Patents

Literature

104results about How to "In line with the concept of circular economy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

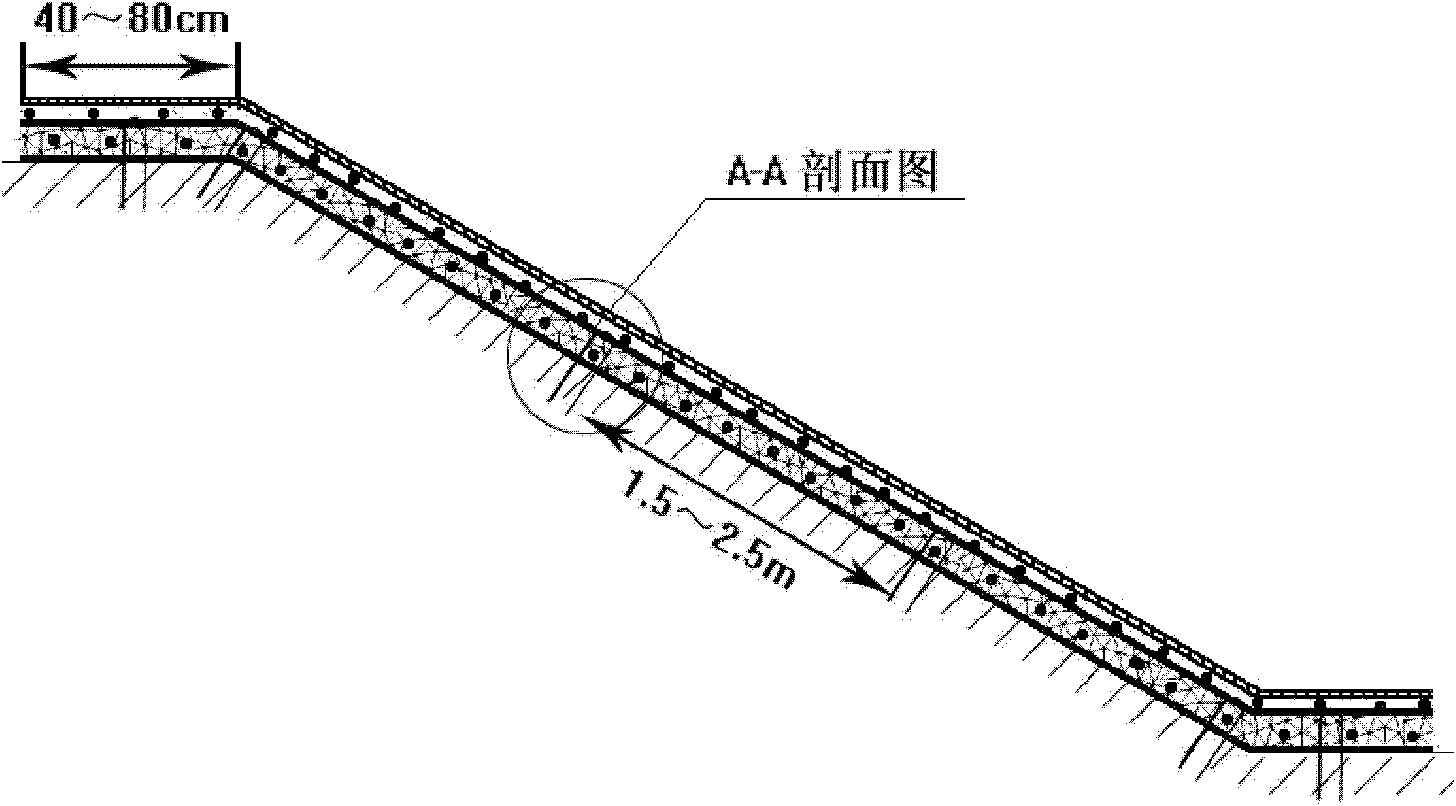

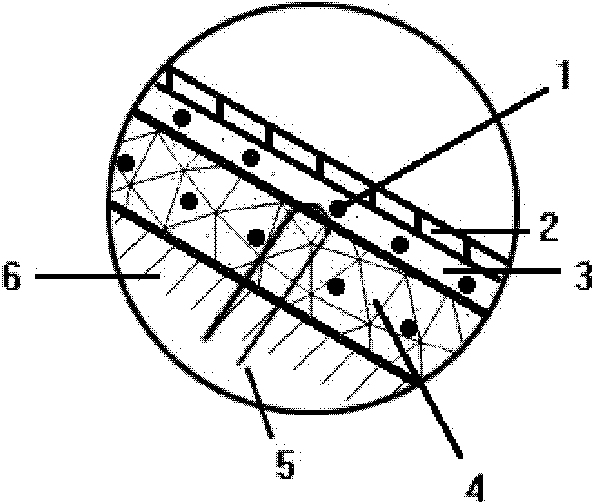

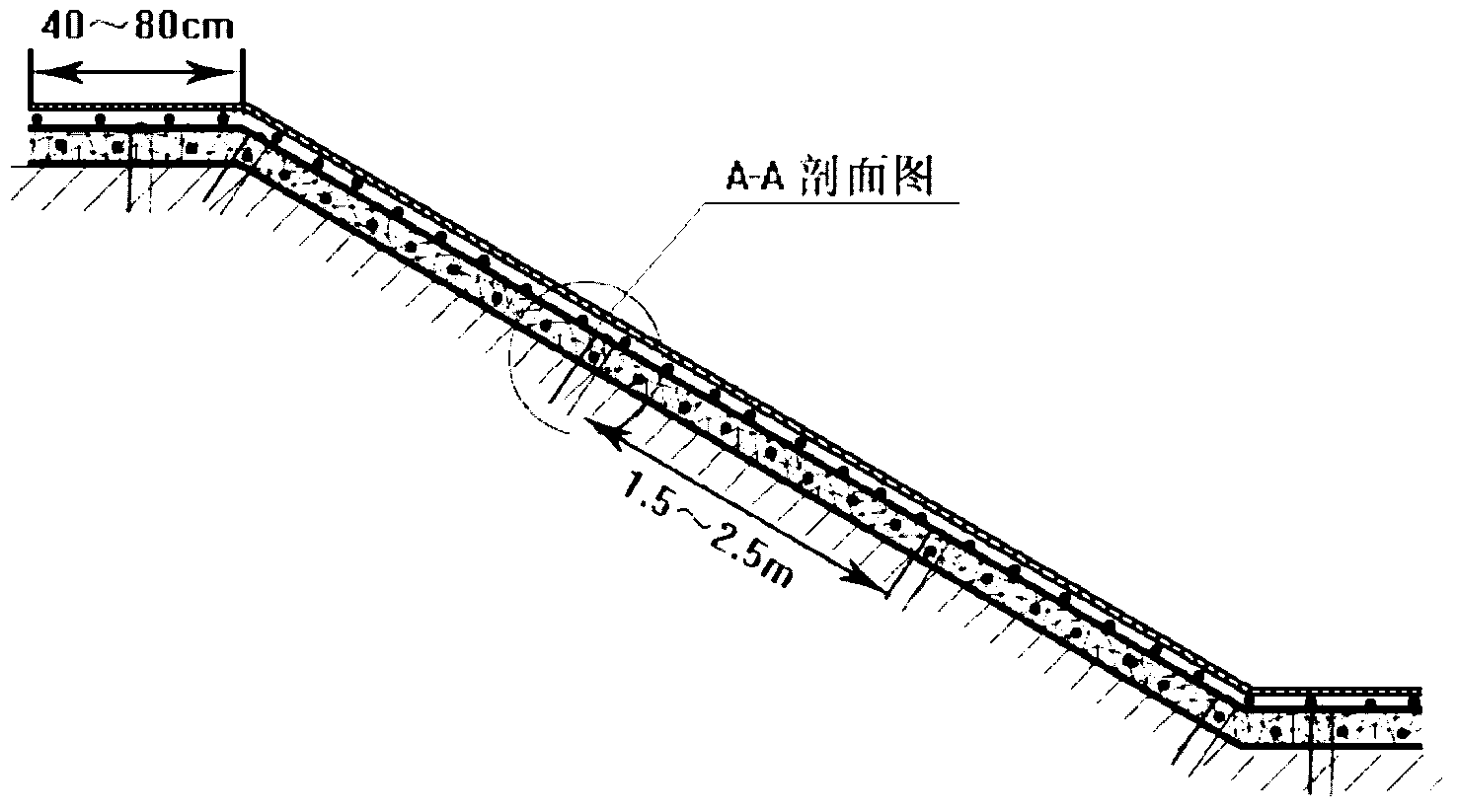

Vegetation restoration method adopting plant fiber blanket with assist of slurry spraying

InactiveCN102138428ASolve the protection problemAchieve the perfect combinationExcavationsHorticultureRevegetationPlant fibre

The invention belongs to the field of ecological engineering and relates to a construction method of spraying and covering planting in an ecological restoration project, namely, a vegetation restoration method adopting a plant fiber blanket with the assist of slurry spraying. The invention is characterized in that the method comprises the following steps: laying a slope through the plant fiber blanket firstly, spraying and covering the slope through slurry and covering the slope through the plant fiber blanket. In the invention, a three-dimensional net made of geotextile material can be replaced; chemical synthetic materials entering the natural world can be obviously reduced when the effect of improving the overall and local stability of the slope is achieved; moreover, vegetable fiber can also increase organic components of soil, is beneficial for improving the capacities of water retaining and constant-temperature keeping of the soil on the surface layer and is beneficial for the growth of vegetation on the slope; when the construction cost is reduced, the low carbon conversion and utilization of agricultural and forestal residuals are realized, agricultural and forestal chains are extended, and the industrial added value of by-products is improved; and the method has a large application value in the soil and water conservation, sand prevention and control and ecological restoration of the damaged vegetation in a project in China.

Owner:北京林丰源生态科技有限公司

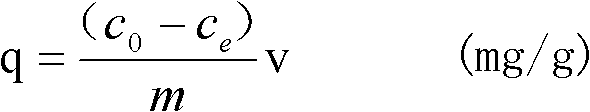

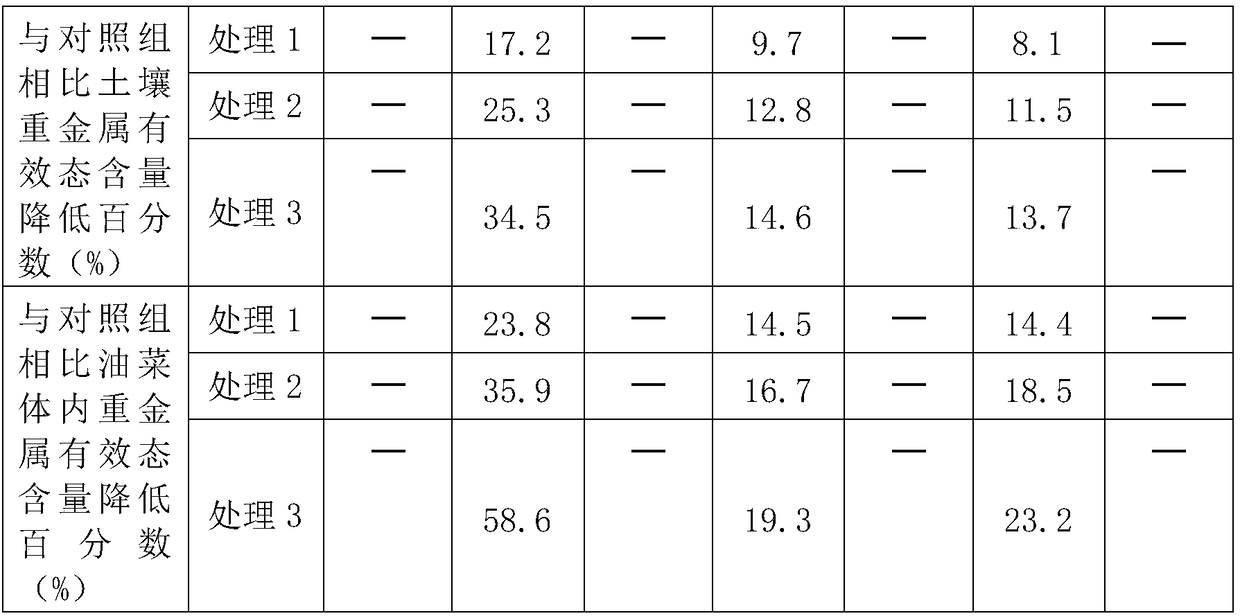

Method for modifying fly ash

ActiveCN101700491ASolve the problem of biological growth and foulingReduce time to chemical modificationOther chemical processesWater/sewage treatment by sorptionUltrasound - actionHigh absorption

The invention relates to a method for carrying out surface modification on waste fly ash and leading the waste fly ash to become an absorbing material with high absorption capacity and sterilization performance, and the method comprises the following steps: mixing the fly ash of 20 meshes with solution of an inorganic acid modifier (mixed solution that HCl: H2SO4 is equal to 1:3) according to the solution-ash ratio of 3: 1, and obtaining the partially modified fly ash under the ultrasonic action; and using a silane coupling agent for processing the surface of the fly ash, and further utilizing the reaction activity of the silane coupling agent for carrying out the further graft reaction, thereby preparing the absorbing material with immobilized polyquaternary ammonium salt sterilization performance and higher absorption capacity.

