Method and device for continuously producing dyes

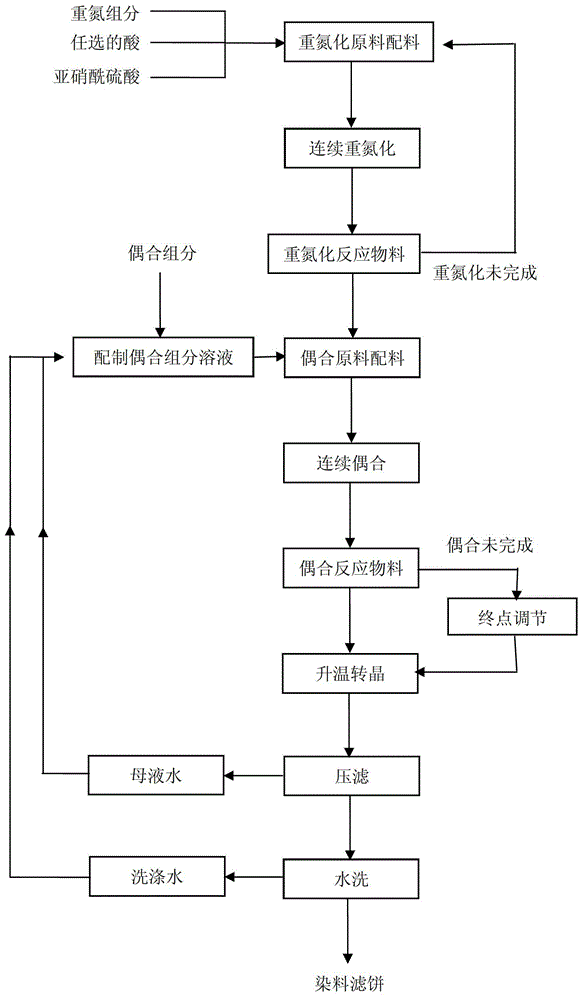

A technology for dyes and detection devices, applied in azo dyes, organic dyes, monoazo dyes, etc., can solve problems such as chemical ratio deviation, process medium toxicity, corrosiveness, flammability, and explosiveness, and difficulty in stirring evenly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Put 1980kg of N,N-diethyl-3-acetamidoaniline into the beating pot of the coupling component, and beat with 20000kg of beating liquid with a mass percentage of 3% sulfuric acid to obtain the coupling component solution J, which is ready for use.

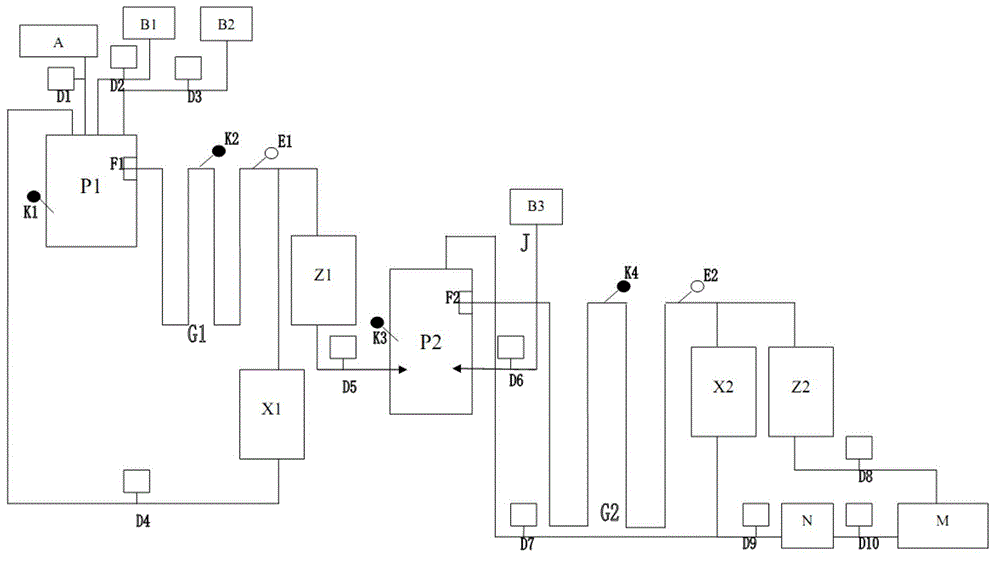

[0076] Add 420kg of nitrosyl sulfuric acid (28% content) into the batching kettle P1, turn on the frozen brine, control the temperature in the kettle at 20°C to 30°C, and slowly twist in 2,4-dinitro-6-chloroaniline ( Diazo component) 200kg is mixed to form an initiator, and then the metering of 2,4-dinitro-6-chloroaniline (diazo component) and nitrosyl sulfuric acid are controlled at 571kg / h and 1200kg / h respectively. Automatic continuous feeding, the mixed material flows from the overflow port to the tubular diazotization reactor G1 for reaction, after the polarity voltage control system E1 detects that the reaction is completed, it flows to the transfer tank Z1, and is continuously pumped by the metering pump D5 to Batching k...

Embodiment 2

[0081] Put 700kg of N,N-diethyl-3-acetamidoaniline into the beating pot of the coupling component, and beat with 15000kg of beating liquid with a mass percent of sulfuric acid of 4.5%, to obtain the coupling component solution J, ready for use.

[0082]Add 380kg of nitrosyl sulfuric acid (28% content) and 660kg of sulfuric acid into the batching kettle P1, turn on the frozen brine, control the temperature in the kettle at 0°C to 5°C, and slowly twist in 2-cyano-4-nitro 200kg of -6-bromoaniline is mixed to form an initiator. After finishing the preparation, the metering control of 2-cyano-4-nitro-6-bromoaniline (diazo component), sulfuric acid and nitrosyl sulfuric acid is 300kg / h, 990kg / h, 570kg / h for automatic continuous feeding, the mixed material flows from the overflow port to the tubular diazotization reactor G1 for reaction, after the reaction is completed by the polarity voltage control system E1, it flows to the transfer tank Z1, and then continuously pumped to the ba...

Embodiment 3

[0087] Put 2050kg of 3-(N,N-diallyl)amino-4-methoxyacetanilide in the beating pot of the coupling component, and beat with 20000kg of sulfuric acid with a mass percentage of 6% to obtain the coupling component Divide solution J and set aside.

[0088] Add 690kg of nitrosyl sulfuric acid (28% content) into the batching kettle P1, turn on the frozen brine, control the temperature in the kettle at 20°C to 30°C, slowly twist in 330kg of 2,4-dinitro-6-bromoaniline Mix and prepare the initiator. After the preparation is completed, the metering control of 2,4-dinitro-6-bromoaniline (diazo component) and nitrosyl sulfuric acid are respectively 495kg / h and 1035kg / h for continuous feeding. The mixed material flows from the overflow port to the tubular diazotization reactor G1 for reaction. After the completion of the reaction is detected by the polarity voltage control system E1, it flows to the transfer tank Z1, and then is continuously pumped to the batching tank P2 by the metering pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com