Method for preparing calcium sulfonate with high base number

A technology of high basic number calcium sulfonate and sulfonic acid, which is applied in the preparation of sulfonate, additives, organic chemistry, etc., can solve the problem of poor conversion effect, slow conversion of Newtonian calcium sulfonate, and poor performance of lubricating grease, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Add 150 milliliters of gasoline (industrial products) in a 500 milliliter three-neck flask with a motor stirrer and a condenser, add 23.7 grams of methanol, 6 grams of distilled water, 43 grams of 150SN neutral oil (produced by Sinopec Yanshan Petrochemical Company), twelve 4 grams of alkylphenol, 16.5 grams of calcium oxide, 21.6 grams of dodecylbenzene high boiler sulfonic acid, after adding, control the reaction temperature at 45-50°C, and after 30 minutes of neutralization reaction, introduce carbon dioxide at a ventilation rate of 0.062L Between / min, when the amount of feed reaches 85% of the theoretical value, add the remaining 25 grams of calcium oxide, continue to feed carbon dioxide to carry out the carbonation reaction, when the carbon dioxide reaches 85% of the theoretical value, stop ventilation, add 20wt% 5 grams of ammonium carbonate solution, react at 45-50°C for 30 minutes, then heat up to 120°C for dealcoholization and water. Add 100 milliliters of gas...

Embodiment 2

[0033] Add 150 milliliters of xylenes (chemically pure) in the 500 milliliters three-necked flask that has motor stirrer and condensing tube, 38 grams of 150SN neutral oil (produced by Sinopec Yanshan Petrochemical Company), 4 grams of lauryl salicylic acid, 8.2 grams of methanol, 20 grams of n-butanol, 18 grams of calcium hydroxide, C 20-28 Add 25 grams of alkylbenzenesulfonic acid, add 3 grams of ammonia water, control the reaction temperature at 45-50°C after adding, neutralize for 30 minutes, feed carbon dioxide, the ventilation rate is between 0.065L / min, and the feeding amount reaches the theoretical value When 90%, add remaining 32.5 grams of calcium hydroxide, continue to feed carbon dioxide and carry out carbonation reaction, when carbon dioxide reaches 90% of theoretical value, stop aeration, add 30wt% sodium carbonate and 8 grams of 20wt% sodium chloride solution , react at 45-50°C for 45min, then raise the temperature to 120°C for dealcoholization and water. Add 1...

Embodiment 3

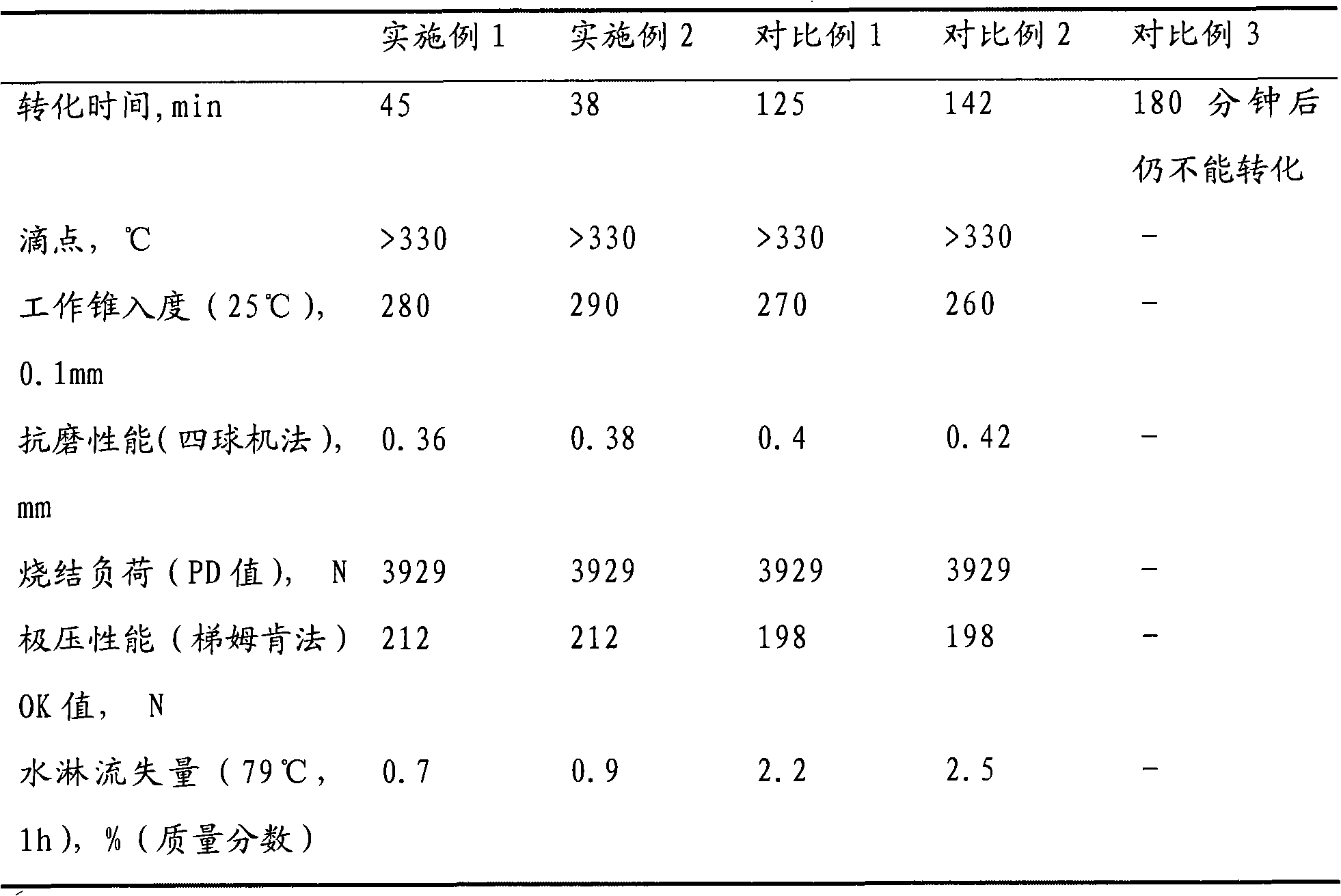

[0042] This embodiment is used to illustrate the effect of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com