Blow-molding-grade TPV (thermoplastic vulcanizate) material for dust shields and preparation method thereof

A dust cover, blow molding technology, applied in the field of TPV materials, can solve problems such as difficulty in blow molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

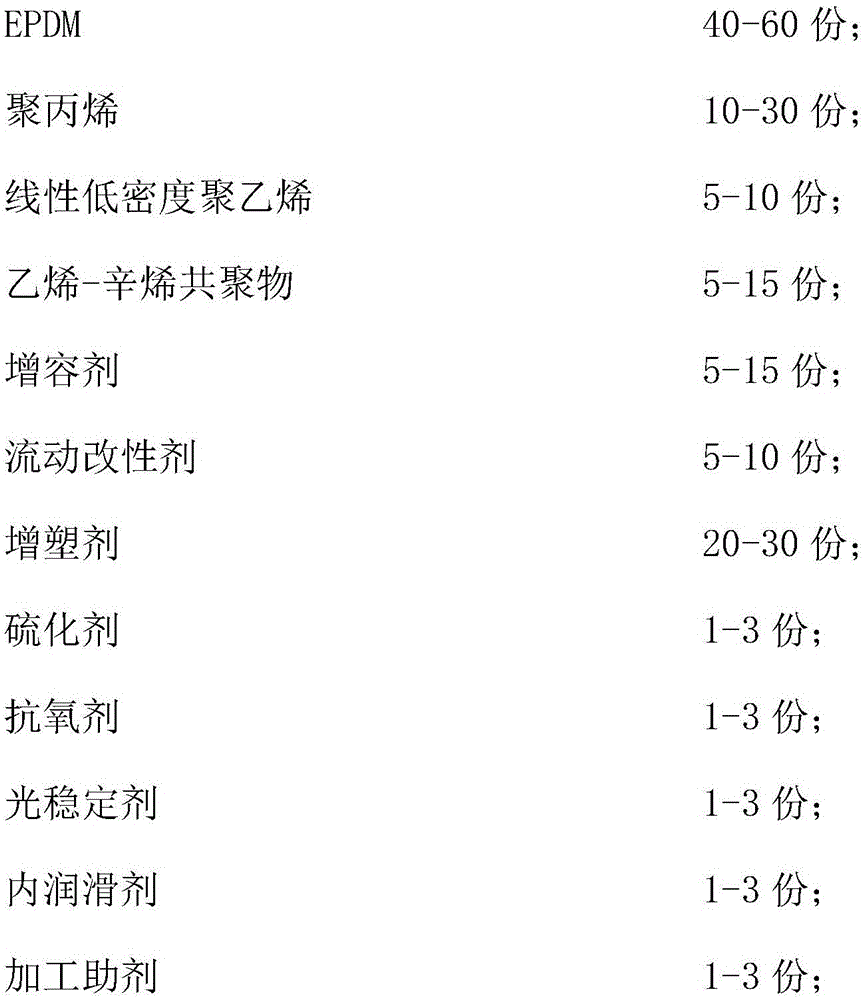

[0021] A kind of TPV material for blow molding grade dust cover, its raw material comprises by weight:

[0022]

[0023]Wherein, the method for preparing the flow modifier includes: adding 15 parts of silane coupling agent and 20 parts of nano-calcium carbonate in a mixed solution of isopropanol and water at a volume ratio of 6:1 by weight, and heating up to 100°C , stirred for 4h, dried at 80°C until the solvent content was 40wt%, and then dried at 140°C until the solvent content was 0wt%, after grinding, the grafted nano-calcium carbonate of silane coupling agent was obtained; the silane coupling agent Add grafted nano-calcium carbonate to water, sonicate for 1 hour, add 0.1 part of sodium bisulfite and 0.6 part of potassium persulfate, raise the temperature to 40 °C under the condition of nitrogen protection, keep stirring for 1 hour, then add 5 parts of styrene and 30 parts of acrylamide, heat up to 60°C, heat and stir for 4 hours, then add excess ethanol, stir, filter ...

