Patents

Literature

178 results about "Moving jaw" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

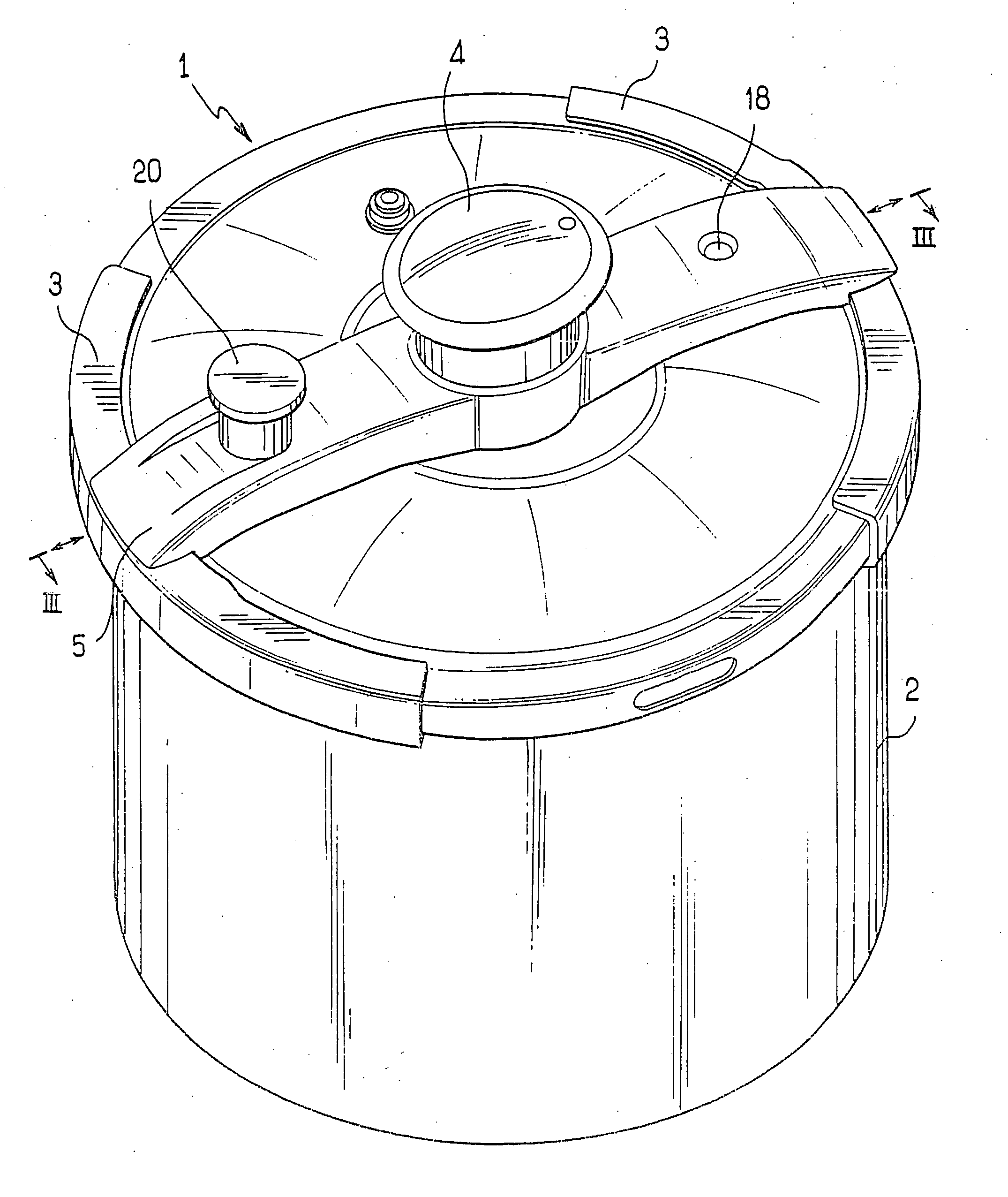

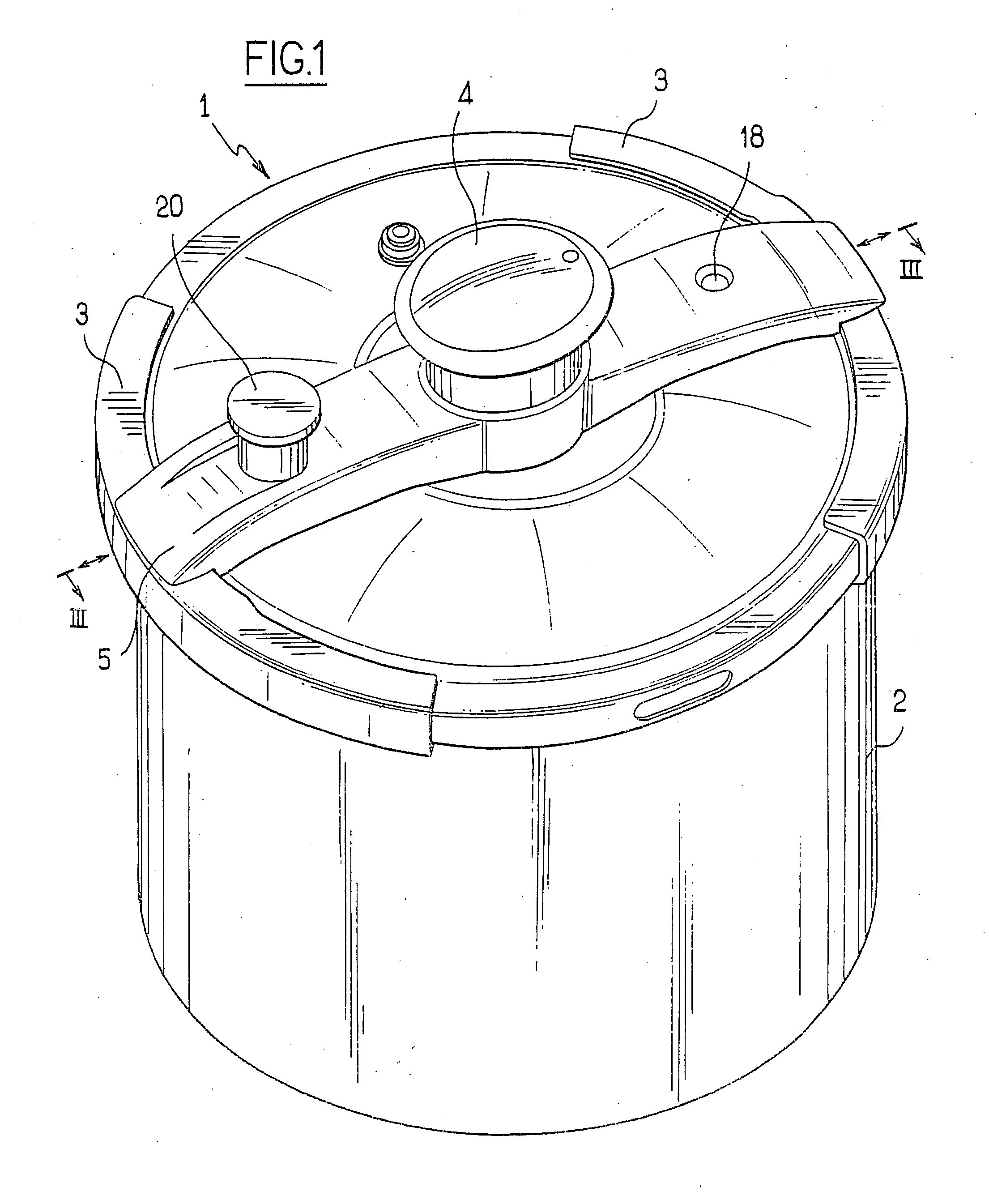

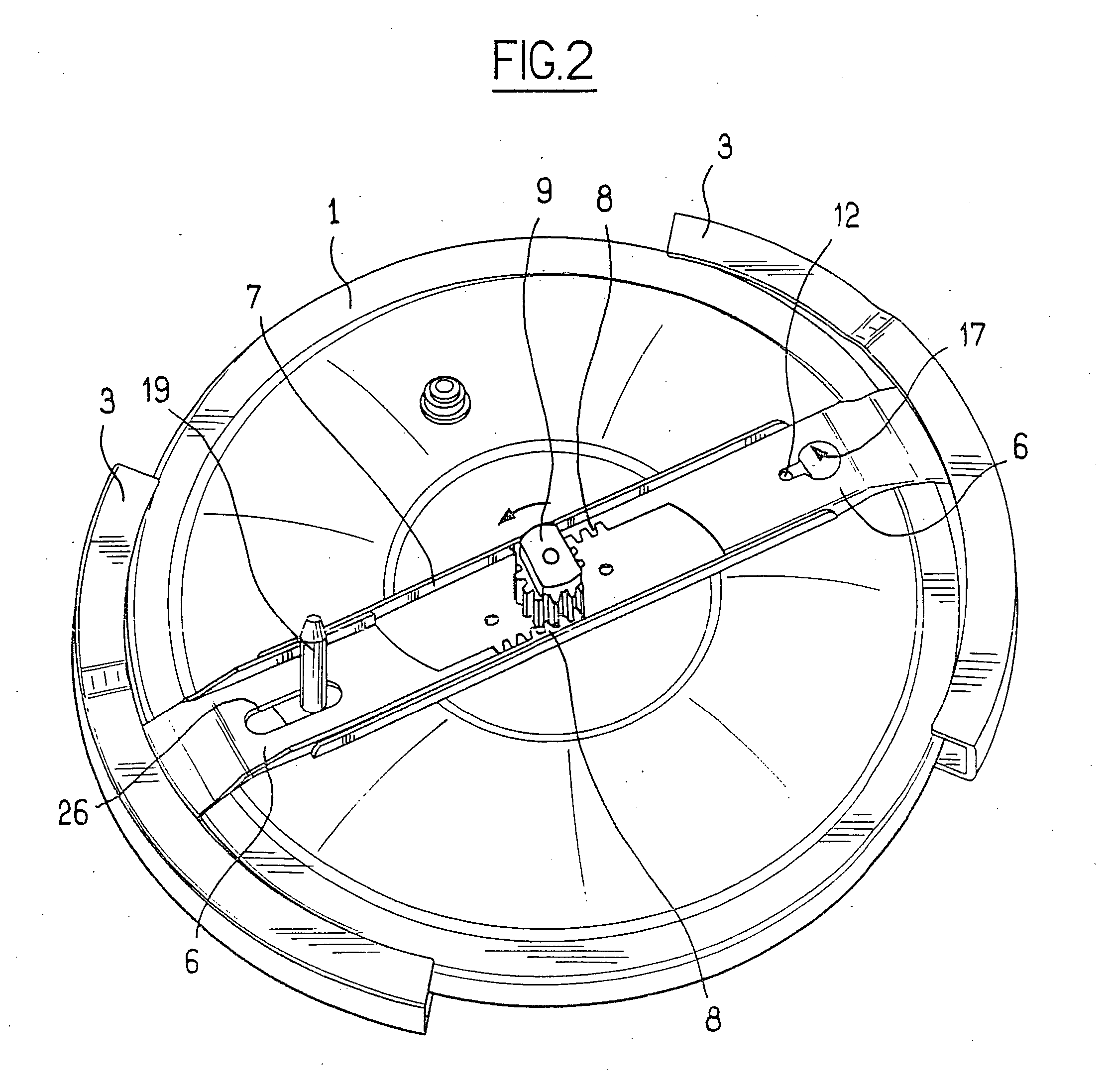

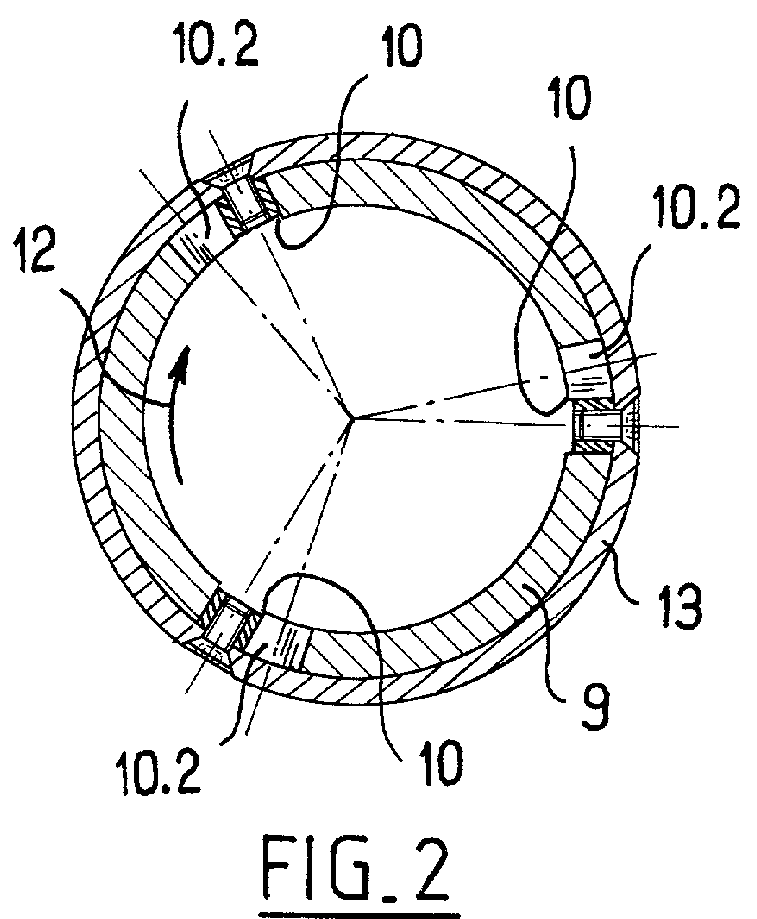

Pressure cooker with a lid having moving jaws

A pressure cooker includes a bowl and a removable lid carrying at least two jaws mounted to move on the lid between a locking position for locking the lid on the bowl and an unlocking position, each jaw being connected to a slider mounted to slide on the lid so that sliding of the slider causes the associated jaw to move towards one of the positions. A pinion is mounted to turn on the lid about an axis that is vertical in operation, each slider having a rack-forming toothed portion which co-operates with the pinion so that turning the pinion causes all of the jaws to move simultaneously towards one of the positions.

Owner:SOC IND DE TRANSFORMATION DE METAUX SISTREETCAR

Screw-tightening spindle fitted with a removable chuck

InactiveUS6543204B2Positive lockAddressing slow performanceCapsThreaded caps applicationMoving jawFree edge

Owner:SERAC GROUP

Screw-tightening spindle fitted with a removable chuck

InactiveUS20010054273A1Positive lockAddressing slow performanceSleeve/socket jointsClosing machinesMoving jawEngineering

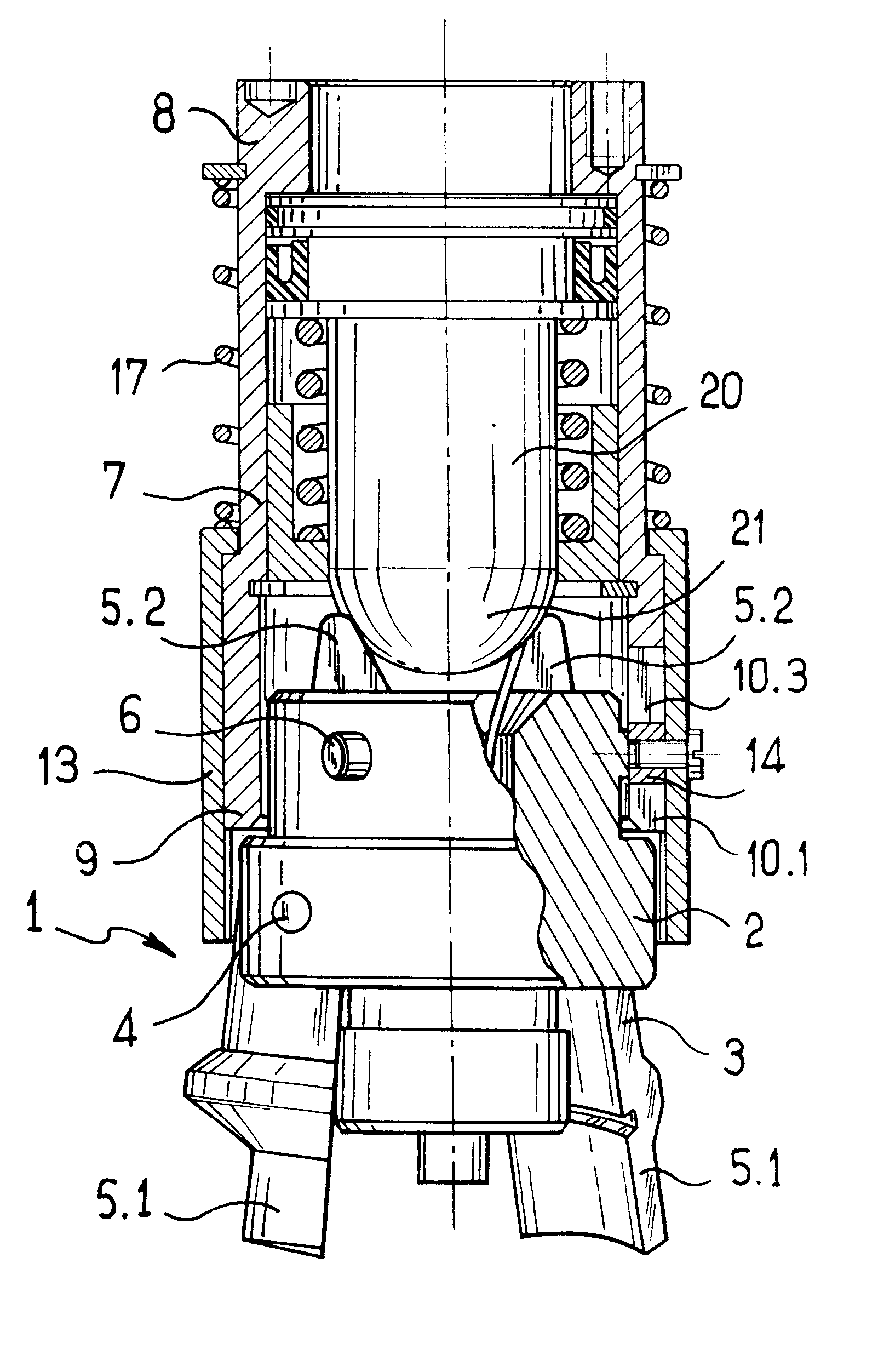

A screw-tightening spindle comprising a drive sleeve associated with a chuck comprising a cylindrical support member fitted with moving jaws, the cylindrical support member being provided externally with at least one stud extending radially outwards, the sleeve including at least one slot having a first segment opening out in a free edge of the sleeve and a second segment having an end portion forming an angle relative to the sleeve suitable for retaining the stud in the end portion of the slot when the stud is engaged therein, the sleeve being fitted with a ring having at least one stop extending radially inwards and received in the slot, the ring being mounted on the sleeve to slide between a locking position in which the stop extends in the first segment of the slot in register with the second segment, and an unlocking position in which the stop is retracted into a third segment of the slot.

Owner:SERAC GROUP

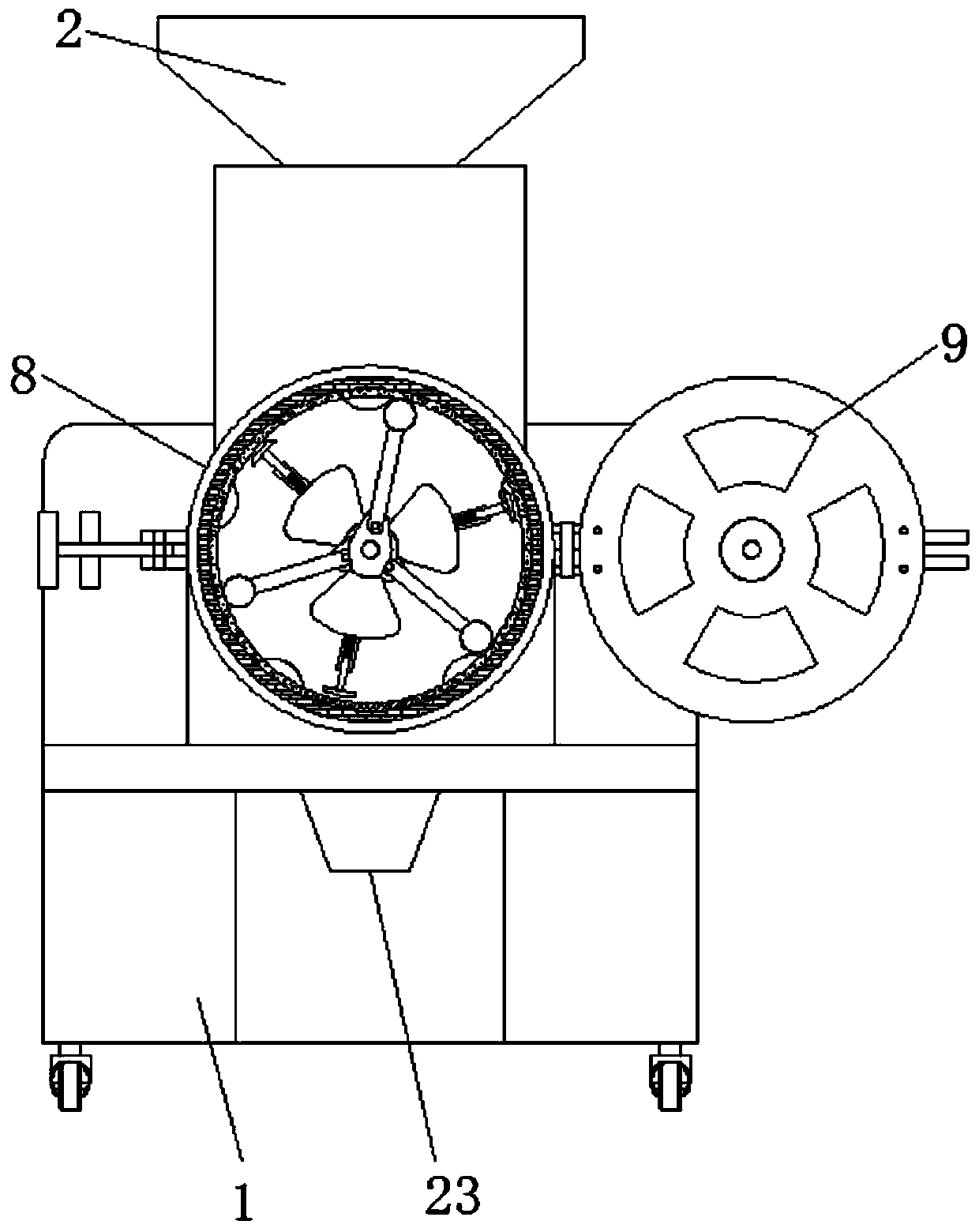

Novel jaw crusher for crushing calcium carbide at high temperature of 400 DEG C

ActiveCN103480446ABlock deliveryTemperature controlGrain treatmentsEngine lubricationMoving jawPolyvinyl chloride

The invention relates to a jaw crusher, in particular to a novel jaw crusher which can crush calcium carbide in a state of the high temperature of 400 DEG C directly in the calcium carbide industry. ZS-1 high-temperature-resistant thermal insulating coatings are applied among a moving jaw protection plate, a moving jaw plate and a moving jaw body, between an edge protection plate and a frame body and between a fixed jaw plate and the frame body respectively, so that a high-temperature thermal insulating layer is formed; a transmission bearing of the crusher adopts 20Cr2Ni4, the hardness of the bearing is HRC 58-60, and the temper temperature is 250 DEG C; the bearing of the crusher comprises an electric lubricant pump, a controller, a distributor and a pipeline connector, and a lubrication system adopts electric single-line progressive lubrication; a rotary speed monitoring protection system is mounted on the crusher; and a temperature sensor which records the changes of the working temperature of a motor is mounted on a driving motor of the crusher. According to the novel jaw crusher, the calcium carbide can be crushed at the temperature of about 400 DEG C, the production cost of PVC (polyvinyl chloride) is reduced, and at the same time, waste caused by import of foreign crushing equipment at a high price is avoided.

