An active activator for building materials of inorganic solid waste and its preparation method

An active stimulant and inorganic solid technology, applied in the field of solid waste resource utilization, can solve problems such as negative impact on product quality, and achieve the effect of improving strength and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

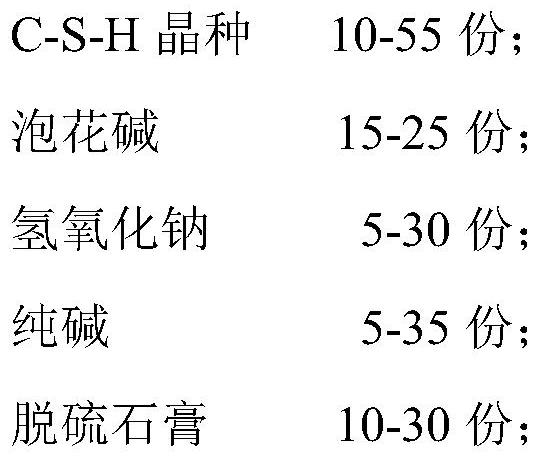

[0028] An active activator for building materials from inorganic solid waste, which is composed of C-S-H seed crystals, sodium hydroxide, sodium hydroxide, soda ash and desulfurized gypsum mixed according to the following mass ratio, with a particle size of 100 mesh:

[0029]

[0030] A preparation method of an active activator for building materials of inorganic solid waste:

[0031] (A) Preparation of seed crystals: first weigh amorphous silica / quick lime=1.5 by mass ratio, put into a mechanically stirred reactor after uniform mixing, then add water 10 times of the total mass of the mixture in the reactor, and React at 140°C for 5 hours, then filter, vacuum dry, grind, and pass through a 100-mesh sieve to obtain C-S-H seed crystals;

[0032] (B) Grinding and sieving: grinding sodium hydroxide, sodium hydroxide, soda ash and desulfurized gypsum respectively, and crossing a 100-mesh sieve;

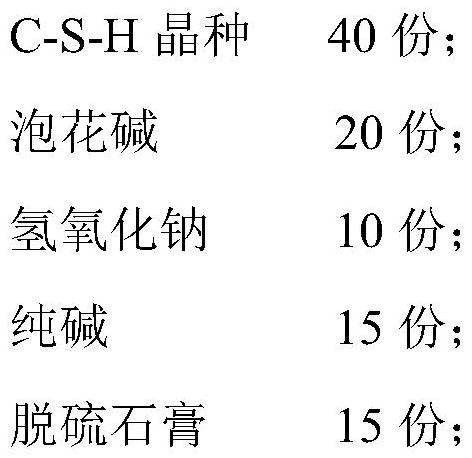

[0033] (C) Mixing and stirring: 40 parts of C-S-H seed crystals; 20 parts of sodiu...

Embodiment 2

[0035] An active stimulator for building materials from inorganic solid waste, which is composed of C-S-H seed crystals, sodium hydroxide, sodium hydroxide, soda ash and desulfurized gypsum mixed according to the following parts by mass, with a particle size of 100 mesh:

[0036]

[0037] A preparation method of an active activator for building materials of inorganic solid waste:

[0038] (A) Seed crystal preparation: take amorphous silica / quicklime=1.65 according to the mass ratio, put it into a mechanically stirred reactor after mixing evenly, and then add amorphous silica and quicklime total mass 12 to the reactor. times water, react at 160°C for 8 hours, then filter, vacuum dry, grind, and pass through a 100-mesh sieve to obtain C-S-H seed crystals;

[0039] (B) Grinding and sieving: grinding sodium hydroxide, sodium hydroxide, soda ash and desulfurized gypsum respectively, and crossing a 100-mesh sieve;

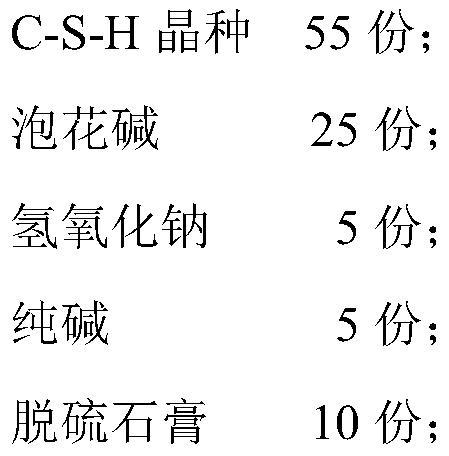

[0040] (C) Mixing and stirring: Weigh 55 parts of C-S-H seed cr...

Embodiment 3

[0042]According to the mass ratio of power plant fly ash: cement: aggregate = 45:15:40, two groups of formulas were weighed respectively. One group without activator was used as the control group, and the other group was added with activator as the experimental group. Building material product performance impact test. The activator used in the experimental group is the active activator prepared in Example 1, and the addition of the activator is 5% of the total mass of cement, power plant fly ash and aggregate, and the control group and the experimental group all add cement, power plant fly ash and 30% water of the total mass of the aggregate, mixed evenly to obtain a mixture, poured the mixture into a mold for molding, and then cured for 28 days at a temperature of 20±3°C and a humidity of 90%, and mixed with an active stimulator The performance test results of the experimental group sample and the contrast blank group sample without adding the active activator (except that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com