Patents

Literature

535 results about "Crystal transformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrafine lead oxide prepared by using waste lead plaster and preparation method thereof

InactiveCN103374657AReduce energy consumptionSimple ingredientsReclaiming serviceable partsLead oxidesFiltrationTwo step

The invention discloses an ultrafine lead oxide prepared by using a waste lead plaster and a preparation method thereof. The preparation method comprises the following steps of: carrying out desulphurization process by mixing the waste lead plaster with an aqueous solution containing a composite desulfurizer for reaction; carrying out filtration to remove the desulphurization filtering solution to obtain the desulfurated lead plaster (filter residue); carrying out a leaching and crystal transformation process by adding a citric acid solution and a reducing agent into the desulfurated lead plaster obtained in the process, and carrying out filtration, washing, and drying to obtain the lead citrate after the desulfurated lead plaster reacts with the citric acid solution; carrying out a roasting process by roasting the lead citrate to obtain the ultrafine lead oxide. According to the preparation method disclosed by the invention, the ultrafine lead oxide is prepared from the waste lead storage lead plaster; a two-step leaching process is adopted; the filtering solution is simple in ingredient and can be recycled; a side product is recycled from the desulphurization solution. The preparation method disclosed by the invention is low in energy consumption, simple in equipment, high in lead recycling rate, and high in ultrafine lead product quality, and has the characteristics of good resource recycling effect, environmentally-friendly and pollution-free production process, and capability of clean production.

Owner:湖北金洋冶金股份有限公司 +1

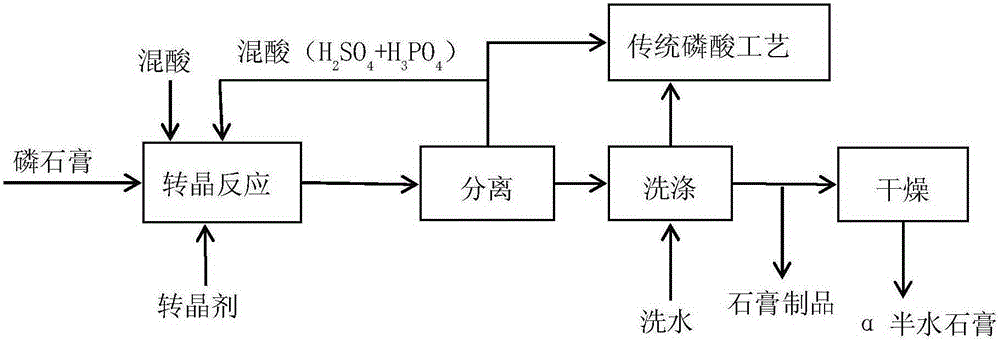

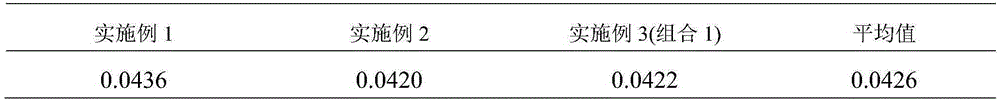

Method for preparing alpha semi-hydrated gypsum from dihydrate gypsum

The invention relates to a method for preparing alpha semi-hydrated gypsum from dihydrate gypsum. The method comprises the following steps: adding dihydrate gypsum and a crystal modifier into a mixed acid water solution containing sulfur acid and phosphoric acid to carry out crystal transformation, carrying out solid-liquid separation, returning a part of liquid phase into a crystal transformation tank for crystal transformation, and conveying another part of liquid phase to an acidolysis tank for use, wherein the acidolysis tank is used for preparing phosphoric acid by decomposing phosphorite by virtue of sulfuric acid; adding washing water to wash a solid phase, and introducing the washing water into the liquid phase for use. The washed solid phase can be prepared into alpha semi-hydrated gypsum powder through drying and can be prepared into gypsum products such as gypsum boards, gypsum blocks, gypsum components and the like by directly adding water without drying. According to the method, the alpha semi-hydrated gypsum is prepared in the mixed acid water solution containing sulfur acid and phosphoric acid, procedures including desulfuration, removal of impurity and the like on raw gypsum can be omitted, furthermore, mixed acid can be recycled, and the obtained alpha semi-hydrated gypsum product is high in strength and stable in quality.

Owner:贵州正磷科技有限公司

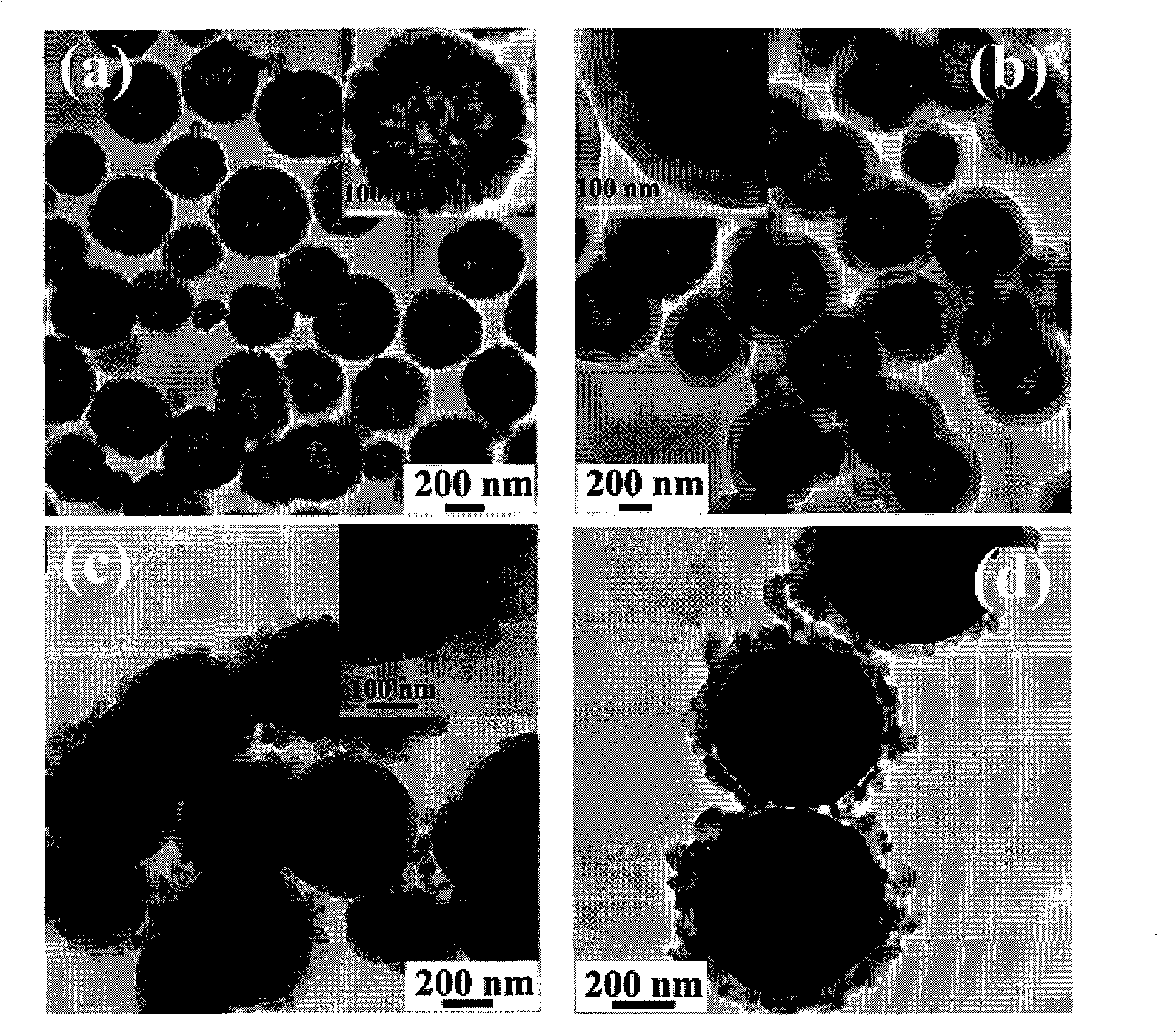

Magnetic inorganic nano corpuscle/zeolite nucleocapsid type composite microsphere and preparation method thereof

InactiveCN101299366ALarger than surfaceGood dispersionInorganic material magnetismPigment treatment with macromolecular organic compoundsChemical synthesisMicrosphere

The invention belongs to the technical field of the advanced nanometre composite material, particularly to magnetic inorganic nano-particle / zeolite putamen compound microsphere and the preparation method. The invention first adopts the collosol-gel chemical synthesis, wraps a layer of amorphous silica on the external surface of the magnetic inorganic nano-particle, then uses the layer by layer self-assembly technology to adsorb the polyelectrolyte with positive charge and the zeolite nano-particle with negtive charge on the magnetic microsphere surface with negtive charge, finally wraps a layer of zeolite materials on the exterior of the magnetic microsphere through the air-solid phase crystal transformation technology, thereby obtaining the magnetic zeolite compound microsphere with the putamen structure. The compound microsphere has strong magnetic responsibility, and the surface can adsorb a great deal of polypeptide, thereby having wide application foreground on the aspect of bioseparation and high efficiency proteid enzymolysis. The invention has simple method, easy obtaining of the raw materials, which is suitable for the enlarged production.

Owner:FUDAN UNIV

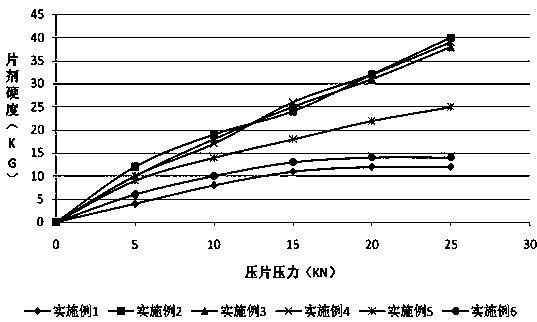

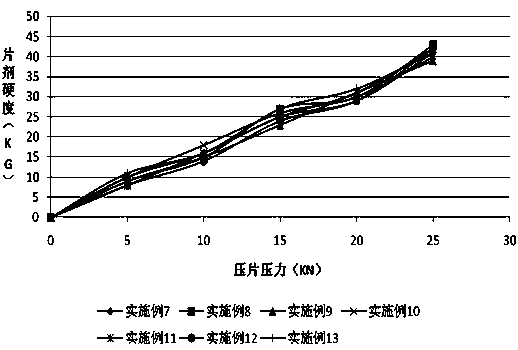

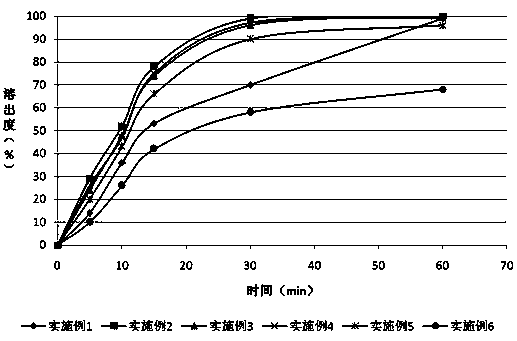

Oral solid preparation of canagliflozin and preparation method thereof

The invention relates to an oral solid medicine composition of canagliflozin and a preparation method thereof. The composition comprises canagliflozin and pharmaceutic adjuvants, wherein the canagliflozin is in an amorphous form, and the average grain size of particles is 2.5-30 microns. The composition can be used for effectively solving the technical problems that the crystal transformation and the compressibility of the canagliflozin in the amorphous form are poor in the preparation process of the solid preparation.

Owner:CHONGQING PHARMA RES INST

Synthetic method of novel ordered macroporous-mesoporous-microporous hierarchical porous silicon-aluminium molecular sieve

ActiveCN103979570AImprove selective catalytic performanceShorten the transmission pathMolecular sieve catalystsCrystalline aluminosilicate zeolitesMolecular sieveHierarchical porous

The invention provides a synthetic method of a novel ordered macroporous-mesoporous-microporous hierarchical porous silicon-aluminium molecular sieve. The method organically combines a template method with a crystal transformation process of a molecular sieve. Through a controllable selection of a macroporous template and a mesoporours template, a three-dimension ordered macroporous-mesoporous hierarchical porous structure having different pore sizes and interpenetrating pores is prepared. A micropore molecular sieve structure guiding agent is used for preparing an ordered micropore structure of the silicon-aluminium molecular sieve, thereby achieving regulation and control of pore sizes of macroporous structures, mesoporous structures and microporous structures. The method is simple, is feasible and is short in synthetic period. Operation conditions of the method are easy to control. Application of the molecular sieve is expected to be expanded into the technical field of organic macromolecule catalysis in which a conventional molecular sieve is not available.

Owner:WUHAN UNIV OF TECH

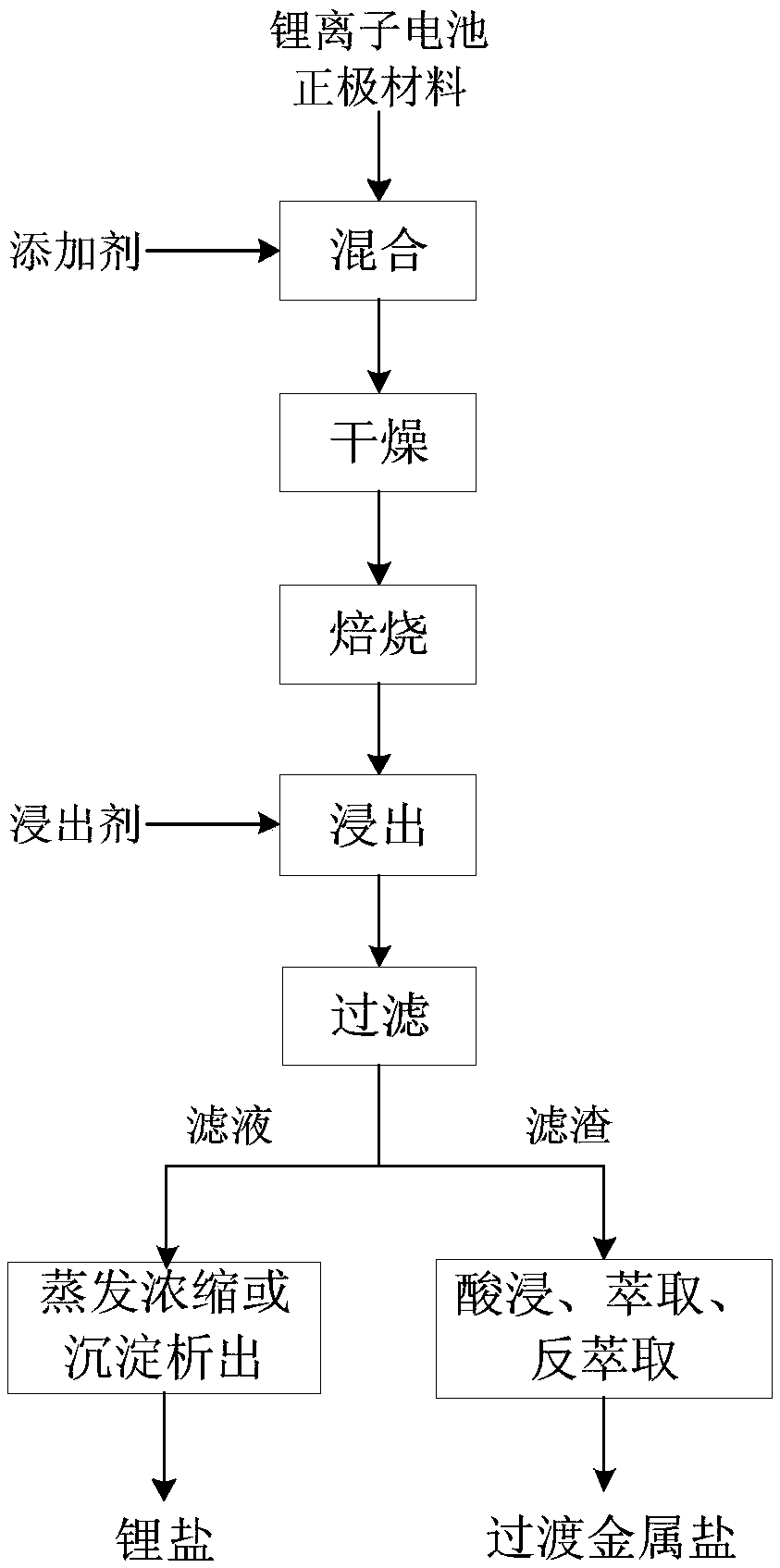

Method for selectively recycling positive electrode materials for lithium ion batteries

ActiveCN108832215AImplement selective extractionEasy to separateWaste accumulators reclaimingProcess efficiency improvementLiquid wasteSlag

The invention provides a method for selectively recycling positive electrode materials for lithium ion batteries. The method comprises the following steps: carrying out transformation processing aftermixing the recycling positive electrode materials for lithium ion batteries with an additive; leaching an obtained transformation product with a leaching agent, and carrying out solid-liquid separation to obtain a lithium-rich solution and a solid slag; and preparing the obtained lithium-rich solution into a lithium salt and the obtained solid slag into a transition metal salt. According to the method, recycling of valuable metals in the positive electrode materials for lithium ion batteries is realized by using in situ crystal transformation and mild leaching methods, particularly, selectiveextraction for lithium is realized, the recycle rate reaches 95% or above, and the recycle rate of other valuable metals such as nickel, cobalt and manganese reaches 98% or above; the method is shortin flow, other impurity ions are not introduced, the product purity is high, secondary pollution and liquid waste disposal can also be avoided, the recycle cost is saved, and the method is easy to realize industrial application.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

