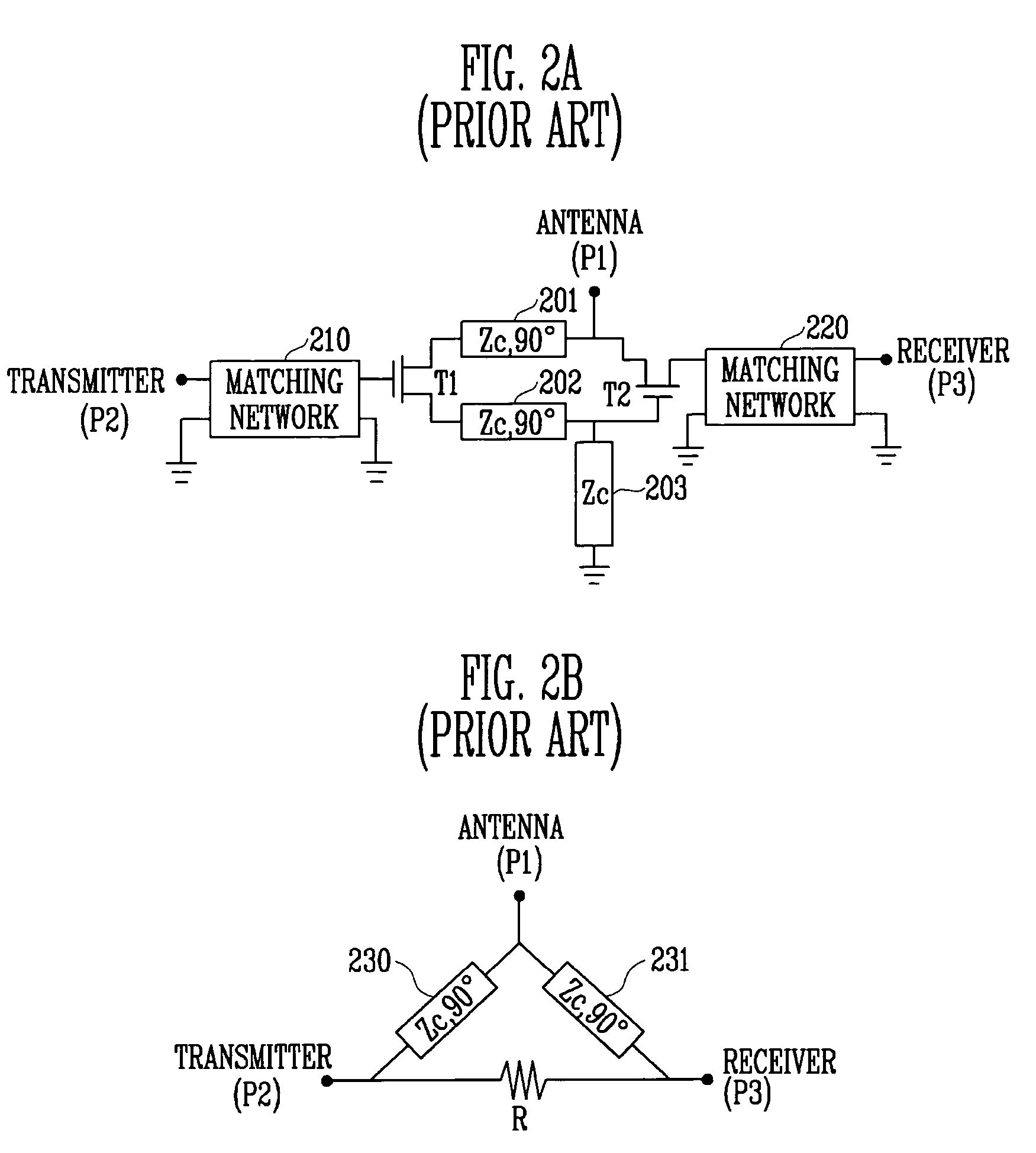

Digitally controlled circulator and radio frequency identification reader having the same

InactiveUS20070096842A1Reduce lossesMultiple-port networksCo-operative working arrangementsControl signalMiniaturization

Provided are a digitally controlled circulator and a radio frequency identification (RFID) reader having the circulator. A power splitter is composed of lumped elements and the values of the elements are digitally changed using switching means, in which the transmission loss of a signal is controlled according to whether the reader is in a transmission state or a reception state. Therefore, the loss can be minimized, and the circulator can be miniaturized and priced down by an integrated circuit (IC) semiconductor process and mounted in a mobile terminal such as a cellular phone.