Owner:CHINA NAT OFFSHORE OIL CORP +1

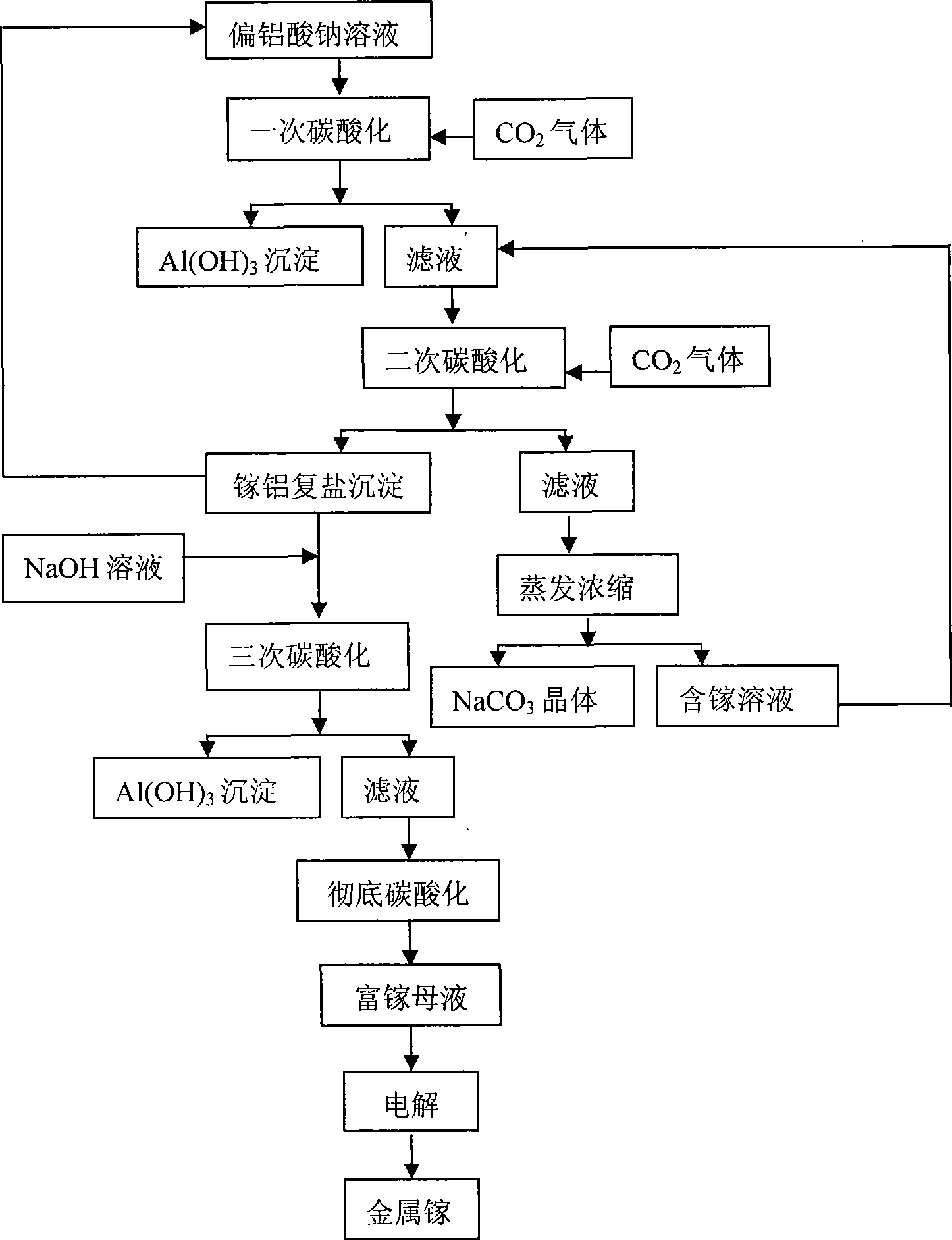

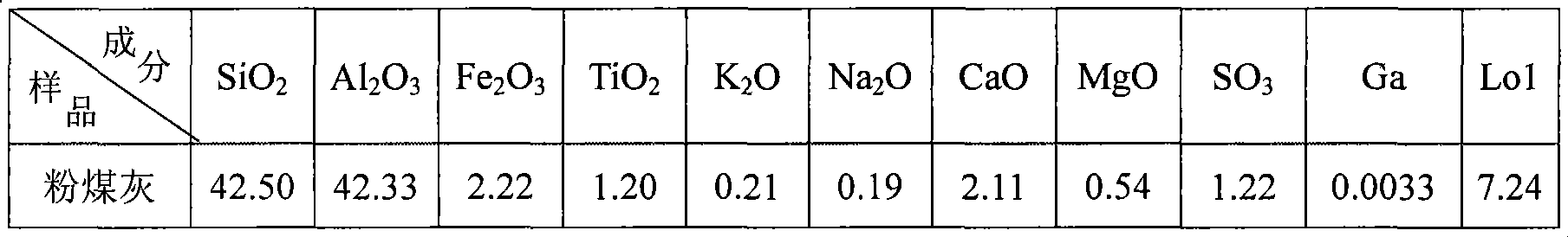

Method for extracting metal gallium from coal ash

InactiveCN101368231AEfficient use ofIn line with the concept of circular economyProcess efficiency improvementAluminateElectrolysis

The invention relates to a method for extracting metal gallium from coal powder ashes, in particular suitable for the ashes of a circulating fluidized bed. In the method, a mother liquor of sodium meta-aluminate is obtained through acid dissolving and alkali dissolving; then aluminum hydroxide is obtained simultaneously during enriching and spearing the gallium through carbon content by steps. The main steps include as follows: CO2 is led into the mother liquor of sodium meta-aluminate to carry out carbon content decomposing; the primary separation between the aluminum and the gallium is realized by primary carbonatation to filter out sodium hydroxide; secondary carbonatation is carried out on the filtrate to obtain the deposit of the complex salt of gallium and aluminum; a sodium carbonate crystal is obtained after the filtered filtrate is condensed and vaporized; the deposit of the complex salt of gallium and aluminum is dissolved in the mother liquor of sodium meta-aluminate; the processes are repeated until the proportion of gallium and aluminum in the complex salt of gallium and aluminum is larger than 1 / 340; then the complex salt of gallium and aluminum is added into the NaOH liquor and electrolyzed, thus obtaining the metal gallium with a purity larger than 99.9 percent which reaches the level of 3; simultaneously, the byproducts of the aluminum hydroxide and the sodium carbonate during the process of carbonatation by steps are obtained. The method has the advantages of simple technique, easy operation, low cost, high comprehensive benefits, and the like.

Owner:JILIN UNIV

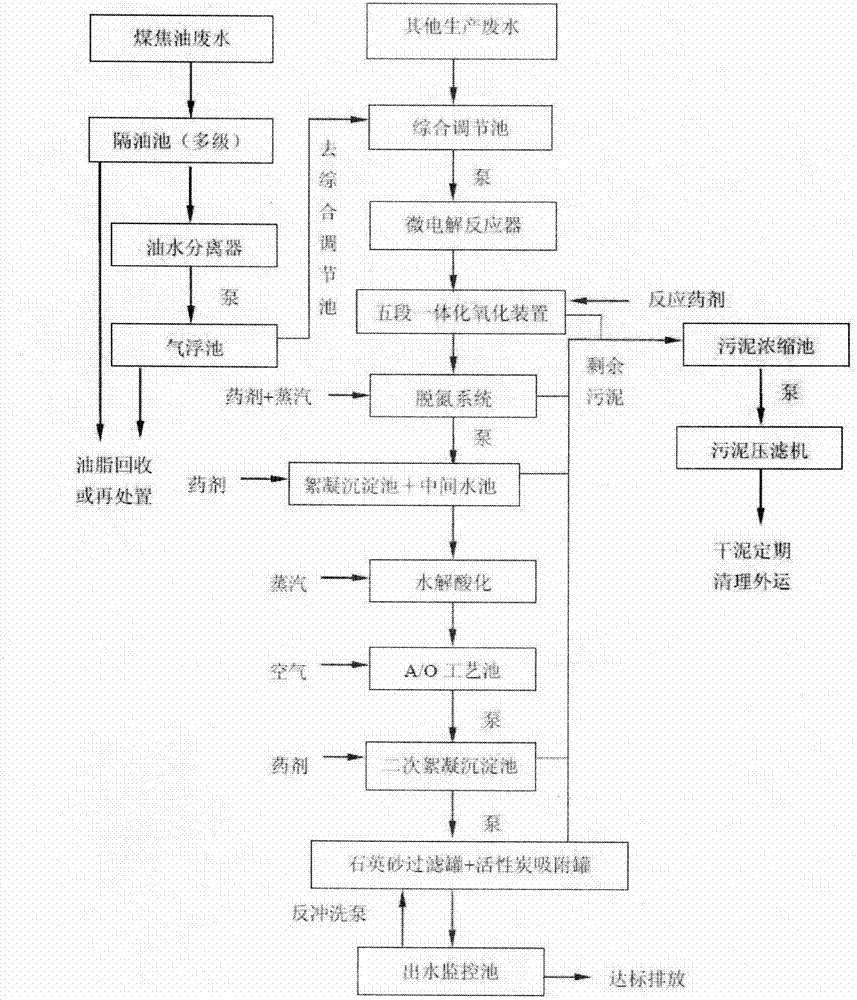

Complete equipment and process for processing coal tar wastewater

InactiveCN103113003AEasy to handleCreate economic valueMultistage water/sewage treatmentChemical oxygen demandElectrolysis

The invention provides complete equipment and process for processing coal tar wastewater, and belongs to the technical field of environmental conservation. The process comprises the following steps of: adopting different removal principles according to different physicochemical properties of heavy oil, light oil and emulsified oil; scientifically and orderly removing the heavy oil, light oil and emulsified oil through three sets of environmental conservation equipment such as a multi-stage oil separator, an oil-water separator and an air floating tank gradually; combining a micro electrolysis reactor with a five-section integrated oxidization device; and firstly destroying a benzene ring by microelectrolysis, and then strongly oxidizing various organic matters through an oxidant, so that the COD (chemical oxygen demand) and the chromaticity are greatly reduced. Ammonia nitrogen can be efficiently removed by a denitrification system; the denitrification system is low on requirements of pH value and temperature, and low in operation cost; the denitrification system is arranged behind the five-section integrated oxidization device; the reaction change of power of hydrogen is fully considered; and the complete equipment complies with the scientific principle, and can be used for reducing feeding of acid and alkali, and lowering the operation cost.