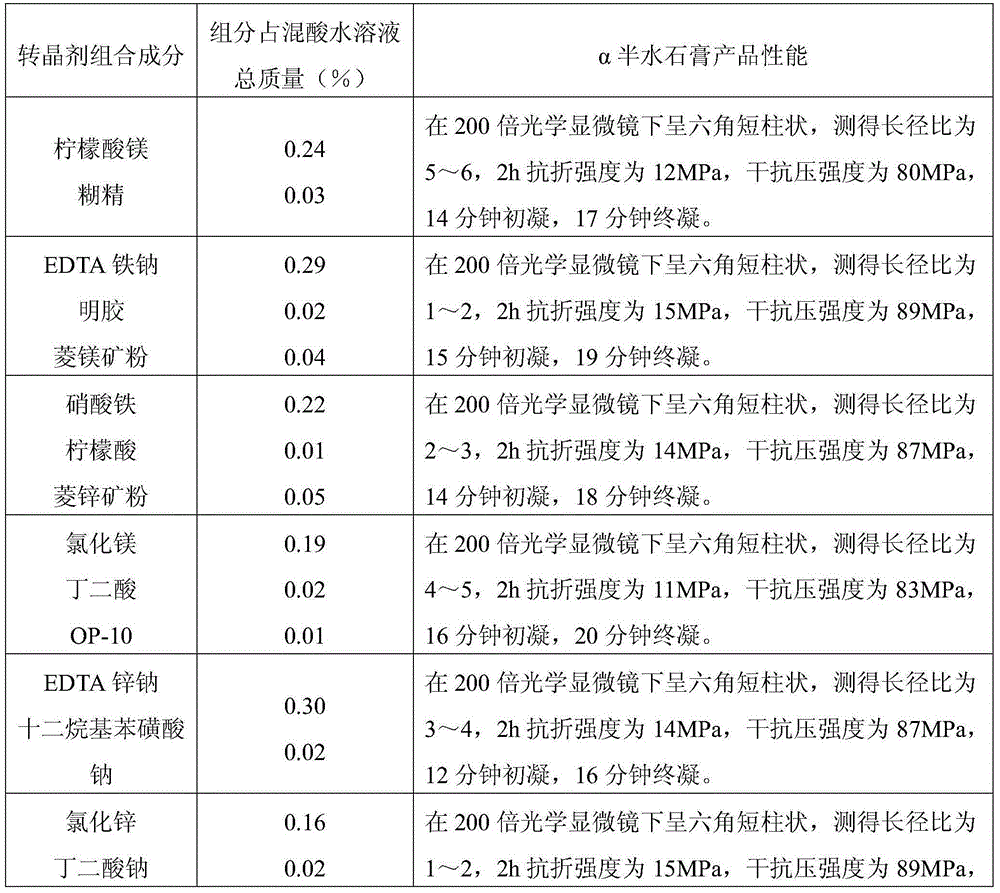

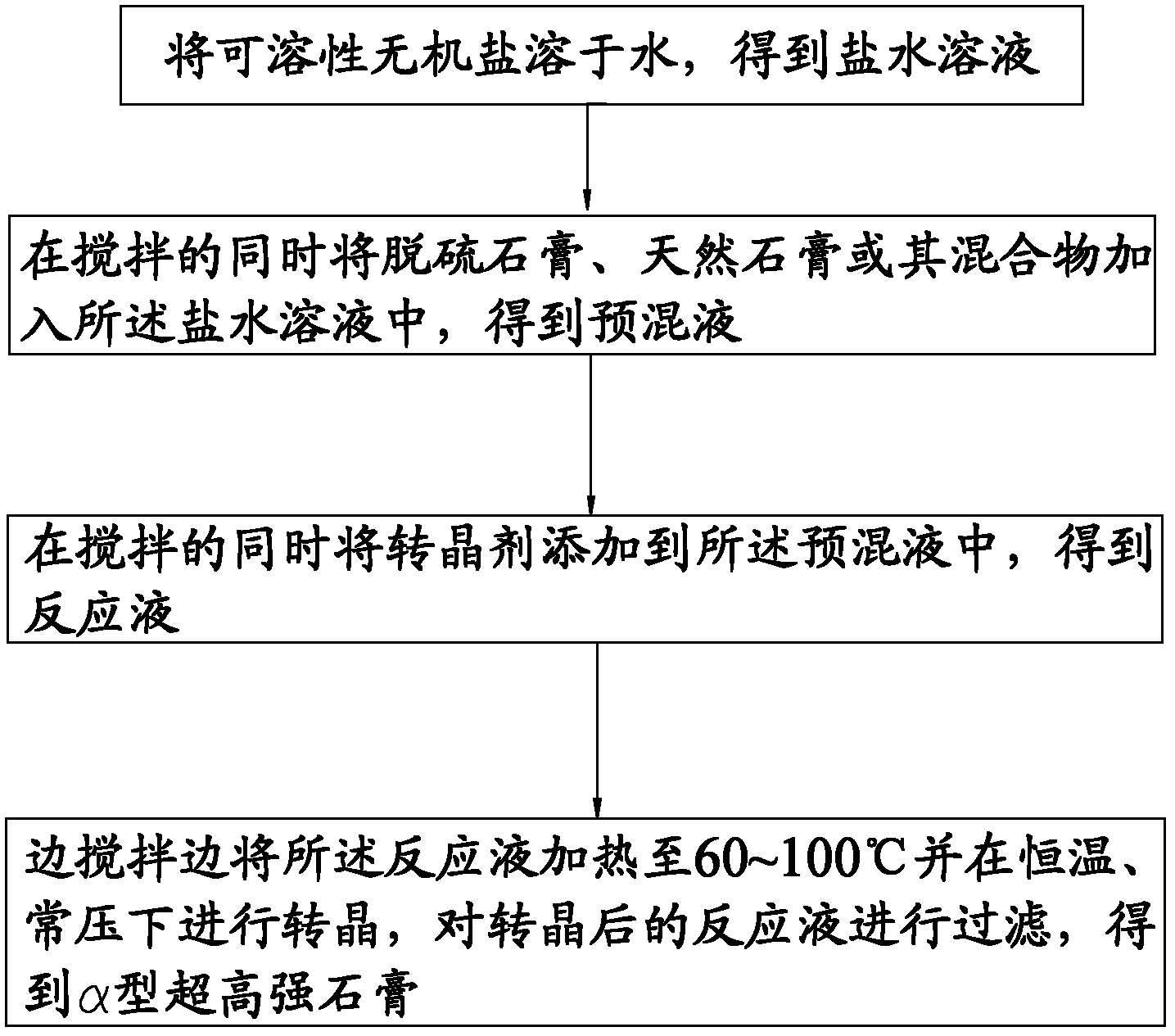

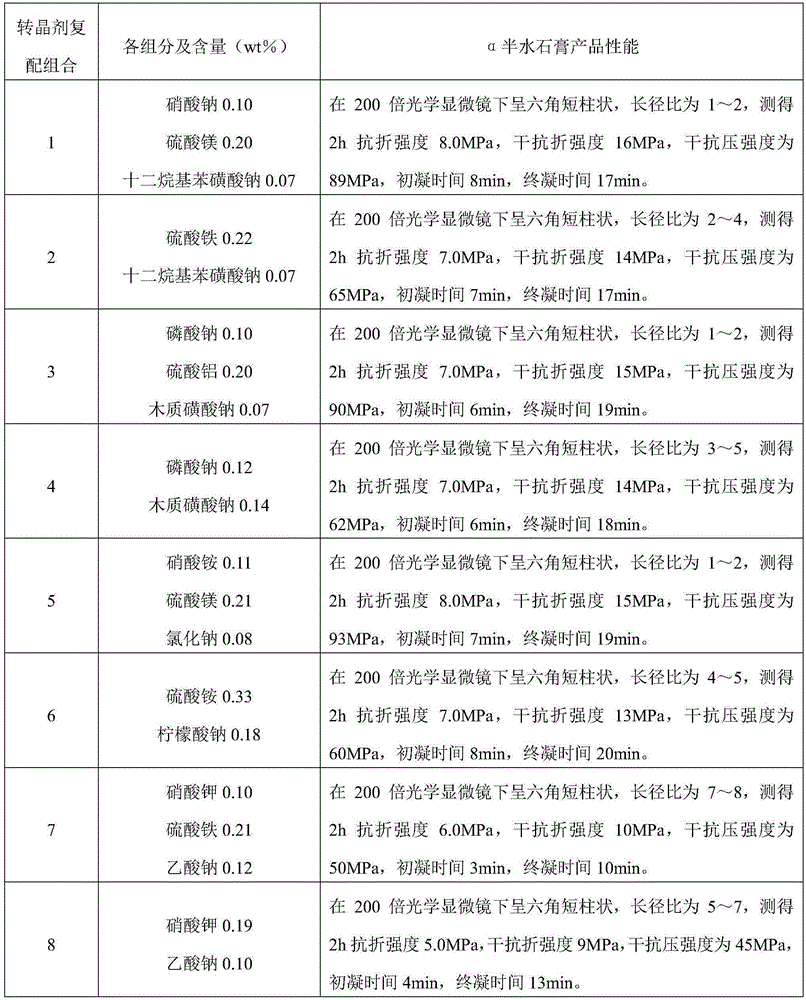

Alpha type ultra-high strength gypsum preparation method

ActiveCN102992375ASimple processImprove securityCalcium/strontium/barium sulfatesInorganic saltsAtmospheric pressure

The present invention discloses an alpha type ultra-high strength gypsum preparation method, which comprises the following steps: a) dissolving a soluble inorganic salt in water to obtain an aqueous salt solution; b) adding desulfurized gypsum, natural gypsum or a mixture of desulfurized gypsum and natural gypsum to the aqueous salt solution to obtain a premix solution; c) adding a crystal transformation agent to the premix solution to obtain a reaction solution; and d) heating the reaction solution to 60-100 DEG C, carrying out crystal transformation at a constant temperature under atmospheric pressure, and filtering the reaction liquid after crystal transformation to obtain the alpha type ultra-high strength gypsum. According to the alpha type ultra-high strength gypsum preparation method of the embodiments of the invention, a safety coefficient is high, and energy consumption is low; and the prepared alpha type ultra-high strength gypsum crystal has a uniform short columnar shape, such that the problem of incomplete crystal development in k gypsum preparation by using desulfurized gypsum is solved so as to increase strength. In addition, a process time is shortened, and cost is reduced.

Owner:国能朗新明环保科技有限公司

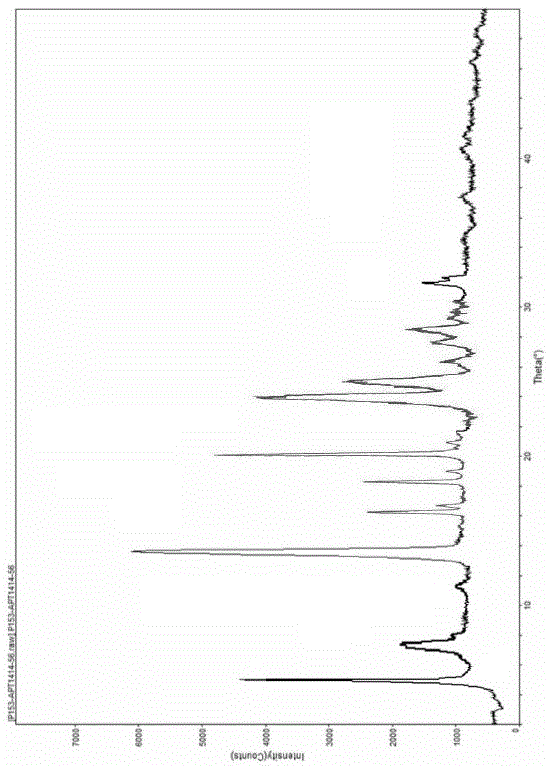

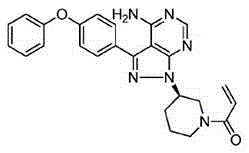

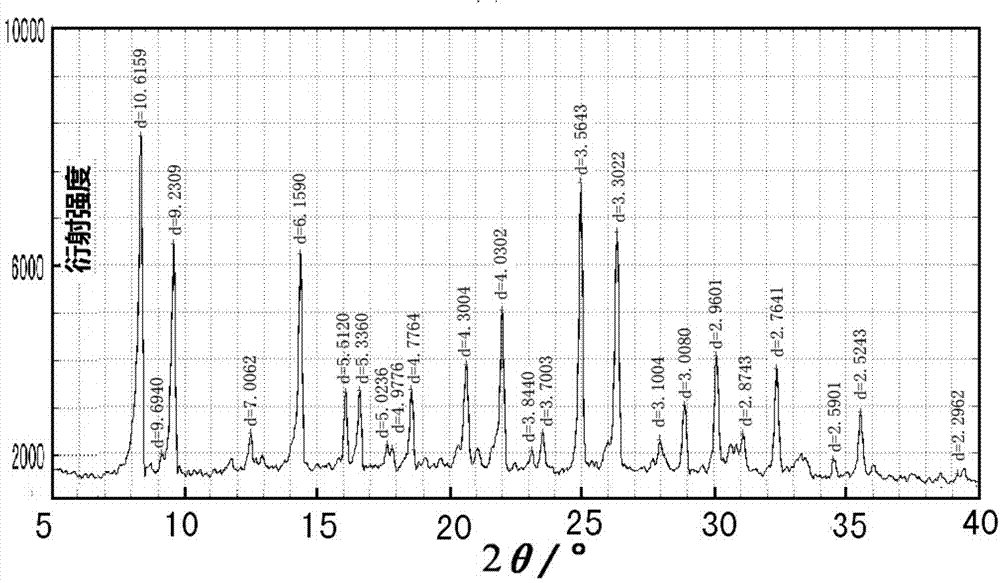

Crystal form F of ibrutinib and preparation method

InactiveCN105646498AImprove stabilityHigh purityOrganic active ingredientsOrganic chemistry methodsSolubilitySolvent

The invention discloses a crystal form F of ibrutinib. The crystal form F is characterized in that X-ray powder diffraction (X-RPD) which adopts Cu-Kalpha radiation and is represented with a 2theta angle has diffraction peaks in positions at angles of 3.7 degrees plus or minus 0.2 degrees, 6.7 degrees plus or minus 0.2 degrees, 13.2 degrees plus or minus 0.2 degrees, 16.1 degrees plus or minus 0.2 degrees, 19.1 degrees plus or minus 0.2 degrees, 20.0 degrees plus or minus 0.2 degrees, 23.8 degrees plus or minus 0.2 degrees and 24.6 degrees plus or minus 0.2 degrees. Related solvents in a preparation process of the crystal form F are cheap, the conditions are mild, the operation is simple, good controllability and reproducibility are realized, further, the prepared crystal form has great stability, the HPLC (high performance liquid chromatography) purity is higher than 99%, and the phenomenon of crystal transformation can be avoided; besides, the solubility is high, the dissolubility is good, and the bioavailability is high.

Owner:孙霖

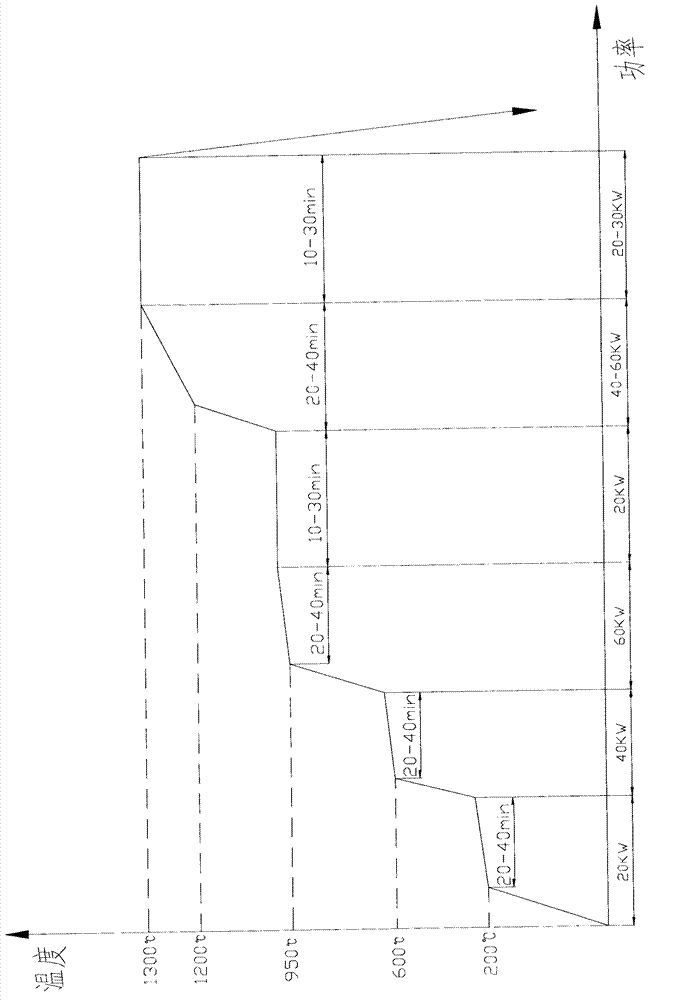

Method for preparing artificial rutile by microwave heating and oxidation sintering

The invention relates to a method for manufacturing artificial rutile, and belongs to the technical field of metallurgy preparation. High titanium slag is used as a raw material, which is broken into pieces and heated by a microwave at the controlled temperature of 850-950 DEG C for 20-40 minutes, cooled to room temperature; thereby the artificial rutile is achieved of TiO2 with a grade of over 90 wt percent. Low-valent titanium in high tiranium slag is oxidized through oxidation calcination to realize the concentration of titanium components; thereby the rutile phase grows and roughens. Meanwhile, since the activity of the mineral surface of the high titanium slag can be enhanced by the microwave heating, the crystal transformation of TiO2 can be realized in relatively low temperature, and desulfuration and the decarburization can be realized.

