Patents

Literature

240results about How to "Realize automatic continuous production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for processing and recycling waste water containing phenolic compounds

InactiveCN102417248AEasy to purifyRealize automatic continuous productionOrganic chemistryOrganic compound preparationFlocculationAlcohol

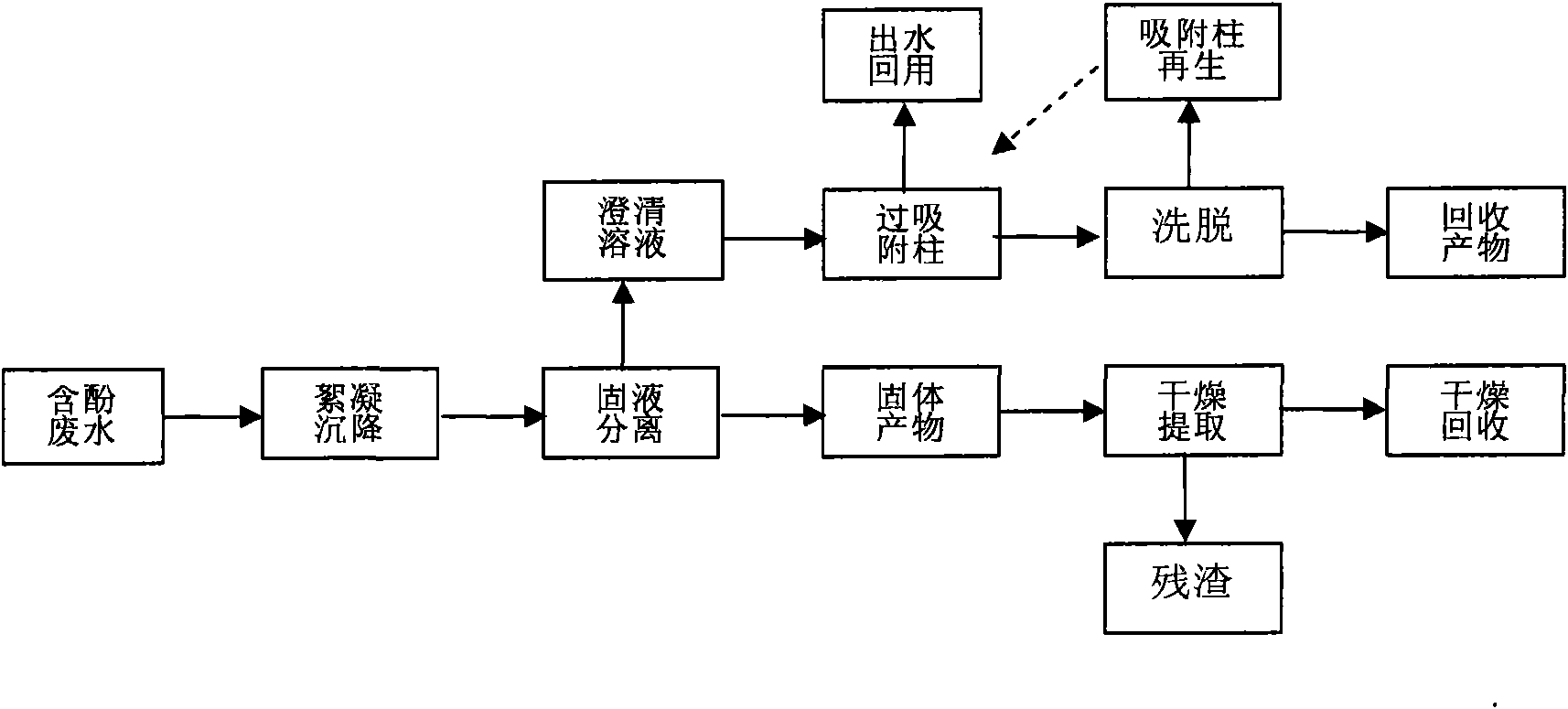

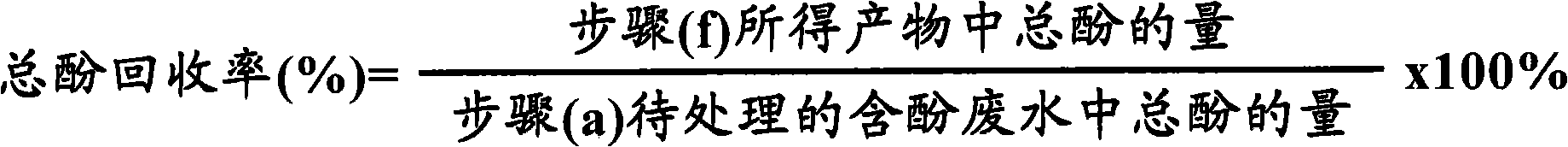

The invention relates to a method for processing and recycling waste water containing phenolic compounds, in particular to a method for recycling phenolic compounds from the phenolic waste water, comprising the following steps: (a) adding a flocculating agent in the phenolic waste water to be processed for flocculation; (b) carrying out solid-liquid separation on the material of the step (a); (c) determining the pH value of the liquid material obtained by the step (b), and adjusting the pH value to acidity; (d) letting the material obtained by the step (c) pass through a resin column, and measuring the total phenol content in water; (e) eluting the resin column which absorbs the phenolic compounds with a small molecular alcohol and / or ketone solvent; and (f) recovering the solvent from the eluate, and drying to obtain a product which is rich in phenolic compounds. Correspondingly, the invention further provides a method for processing the waste water containing phenolic compounds and the obtained phenolic product. According to the invention, the method disclosed herein is suitable for processing the waste water with low phenol content, and is environmental friendly; by using the raw materials which has the advantages of low pollution, or low price, or easy processing, and or recycling property, the method has the advantages of low cost and low energy consumption.