Owner:唐山汇力科技有限公司

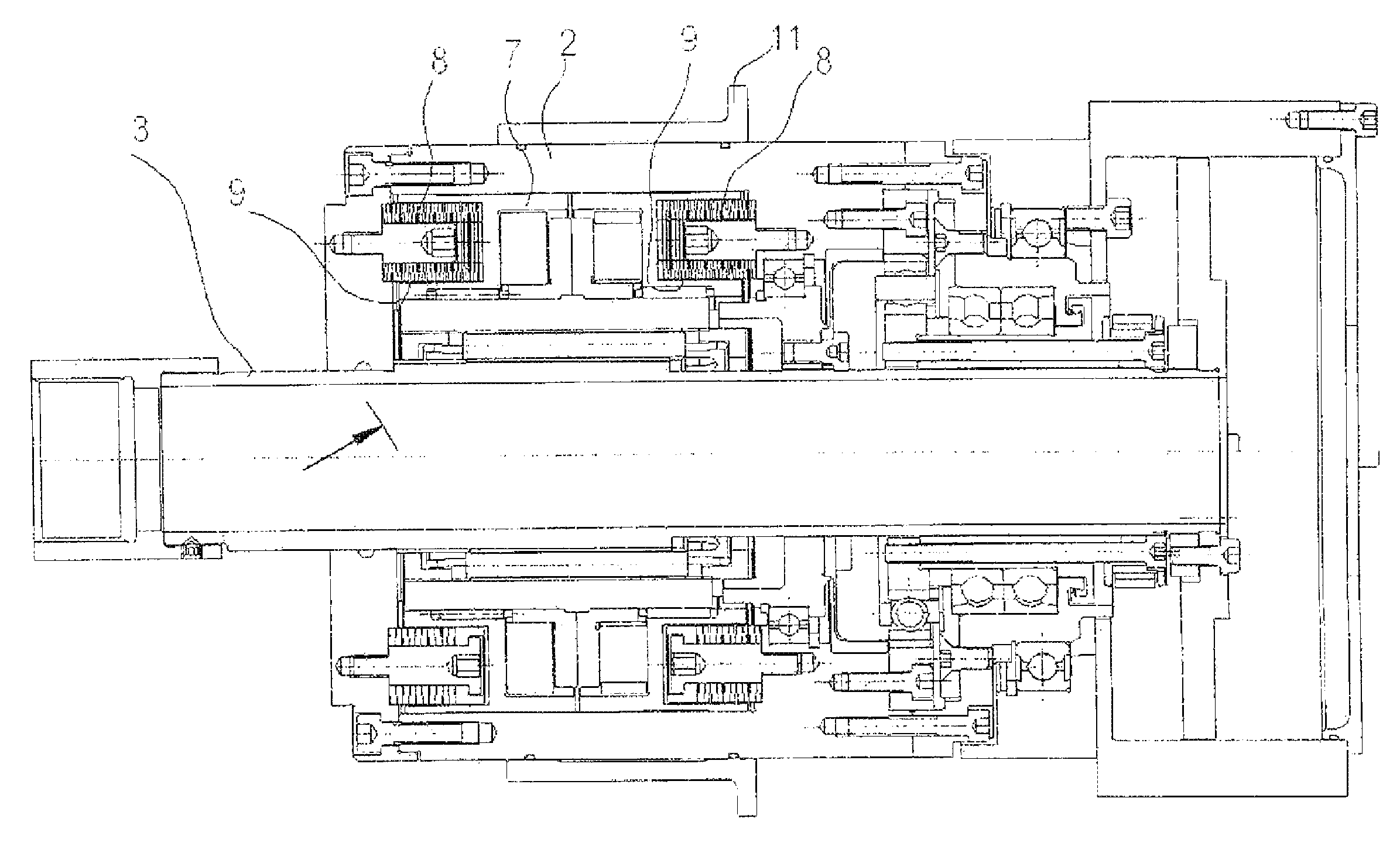

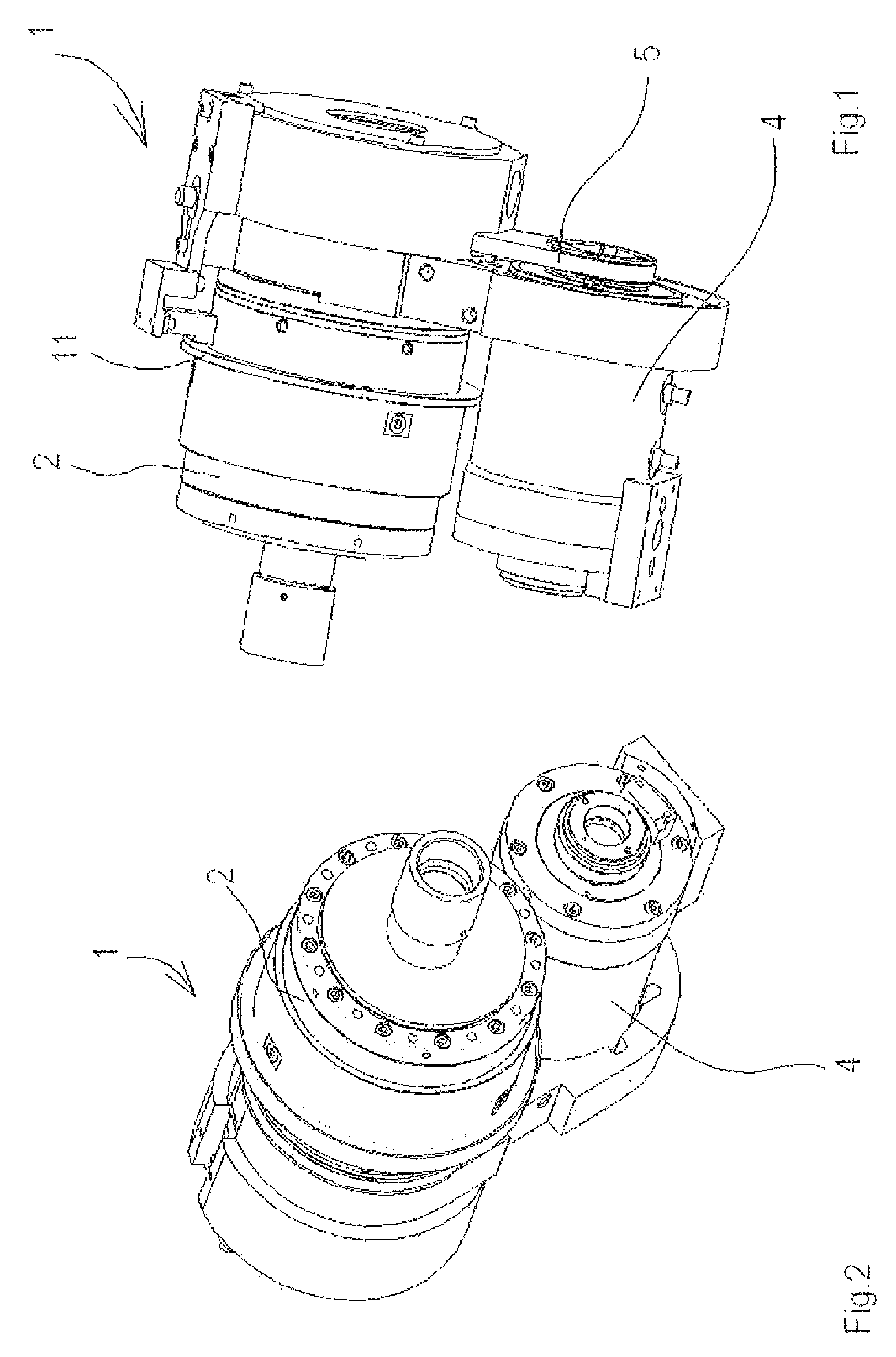

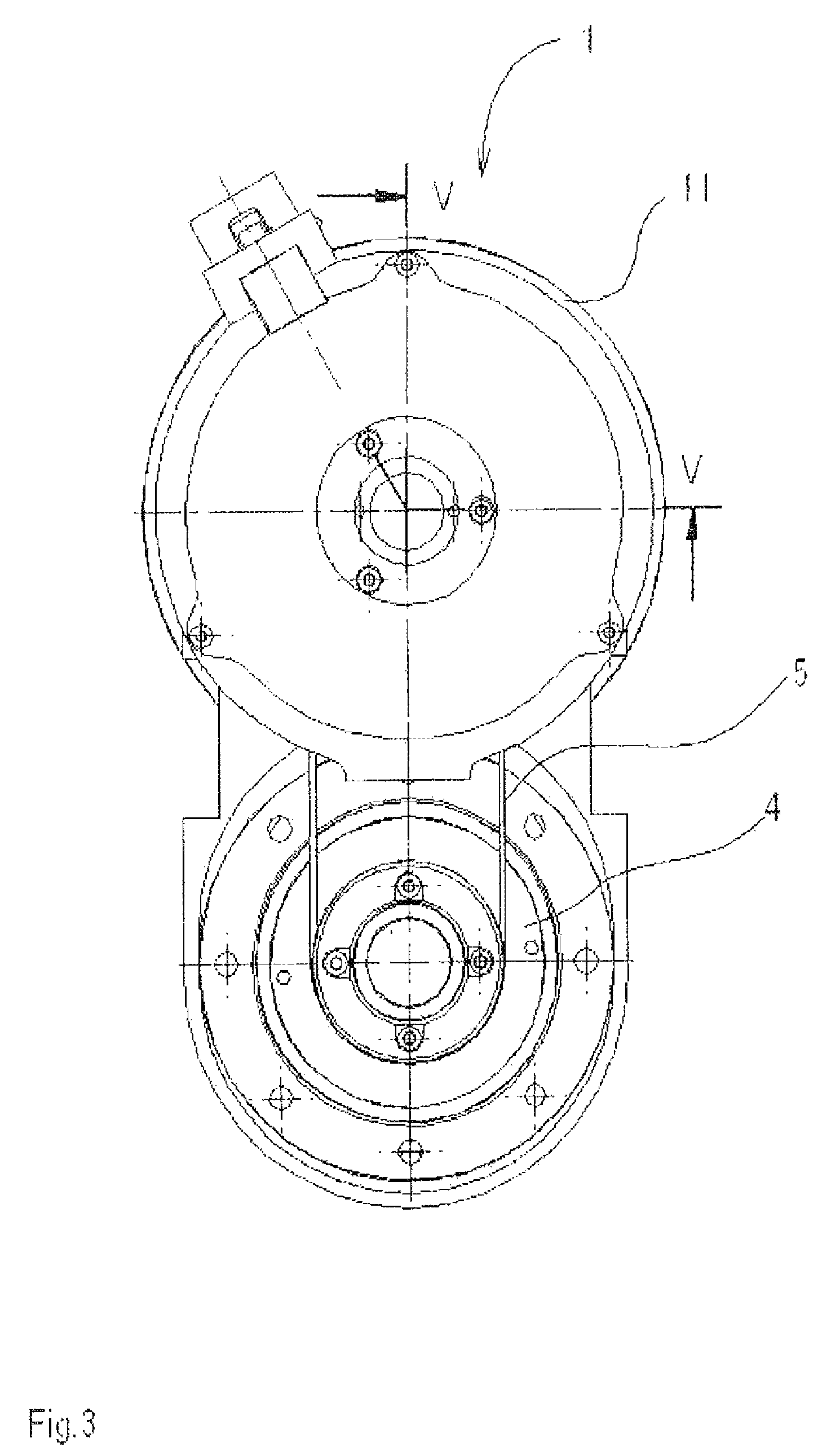

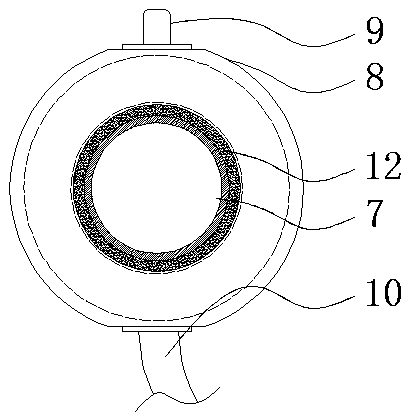

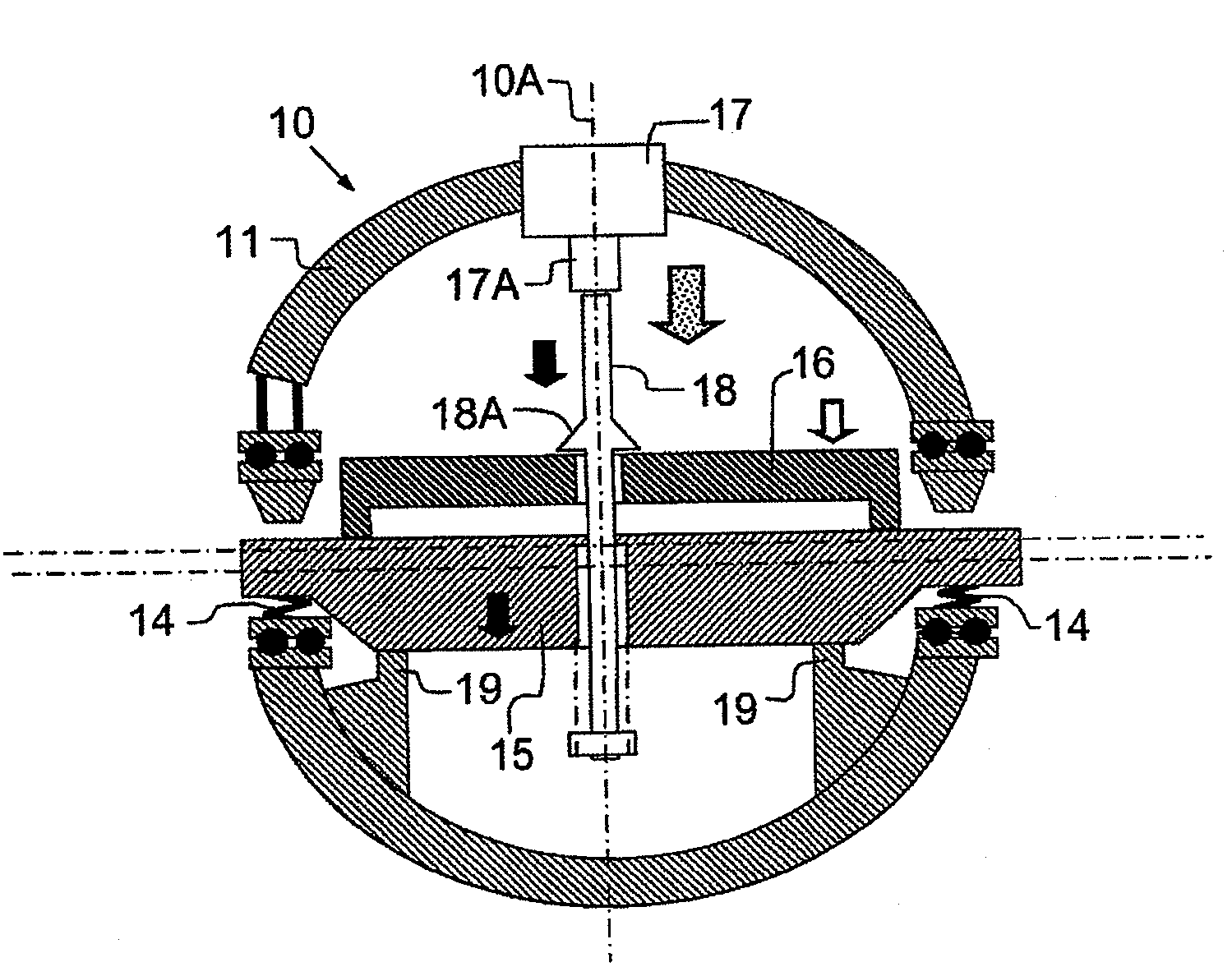

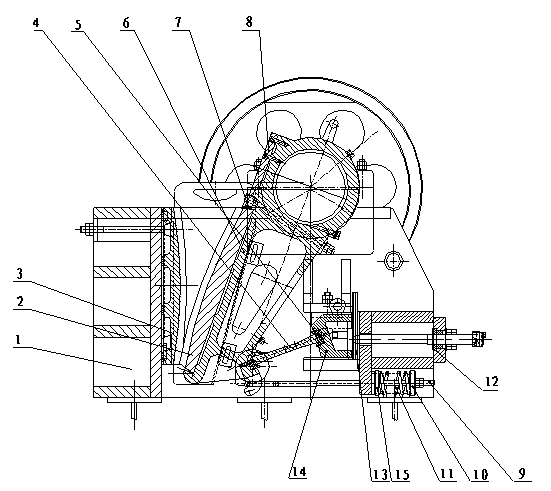

Method of chucking a tool or a workpiece and apparatus for carrying out the method

InactiveUS8752281B2Avoid problemsRapid positioningAttachable milling devicesAssembly machinesDrive wheelMoving jaw

The invention relates to a method of clamping a tool or a workpiece, using an electric actuator (1) having a housing (2) attached to a work spindle of a machine tool and in which a threaded spindle (3) for moving jaws of a chuck is axially displaceable, and an electric servomotor (4) having a rotor connected with a drive wheel (6) that moves a nut (7) on the threaded spindle (3), a first sensor being associated with the threaded spindle (3) for detecting the axial position thereof, and a second sensor being associated with the spindle nut (7) for detecting the axial position thereof, and including the method step of determining the position of the threaded spindle (3) by the first sensor when a slight axial force occurs due to contact of the clamping jaws with the tool or the workpiece, and continued movement of the spindle nut (7) until a specified sensor difference (12) between the first sensor and the second sensor is determined by the second sensor. The invention further relates to an apparatus for carrying out the method.