Owner:ELECTRONICS & TELECOMM RES INST

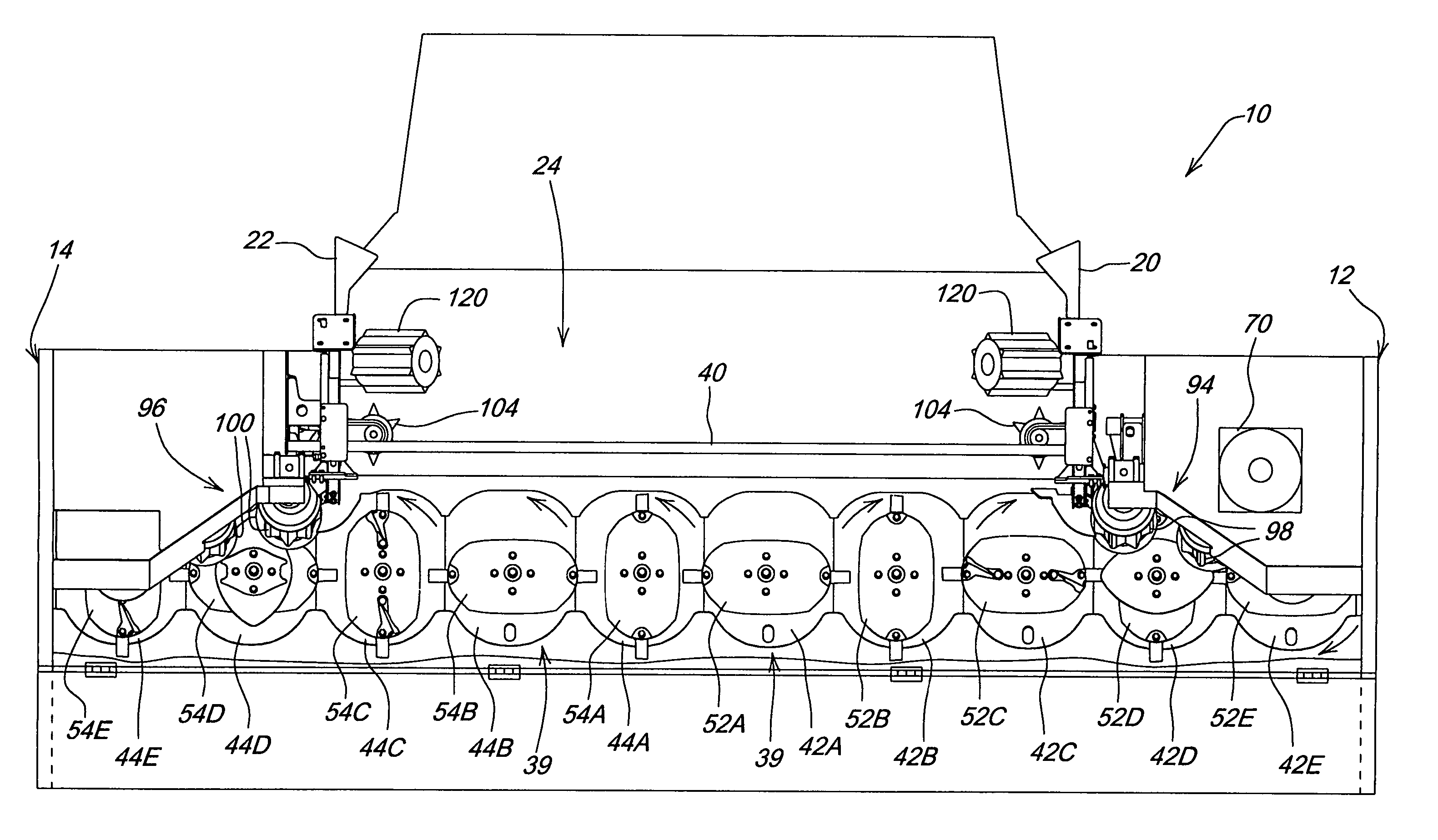

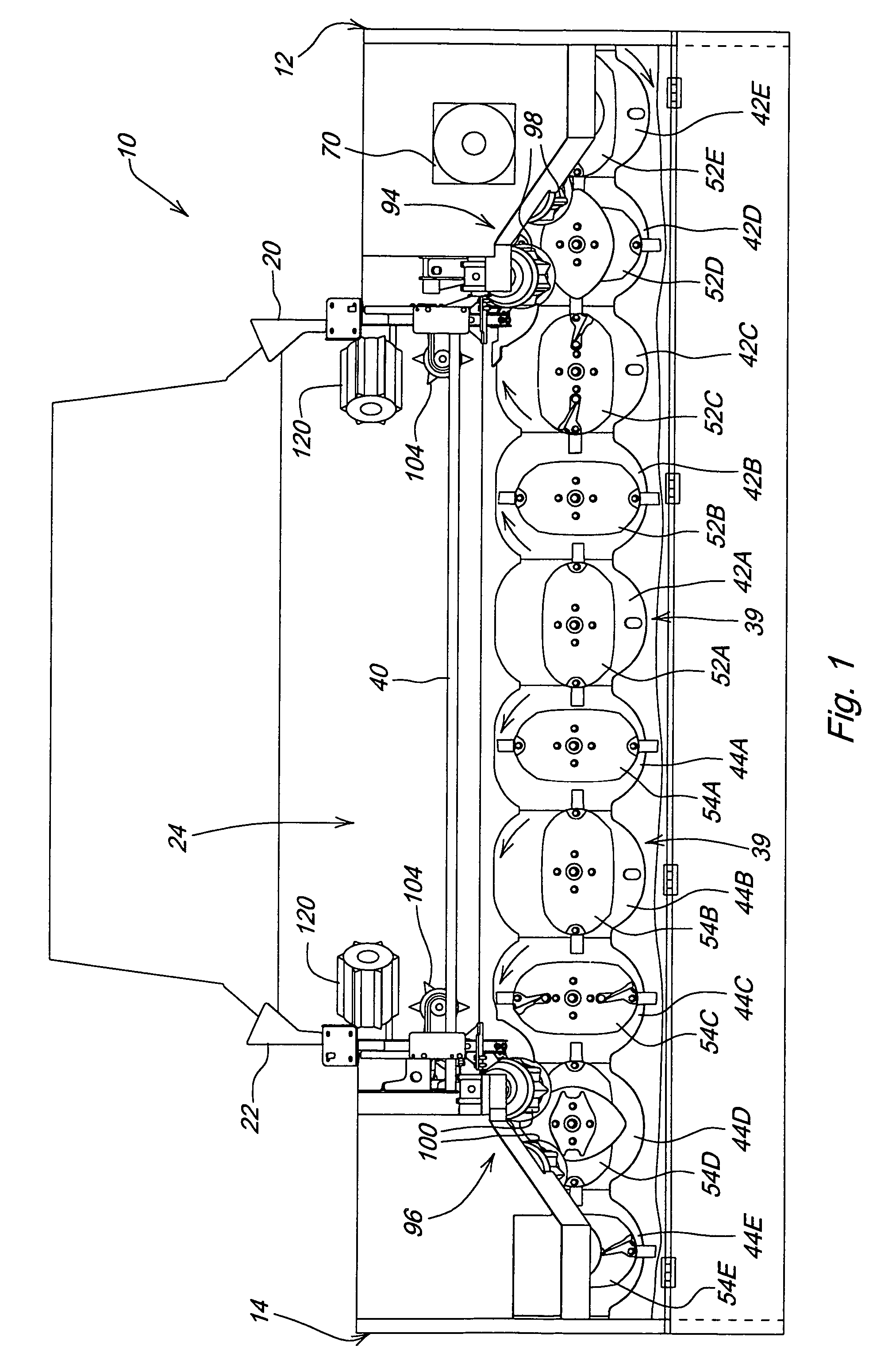

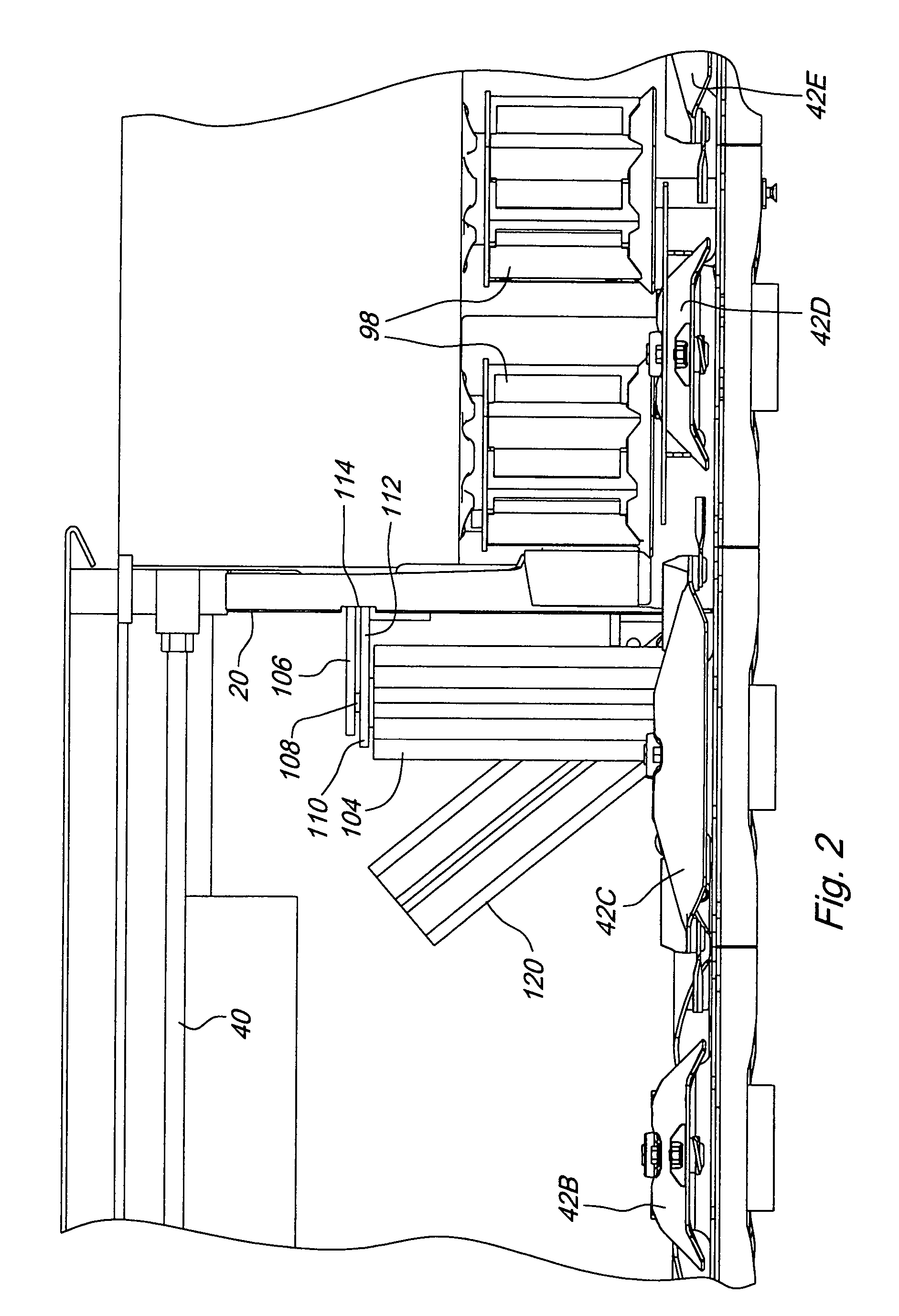

Rotary platform having converging elements for specialty crops

A rotary platform is provided for the harvest of specialty crops such as grass seed. In particular the conditioning rolls are removed from the header to reduce seed shatter and converging elements are added inside the conditioner opening on both sides and to the rear of the cutterbar to feed the crop around the conditioner opening corner and to the rear of the platform. Additional converging elements are provided behind the first converging elements at a angle less then 90 DEG. to the ground so as to form the top of the windrow so that there is minimal seed loss. The converging elements may or may not be powered and the angle of the second converging element can be adjustable. The rotary knives perform the cutting function more efficiently than a sickle cutterbar, and the converging elements move the crop toward the center to form a windrow with less disturbance.