Owner:ENN SCI & TECH DEV

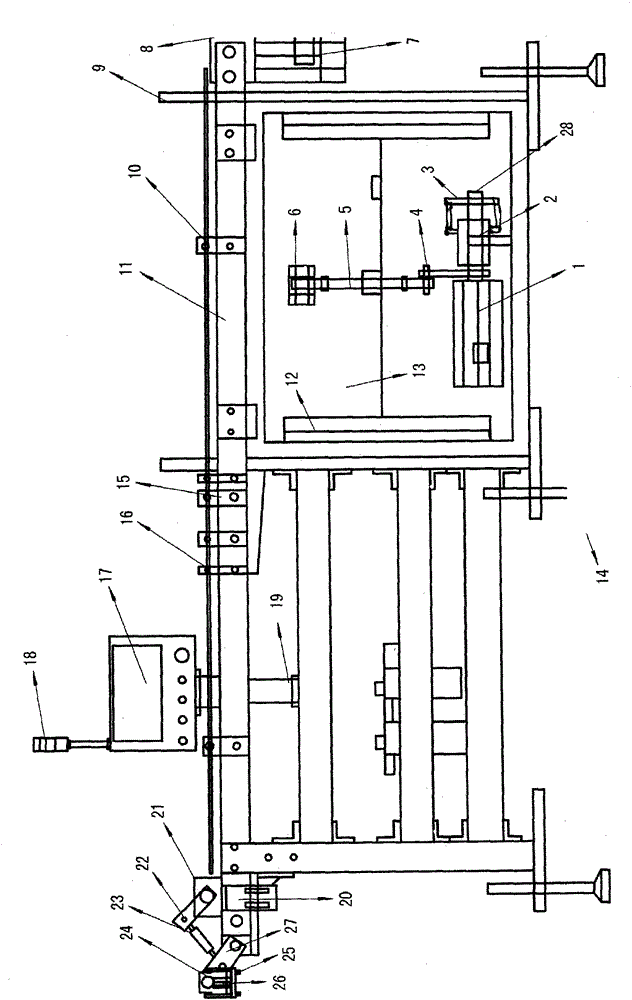

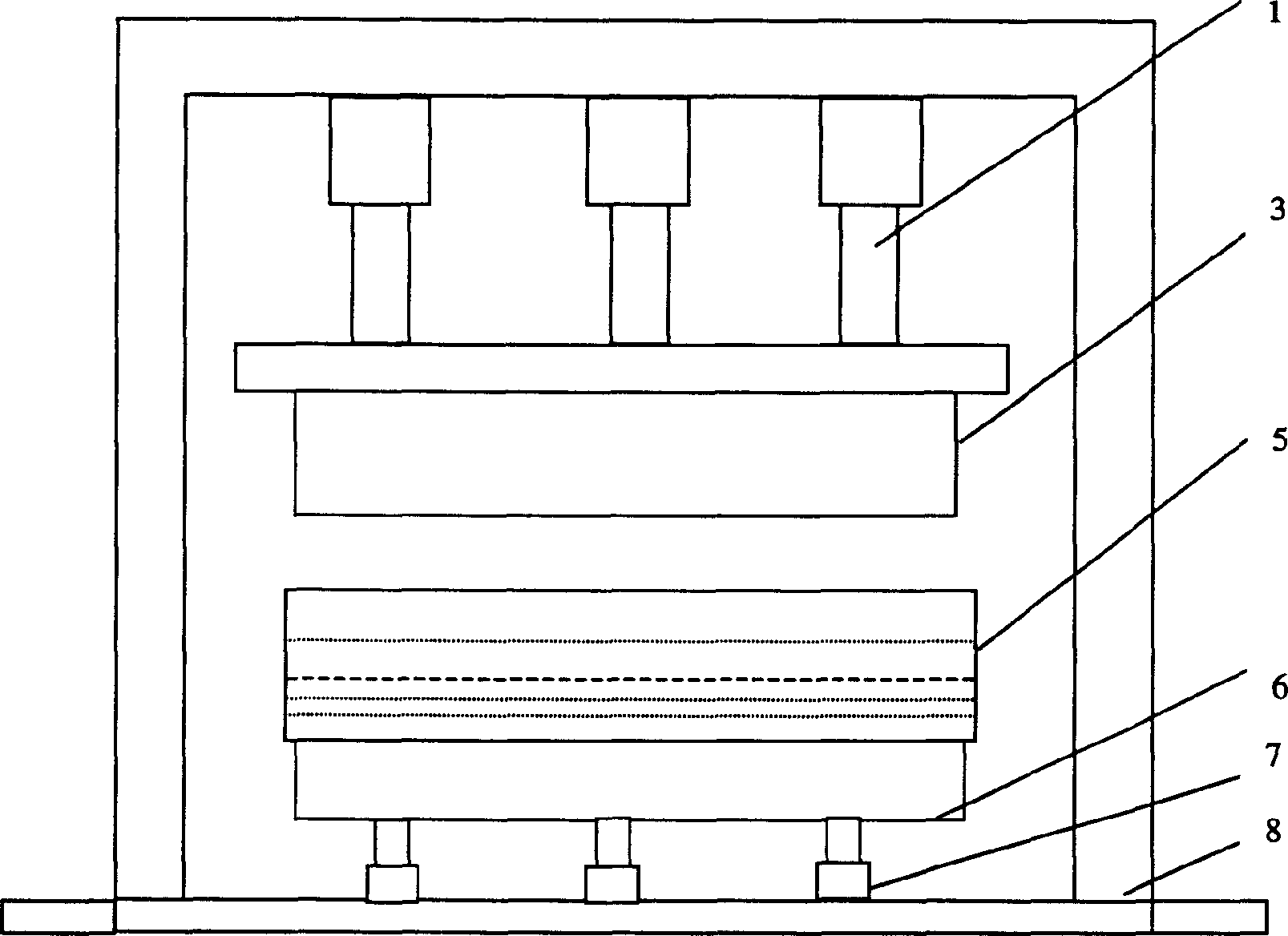

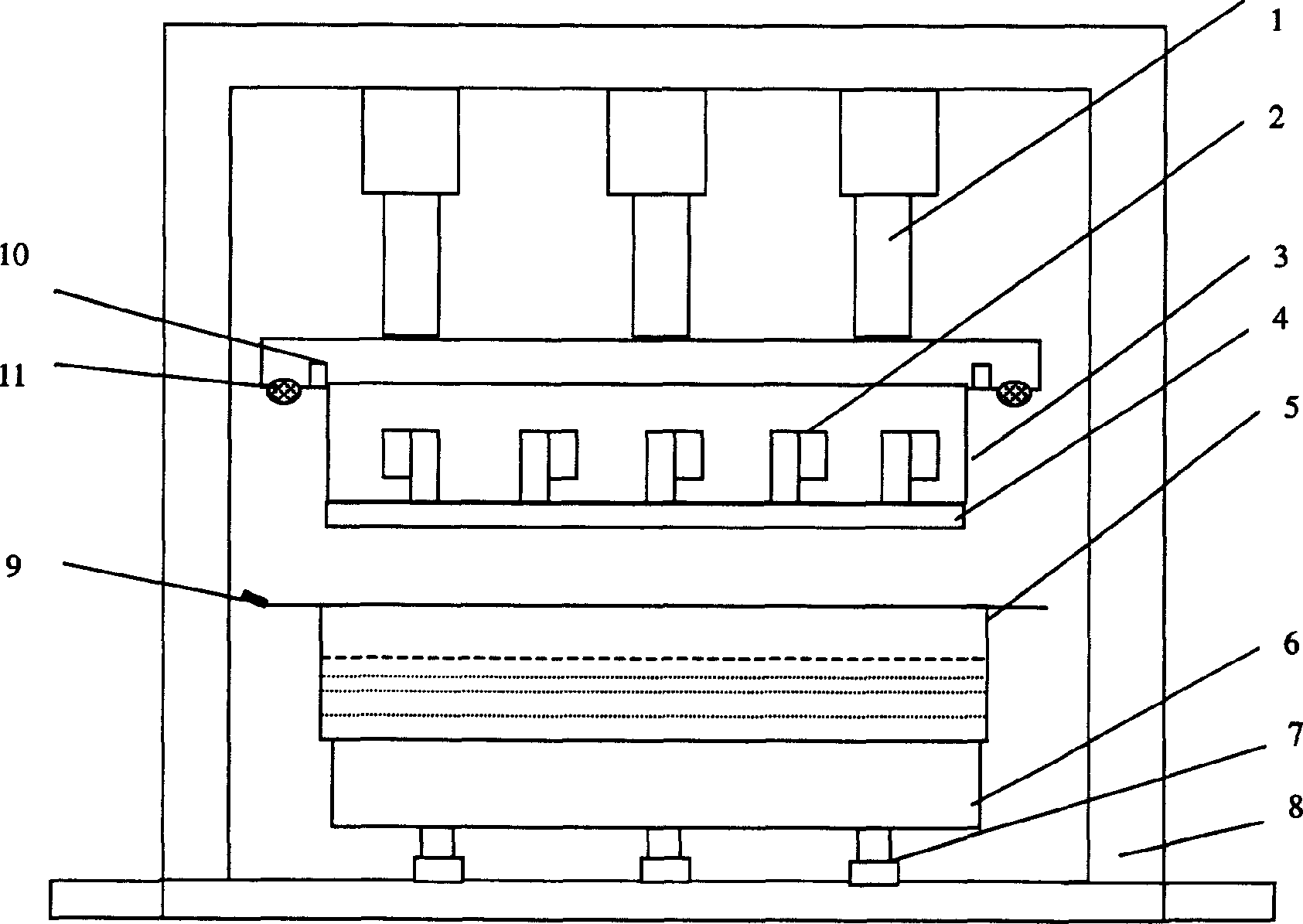

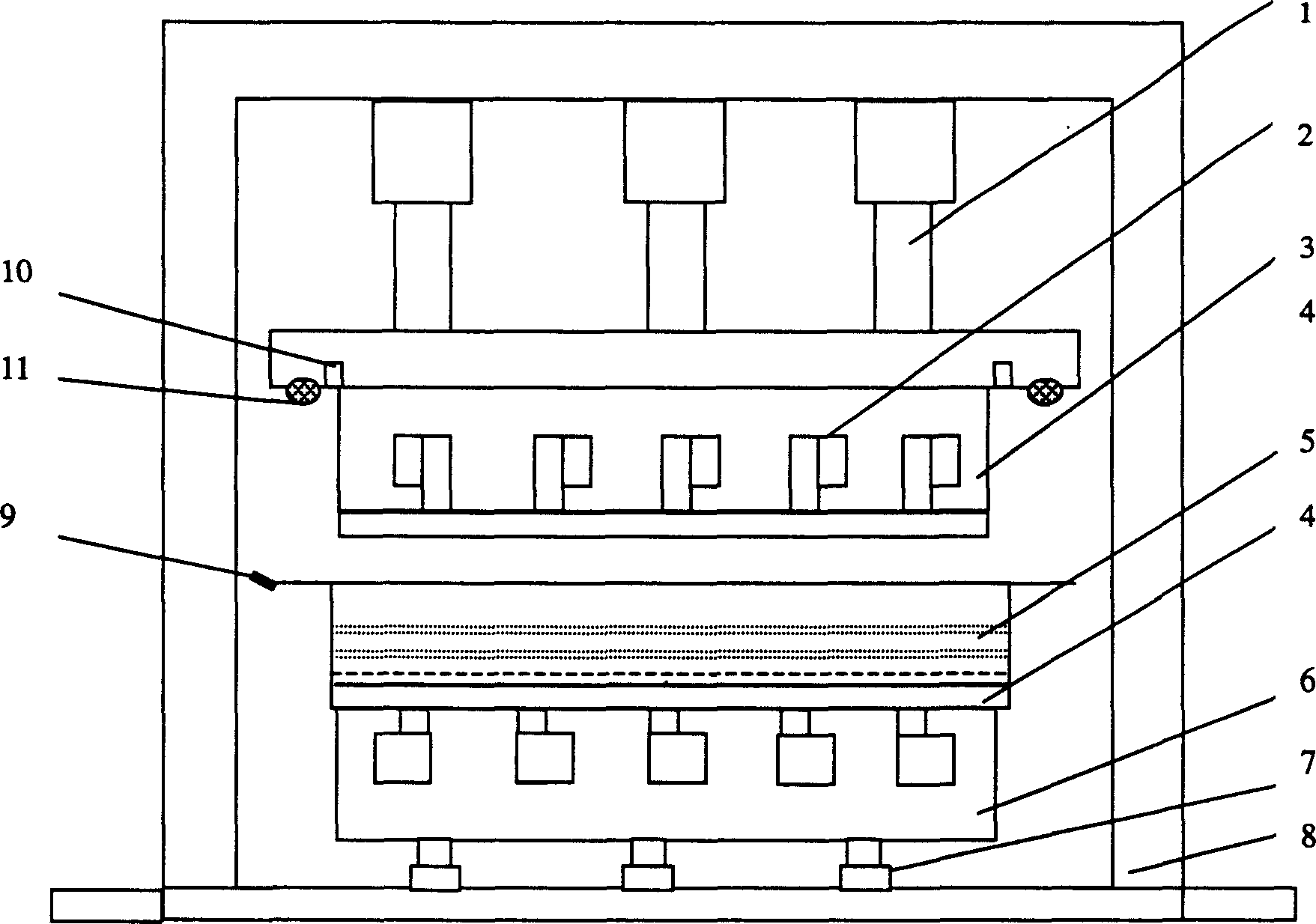

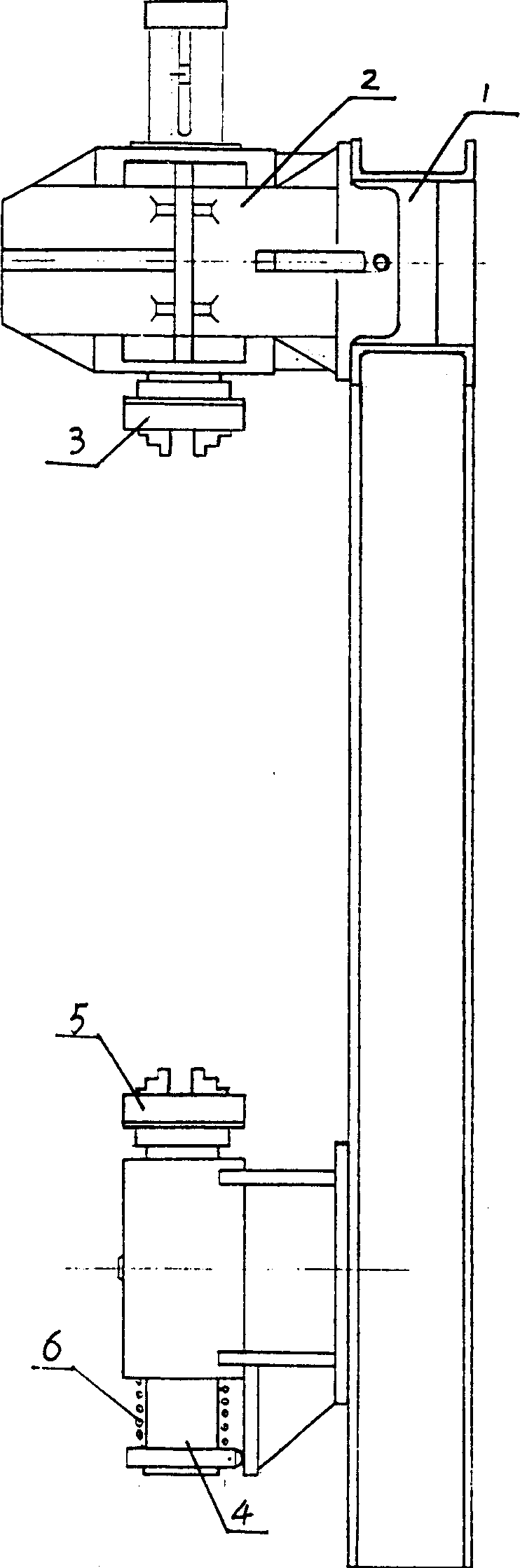

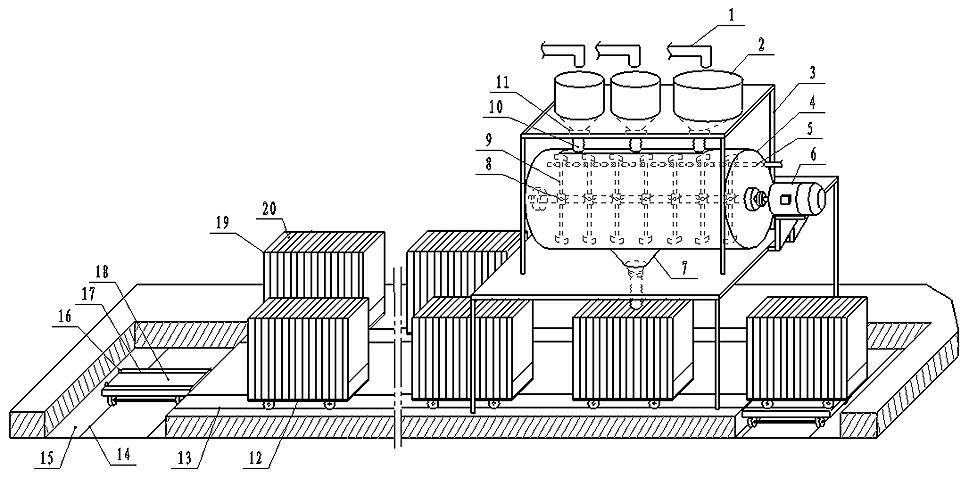

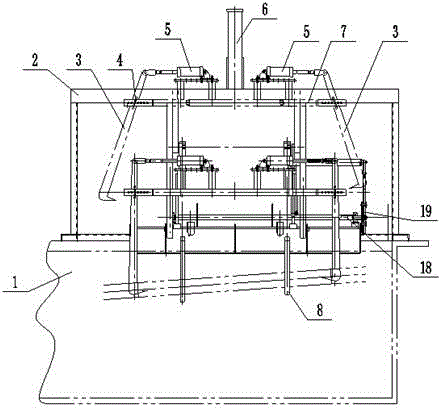

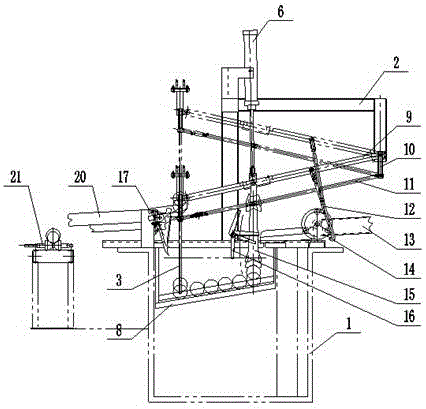

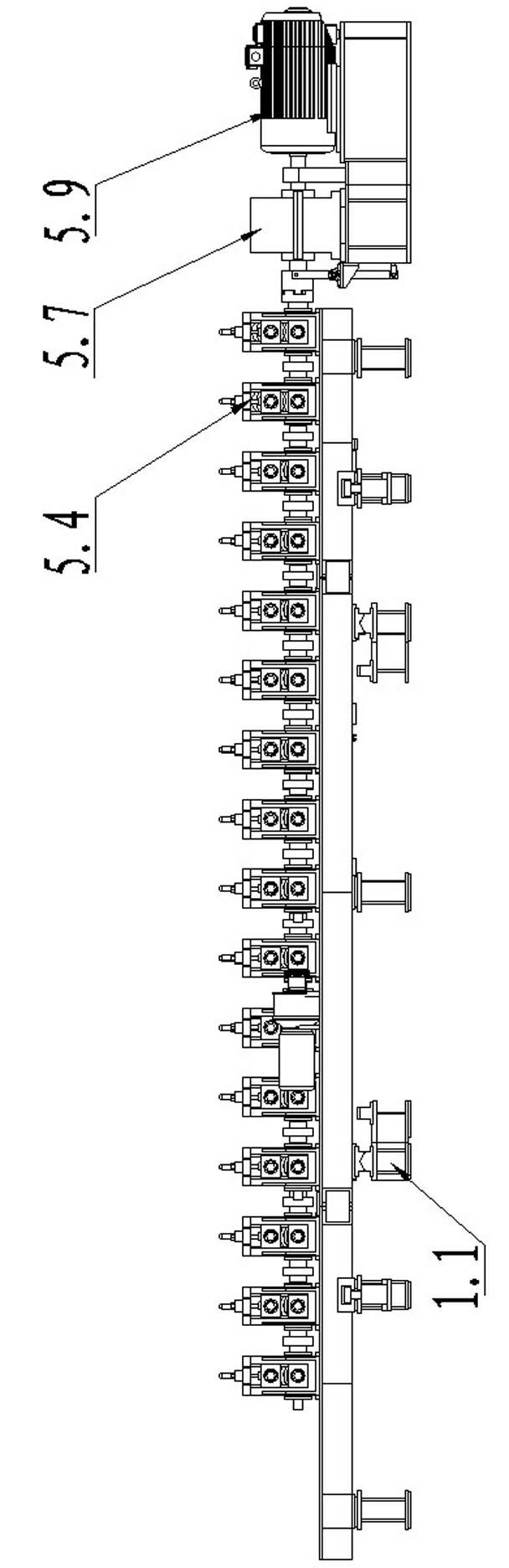

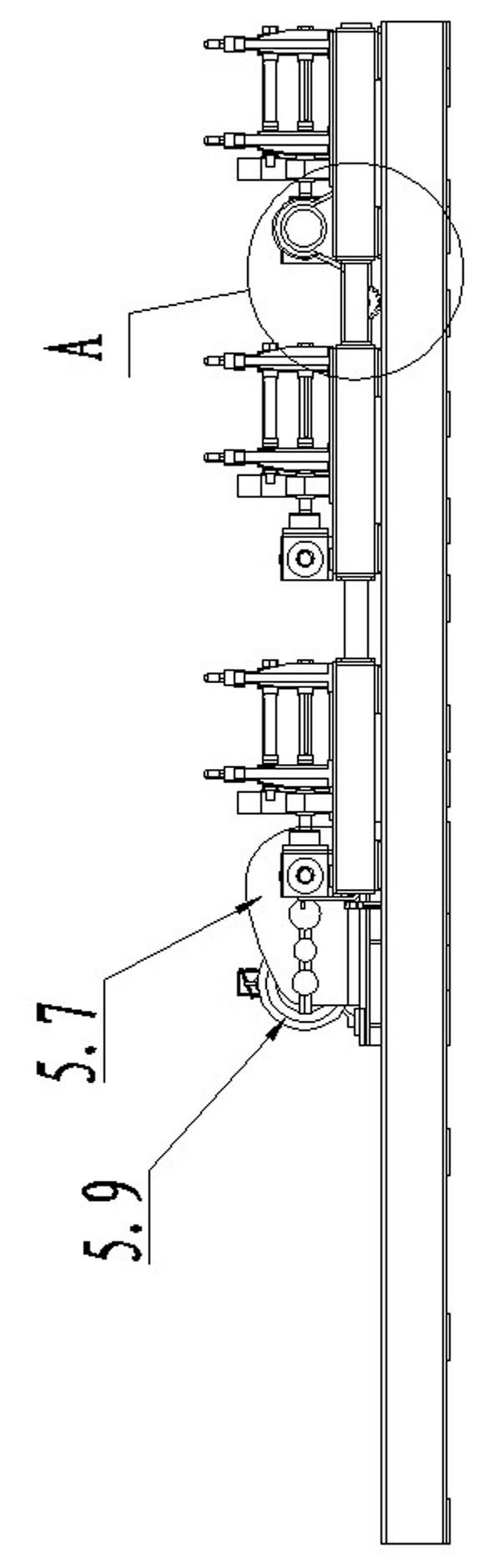

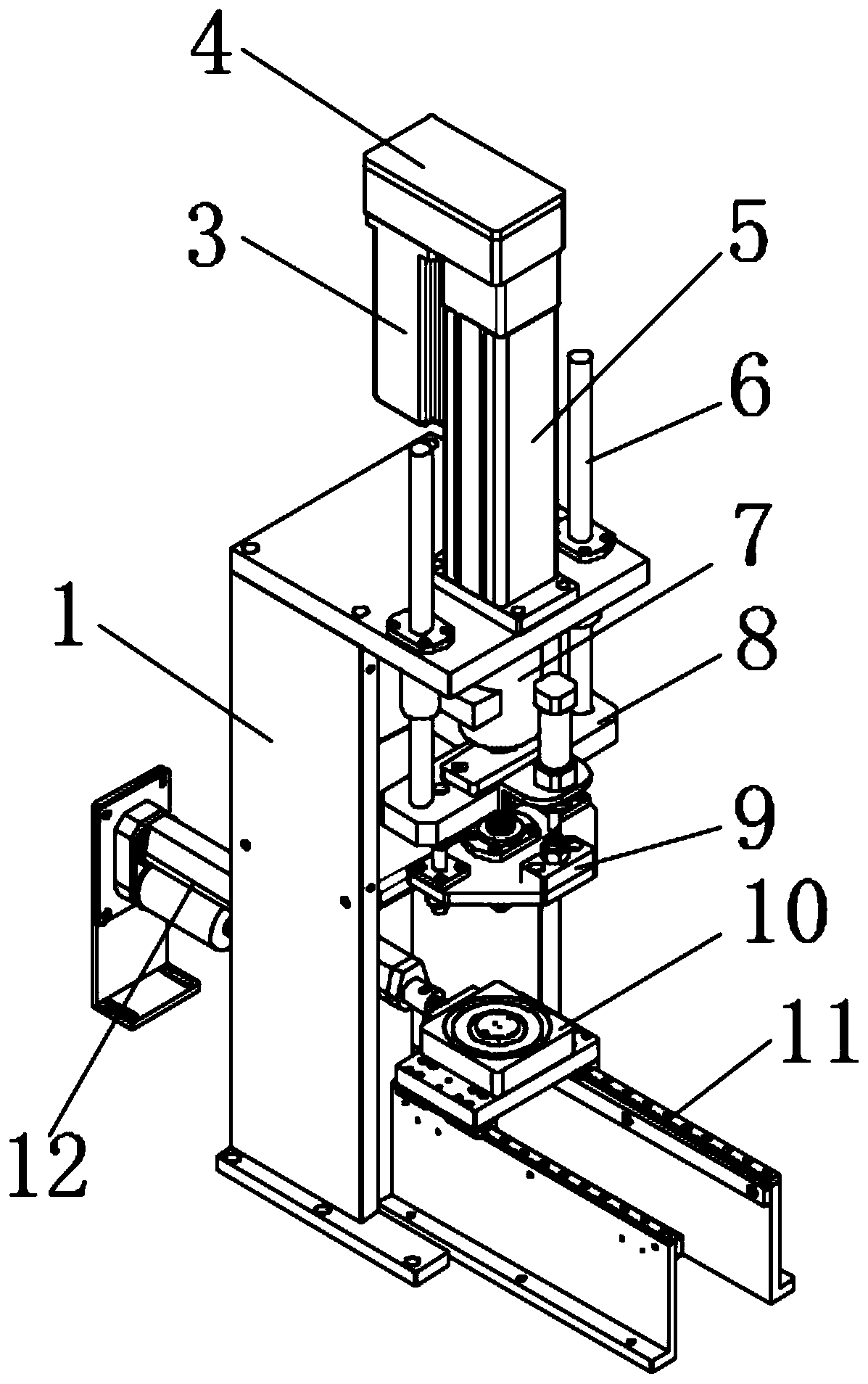

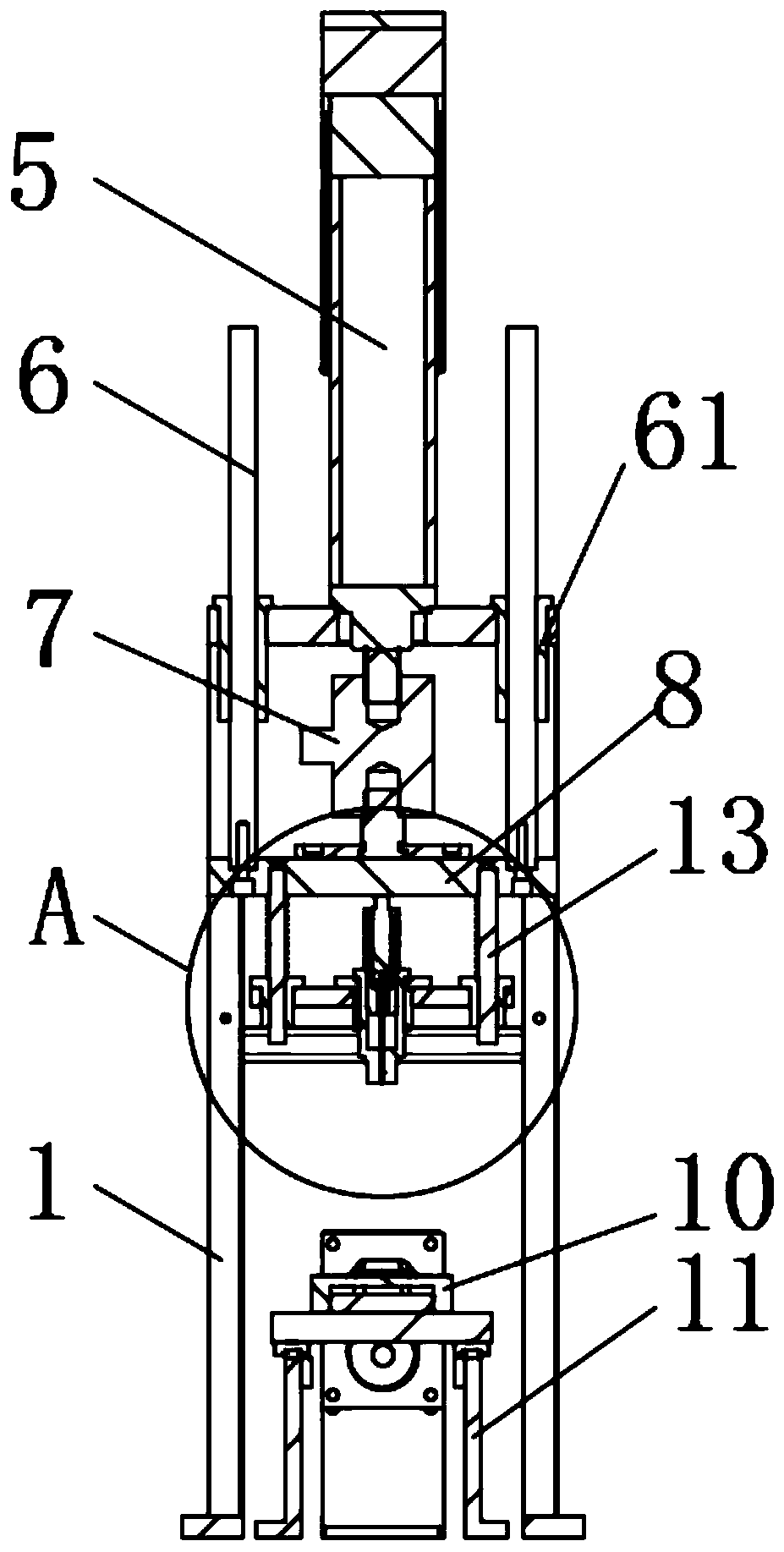

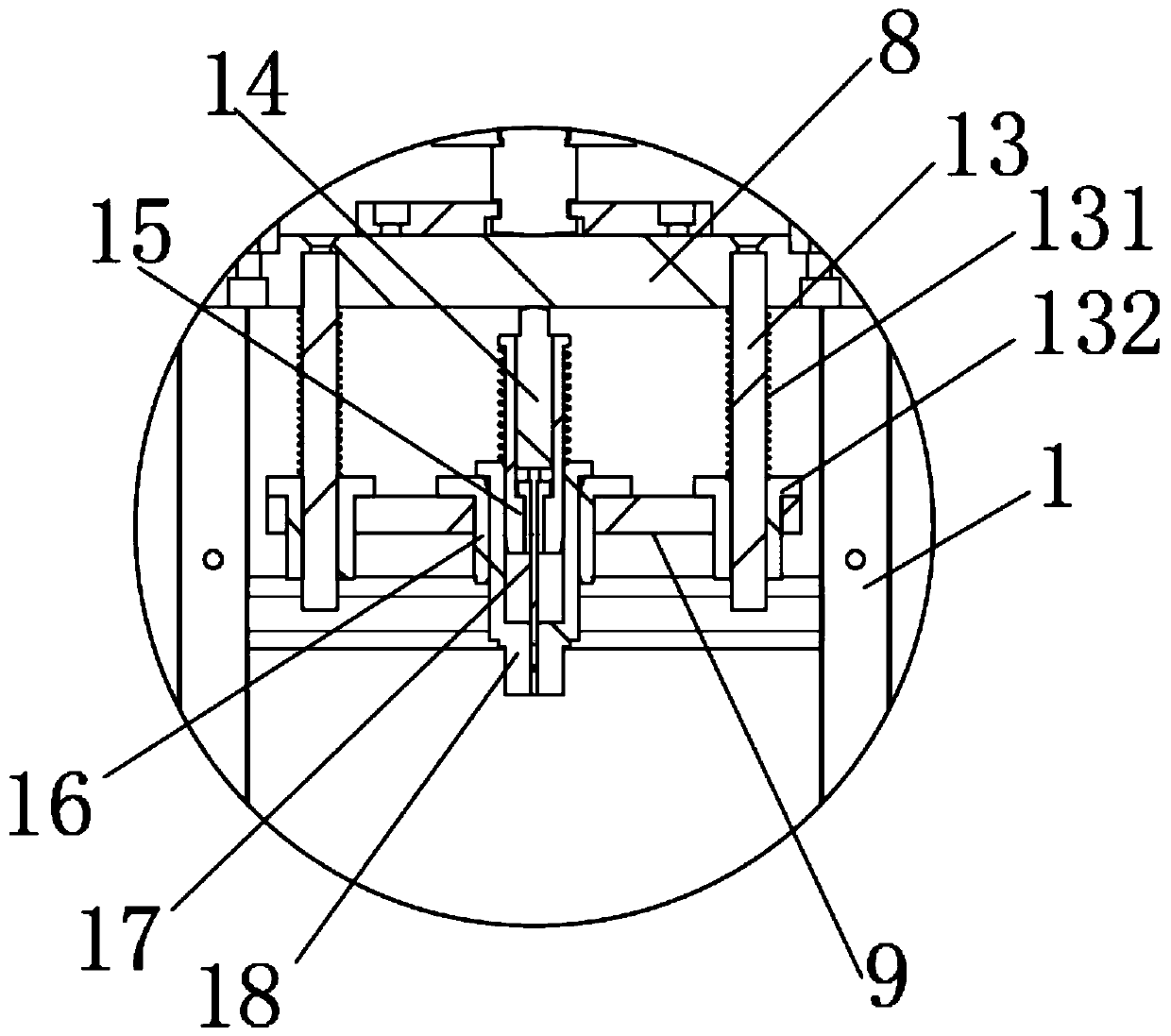

Automatic blank removing machine for rough castings

ActiveCN102847908ARealize automatic continuous productionReduce labor intensityControl systemWorking environment

