Carbonatation processing method of steel scoria

A treatment method and carbonation technology, applied in the field of solid waste resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

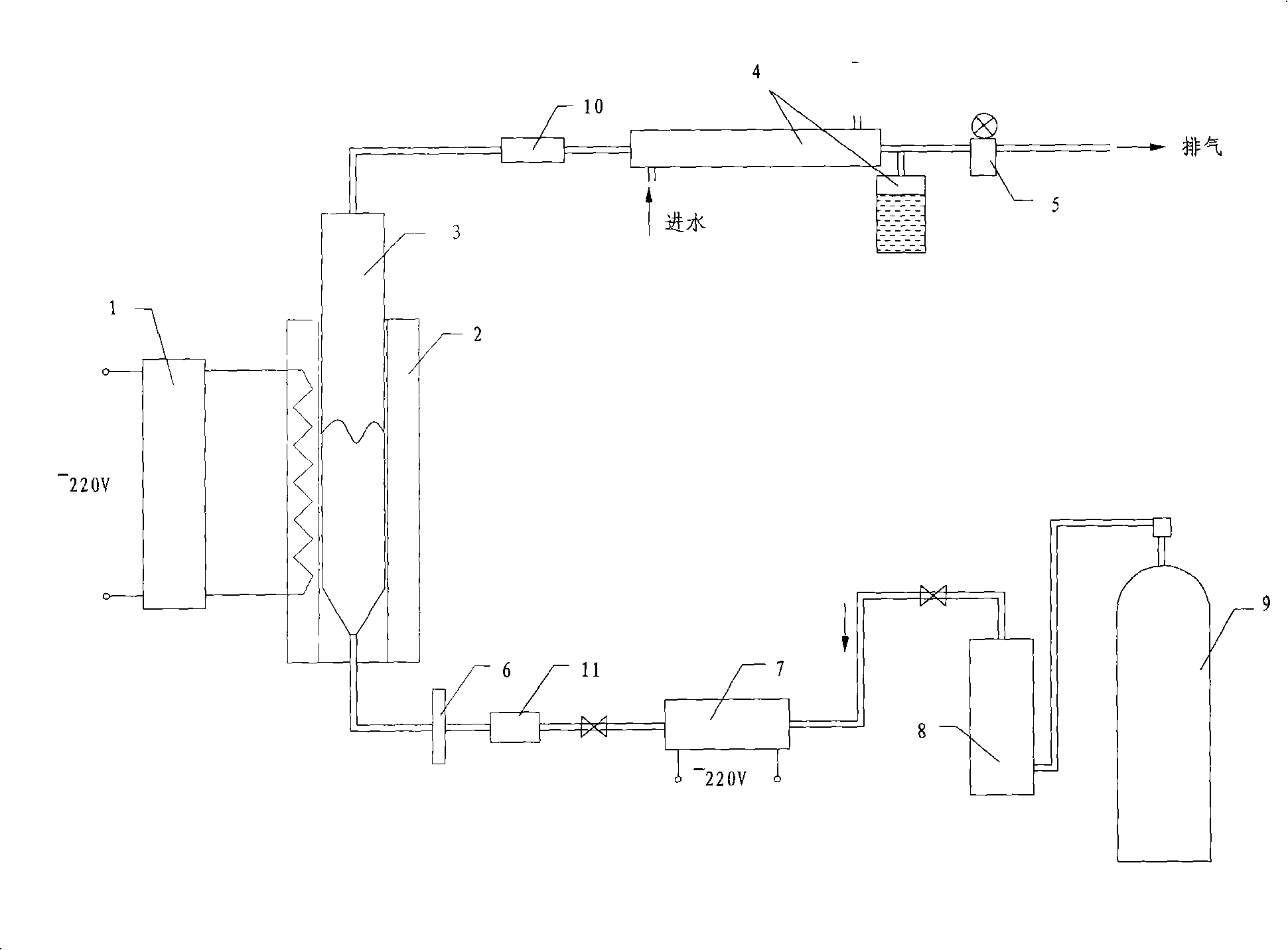

[0018] The steel slag carbonation treatment method provided by the invention adopts an ebullating bed reactor. The temperature of the reactor is controlled by an automatic control system and a heating furnace, and the reactor can be freely converted between vertical and horizontal. The vertical type is adopted when the boiling reaction is in progress, and the horizontal type is adopted when the material is poured after the reaction is completed.

[0019] First, steel slag is filled in the fluidized bed reactor, and then the heating furnace is started to heat the material. When the temperature rises to the preset reaction temperature, turn on the carbon dioxide gas source and the steam generator switch to supply gas, and the gas supply volume should be such that the material in the reactor is in a boiling state. The boiling state of the steel slag material in the fluidized bed reactor makes the steel slag fully contact with carbon dioxide and water vapor and react quickly, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com