High-hardness and low-temperature-resistant TPV material and preparation method thereof

A technology with low temperature resistance and high hardness, which is applied in the field of TPV materials, and can solve the problems of TPV material hardness influence and low temperature performance of TPV

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

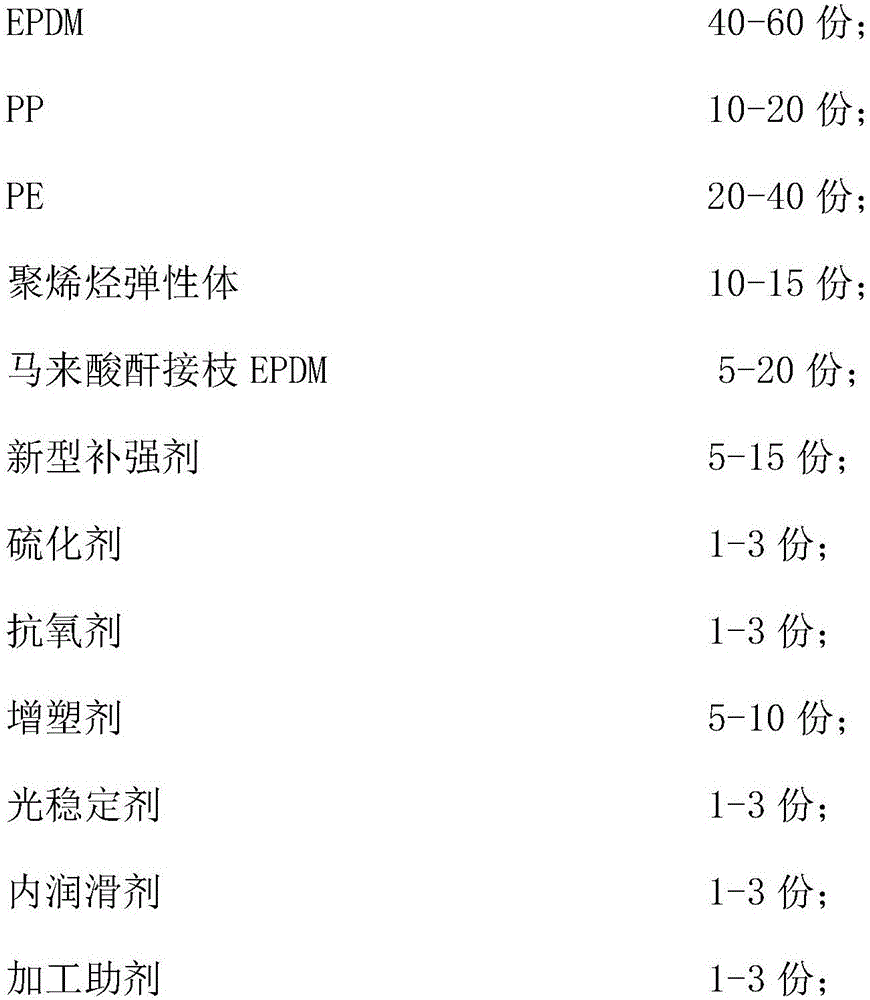

[0020] A high-hardness and low-temperature resistant TPV material, the raw materials of which include by weight:

[0021]

[0022] Wherein, the EPDM is made by copolymerizing 20wt% ethylene, 78wt% propylene and 2wt% vinyl norbornene; the PP is made of 50wt% copolymerized polypropylene and 50wt% homopolymerized polypropylene The comonomer of the copolymerized polypropylene is ethylene, the flexural modulus of the copolymerized polypropylene is ≤1100MPa, and the melt index is 0.5g / 10min; the melt index of the homopolymerized polypropylene is 5.0g / 10min;

[0023] The method for preparing the novel reinforcing agent comprises: adding HCl and H in a molar ratio of 1:3 to 2 SO 4 Add 60 mesh fly ash to the mixed acid solution, the frequency is 20KHz, the sound intensity is 0.3W / cm 2The modified fly ash was obtained by ultrasonic reaction for 1 h under the conditions of filtration, water washing, drying and grinding; toluene was added to the modified fly ash and stirred evenly,...