Owner:KUNMING UNIV OF SCI & TECH

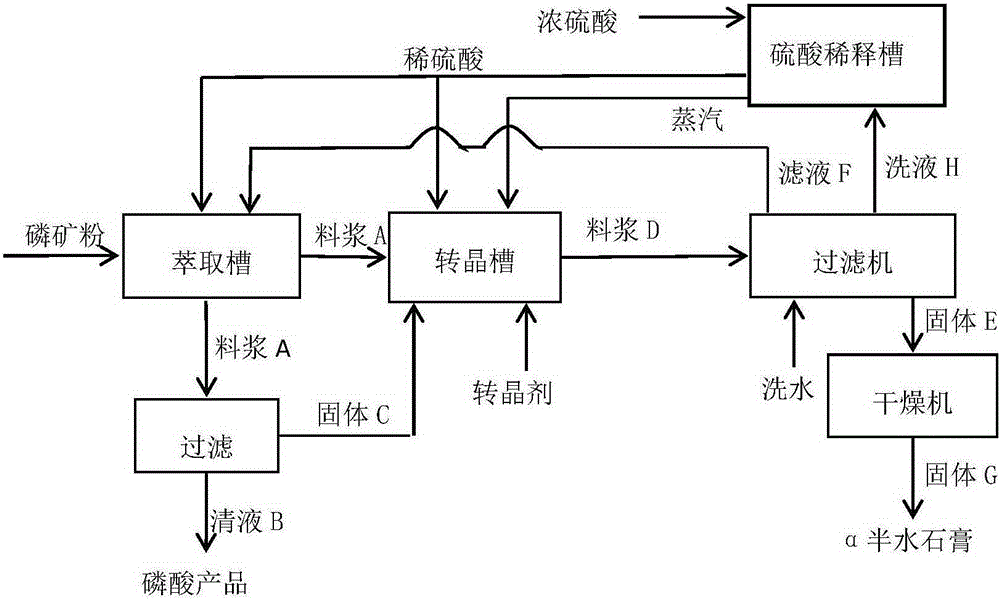

Production method for by-product alpha-hemihydrate gypsum of wet-process phosphoric acid

ActiveCN105253867ACrystalline form does not changeForm won't changeCalcium/strontium/barium sulfatesPhosphorus compoundsPhosphatePhosphoric acid

The invention discloses a production method for a by-product alpha-hemihydrate gypsum of wet-process phosphoric acid. The method comprises the following steps: adding ground phosphate rock and a part of dilute sulfuric acid into an extraction tank, carrying out an extraction reaction, separating a clear liquid from obtained mixed slurry, using the clear liquid as a finished product phosphoric acid, sending the phosphoric acid into an acid pool, and transferring a separated solid and residual mixed slurry into a crystal transformation tank together; adding sulfuric acid and a crystal transformation agent into the crystal transformation tank, carrying out a crystal transformation reaction at 60 to 130 DEG C for 1.5 to 7.5 h, subjecting obtained mixed acid slurry to solid-liquid separation, and subjecting the obtained solid to drying so as to obtain gypsum powder or adding water into the solid without drying so as to prepare gypsum products like gypsum boards, gypsum building blocks and gypsum members. The production method provided by the invention improves traditional technology and the prior art, eliminates discharge of phosphogypsum and acid non-soluble substances, reduces the content of phosphorus in gypsum, improves the utilization rate of phosphorus, makes full use of dilution heat of concentrated sulfuric acid and realizes energy saving and emission reduction.

Owner:贵州正磷科技有限公司

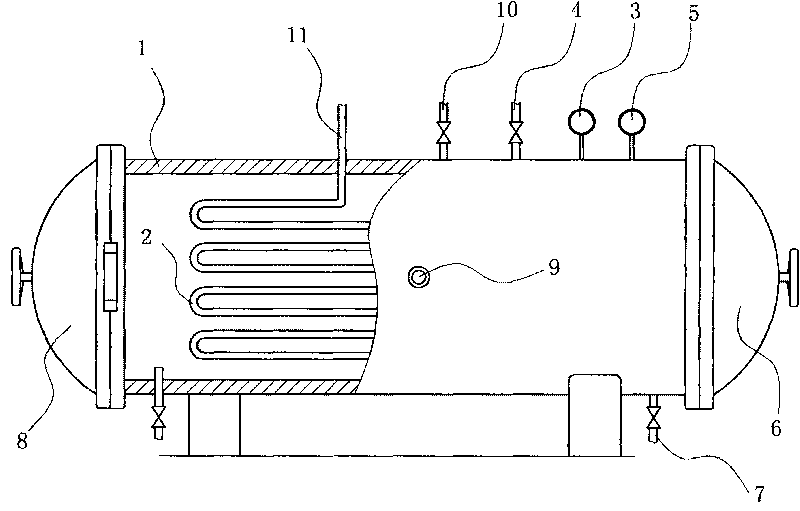

Alpha-type semi-hydrated gypsum autoclave and production method thereof

The invention discloses an alpha-type semi-hydrated gypsum autoclave, which comprises a horizontal autoclave body. The horizontal autoclave body is provided with a feed end cover and a discharge end cover. A cavity wall of a cavity of the horizontal autoclave body is provided with a hot oil heating device. The hot oil heating device is connected to the outside of the horizontal autoclave body by a heat-transfer oil tube. The horizontal autoclave body is also provided with a steam inlet, a steam outlet and a water outlet. The Alpha-type semi-hydrated gypsum autoclave is used and double heat sources of heat-transfer oil and steam are adopted to heat to carry out dehydration; gypsum ore is arranged in the horizontal autoclave body, and then the steam is injected into the horizontal autoclave body from the steam inlet; the temperature of the steam is kept between 120 degree C to 170 degree C; the pressure is between 0.3MPa to 0.7MPa; simultaneously the heated heat-transfer oil is pumped in the heat-transfer oil tube under the hermetic condition; the temperature of the heat-transfer oil is kept between 170 degree C to 220 degree C; the heat-transfer oil and the steam are used for heating for 5 to 8 hours to complete producing semi-hydrated gypsum. As the Alpha-type semi-hydrated gypsum autoclave is used and double heat sources of the heat-transfer oil and the steam are adopted for heating, the gypsum has rapid and excellent crystal transformation in the crystal transformation process, and the product has the advantages of rapid water filtration, high intensity and excellent toughness.