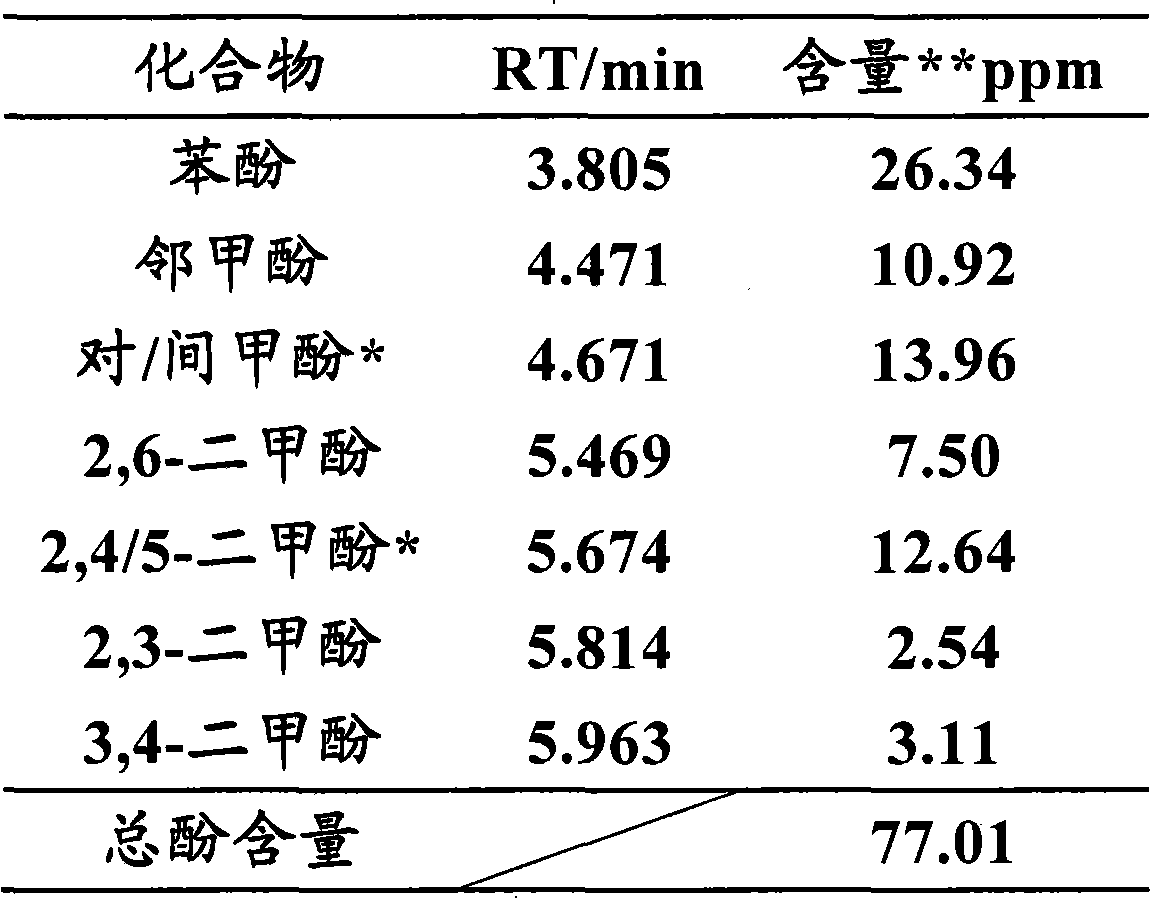

The invention relates to an automatic blank removing machine for rough casting. The automatic blank remover comprises a control system and a transmission chain driven by a driving system; the transmission chain is stepped in a batch type; clamps for carrying materials are mounted equidistantly on the transmission chains; a cooling station, a first blank removing station and a second blank removing station are arranged along the travelling direction of the transmission chain in sequence; the clamps pause in the cooling station, the first blank removing station and the second blank removing station; the materials carried by the clamps are cooled when the clamps pause in each station and removed discharged overflowing material or blank products; and a clamping fixing mechanism and a blank removing mechanism are arranged in the first blank removing station and the second blank removing station. According to the automatic blank removing machine for rough casting, blank products can be removed continuously and automatically from the material pieces to finish the separating operation of flowing channel body, blank products and discharged overflowing materials for realizing automatic production and improving working efficiency; and meanwhile, labor is saved, work strength of workers is reduced and working environment is improved.

Owner:百冠(福建)机械科技发展股份有限公司

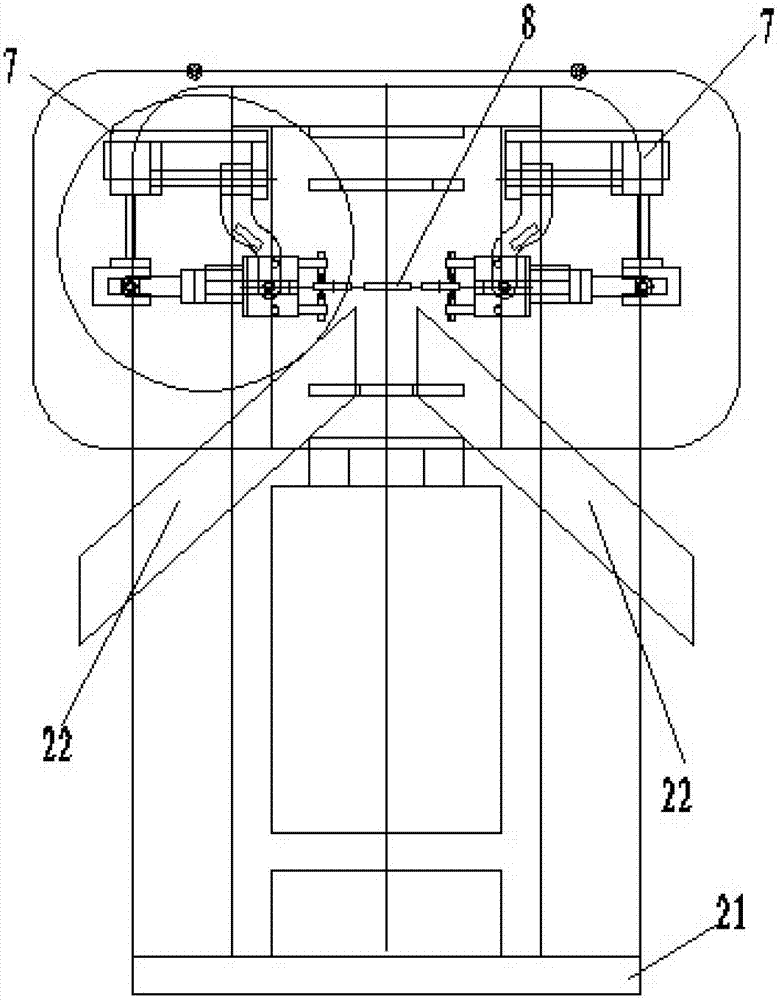

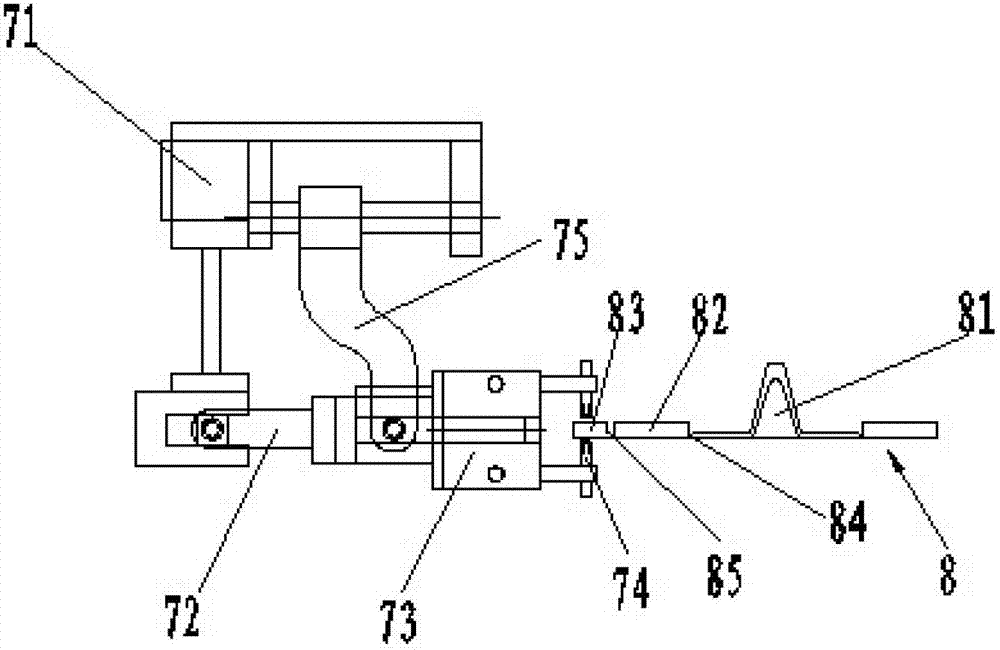

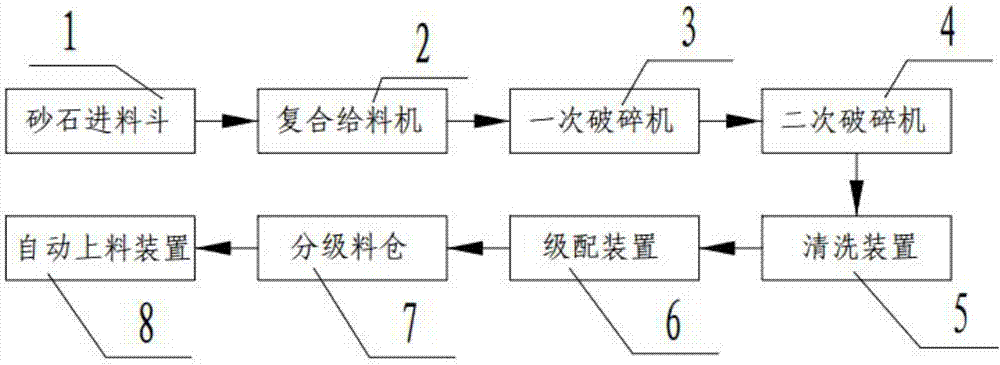

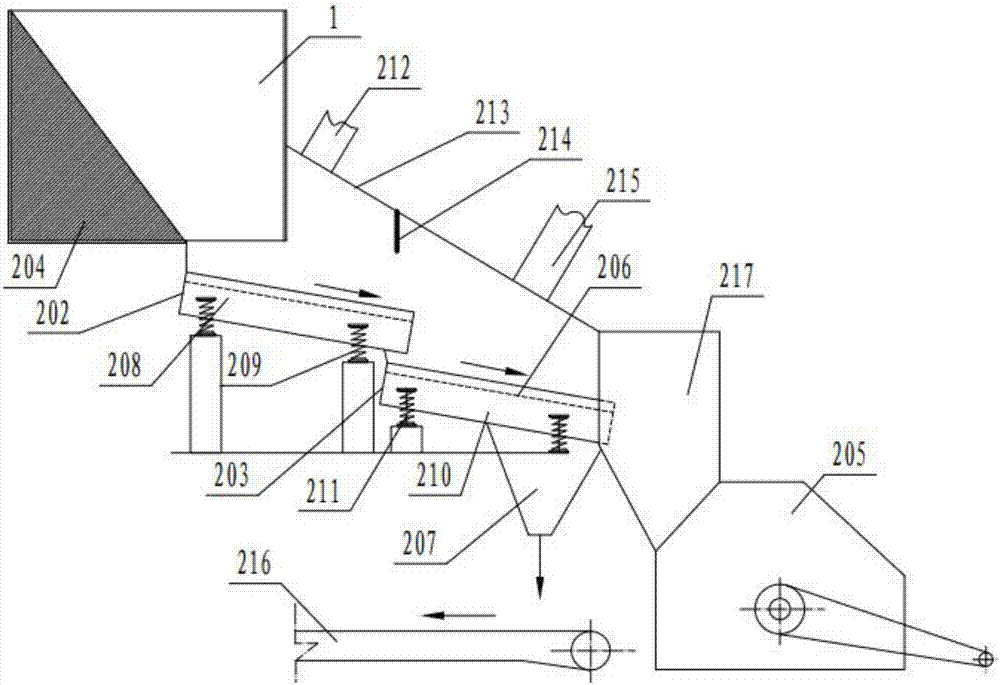

Sand production line

PendingCN107497580AIncrease productivityReduce labor intensitySievingGas current separationProcess engineeringEnvironmental geology

The invention discloses a sand production line. The sand production line comprises a sand feeding hopper, a composite feeding machine, a primary crusher, a secondary crusher, a cleaning device, a grading device and a classifying stock bin, wherein a discharging port of the sand feeding hopper is connected to the feeding end of the composite feeding machine, the discharging end of the composite feeding machine is connected to a feeding hopper I of the primary crusher, a collecting hopper I of the primary crusher is connected to a feeding hopper II of the secondary crusher through a conveying belt, a collecting hopper II of the secondary crusher is connected to the cleaning device through a conveying belt, the cleaning device is connected to the grading device through a conveying belt, and the grading device is connected to the classifying stock bin through a conveying belt. According to the sand production line, by means of the sand feeding hopper, the composite feeding machine, the primary crusher, the secondary crusher, the cleaning device, the grading device and the classifying stock bin, automatic and continuous sand production can be realized, the production efficiency is high, the labor intensity can be reduced, and automatic monitoring and unattended operation can be realized.

Owner:遵义同兴源建材有限公司

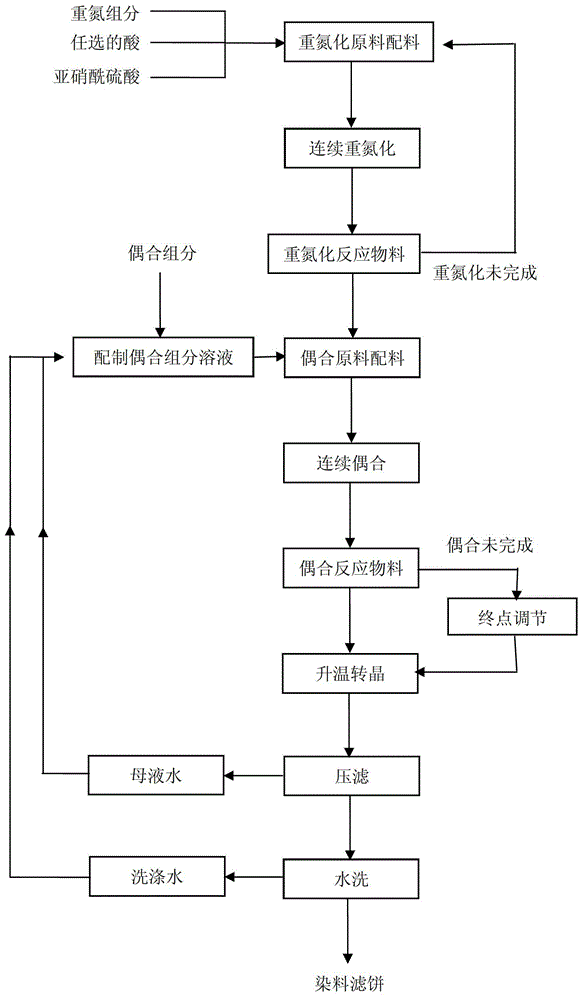

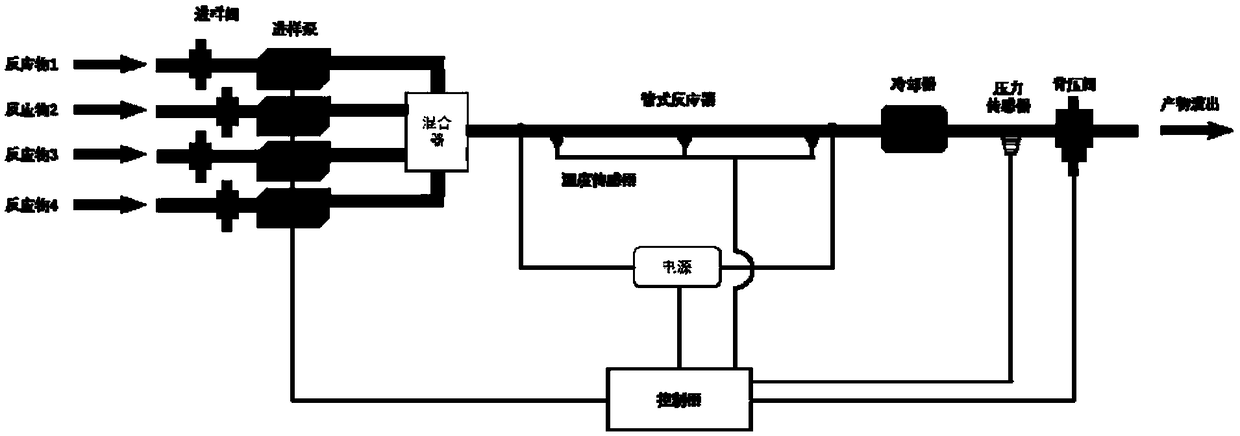

Method and device for continuously producing dyes

ActiveCN103146221ARealize automatic continuous productionThree wastes are produced lessMonoazo dyesWash waterReaction temperature

The invention discloses a method and a device for continuously producing dyes. The method comprises the following steps: adding diazotization reaction raw materials into an ingredient kettle, controlling temperature in the kettle, allowing the materials to flow in a tubular reactor through an overflow orifice, detecting the reaction state through an online detection device, continuously discharging the diazotization compound solution obtained through the reaction, continuously feeding the diazotization compound solution and a coupling component solution according to a specified ratio, allowing the materials to flow into the tubular reactor through the overflow orifice, detecting the reaction state through the online detection device, transferring the coupling reaction materials into a crystal transformation kettle, performing crystal transformation, and performing filter pressing to obtain a dye filter cake, wherein the filter cake mother solution and the wash water are circulated for preparing the coupling component solution. The reaction temperature, material flow and reaction state detection device are automatically subjected to interconnected control. According to the method, automatic and continuous dye production is realized, the production capacity, the product quality and yield are improved, the labor intensity and working conditions of workers are improved, the waste water, water gas and waste residue amounts in the dye production process are greatly reduced, and circular economy and cleaner production process are realized.