Owner:NANJING ZIDU ENVIRONMENTAL PROTECTION SCI & TECH

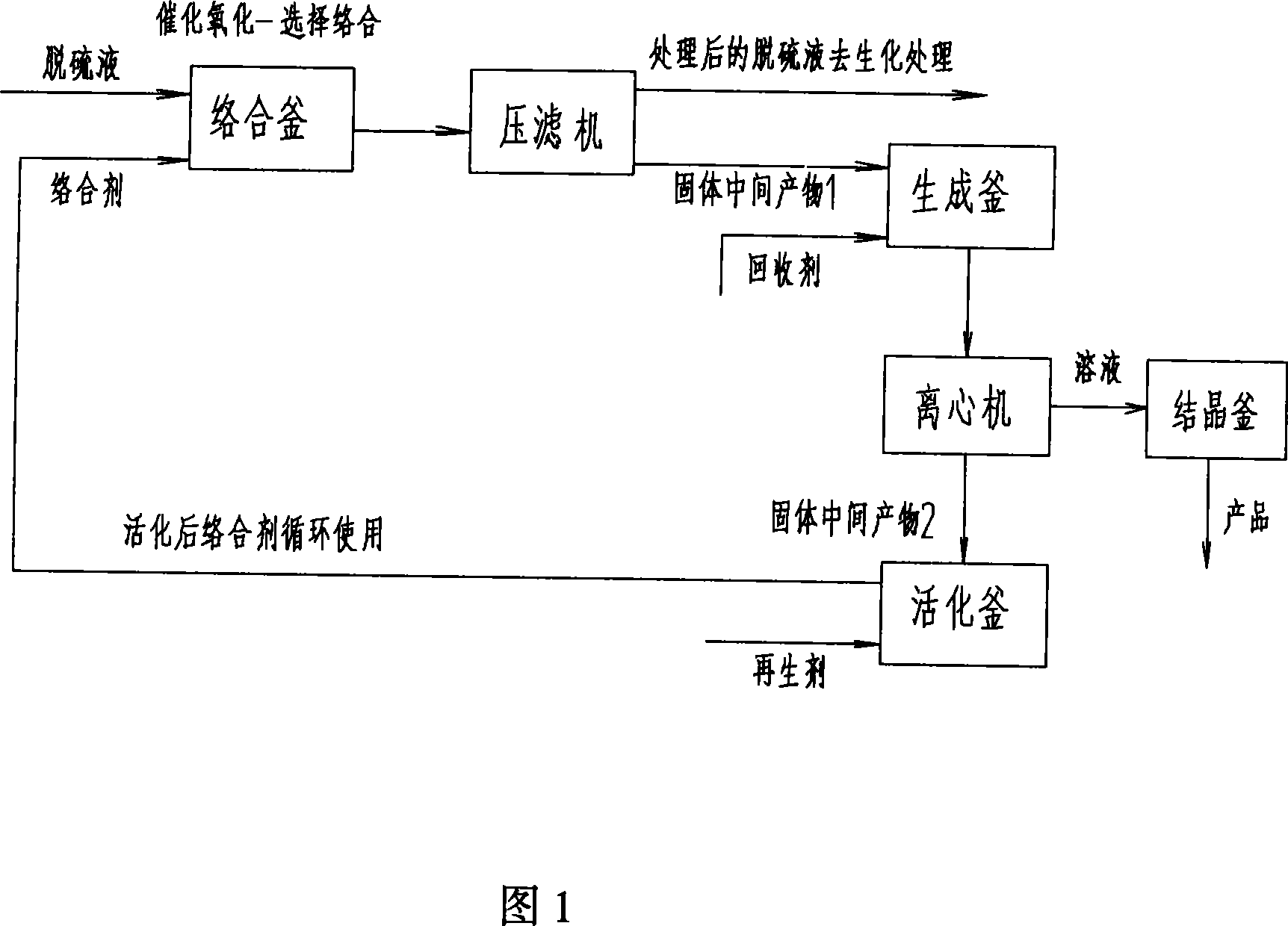

Process technique for discharged doctor solution of HPF desulfurization system of coke-oven plant

InactiveCN101219340AAvoid pollutionLow running costDispersed particle separationLiquid wasteSocial benefits

The invention relates to a processing technique for discharging desulfurization solution of a coke-oven plant HPF desulfurization system, which pertains to the waste fluid process technical field and is used for solving the problems of reducing COD content in the desulfurization solution and recycling a plurality of thiocyanate products. Particularly, the method comprises the procedures that: A. catalytic oxidation-selection of complexing; B. filter pressing or centrifugal separation; C. product generation; D. regeneration of complexing agents. The method of the invention is characterized in that: 1. using SCN<-> in the desulfurization solution produces chemical products such as NaSCN, KSCN, etc.; 2. the processed COD is reduced from 140000mg / L to 15000mg / L; 3. the invention has relatively small technical investment and simple operation; 4. the complexing agents can be recycled, thus having low operating cost and obvious economic benefits. The invention has novel research thought and reasonable technique, and conforms to a concept of circular economy and has quite good economic and social benefits.

Owner:HEBEI IRON AND STEEL

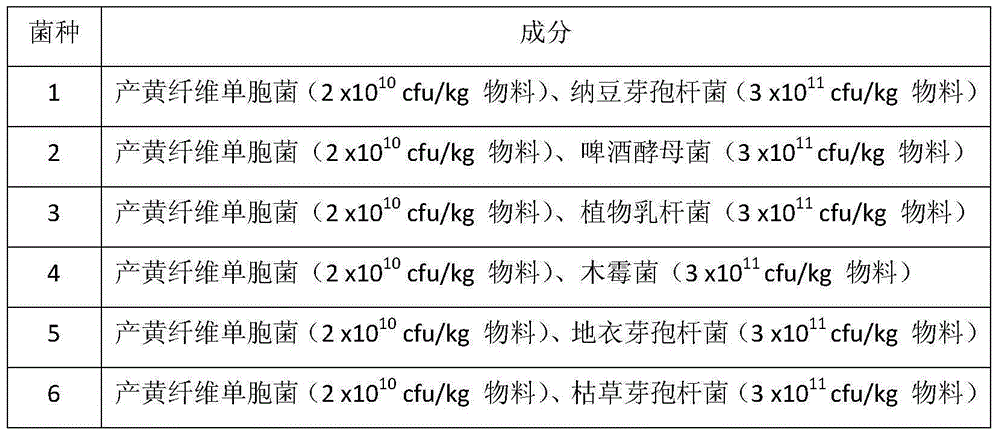

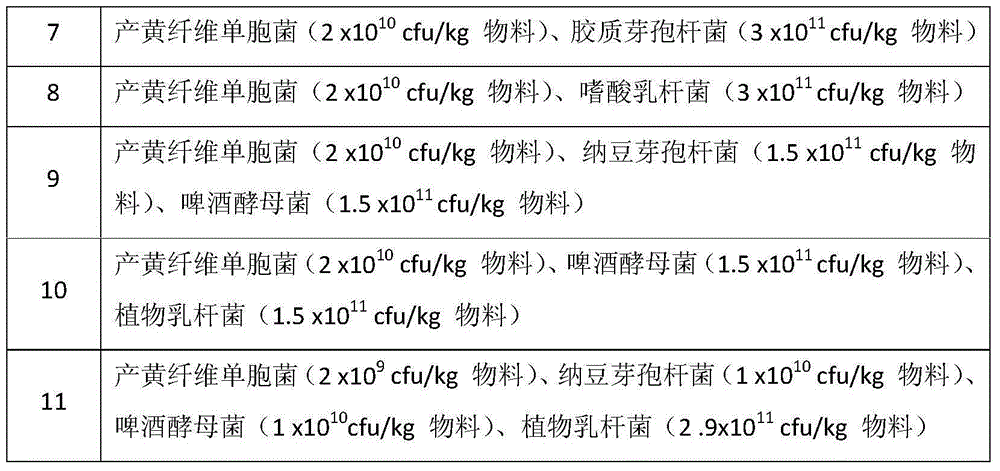

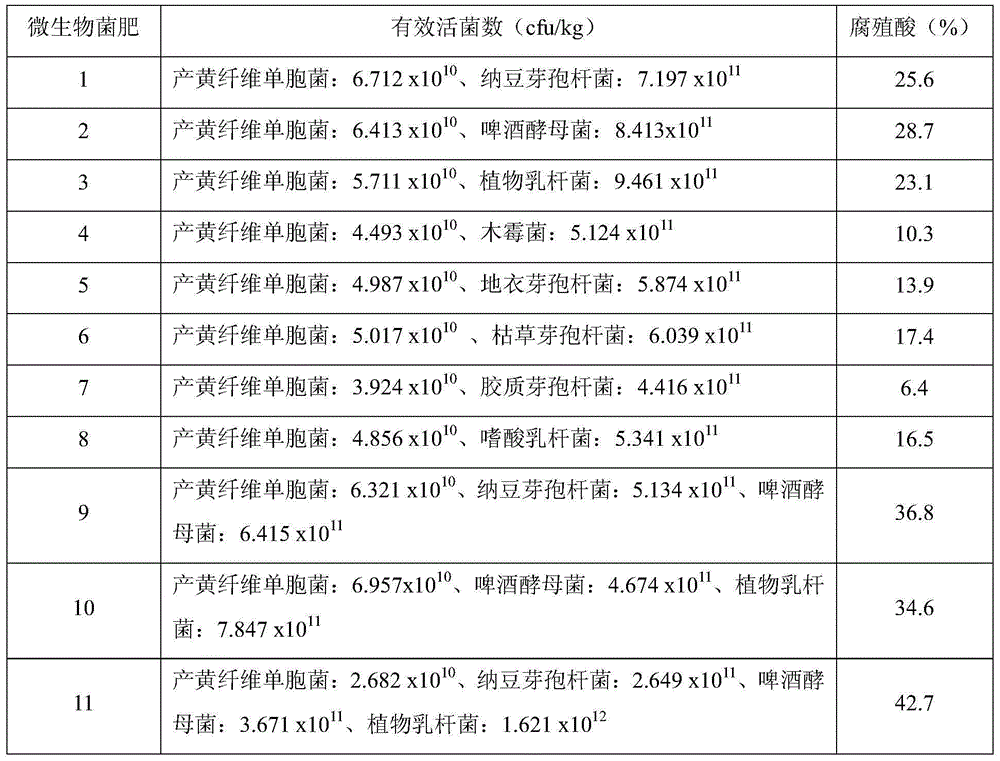

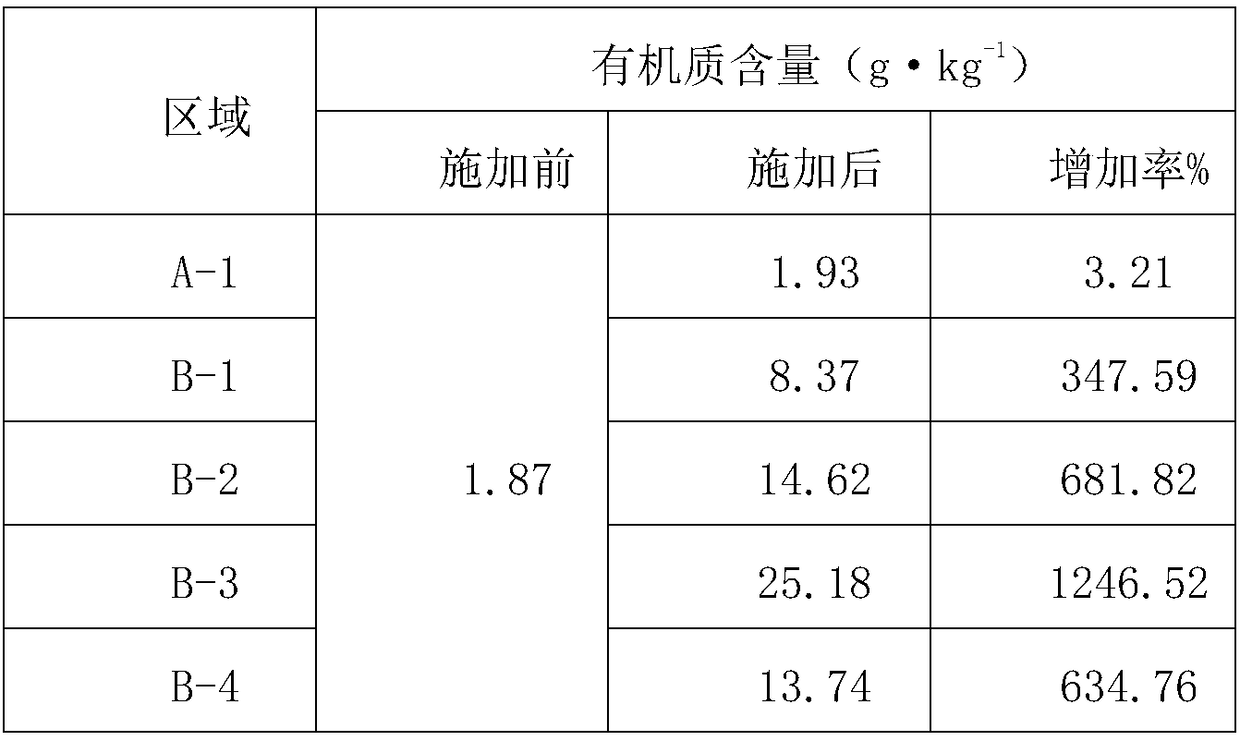

Microbial fertilizer manufacturing method, prepared microbial fertilizer and compound microorganism preparation

The invention provides a microbial fertilizer manufacturing method. Antibiotic fungus residue serves as a base material, and compound microorganisms are adopted to perform solid fermentation on materials, wherein the materials comprise waste rich in plant fiber and the antibiotic fungus residue. The compound microorganisms comprise cellulose decomposition bacteria and one or more of bacillus natto, saccharomyces cereviseae and lactobacillus plantarum. According to the microbial fertilizer manufacturing method, the problem that it is difficult to treat the fermented antibiotic fungus residue in a pharmaceutical factory at present can be solved. Furthermore, beneficial ingredients in the antibiotic fungus residue are can be utilized and converted into a microbial fertilizer, so as to solve the problem that at present, the soil hardening occurs and the fertility declines.