Owner:孙恩光

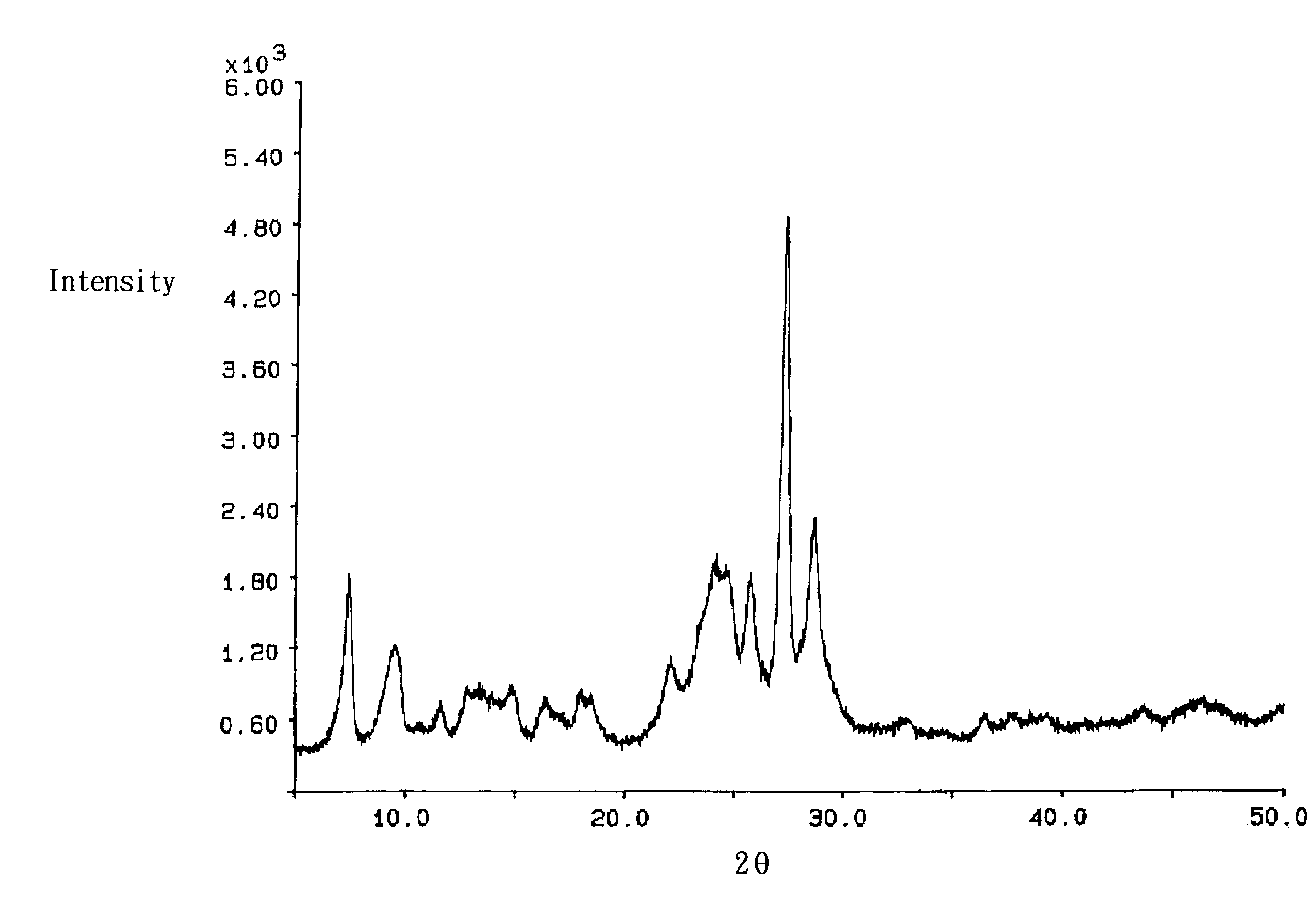

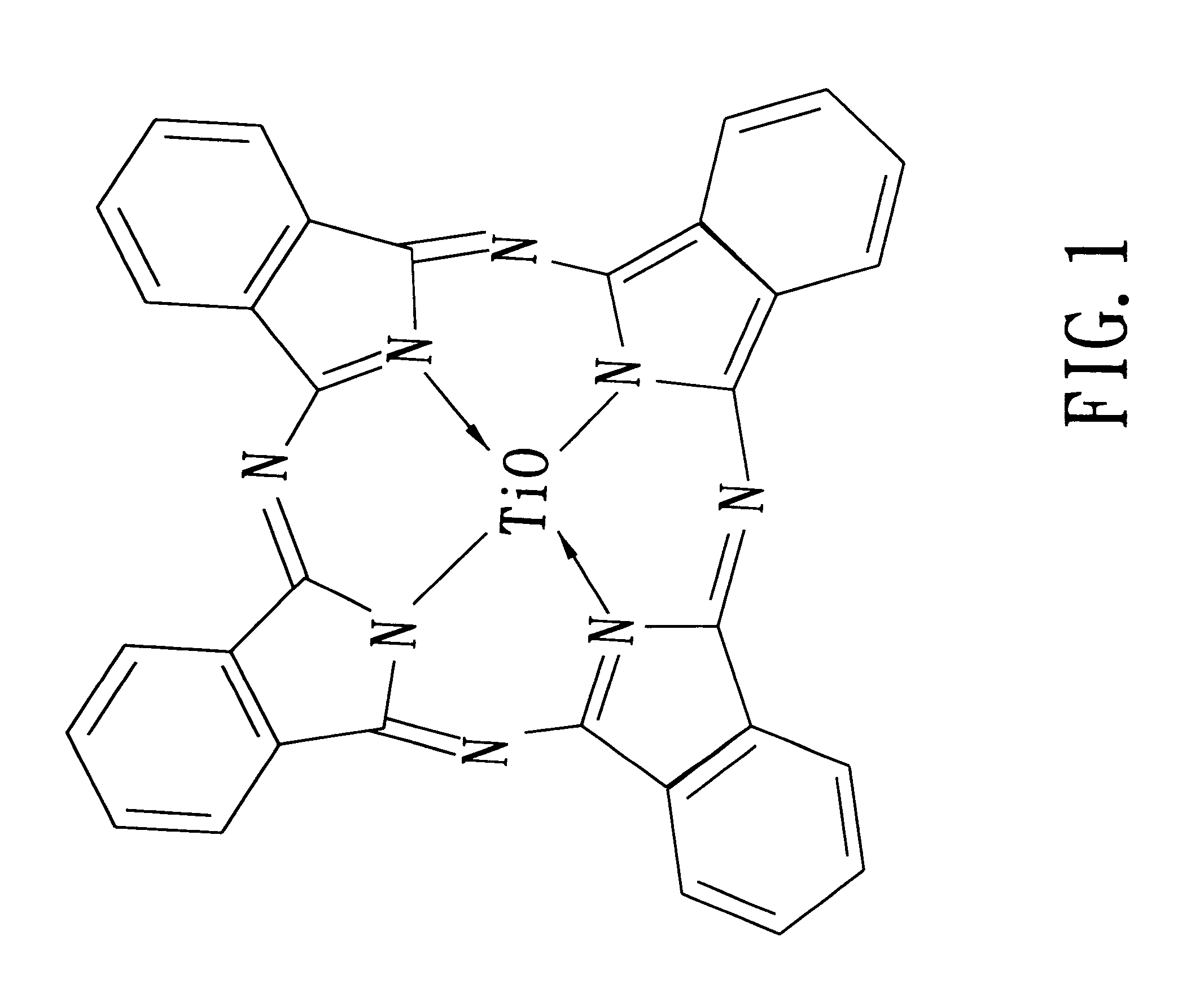

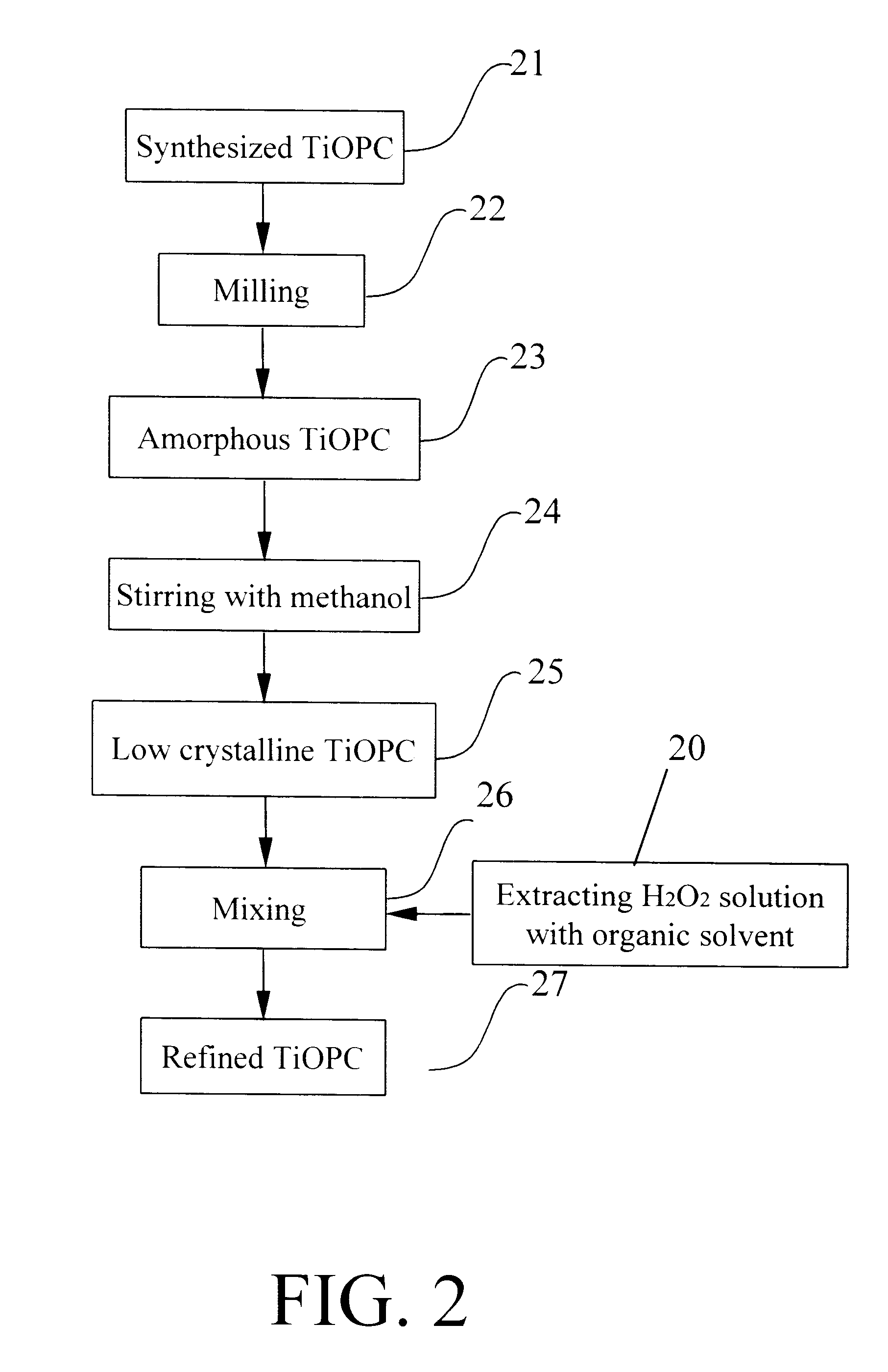

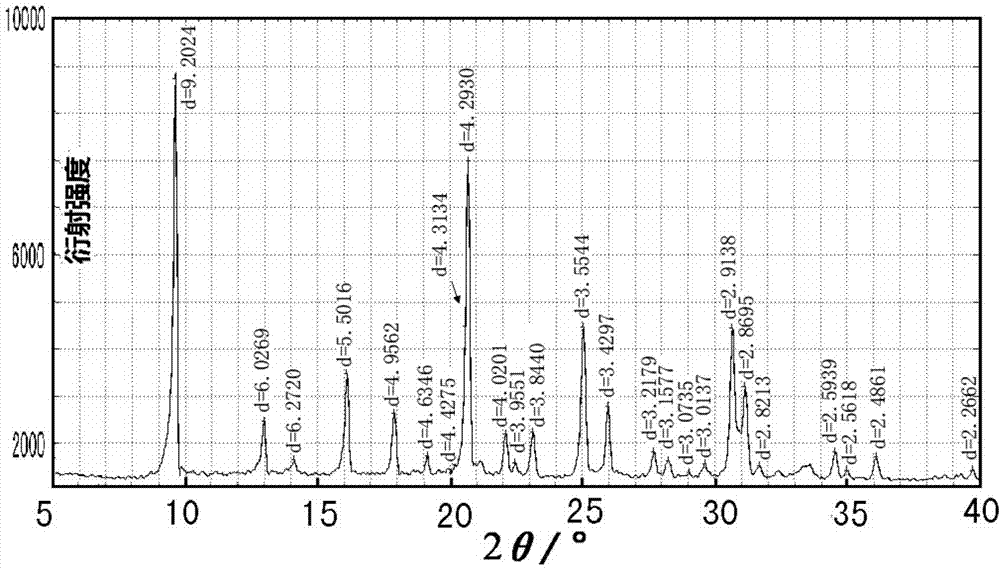

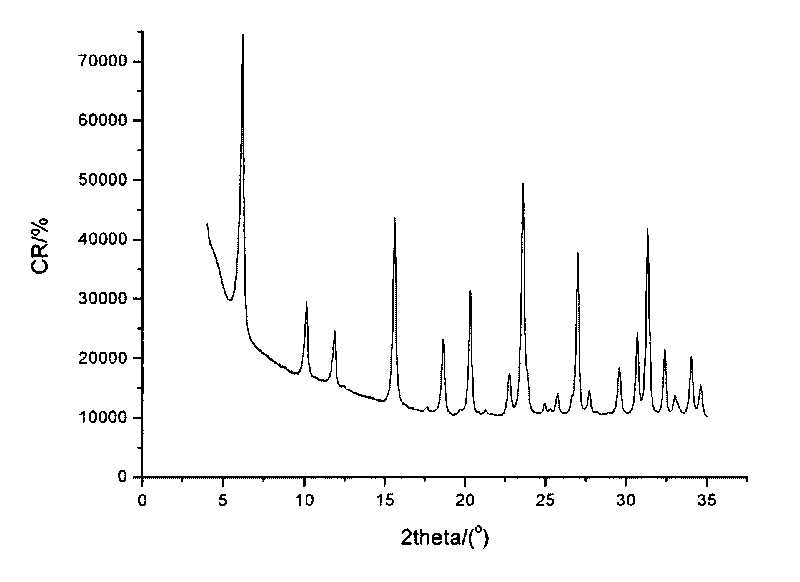

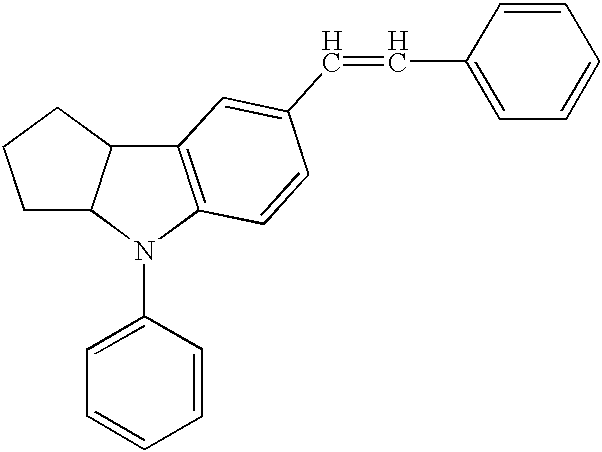

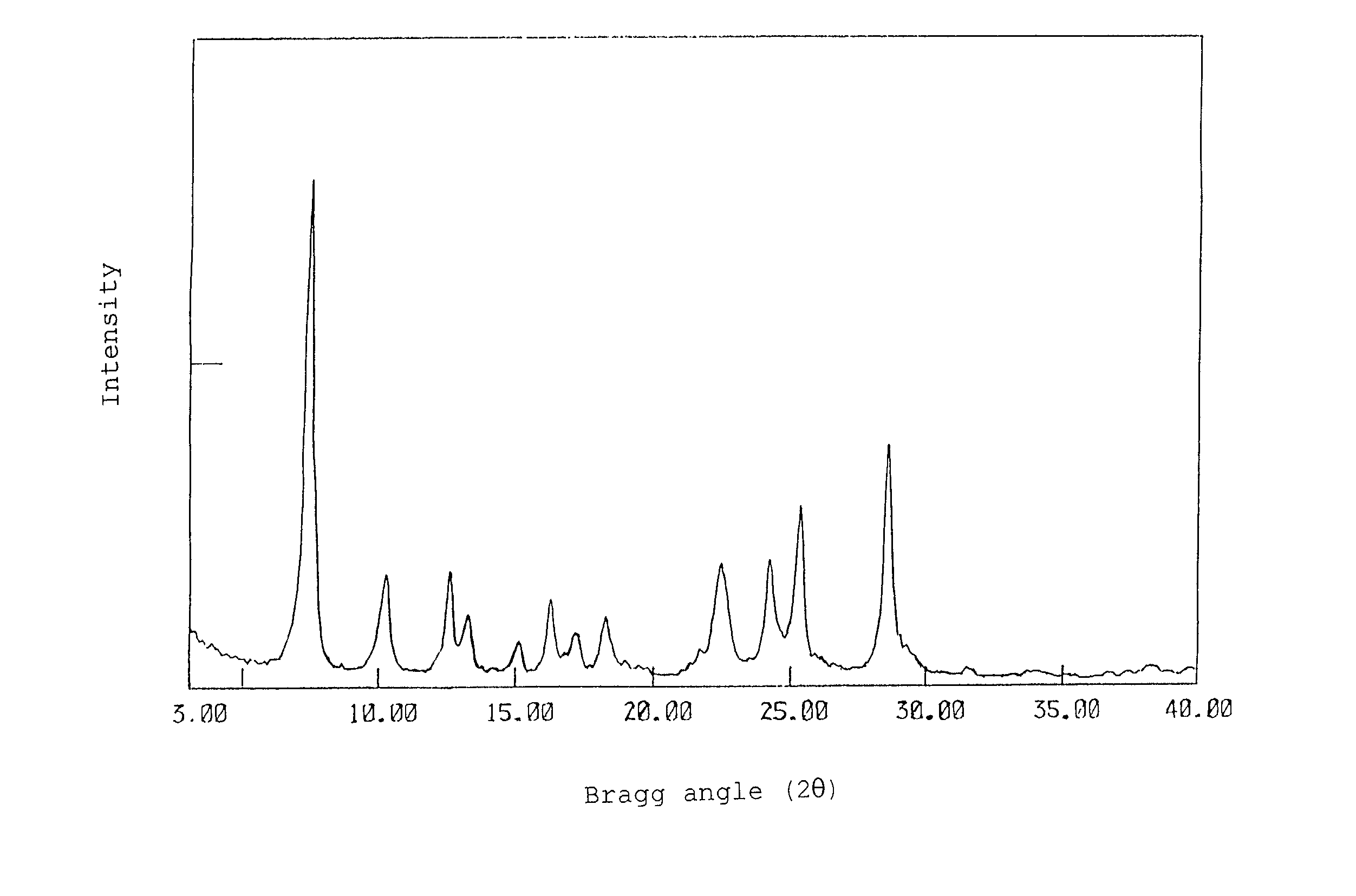

Titanyl phthalocyanine, method for production thereof and electrophotographic photoreceptor containing the same

InactiveUS6284420B1Increase photosensitivityPromote absorptionPorphines/azaporphinesElectrographic process apparatusResonancePhthalocyanine

A peroxide-modified titanyl phthalocyanine for use in preparing charge generating layer of a photoreceptor is disclosed. The peroxide-modified titanyl phthalocyanine is obtained by subjecting titanyl phthalocyanine to a peroxide-induced complexation-mediated crystal transformation at a low temperature. The peroxide-modified titanyl phthalocyanine is characterized by having Bragg diffraction angles of 7.3, 9.4, 14.0, 24.1, 25.7, 27.2 and 28.5 degrees, and vibrational absorption resonances at 1486 cm (superscript: -1), 1420 cm (superscript: -1), 1134 cm (superscript: -1), 1078 cm (superscript: -1), 966 cm (superscript: -1), 900 cm (superscript: -1), 762 cm (superscript: -1) and 736 cm (superscript: -1). The photoreceptor exhibits excellent photosensitivity at wavelengths in the near-infrared range and has a unique crystal form, especially the peroxide-modified titanyl phthalocyanine shows a higher distinct absorption peak at the wavelength of 780 nm.

Owner:TAIWAN SALT INDAL CORP +1

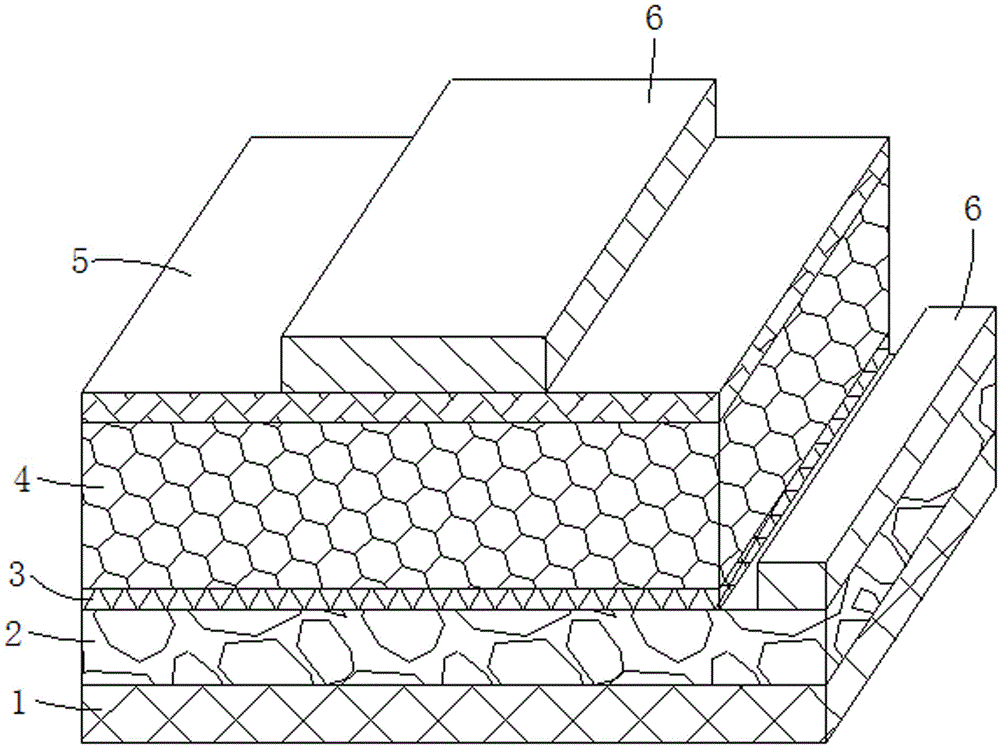

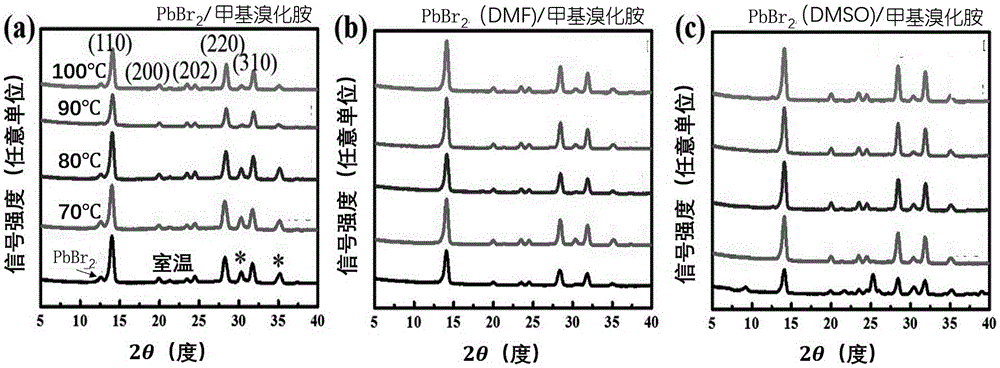

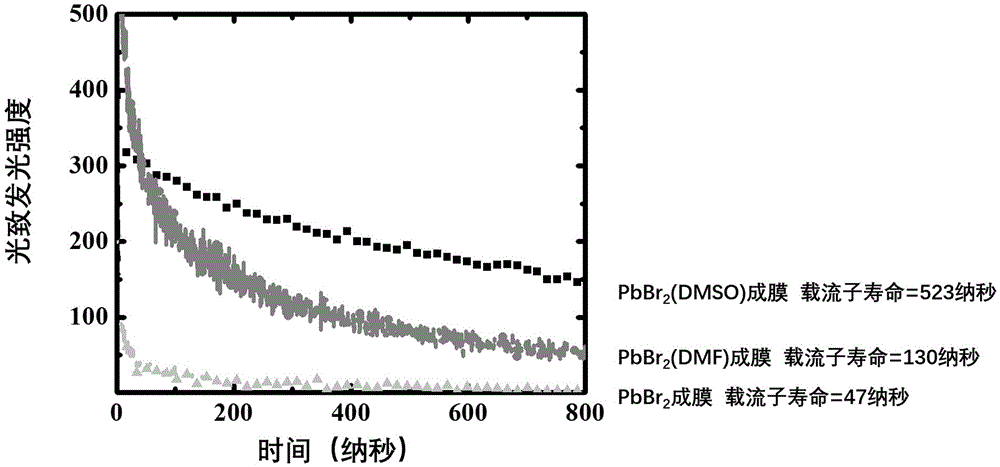

Perovskite material based light-emitting diode and preparation method therefor

ActiveCN105609652ASimple processSave raw materialsSolid-state devicesSemiconductor/solid-state device manufacturingN dimethylformamideSurface layer

Owner:HANGZHOU MICROQUANTA SEMICON CO LTD

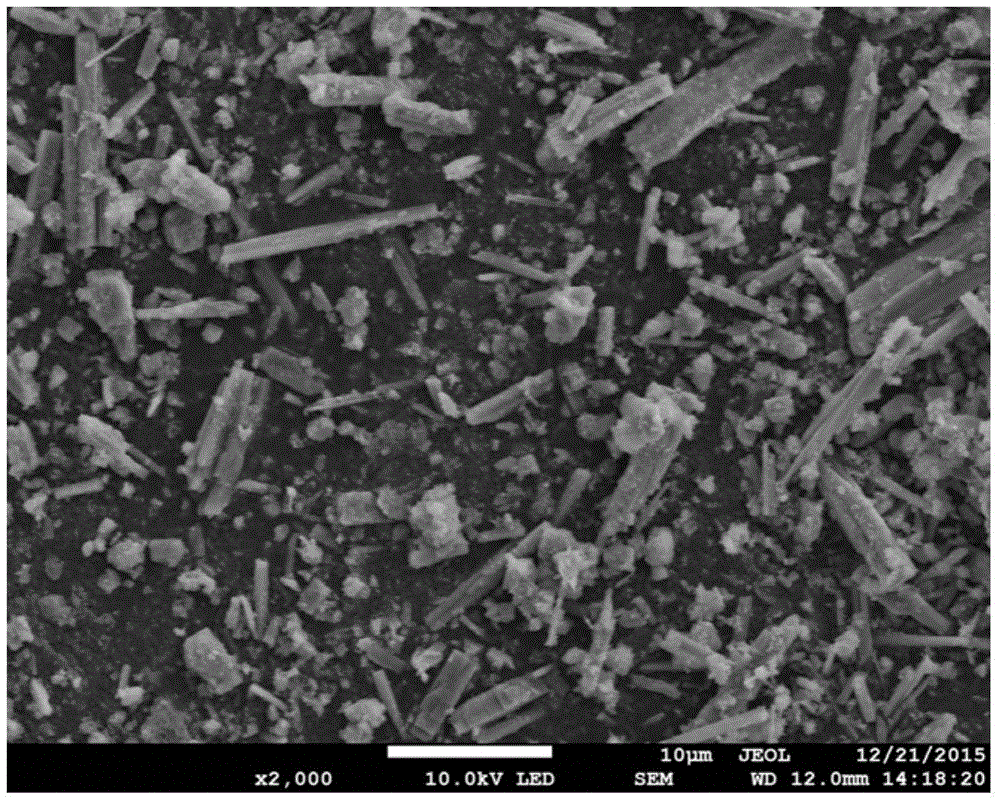

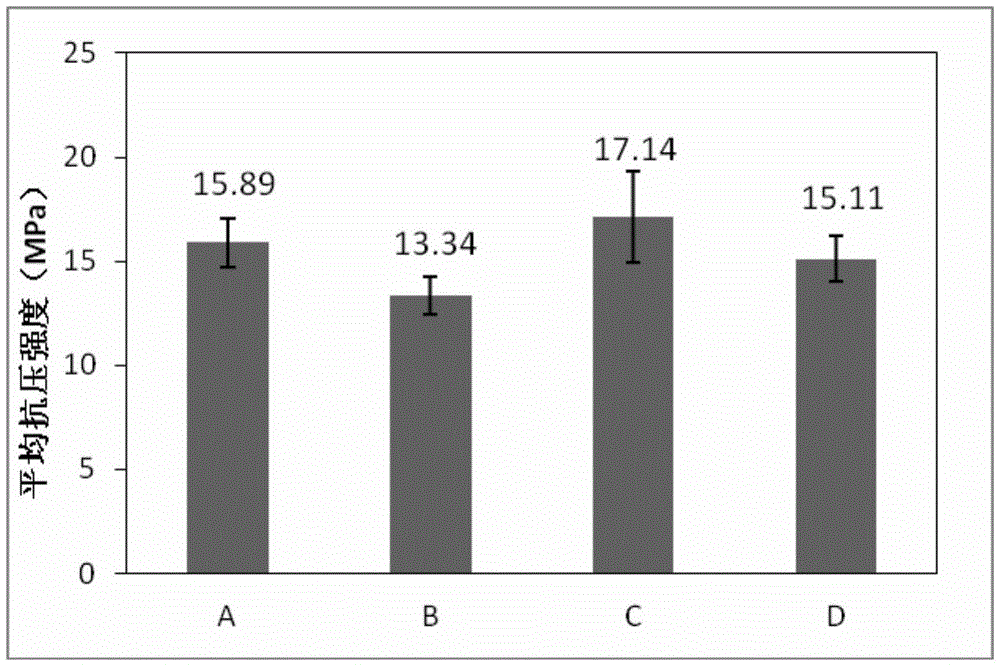

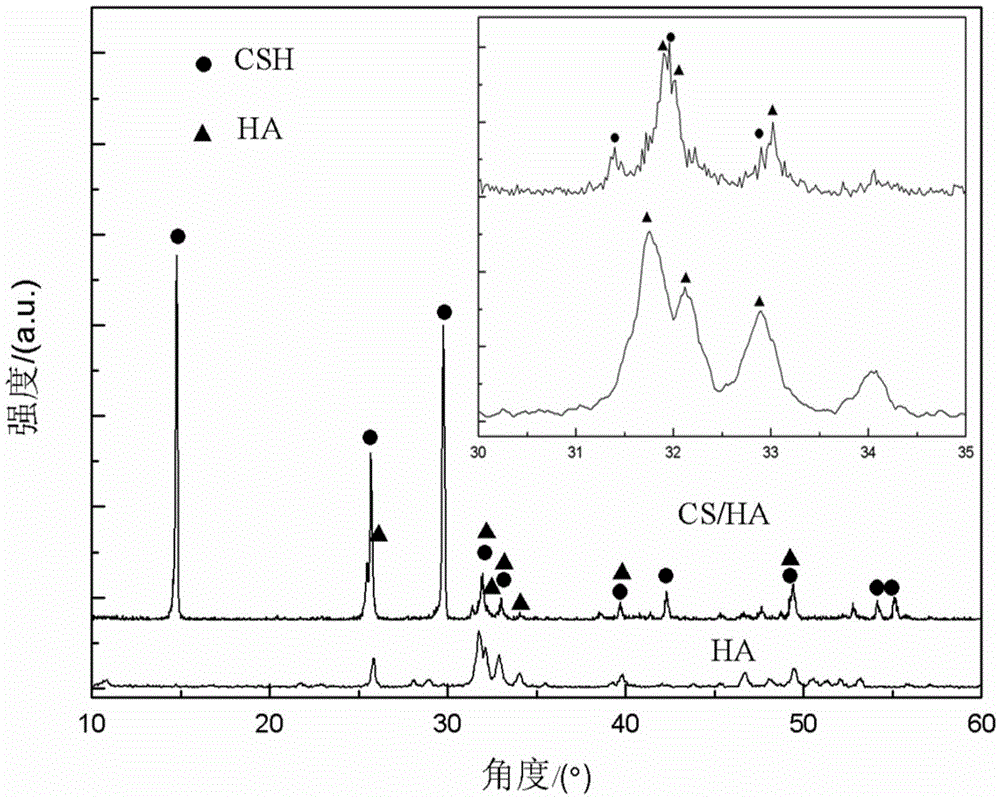

Composite bone cement and preparation method thereof

ActiveCN105536070AEasy injectionImprove mechanical propertiesTissue regenerationProsthesisMass ratioHigh pressure

The invention relates to composite bone cement for repairing bone tissues and a preparation method thereof. The bone cement is prepared from the following components in percentage by mass: 90-99.9 percent of calcium sulfate / calcium phosphate composite and 0.1-10 percent of additives. The method comprises the following steps: uniformly mixing raw materials, drying in an oven at 70 DEG C, grinding, and performing a crystal transformation reaction in a high-pressure kettle at a temperature of 120-200 DEG C and a pressure of 0.1-1MPa for 3-8 hours; after reaction, drying in an oven at 80-100 DEG C for 12 hours, and uniformly grinding to obtain bone cement powder; and weighing the bone cement powder, adding the powder into a liquid in a powder-liquid mass ratio of (1-3):1, uniformly stirring, and curing to obtain the bone cement. The prepared bone cement has the advantages of high tensile strength, good injection performance, good water scattering resistance, controllable degradation and the like, has excellent biological activity, compatibility and safety, and is used for fixing multiple bone fractures and filling bone defects.