Owner:ZHEJIANG DIBANG CHEM

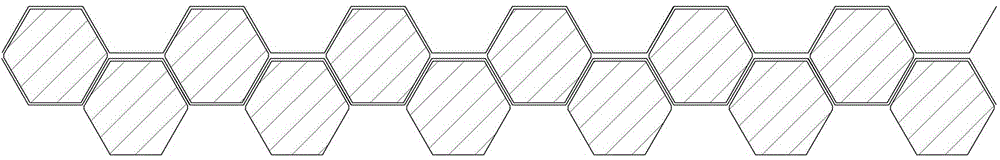

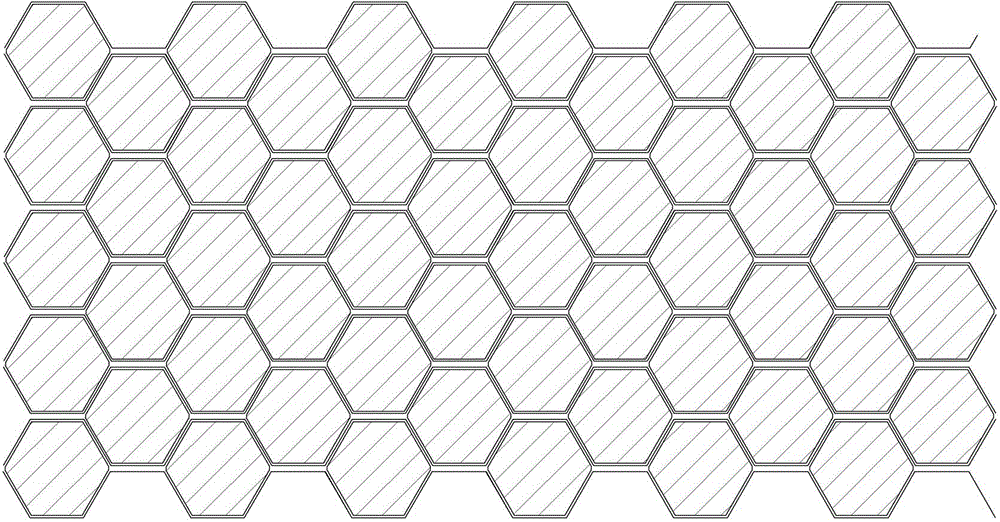

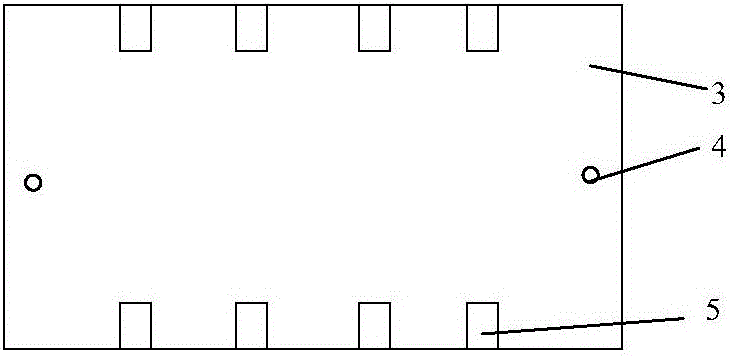

Hexagonal honeycomb, preparation method and application thereof

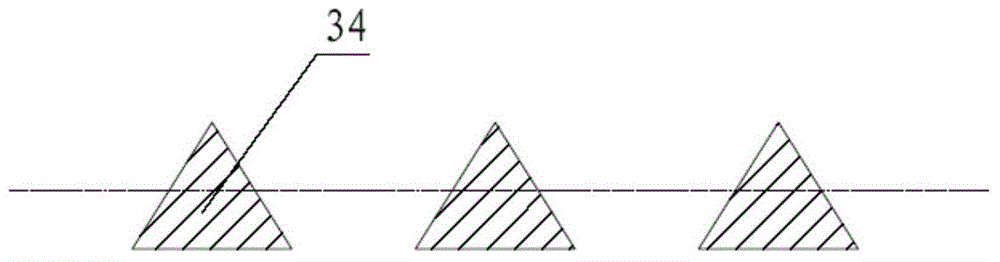

ActiveCN105835484AOvercoming contact problemsAchieve contactSynthetic resin layered productsLaminationProduction lineSurface layer

The invention discloses a hexagonal honeycomb, a preparation method and application thereof. The hexagonal honeycomb includes a plurality of hexagonal honeycomb units and plastic films arranged on the upper surfaces and lower surfaces of the honeycomb units, each honeycomb unit has six side walls, two sides walls in the vertical direction between the honeycomb units are not connected, and the remaining four side walls are the common side walls of two neighboring units. According to the hexagonal honeycomb, the plastic films are fused on the upper surface and the lower surface of the hexagon, the upper surface and the lower surface of the hexagon are all sealed, thus overcoming the problem of line contact between a round tube honeycomb surface layer (various sheets) and a honeycomb core layer, realizing surface contact and greatly improving the strength. Two side walls in the vertical direction between the honeycomb units are not connected, certain gap can exist, thus endowing a honeycomb plate with better sound and heat insulation benefits. The method provided by the invention can realize automatic continuous production, and compared with traditional honeycomb production lines, the production efficiency can be increased by 8-10 times. The honeycomb does not contain any glue or other harmful solvents, and can realize 100% recovery.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV

Solar polyurethane thermal insulation material

Owner:SHANDONG LINUO PARADIGMA

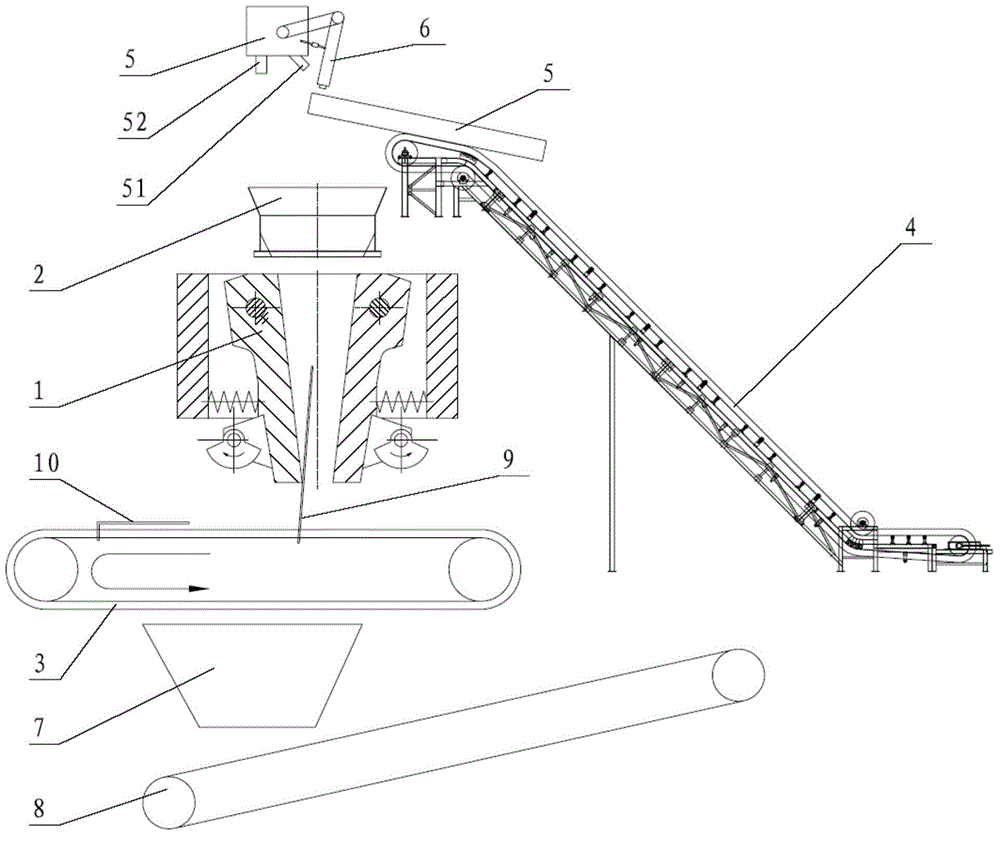

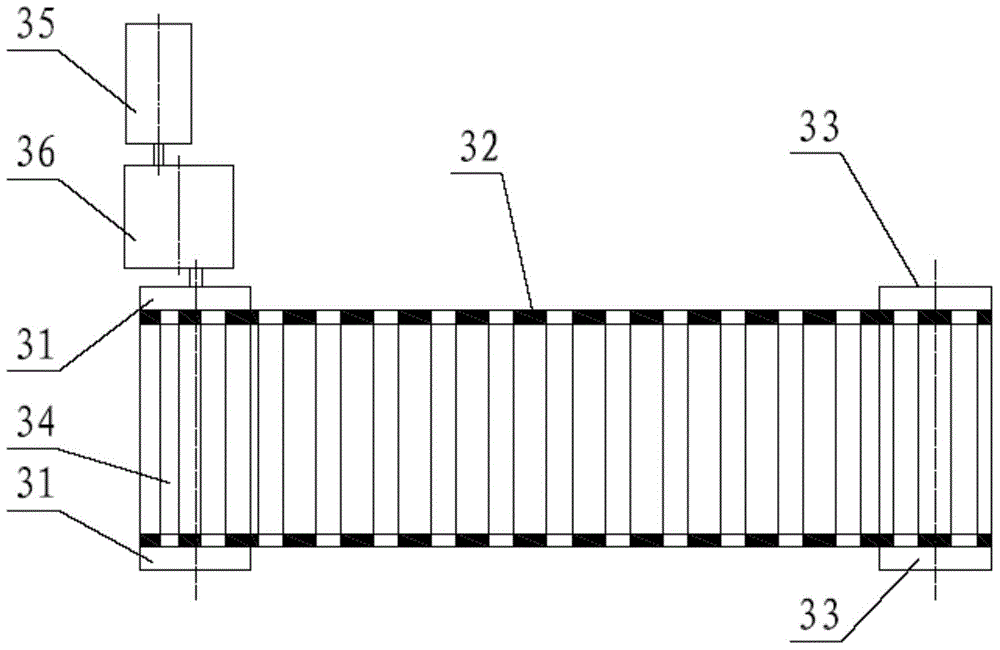

Reinforced-concrete breaking treatment system

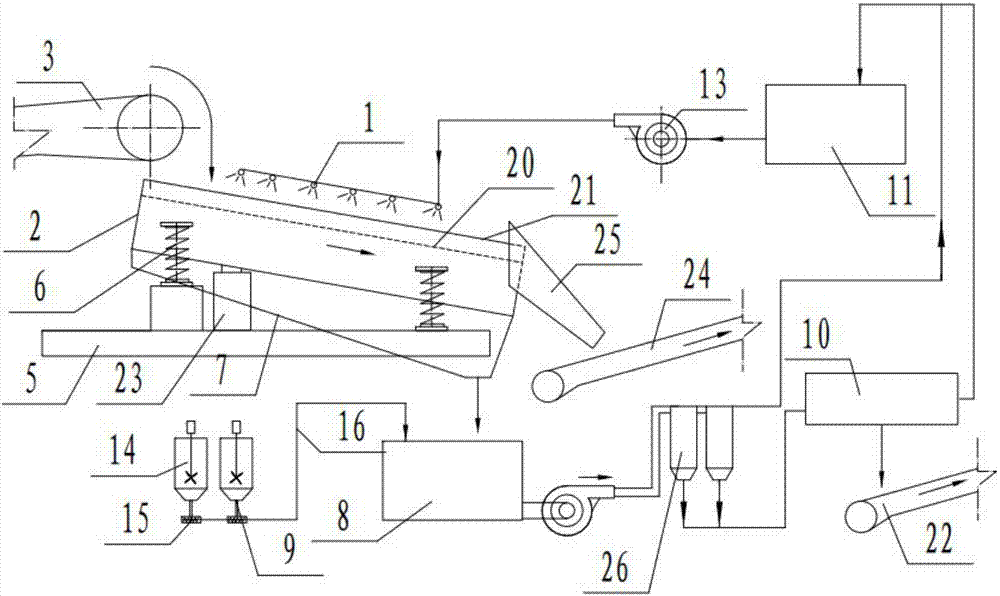

ActiveCN104984808ASolve processing problemsRealize automatic continuous productionGrain treatmentsReinforced concreteChain type

The invention discloses a reinforced-concrete breaking treatment system. The reinforced-concrete breaking treatment system comprises a double-acting-jaw vibratory jaw type breaking machine (1), a hopper (2), an automatic feeding mechanism, a chain-type reinforced-concrete separating and concentrated unloading machine (3) and a unloaded-material collecting and discharging mechanism, wherein reinforced concrete is conveyed into the hopper (2) arranged above the double-acting-jaw vibratory jaw type breaking machine (1) by the automatic feeding mechanism and enters the double-acting-jaw vibratory jaw type breaking machine (1) for breaking by an opening under the hopper (2); the reinforced concrete is broken and separated into concrete blocks and steel bars which are separated by the chain-type reinforced-concrete separating and concentrated unloading machine (3) and are discharged by the unloaded-material collecting and discharging mechanism. The reinforced-concrete breaking treatment system disclosed by the invention has the advantages that the applicability to materials such as building wastes of broken ores and concrete and the like, especially the building wastes of reinforced-concrete structural parts containing steel bars can be broken and treated, the treatment difficulty can be solved, automatic continuous production can be realized, the needs of comprehensive utilization of national building wastes and green building policies can be met, the working efficiency is high and the cost can be saved.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

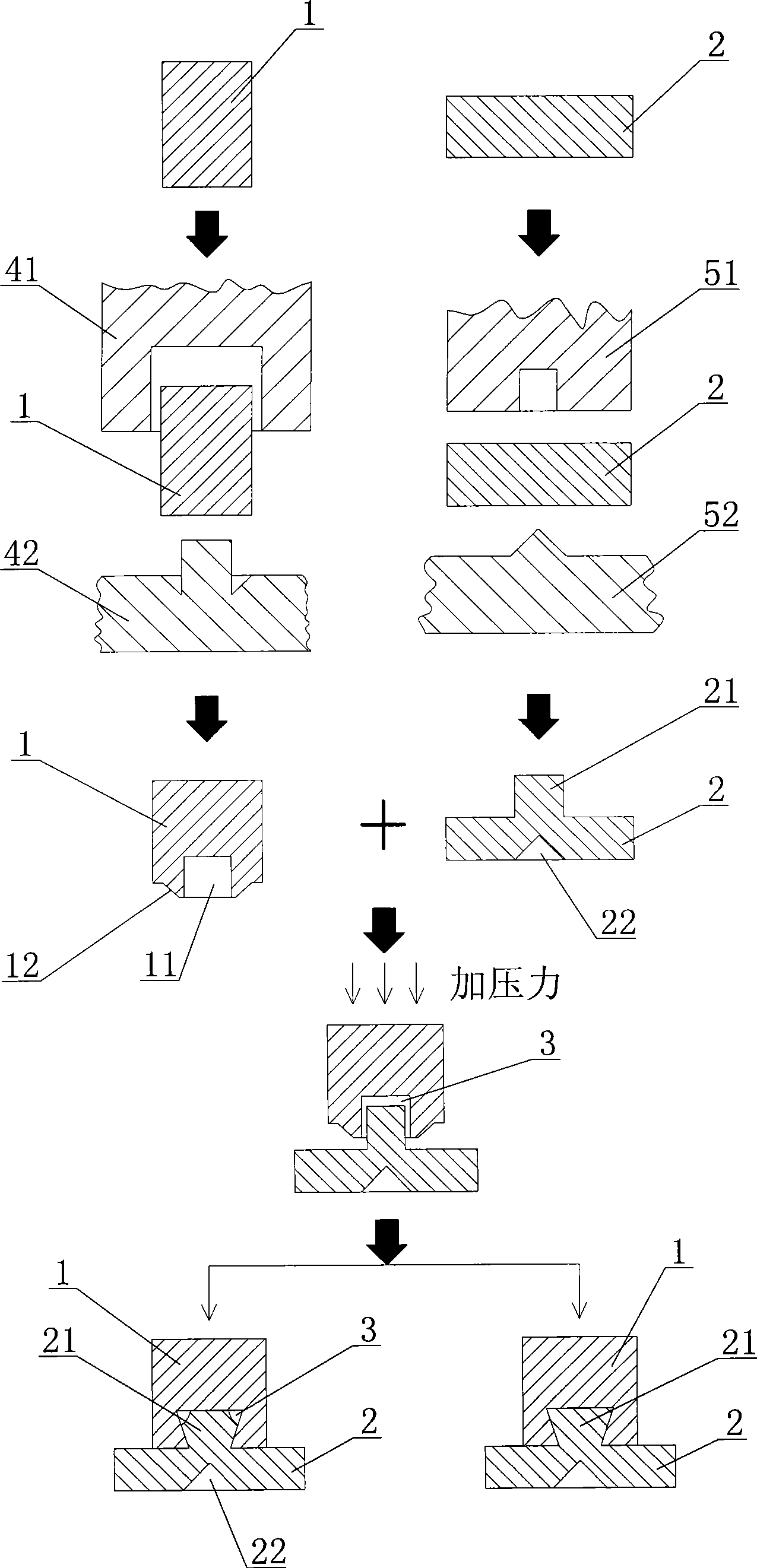

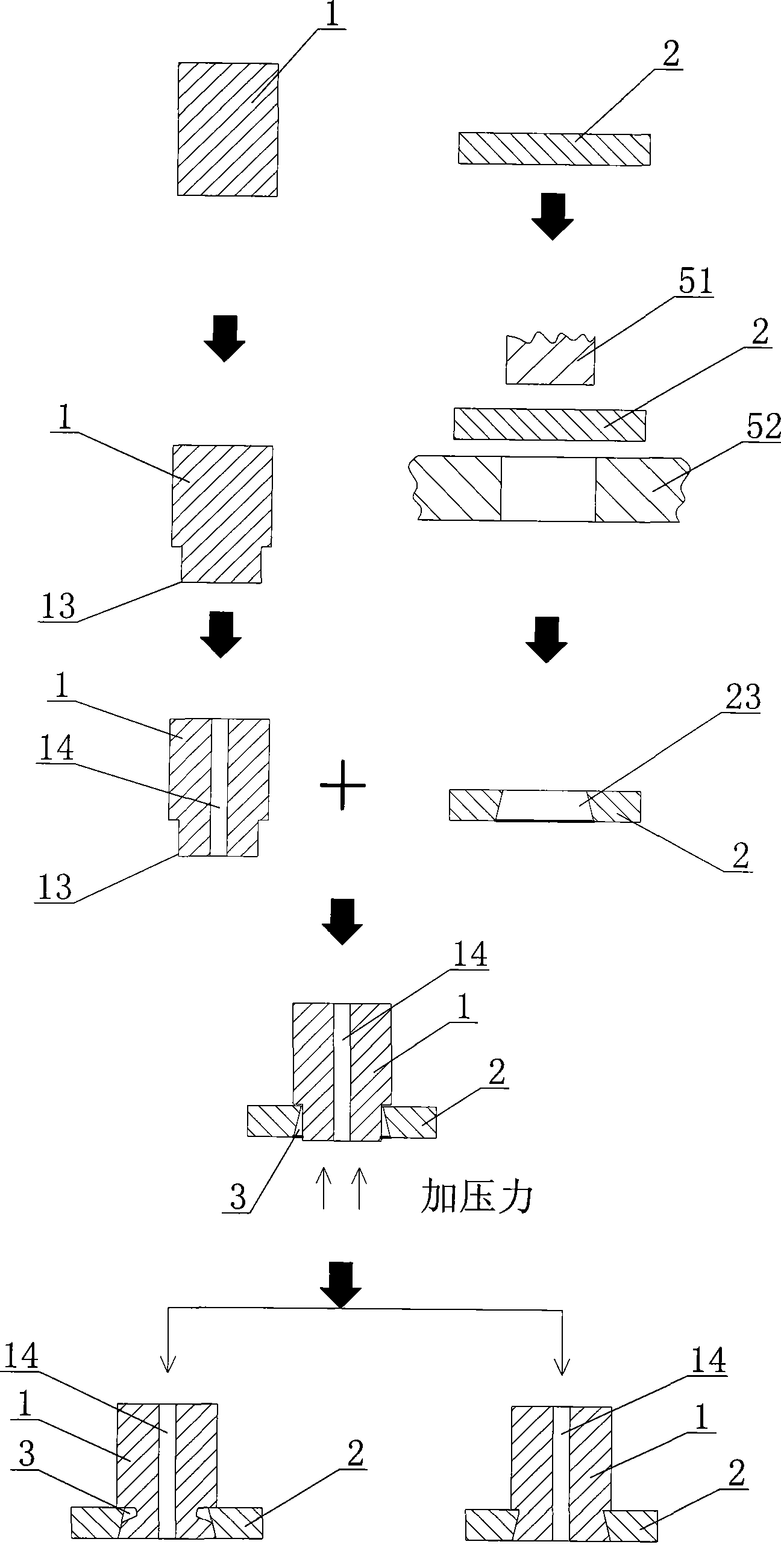

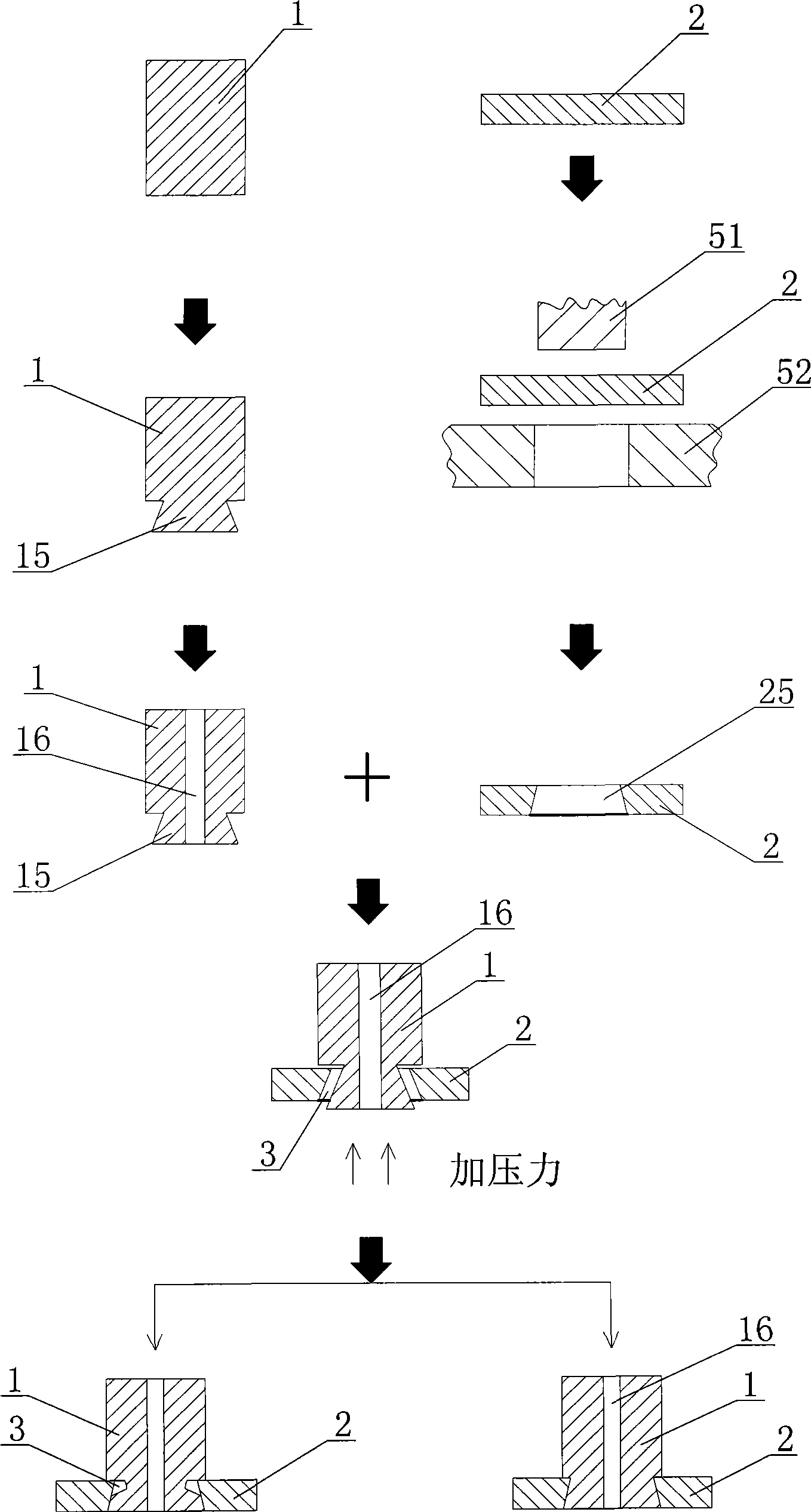

Riveting method

The invention relates to a riveting method, which comprises the following steps: firstly, two metal elements to be riveted are pretreated by utilizing the prior machining method of punching or lathe processing, and a gap is formed on a riveted point of the two metal elements to be riveted; and secondly, pressure is applied on the riveted point of the two metal elements to be riveted through combined punched riveting, so that the two metal elements mutually extrude and fill up the gap to form firm connection. The riveting method adopts the two-step method of combining pretreatment by the prior machining method and filling of hollow cavities and expanded angles, and performs the pretreatment of certain shape on the metal elements to be mutually riveted by utilizing the prior machining method of punching or lathe processing first; after the riveted point is formed, the combined punched riveting is used to make the two metal elements provided with the hollow cavities before combination mutually extrude influenced by punching and fill up the hollow cavities to form a reversely suspended locking mechanism which is partially filled or fully filled, so the aim of firm riveting is achieved.

