Reinforced-concrete breaking treatment system

A reinforced concrete and processing system technology, applied in the field of mechanical structures, can solve problems such as difficult unloading, difficult handling, and inability to continue unloading and conveying, and achieve the effects of cost saving and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

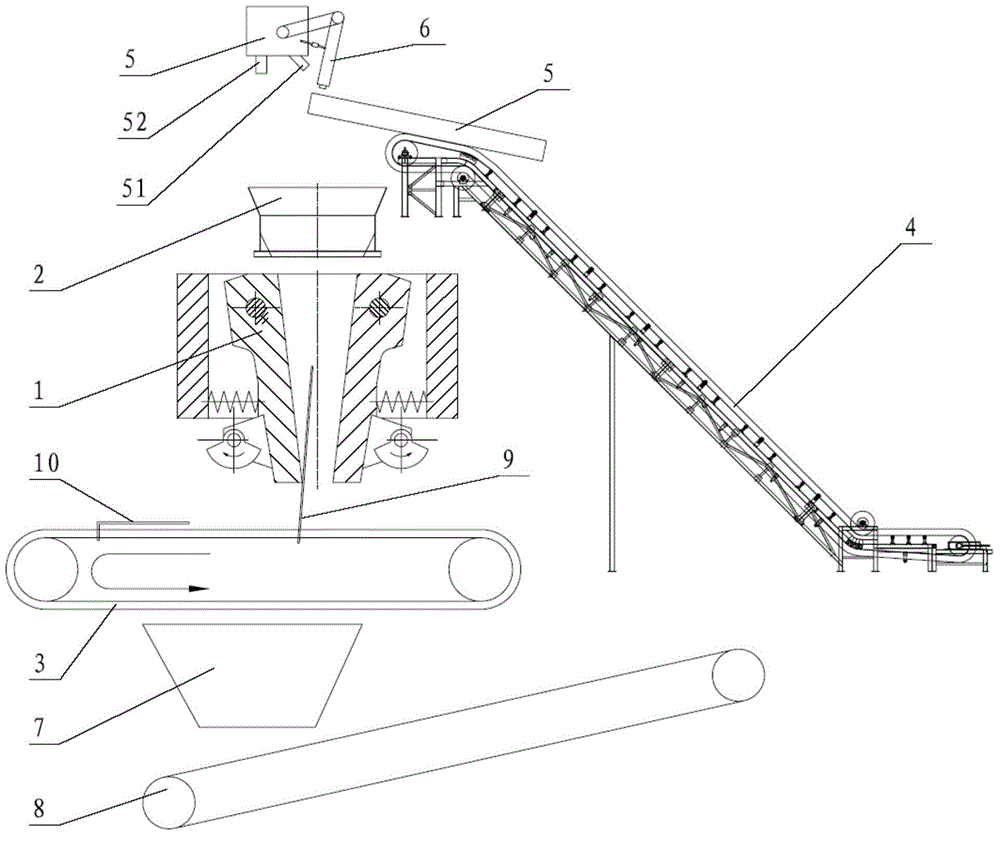

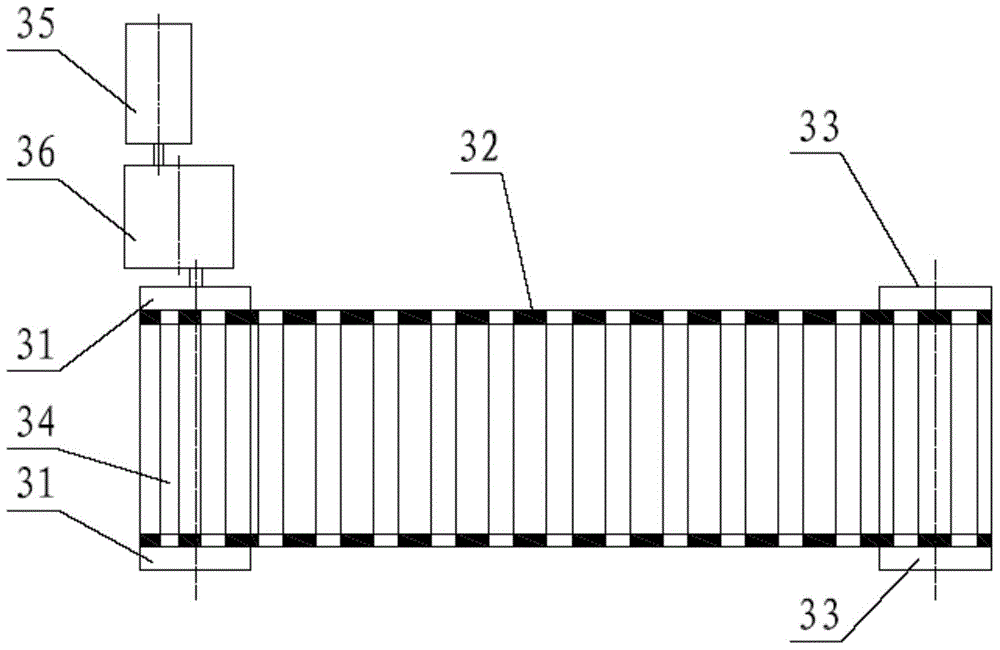

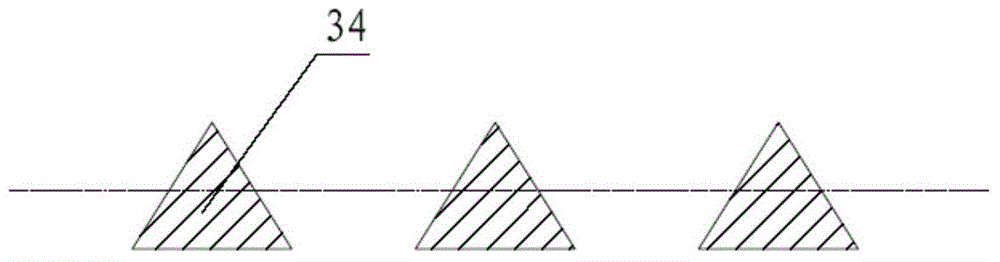

[0025] like figure 1 and figure 2 As shown in the figure, a reinforced concrete crushing and processing system includes a double-moving jaw vibrating jaw crusher 1, a hopper 2, an automatic feeding mechanism, a chain-type reinforced concrete separating and unloading machine 3, and a discharging collection and discharge mechanism; the reinforced concrete is automatically The feeding mechanism is transported to the hopper 2 located above the double-moving jaw vibrating jaw crusher 1, and enters the double-moving jaw vibrating jaw crusher 1 from the lower opening of the hopper 2 for crushing; There may be sparse, small amounts of concrete blocks attached). The crushed concrete blocks and steel bars are separated by the chain-type reinforced concrete separating and unloading machine 3, and discharged by the unloading collection and discharge mechanism.

[0026] The double-moving jaw vibrating jaw crusher 1 is the product of the patent number: ZL 201120112697.3, which is not the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com