Owner:山东明德生物医学工程有限公司

Lithium ion battery diaphragm and its production method

InactiveCN1514501AHigh crystallization conversion rateLow priceCell component detailsPorosityElectrical battery

Characters of the invention are that crystal-nucleating agent of amide family compound is added into polyolefine resin. The procedure of the method includes following steps. (1) Under computer full control, hoisting system adds polyolefine resin containing 0.001-3% crystal-nucleating agent to extruder. In temperature 130-280 deg.C, the material is melted and extruded out. Then, primal flat film is rolled and obtained by using cooling roller to treat the material at temperature 40-110 deg.C. (2) The said primal flat film is fed into vertical and horizontal biaxial stretcher for stretch formability. Finally, heat customization is carried out. The selected crystal-nucleating agent possesses high crystal transformation ratio, and abundant source. Battery diaphragm provides features of high porosity, shapely hole shape, good intensity in both directions, and low cost. The invention can be applied to lithium cell, secondary cell or other type batteries after hydrophilic treatment.

Owner:XINXIANG ZHONGKE SCI&TECH

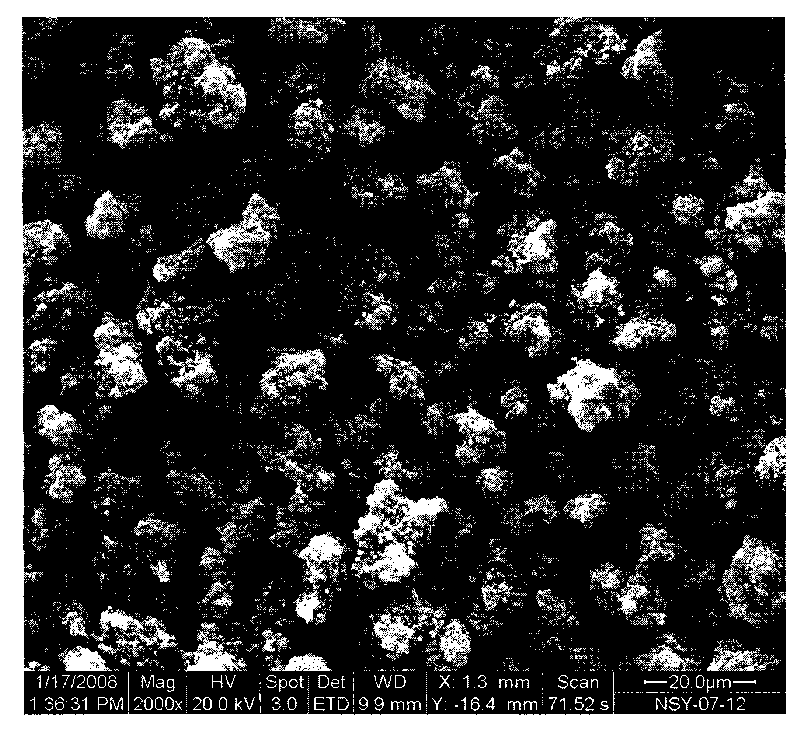

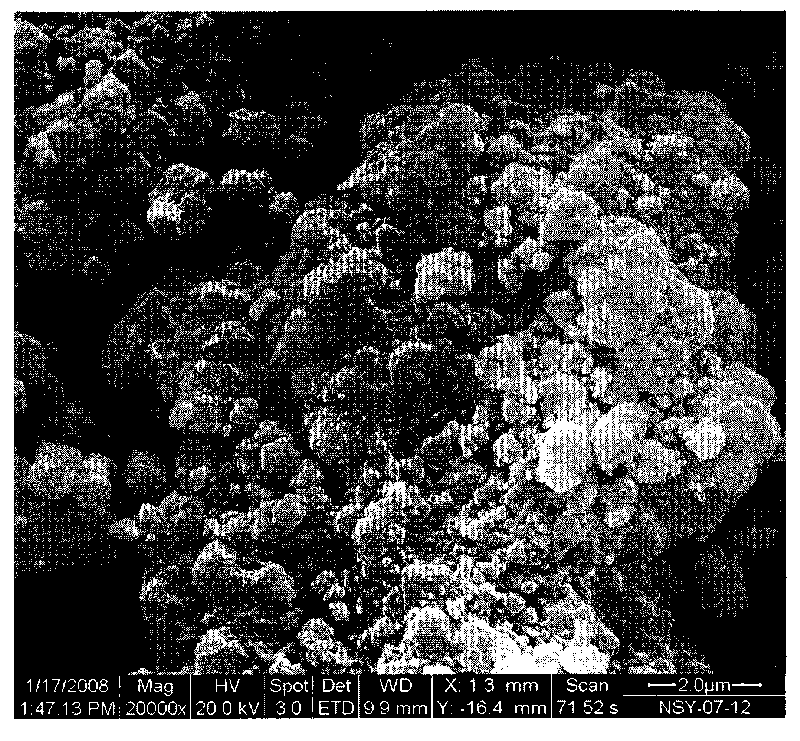

Nano-polycrystalline SAPO molecular sieve with high specific surface area, and preparation method and application thereof

InactiveCN104760975AImprove performanceNew structureMolecular sieve catalystsOther chemical processesPhosphoric acidAluminium phosphate

The invention belongs to the technical field of zeolite molecular sieve materials, and concretely relates to a nano-polycrystalline SAPO molecular sieve with a high specific surface area, and a preparation method and an application thereof. The nano-polycrystalline SAPO molecular sieve with a high specific surface area is a CHA structure type or RHO structure type or CHA structure and RHO structure eutectic silicoaluminophosphate (SAPO) molecular sieve, is synthesized through a gas and solid phase crystal transformation reaction of a amorphous silica alumina phosphorus oxide dry glue in steam of a water and diethylamine mixed template, and is especially suitable for catalyzing adsorbing separation of micro-molecular gases from low carbon olefins prepared from methanol.

Owner:SHANGHAI FUYU NEW MATERIAL TECH

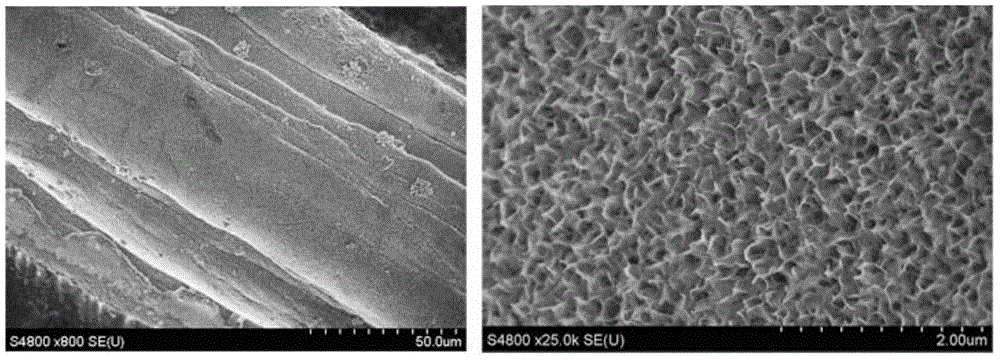

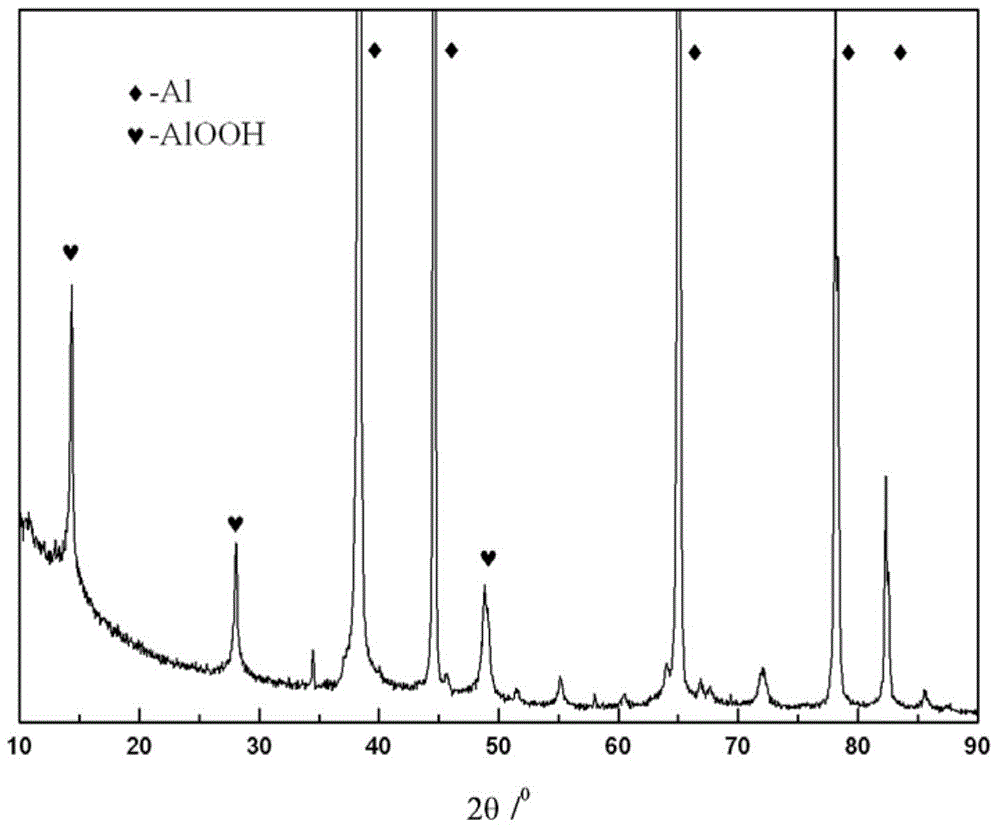

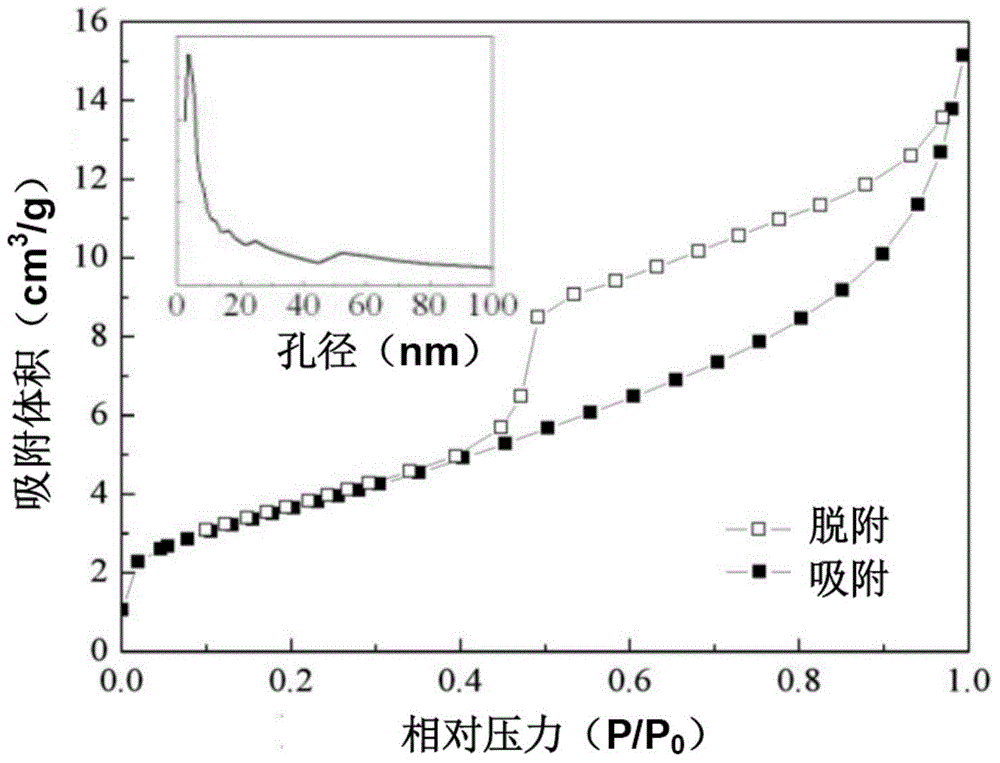

Aluminum matrix-mesoporous alumina composite material and preparation method and application of aluminum matrix-mesoporous alumina composite material

ActiveCN104148040AImprove thermal conductivityImprove permeabilityHydrogenCatalyst carriersAlumina compositePore diameter

The invention discloses an aluminum matrix-mesoporous alumina composite material and a preparation method and application of the aluminum matrix-mesoporous alumina composite material. The composite material consists of an aluminum matrix and a mesoporous alumina layer growing on the surface of the aluminum matrix, wherein the mass percent of mesoporous alumina is 0.05-50%, and the most probable pore diameter of a mesopore is 2-20nanometers. The preparation method of the composite material comprises the following steps: firstly, carrying out in-situ growth on pseudo-boehmite on the surface of the aluminum matrix via the reaction of aluminum and water under a hydrothermal condition, and then carrying out high-temperature roasting and crystal transformation on the generated pseudo-boehmite. The composite material provided by the invention has the advantages of good heat conductivity, high permeability, easiness in forming, filling and storage, and the like, is an ideal catalyst carrier, and can be used for preparing a catalyst loading activity metal or activity metal and auxiliary metal oxides as the catalyst carrier.