Owner:ROHM GMBH

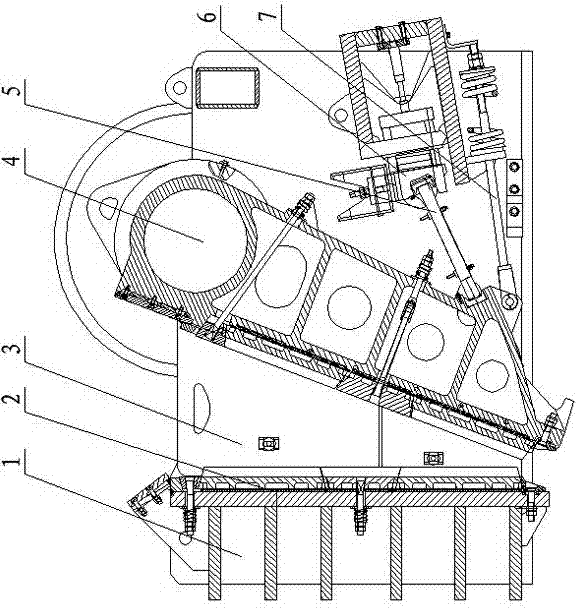

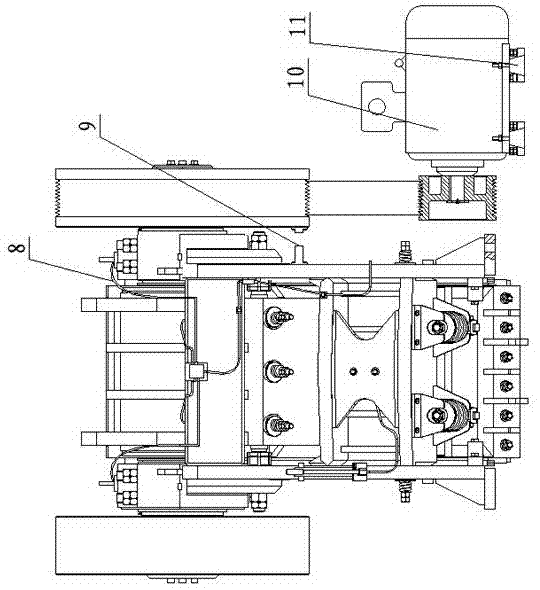

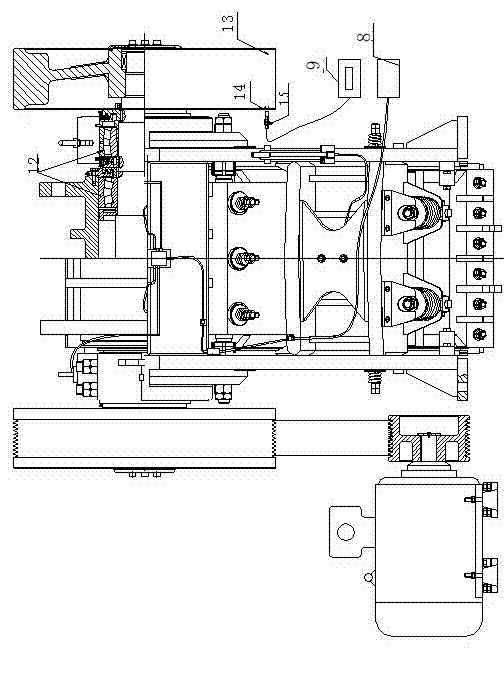

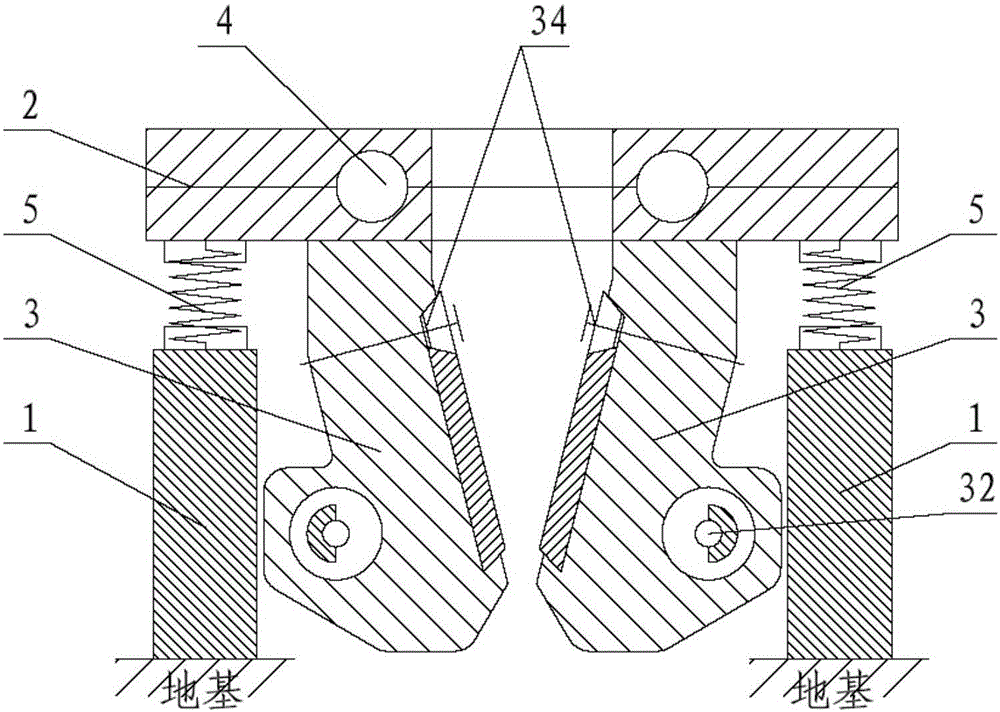

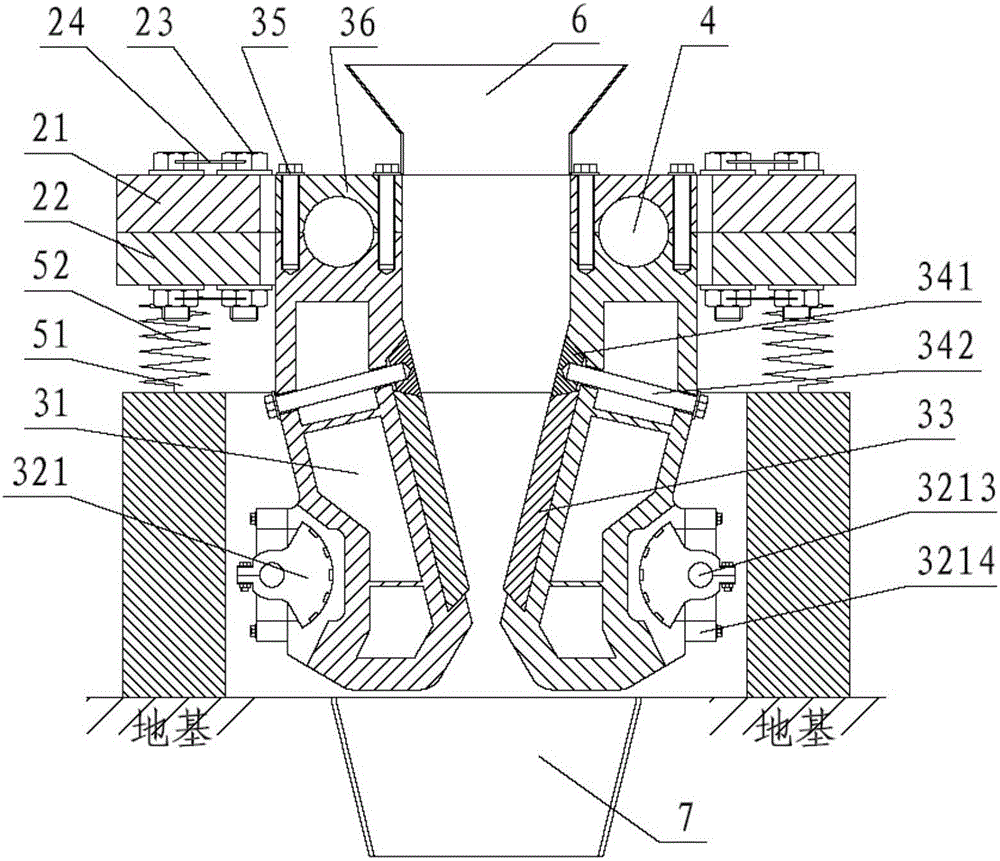

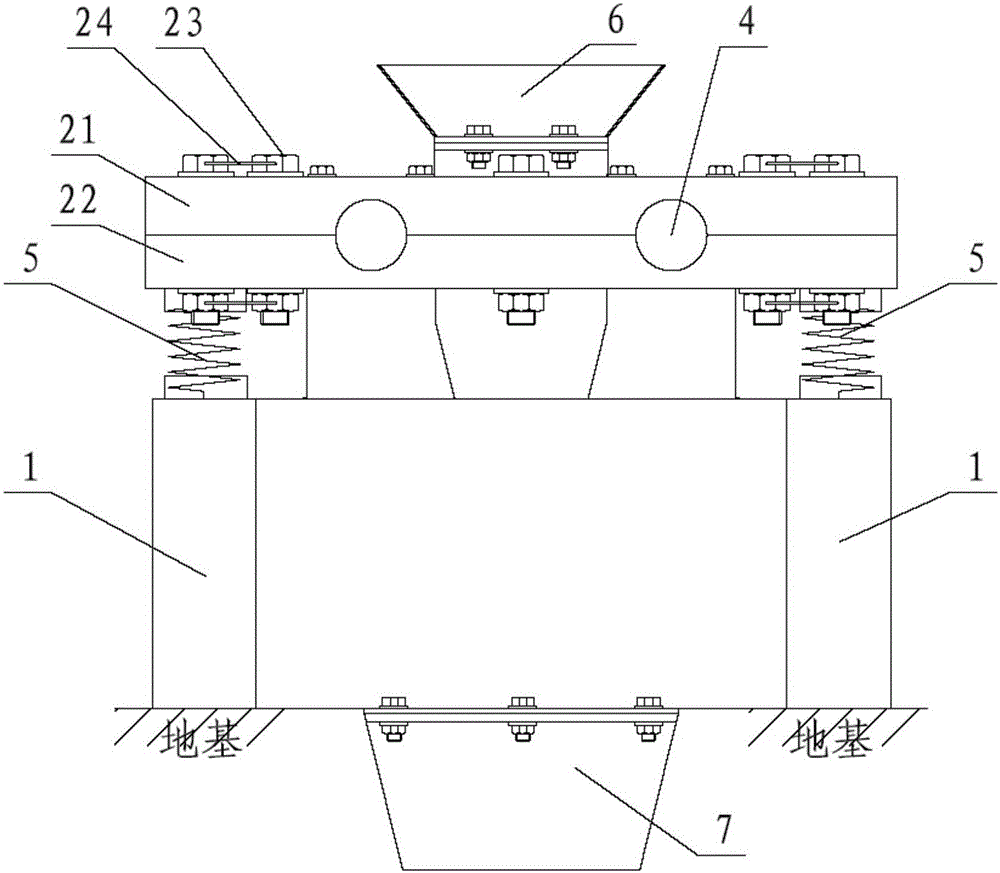

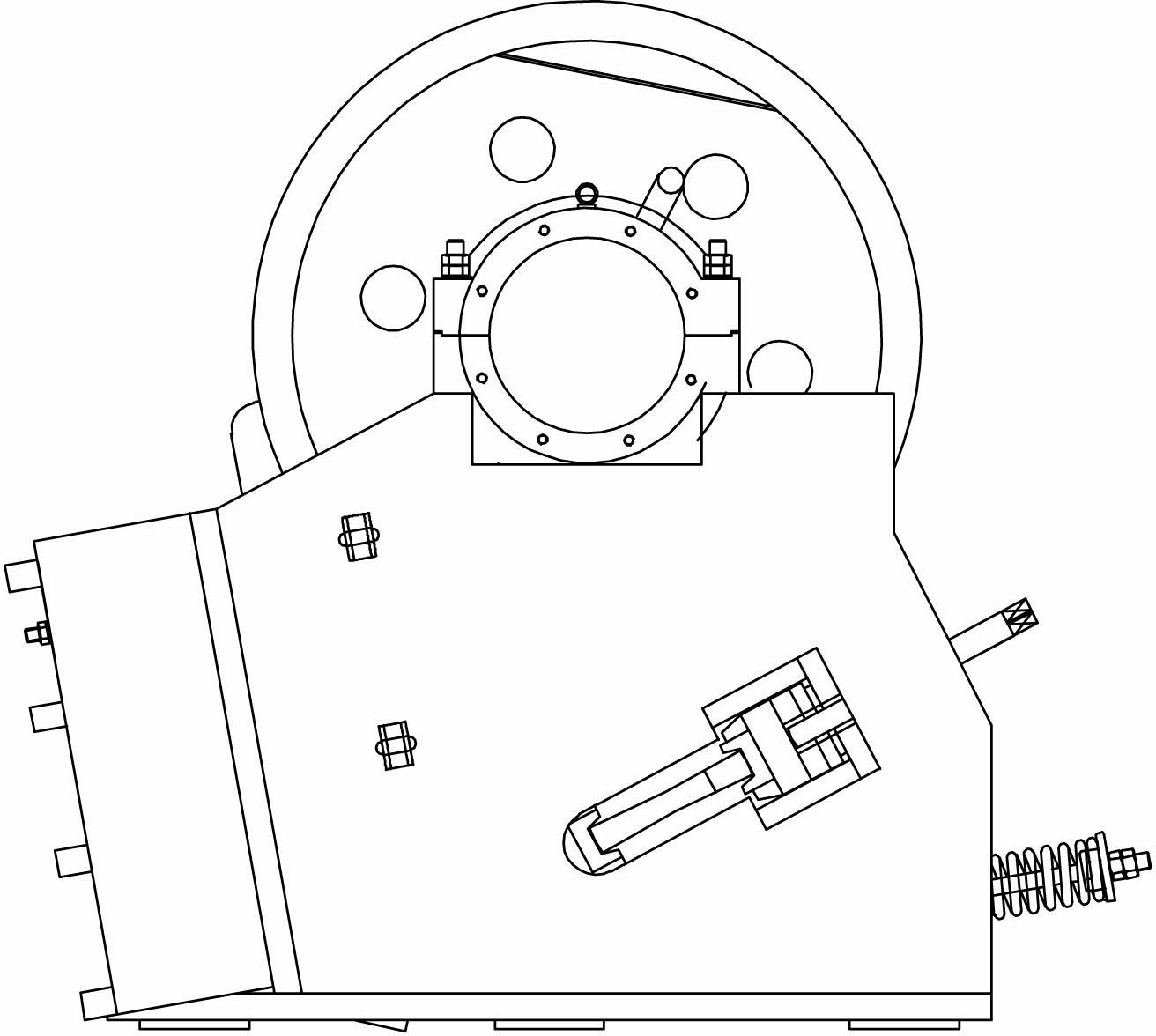

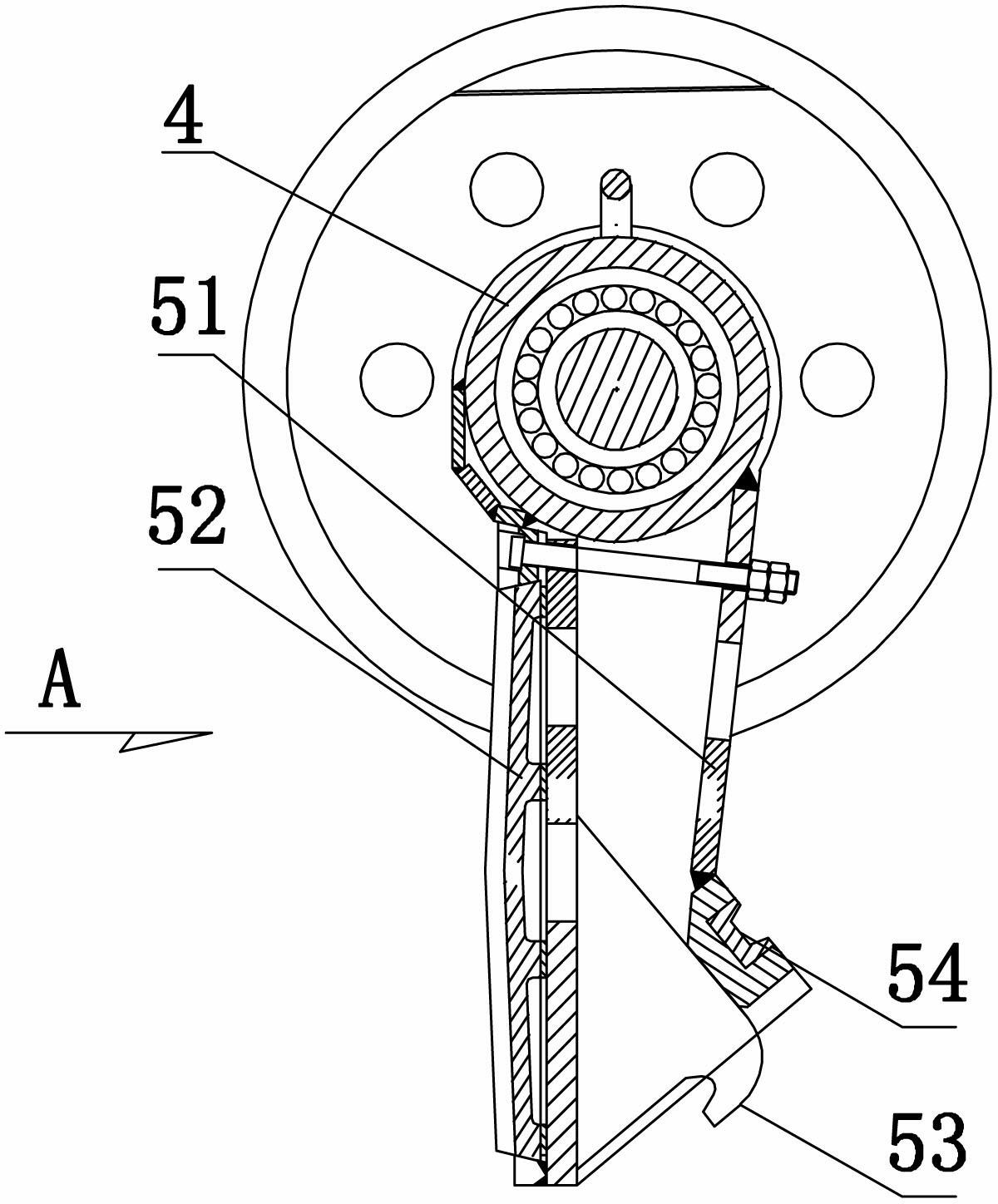

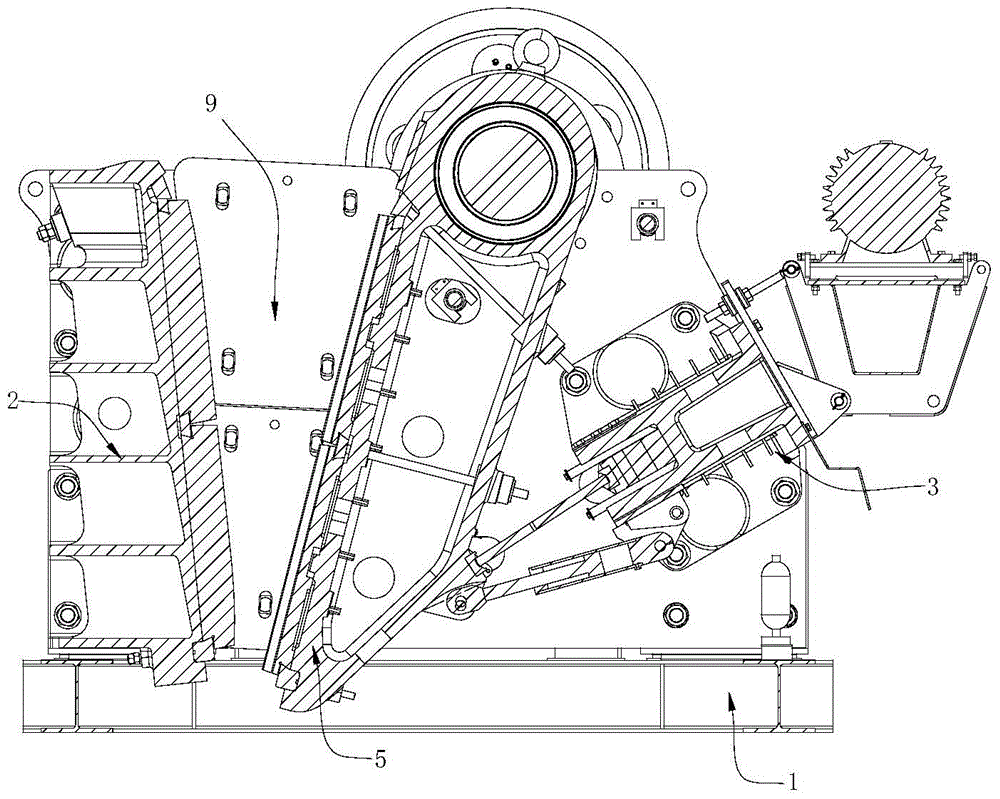

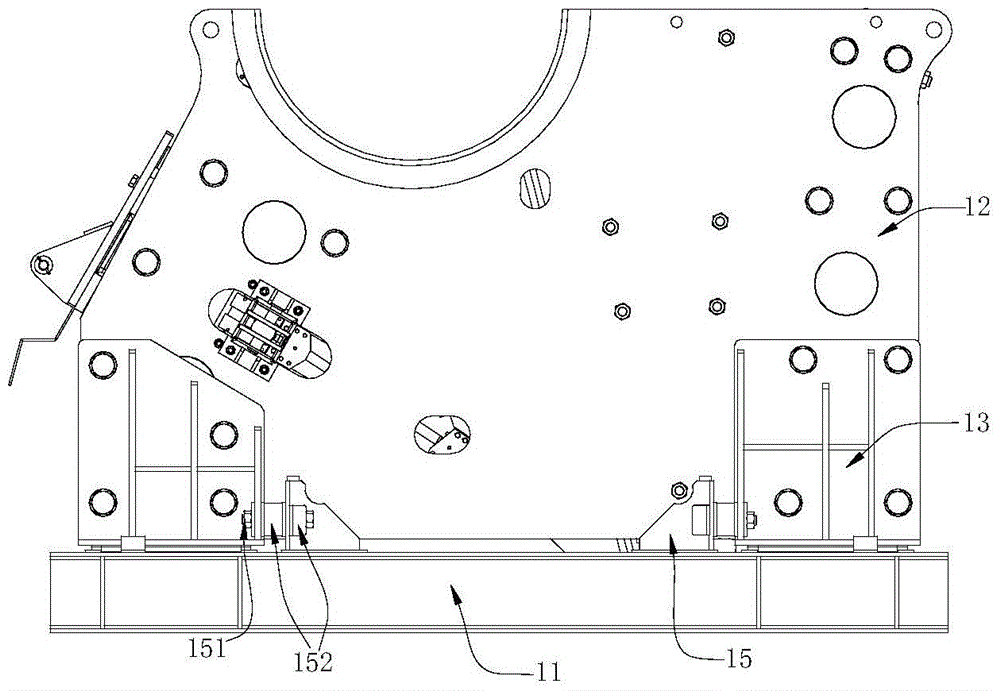

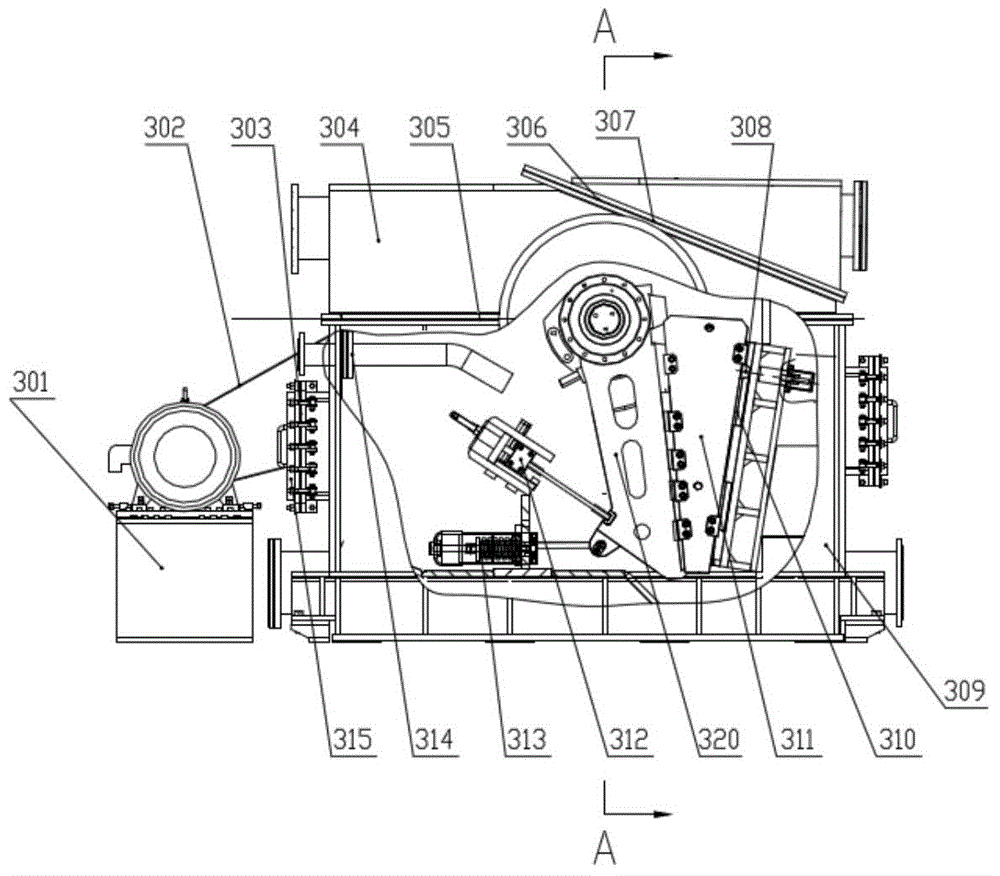

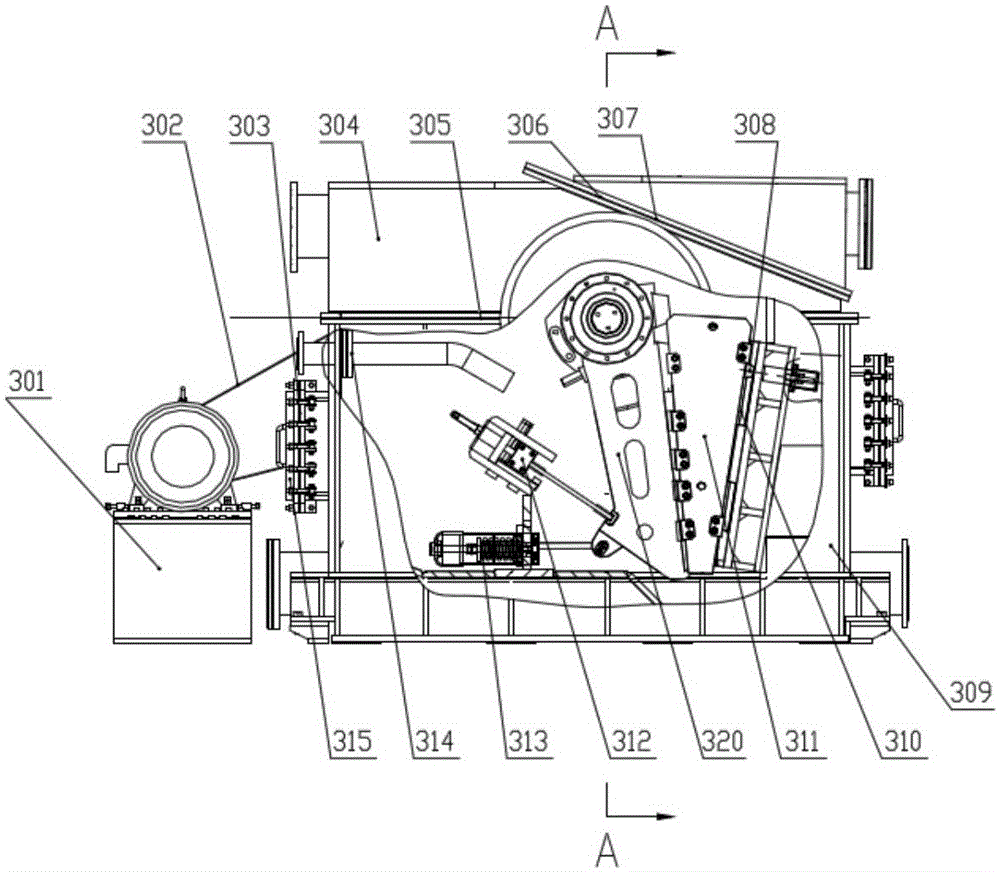

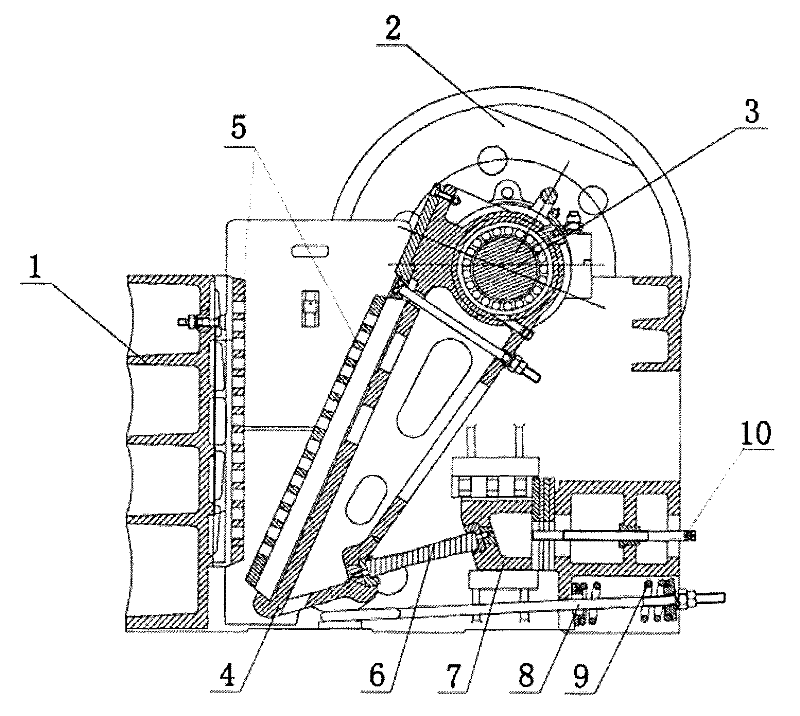

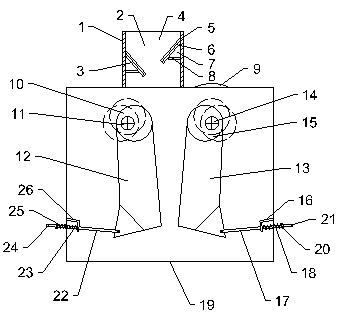

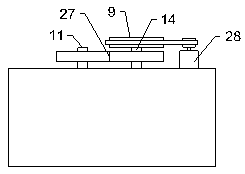

Vibration self-synchronizing crusher of double vibrators

ActiveCN105032535AReduce energy consumption in production operationsSimple structureGrain treatmentsResource developmentMoving jaw

The invention discloses a vibration self-synchronizing crusher of double vibrators. The vibration self-synchronizing crusher comprises racks (1), a crusher body assembly (2), two work moving jaw assemblies (3) and torsion shafts (4). The racks (1) are arranged on foundations. The crusher body assembly (2) is arranged above the racks (1). The two ends of the torsion shafts (4) are fixed to the crusher body assembly (2). The two work moving jaw assemblies (3) are fixed to the middles of the torsion shafts (4) and arranged in a bilateral symmetry manner. Elastic shock absorber assemblies (5) are arranged between the racks (1) and the crusher body assembly (2). The work moving jaw assemblies (3) comprise moving jaw bodies (31) and shock absorber assemblies (32). The shock absorber assemblies (32) drive the work moving jaw assemblies (3) to perform high-frequency synchronization reciprocating motion. High-frequency pulsation is applied to materials, and vibration crushing of the materials is achieved. The vibration self-synchronizing crusher is suitable for crushing high-hardness brittle materials and building waste, the energy consumption of production is effectively lowered, and the energy conservation and the consumption reduction in the crushing and grinding process stages of the resource development are achieved.

