Production method for by-product alpha-hemihydrate gypsum of wet-process phosphoric acid

A technology of hemihydrate gypsum and wet-process phosphoric acid, which is applied in chemical instruments and methods, nitric acid, phosphorus compounds, etc., can solve the problems of uncontrollable length-to-diameter ratio of α hemihydrate gypsum, application restrictions, and restrictions on high-end applications, etc., to achieve industrialization Continuous large-scale production, improve utilization rate, and solve difficult-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

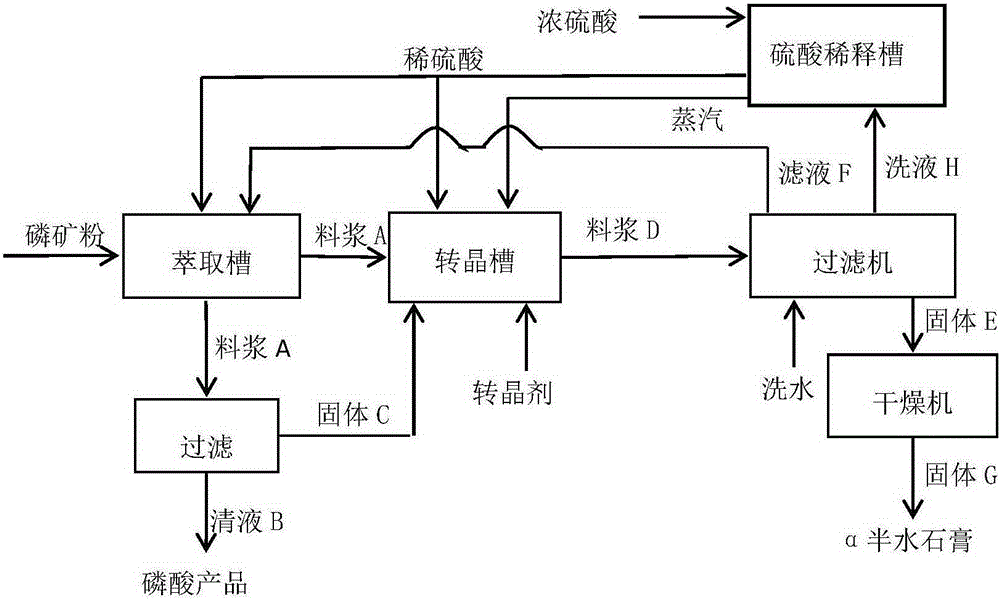

Method used

Image

Examples

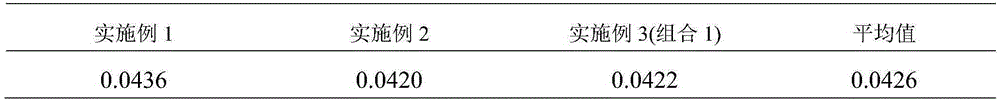

Embodiment 1

[0053] Embodiment 1. The phosphate rock is collected in Kailin, Guizhou; the content of phosphorus pentoxide in the phosphate rock is about 32%.

[0054] A kind of production method of wet-process phosphoric acid by-product α hemihydrate gypsum, the steps are as follows:

[0055] (1) First, phosphate rock powder and dilute sulfuric acid with a mass concentration of 20% are added to the extraction tank at a solid-to-liquid mass ratio of 1:4, the fineness of the phosphate rock powder is 100 mesh, and the content of phosphorus pentoxide in the phosphate rock is 32 %, under continuous stirring, the temperature of the extraction tank was controlled at 80°C for an extraction reaction for 30 minutes to obtain a mixed slurry A;

[0056] (2) Separate 1 / 6 of the volume of the mixed slurry A obtained in step (1) through a filter for solid-liquid separation to obtain clear liquid B and solid C, and the separated clear liquid B is sent to the acid storage as finished phosphoric acid , the...

Embodiment 2

[0062] Embodiment 2, the phosphate rock is collected in Lufa, Guizhou; the content of phosphorus pentoxide in the phosphate rock is 27%.