Owner:李殷德

Automatic pipe laying machine

The invention discloses an automatic pipe laying machine. The automatic pipe laying machine consists of four main structures: a flexible pipe jacking and loading mechanism, a belt conveyor line mechanism, a front head and back head distinguishing mechanism and a rotary translation mechanism. According to the automatic pipe laying machine, manual operation is replaced, and a series of actions of automatic pipe trimming, automatic pipe feeding, automatic pipe turning and automatic pipe laying are realized. In this way, automatic continuous production can be realized, and a worker can operate and keep an eye on several pieces of equipment, so that the labor cost is remarkably reduced; and the automatic pipe laying machine has the characteristics of being wide in application range, simple and convenient to operate, high in efficiency and stable in operation.

Owner:HEBEI ANTAI PLASTIC PACKAGING PROD LTD

Light-penetrating concrete preparation process based on optical fibers wrapped with mortar

ActiveCN104827565AReduce workloadReduce labor intensityConstruction materialFibre light guidesCement mortarOptical fiber cable

The invention discloses a light-penetrating concrete preparation process based on optical fibers wrapped with mortar. The process comprises the steps of making the straightened optical fibers penetrate through the cement mortar so that the mortar can adhere to the surfaces of the optical fibers; making the optical fibers to which the cement mortar adheres pass through a shaping barrel so that excessive mortar can be scrapped off; after the cement mortar wrapping the surfaces of the optical fibers is hardened, cutting the optical fibers into equilong optical fiber core strips; aligning the two ends of the optical fiber core strips, and arranging the optical fiber core strips closely together by way of bundling or stacking in formworks; pouring the cement mortar into gaps among the optical fiber core strips; after the cement mortar is hardened, grinding the two ends, in the optical fiber arrangement direction, of concrete, and obtaining the light-penetrating concrete when the optical fiber ends are exposed. By means of the preparation process, when the optical fiber core strips are closely arranged, the array is orderly, spaces among columns and rows of the optical fiber array can be adjusted through thickness variance of a mortar wrapped layer at the surface of the optical fiber, and by utilizing the formworks in different cross-section shapes, the light-penetrating concrete with various forms can be fabricated; in addition, the automated continuous production is achieved, and the fabrication cost of the light-penetrating concrete is greatly reduced.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

Microwave hot forming apparatus

The present invention combines microwave heating technology and traditional press. The microwave hot forming apparatus includes pressing unit, microwave heater, upper and lower molds and demolding unit. The microwave heater is set inside the upper mold and / or in the bottom of the lower mold, microwave acts on the material via the energy locking port and microwave transparent window in the bottom board to heat the material via its dielectric loss. While heating, the material is microwave heated to cure and form. The present invention has the simultaneous heating of inside and outside of the material, and the heating is homogeneous, fast and high in efficiency. The present invention combines formation, curing and stoving.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Superfine crushing wall-breaking method of haematococcus pluvialis cell

The invention relates to a wall-breaking method of algae, and in particular relates to a superfine crushing wall-breaking method of a haematococcus pluvialis cell. According to the method, superfine crushing equipment is adopted and is matched with liquid nitrogen equipment, so that the haematococcus pluvialis is frozen instantaneously to become brittle. Therefore, the wall-breaking rate is improved, and the protection environment of a low temperature and oxygen isolation are realized. After the wall-breaking treatment is carried out on the haematococcus pluvialis cell by using the method, the active substance of the haematococcus pluvialis cell has a high leaching rate and is not oxidated, so that the extraction ratio of the active substance is improved. The method is simple in process and convenient to operate, and can be used for performing the one-step treatment on a small quantity of samples in a short time and can also be matched with continuous equipment, sample collection equipment and the like to realize the automatic and continuous production, i.e., the mechanization degree is higher, so that the method is suitable for industrialized production. In addition, the samples are not polluted during the equipment running process, so that the safety is high.

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

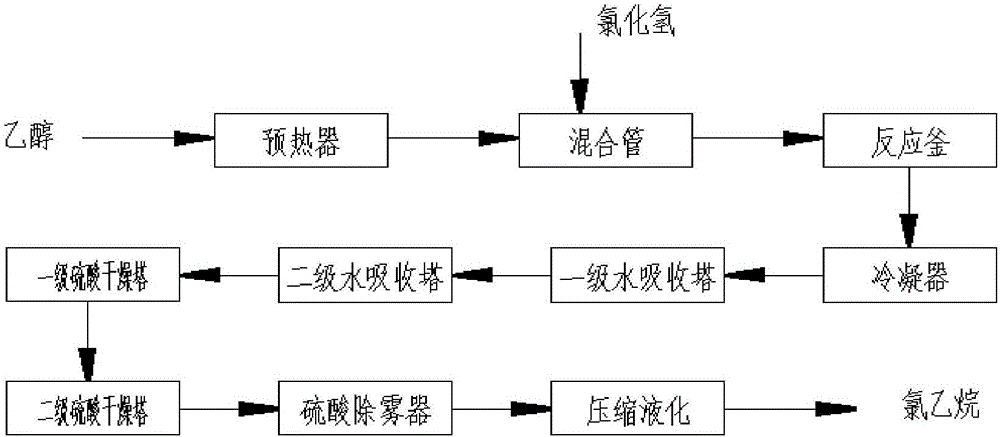

Continuous production method of ethyl chloride

ActiveCN106831315APromote dehydrationReduce shockHalogenated hydrocarbon separation/purificationGas phaseReaction rate

The invention discloses a continuous production method of ethyl chloride. The method comprises the following steps: (1) mixing: preheating ethanol to 50-100 DEG C by a preheater, sending the ethanol into a mixing tube, sufficiently mixing with hydrogen chloride gas, and continuously introducing the mixture into a reaction kettle; (2) reaction: preparing a zinc chloride water solution in a reaction kettle, carrying out reaction on the chlorine hydride and ethanol at 100-160 DEG C under the pressure of 0.01-0.2 MPa under the action of zinc chloride to remove water, condensing the gas-phase system by a condenser to obtain a gas-phase ethyl chloride crude product and a condensate, and returning the condensate to the reaction kettle; and (3) refinement: sequentially passing the ethyl chloride crude product through a two-stage water absorption tower, a two-stage sulfuric acid drying tower and a sulfuric acid demister, and liquefying by compression to obtain the ethyl chloride finished product. The temperature of the ethanol is enhanced before the reaction, and the chlorine hydride and ethanol are mixed, thereby enhancing the reaction rate; and the method has the advantages of high conversion rate of ethanol, low productive energy consumption and high product purity.

Owner:ZHEJIANG DIBANG CHEM

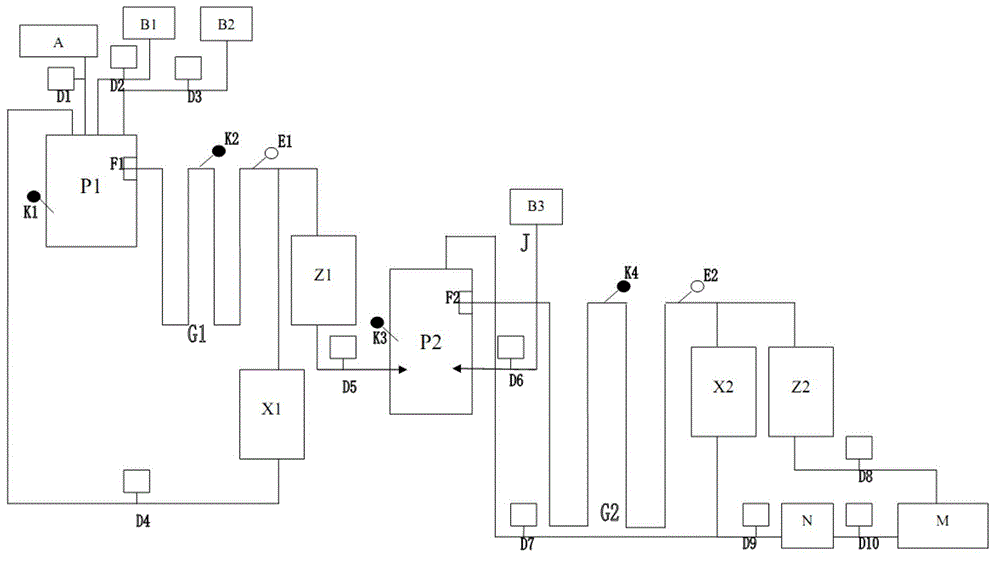

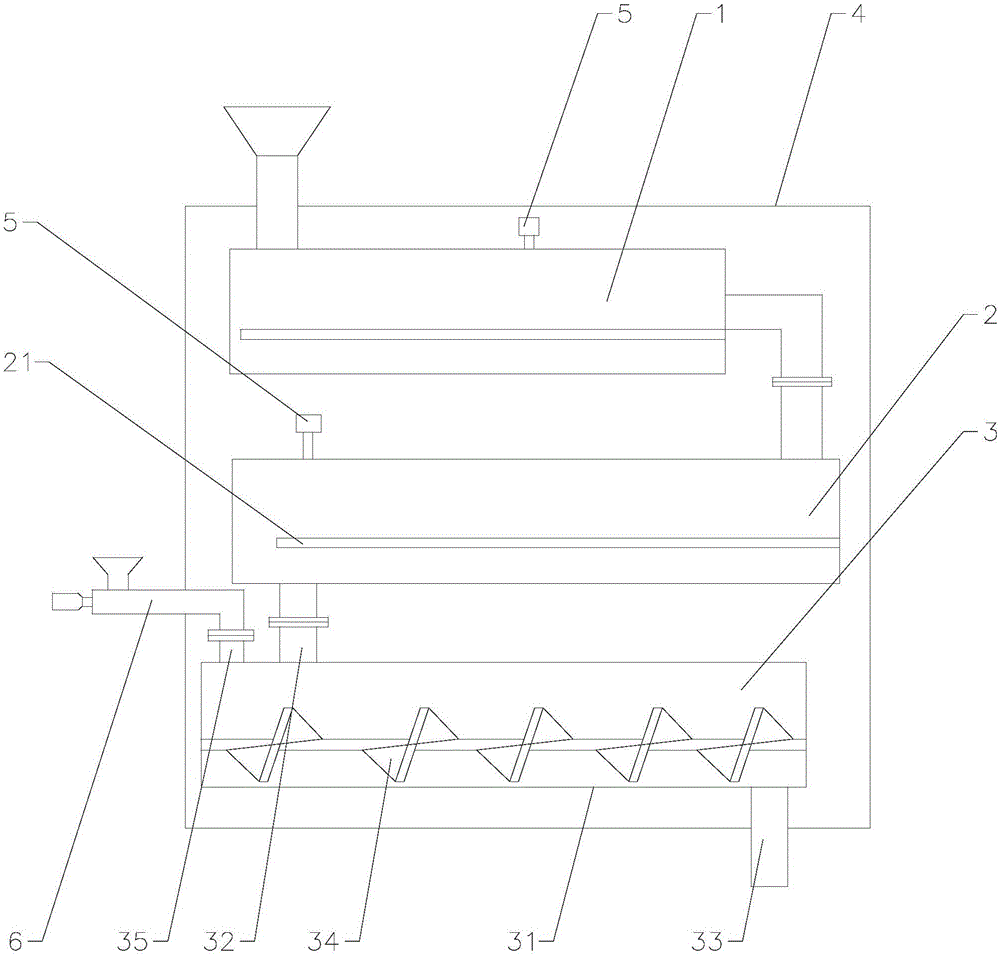

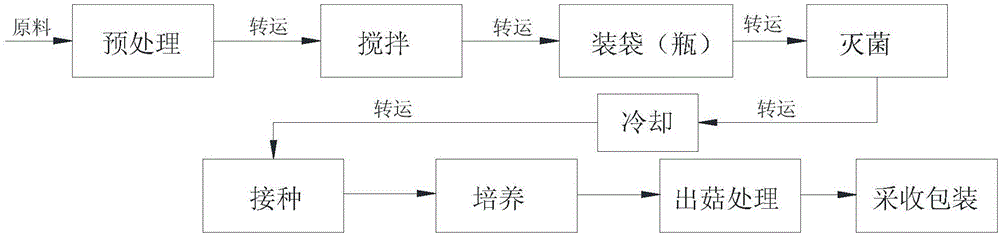

Production equipment for edible mushroom inoculation

InactiveCN105075661AMeet the requirements of industrial mass productionReduce occupancyCultivating equipmentsMushroom cultivationBiotechnologyAnimal science

The invention relates to the technical field of edible mushroom inoculation and especially relates to a kind of integrated production equipment for the edible mushroom inoculation. The production equipment for the edible mushroom inoculation comprises a sterilization device, a cooling device, an inoculation device, a control device and a box body, wherein the inoculation device comprises a shell body, a feeding connecting hole, a discharge connecting hole and a first transmission mechanism used to stir and convey a solid culture medium, the shell body is equipped with a feeding hole used to add edible mushroom bacteria into the solid culture medium, and the feeding connecting hole and the discharge connecting hole are disposed in the shell body and firmly connected to the shell body; and the sterilization device, the cooling device and the inoculation device are disposed inside the box body, an outlet of the sterilization device is firmly connected to an inlet of the cooling device, an outlet of the cooling device is firmly connected to the feeding connecting hole, and the control device is connected to the first transmission mechanism by signals. In this way, problems such as that an existing edible mushroom inoculation device cannot realize automatic and continuous production can be effectively solved.

Owner:JIANGSU TIAN DE POWER EQUIP

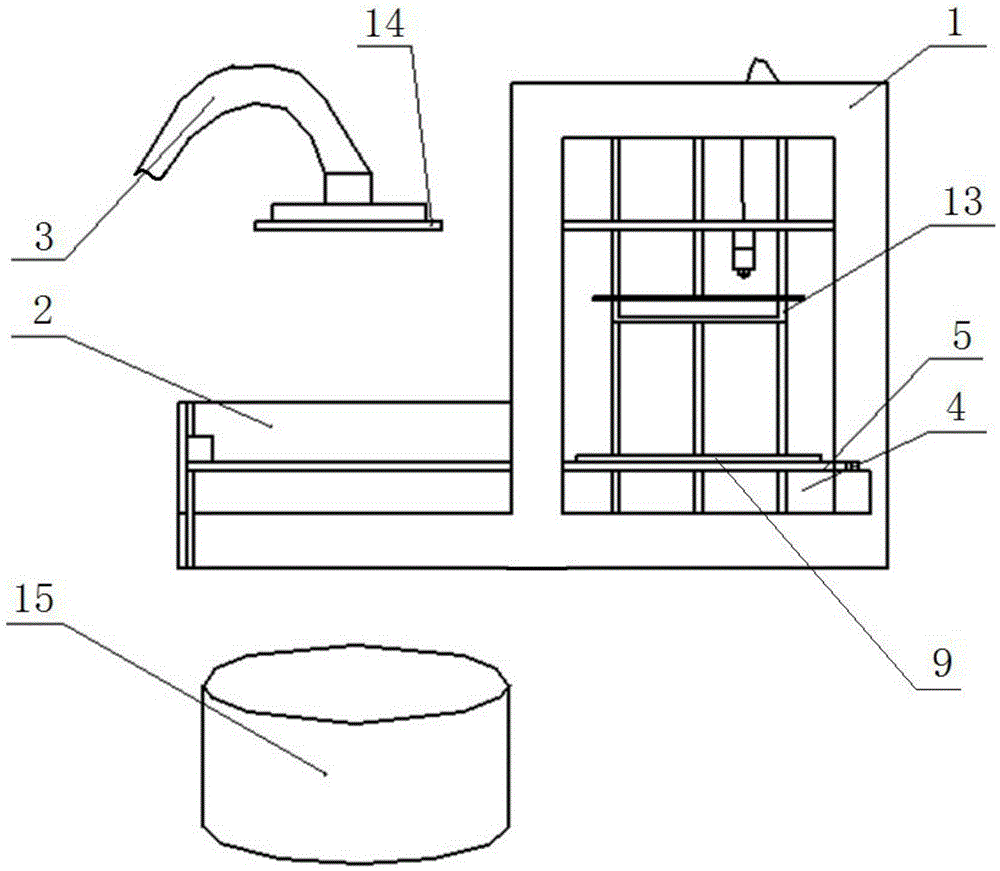

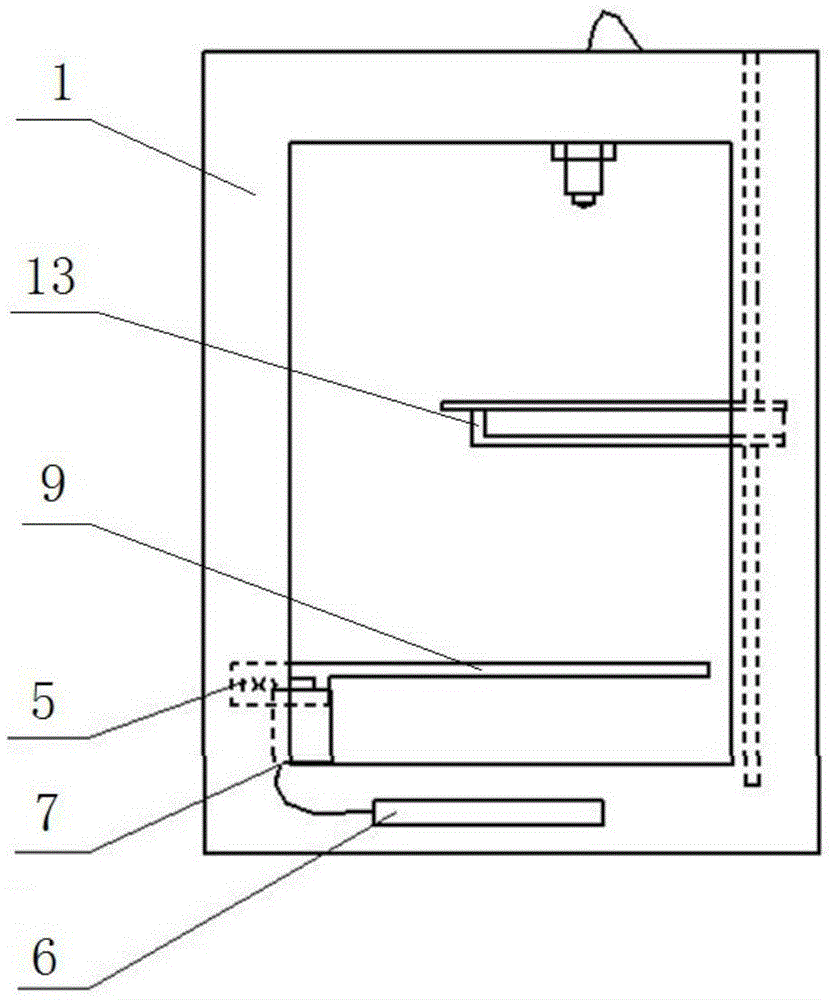

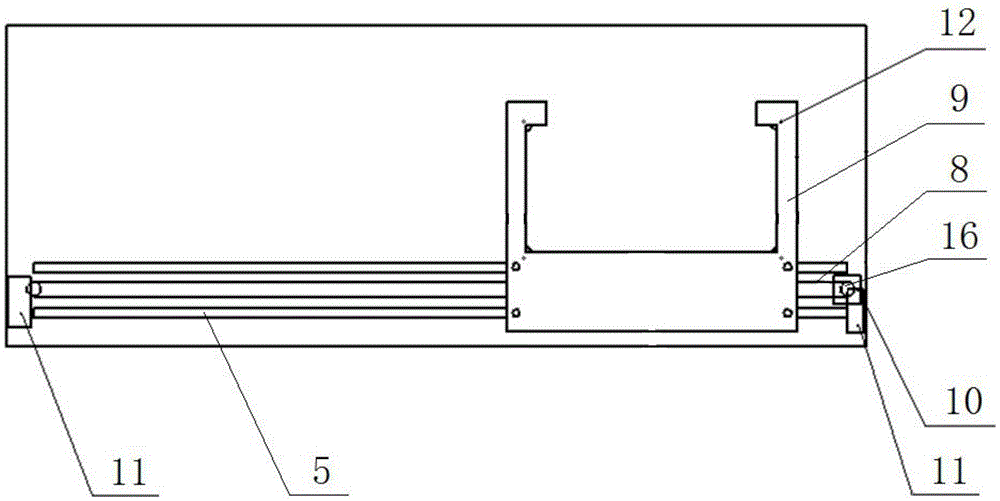

3D printer continuous printing system with automatic discharging and replacing functions