Owner:易高卓新节能技术(上海)有限公司

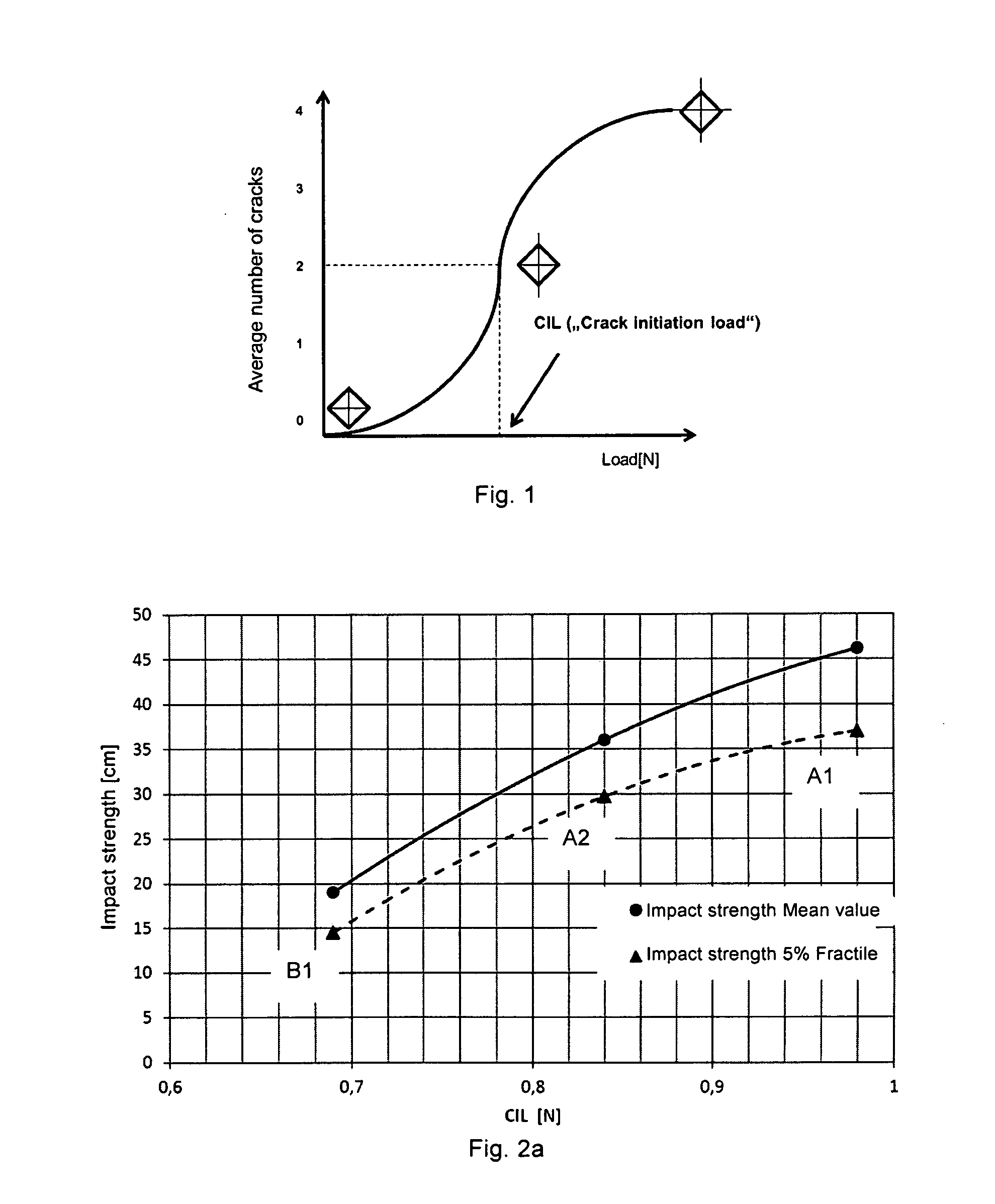

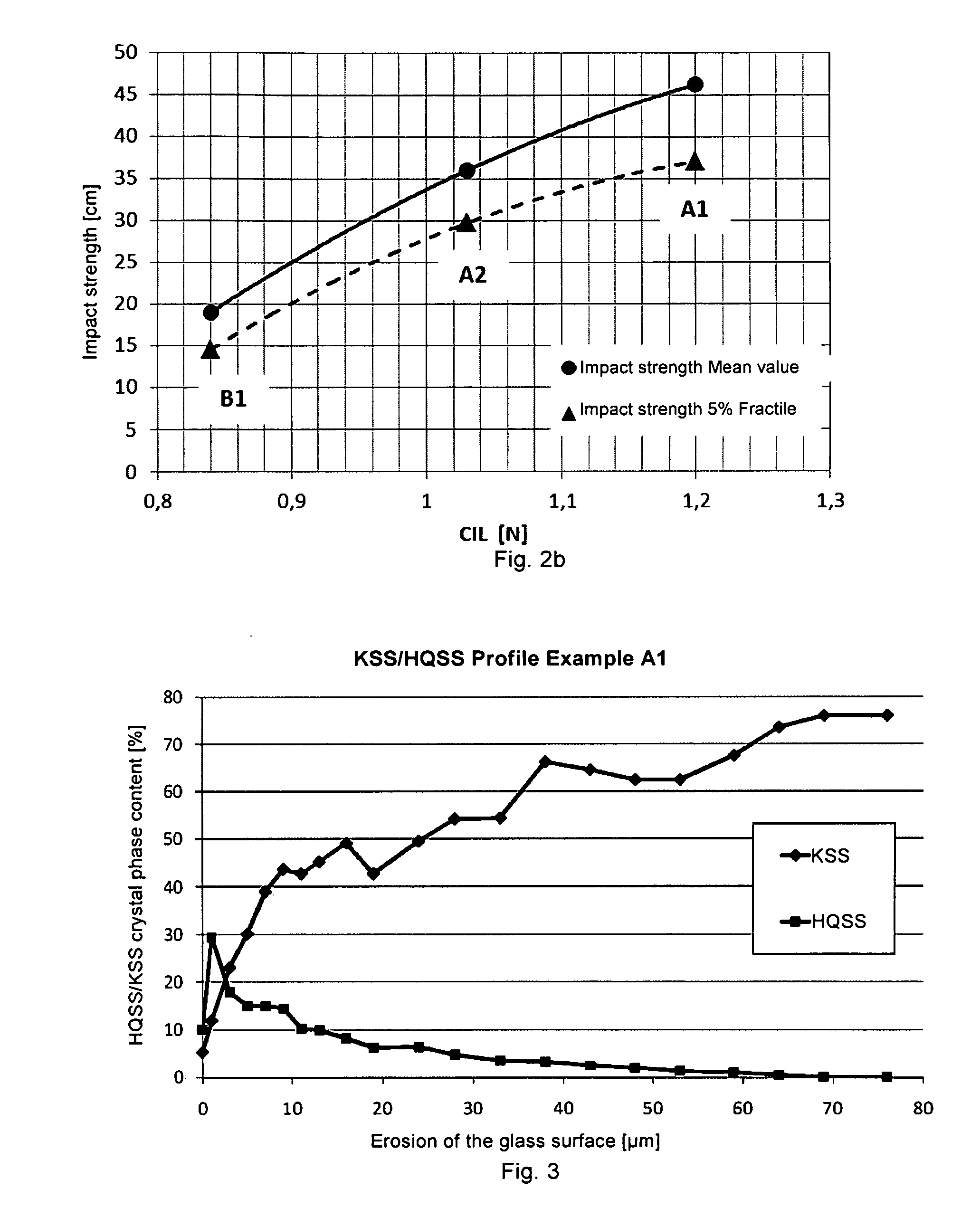

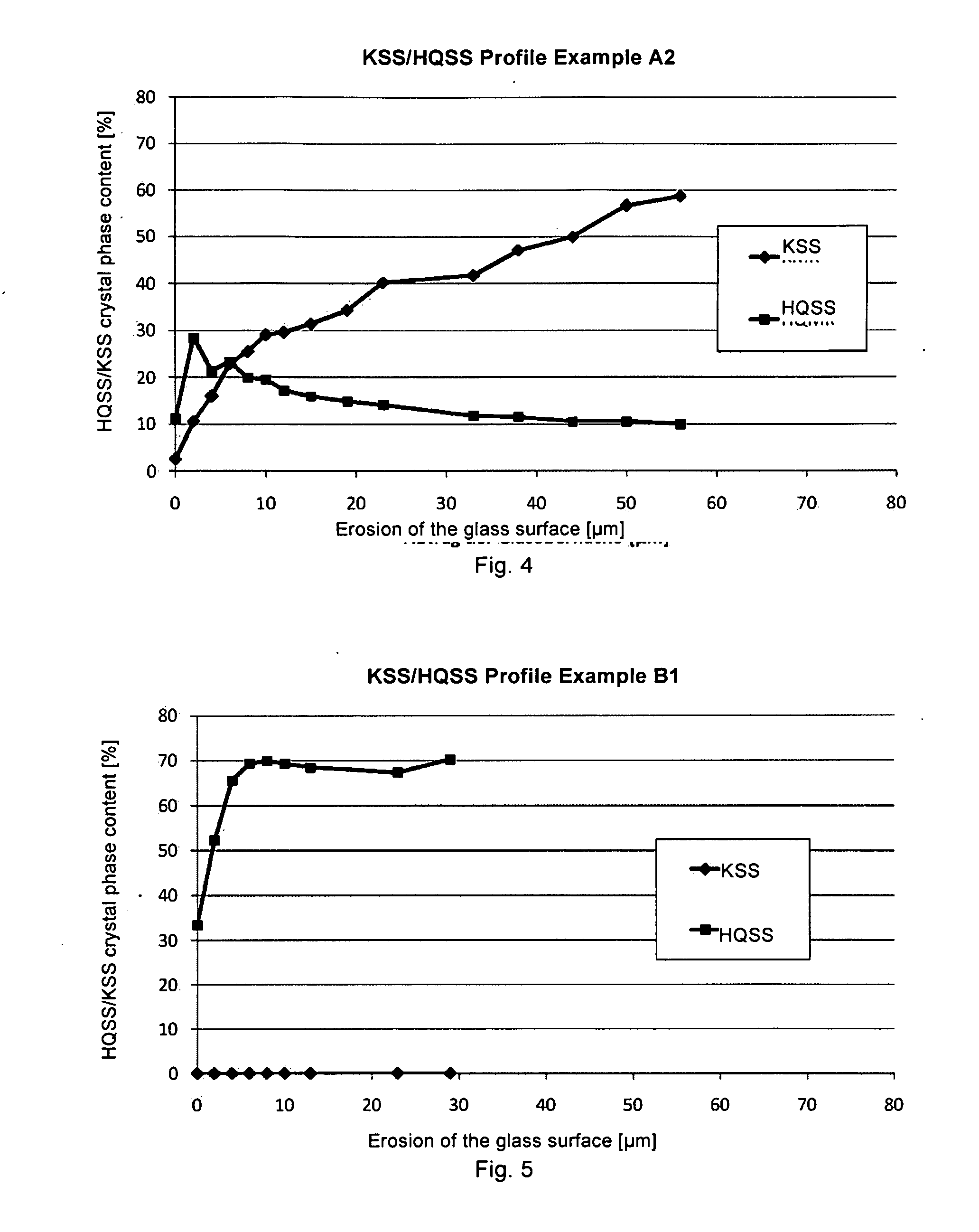

Glass ceramic substrate made of a transparent, colored LAS glass ceramic and method for producing it

A glass ceramic substrate made of a transparent, colored LAS glass ceramic is provided. The glass ceramic has a gradient layer with keatite solid solution and an underlying core with high-quartz solid solution as predominant crystal phase. The keatite solid solution in a depth of 10 μm or greater exceeds 50% of the sum of the high-quartz solid solution proportion and keatite solid solution proportion. The ceramization includes a crystal transformation step, in which the high-quartz solid solution is transformed at a maximum temperature in the range of 910° to 980° and a time period of between 1 and 25 minutes in part into the keatite solid solution.

Owner:SCHOTT AG

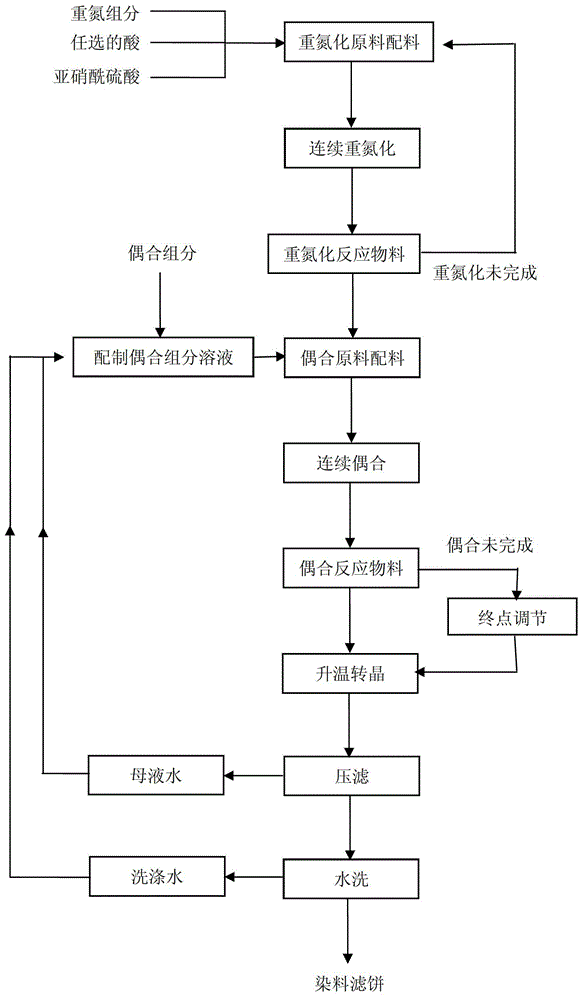

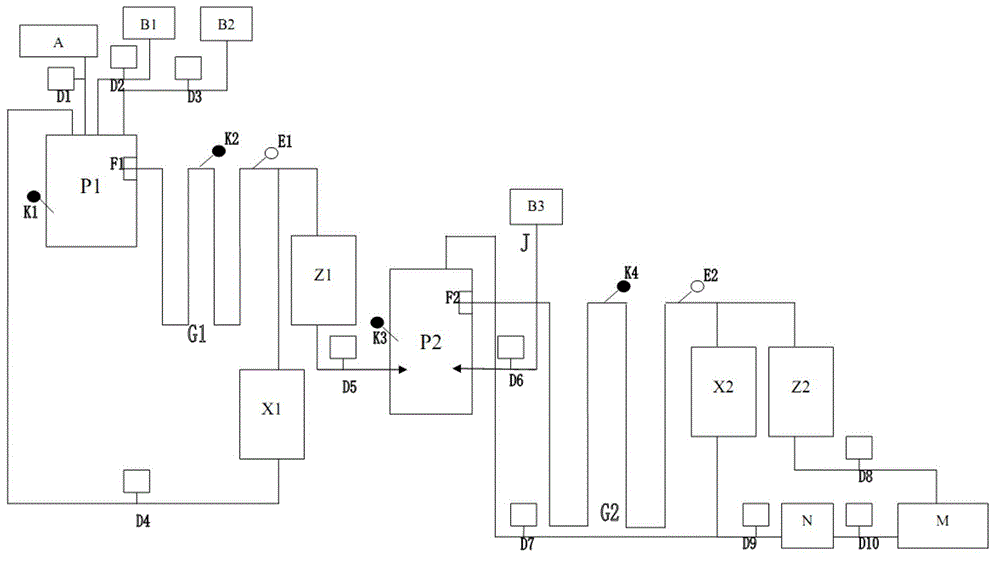

Method and device for continuously producing dyes

ActiveCN103146221ARealize automatic continuous productionThree wastes are produced lessMonoazo dyesWash waterReaction temperature

The invention discloses a method and a device for continuously producing dyes. The method comprises the following steps: adding diazotization reaction raw materials into an ingredient kettle, controlling temperature in the kettle, allowing the materials to flow in a tubular reactor through an overflow orifice, detecting the reaction state through an online detection device, continuously discharging the diazotization compound solution obtained through the reaction, continuously feeding the diazotization compound solution and a coupling component solution according to a specified ratio, allowing the materials to flow into the tubular reactor through the overflow orifice, detecting the reaction state through the online detection device, transferring the coupling reaction materials into a crystal transformation kettle, performing crystal transformation, and performing filter pressing to obtain a dye filter cake, wherein the filter cake mother solution and the wash water are circulated for preparing the coupling component solution. The reaction temperature, material flow and reaction state detection device are automatically subjected to interconnected control. According to the method, automatic and continuous dye production is realized, the production capacity, the product quality and yield are improved, the labor intensity and working conditions of workers are improved, the waste water, water gas and waste residue amounts in the dye production process are greatly reduced, and circular economy and cleaner production process are realized.

Owner:ZHEJIANG DIBANG CHEM

Composite material containing double-pore structure Y-type zeolite, and preparation method thereof

ActiveCN101746778AAvoid secondary reactionsFaujasite aluminosilicate zeoliteAmorphous matrixMaterials science

The invention discloses a composite material containing double-pore structure Y-type zeolite, which is characterized in that the composite material contains NaY zeolite and the balance of amorphous matrix; based on the weight of the composite material, the NaY zeolite accounts for 40 to 85 percent; the secondary structure of the composite material is a similar sphere; the similar sphere is formed by staggering and stacking Y-type zeolite generated by crystallization andmetakaolin amorphous intermediates generated during crystal transformation, and has gaps and holes; the sphere also has nest channels inside; the particle size is 3,000 to 25,000 nm; the surface area measured by a BET method is 280 to 800 M<2> / g; the total pore volume is 0.35 to 0.45 ml / g; the pore volume of 1.7 to 300 nm middle / big holes is 0.05 to 0.150 ml / g and accounts for 20 to 35 percent of the total pore volume.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for synthesizing acetylacetone metallic compound

InactiveCN101503343AOmit washingOmit drynessPreparation of aldehyde/ketone chelatesRoom temperatureMembrane reactor

The invention provides a method for preparing acetylacetone metallic compound, comprising soluble metal salt solution and aqueous alkali are quickly mixed together through a full back-mixing liquid membrane reactor to prepare precipitation grout of hydroxide with nanometer level, the precipitation of hydroxide is not needed to be separated and directly added with acetylacetone to react at the normal temperature to obtain the acetylacetone metallic compound. The method adopts the full back-mixing liquid membrane reactor to synthesize hydroxide with nanometer level, thus shortening the reaction time between the hydroxide and the acetylacetone and improving the preparation efficiency; meanwhile, by controlling the adding quantity of alkali and the acetylacetone in the crystal-transformation process, the reaction yield is greatly improved. The preparation method is simple in technique, convenient in operation and short in reaction time, and the obtained product has the yield being more than 95%.