Owner:DEERE & CO

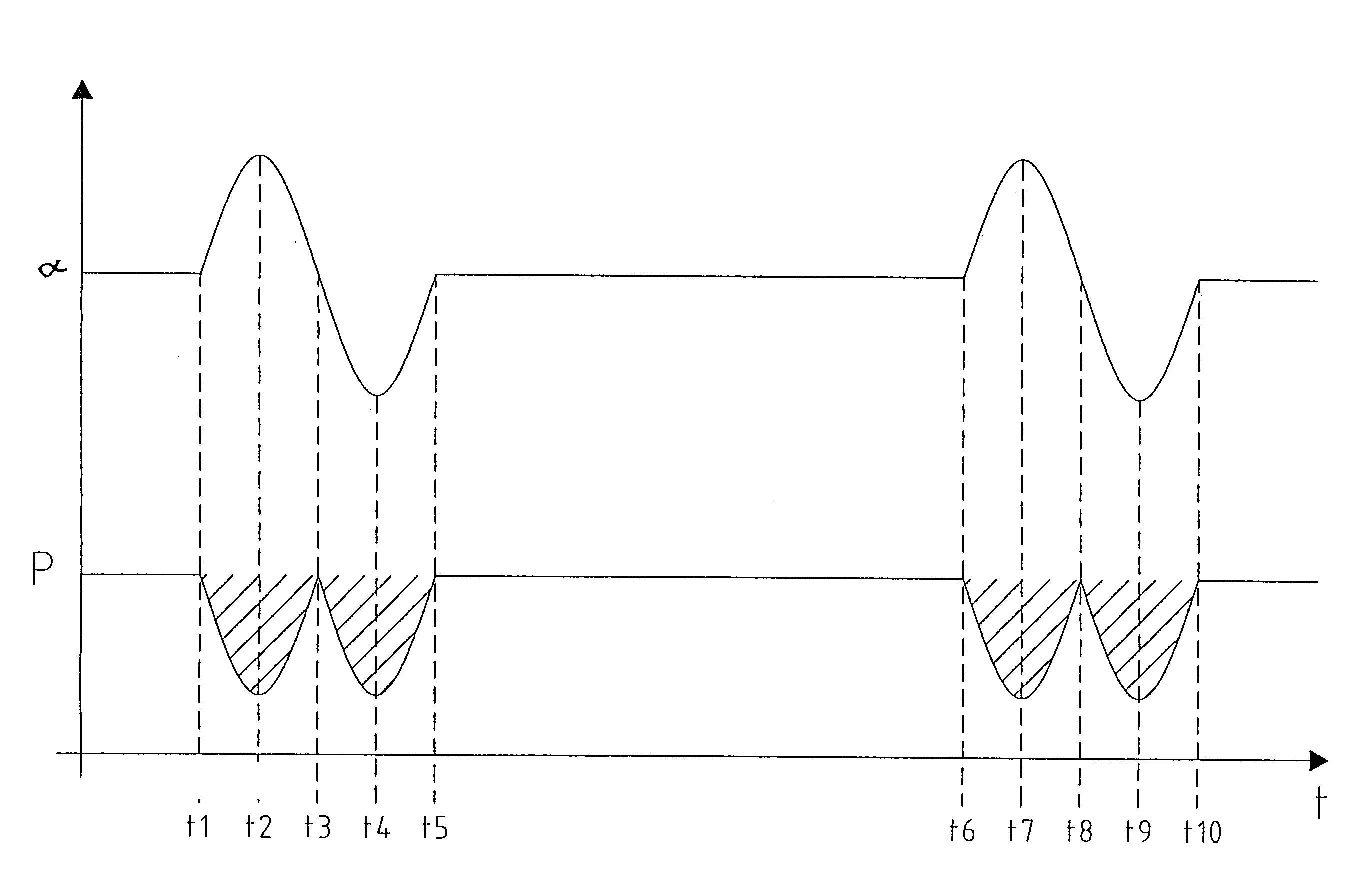

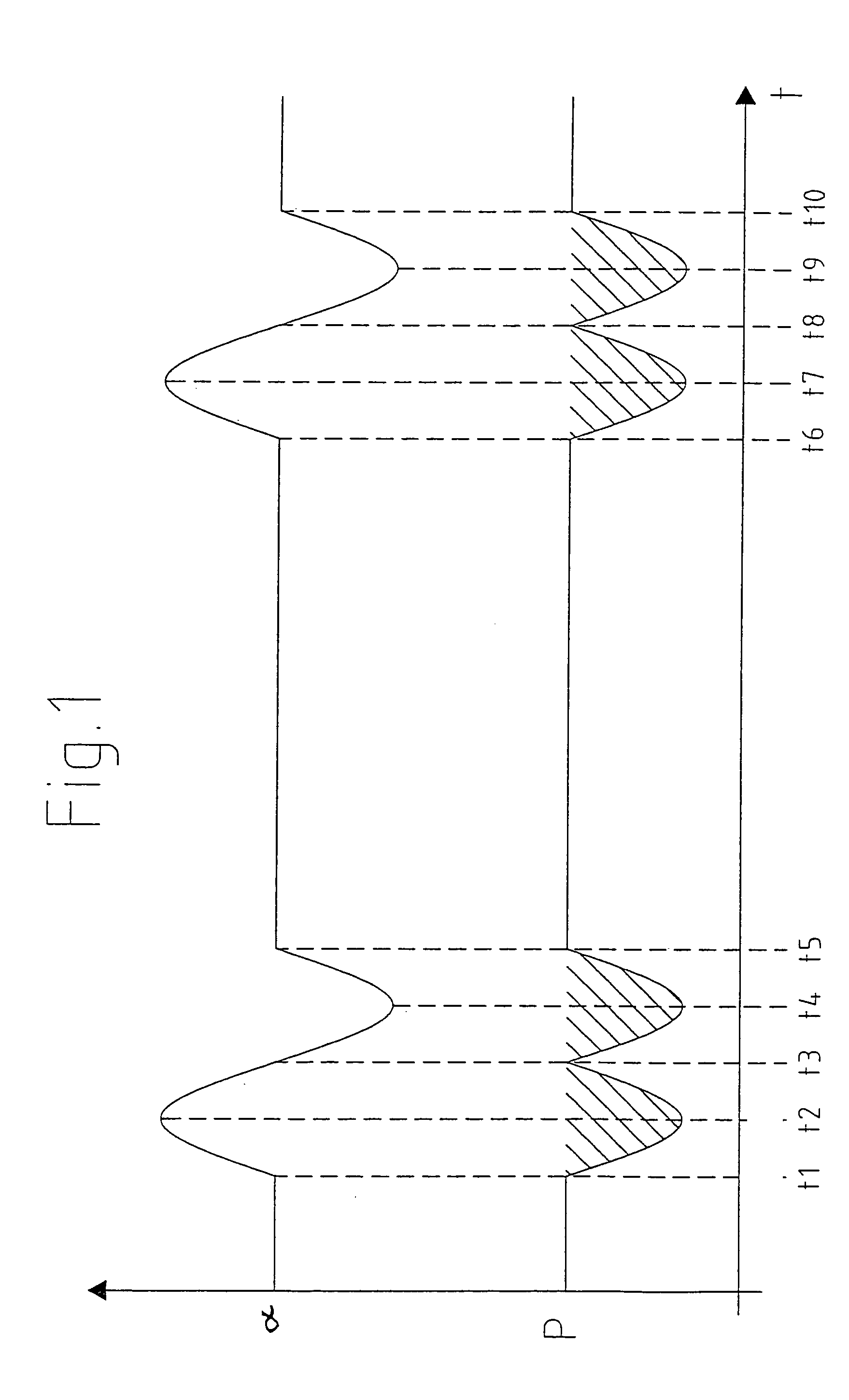

Method for maximizing the energy output of a wind turbine

A method is provided for controlling a wind turbine, and a wind turbine is provided with a control device for controlling a wind turbine. A method and a wind turbine are developed so that losses of yield, particularly as a result of variations in the conversion of the kinetic energy of the wind into electrical energy, e.g., in the rotor, drive train and generator, are minimized as far as possible. A method is provided for controlling a wind turbine, wherein at least one operational setting is varied within predefined limits.

Owner:WOBBEN ALOYS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com