Nitrile/EPDM for ozone and low temperature resistant seals

A technology of EPDM rubber and nitrile rubber, which is applied in the field of rubber seals, can solve the problems of poor sunlight crack resistance, narrow heat resistance temperature range, poor ozone resistance and low temperature resistance, and achieve excellent durability. Weather resistance, improved tear strength, improved cross-linking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

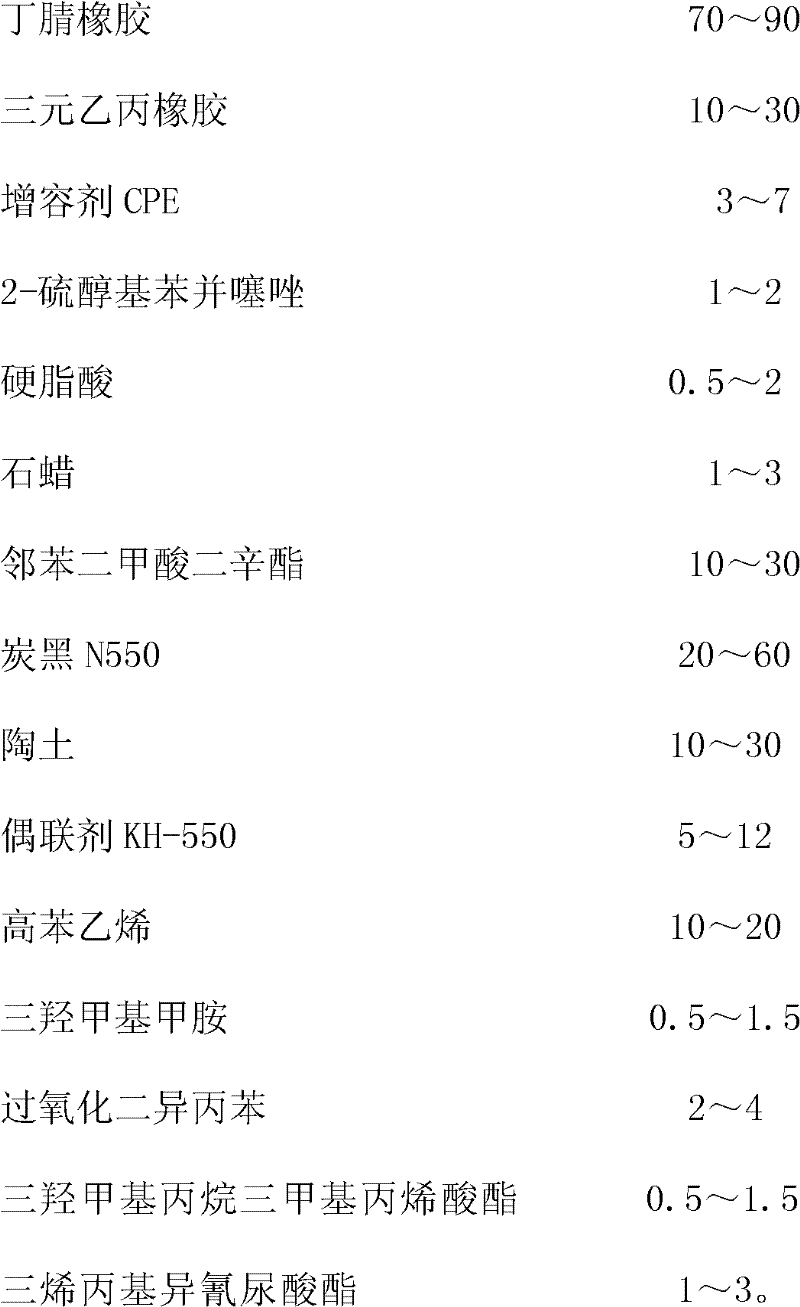

Method used

Image

Examples

Embodiment Construction

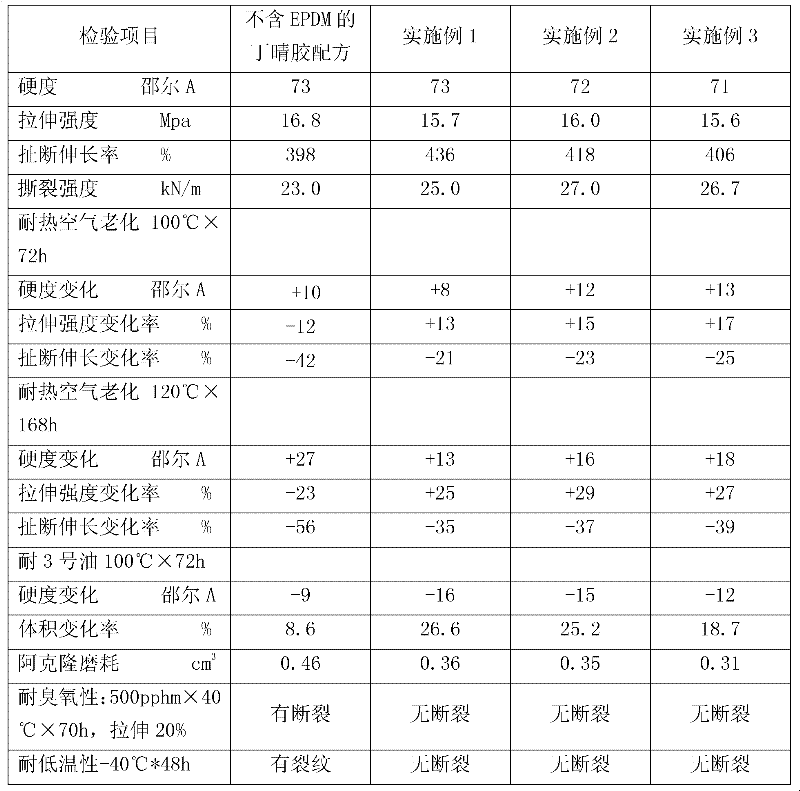

[0022] According to the raw materials in the formula of the embodiment, the film is made into a film for testing and testing. The performance comparison between the formula of nitrile rubber / EPDM (NBR / EPDM) ozone-resistant and low-temperature resistant sealing ring and the formula of nitrile rubber without EPDM is as follows:

[0023]

[0024] The usual conditions are: the ozone resistance of ordinary NBR formula film can reach the experimental condition of 50pphm / 40℃ / 72h / 20% without cracking, and the experimental condition of low temperature resistance is -30℃ / 22h. There is no cracking, and after the heat-resistant air aging test condition is 100℃×72h, the hardness change is within 0~+15, the change rate of tensile strength is within -15, and the change rate of elongation at break is within -50.

[0025] And we use more severe conditions, through the performance comparison analysis of the ozone-resistant low-temperature resistance formula of the nitrile rubber / EPDM blend ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com