Embodiment 2

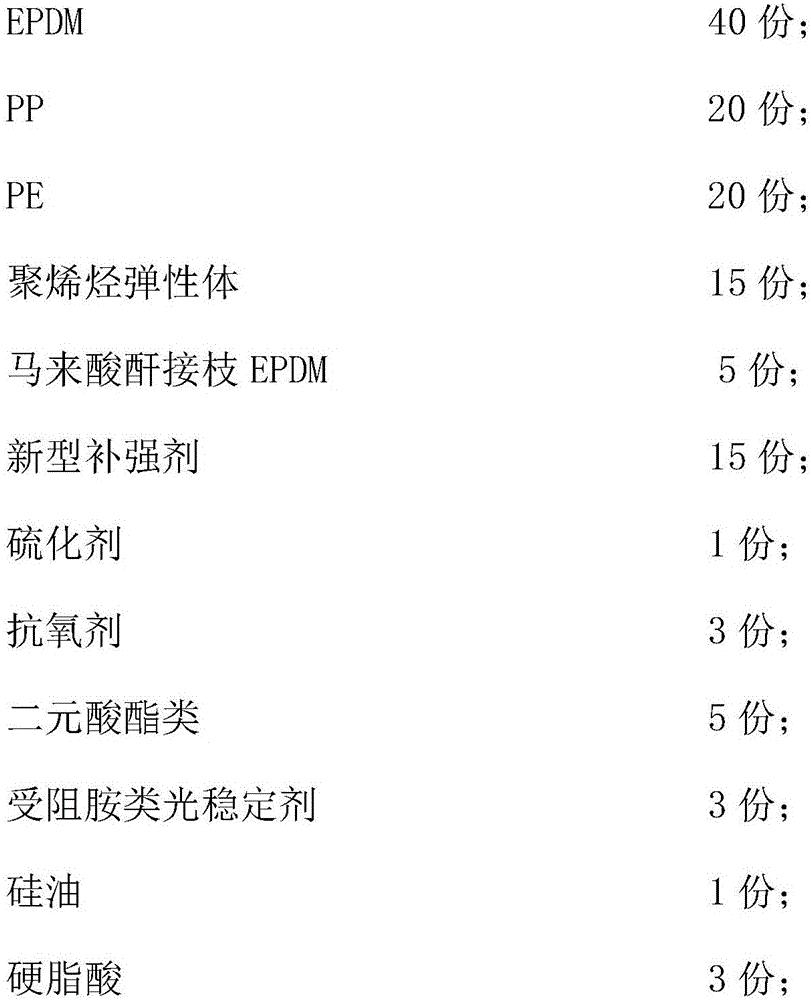

[0027] A high-hardness and low-temperature resistant TPV material, the raw materials of which include by weight:

[0028]

[0029] Wherein, the EPDM is copolymerized by 50wt% ethylene, 40wt% propylene and 10wt% vinyl norbornene; the PP is composed of 80wt% copolymerized polypropylene and 20wt% homopolymerized polypropylene composition; the comonomer of the copolymerized polypropylene is butene, the flexural modulus of the copolymerized polypropylene is less than or equal to 1100MPa, and the melt index is 5.0g / 10min; the melt index of the homopolymerized polypropylene is 0.5g / 10min;

[0030] The method for preparing the novel reinforcing agent comprises: adding HCl and H with a molar ratio of 1:5 2 SO 4 Add 40 mesh fly ash to the mixed acid solution, the frequency is 40KHz, the sound intensity is 0.1W / cm 2 The modified fly ash was obtained by ultrasonic reaction for 3 hours under the conditions of filtration, washing, drying and grinding; toluene was added to the modifie...

Embodiment 3

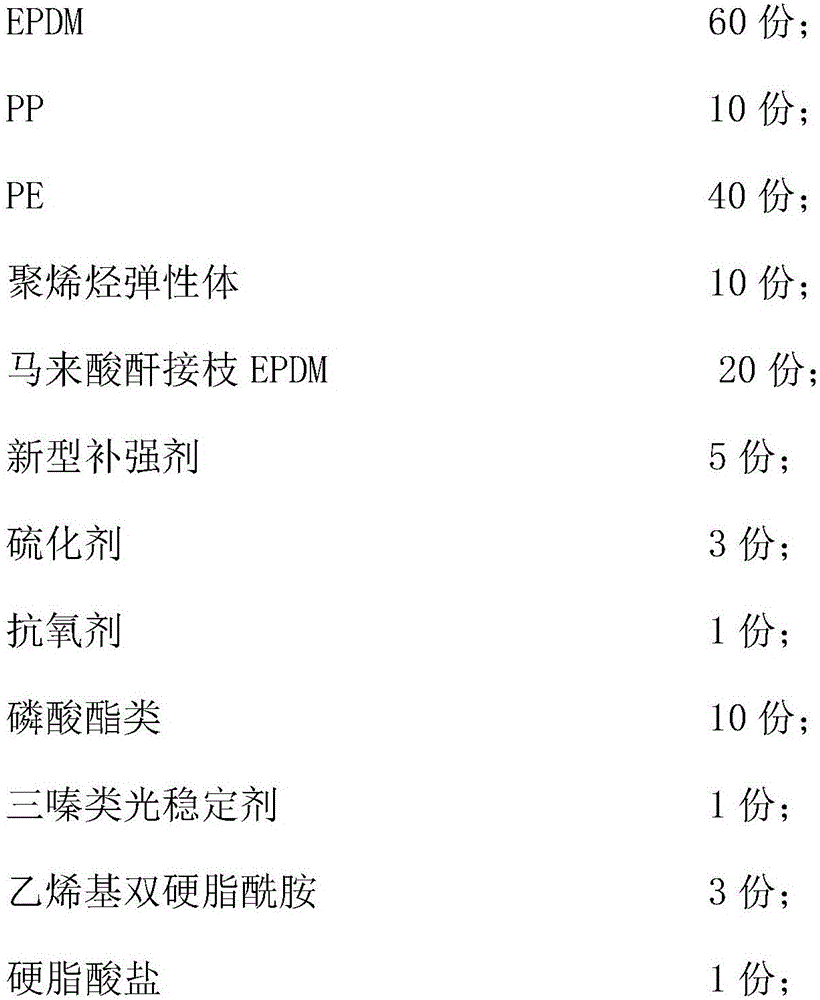

[0034] A high-hardness and low-temperature resistant TPV material, the raw materials of which include by weight:

[0035]

[0036]

[0037] Wherein, the EPDM is copolymerized by 35wt% ethylene, 59wt% propylene and 6wt% vinyl norbornene; the PP is composed of 65wt% copolymerized polypropylene and 35wt% homopolymerized polypropylene The comonomer of the copolymerized polypropylene is hexene, the flexural modulus of the copolymerized polypropylene is less than or equal to 1100MPa, and the melt index is 2.5g / 10min; the melt index of the homopolymerized polypropylene is 3.0g / 10min;

[0038] The method for preparing the novel reinforcing agent comprises: adding HCl and H in a molar ratio of 1:4 to 2 SO 4 Add 50 mesh fly ash to the mixed acid solution, the frequency is 25KHz, the sound intensity is 0.2W / cm 2 The modified fly ash was obtained by ultrasonic reaction for 2.5h under the conditions of filtration, water washing, drying and grinding; toluene was added to the modif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural modulus | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com