Owner:嘉兴市中正置业有限公司

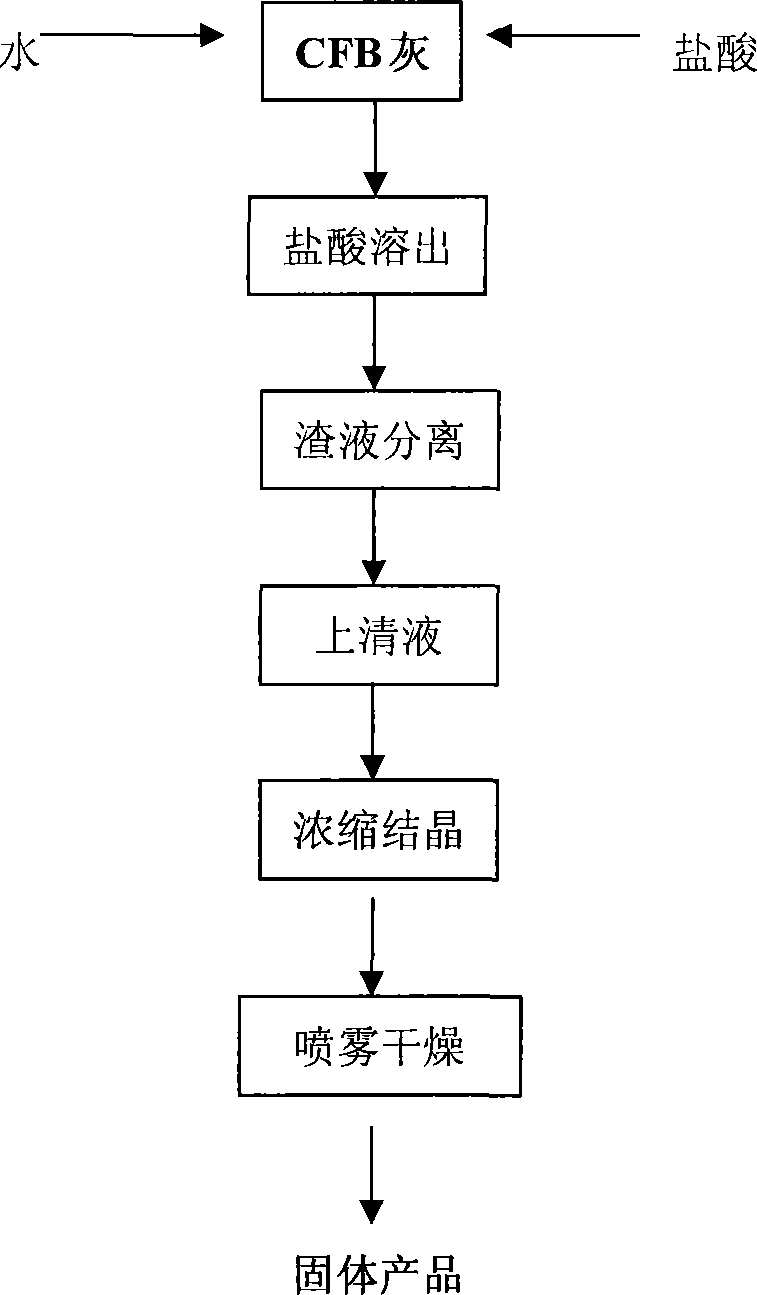

Method of preparing crystal aluminum chloride from circulation fluid bed fly ash

The present invention relates to a preparation method for crystalloid aluminum chlorate, in particular to a preparation method for crystalloid aluminum chlorate by using the circulating fluidized bed fly ash as raw material. By means of the better chemical activity of the aluminum contained in the circulating fluidized bed fly ash, the aluminum chlorate solution is obtained from the circulating fluidized bed fly ash by a direct acid dissolution process, and then the supernatant is obtained by separating the slag from the liquid in a setting tank, and the supernatant is concentrated and crystalled, finally, the solid crystalloid aluminum chlorate is obtained after spray drying. The present invention has a wide range of raw material, a low cost, a simple manufacturing process, quality product, less energy consumption, and meets the circular economy conception.

Owner:JILIN UNIV

Method for preparing heavy metal adsorbent by using modified bagasse

InactiveCN102218303ASimple methodLow costOther chemical processesEnergy based wastewater treatmentChemistryPotassium permanganate

The invention provides a method for preparing a heavy metal adsorbent by using modified bagasse. The method comprises the following steps of: a. stoving or drying the bagasse, and then crushing and sieving so as to obtain bagasse powder; b. immersing the bagasse powder in a potassium permanganate solution with the concentration of (0.8 to 1.2) g / L, uniformly stirring, importing nitrogen and removing oxygen, and reacting for 40 to 80 minutes at the temperature of 40 DEG C to 70 DEG C; d. then adding acrylonitrile and N, N,-methylenediacrylamide, importing nitrogen and removing oxygen again, and reacting for 40 to 80 minutes at the temperature of 40 DEG C to 70 DEG C; e. in the step d, adding a hydroquinone solution with the concentration of (8 to 12) mg / L 2 to 5 minutes before the reaction is finished; and f. washing a reactant, draining, filtering and drying so as to obtain a heavy metal adsorbent crude product, wherein the addition amounts of the acrylonitrile, the N, N,-methylenediacrylamide and the hydroquinone solution respectively account for 0.1% to 0.3%, 1% to 3%, 0.05% to 0.1% of the weight of the bagasse powder. The adsorbent prepared with the method has the advantages of simple using method, low cost and excellent adsorption effect.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

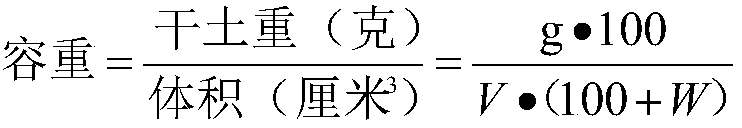

Iron tailing soil improvement agent and iron tailing soil improvement method

ActiveCN108795440AAdjustable pHMaintain pHAgriculture tools and machinesContaminated soil reclamationLoss ratePorosity

The invention relates to an iron tailing soil improvement agent and an iron tailing soil improvement method. The iron tailing soil improvement agent comprises biochar, rice husks, ceramsite, organic fertilizers, attapulgite powder and planting soil. A mass ratio of the biochar to the rice husks to the ceramsite to the organic fertilizers to the attapulgite powder to the planting soil is (0.5-3):(0.2-1):(0.5-1.5):(1-4):(1-2.5):(1.0-2.2). The iron tailing soil improvement agent and the iron tailing soil improvement method have the advantages that the particle size of soil can be improved by theaid of the iron tailing soil improvement agent, the loss rate of water in the soil can be eased, the water retention capacity can be enhanced, organic matters can be quickly and effectively supplemented, the content of organic matters in tailing can be effectively increased, and suitable environments can be provided for plant growth; the rice husks and the ceramsite are matched with one another, the porosity of iron tailing soil can be improved, the hardening degree of the soil can be lowered, the tailing soil can keep in excellent gas-permeable and soft states for a long term, accordingly, the iron tailing soil improvement agent and the iron tailing soil improvement method are favorable for respiration of animals and plants in the soil, and the survival rate can be increased.

Owner:SHANDONG UNIV

Method for promoting anaerobic sludge fermentation to produce short-chain fatty acids by utilizing reduced iron powder

The invention belongs to the technical field of environmental protection and recycling and relates to a method for promoting anaerobic sludge fermentation to produce short-chain fatty acids. The method comprises the following steps of: (1) putting sludge into a container, discharging the supernatant liquid, and obtaining a sludge sample; and (2) adding reduced iron powder into the sludge sample, filling nitrogen for oxygen displacement in a reactor, sealing the reactor, uniformly mixing substances in the reaction system, controlling the fermentation temperature, and performing anaerobic fermentation. The sludge can be effectively reduced, the environmental pollution is reduced, the sludge can be recycled, and lots of short-chain fatty acids with high utilization values are produced.

Owner:TONGJI UNIV

The synthetic method of taurine

InactiveCN102285905APromote generationHigh market valueOrganic chemistryOrganic compound preparationEthanolamine HydrochlorideAddition reaction

The invention discloses a method for synthesizing taurine, which is to prepare taurine by preparing ethanolamine hydrochloride through addition reaction of ethylene oxide and industrial ammonium chloride which is byproduct from alkali making plants and by chlorination, sulfonation and neutralization. The method solves the inconvenience of high-temperature and high-pressure reaction of ethoxy sulfonate and liquid ammonia and side reaction forming imino diethyl sulfonate; in the chlorination, thionyl chloride is used as a chlorinating agent to ensure high conversion rate, byproducts HCl and SO2 both are gases which escape naturally and easy to remove by volatilization, the SO2 and HCl by products can be used to make sodium sulfite and hydrochloric acid, which are to be used in following sulfonation and neutralization reactions, and the method thus is basically in accordance with a philosophy of circular economy; in chlorination, an inhibitor is added to prevent self-phase oxidation-reduction reaction of the sulfite and extra consumption brought by the self-phase oxidation-reduction reaction of the sulfite; in reactions in all reactions, a theoretical amount is reached approximately; and sodium chloride is almost the only byproduct, and thus the environment protection and remediation pressures of enterprises are relieved.

Owner:薛荔

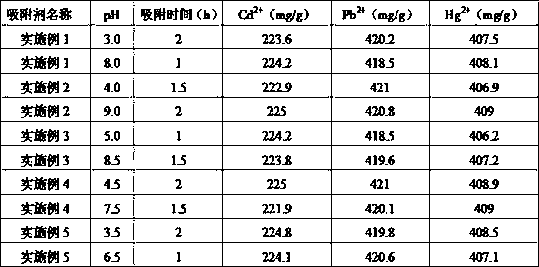

Preparation method and application of bagasse mercapto-biosorbent

InactiveCN103191703AImprove adsorption capacityHas sulfhydryl propertiesOther chemical processesWater/sewage treatment by sorptionAcetic acidFiltration

The invention discloses a preparation method and an application technology of a bagasse mercapto-biosorbent. The preparation method is characterized by comprising the following steps of: adding 35-45wt% of mercaptoacetic acid, 18-25wt% of tetrahydrofuran, 12-22wt% of alkalized bagasse and 0.15-1.0wt% of concentrated sulphuric acid in a triangular flask with a plug, performing a sealed room-temperature reaction for 2-4 hours, and adding 8-18wt% of sodium sulphide and 8-18wt% of water, wherein the sum of the percentages of all the components is 100%; plugging, and performing a static reaction for 48-60 hours at 40-45 DEG C; and then washing with deionized water, performing suction filtration until the filtrate is neutral, washing by a small amount of ethanol, placing in an oven at 55-65 DEG C and drying, so as to obtain the bagasse mercapto-biosorbent, wherein the bagasse mercapto-biosorbent is high in adsorption capacity for Cd2, Pb<2+> and Hg<2+>, fast in adsorption speed, good in physicochemical stability and mechanical stability, strong in regeneration capacity, high in repeated use times, low in cost, and capable of utilizing agricultural waste.