Owner:BEIJING KAITE CRUSHER +1

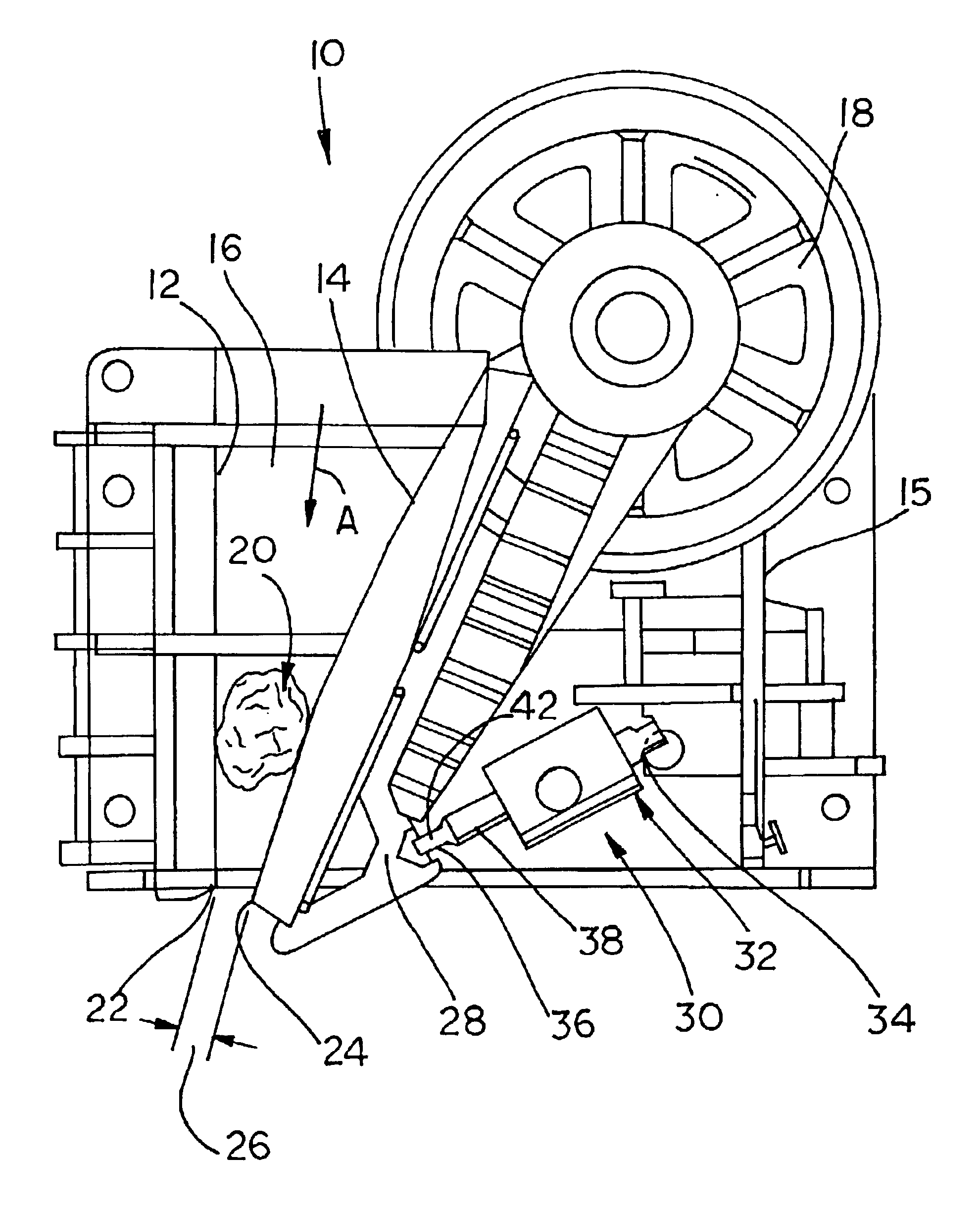

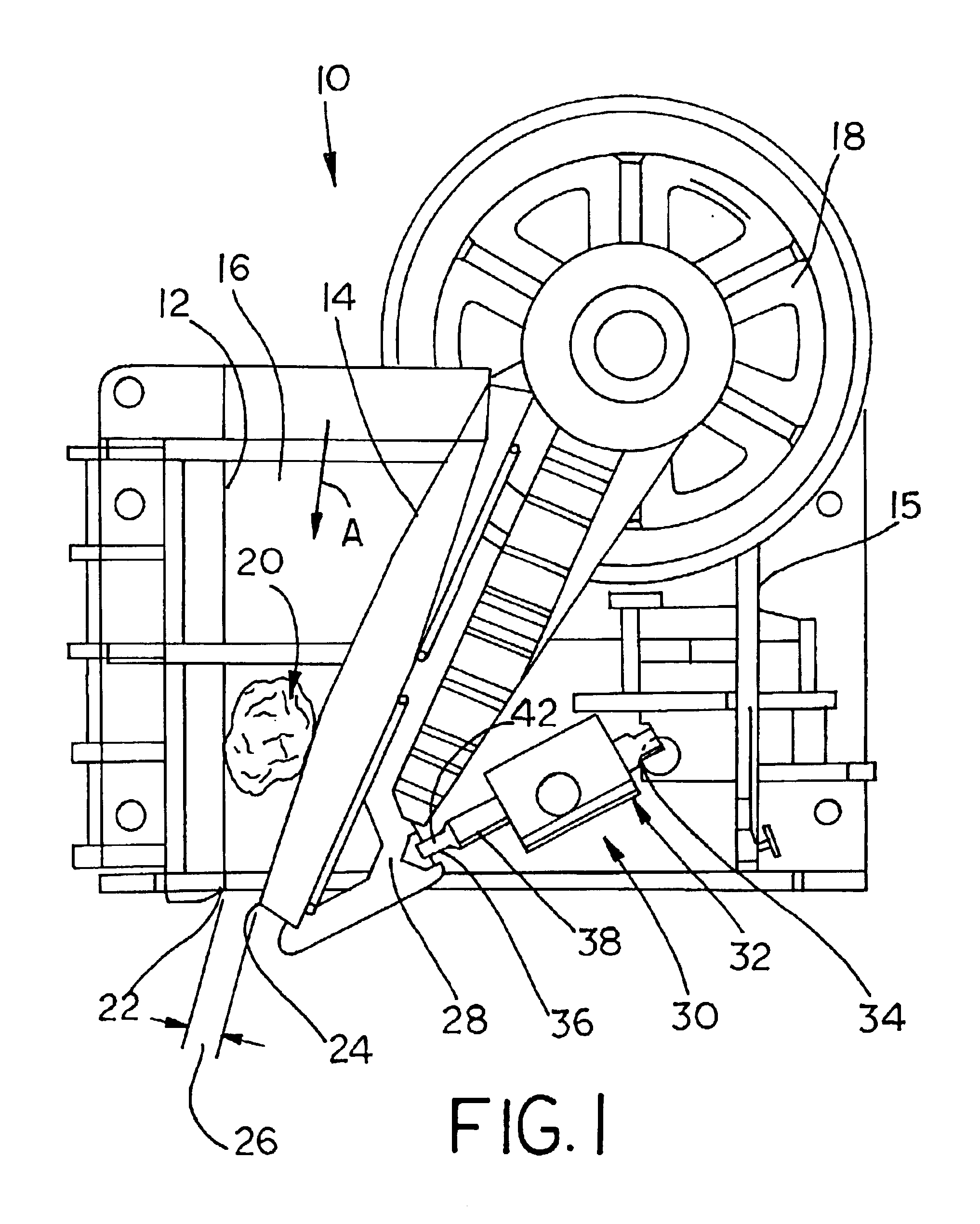

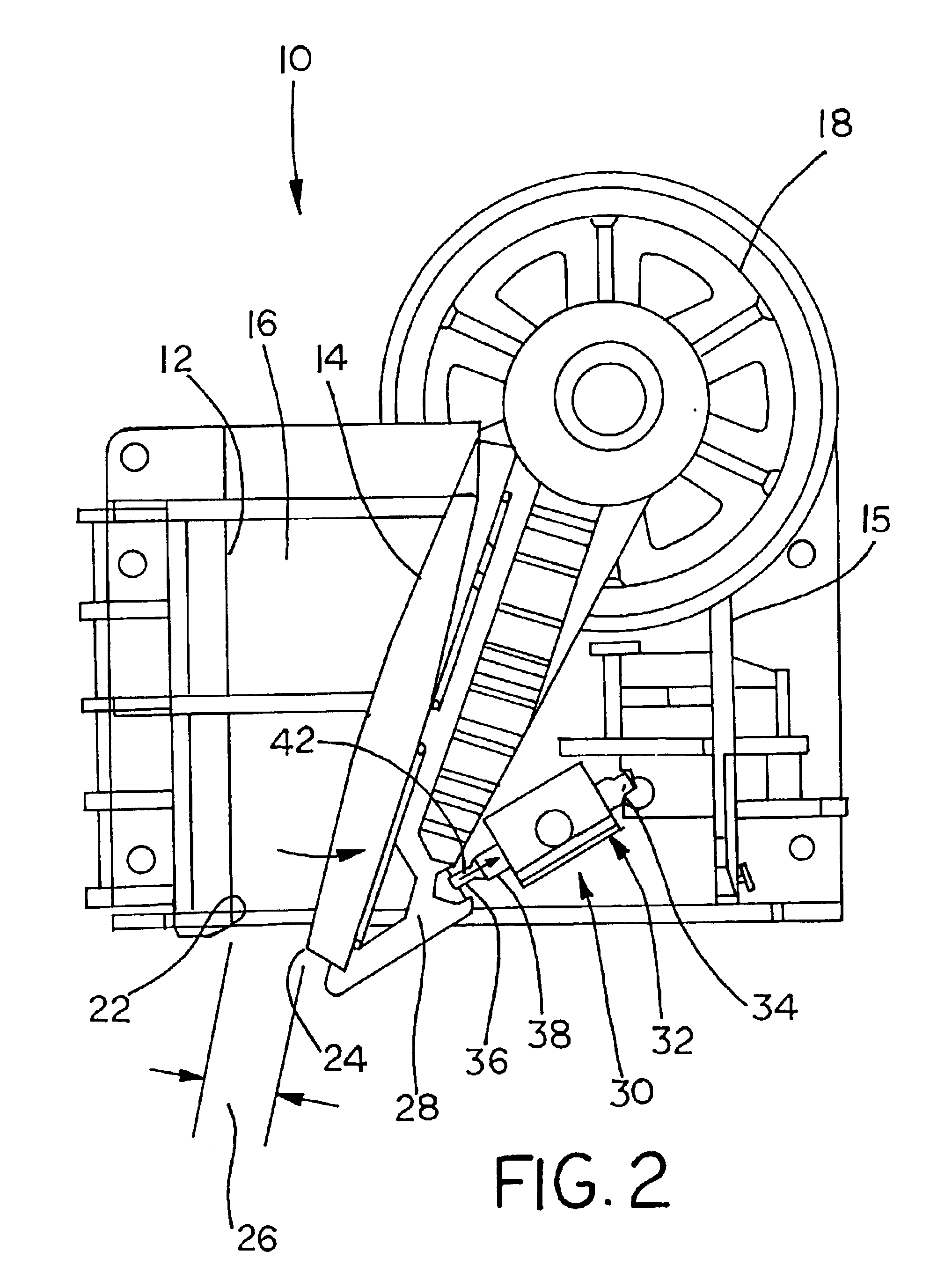

Dynamic tramp iron relief system

A jaw crusher having a dynamically adjustable tramp iron relief system is disclosed. A moveable jaw and a stationary jaw define a crushing chamber, with a lower portion of the moveable jaw cooperating with a lower portion of the stationary jaw to define a closed side setting gap. A hydraulic tramp iron relief system operatively connects at least one of the jaws to the frame and is arranged to permit uncrushable material to pass through the crushing chamber by permitting the lower portion of the jaw to shift to a shifted position in which the gap is increased. The tramp iron relief system includes an adjustable hydraulic cylinder, the hydraulic cylinder arranged to permit the gap to be adjusted during operation of the crusher.

Owner:TEREX USA

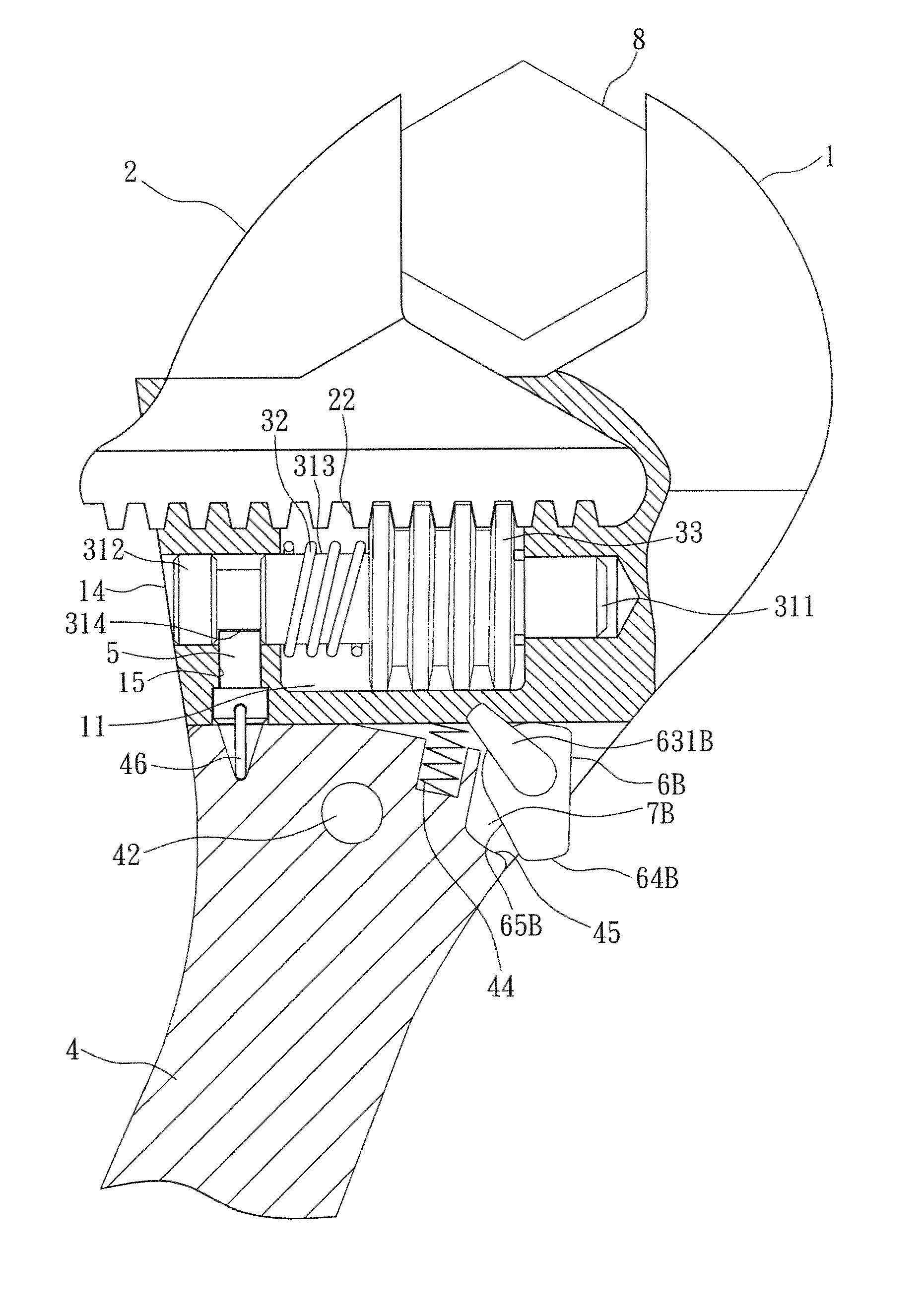

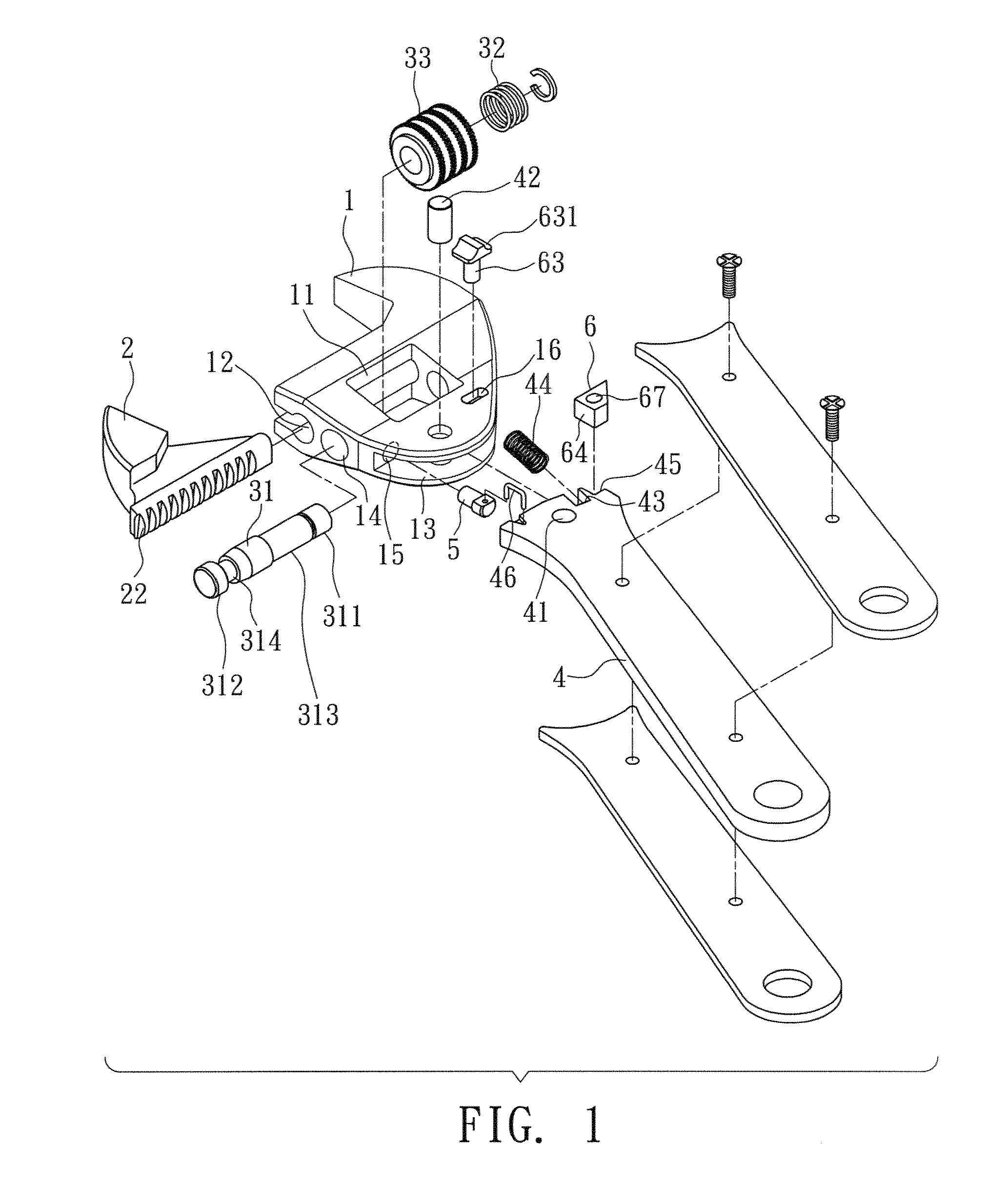

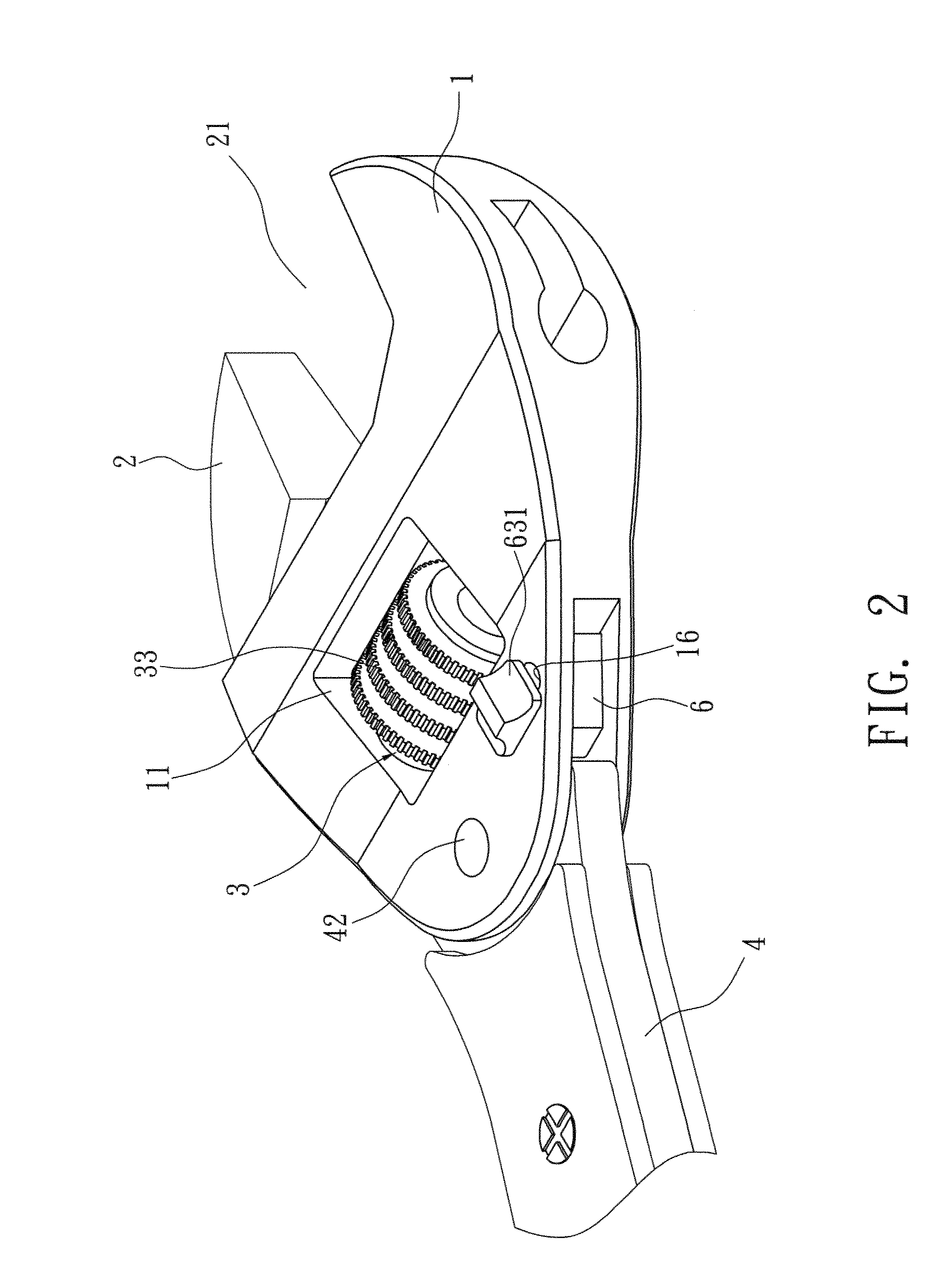

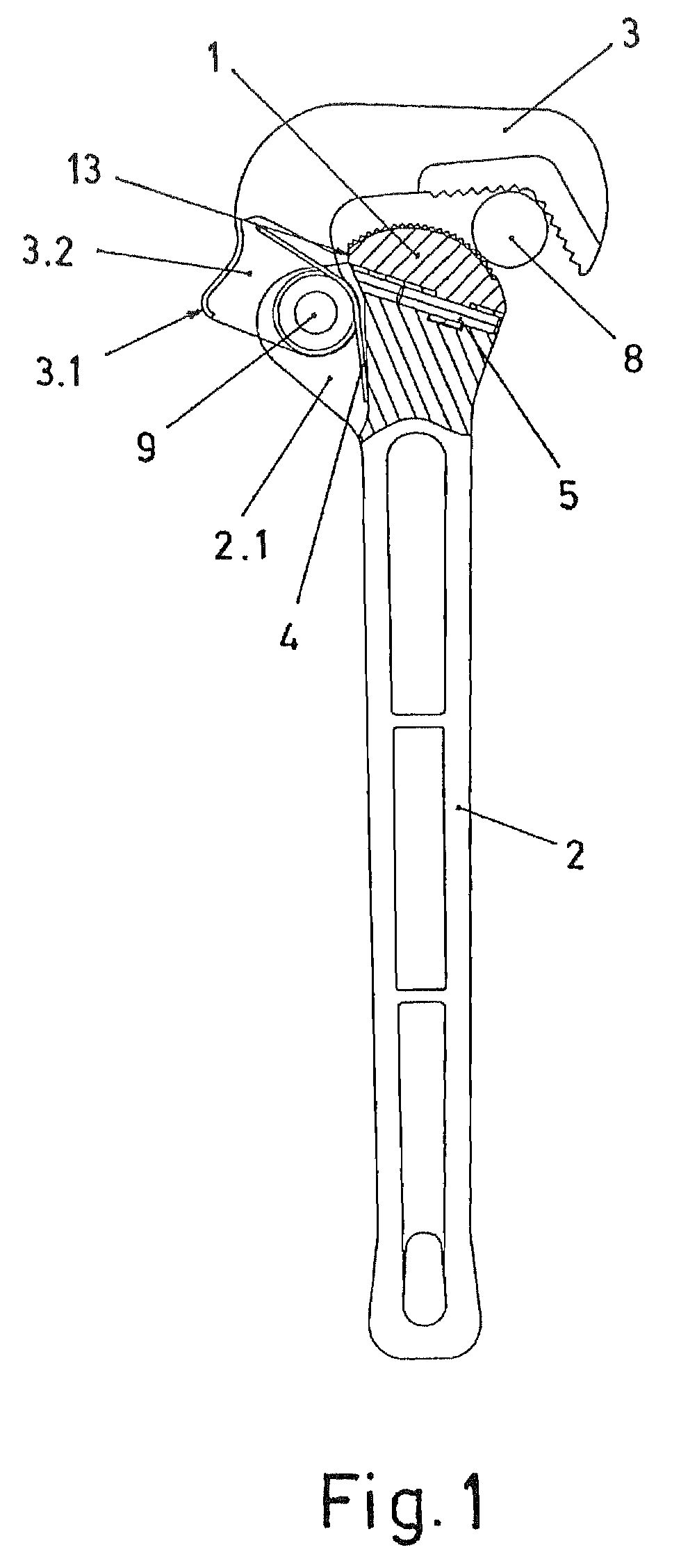

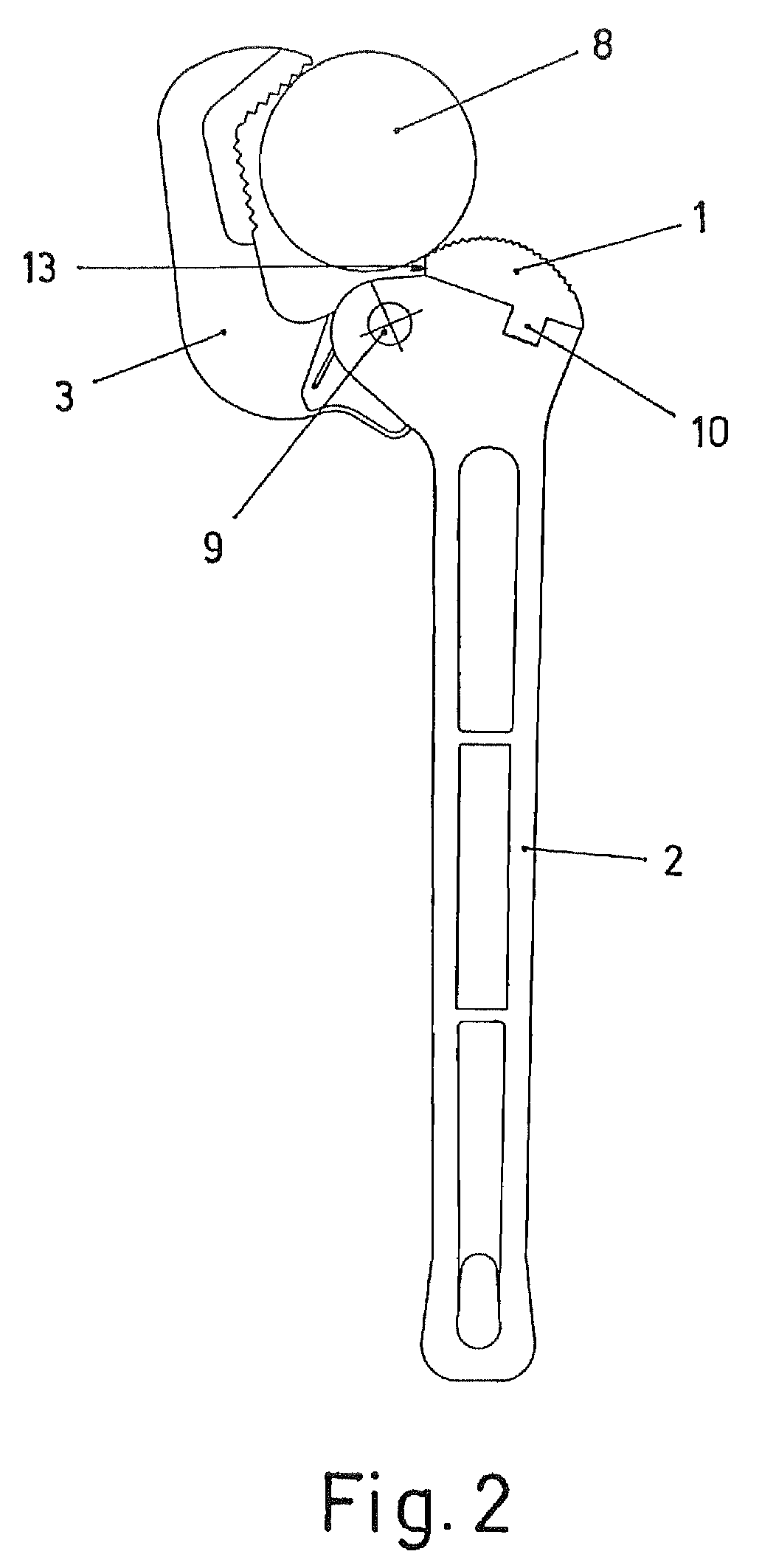

Swing Wrench

A swing wrench includes a fixing jaw, a moving jaw, an acting set, and a handle pivotally fixed to the bottom of the fixing jaw. A fixing element is disposed between the bottom of the fixing jaw and the front end of the handle. A limiting section is disposed around the fixing element. A fixing part is formed at the front end of the handle, opposite to the fixing element. The limiting section of the fixing element can engage or move away from the fixing part of the handle. When the limiting section is away from the fixing part, a swing space is formed in between for the handle to pivotally swing with respect to the fixing jaw.

