Method for modification treatment of coal ash

A technology for fly ash and modification, applied in the field of treating nickel-containing wastewater, can solve the problems of low adsorption capacity of fly ash, unable to meet the requirements of nickel discharge, etc., and achieve the effect of remarkable removal effect, low cost and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

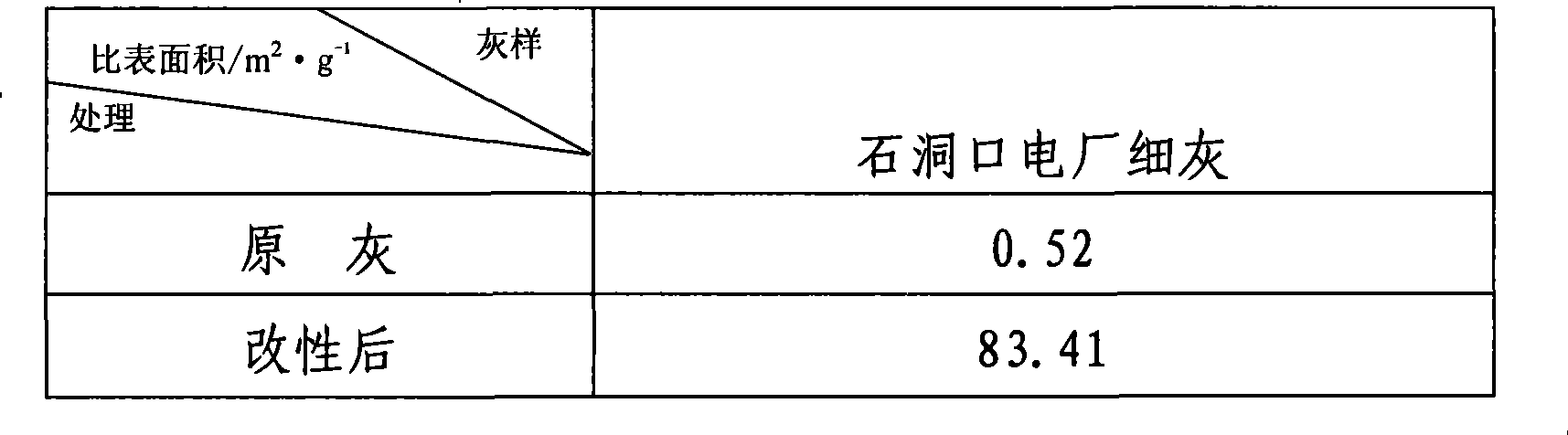

[0007] The present invention is described in further detail below by way of examples, a kind of method to fly ash modified treatment, its step is: the sodium hydroxide solution of fly ash and 2mol / L is mixed by the solid-liquid ratio of 1:6 solution, microwave reaction at 85°C for 20 minutes, then stirred at 100°C for 12 hours, washed with deionized water and 95% ethanol after the reaction, then saturated with 1mol / L sodium chloride, and finally heated at 110°C drying to obtain modified fly ash. The fly ash of Shidongkou Power Plant is modified by the present invention, and then the specific surface area of the fly ash before and after modification is measured, and the results are shown in Table 1. It can be seen from Table 1 that the specific surface area of the modified fly ash has increased many times.

[0008] Table 1 Comparison of specific surface area before and after modification of fly ash in Shidongkou Power Plant

[0009]

[0010] Utilize Shidongkou power pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com