Embodiment 2

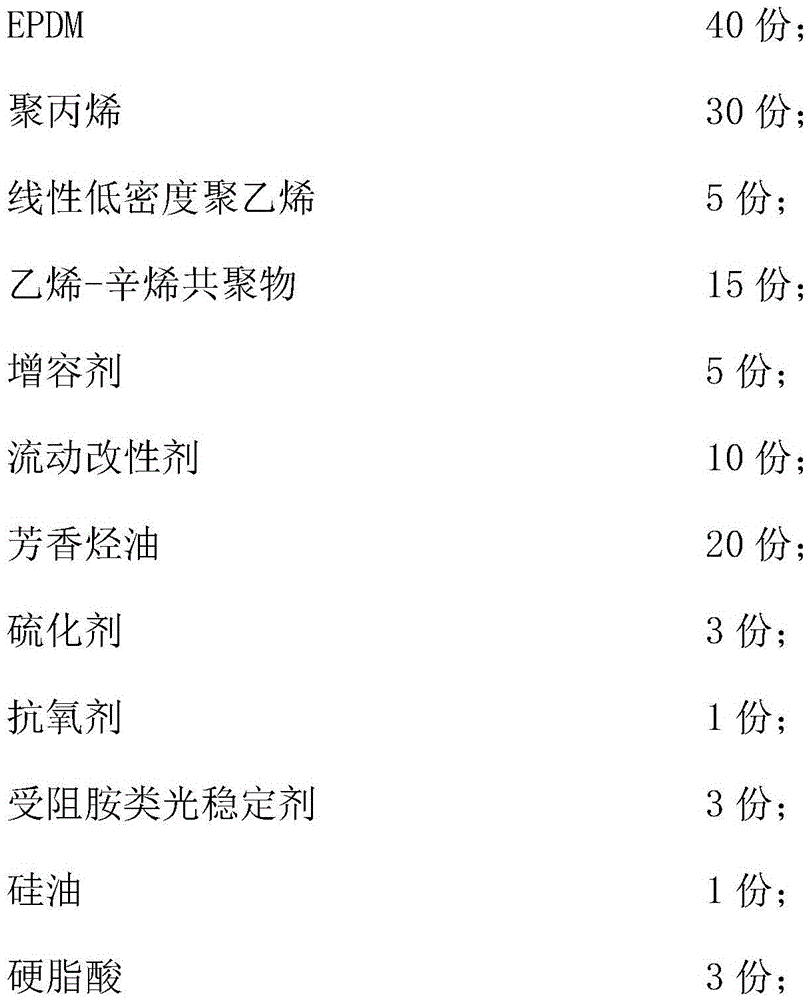

[0027] A kind of TPV material for blow molding grade dust cover, its raw material comprises by weight:

[0028]

[0029]

[0030] Wherein, the method for preparing the flow modifier includes: adding 10 parts of silane coupling agent and 30 parts of nano-calcium carbonate to a mixed solution of isopropanol and water at a volume ratio of 8:1 by weight, and heating up to 80°C , stirred for 6h, dried at 60°C until the solvent content was 60wt%, and then dried at 120°C until the solvent content was 3wt%, after grinding, the grafted nano-calcium carbonate of silane coupling agent was obtained; the silane coupling agent Add grafted nano-calcium carbonate to water, sonicate for 0.5h, add 0.3 parts of sodium bisulfite and 0.4 parts of potassium persulfate, raise the temperature to 60°C under the condition of nitrogen protection, keep stirring for 0.5 hours, then add 15 parts of styrene and 15 parts of acrylamide, heated up to 80°C, kept stirring for 2 hours, then added excess eth...

Embodiment 3

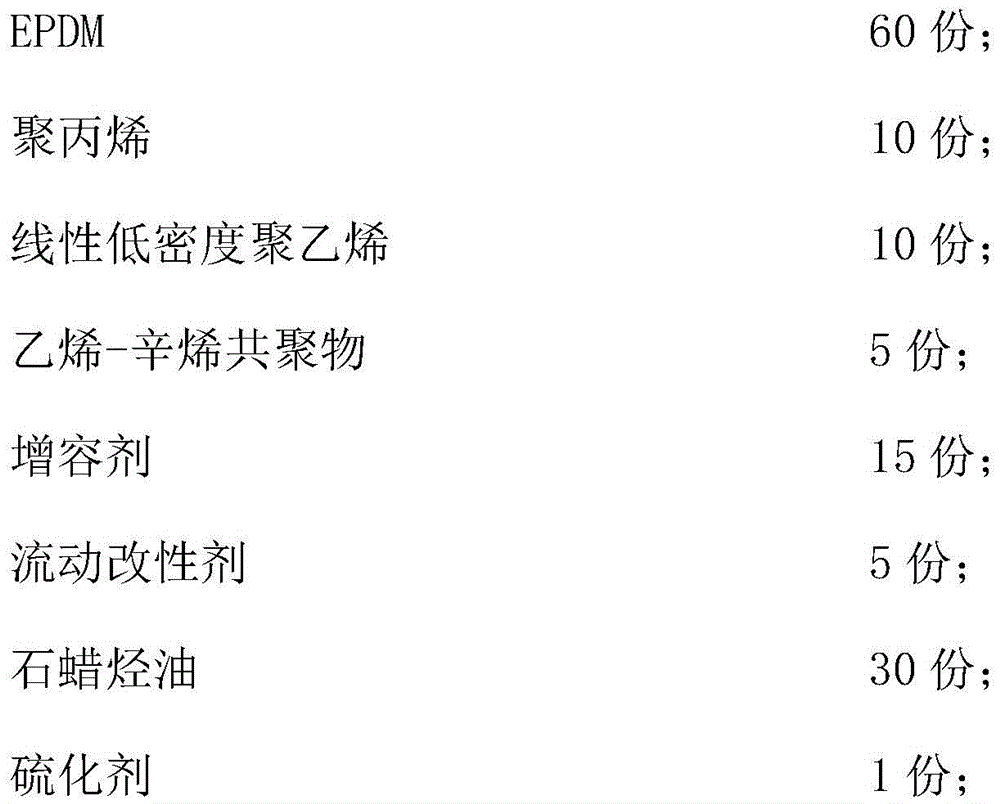

[0034] A kind of TPV material for blow molding grade dust cover, its raw material comprises by weight:

[0035]

[0036] Wherein, the method for preparing the flow modifier includes: adding 12 parts of silane coupling agent and 25 parts of nano-calcium carbonate in a mixed solution of isopropanol and water at a volume ratio of 7:1 by weight, and heating up to 90°C , stirred for 5h, dried at 70°C until the solvent content was 50wt%, and then dried at 130°C until the solvent content was 2wt%, after grinding, the grafted nano-calcium carbonate of the silane coupling agent was obtained; the silane coupling agent Add grafted nano-calcium carbonate into water, sonicate for 0.7h, add 0.2 parts of sodium bisulfite and 0.5 parts of potassium persulfate, raise the temperature to 50°C under nitrogen protection, keep stirring for 0.7 hours, then add 10 parts of styrene and 22 parts of acrylamide, heat up to 70°C, heat and stir for 3 hours, then add excess ethanol, stir, filter with suc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com