[0063] A kind of production method of wet-process phosphoric acid by-product α hemihydrate gypsum, the steps are as follows:

[0064] (1) Firstly, phosphate rock powder and dilute sulfuric acid with a mass concentration of 30% are added to the extraction tank at a solid-to-liquid mass ratio of 1:3. The fineness of the phosphate rock powder is 100 mesh, and the content of phosphorus pentoxide in the phosphate rock is 27%. , under continuous stirring, control the temperature of the extraction tank at 70°C for 50 minutes of extraction reaction to obtain a mixed slurry A;

[0065] (2) Separate 2 / 3 of the volume of the mixed slurry A obtained in step (1) through a filter for solid-liquid separation to obtain clear liquid B and solid C, and the separated clear liquid B is sent to the acid storage as finished phosphoric acid , the solid C is tran...

Embodiment 3

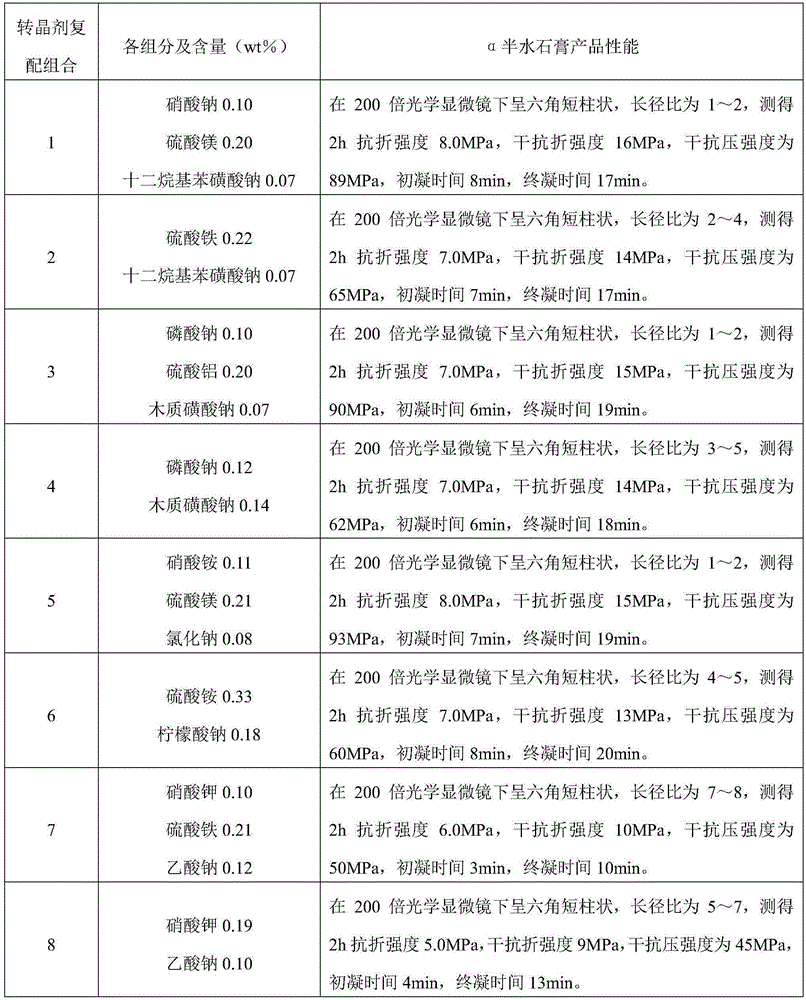

[0072] With the production method of a kind of wet-process phosphoric acid by-product α hemihydrate gypsum described in embodiment 1, the difference is that the crystal modifier component and content of use are different, as shown in table 1:

[0073] Table 1 crystal transformation agent component, content and the performance that obtains product

[0074]

[0075] It can be known from the above table that the present invention can produce gypsum powder with an aspect ratio of <10 or less. It can be seen that the shape of the α hemihydrate gypsum prepared by the present invention can be controlled, and α hemihydrate gypsum powders with different aspect ratios can be prepared by adjusting the formula of the crystal modifier to meet different market demands.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com