InactiveCN105563838AHigh degree of automationRealize automatic continuous productionAdditive manufacturing apparatusMarine engineeringOptical axis

The invention discloses a 3D printer continuous printing system with the automatic discharging and replacing functions. The 3D printer continuous printing system comprises a printer, a replacing platform arranged on the left side of the printer, a mechanical arm arranged above the replacing platform and an automatic discharging and replacing device arranged below the printer. The automatic discharging and replacing device comprises horizontal polished shafts, a controller, a driver and a replacing plate. One end of each horizontal polished shaft is connected to the printer and the other end of each horizontal polished shaft is connected to the replacing platform. The replacing plate is installed on the horizontal polished shafts in a sliding manner. The driver drives the replacing plate to move along the horizontal polished shafts and is connected to the controller. The controller is connected to the printer. A blanking hole is formed in the replacing plate. The shape of the blanking hole is matched with that of the printing platform. Blanking devices are arranged on the periphery of the blanking hole in the replacing plate and connected to the controller. By the adoption of the printing system, the 3D printer can conduct automatic continuous production under the condition of unmanned observation, and benefits can be increased for an enterprise.

Owner:WUHAN JIUZHOUZAOWU TECH CO LTD

Derust method and device of metallic material

InactiveCN1830589ASimple structureReliable performanceWork treatment devicesExtrusion cleaning devicesMetallic materialsDiiron Trioxide

Owner:肖金安

Automatic production line for lightweight wall materials

InactiveCN102528921ARealize automatic continuous productionIncrease productivityCeramic shaping plantsProduction lineEngineering

The invention discloses an automatic production line for lightweight wall materials. The automatic production line mainly comprises a feeding system, a mixing system, a material transporting system and forming dies, wherein the feeding system consists of bins and feeding pipes which are connected with the bins; a stirrer of the mixing system is arranged on a support, feeding hoppers are arranged on the support above the stirrer, and a discharge hole is formed on the lower part of the stirrer; and the feeding pipes are arranged above the feeding hoppers of the stirrer, the upper part of a shell of the stirrer is provided with a plurality of fixed feeding holes, the feeding hoppers are positioned above the feeding holes, and an electronic scale is arranged at the lower port of each of the feeding hoppers. When the production line is used, different types of materials are respectively stored in the different bins and conveyed to the feeding hoppers by the feeding pipes automatically, the materials are accurately weighed by the electronic scales below the feeding hoppers, the uniformly stirred materials are discharged to the forming dies from the space below the stirrer, the forming dies are circularly transported on a rail transport vehicle, and fixed drying and demoulding treatment are performed at the other end of a production site.

Owner:云南鑫鼎建材有限公司

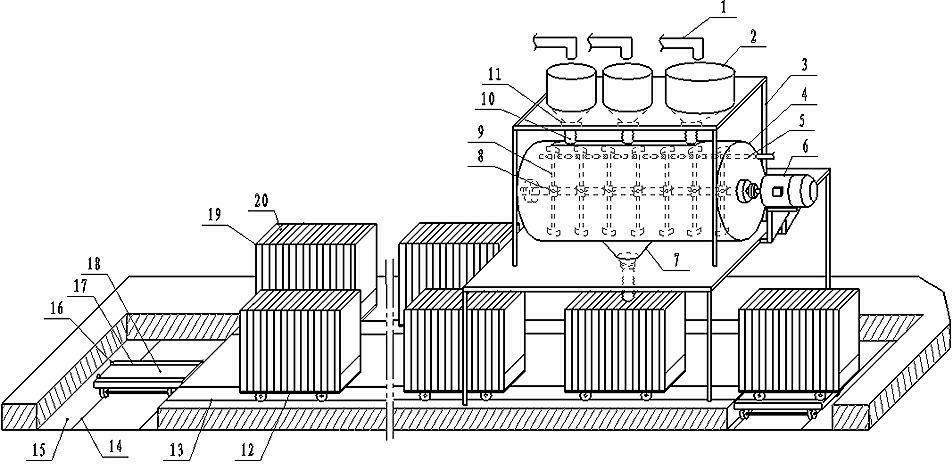

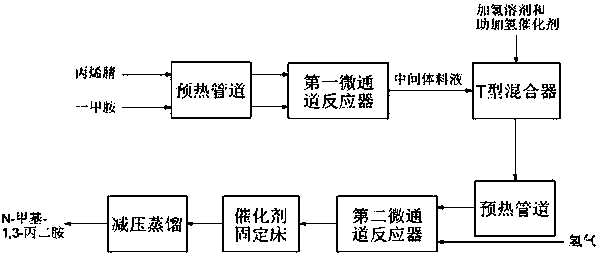

Preparation process method of N-methyl-1, 3-propane diamine

ActiveCN111454159AQuick disperse transferWell mixedCarboxylic acid nitrile preparationOrganic compound preparationAminopropionitrilePtru catalyst

The invention discloses a preparation process method of N-methyl-1, 3-propane diamine, and belongs to the technical field of organic synthesis. According to the method, monomethylamine and acrylonitrile are used as raw materials, an intermediate 3-methylaminopropionitrile is generated through a reaction in a micro-channel reactor, the intermediate is mixed with hydrogen and enters a catalyst fixedbed for a hydrogenation reaction, and finally the product N-methyl-1, 3-propane diamine is obtained. According to the preparation process method of N-methyl-1, 3-propane diamine, the method is simple, continuous production can be achieved, the reaction time is short, the side reaction occurrence probability is low, the product yield reaches 90-95%, and the productivity is improved.

Owner:DALIAN UNIV OF TECH +1

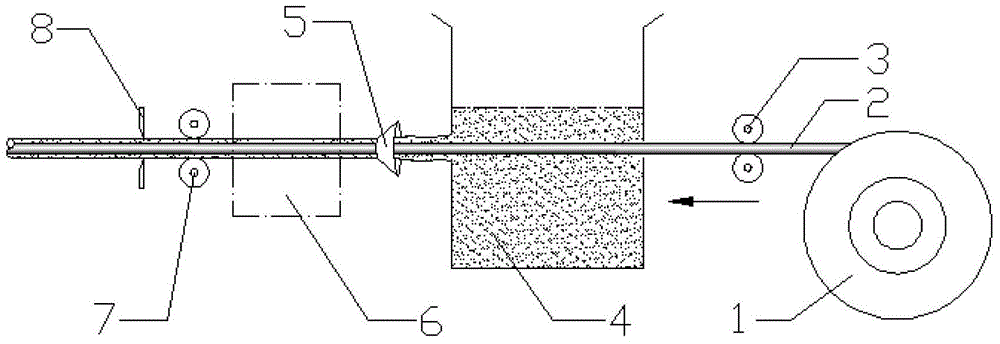

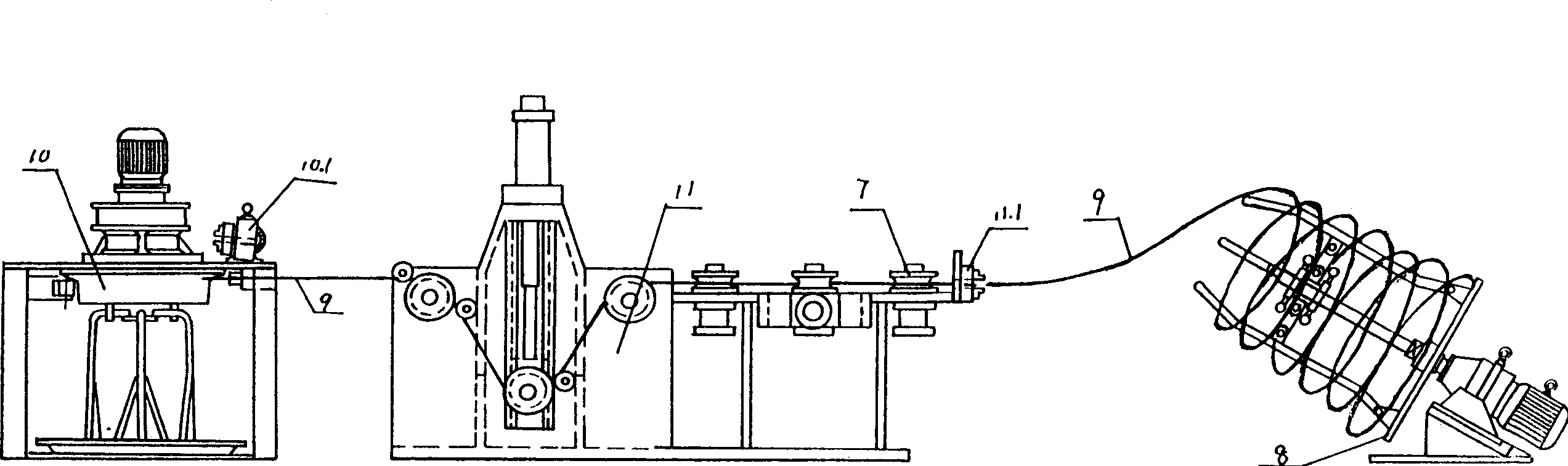

Continuous production line for flexible galvanized steel pipe

ActiveCN106756702AImprove surface qualityFree laborHot-dipping/immersion processesProduction lineEngineering

The invention discloses a continuous production line for a flexible galvanized steel pipe, and belongs to the technical field of hot-galvanizing automatic production. The continuous production line comprises a zinc pot and a main support, wherein the zinc pot is arranged below the main support; liquid zinc is stored in the zinc pot; the main support comprises a feeding mechanism, a downward pressing mechanism, a lifting mechanism, a poking mechanism and a delivery mechanism; the feeding mechanism and the downward pressing mechanism convey steel pipes into liquid zinc in the zinc pot; the lifting mechanism extracts liquid zinc from the zinc pot; the poking mechanism conveys galvanized steel pipes to the delivery mechanism; the downward pressing mechanism enables the feeding mechanism, the lifting mechanism and the poking mechanism to be connected through a four-bar mechanism; the delivery mechanism is arranged in the rear of the poking mechanism. The adopted automatic production line can realize continuous production of galvanized steel pipes, improve the surface quality and liberate the labor force, and can be applied to steel pipes with different pipe diameters.

Owner:山东鲁盟威金属科技有限公司

Combining arrangement device for multiple kinds of boards

ActiveCN106659109AIncrease productivityRealize automated productionElectrical componentsEngineeringContinuous production

The invention provides a combining arrangement device for multiple kinds of boards. The combining finishing device comprises a feeding conveying mechanism, a conveying aligning mechanism, a centering / punching / pin-mounting mechanism, an overturning mechanism, a conveying / centering / rotating mechanism, a metal sheet feeding mechanism, a three-surface adhesive tape adhering mechanism and a blanking mechanism. The conveying aligning mechanism, the centering / punching / pin-mounting mechanism, the overturning mechanism, the conveying / centering / rotating mechanism, the metal sheet feeding mechanism and the three-surface adhesive tape adhering mechanism are successively arranged between the feeding conveying mechanism and the blanking mechanism. The combining arrangement device has high production efficiency and totally realizes automatic production. An integrated design is applied to the feeding mechanism, the conveying mechanism, a centering mechanism, a combining mechanism, a punching mechanism, a pin mounting mechanism, the three-surface adhesive tape adhering mechanism, etc. Furthermore the combining arrangement device has advantages of realizing automatic continuous production, improving production efficiency, effectively reducing production cost and manufacture cost and realizing high stability of products.

Owner:尹乐琼

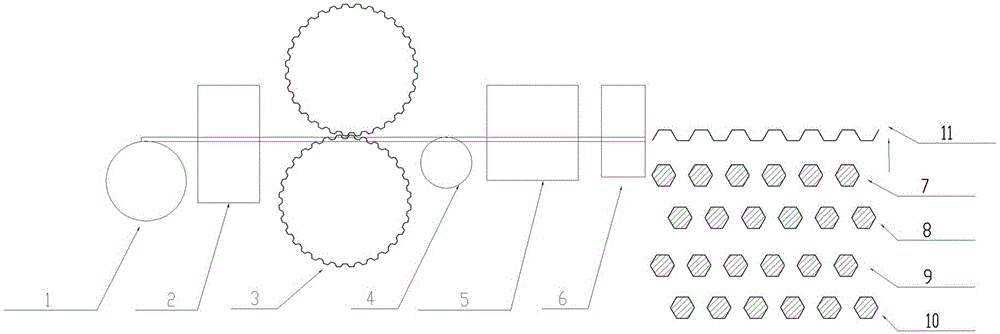

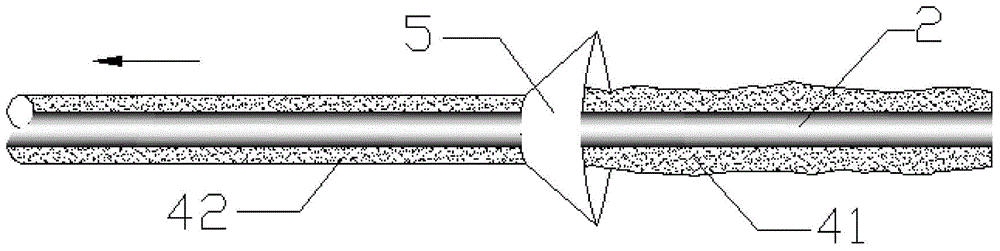

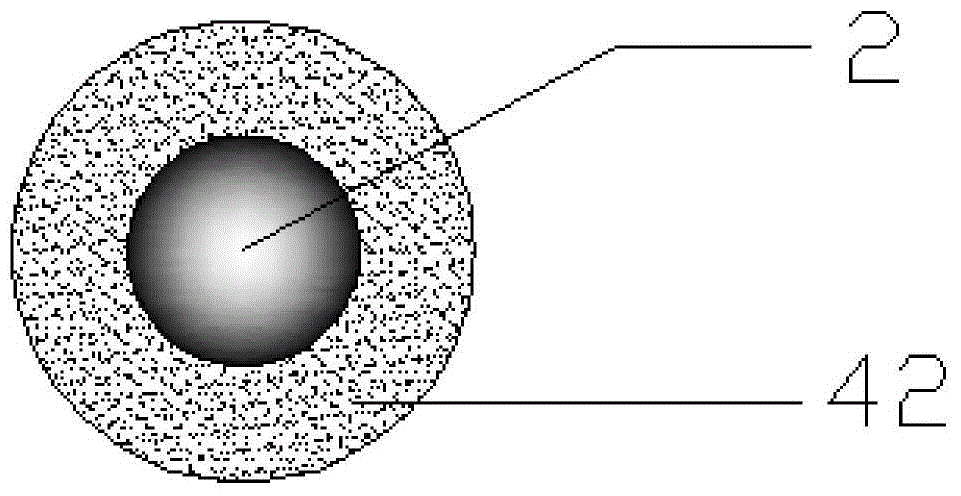

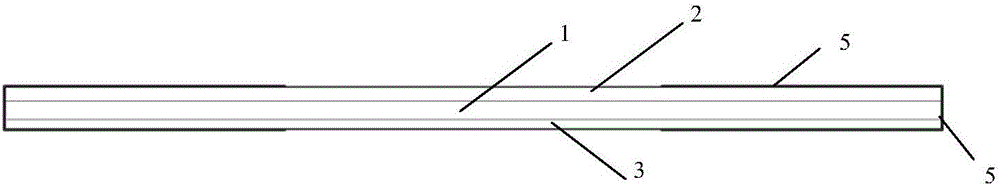

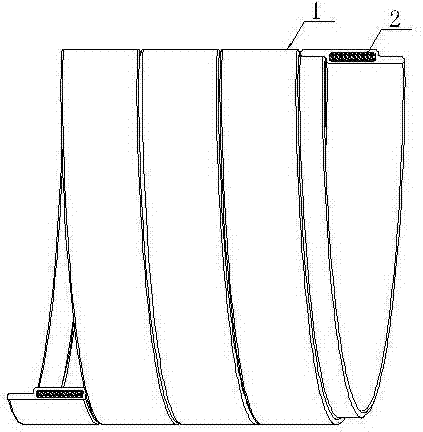

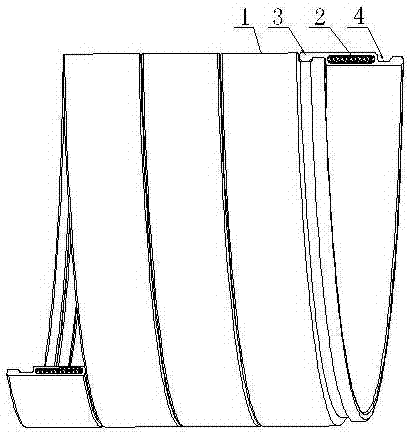

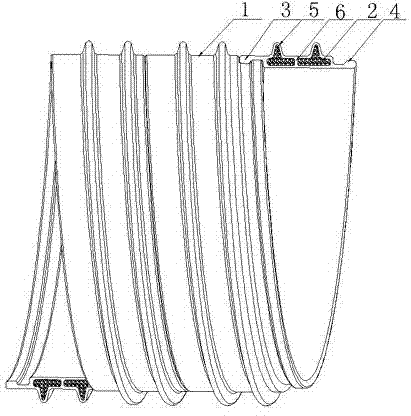

Foamed reinforced plastic winding pipe, manufacturing method of foamed reinforced plastic winding pipe and special equipment for foamed reinforced plastic winding pipe

InactiveCN104329518AImprove tensile propertiesIncrease stiffnessRigid pipesHigh resistanceWinding machine

The invention discloses a foamed reinforced plastic winding pipe, a manufacturing method of the foamed reinforced plastic winding pipe and special equipment for the foamed reinforced plastic winding pipe. The foamed reinforced plastic winding pipe consists of a plastic pipe formed by spiral winding; a foamed layer is arranged between the outer wall and the inner wall of the winding pipe; a plastic extruder and a foaming material extruder are simultaneously connected to an extrusion die; the plastic extruder extrudes the inner wall and the outer wall of the pipe by a hole on the side wall of the die; the foaming material extruder extrudes a foaming material by a hole on a core rod of the extrusion die; the extruded pipe is rolled up by a roll-up machine after being sized by a vacuum cooling sizing machine so as to obtain a plastic section and the rolled plastic section is transferred into a spiral winding machine to be subjected to winding and forming to obtain the foamed reinforced plastic winding pipe. The foamed reinforced plastic winding pipe has the characteristics of strong pressure resistance, light weight, high resistance to tension in the axial direction of a pipe body, simple production method and high production efficiency.