Owner:UNIV OF JINAN

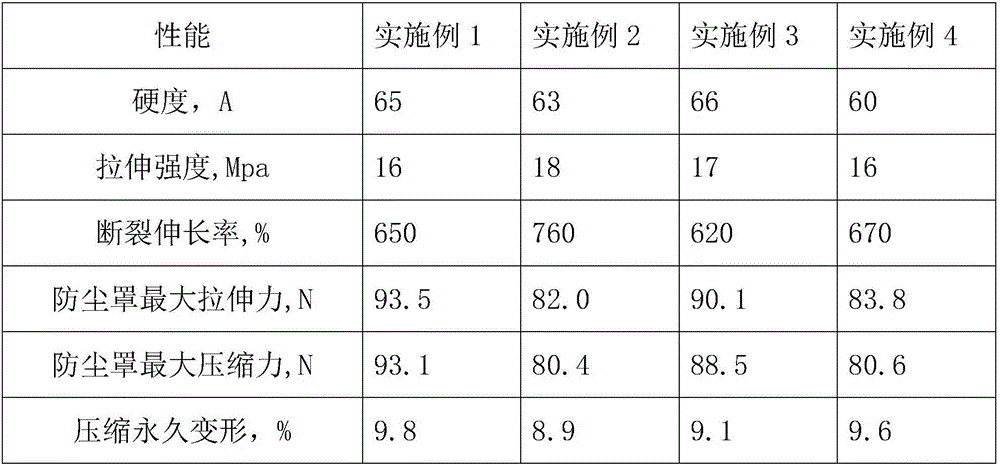

Thermoplastic vulcanized rubber material for automobile steering dedusting cover and preparation method of thermoplastic vulcanized rubber material

The invention discloses a thermoplastic vulcanized rubber material for an automobile steering dedusting cover and a preparation method of the thermoplastic vulcanized rubber material. The thermoplastic vulcanized rubber material comprises, by weight, 100-300 parts of ethylene-propylene-diene monomer rubber, 100-300 parts of polypropylene, 40-100 parts of thermoplastic elastomer, 10-40 parts of modified montmorillonite, 10-30 parts of multiwalled carbon nanotubes, 5-20 parts of calcium carbonate, 5-15 parts of compatilizer, 0.2-10 parts of a vulcanizing agent, 20-100 parts of paraffin oil, 1-5 parts of active oxygen zinc powder, 1-3 parts of main ultraviolet absorbent, 0.5-1 part of auxiliary ultraviolet absorbent, 1-3 parts of primary antioxidant, 0.5-1 part of auxiliary antioxidant and 1-3 parts of a lubricating agent. The thermoplastic vulcanized rubber material has the advantages of being high in strength, good in fire resistance, high in durability and good in toughness.

Owner:安徽中翰高分子科技有限公司

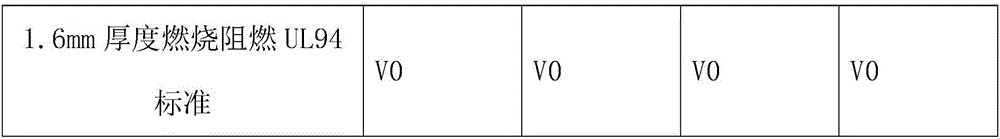

Compound repair agent for heavy metal polluted soil and application thereof

ActiveCN109233840AReduced mobility and bioavailabilityReduce environmental risksContaminated soil reclamationOrganic fertilisersFertilizerAgriculture

The invention relates to a compound repair agent for heavy metal polluted soil which is characterized by being prepared from the following raw materials in percent by weight: 40-55% of charcoal, 15-35% of bone powder and 15-35% of coal ash. By taking agricultural or industrial solid wastes which are wide in source and easy to obtain as a raw material, the compound repair agent is simple in process, sufficient in raw material, low in cost and obvious in application effect, reduces the heavy metal mobility and bioavailability of soil, and can solve the problem of sustainable utilization of heavymetal pollution in farmlands and fields of industrial and mineral industry. The application method is simple, the using process is labor-saving, the physical and chemical properties of soil can be also improved effectively, the fertilizer retaining and water retaining ability of soil is improved, and the compound repair agent is easy to popularize and apply.

Owner:ANSTEEL GRP MINING CO LTD

Integrated biological and gasifyign treatment process for dewatered city domestic garbage

InactiveCN1857803AImprove processing efficiencyImprove efficiencySolid waste disposalLitterEnvironmental engineering

The integrated biological and gasifying treatment process for dewatered city domestic garbage is the following steps: breaking trash bag; separating; gasifying the separated recyclables capable of being gasified in a gasifying furnace to produce fuel gas; collecting organic matters and refuse percolate and anaerobic fermenting; using the marsh gas generated during fermentation as fuel, drying the marsh gas residue and incinerating in incinerator; and burning the fuel gas in a boiler to provide energy. The present invention has high garbage treating efficiency and benefit and less secondary pollution.

Owner:南京绿展能源有限公司

Method for protecting storage tank by using flue gas

ActiveCN101417729ARealize comprehensive utilizationEnsure safetyDispersed particle separationLarge containersCombustionPositive pressure

The invention relates to a method for protecting storage tanks by purifying flue gas, which uses the purifying treated flue gas as positive pressure protecting gas for sewage water tanks containing sulfur and oil and oil tanks containing sulfur to lead gas in the tanks to contain trace oxygen or not to contain oxygen, and avoids the sewage water tanks and oil tanks from generating self-combustion explosion phenomena caused by the oxidation of ferrous sulfide when in normal use; the positive pressure protecting gas discharged from the sewage water tanks containing sulfur and oil and the oil tanks containing sulfur is introduced into an incinerator to be treated or into an oxidized absorption-sorption device to be treated, and the purified gas reaching standards can be discharged. The method for protecting the storage tanks by purifying flue gas has simple process and equipment, safety and environmental protection and low running cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Nano-manganese dioxide for removing underground water heavy metal pollution and preparation method of nano-manganese dioxide for removing underground water heavy metal pollution

ActiveCN106319019AGood for oxidation adsorptionIrregular spatial structureBacteriaMicroorganism based processesPseudomonas putidaCell culture media

Disclosed are nano-manganese dioxide for removing underground water heavy metal pollution and a preparation method of the nano-manganese dioxide for removing underground water heavy metal pollution. The preparation method includes the steps of 1), inoculating one or more of Leptothrix discophora SS-1, Pseudomonas putida MnB1 and Bacillus sp SG-1 to a microbial growth medium and culturing at 25-30 DEG C; 2), centrifuging a mixture obtained in the step 1 to obtain a bacterial body and cleaning and precipitating the bacterial body; 3), inoculating the bacterial body obtained in the step 2 to a manganite culture medium and culturing at 25-30 DEG C; 4), adding MnCl2 and Na3VO4 into a product obtained in the step 3 and culturing at 28-30 DEG C so as to obtain black precipitate, namely the nano-manganese dioxide.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Method for modification treatment of coal ash

The invention discloses a method for modification treatment of pulverized fuel ash. The pulverized fuel ash and a sodium hydroxide solution with the concentration of 2mol / L are prepared into a mixed liquid according to the solid-to-liquid ratio of 1 to 6, the mixed liquid is subjected to microwave reaction for 20 minutes at the temperature of 85 DEG C and then is stirred to react for 12 hours at the temperature of 100 DEG C, deionized water and 95 percent alcohol are used to wash after the reaction is finished, then sodium chloride with the concentration of 1 mol / L is used to saturate, and finally modified pulverized fuel ash is obtained through the drying at the temperature of 110 DEG C. The modified pulverized fuel ash prepared by the method is added into each liter of wastewater containing nickel to ensure that the ash and the wastewater are fully stirred and mixed, and the treatment to the wastewater containing the nickel can be finished at normal temperature. The modified pulverized fuel ash is utilized to treat the wastewater containing the nickel with the concentration of 200 mg / L or so, which has remarkable effect.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER +1

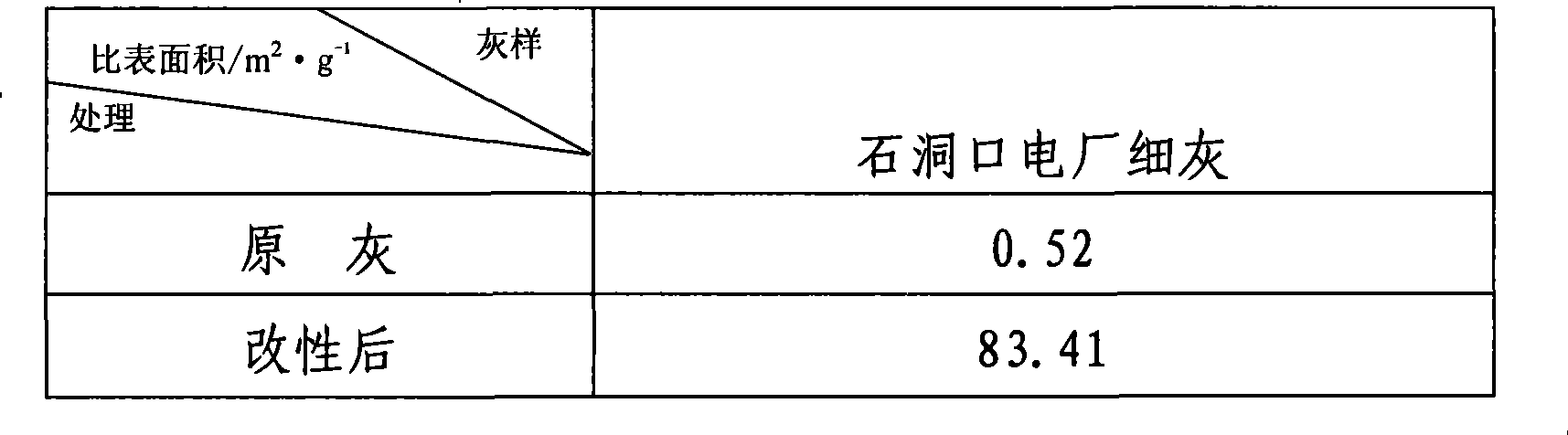

Production technique for preparing architectural ornament phosphorus slag cast stone by employing high-temperature phosphorus slag liquid

The invention relates to a technique for the preparation of phosphorus dregs cast stone used for construction decoration and using high temperature phosphorus dregs fluid. The invention is characterized in that: firstly, the configuration and the preheating of auxiliary raw material: quartz sand and kaoline are taken as auxiliary raw materials and heated to 1,300-1,450 DEG C; secondly, hot ingredient: the high-temperature phosphorous dregs fluid, which is discharged from a phosphorus electric stove, passes a fluid groove and flows into a pond kiln, and the auxiliary raw material is put into a pond kiln simultaneously, wherein, the quality ratio of the phosphorus dregs to the auxiliary raw material is 65-75:25-35; thirdly, melting: the melting mix of the phosphorous dregs and the auxiliary raw material reaches 1,450-1,580 DEG C; fourthly, shaping; last, crystallization and annealing: the crystallization is processed under 1,000-1,150 DEG C for 60-120 minutes, and then is annealed to room temperature, thus a product is made. The invention can effectively use the thermal energy of the high-temperature phosphorous dregs fluid to realize the conversion of the phosphorous dregs fluid into the resources and reduce the energy consumption and the cost of cast stone production, thereby causing the phosphorous dregs cast stone adaptive to the purpose of large-scale construction decoration.