Owner:HUANG PING WEN

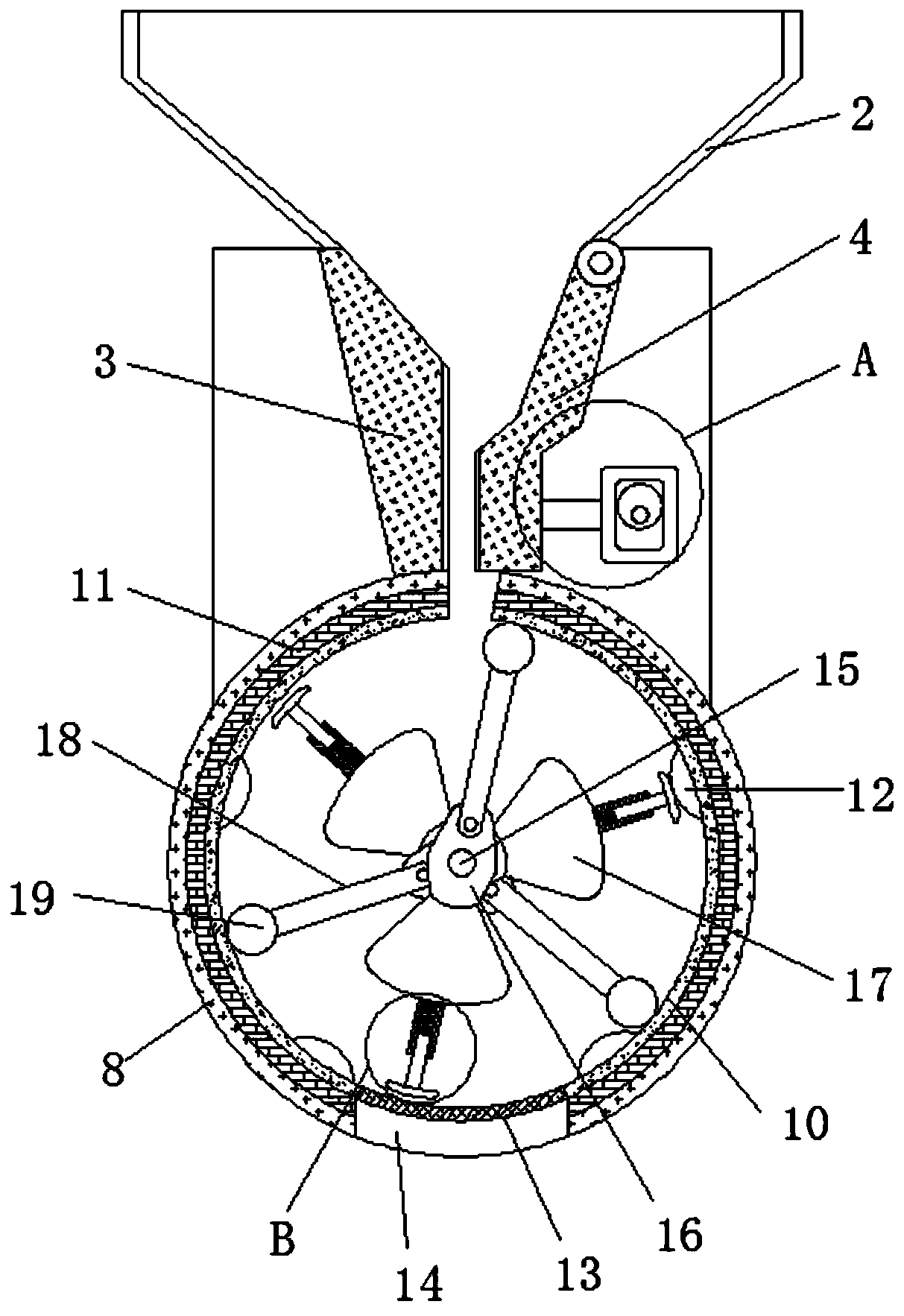

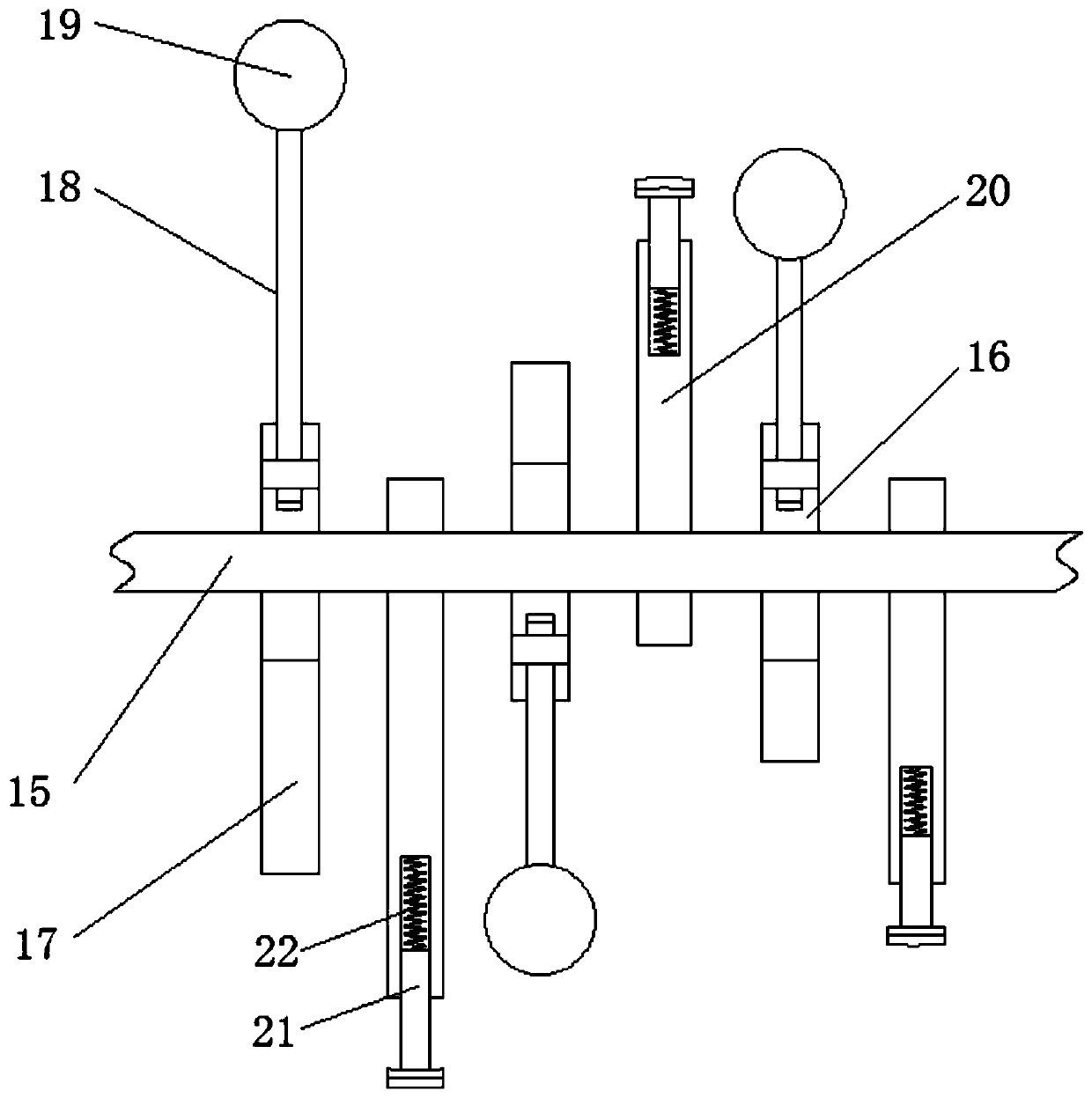

Novel material crushing device using rotational centrifugal force principle

InactiveCN111068816AGuaranteed crushing effectGood secondary crushing effectGrain treatmentsMoving jawEngineering

The invention relates to the technical field of new materials and discloses a novel material crushing device using a rotational centrifugal force principle. The novel material crushing device comprises a support, wherein the top of the support is fixedly connected with a feeding port, the bottom of the feeding port is fixedly connected with a fixed jaw, the inner part of the support is hinged witha movable jaw, the outer part of the movable jaw is fixedly connected with a push rod, the outer part of the push rod is fixedly connected with a push ring, the inner part of the push ring is movablyconnected with a cam, a fine crushing chamber is fixedly connected to the bottom of the fixed jaw, a cover plate is hinged to the outside of the fine crushing chamber, a reinforcing plate is fixedlyconnected to the inside of the fine crushing chamber, a sealing ring is fixedly connected to the inside of the fine crushing chamber, the effect of preliminarily crushing rare earth minerals is achieved through the matched use of the fixed jaw and the movable jaw, and the effect of twice crushing is achieved, so that the crushing effect is guaranteed and the secondary crushing effect and the crushing efficiency are improved.

Owner:中科纳通山东新材料有限公司

Jaw crusher with V-shaped crushing cavity

A jaw crusher with a V-shaped crushing cavity comprises a framework and a side lining plate component. An eccentric shaft is mounted on the framework via a bearing block, flywheels are arranged at two ends of the eccentric shaft, one flywheel is also utilized as a transmission wheel, a moving jaw component is mounted on the eccentric shaft, a fixed toothed plate is mounted at a position corresponding to the moving jaw component, the crushing cavity formed by the moving jaw component, the side lining plate component and the fixed toothed plate is 'V'-shaped, one end of an adjusting base is mounted in a slide way of a framework rear wall component while the other end of the adjusting base matches with the lower portion of the moving jaw component, one end of a draw bar is connected with the moving jaw component while the other end of the draw bar is mounted in the framework rear wall component, and a spring is disposed on the draw bar. Yield of the jaw crusher is increased by about 35% to 40%. By the aid of the structure of the special V-shaped crushing cavity, materials can form a laminated crushing layer excellently, and corners of the materials can be crushed sufficiently in a laminating crushing process, so that the materials are in the shape of a regular polyhedron.

Owner:HUBEI ZHIJIANG XIAJIANG MINING MASCH CO LTD

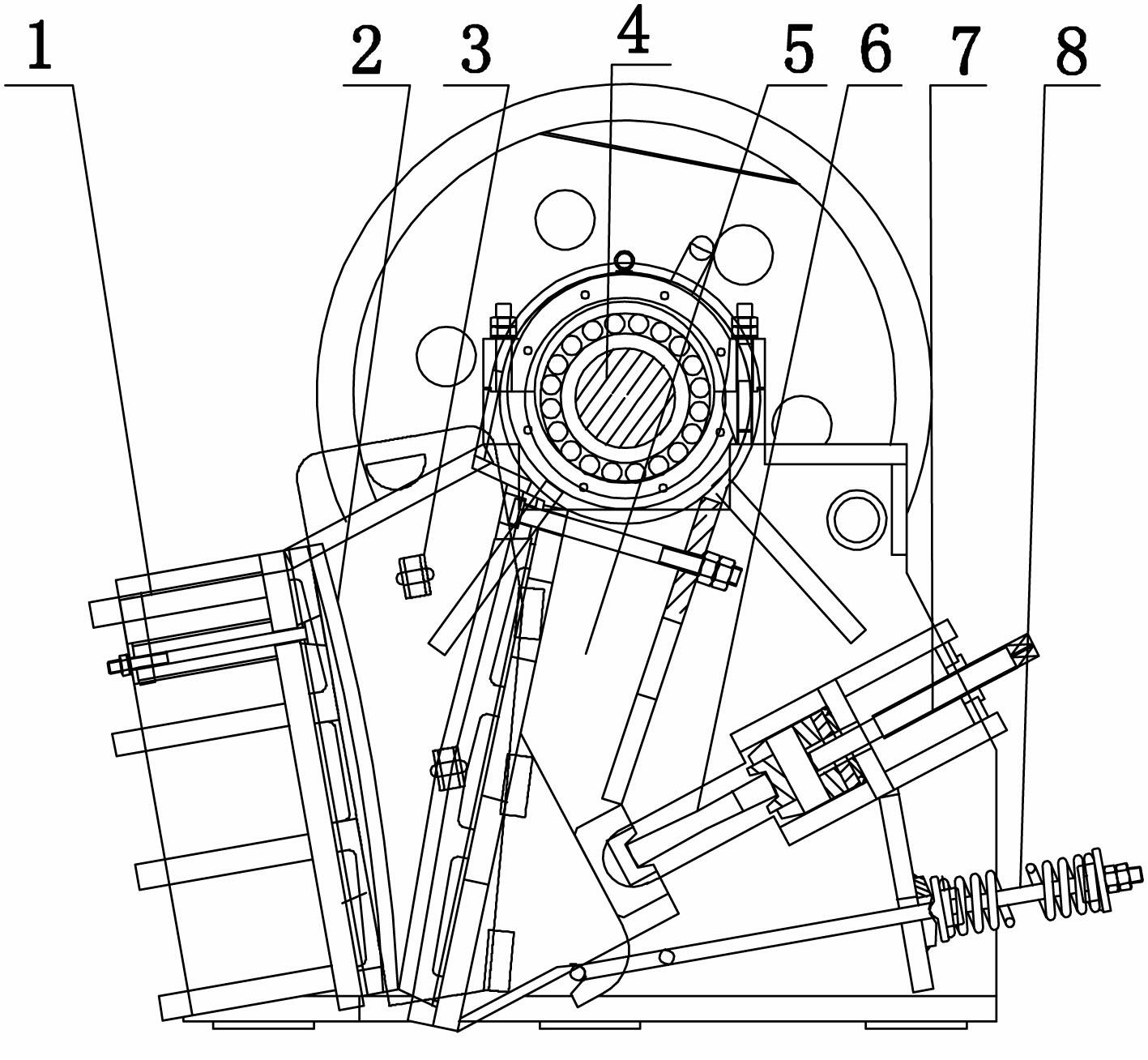

Jaw Crusher

The invention relates to the field of mining equipment, and particularly relates to a novel jaw crusher. The novel jaw crusher comprises a rack and a moving jaw group arranged on the rack, wherein the rack comprises a main rack body, a fixed jaw rack arranged at the front end of the inside of the main rack body, and a toggle plate rack arranged at the back end of the inside of the main rack body, and the moving jaw group is arranged on the main rack body between the fixed jaw rack and the toggle plate rack; a crushing cavity is arranged between the moving jaw group and the fixed jaw rack. The novel jaw crusher has the advantages of good damping effect and long service life of rack.