Owner:烟台方大滚塑有限公司

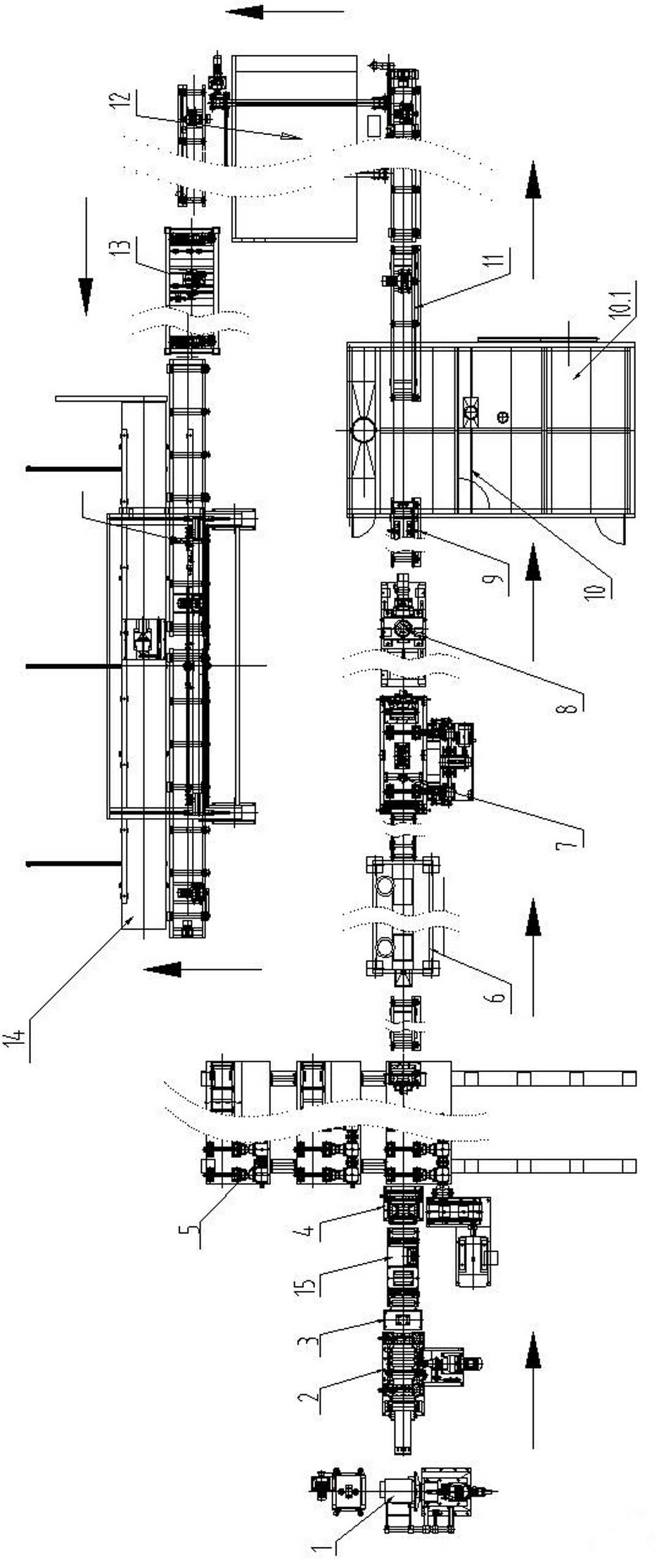

Automatic production line for full-continuous container section bar

InactiveCN102632387ARealize continuous productionSave materialOther manufacturing equipments/toolsProduction lineSprayer

The invention provides an automatic production line for a full-continuous container section bar. The automatic production line comprises a material winder, a leveling machine, a head and tail shearing machine, an upright guide roller, a cold-rolling forming machine, a sanding machine, a correction machine, a pair of fixed scale tracking scissors, a painting spraying conveyer, paint sprayer, a drying conveyer, a dryer, a chamfering machine and an aggregate stocker, wherein a steel band welding machine is arranged between the head and tail shearing machine and the upright guide roller; a sliding guide rail is arranged on a stander of the cold-rolling forming machine; a supporting plate is arranged on the sliding guide rail; a sliding chute matched with the sliding guide rail is formed at the bottom of the supporting plate; a cold-bending forming die is fixedly arranged on the upper surface of the supporting plate; a transmission motor I and a chain wheel are arranged on the stander; and the supporting plate is connected with the motor I through a chain. The automatic production line has the advantages of high automation degree, high production efficiency, low worker labor intensity and low cost, and the labor resources are saved.

Owner:SHANDONG AOYU PRECISION MACHINARY

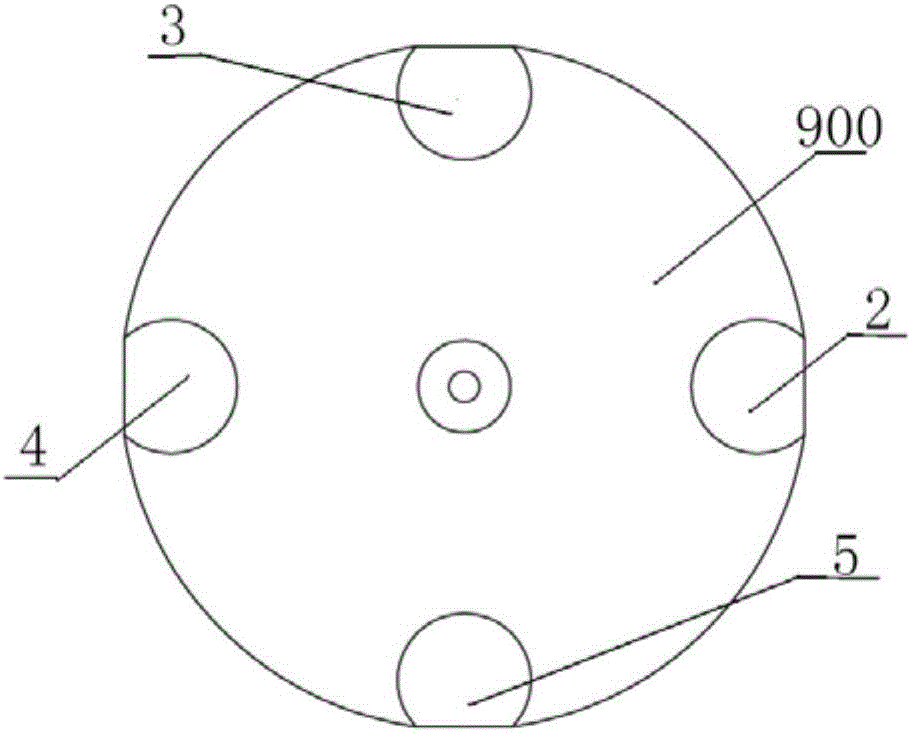

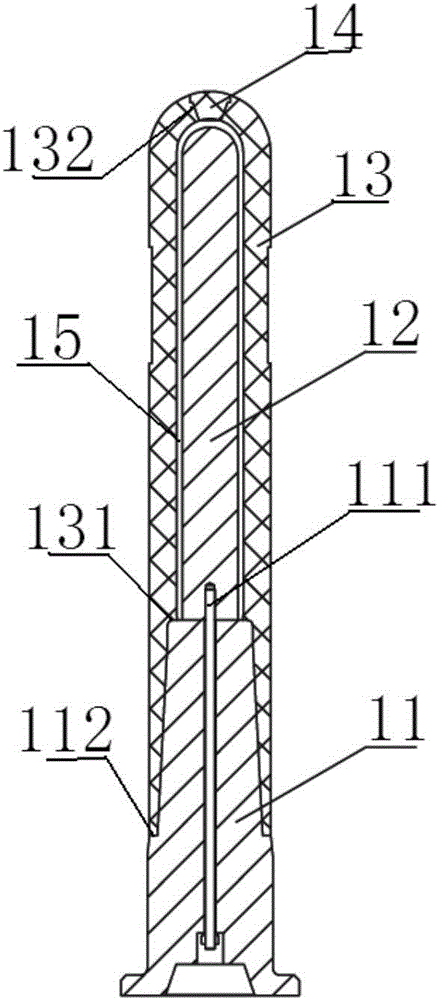

Forming method for solid electrolyte ceramic tube of sodium-sulfur cell

ActiveCN106182343ARealize automatic continuous productionIncrease productivityDischarging arrangementMouldsSulfurSodium–sulfur battery

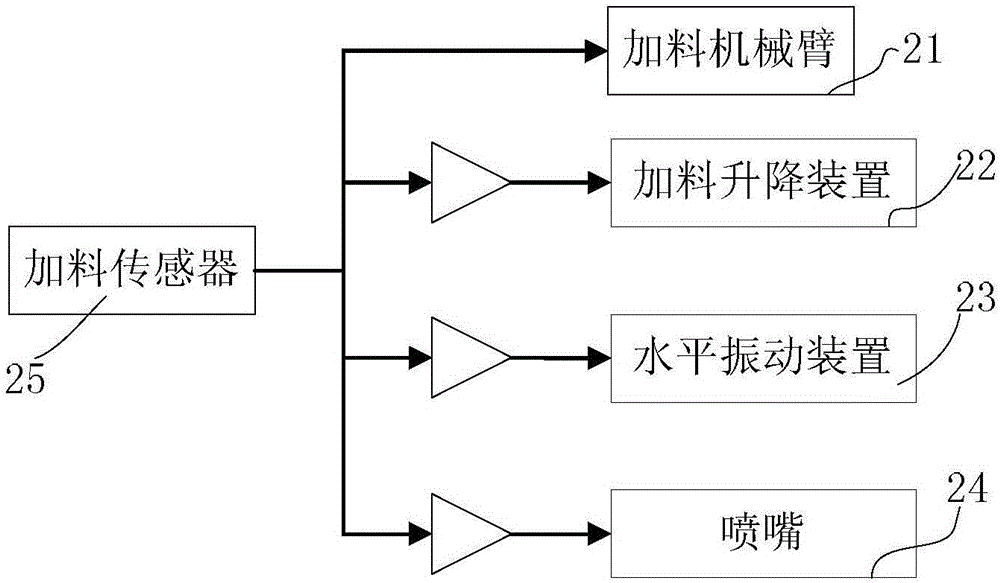

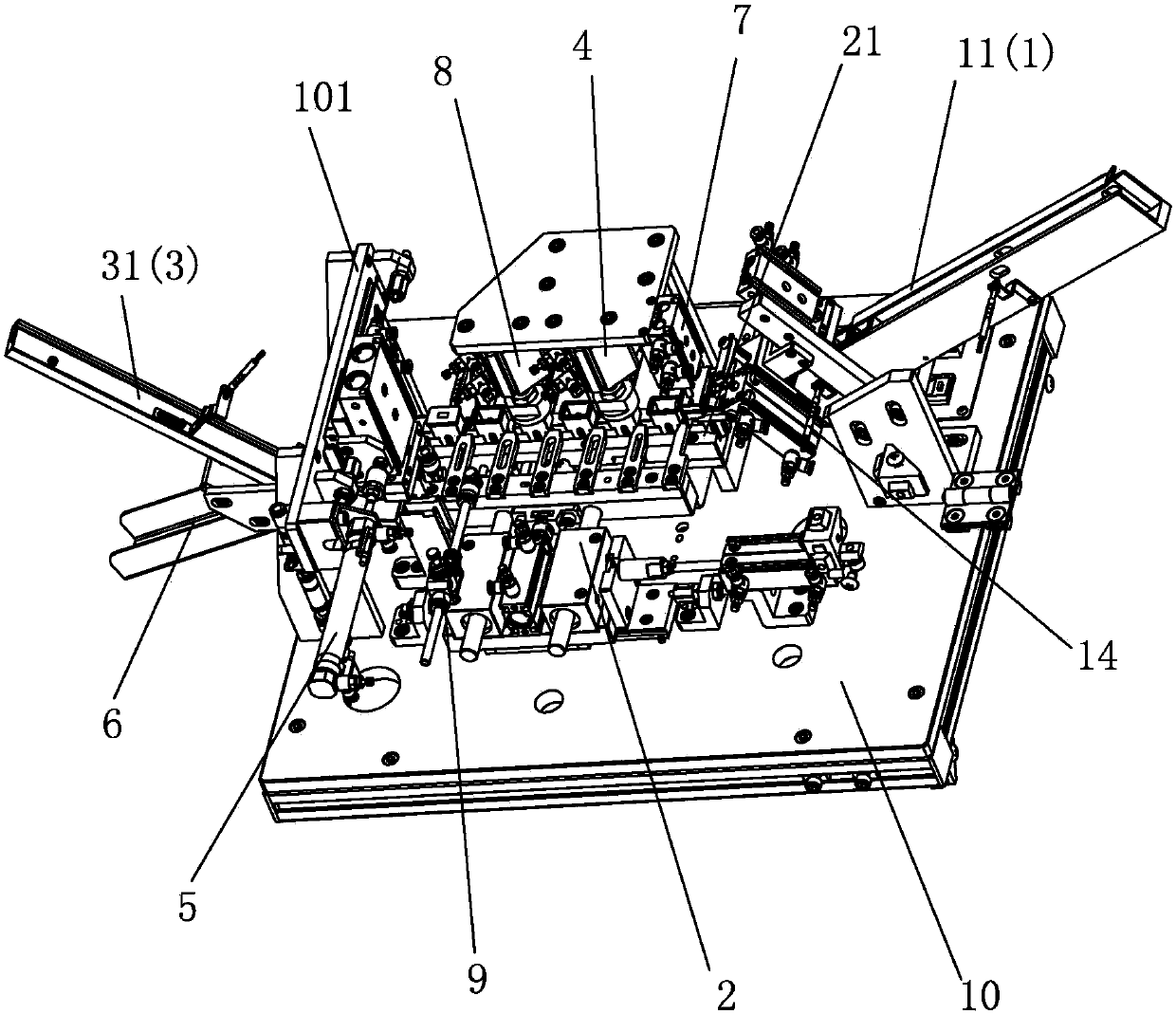

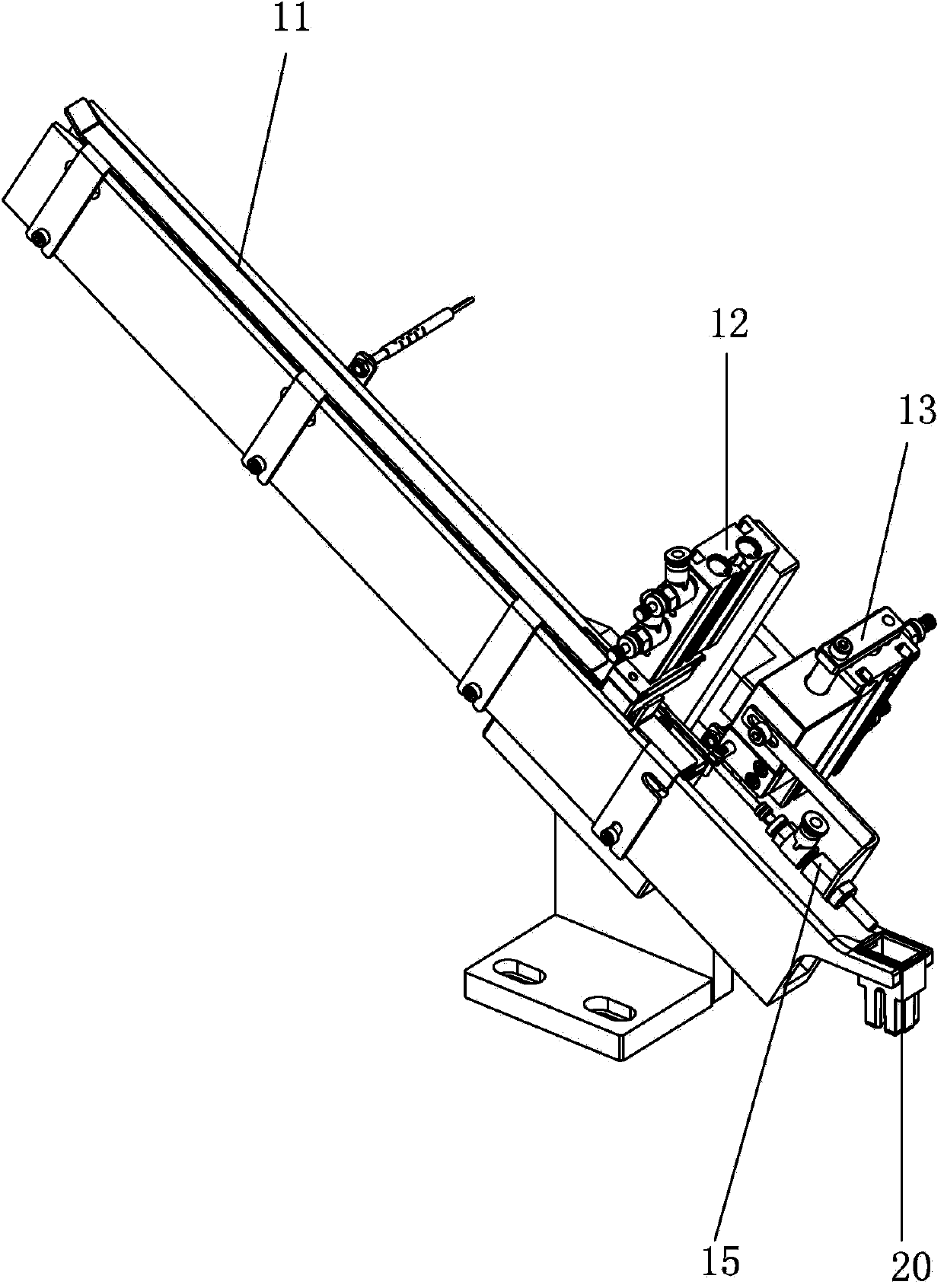

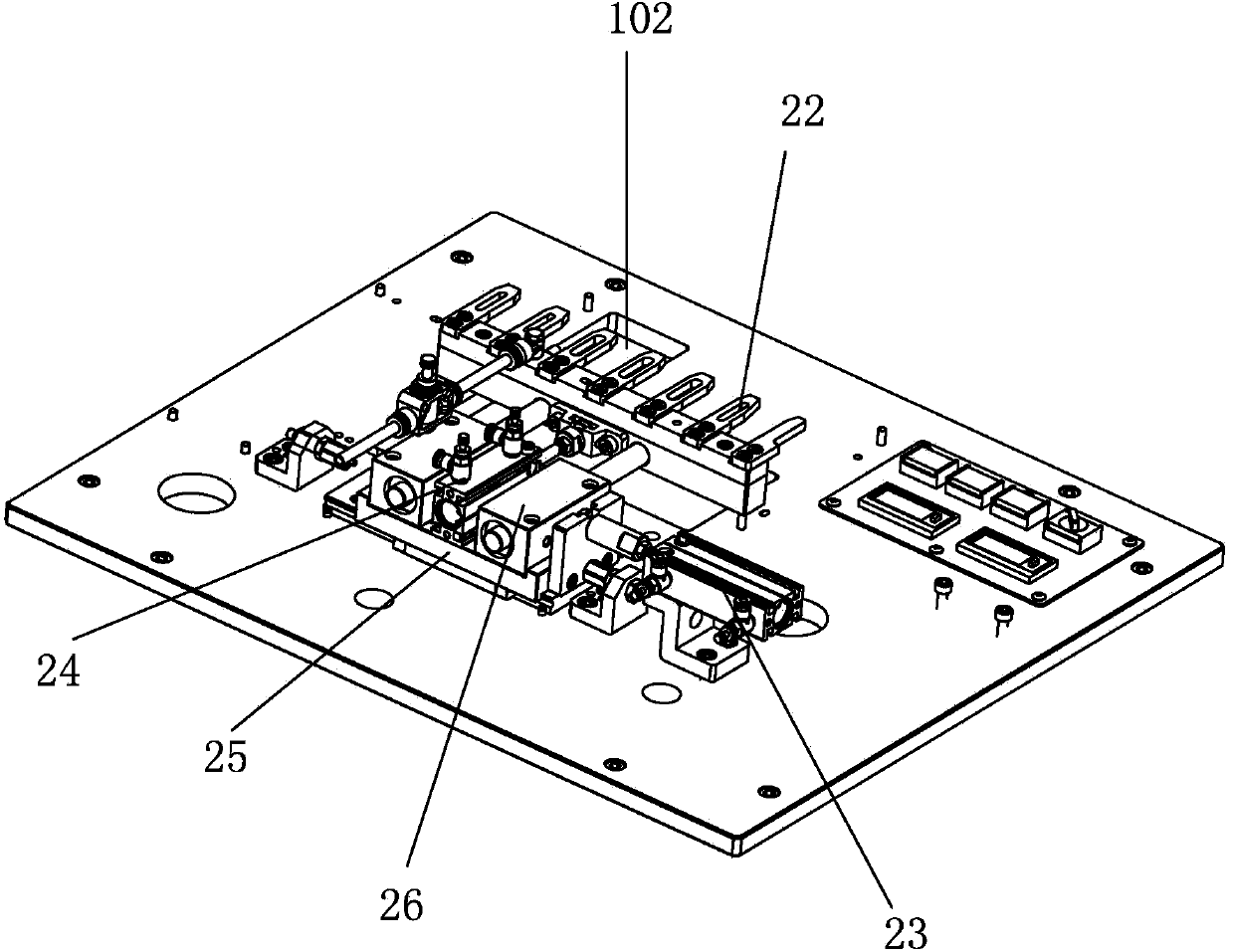

The invention discloses a forming method for a solid electrolyte ceramic tube of a sodium-sulfur cell. The forming method for the solid electrolyte ceramic tube of the sodium-sulfur cell comprises the following steps of material adding, specifically, Na-beta''-Al2O3 powder is added into a mold cavity of a forming mold corresponding to the solid electrolyte ceramic tube of the sodium-sulfur cell in shape, and the top of the mold cavity is sealed; pressing, specifically, the radial outer side of the forming mold is sleeved with a main bag of a main pressure vessel, the forming mold is locked through a bottom sealing cover located at the bottom of the main bag, the main pressure vessel is made to communicate with a pressure pump, pressurization media are injected to the radial outer side of the main bag through the pressure pump, and the Na-beta''-Al2O3 powder in the mold cavity is pressed into a green body of the solid electrolyte ceramic tube of the sodium-sulfur cell; and demolding, specifically, the green body of the solid electrolyte ceramic tube of the sodium-sulfur cell is taken out of the forming mold.