Owner:BEIJING UNIV OF CHEM TECH

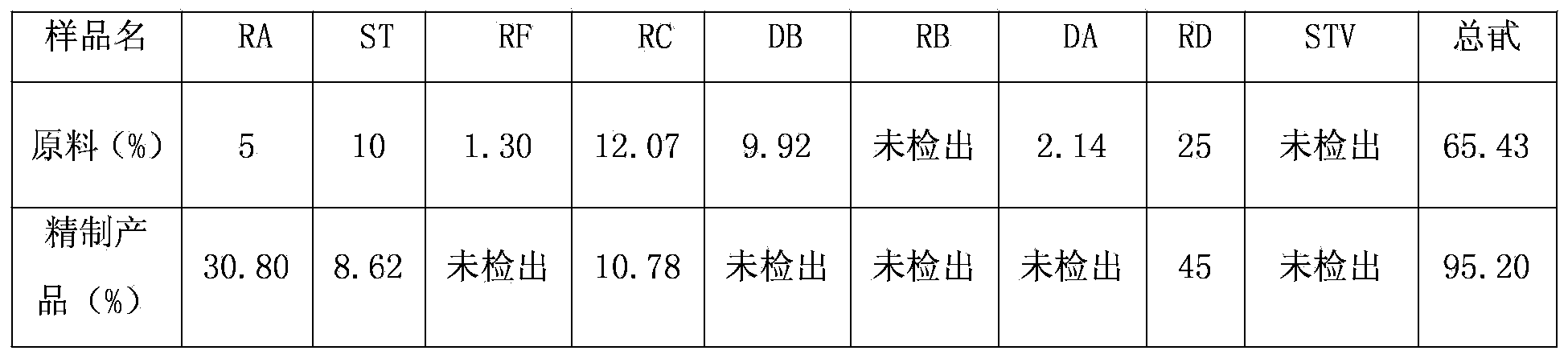

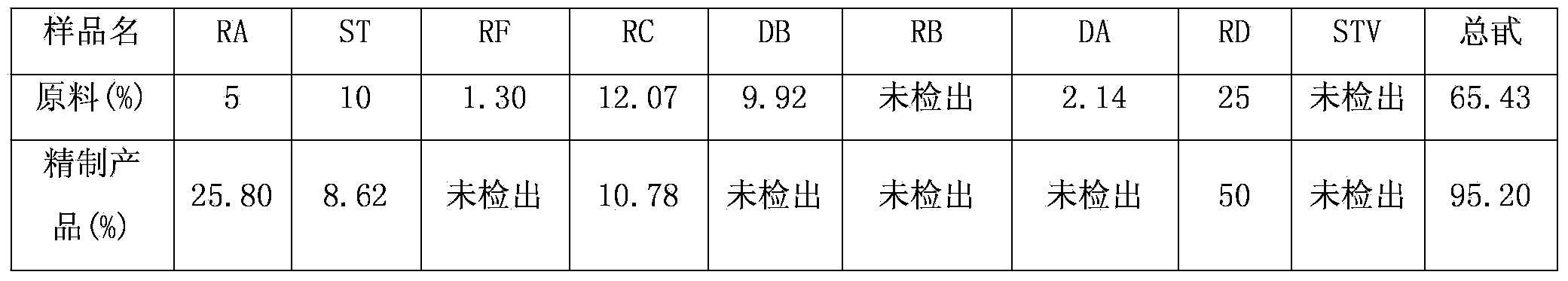

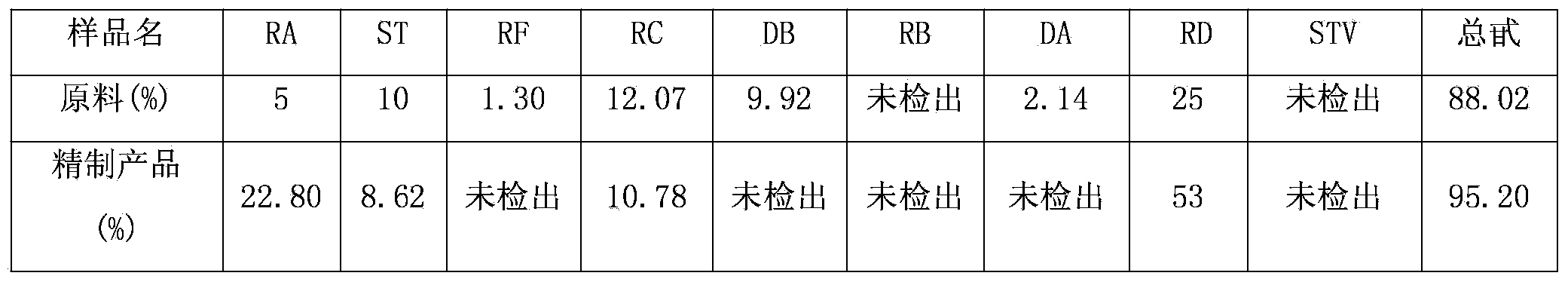

Method for extracting rebaudioside D from stevioside crystalline mother liquor sugar

ActiveCN103709215AHigh puritySimple processSugar derivativesSugar derivatives preparationRebaudioside DSolvent

The invention discloses a method for extracting rebaudioside D from stevioside crystalline mother liquor sugar, and belongs to the fields of bioengineering and novel sweetening agents. The method mainly comprises the following steps: dissolving primary crystal transformation mother liquid sugar after RA extraction into a mixed organic solvent of water and methanol with the ratio of 1:(7-10); keeping the stirring speed at 20-100rpm / min at 50-70 DEG C for 1-10 hours to crystallize; removing impurities in the mother liquor after washing a solid substance by solid-liquid separation; baking to obtain a high-purity rebaudioside D (RD) product. The ratio of the RD in the raw material sample can be improved to over 50% from 20-30% by primary crystallization, and the RD product with high purity can be obtained by repeating for a plurality of times on the basis, so that a foundation is established for production of the high-purity RD product. The method is simple in technology, low in energy consumption, and easy to produce, and is used for stirring and controlling temperature in production. The mother liquor can be recycled after being concentrated, and the solvent can be recycled after being distilled. Thus, good economic benefits and low environmental pollution are achieved.

Owner:天津北洋百川生物技术有限公司

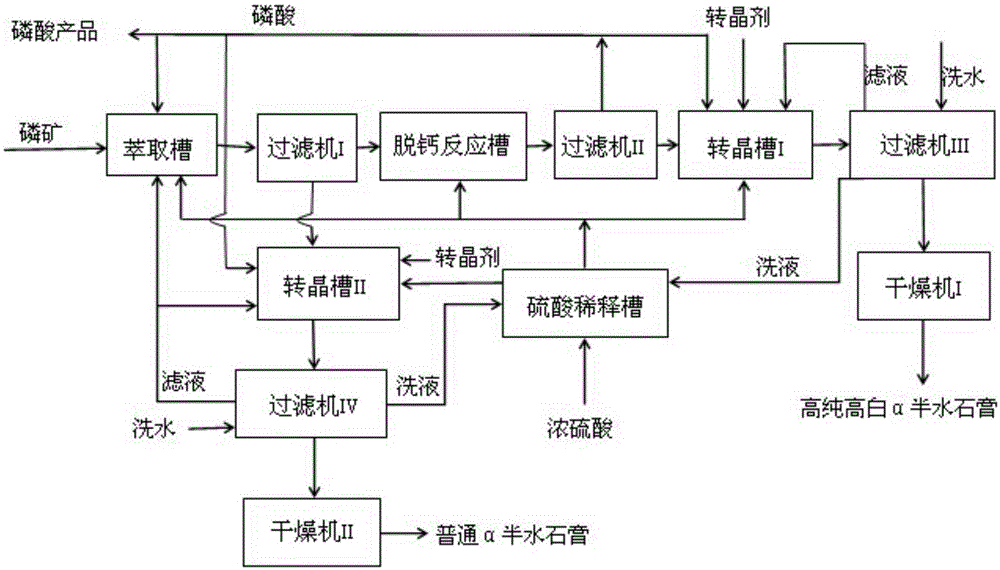

Method for production of wet process phosphoric acid and byproducts alpha-hemihydrated gypsum and high purity and high whiteness alpha-hemihydrated gypsum

ActiveCN105217590AHigh purityHigh whitenessCalcium/strontium/barium sulfatesPhosphorus compoundsPhosphoric acidMonocalcium phosphate

The invention relates to a method for production of wet process phosphoric acid and byproducts alpha-hemihydrated gypsum and high purity and high whiteness alpha-hemihydrated gypsum. The method includes: adding phosphoric acid and ground phosphate rock into an extraction tank to conduct extraction reaction, then adding sulfuric acid for further reaction to make 30%-50% of calcium ions generate dihydrate gypsum, transferring the part of dihydrate gypsum into a crystal transformation tank, adding a crystal modifier and controlling the crystal transformation conditions to obtain 30%-50% of ordinary alpha-hemihydrated gypsum, letting the other 50%-70% of calcium ions exist in the form of monocalcium phosphate in a phosphoric acid leaching solution, performing separation, then leading the phosphoric acid leaching solution into a decalcification reaction tank, adding a washing lotion diluted sulfuric acid solution, firstly performing decalcification, then controlling the crystal transformation conditions to subject the solid to crystal transformation reaction so as to generate high purity and high whiteness alpha-hemihydrated gypsum. The method provided by the invention not only reduces the content of phosphorus in the by-product alpha-hemihydrated gypsum, but also realizes industrial production of wet process phosphoric acid and the byproducts alpha-hemihydrated gypsum and high purity and high whiteness alpha-hemihydrated gypsum, thus meeting different requirements of industrial production requirements and market demands.

Owner:贵州正磷科技有限公司

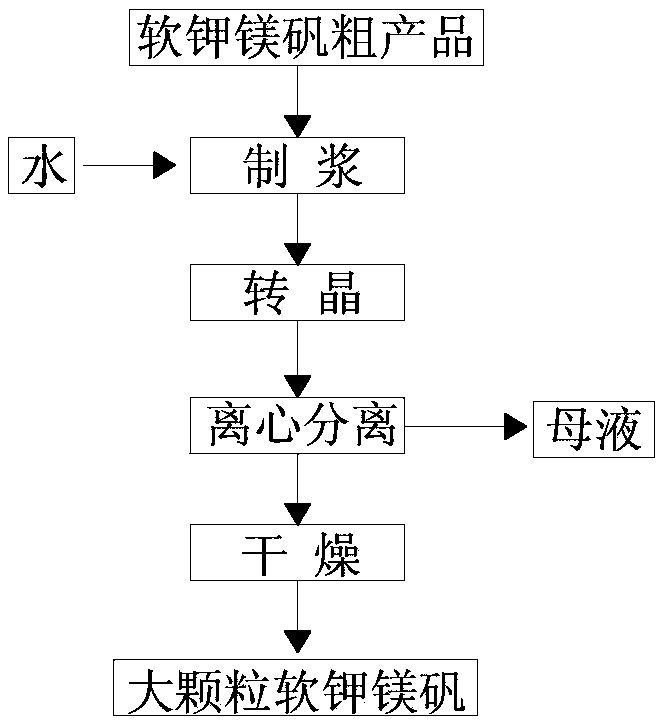

Method for preparing large-particle picromerite

The invention relates to a method for preparing a large-particle picromerite from picromerite crude product. The method comprises the following steps: taking picromerite crude product gained through flotation as raw materials, and through a crystal transformation step of reducing the temperature from 50-70 DEG C to 20-30 DEG C, enabling compound leonite with four crystal water (or langbeinite without crystal water) to be changed into compound picromerite with six crystal water. The particle diameter of the prepared large particle picromerite can reach 620.5 micrometers to the maximal extent, the problem that fine particle picromerite is not easy to separate and dry and easy to agglomerate is solved, and meanwhile the potassium ion recovery ratio in the technology can reach above 80 %.

Owner:HEBEI UNIV OF TECH +1

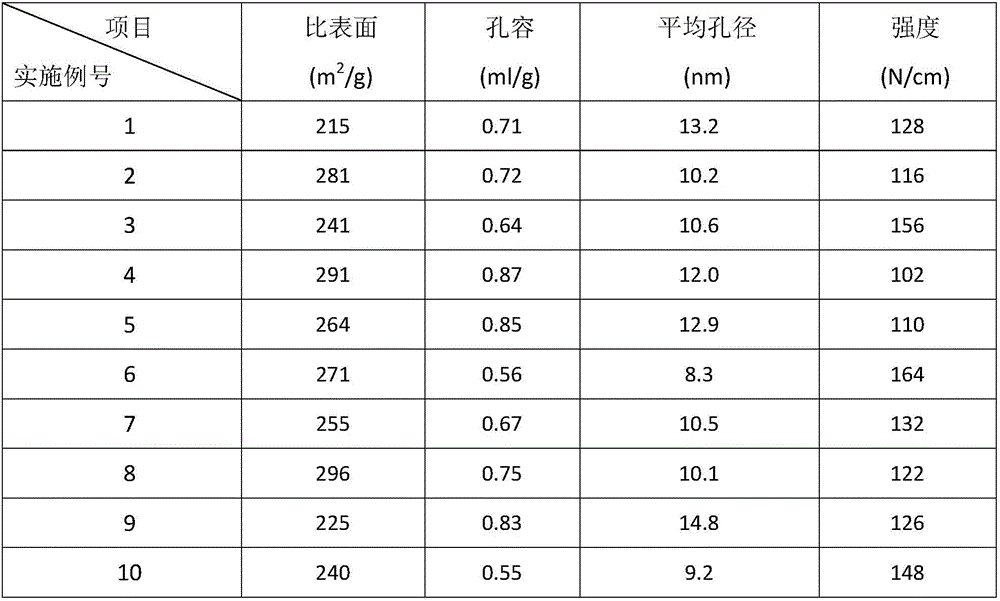

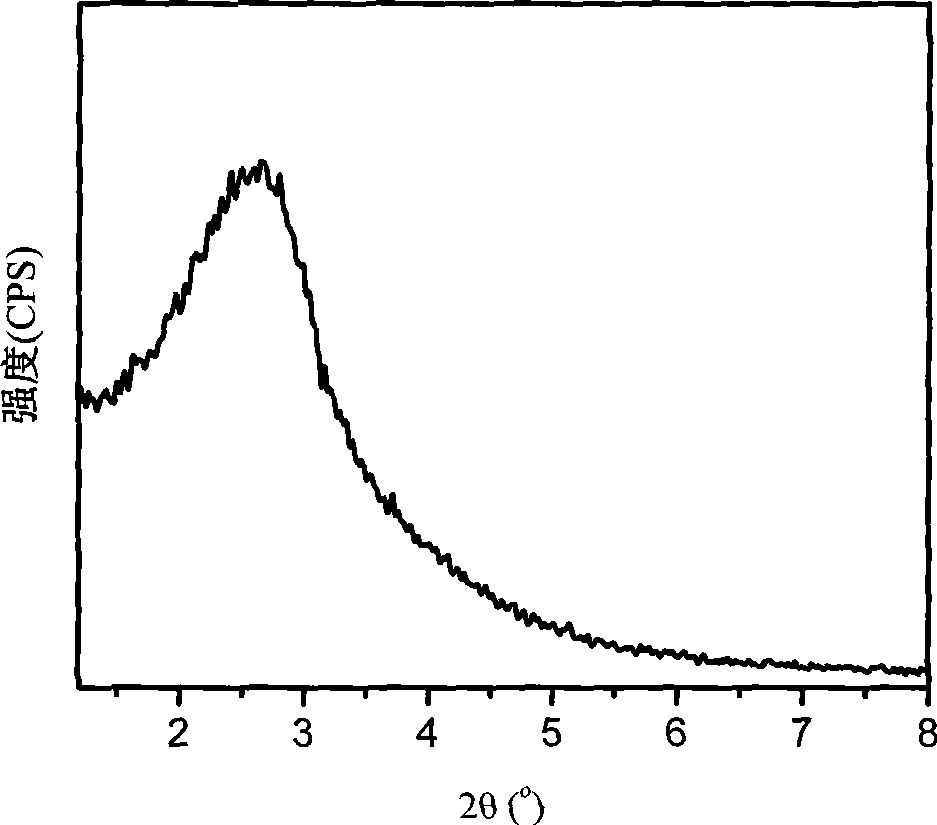

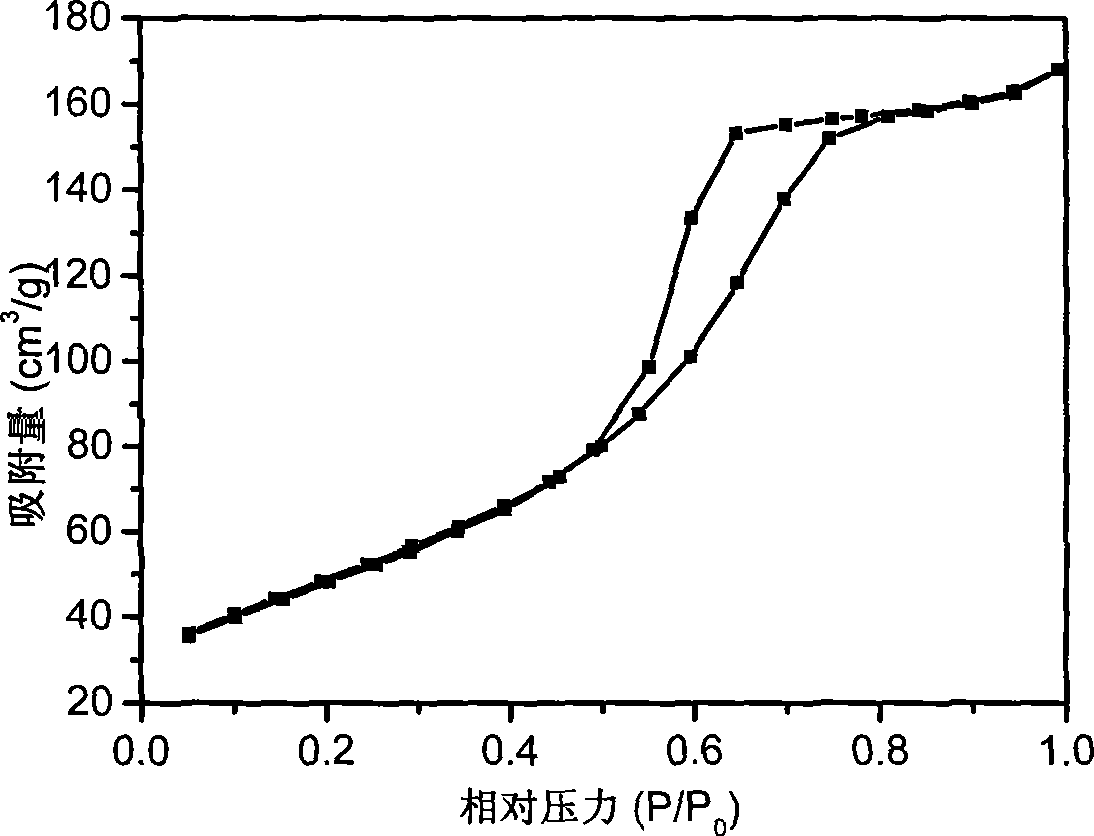

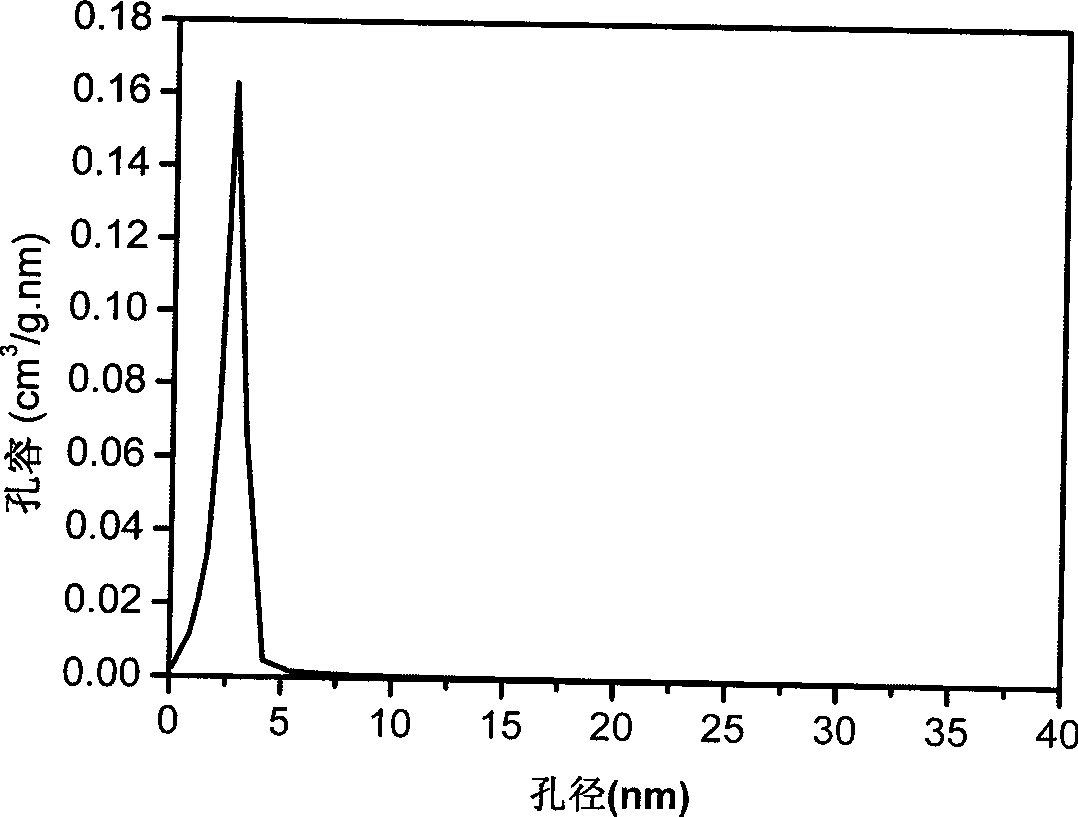

Method for preparing alumina carrier with large pore volume

ActiveCN106747591ALarge hole volumeHigh strengthCatalyst carriersCeramicwareUltimate tensile strengthNanotechnology