Owner:ZHEJIANG ZHEKUANG HEAVY IND CO LTD

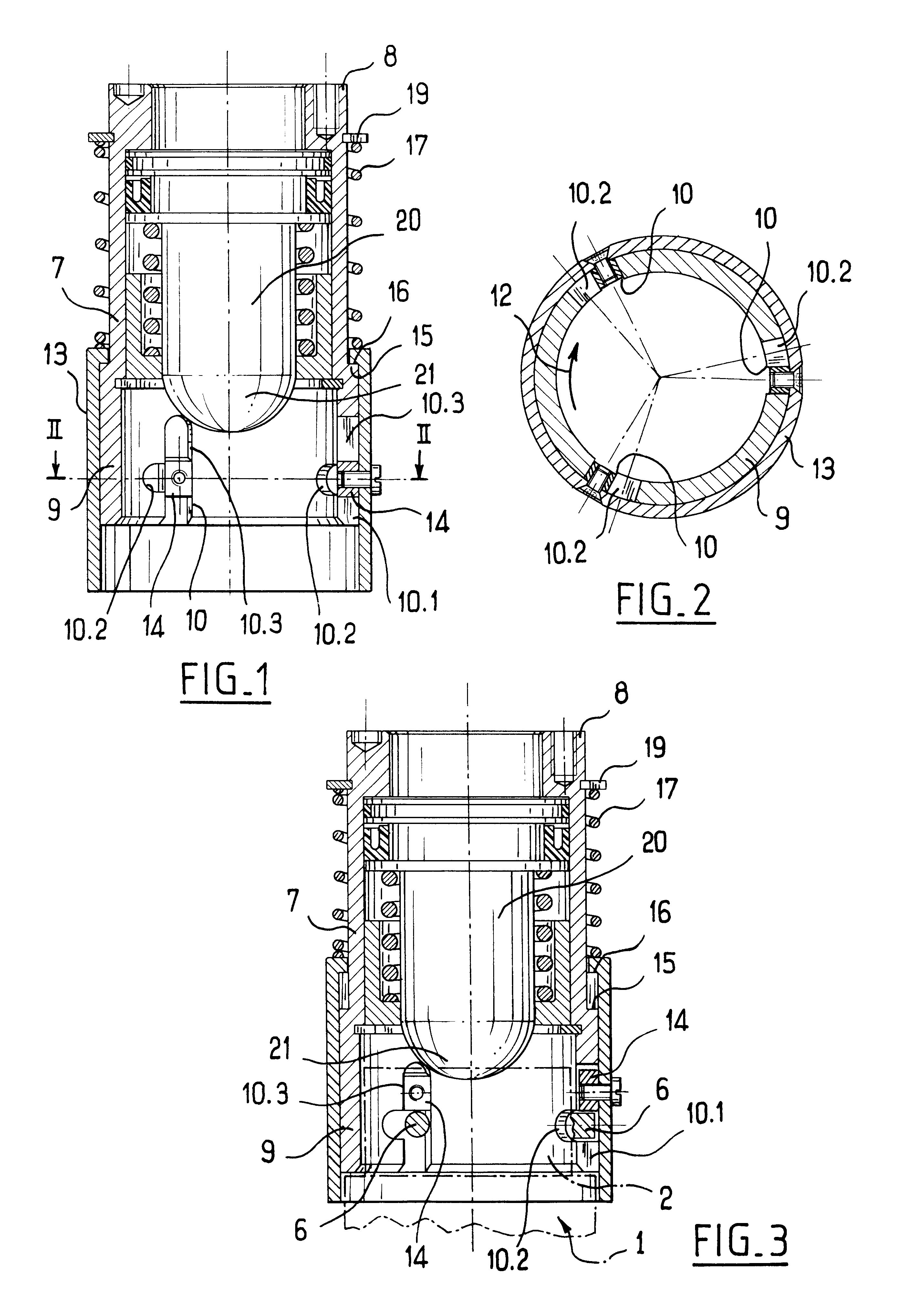

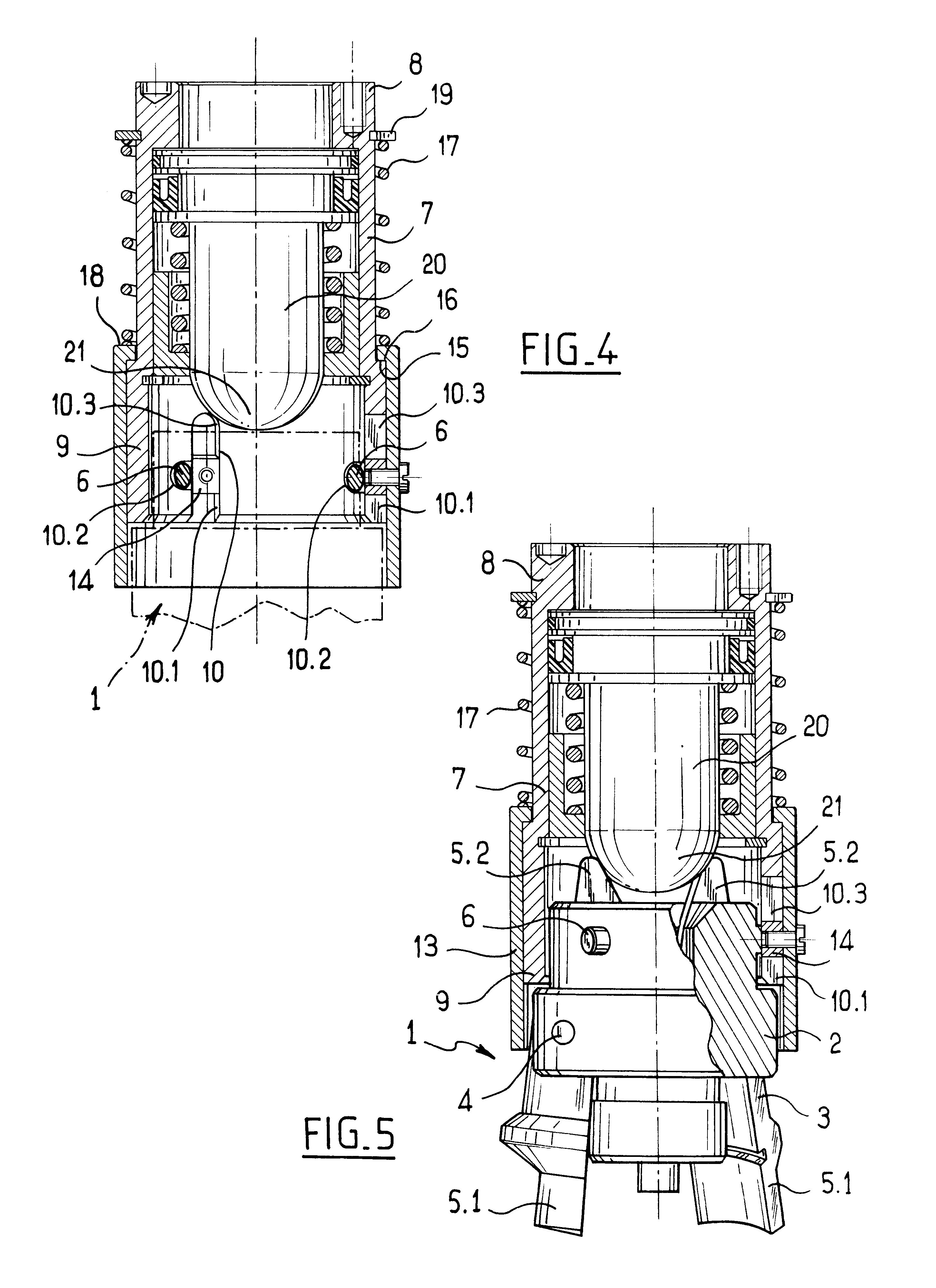

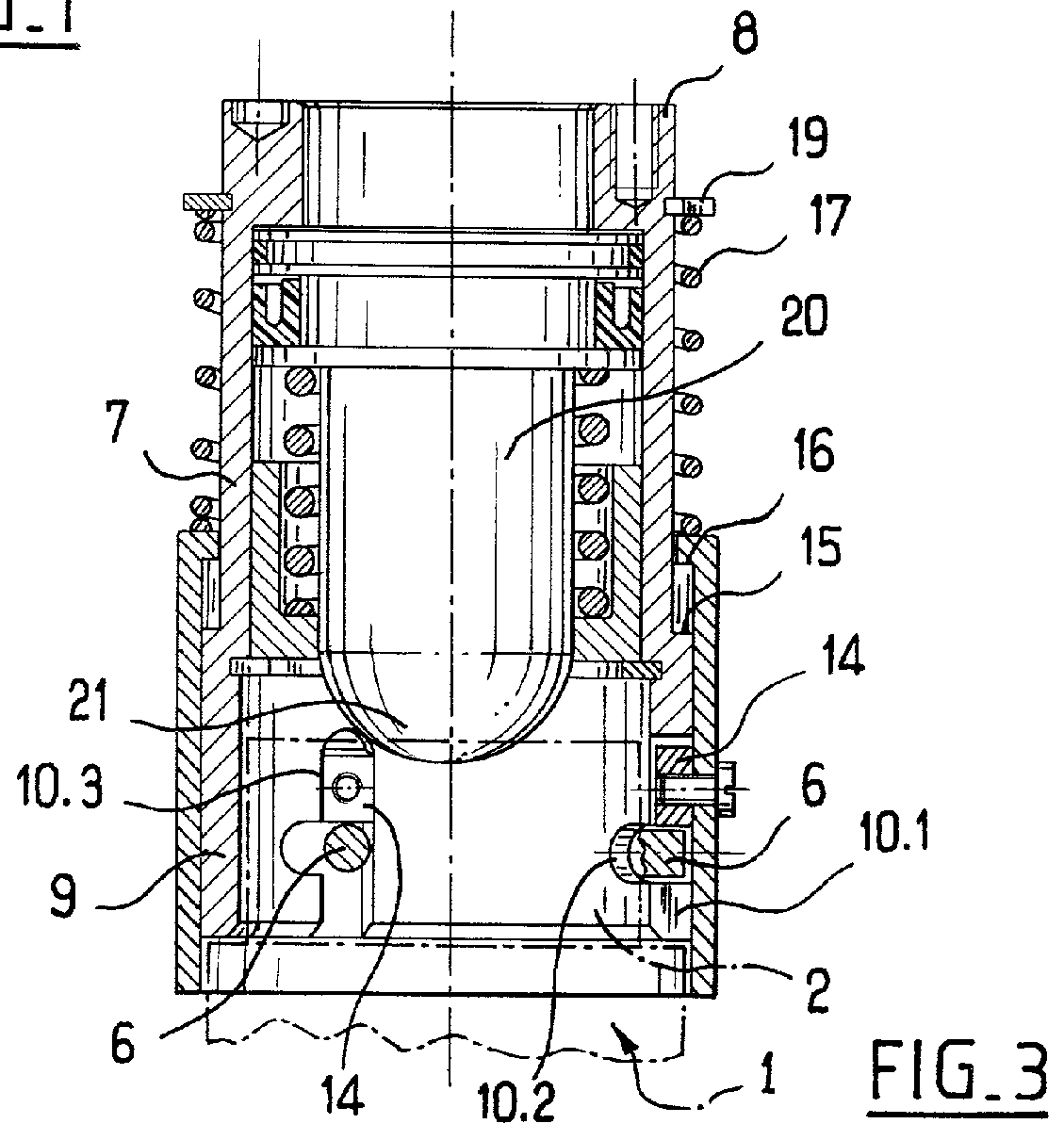

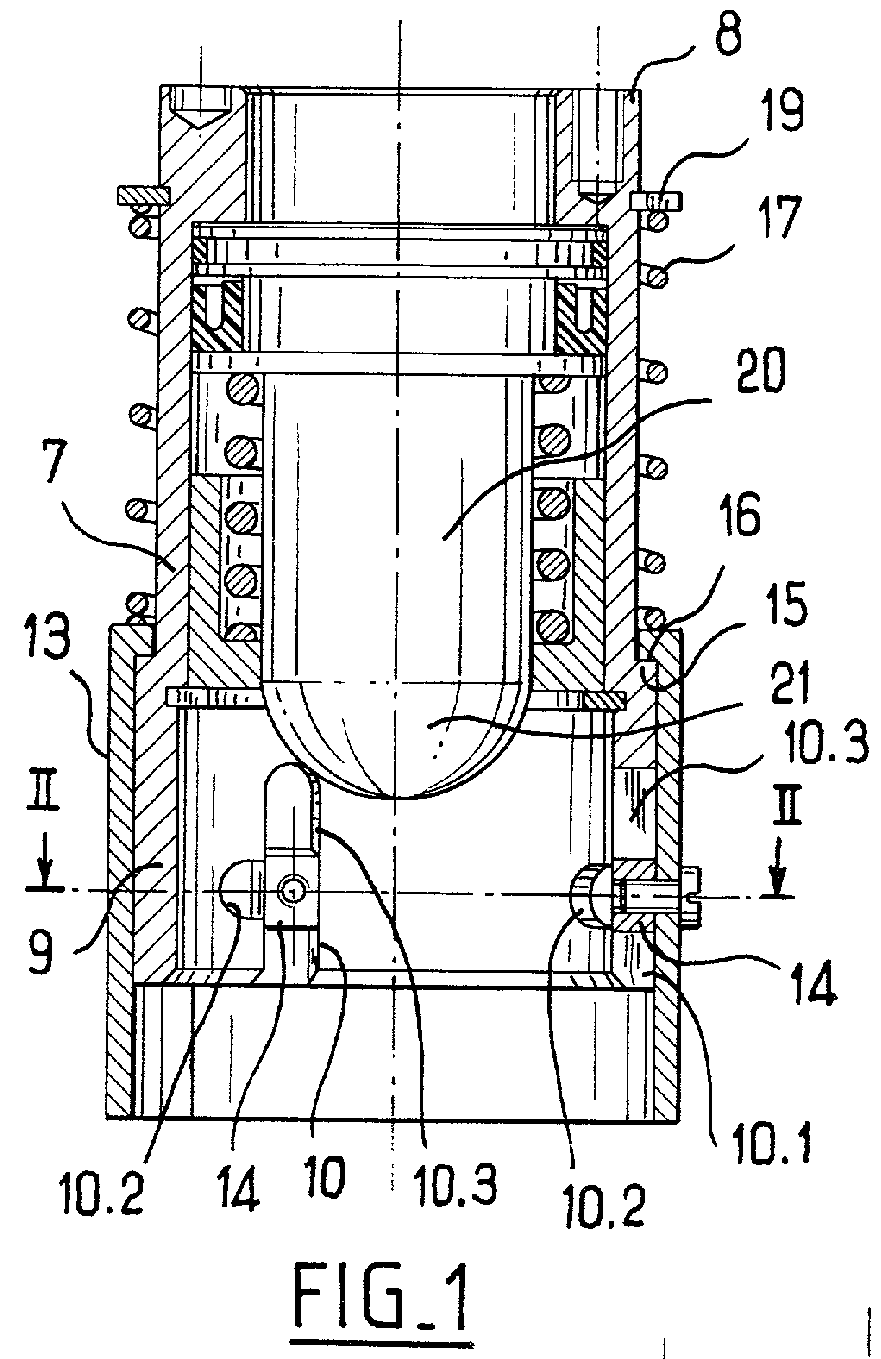

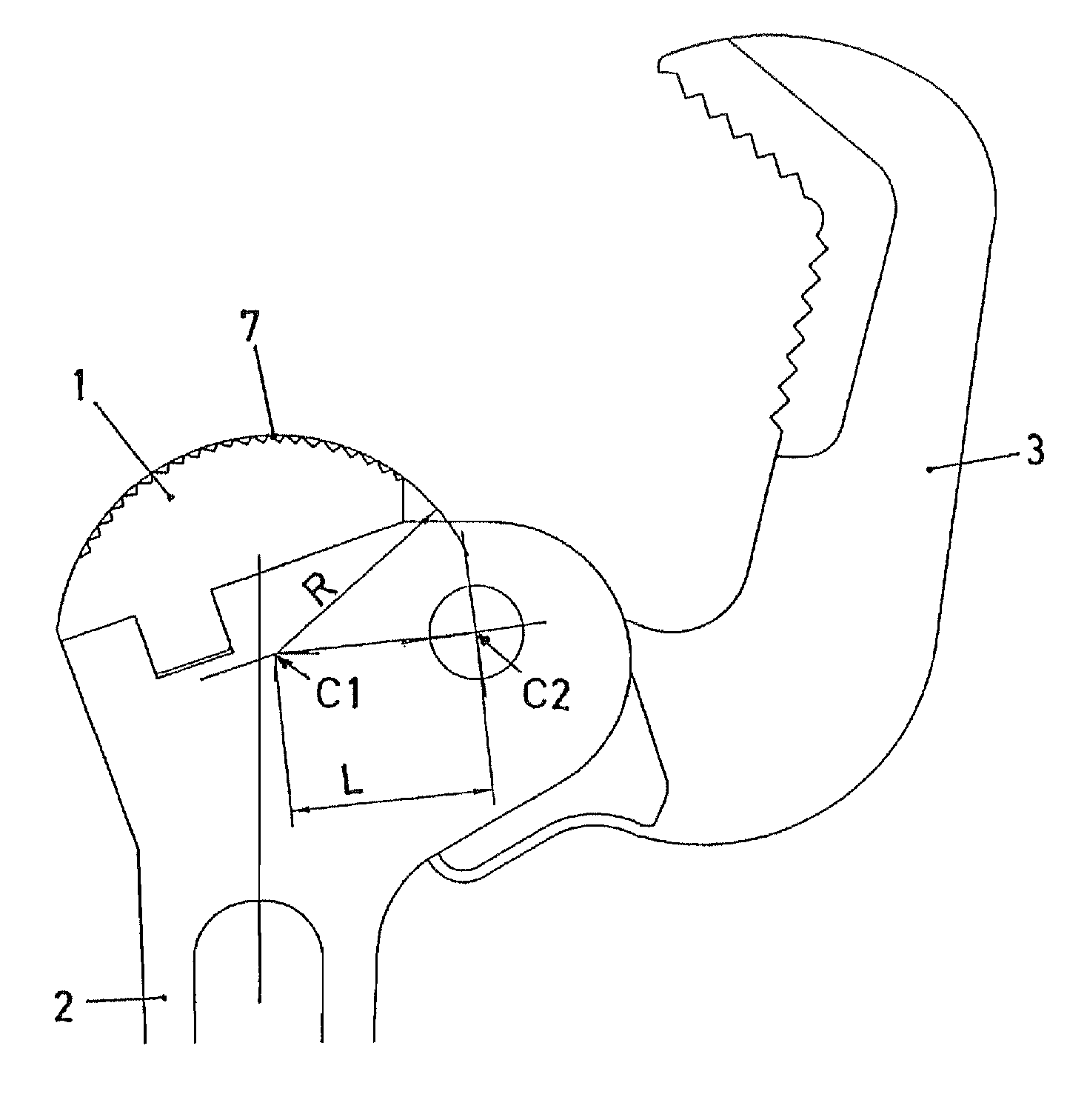

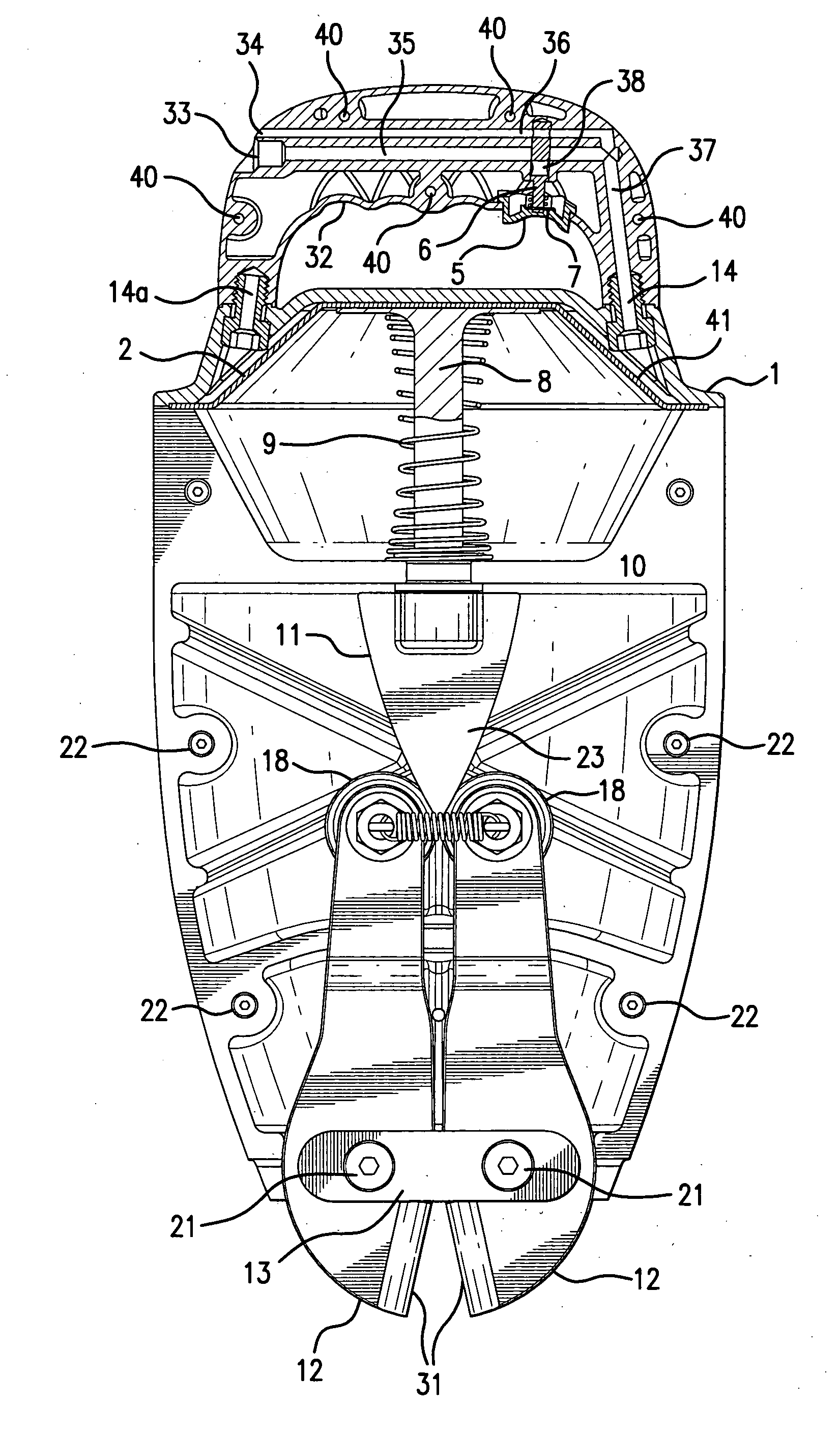

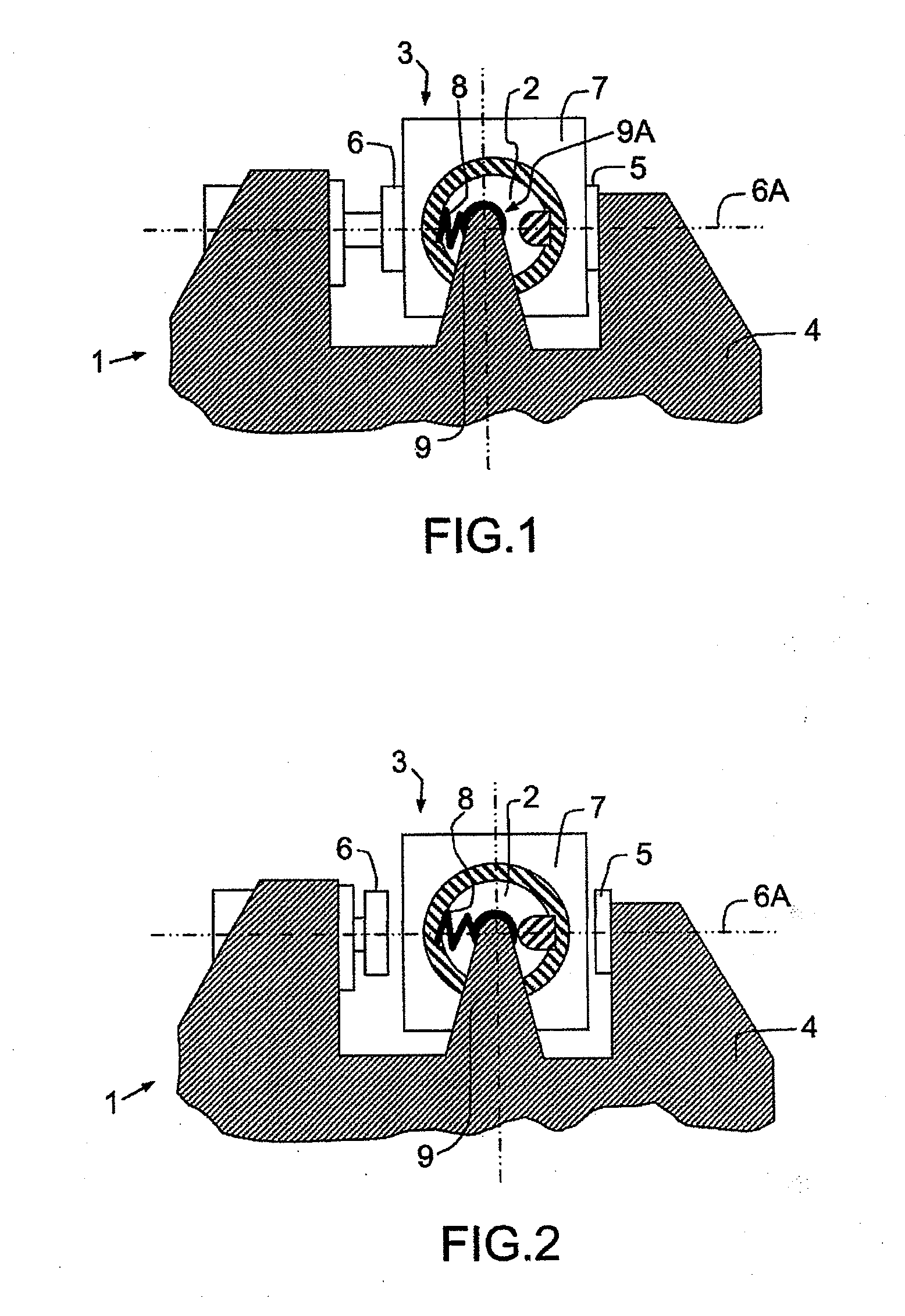

Manual wrench for actuating cylindrical elements

The invention relates to a manual wrench for actuating cylindrical elements. The inventive wrench comprises a fixed jaw (1) and a moving jaw (3) which are disposed on one end of a handle (2), whereby the fixed jaw (1) is secured with a transverse keyed assembly. The invention also includes an elastic pin (5) which extends through said keying. Moreover, the face of the fixed jaw (1) that faces the moving jaw (3) is equipped with a toothed section (7) comprising identical teeth which extend along a curved zone such as to define a single arc.

Owner:EGA MASTER

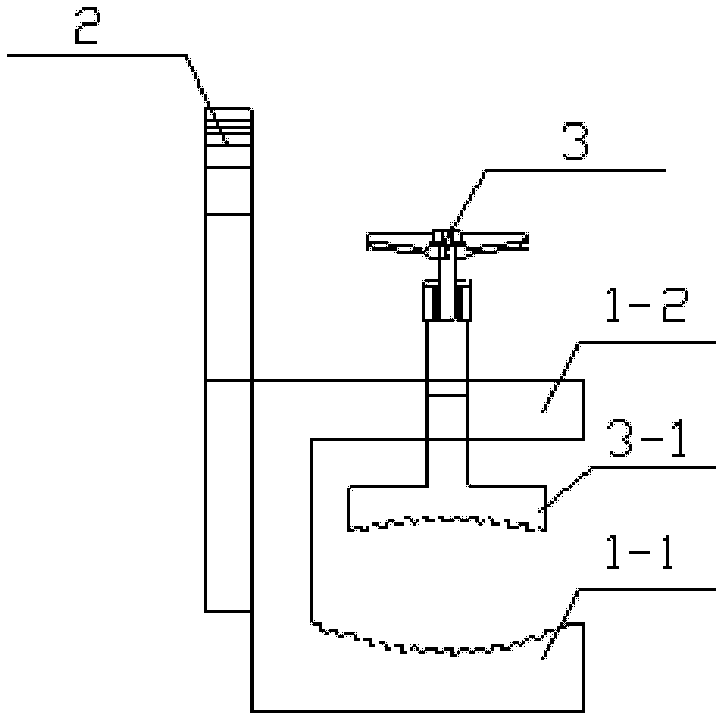

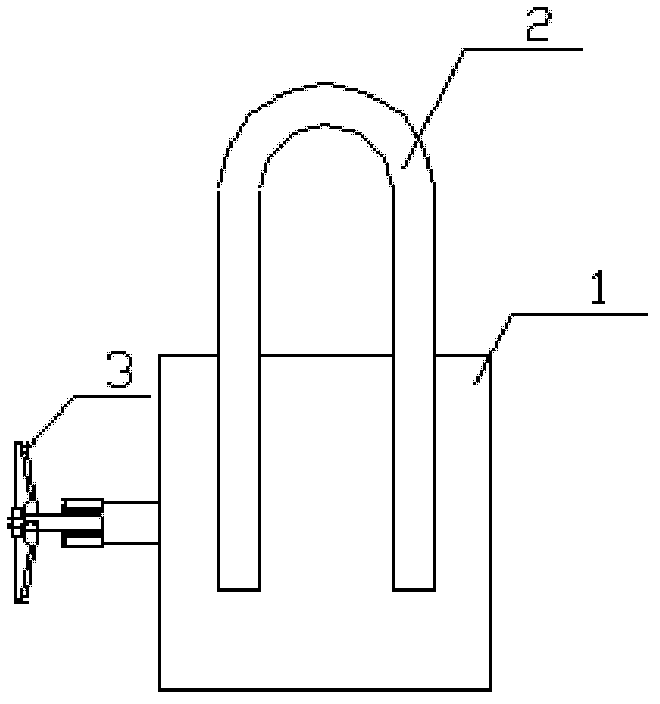

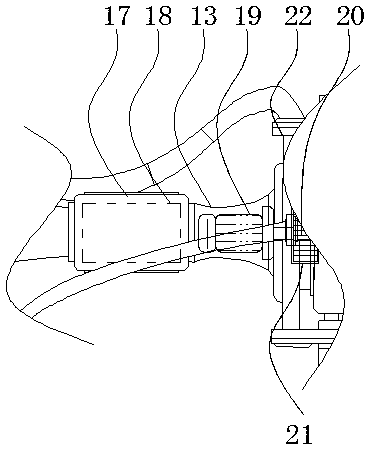

Muddy water circulation and stone crushing method for shield tunneling machine

ActiveCN104959183AImprove gravel effectImprove performanceGrain treatmentsTunnelsMoving jawCrushed stone

The invention provides a muddy water circulation and stone crushing method for a shield tunneling machine. The method comprises the following steps: mixing ballast soil and stone blocks after being cut by a cutter disc with mud injected from the outside of a tunnel to form a fluid which enters an air cushion cabin, conveying the fluid in the air cushion cabin to a mud pipeline crushing machine outside the air cushion cabin under the action of a mud discharging pump, crushing the stone blocks from the air cushion cabin in the mud pipeline crushing machine, and discharging the crushed stone blocks along with the mud outside the tunnel from a mud discharging pipe. The mud pipeline crushing machine comprises a sealing gasket, a rack and a moving jaw assembly and is a closed jaw crushing machine capable of internally sealing the mud fluid with the pressure being up to 0.5MPa or more. The invention provides the muddy water circulation and stone crushing method for the shield tunneling machine, which can be used for improving the stone crushing capacity of a muddy water circulation system of the shield tunneling machine, improving the performance of the muddy water circulation system, and improving the ballast-carrying conveying capacity of the muddy water circulation system. The method provided by the invention is used for improving the geology adaptability and the tunneling efficiency of the shield tunneling machine.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Large-diameter reinforcing steel bar lifting tongs

The invention relates to a pair of large-diameter reinforcing steel bar lifting tongs, and belongs to the technical field of civil engineering construction. The pair of tongs comprises a tongs frame with a groove; a lifting ring extends from the tongs frame; a clamping wall forming a regular jaw is mounted on one side of the groove; a mounting wall for mounting a moving jaw is arranged on the other side of the groove; a clamping handle is arranged on the outer side of the mounting wall through a screw pair and drives the moving jaw to move in a direction opposite to the regular jaw; at least one surface of the moving jaw opposite to the regular jaw is a concave cambered surface with clamping veins; and the clamping veins are matched with reinforcing steel bar threads. When the large-diameter reinforcing steel bar lifting tongs are used, a reinforcing steel bar is placed in the groove of the tongs frame, then the clamping handle is rotated to enable the moving jaw and the regular jaw to tend to be gathered up to clamp the reinforcing steel bar conveniently and reliably, and afterwards the lifting ring is hooked by lifting equipment such as a crane, so that the reinforcing steel baris easily and safely lifted.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

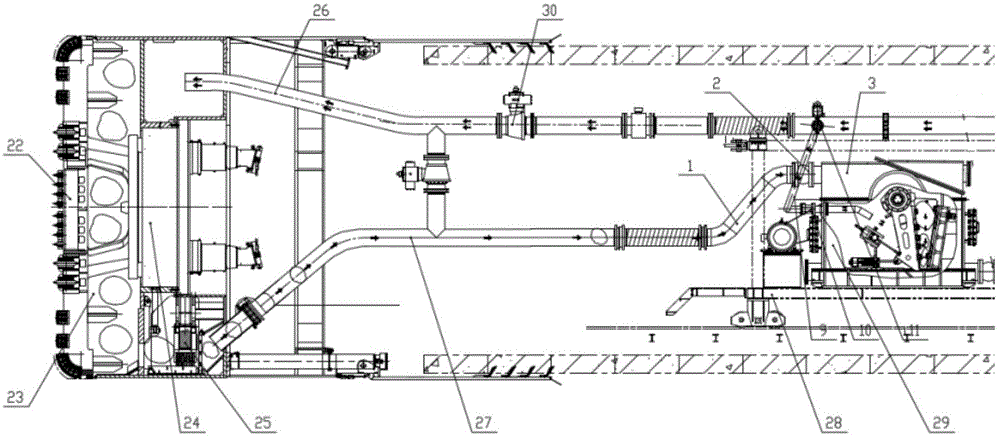

Mud water circulation and stone crushing system for shield tunneling machine

ActiveCN105065007ASafe and reliable maintenance stepsImprove crushing abilityGrain treatmentsTunnelsMoving jawCrushed stone

The invention provides a mud water circulation and stone crushing system for a shield tunneling machine. The system comprises a mud incoming pipe, an air cushion bin, a discharge pipe, a mud line crusher, a mud discharge pump and a mud discharge pipe which are connected in series successively. The discharge pipe is used for conveying mud and gravels from the air cushion bin to the mud line crusher; the mud line crusher crushes the gravels from the air cushion bin; the mud line crusher is a mud fluid closed jaw crusher comprising a seal pad, a frame and a moving jaw assembly and having an interior sealable pressure up to above 0.5Mpa. The system is better than a hydraulic jaw crusher in the air cushion bin of the shield tunneling machine in terms of crushing capacity, service life and reliability; the problems that an existing shield tunneling machine experiences delayed discharge and pipe jamming in water-rich sand cobble are solved; by mounting the system on a trailer, personnel needs to enter the bin with pressure for maintenance fewer times, application cost and construction risk of the shield tunneling machine are decreased, and geological adaptability and tunneling efficiency of the shield tunneling machine are improved.

Owner:CHINA RAILWAY CONSTR HEAVY IND

Bolt cutter

InactiveUS20110203116A1Easy to operatePortable handheld shearing machinesMetal working apparatusBolt cutterMoving jaw

A cutting apparatus used primarily to cut bolts or other cylindrical articles employing a source of compressed air to force a pair ofjaws together. The apparatus includes a handle provided with a trigger and a main body portion including a pair of laterally moving jaws. Compressed air will flow through the handle portion into the main body portion, thereby forcing a diaphragm downward forcing a piston to move in the direction of the jaws. A gear cam would force the proximal end of the jaw assembly outward, thereby forcing the jaws inward against one another, thereby cutting the cylindrical article.

Owner:VARY FR R C

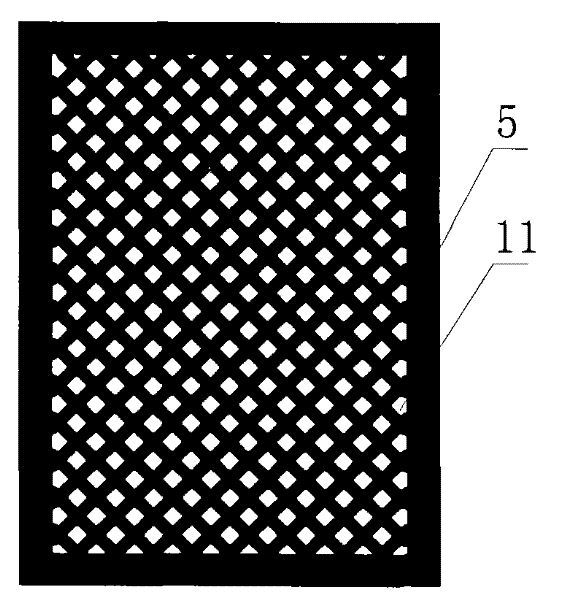

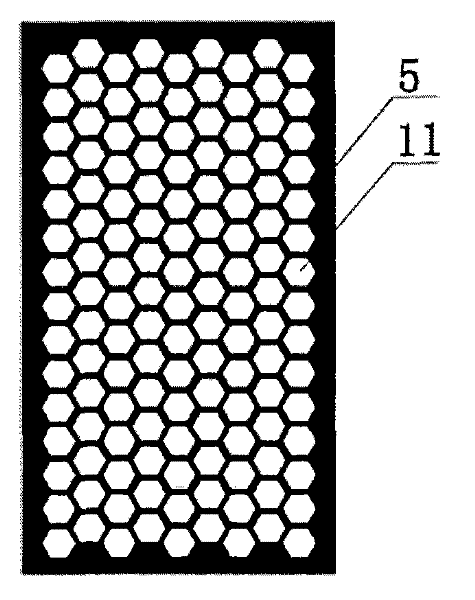

A high-efficiency jaw crusher with large bite force

InactiveCN102259042AMaximize Shatter EffectFully frustrating, shearing and crushing functionsGrain treatmentsDrive shaftMoving jaw

The invention discloses a high-efficiency jaw crusher with large bite force, wherein a drive shaft, a crushing pair, a moving jaw and a toggle plate are arranged on a rack; the crushing pair comprises a pair of tooth plates standing opposite each other so as to form a crushing cavity; one tooth plate is fixedly connected on the rack and the other tooth plate is fixedly connected on the moving jaw; the upper end of the moving jaw is pivoted on the drive shaft and the lower end of the moving jaw is pivoted on the toggle plate; a driving wheel is connected on the drive shaft; and the tooth plates are flat plates with reticular mesh structures. According to the invention, a traditional way of setting tooth form on the basis of a conventional technical tooth plate is broke through; a toothless tooth plate is provided; the tooth form design is replaced by a honeycomb reticular mesh design to ensure that the crushing functions of split, breaking and extrusion are strengthened; the most remarkable effect is that a crushing mechanism mainly based on extrusion and squash in the prior art is changed into comprehensive application mainly based on filing and shear and supplementarily based on the split, the breaking and the extrusion; and then, larger crushing bit force are provided and the crushing performance is greatly improved.

