Bulk curer heat supply and ventilation system supplied by combined solar energy-air source heat pump double heat sources

A technology of air source heat pump and dense barn, which is applied in the field of heating and ventilation system of dense barn, can solve the problem that the solar air collector cannot operate around the clock, and achieve the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

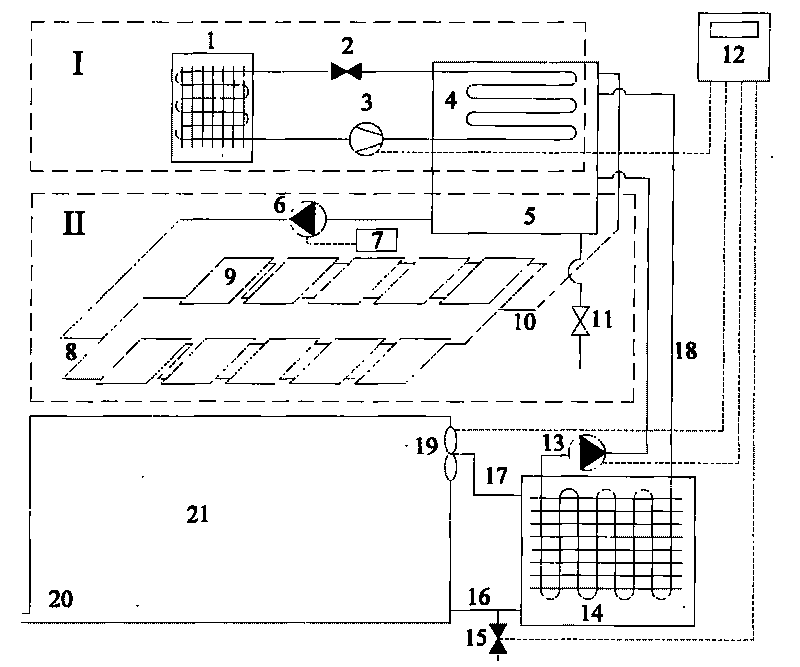

[0016] The present invention is further described in conjunction with the accompanying drawings and examples. See figure 1 , the present invention consists of an air source heat pump hot water subsystem I, a solar hot water subsystem II, a general controller 12, a frequency conversion circulating water pump 13, an air-water heat exchanger 14, a fresh air valve 15, a replenishment valve 11, and a return air pipe 16 , air supply pipe 17, heat preservation hot water pipe 18, circulation fan 19 etc. constitute. The condenser 4 of the air source heat pump hot water subsystem I is placed in the hot water tank 5 of the solar hot water subsystem II, and the replenishment valve 11 is installed at the bottom of the hot water tank 5 . Both ends of the air side of the air-water heat exchanger 14 are connected to the air supply pipe 17 and the return air pipe 16 respectively. Circulation blower 19 is installed on the body of wall of intensive barn, and its air inlet links to each other w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com