Owner:上海电气企业发展有限公司

Health-care rabbit meat food with flavor of dried orange peel and preparation method of health-care rabbit meat food

InactiveCN105341710AImprove bad smellImprove rough tasteFood ingredient functionsDietary fiberDeep frying

The invention relates to a health-care rabbit meat food with the flavor of dried orange peel and a preparation method of the health-care rabbit meat food. A lactic acid fermentation technique and an enzymolysis technique are adopted for treating rabbit meat products for the first time, besides, dried orange peel powder, a flavor inhibitor, water-soluble dietary fiber and a sweetening agent are added, and a steaming technology and a secondary deep-frying technology are combined, so that the nutrition, the flavor and the mouth feel of the health-care rabbit meat food are improved, and the shelf life of the health-care rabbit meat food is prolonged. The health-care rabbit meat food with the flavor of the dried orange peel, prepared by the preparation method disclosed by the invention, is rich in nutrition, fresh, tender and mellow rather than greasy, rich in flavor and long in shelf life; besides, the preparation method is simple and easy to operate, and large-scale automated continuous production can be realized.

Owner:严洪霞

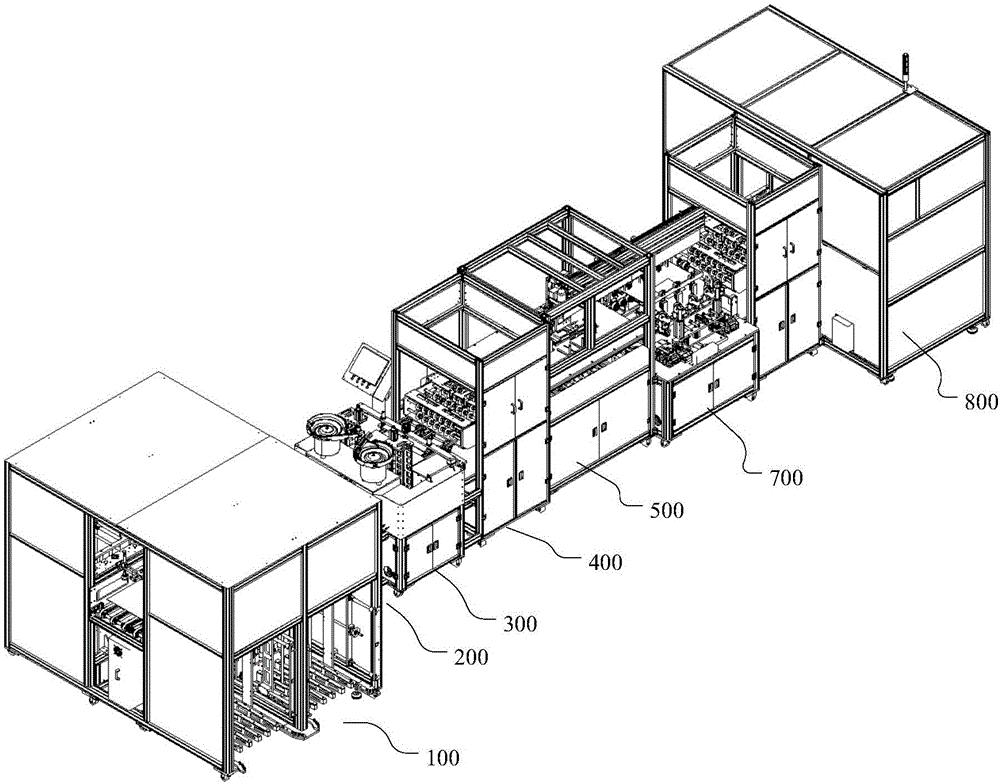

Automatic assembling machine for inserted type fuse and automatic assembling method for inserted type fuse

ActiveCN103996574AReduce labor intensityRealize automatic continuous productionFuse device manufactureEngineeringUltimate tensile strength

The invention discloses an automatic assembling machine for an inserted type fuse and an automatic assembling method for the inserted type fuse. The assembling machine comprises a machine table base. The machine table base is provided with a first feed device, a conveying device, a second feed device, a hole expanding device, an upper cover loading device and a discharge device, wherein the first feed device is used for conveying base parts after case parts and metal parts are assembled, the conveying device is used for conveying the base parts so that the base parts can pass through all working procedures sequentially, the second feed device is used for conveying upper covers, the hole expanding device is used for expanding connecting insertion holes of the base parts, the upper cover loading device is used for loading the upper covers to the base parts, and the discharge device is used for outputting finished products. The base parts are conveyed from a first feed channel to the tail end of a conveying rail, located through a pawl mechanism and sequentially conveyed to stations corresponding to the hole expanding device and the upper cover loading device so that the corresponding working procedures can be finished, and finally the base parts are output through the discharge device; automatic continuous production is achieved, the labor intensity of workers is greatly reduced, the labor productivity is improved, the assembly quality is ensured, and operation is easy and convenient to carry out.

Owner:吉门保险丝制造(厦门)有限公司

Explosive pressing device of explosive charging plate

The invention discloses an explosive pressing device of an explosive charging plate. The explosive pressing device comprises an auxiliary mounting frame, a main lifting plate, an auxiliary lifting plate, an auxiliary lifting plate driving structure, a main lifting plate driving structure, a pressing head arranged on the auxiliary lifting plate and a punching needle. The explosive charging plate aligned with an explosive charging through hole is arranged below the pressing head, and the explosive charging through hole communicates with an explosive charging pipe. The explosive pressing device has the beneficial effects that the punching needle can slide in the explosive charging through hole to press explosive in the explosive charging through hole into the explosive charging plate, the size of the explosive charging through hole can be designed to control the explosive charging accuracy, the explosive charging accuracy can reach the millimeter level, remote and automatic control is better achieved, the automatic degree of the explosive charging process is improved, and a worker is prevented from being in direct contact with explosive so that the safety performance can be enhanced.Automatic and continuous production can be achieved, the explosive charging efficiency is improved, the explosive charging quality is improved, and the explosive charging quality stability is improved.

Owner:绵阳市奥派科技有限公司

High-density aluminum silicate fiberboard and production method thereof

InactiveCN109437686AOvercome heavy water useOvercome continuityCeramic shaping plantsAuxillary shaping apparatusHigh densityAluminum silicate

The invention discloses a high-density aluminum silicate fiberboard and a production method thereof. The production method of the high-density aluminum silicate fiberboard comprises the steps as follows: in the advancing process of a fiber layer, sequentially and continuously gluing the fiber layer, removing surplus glue solution and molding the fiber layer by extrusion to form the fiberboard. Thus, links such as pulping, pumping, mold forming, demolding and patching are omitted, the defects of large water consumption, failure of continuous forming and the like are overcome, the high-density aluminum silicate fiberboard is obtained through extrusion forming, and automatic and continuous production can be realized, so that problems of complex production process, large water consumption, failure of continuous production and the like are solved.

Owner:唐山华纤科技有限公司

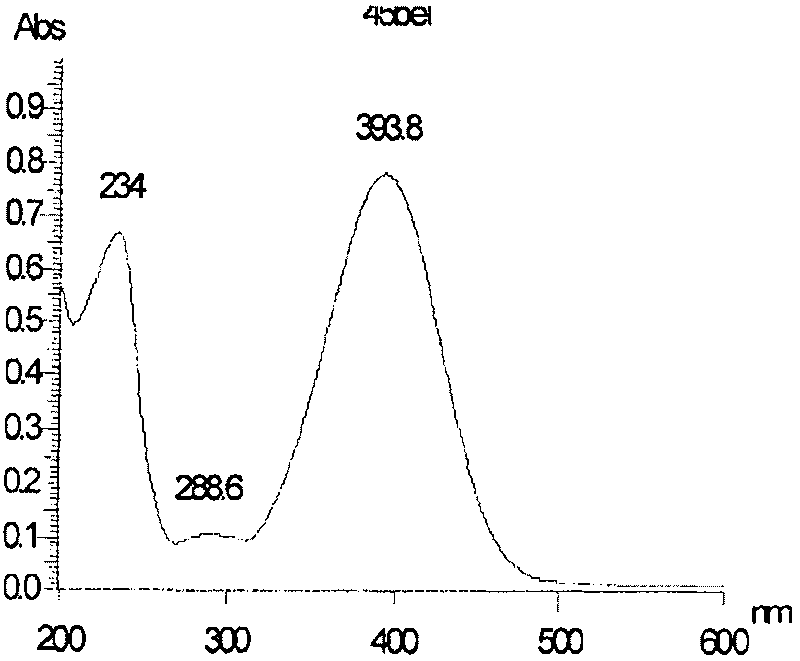

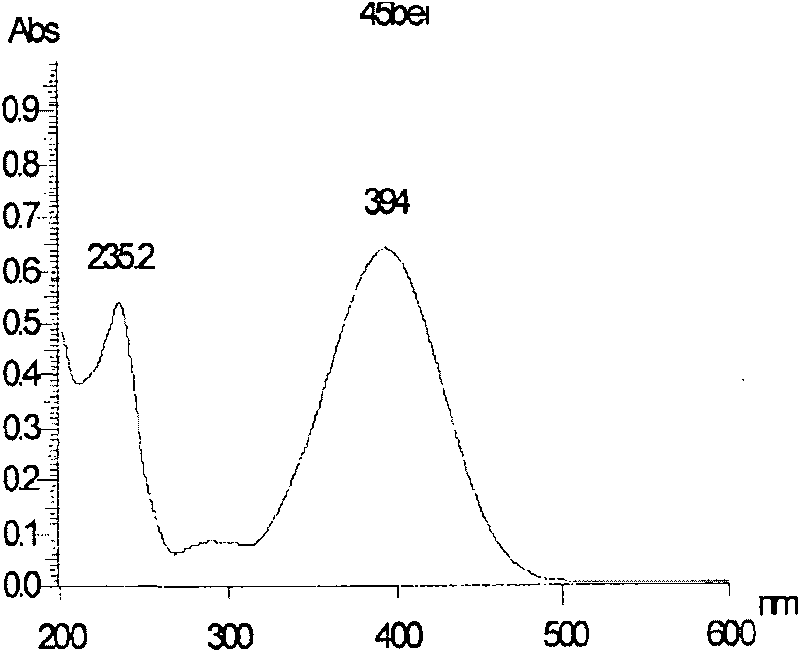

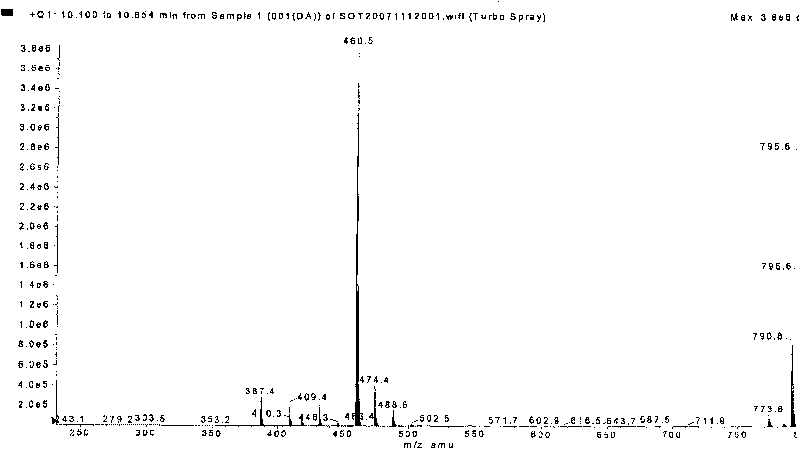

Method for preparing liquid chromatography of monascin and monascus anka flavine pure product

InactiveCN101255168BSimple processEasy to operateOrganic chemistrySolid sorbent liquid separationMonascus ankaAutosampler

The liquid chromatography preparation method for pure products of monascin and ankaflavine belongs to a preparing method for pure products, which uses preparative liquid chromatograph, C18 chromatographic column, wherein the column temperature is room temperature, to detect the target components of which the wave length is 233nm or 394nm, the ratio of mobile phase methanol methanol and water is 8:2, the feeding amount for sample is 1ml, the flow speed is 5ml / min, and the collecting retention times are 37. 733min (monascin) and 68. 100min (ankaflavine) respectively, while the continuous production can be realized by matching the equipment with automatic sampling feeder, automatic collector. The technology can be applied to monascus pigment products with monascin and ankaflavine such as monascus rice flour, monascus pigment powder pasted monascus pigment. The preparing process is simple, convenient in operation, rapid and highly effective, has high automaticity, and can prepare the pureproducts of monascin and ankaflavine at the same time with high product purity and big preparing amount.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

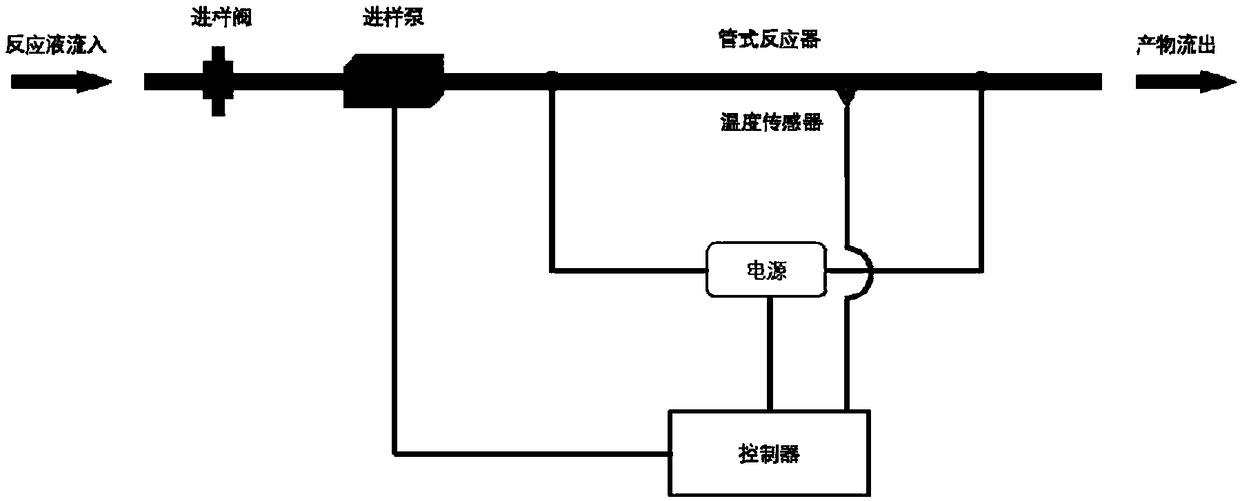

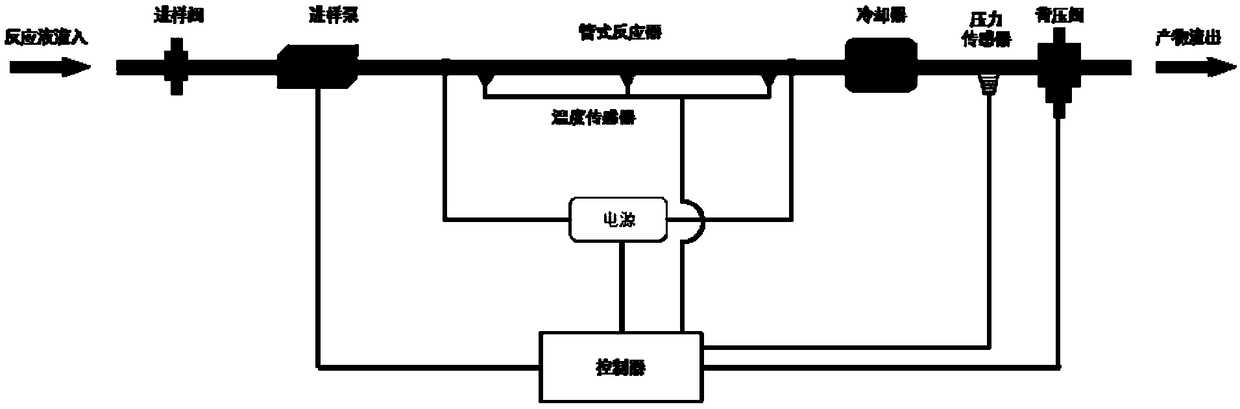

Continuous flowing preparation system and method

InactiveCN108889262AHeating fastAdapt to heating needsChemical/physical/physico-chemical stationary reactorsReaction temperatureProcess engineering

The invention discloses a continuous flowing preparation system and method. The system comprises a controller, and a sample feeding channel, a reactor and a sample discharging channel successively connected. A reaction liquid enters a tubular reactor through the sample feeding channel and a product flows out from the sample discharging channel; the reactor is the tubular reactor which comprises aconductive reaction tube and a power supply module. The power supply module comprises a power supply output end and a control end. The output end of the power supply is electrically connected to two ends of the reaction tube; a temperature sensor is arranged on the reaction tube, the temperature sensor detects a temperature signal in the reactor and transmits the temperature signal to the controller, and the controller controls the output voltage of the power supply module through the control end of the power supply module according to the received temperature signal so as to control the reaction temperature in the reactor. The system and method can overcome the defects that an existing flowing chemical synthetic system is limited in heat transfer rate and is not suitable for large flow continuous flowing preparation, improves the heat transfer efficiency of the reactor and the production efficiency of flowing synthesis, and multiple parameters in the reaction process can be adjusted.

Owner:苏州欣影生物医药技术有限公司

Polymethacrylimide foamable particle rapidly prepared by photo-initiation

The invention relates to the field of new material preparation, and discloses a polymethacrylimide foamable particle rapidly prepared by photo-initiation. Through introducing subsection polymerizationand photo-initiation polymerization, reaction time is greatly shortened, reaction efficiency is improved, and automatic continuous production is realized. Through controlling a thickness of a board within a certain range, and crushing, a crushing yield can be greatly improved. The invention provides a low-cost polymethacrylimide foamable particle rapidly prepared by the photo-initiation and a preparation method thereof, and solves problems of the existing PMI foamable particle preparation process that the reaction period is long, the raw material price is expensive, the crushing yield is low,the adhesive property between the particles of an intra-mode foaming product is poor and the like.

Owner:CASHEM ADVANCED MATERIALS HI TECH CO LTD ZHEJIANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com