Owner:ZHEJIANG SHENGDA MACHINERY

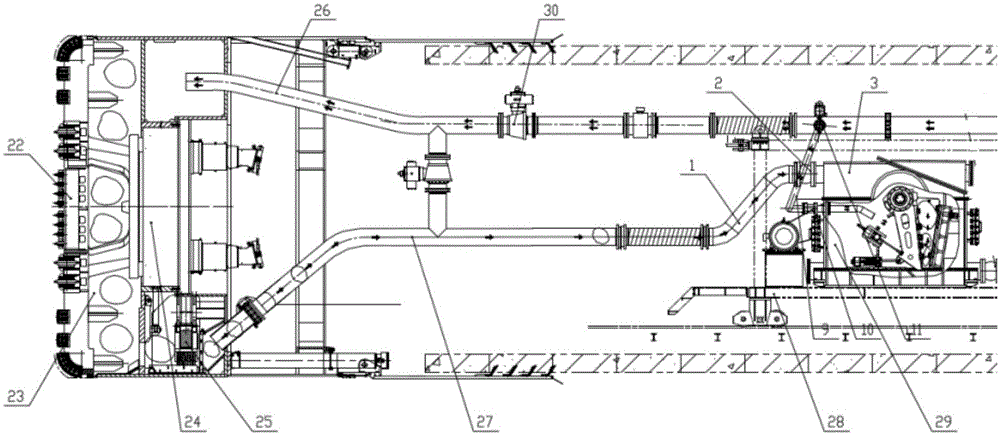

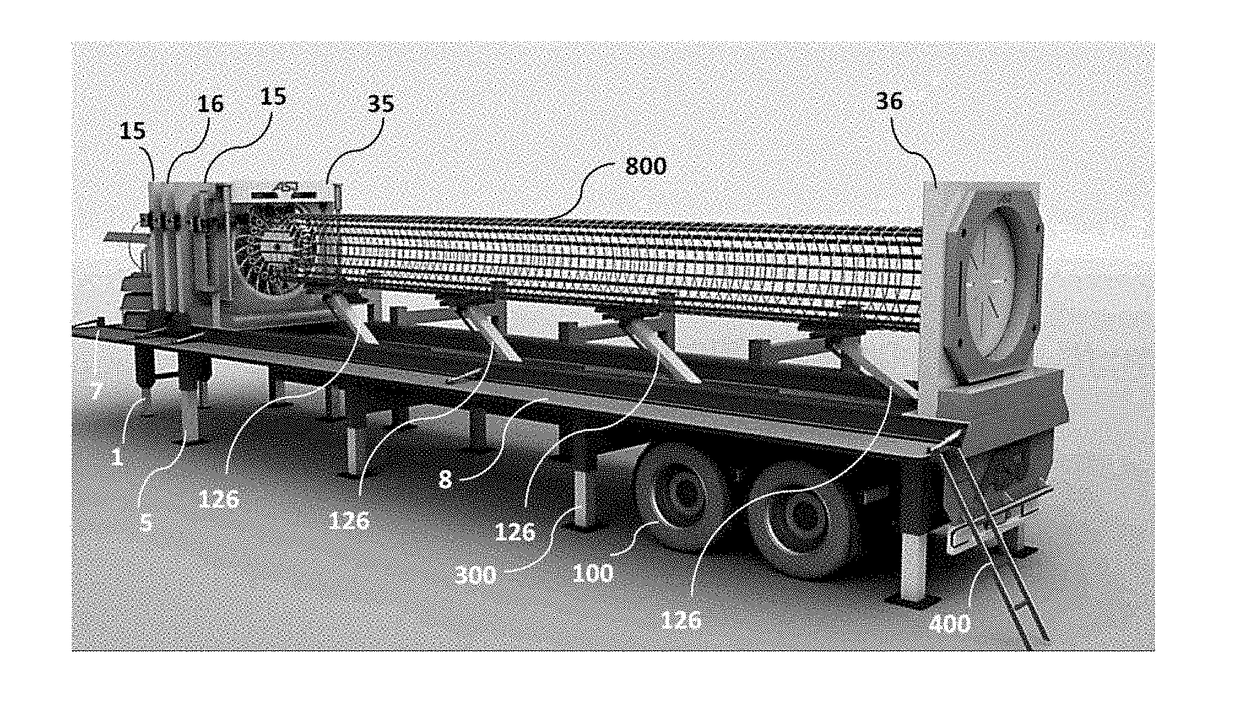

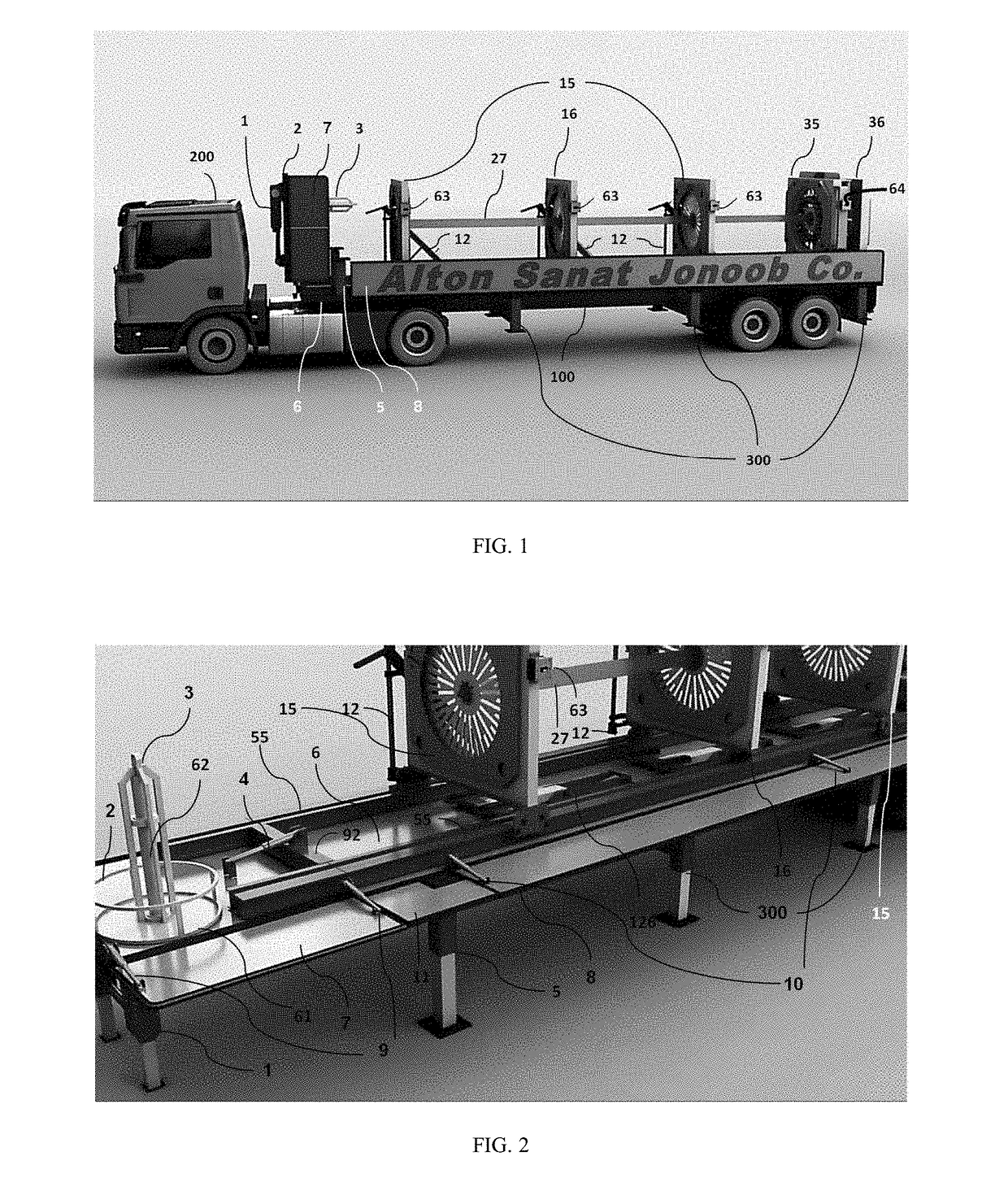

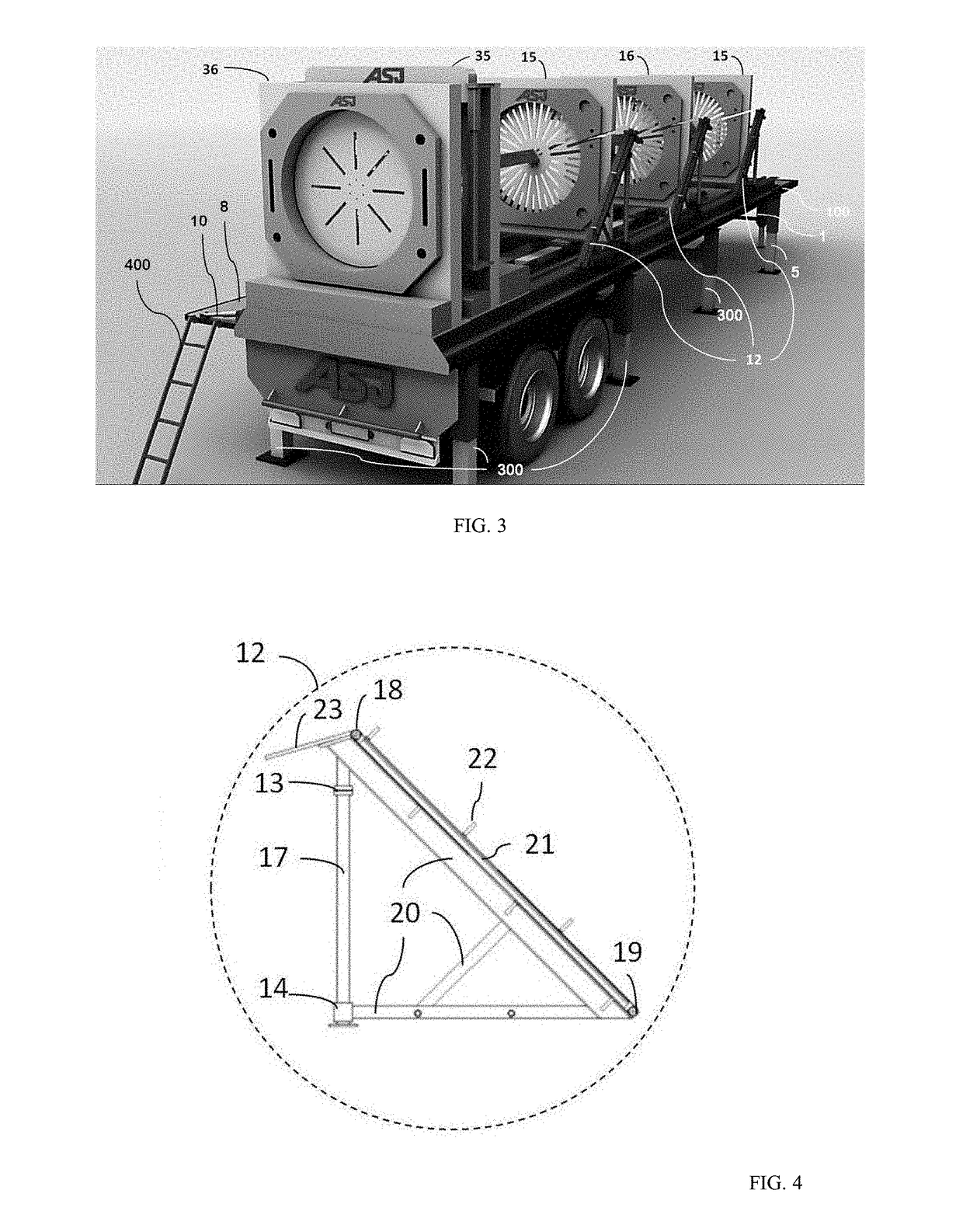

Portable, Compact and Automated Cage Making Machine

ActiveUS20180236527A1High strengthPrevent wasting tensional resistanceWire networkBuilding reinforcementsMoving jawOperation mode

The invention is an automated machine for reinforcement of piles, pillars, beams, and reinforcing cages in location of construction projects. This machine consists of main elements like loading arms and feeding jaws of longitudinal bars, rotating winch for stirrup and its guides, fixed and moving jaws and welding robot. It can be installed on a specified flat trailer in resting mode and come to an operative mode in project location and will be ready to use. To make reinforcing cages, an automated method for continuous winding of stirrup around longitudinal bars has been applied, and two intelligent welding systems (resistive spot and CO2 welding methods) have been utilized for joints in this machine.

Owner:DAVOODI OMID +2

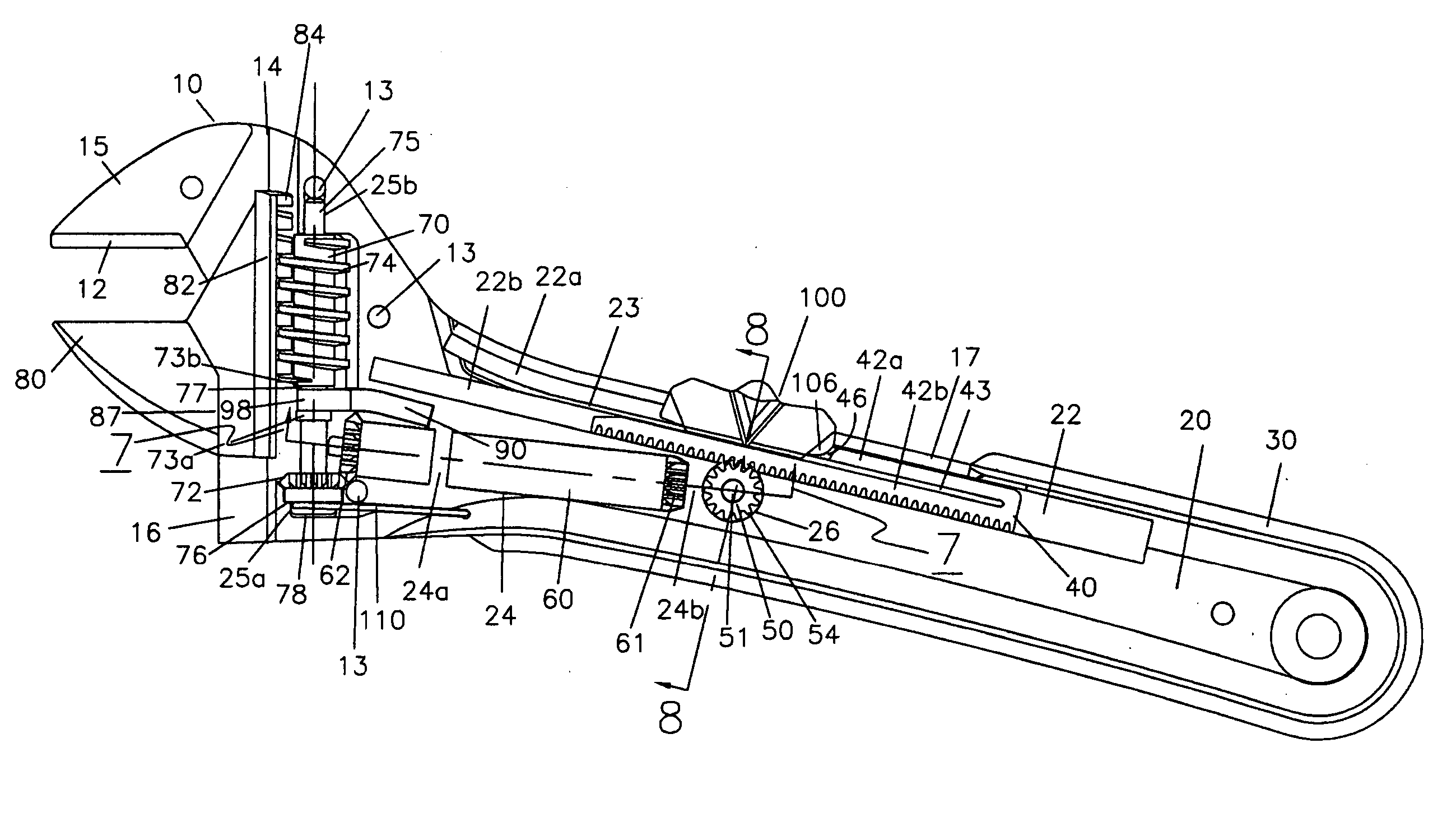

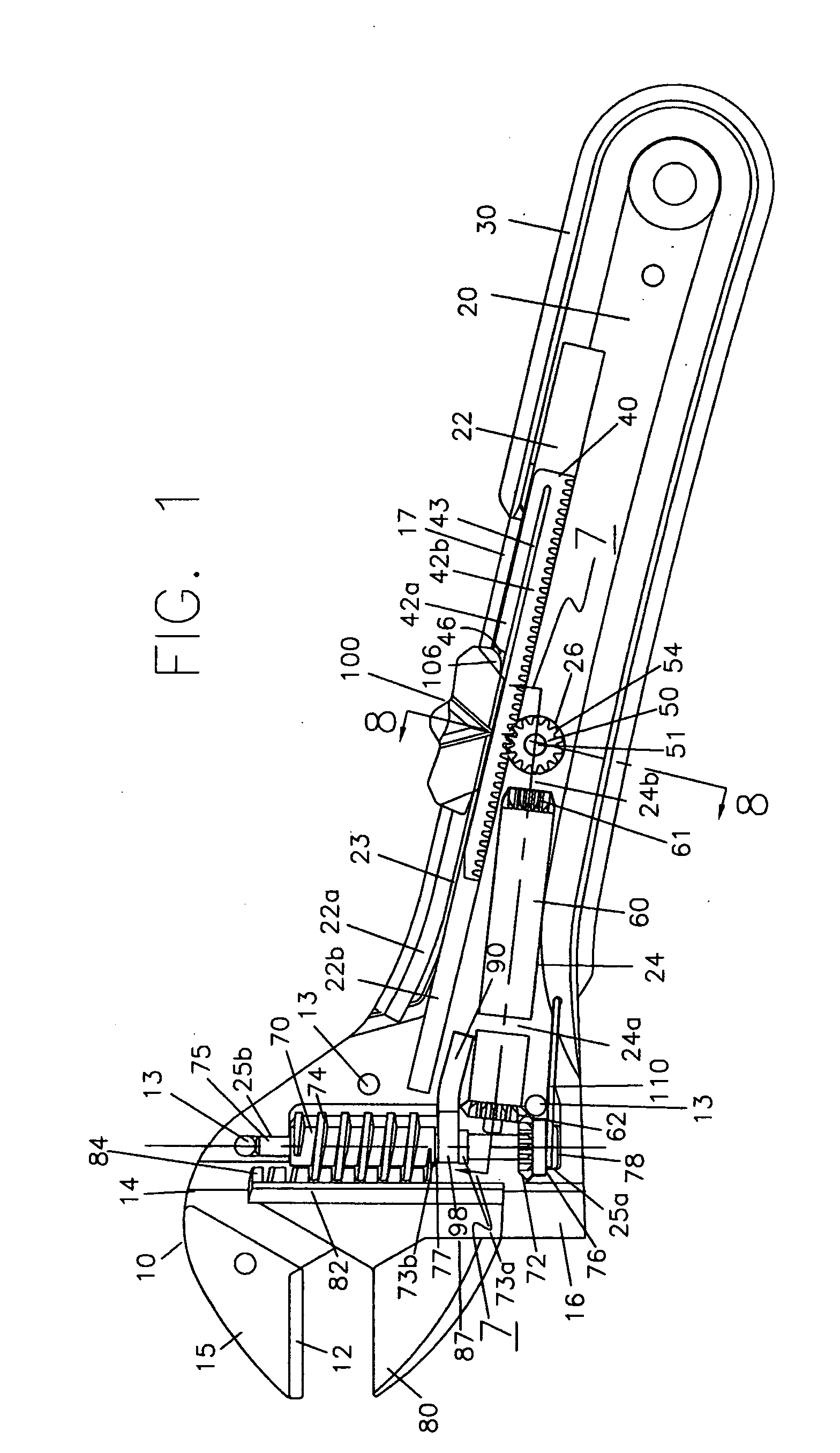

Laminated wrench construction system

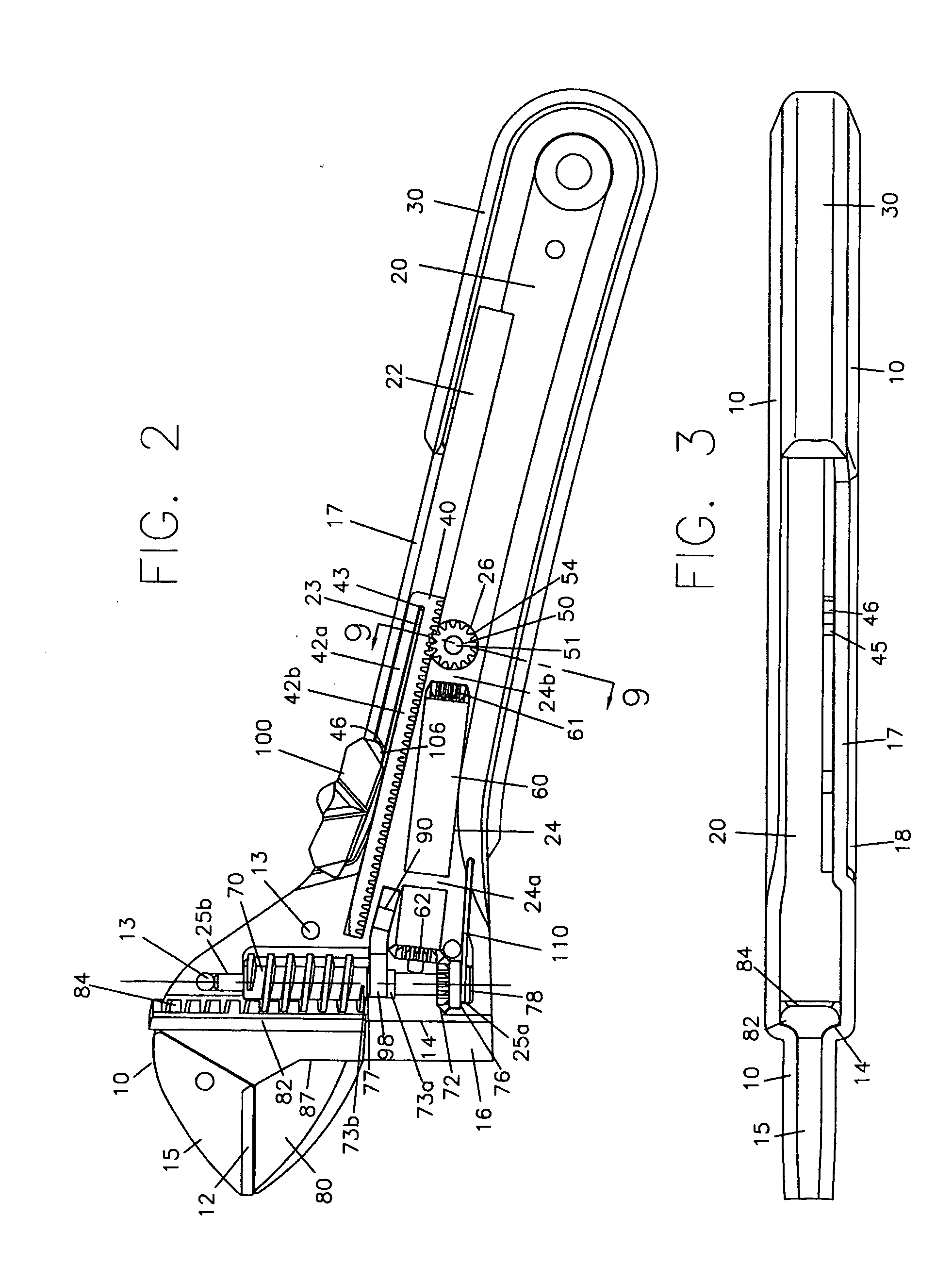

InactiveUS20050274231A1Easy to handleReadily held in repeatable position in useSpannersWrenchesGear driveMoving jaw

A slide switch adjustable wrench uses a laminated steel construction method that includes a stepped surface to form a guide for the worm gear driven moving jaw. A molded or similarly formed body is sandwiched between the steel housing sides to form a sturdy structure. The body provides cavities, bearings and other features to support and guide moving parts within. A rack and pinion drive system uses simple molded gears to amplify about 2 inches of switch travel into about 6 turns of the worm gear. An overmolded rubber edge grip bonds to the body to create a recess in the body; this recess seamlessly fits the steel sides to form a smooth continuously contoured grip surface.

Owner:MARKS JOEL +1

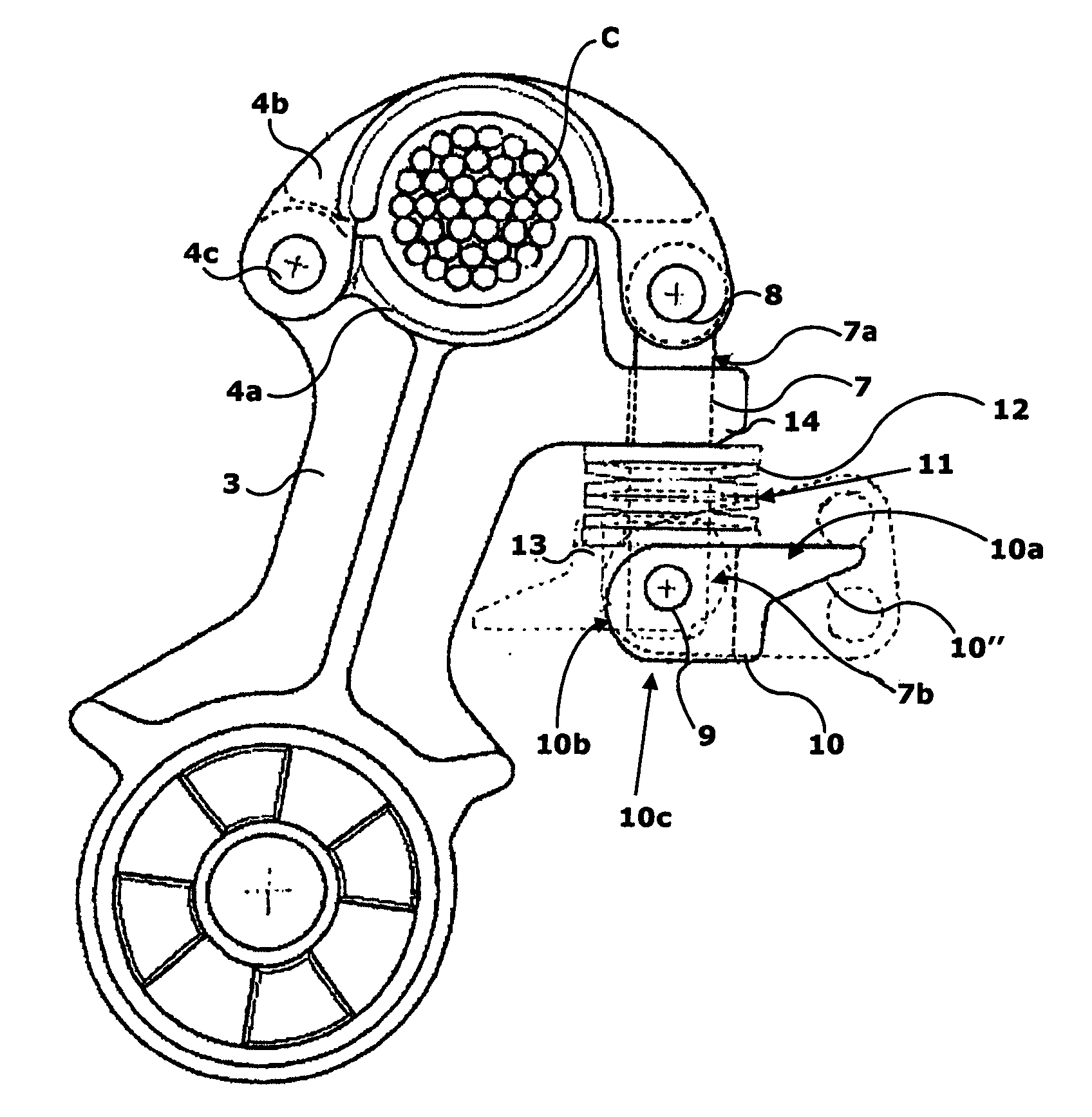

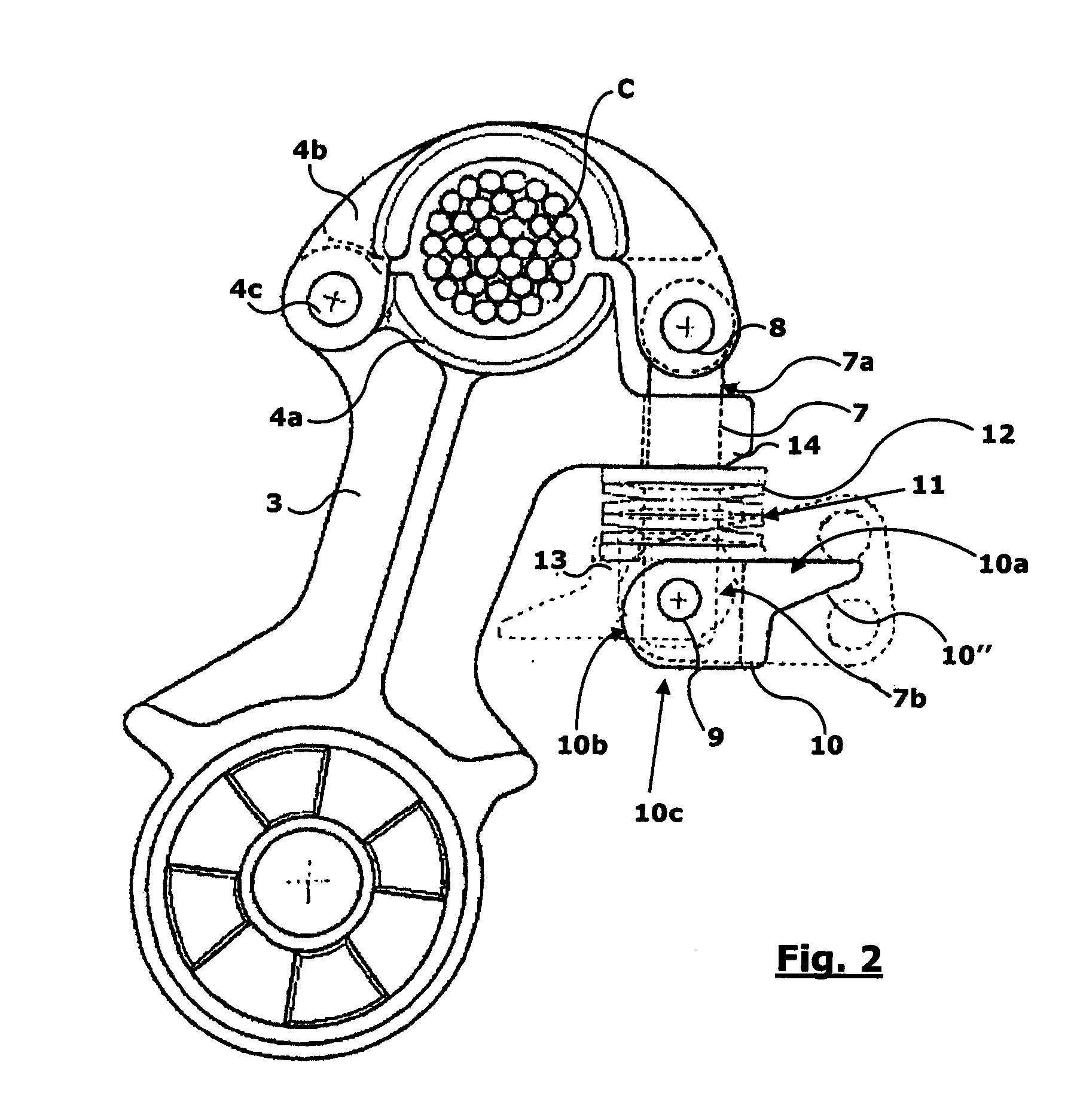

Anchoring Clamp on Bundle Wires for High-Voltage Electric Lines and Dampening Spacer Provided with Such Clamp

ActiveUS20160006231A1Remove restrictionsMaintaining distance between parallel conductorsDevices for damping mechanical oscillationsMoving jawEngineering

The present invention relates to a clamp and a spacer for bundle-shaped wires of high-voltage electric lines, as well as a relative mounting kit. The clamp comprises an arm for fastening to wires, at the free end of which two fixed jaws are formed. The second jaw being movable through disengageable tightening means, both jaws being provided with opposite saddles for the housing of wire, wherein the second moving jaw has a first end mounted rotating on a pin, carried by said fastening arm in a position coinciding with a first end of the first jaw, while with a second end it is apt to cooperate with tightening means. The tightening means comprise a tie rod having an end mounted rotating on the jaw and a distal end constrained through a constraint pin to a cam lever.