The invention provides a method for preparing an alumina carrier with a large pore volume. The preparation method comprises the following steps: performing solid phase crystal transformation on amorphous alumina under the action of an additive; knitting; molding; drying; sintering to obtain the alumina carrier. The alumina carrier prepared by the method has the characteristics of simple method, low water consumption, low cost, large pore volume and high mechanical strength, and is suitable for the field of various catalysts, particularly for the field of oil product hydrogenation catalysts needing large pore volumes.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Production method of gypsum board

The invention discloses a production method of a gypsum board, which comprises the following steps: adding glass fibers, a surfactant, a foaming agent and modified starch into hemihydrate gypsum slurry, uniformly agitating, forming, solidifying, cutting and drying to obtain the gypsum board. A preparation method of the hemihydrate gypsum slurry comprises the following steps: pre-heating sulfuric acid solution, adding a crystal transformation agent and a seed crystal into the sulfuric acid solution, uniformly adding calcium powder into the sulfuric acid solution and controlling the reaction temperature to obtain the hemihydrate gypsum slurry after the end of reaction. Compared with the prior art, the production method has the benefits that the hemihydrate gypsum slurry prepared by industrial waste acid as well as the calcium powder is directly used for the production of the gypsum board, the cost is reduced, the process flow is shortened, the exploitation of natural gypsum is reduced, and the production method has the advantage of low energy consumption.

Owner:LOMON BILLIONS GRP CO LTD

Monosodium glutamate production technology

The invention discloses a monosodium glutamate production technology which comprises the following steps: fermenting glutamic acid; extracting glutamic acid: a glutamic acid fermentation broth is subjected to pasteurization and two-stage ultrafiltration to obtain bacteria paste and a glutamic acid clear solution, the glutamic acid clear solution is subjected to evaporation and concentration, and is separated after continuously isoelectric cooling to obtain crystallized alpha-glutamic acid and a separated mother solution; mixing, heating and keeping warm and separating alpha-glutamic acid and a crystal transformation mother solution to obtain the glutamic acid, preparing a suspension liquid through mixing the glutamic acid and water, controlling the crystal transformation pH value to be 4.0-5.0, rising the temperature, carrying out the crystal transformation to obtain beta-glutamic acid, neutralizing with a sodium carbonate water solution, then performing activated carbon decolorizing, filtering, carrying out decoloration and iron removal on the filtrate through a granular activated carbon column, performing evaporative crystallization and centrifugal separation on the decoloring solution, drying and screening to obtain the finished product. The monosodium glutamate production technology has the advantages that the discharge of waste liquid during the monosodium glutamate production process is reduced, the consumption of chemicals is reduced, the production cost is reduced, the economic benefit is improved, and the resource recycling is facilitated.

Owner:广州奥桑味精食品有限公司

Method for preparing mesoporous titanium dioxide

The invention relates to a method for preparing mesoporous titanium dioxide, which comprises the following steps: adopting a silanes compound as a template agent; enabling the silanes compound to form silicon oxide during the calcining process; and attaching the silicon oxide onto the inner wall of a titanium dioxide pore channel. Because the crystal transformation temperature of the silicon oxide is greatly higher than that of the titanium dioxide, the silicon oxide can not be changed when the titanium dioxide carries out crystal transformation under the high temperature and crystal grains grow. Therefore, the silicon oxide can play a supporting role, thereby keeping the mesoporous structure of the titanium dioxide and improving the thermal stability of the silicon oxide.

Owner:EAST CHINA UNIV OF SCI & TECH

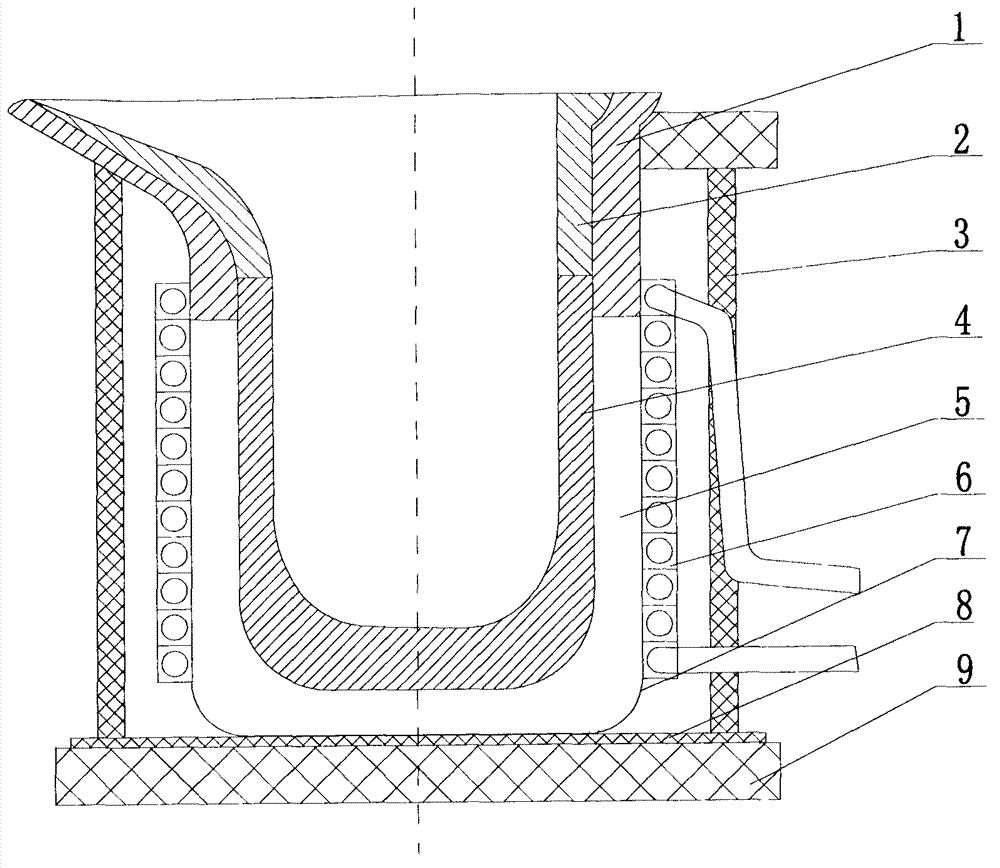

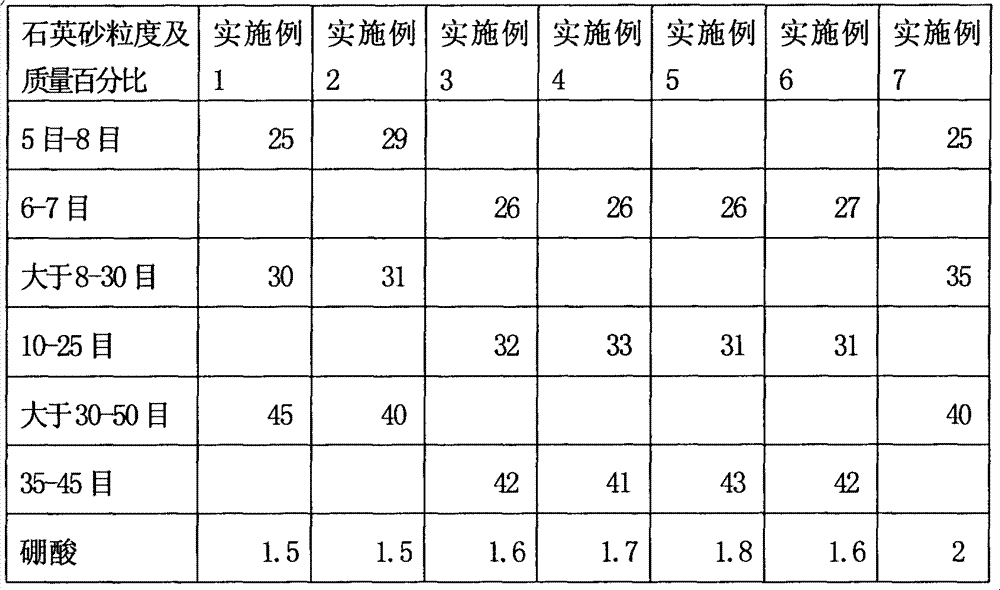

Furnace building method of intermediate-frequency induction furnace for copper alloy smelting

ActiveCN102889789AReduce adverse effectsHigh densityLinings repairIntermediate frequencyCrystal transformation

The invention relates to a furnace building method of an intermediate-frequency induction furnace for copper alloy smelting, which comprises the following steps: firstly, preparing a lining material of a furnace-body outer lining and a fire-door lute, and laying a layer of epoxy plate and placing an induction coil on an asbestos board base; laying a glass fiber fabric on the inner wall of the induction coil and the epoxy plate, so that the glass fiber fabric is formed into a pocket shape; hierarchically adding the lining material of the furnace-body outer lining into the glass fiber fabric pocket, and hierarchically tamping and knotting the obtained product so as to form a furnace bottom; then, placing a graphite crucible on the midmost position of the furnace bottom and compacting the furnace bottom; hierarchically adding the lining material of the furnace-body outer lining into a space between the glass fiber fabric bag and the graphite crucible, and tamping and knotting the lining material so as to obtain the furnace-body outer lining, so that the top surface of the furnace-body outer lining is lower than the top surface of the graphite crucible and the top surface of the induction coil; adhering a fire door to the top surface of the graphite crucible through the fire-door lute, filling the fire-door lute between the fire door and the glass fiber fabric bag, and carrying out tamping and flattened-brushing on the fire-door lute so as to obtain a fire-door outer lining; carrying out sintering on the outer lining by using an oven, so that silica has crystal transformation; and after the whole furnace is hardened, stopping heating so as to complete the furnace building. The method disclosed by the invention has the characteristics of high strength, good furnace-body combined performances and long service life.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

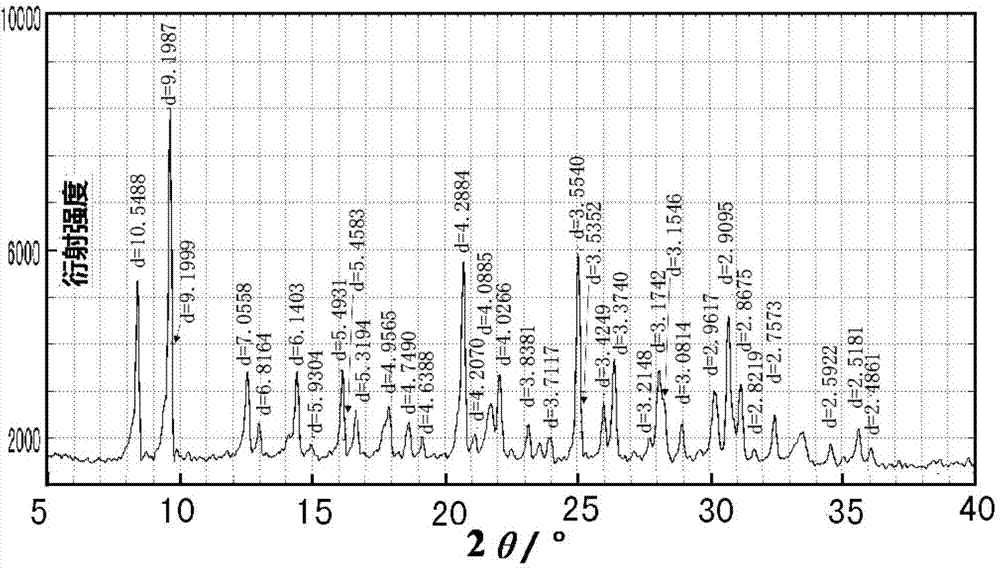

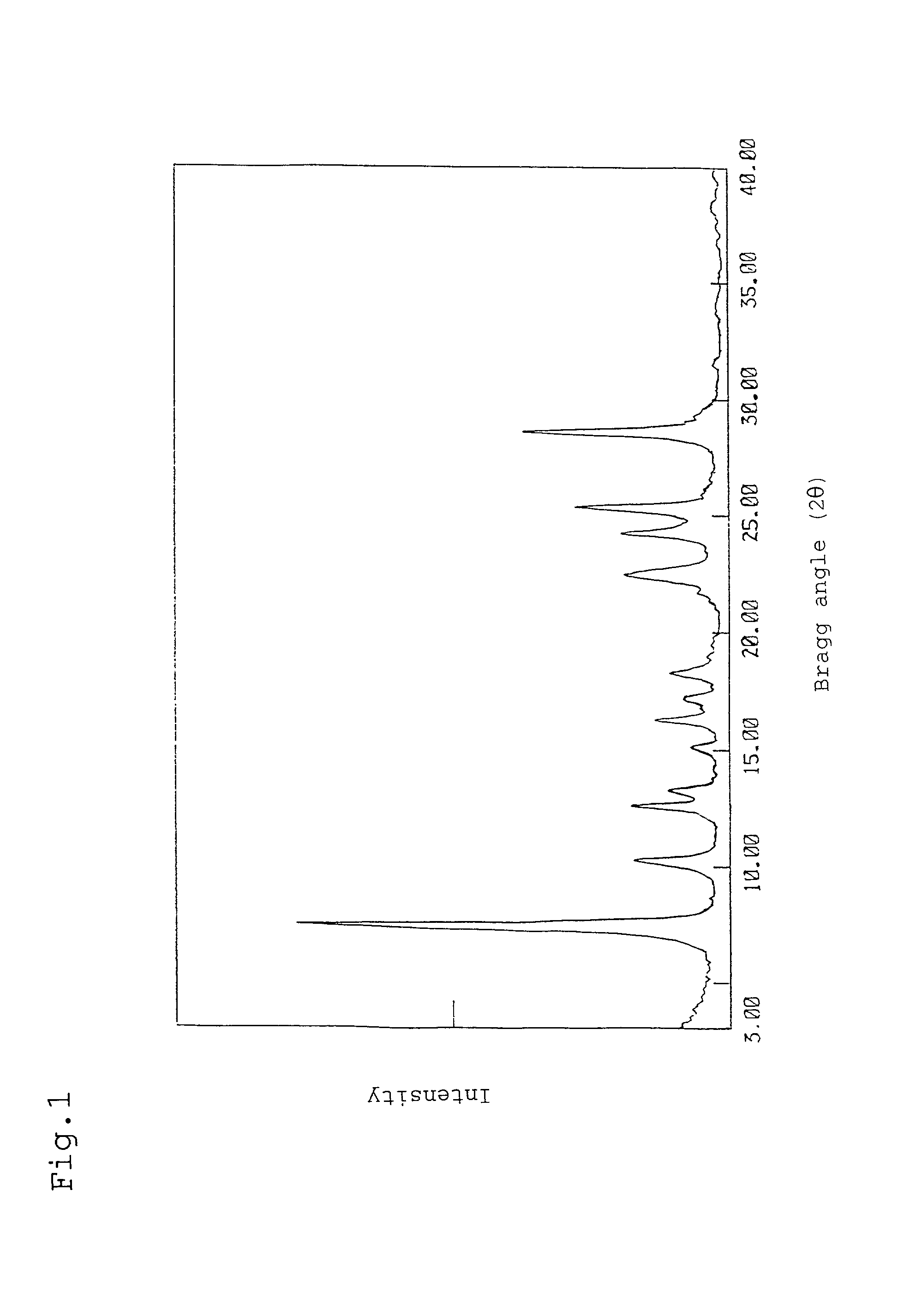

Phthalocyanine composition, process for production thereof, and electrophotographic photoreceptor

InactiveUS20020081508A1Improve performanceImprove charging effectPorphines/azaporphinesElectrographic process apparatusX-rayPhthalocyanine

Disclosed are a phthalocyanine composition suitable for use in an electrophotographic photoreceptor that exhibits a high charge potential and a high sensitivity and which exhibits stable performances without causing a change in various properties in repeated use, a process for the production thereof, and an electrophotographic photoreceptor to which the above phthalocyanine composition is applied. The present invention provides a phthalocyanine composition comprising a oxytitanium phthalocyanine and a metal-free phthalocyanine and having a crystal form having peaks at Bragg angles (2theta±0.2°) of 7.0°, 9.0°, 14.1°, 18.0°, 23.7° and 27.3°, and having no peak at a Bragg angle (2theta±0.2°) of 9.5°, in CuKalpha 1.541-angstrom X ray diffraction spectrum, a process for the production of the above phthalocyanine composition, comprising carrying out crystal transformation treatment of an amorphous oxytitanium phthalocyanine and an amorphous metal-free phthalocyanine in a solvent containing water and a naphthalene, and an electrophotographic photoreceptor comprising an electrically conductive substrate and a photosensitive layer formed thereon, the photosensitive layer containing the above phthalocyanine composition as a charge-generating material.

Owner:HODOGOYA CHEMICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com