Alpha type ultra-high strength gypsum preparation method

An ultra-high-strength, gypsum technology, applied in the direction of calcium/strontium/barium sulfate, etc., can solve the problems of high pressure, high operational risk, incomplete crystal development, etc., to reduce production costs and energy consumption, high safety factor, Resolve the effects of underdeveloped crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

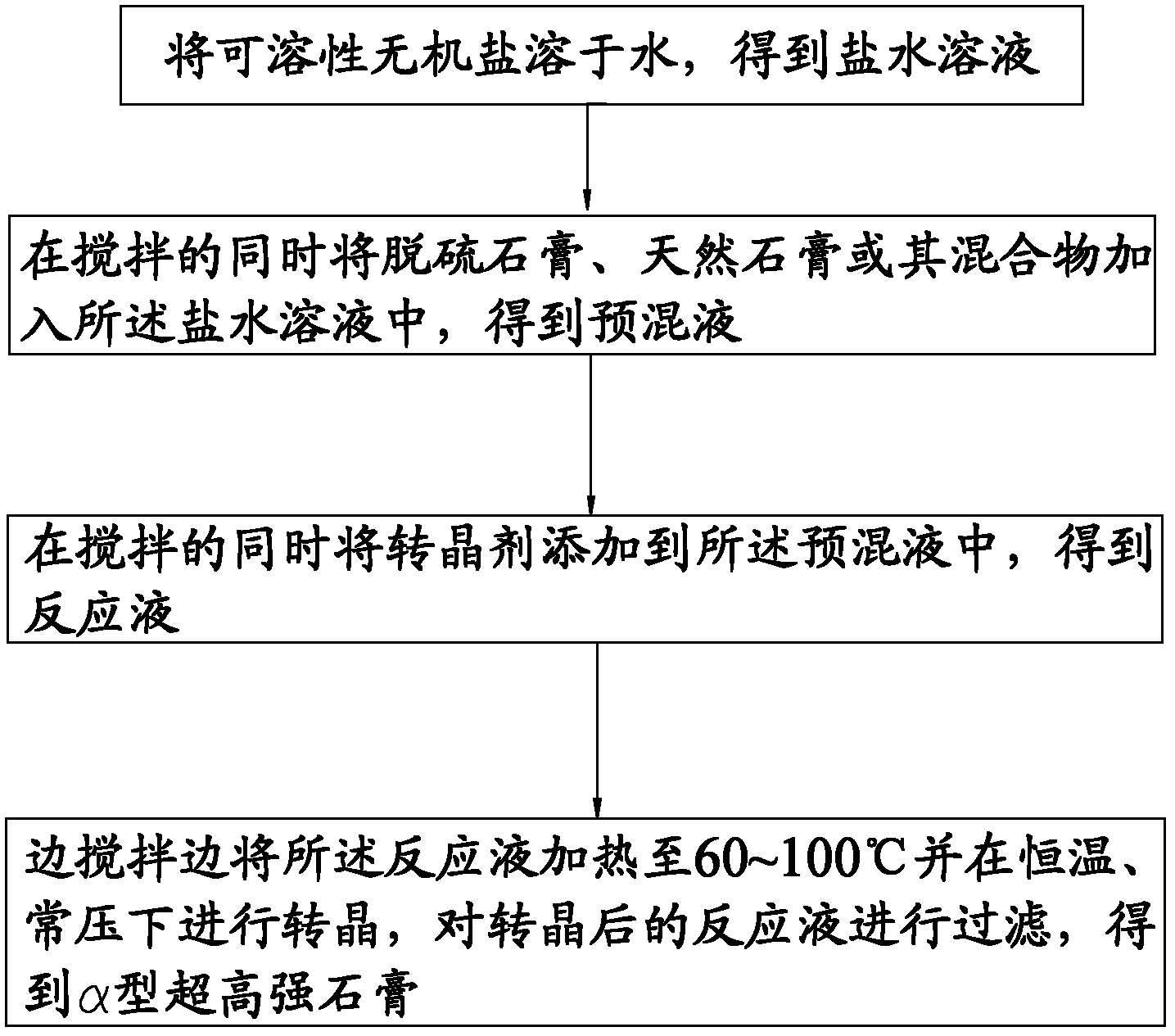

[0028] Such as figure 1 As shown, the preparation method of α-type ultra-high-strength gypsum according to the embodiment of the present invention includes the following steps:

[0029] a) Dissolving the soluble inorganic salt in water to obtain a saline solution.

[0030] There is no particular limitation on the soluble inorganic salt used as long as it has high solubility. For example, in some examples of the present invention, the soluble inorganic salt may use soluble chloride salt, soluble nitrate salt or a combination thereof. By using such soluble chloride salts, soluble nitrate salts or combinations thereof, the phase transition point of dihydrate gypsum and hemihydrate gypsum can be effectively lowered, and the boiling point of its aqueous solution can be raised.

[0031] As the soluble chloride salt, for example, one or more of commonly used calcium chloride, sodium chloride, potassium chloride, and magnesium chloride can be used.

[0032] As the soluble nitrate, ...

Embodiment 1

[0049] First, mix the NH 4 NO 3 : 2 parts by weight, Cacl 2 : 2 parts by weight and NaNO 3 : 1 part by weight was dissolved in 150 parts by weight of water to obtain a saline solution, and the saline solution was heated to 70°C.

[0050] Next, 100 parts by weight of desulfurized gypsum was added to the above-mentioned saline solution while stirring to obtain a premixed solution.

[0051]After the premix is mixed evenly, add C 4 h 6 o 6 : 0.01 parts by weight, Al 2 (SO 4 ) 3 : 0.2 parts by weight to obtain a reaction liquid.

[0052] Thereafter, the reaction solution was heated to boiling and kept at normal pressure for 3-4 hours to perform crystallization. Finally, the reaction solution after crystal transformation is filtered, washed, and dried to obtain high-purity α-type ultra-high-strength gypsum.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com