Owner:浙江中地大科技有限公司

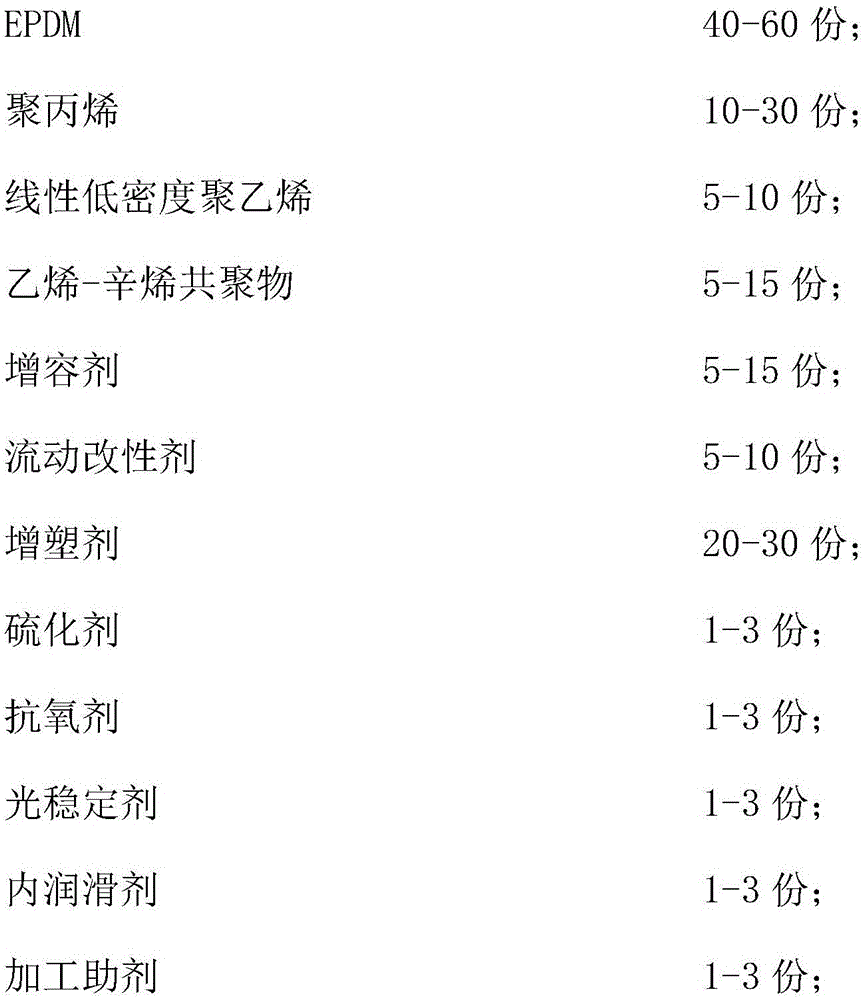

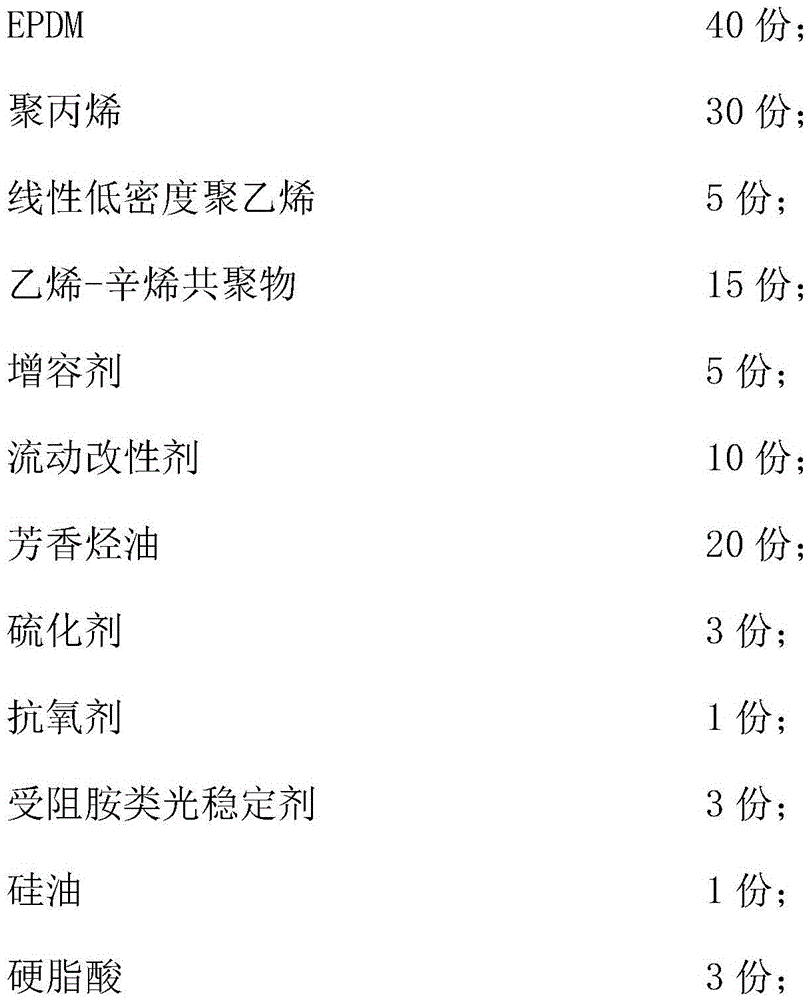

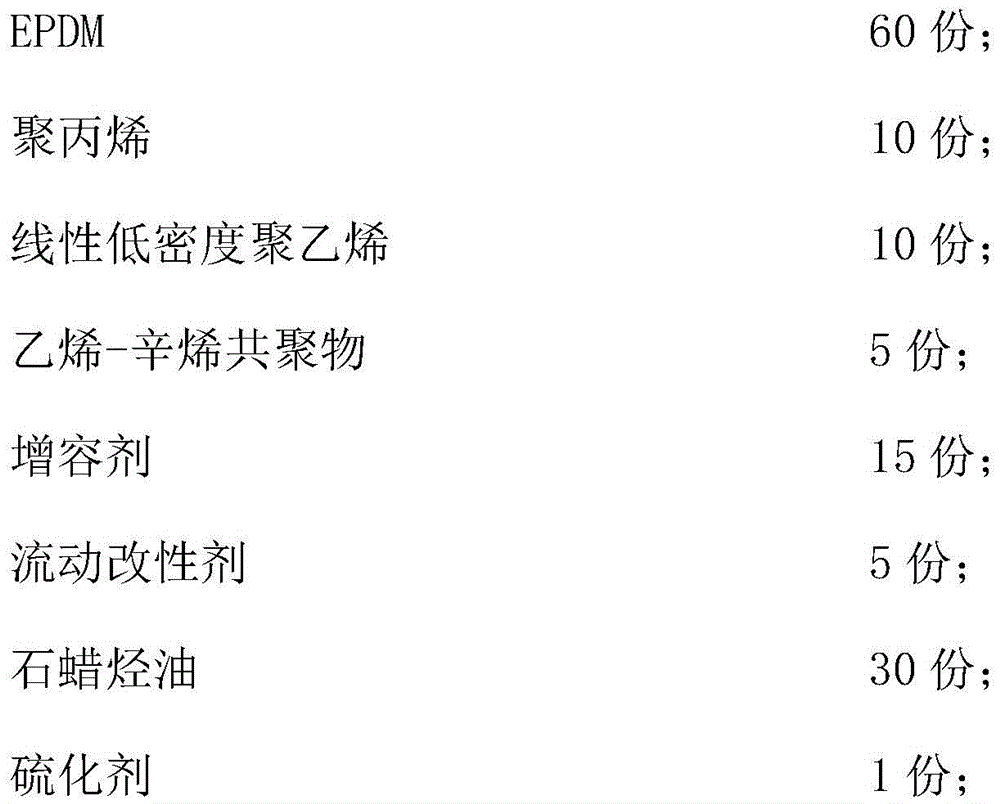

Blow-molding-grade TPV (thermoplastic vulcanizate) material for dust shields and preparation method thereof

InactiveCN105670134AImprove melt strengthImprove blow molding processabilityThermoplasticLinear low-density polyethylene

The invention discloses a blow-molding-grade TPV (thermoplastic vulcanizate) material for dust shields. The blow-molding-grade TPV material for dust shields is prepared from the following raw materials in parts by weight: 40-60 parts of EPDM (ethylene-propylene-diene monomer), 10-30 parts of polypropylene, 5-10 parts of linear low density polyethylene, 5-15 parts of ethylene-octylene copolymer, 5-15 parts of compatibilizer, 5-10 parts of flow modifier, 20-30 parts of plasticizer, 1-3 parts of vulcanizing agent, 1-3 parts of antioxidant, 1-3 parts of light stabilizer, 1-3 parts of internal lubricant and 1-3 parts of processing aid. The TPV material has the advantages of favorable melt strength, excellent blow molding processability, favorable mechanical properties, excellent processability and favorable appearance.

Owner:安徽韧达高分子材料有限公司

Method for preparing gypsum by removing sulfate radicals from mineral salts with waste distillation liquid from ammonia alkali factory

ActiveCN102153127AEliminate the effects ofHigh whitenessCalcium/strontium/barium sulfatesSulfate radicalsDistillation

The invention discloses a method for preparing gypsum by removing sulfate radicals from mineral salts with a waste distillation liquid from an ammonia alkali factory, which comprises the following steps of: (1) precipitating and separating solid suspended matters in the waste distillation liquid from the ammonia alkali factory through a primary precipitator to obtain a clear waste liquid; (2) mixing the clear waste liquid with saltpeter-containing mineral salt brine to fully react in a primary reactor; (3) conveying the mixed liquid in the step (2) into a secondary reactor, and simultaneouslyadding a precipitating-aid and antisludging agent into the secondary reactor to fully react; (4) conveying the mixed liquid in the secondary reactor into a secondary precipitator to precipitate and separate, recovering the supernatant, conveying gypsum slurry flowing out from the bottom of the precipitator to a primary dewatering device, and fully dewatering the gypsum slurry to obtain coarse gypsum; and (5) conveying the dewatered coarse gypsum into a slurry compounding barrel, adding water to prepare slurry, continuing conveying the slurry to a secondary dewatering device, and fully dewatering the slurry to obtain the gypsum product. The method provided by the invention is simple, has low production cost and is extremely applicable to popularization and application.

Owner:GUANGDONG NANFANG SODA ASH IND

Novel green flame-retardant waterproof wood-plastic composite material and preparation method thereof

The invention discloses a novel green flame-retardant waterproof wood-plastic composite material and a preparation method thereof. The novel green flame-retardant waterproof wood-plastic composite material comprises, by weight parts, 8-10 parts of polyurethane elastomer, 30-40 parts of ethylene-vinyl acetate copolymer, 8-12 parts of smoke suppression flame retardant, 7-9 parts of composite fiber,5-7 parts of coupling agent, 4-8 parts of inorganic filler, 40-60 parts of waste wood, 10-20 parts of modified bamboo powder, 2-4 parts of fragrant wood powder, 30-50 parts of polyvinyl chloride resin, 8-12 parts of anti-wear additives and 10-14 parts of processing aids. The novel green flame-retardant waterproof wood-plastic composite material has good anti-moisture, abrasion resistance, corrosion resistance and flame retardant effect, and has excellent antibacterial and anti-insect property; at the same time, in the preparation method, a large amount of waste wood is adopted, which saves resources and protects the environment, the cost is low, the raw materials are easy to obtain, a process is simple, and the novel green flame-retardant waterproof wood-plastic composite material has highpractical value and good application prospects.

Owner:张莉敏

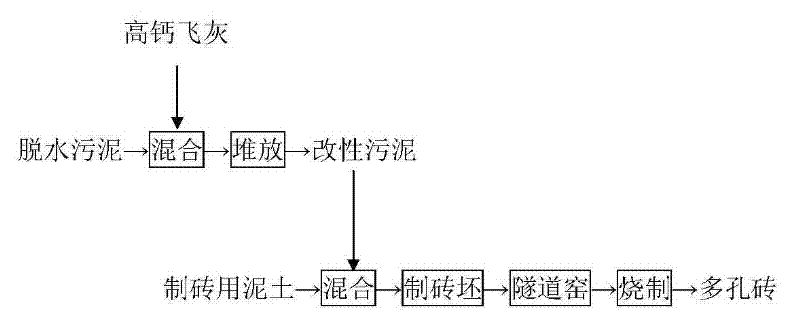

High calcium fly ash modified sludge, its preparation method and method for preparing perforated brick using modified sludge

InactiveCN102219420AHigh strengthLight textureSolid waste managementCircular economyBuilding material

The invention, belonging to the technical field of construction material, environmental protection and resource exploitation, relates to a high calcium fly ash modified sludge, its preparation method, and a method for preparing a perforated brick using the modified sludge. The high calcium fly ash modified sludge is prepared by mixing general waste dewatered sludge with high calcium fly ash, wherein, the high calcium fly ash accounts for 15-30 wt%. The preparation method of the high calcium fly ash modified sludge comprises the following steps: preparing materials, selecting the high calcium fly ash with more than 40% of calcium oxide and the calorific value of more than 1800 calorie / gram and the general solid waste dewatered sludge; mixing the high calcium fly ash and the general solid waste dewatered sludge uniformly according to the water content of the sludge; stacking the uniformly mixed sludge mixture in the principle of minimizing the outer superficial area. The method for preparing a perforated brick by using the high calcium fly ash modified sludge provided by the invention is operated at normal temperature, with the advantages of simple operation, small investment and low operation cost, meeting the conception of circular economy, and is a idealist method for sludge recycling..

Owner:王传开 +1

Method for preparing biodiesel by catalysizing cotton seed oil by organic alkali

InactiveCN101469272AIncrease cetane numberHigh flash pointBiofuelsLiquid hydrocarbon mixture productionOrganic baseCottonseed oil

The invention discloses a method for producing biodiesel by using an organic base to catalyze cottonseed oil, which comprises the following steps: using crude cottonseed oil as a raw material, removing impurities, heating the raw material and performing vacuum dehydration; adding methanol, adding 1,5,7-trisazoheterobicyclo-[4,4,0]-5-decylene (TBD) as a catalyst, adding tetrahydrofuran as a cosolvent, and performing an interesterification reaction in a reactor under stirring. After the reaction, the mixture is kept stand to separate out a glycerin layer, and superfluous methanol and catalyst are distilled out to obtain the finished product. The method has simple process and convenient operation, adopts the cosolvent to speed up the reaction, reduce the reaction time and reduce the energy consumption, and has high conversion efficiency. The obtained biodiesel has the advantages of high flash point, high cetane number, and safe transportation, storage and use.

Owner:上海融新能源环境科技有限公司 +3

Environment-friendly high-strength fragrant wood-plastic material and preparation method thereof

InactiveCN108084639AImprove adsorption capacityHigh ion exchange capacityProcedure AgentsWear resistant

The invention discloses an environment-friendly high-strength fragrant wood-plastic material and a preparation method thereof. The environment-friendly high-strength fragrant wood-plastic material isprepared from the following raw materials in parts by weight: 60-70 parts of amino resin, 7-9 parts of modified bamboo powder, 7-9 parts of modified diatomite, 8-14 parts of acrylate impact modifier,5-7 parts of coupling agent, 8-10 parts of mixing rubber, 30-40 parts of waste straw, 20-30 parts of waste wood, 3-5 parts of heat stabilizer, 12-18 parts of natural plant essential oil, 8-12 parts offlame retardant additive, 8-12 parts of wear-resistant additive, and 10-14 parts of processing agent. The wood-plastic material disclosed by the invention is good in wear resistance, good in corrosive resistance, flame retardant, free from formaldehyde and free from pollution; furthermore, the wood-plastic material is excellent in antibacterial performance, mothproof, humidity resistance and capable of purifying the air; the product emits the plant fragrance; and meanwhile, the preparation method disclosed by the invention adopts a large number of waste wood materials, the resource is saved,the environment is protected, the cost is low, the raw materials are easy to obtain, and the process is concise. The environment-friendly high-strength fragrant wood-plastic material has high practical value and good application prospect.

Owner:ANHUI YINUO WOOD PLASTIC SHEET TECH CO LTD

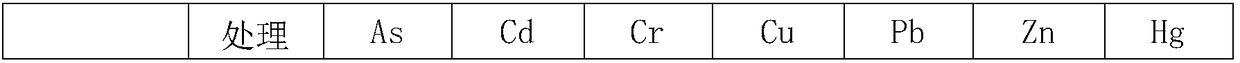

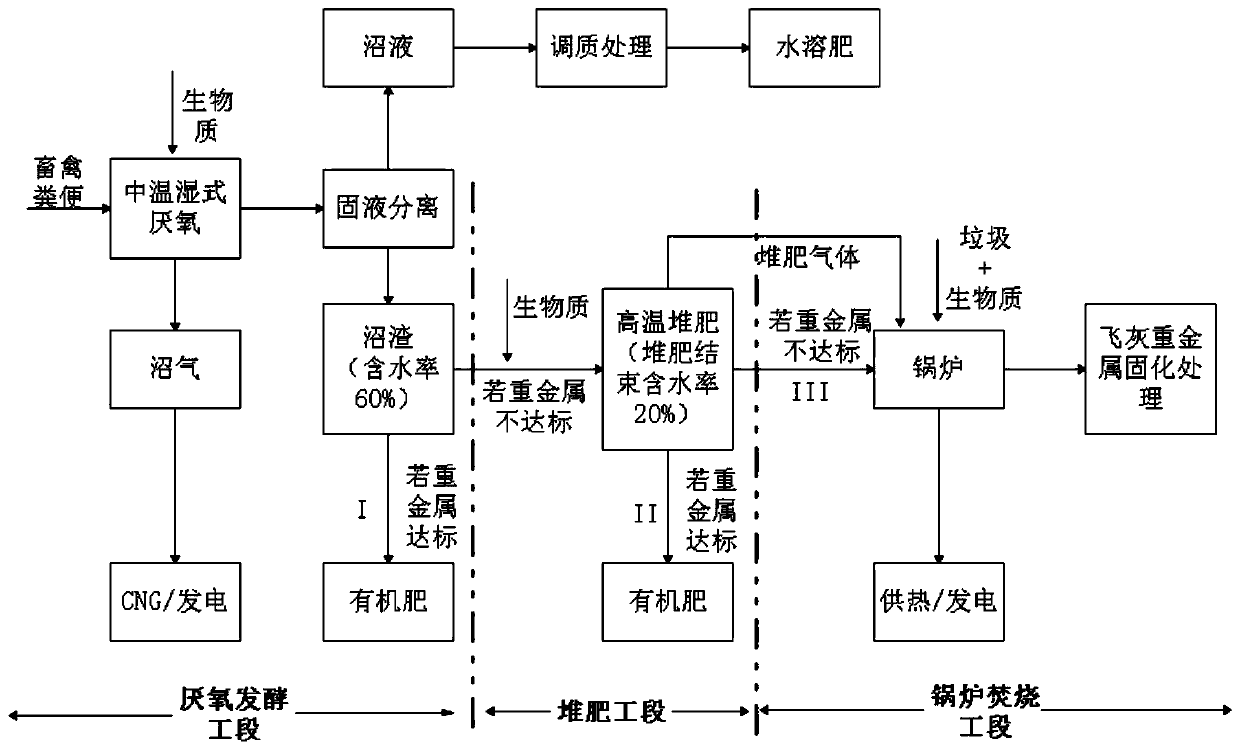

Farm livestock waste and domestic waste co-utilization and heavy-metal control process

InactiveCN110117199AImprove fertilizer efficiencyRealize resourcesBio-organic fraction processingChemical industryResource utilizationCo composting

The invention discloses a farm livestock waste and domestic waste co-utilization and heavy-metal control process. Three parts are included, namely, the anaerobic fermentation station, the composting station and the boiler incineration station. According to the process, various by-products (biogas, a water-soluble fertilizer and a solid organic fertilizer) of an anaerobic fermentation process can be obtained; through the composting process, the efficiency of the organic fertilizer can be improved and the water content can be reduced with low energy consumption; through the incineration process,pollutant reduction is achieved, and heavy metals are gathered into fly ash, and the low-cost and safe treatment of the heavy metals is achieved. The technical problem is solved that the heavy metalsin anaerobic fermentation and composting products cannot be effectively controlled, meanwhile the defects can be made up for that the incineration cost is high and energy consumption for livestock excrement drying and incineration is high when single raw materials of biomass or domestic waste are insufficient, and the resource utilization, hazard-free treatment, reduction and economical treatmentof the waste are truly achieved.

Owner:JIANGXI THERMAL POWER CONSTR CORP

High tear-resistant cable sheath material

The invention discloses a high tear-resistant cable sheath material. The high tear-resistant cable sheath material is prepared from the following raw materials in parts by weight: 53 to 69 parts of nitrile rubber, 18 to 32 parts of polypropylene, 10 to 18 parts of butadiene styrene rubber, 6 to 12 parts of polyurethane elastomer, 1 to 3 parts of black carbon N330, 18 to 27 parts of organophosphate ester modified nanometer clay, 2 to 5 parts of calcium carbonate, 4 to 10 parts of polyester fiber, 0.5 to 2 parts of sulfur powder, 2 to 4 parts of accelerant DM, 1 to 3 parts of accelerant TT, 1 to 5 parts of active zinc oxide, 1 to 3 parts of main antioxidant, 0.5 to 1 part of auxiliary antioxidant, 1 to 3 parts of main ultraviolet absorbing agent, 0.5 to 1 part of auxiliary ultraviolet absorbing agent, 5 to 12 parts of paraffin oil, 2 to 6 parts of trioctyl trimellitate, 3 to 5 parts of tributyl citrate, and 1 to 3 parts of lubricating agent. The high tear-resistant cable sheath material has the advantages that the tear-resistant property, tensile strength and other mechanical property are excellent, the flame-retardant property is good, and the anti-aging property is realized.

Owner:天长市康宁甘油科技有限公司

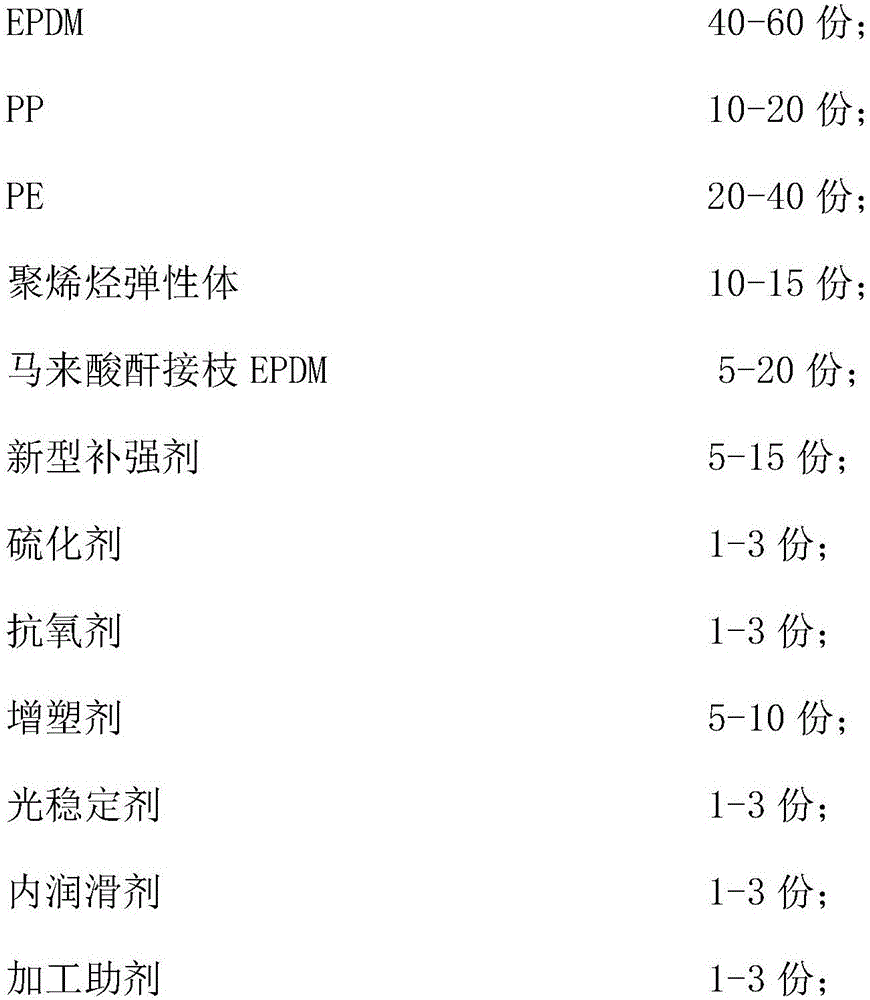

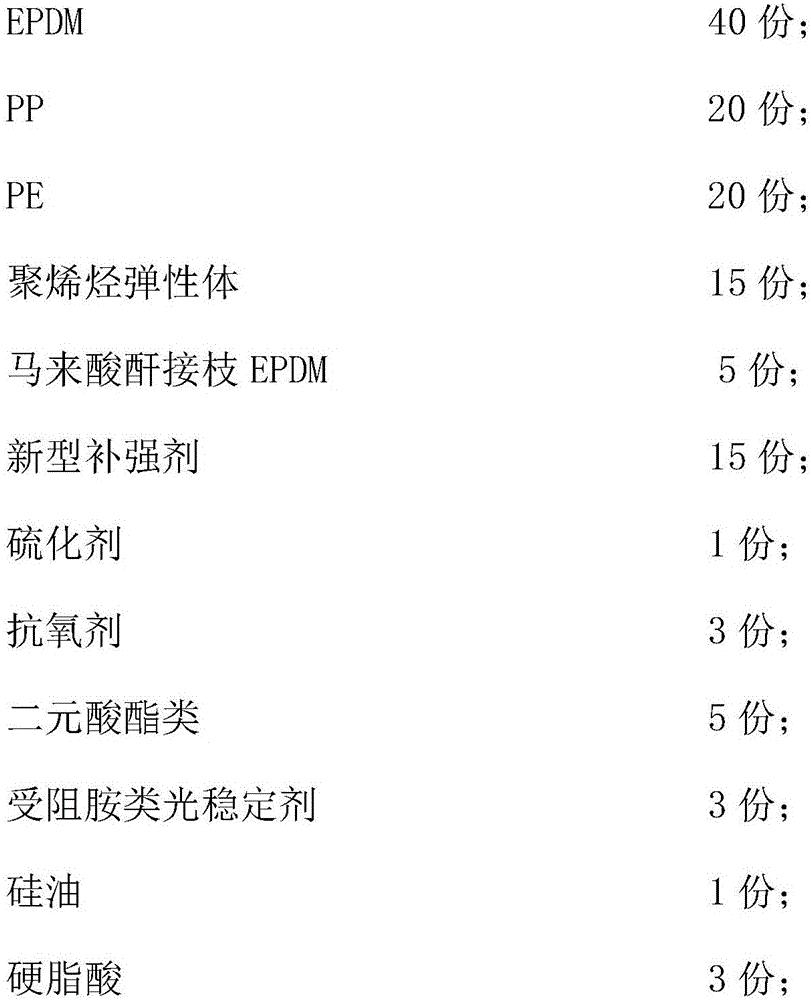

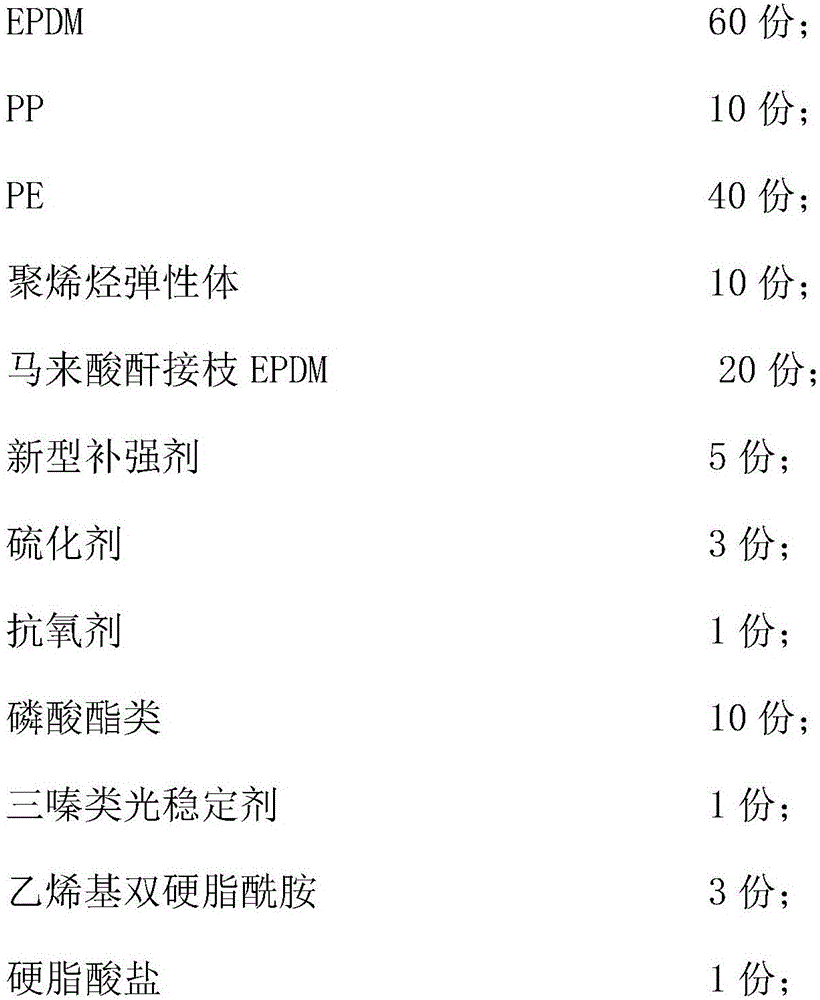

High-hardness and low-temperature-resistant TPV material and preparation method thereof

InactiveCN105778299AImprove low temperature resistanceImprove mechanical propertiesElastomerPolyolefin

The invention discloses a high-hardness and low-temperature-resistant TPV material.The high-hardness and low-temperature-resistant TPV material is prepared from, by weight, 40-60 parts of EPDM, 10-20 parts of PP, 20-40 parts of PE, 10-15 parts of polyolefin elastomer, 5-20 parts of maleic anhydride grafted EPDM, 5-15 parts of novel reinforcing agent, 1-3 parts of vulcanizing agent, 1-3 parts of antioxidant, 5-10 parts of plasticizer, 1-3 parts of light stabilizer, 1-3 parts of internal lubricant and 1-3 parts of processing aid.The TPV material is good in mechanical performance and excellent in low temperature resistance performance and meanwhile is excellent in processability and excellent in appearance.

Owner:安徽韧达高分子材料有限公司

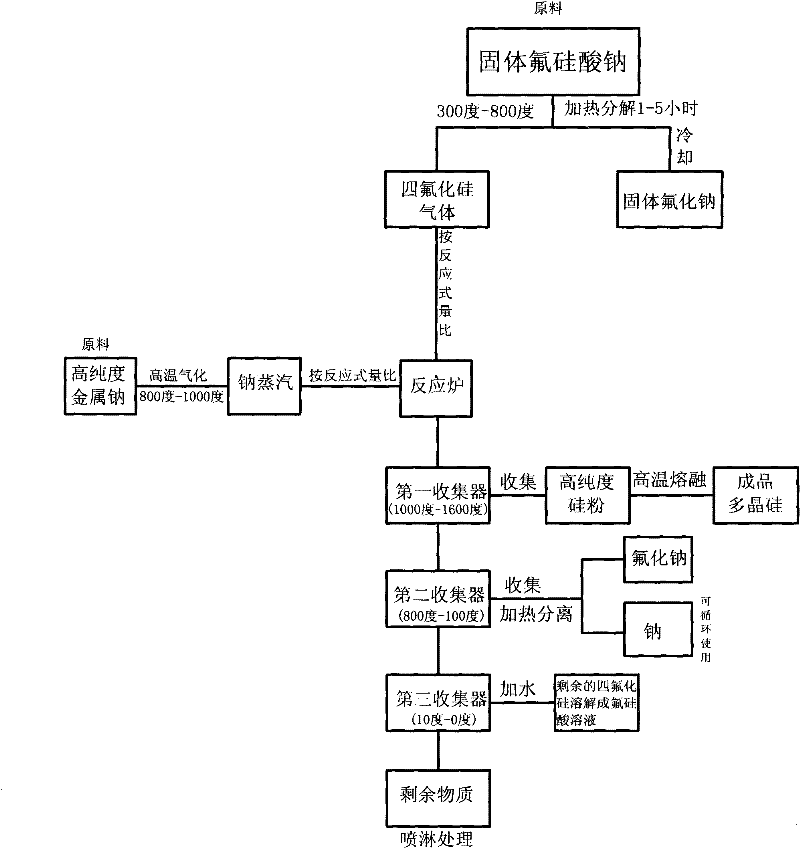

A kind of process method of producing solar grade polysilicon by sodium cycle method

InactiveCN102267697ASimple production processNo toxic gas emissionsPolycrystalline material growthSilicon halogen compoundsChemistryPolycrystalline silicon

The invention relates to a process for producing solar grade polysilicon with a sodium circulation method. The process comprises the following steps: heating sodium fluosilicate Na2SiF6 to decompose to a silicon tetrafluoride (SiF4) gas and sodium fluoride NaF; vaporizing metallic sodium Na to a sodium (Na) steam at a high temperature; allowing the silicon tetrafluoride (SiF4) gas and the sodium (Na) steam to enter a reaction furnace to generate high purity silicon powder, allowing the high purity silicon powder to enter a first collector, and carrying out high temperature fusion to prepare finished products of polysilicon; allowing other mixed gases to enter a second collector, allowing sodium fluoride NaF to deposit with unreacted sodium Na, and carrying out heating separation on sodiumfluoride NaF and sodium Na; allowing the other gases to enter a third collector, cooling, collecting the residual silicon tetrafluoride (SiF4) gas, adding water to dissolve into a solution of fluosilicic acid (H2SiF6); and carrying out spray processing on residual substances. The process for producing solar grade polysilicon with the sodium circulation method, which has the advantages of simple production technology, no discharge of toxic gases, wide source and cheapness of raw materials, and accordance of the concept of Chinese circular economy, allows generated byproducts to be effectively utilized, the production cost to be substantially saved, and the development of the solar photovoltaic industry to be effectively promoted.

Owner:刘新林

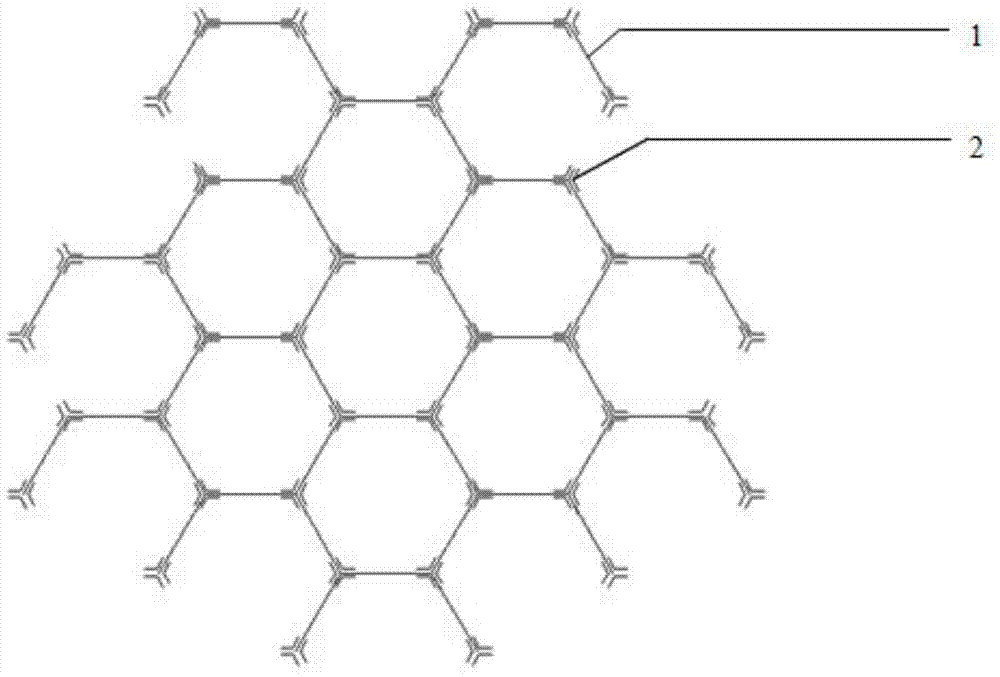

Honeycomb-shaped bamboo plywood wet type electric precipitator anode

ActiveCN104759351AImprove dust removal efficiencyEasy to transportElectrode constructionsActivated carbonCircular economy

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com