Owner:A SALVI & C SPA

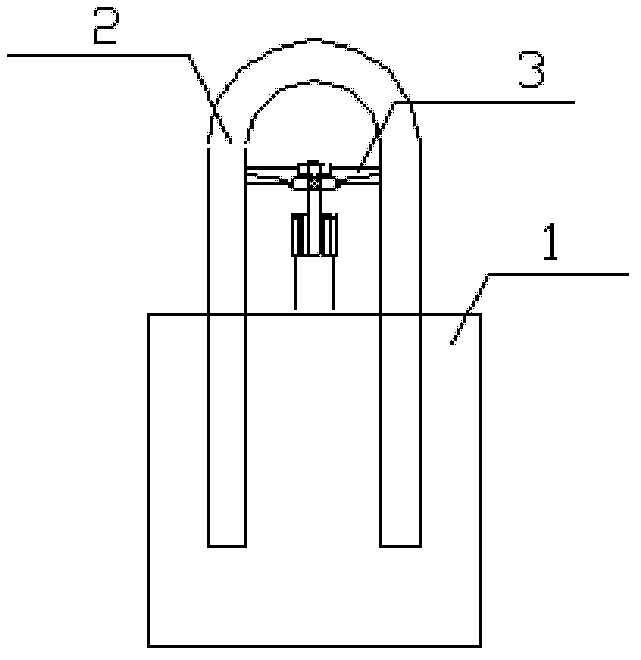

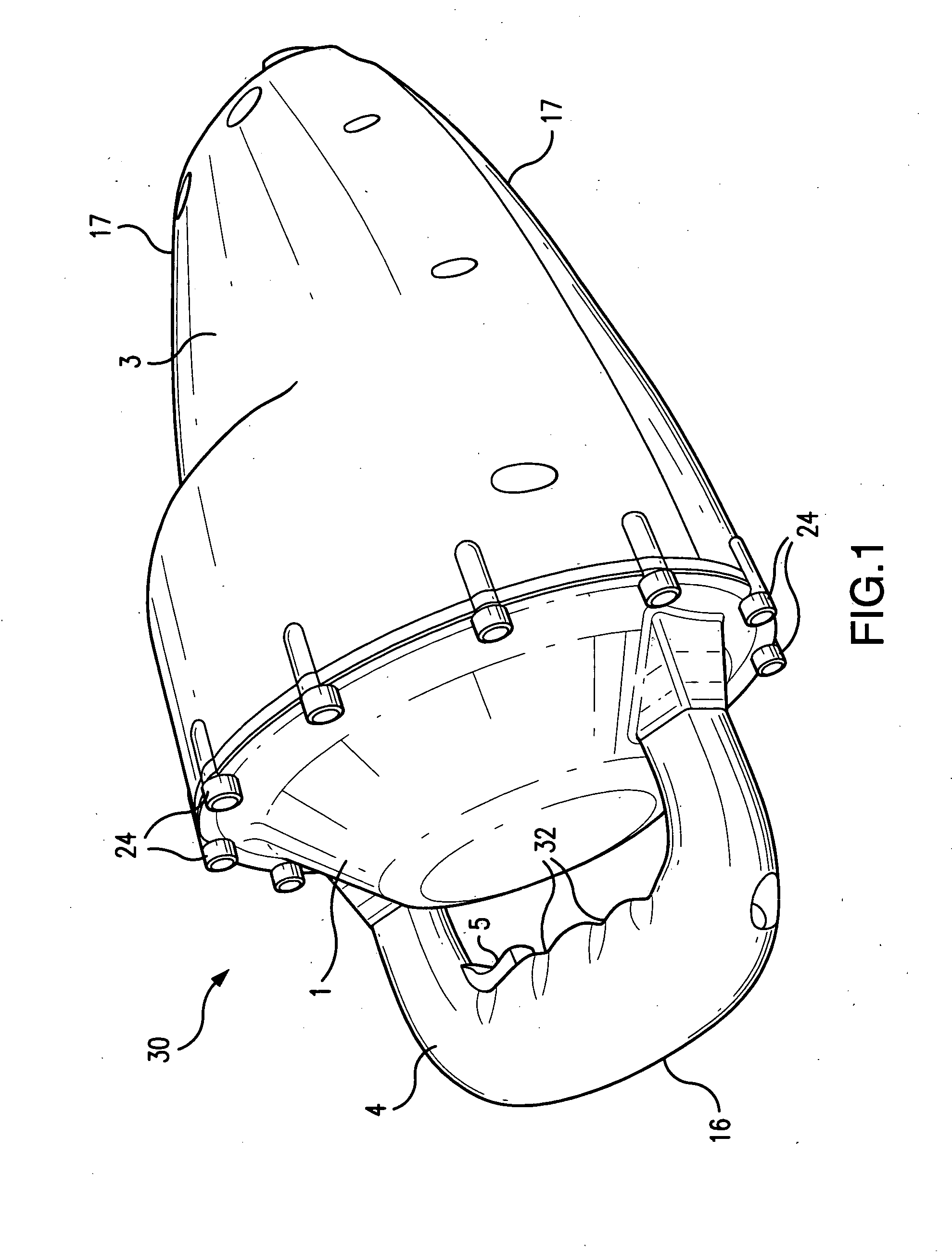

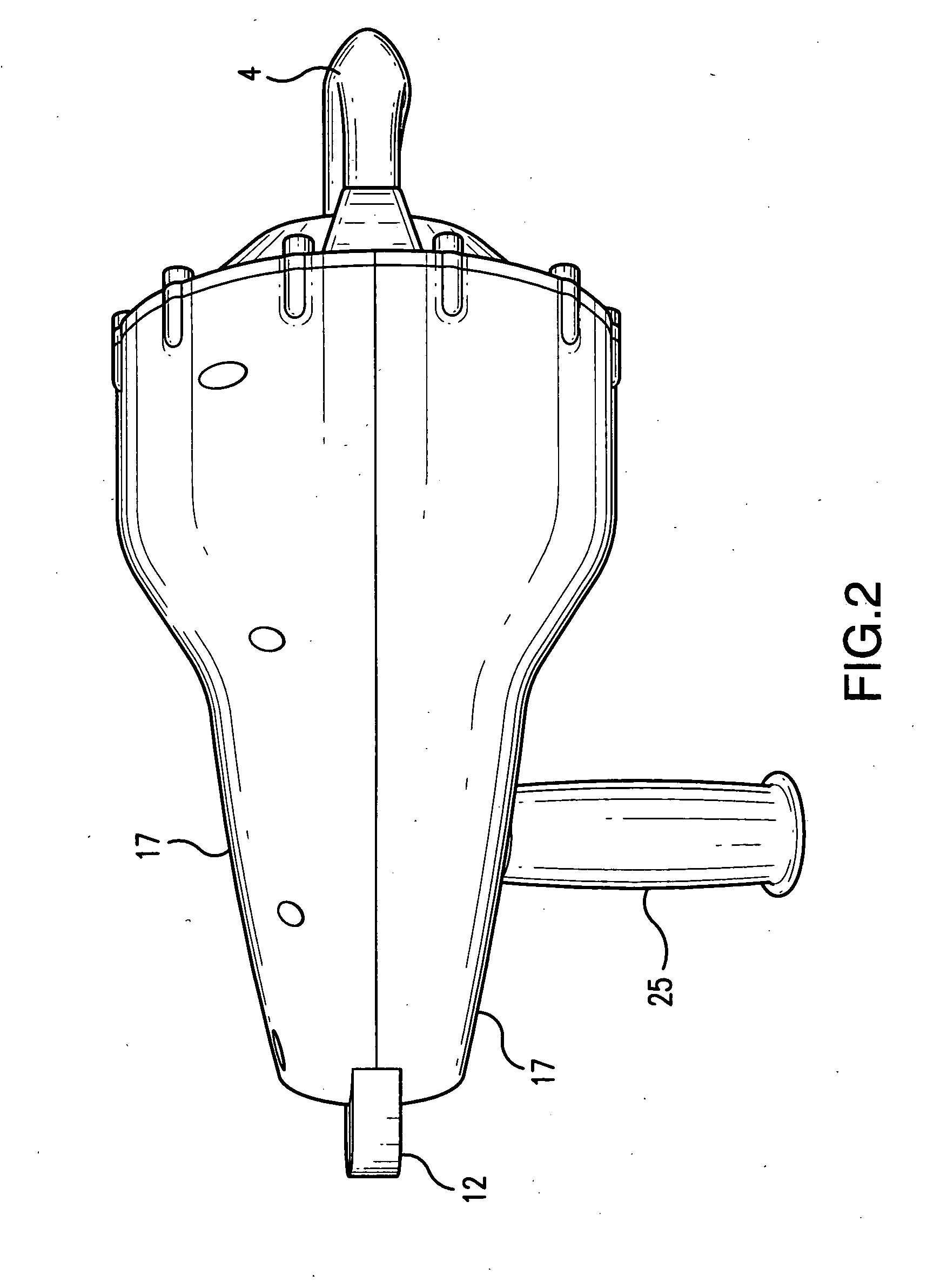

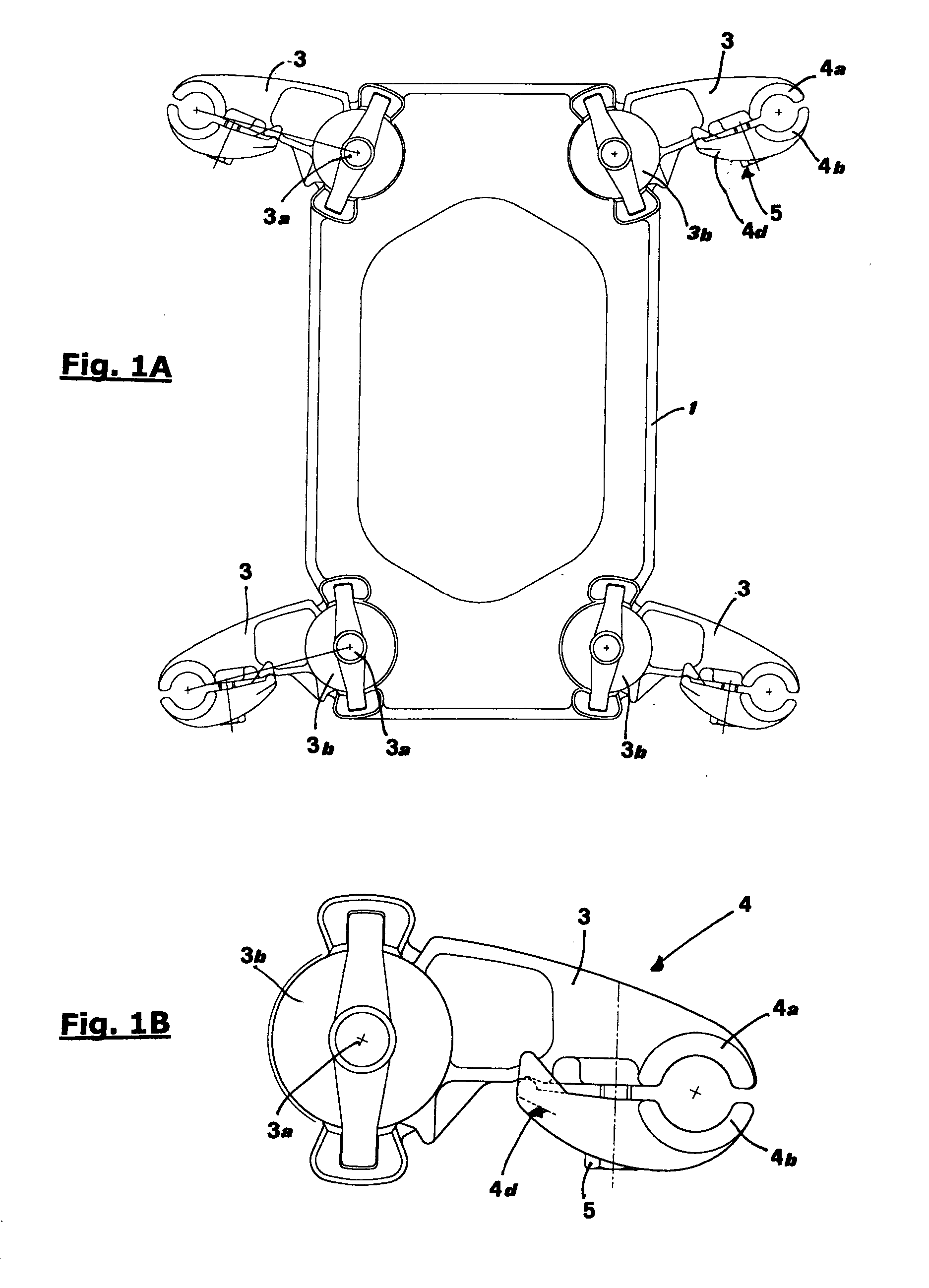

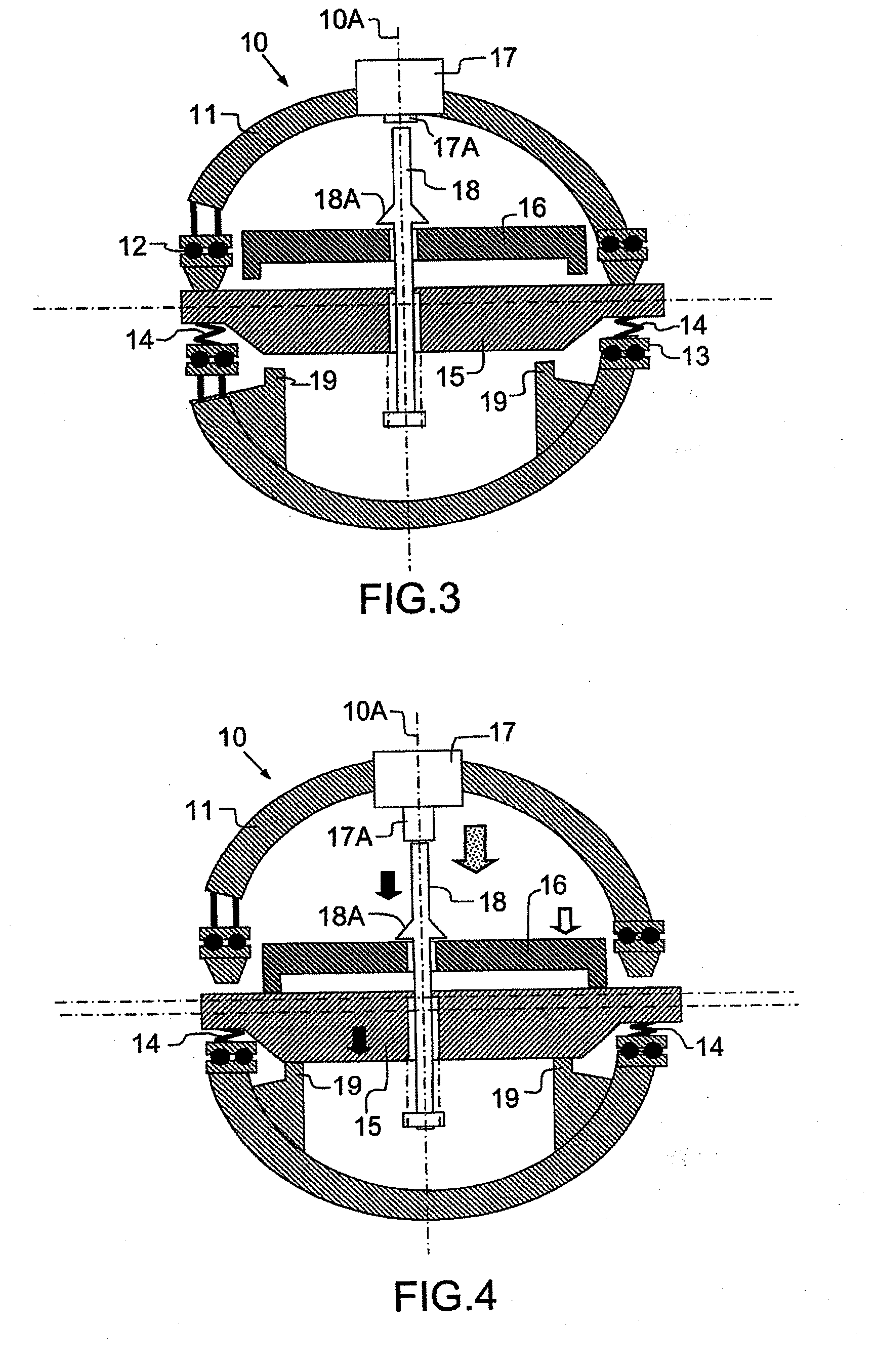

Process for the manufacture of containers which have an integral handle, and containers manufactured thereby

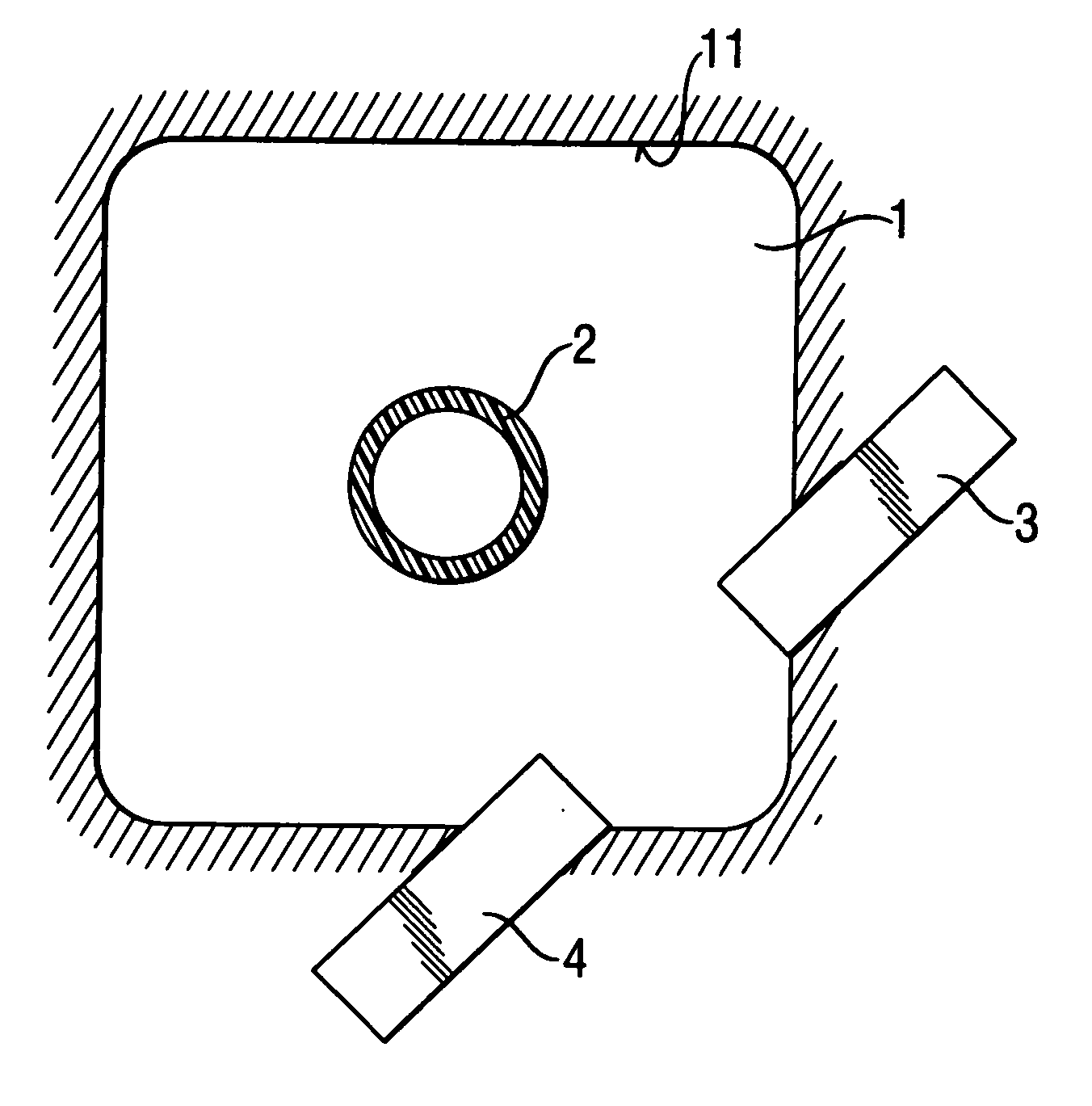

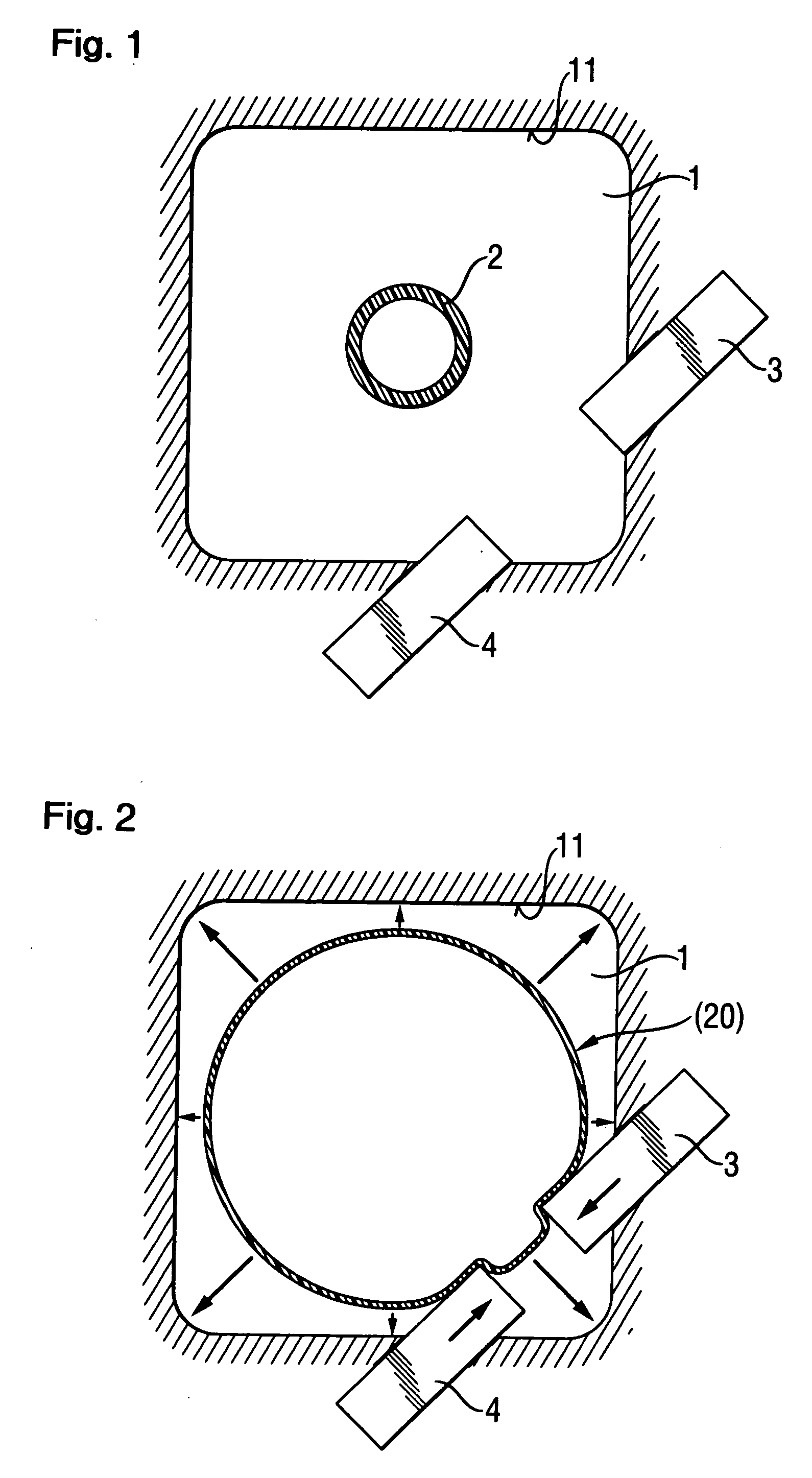

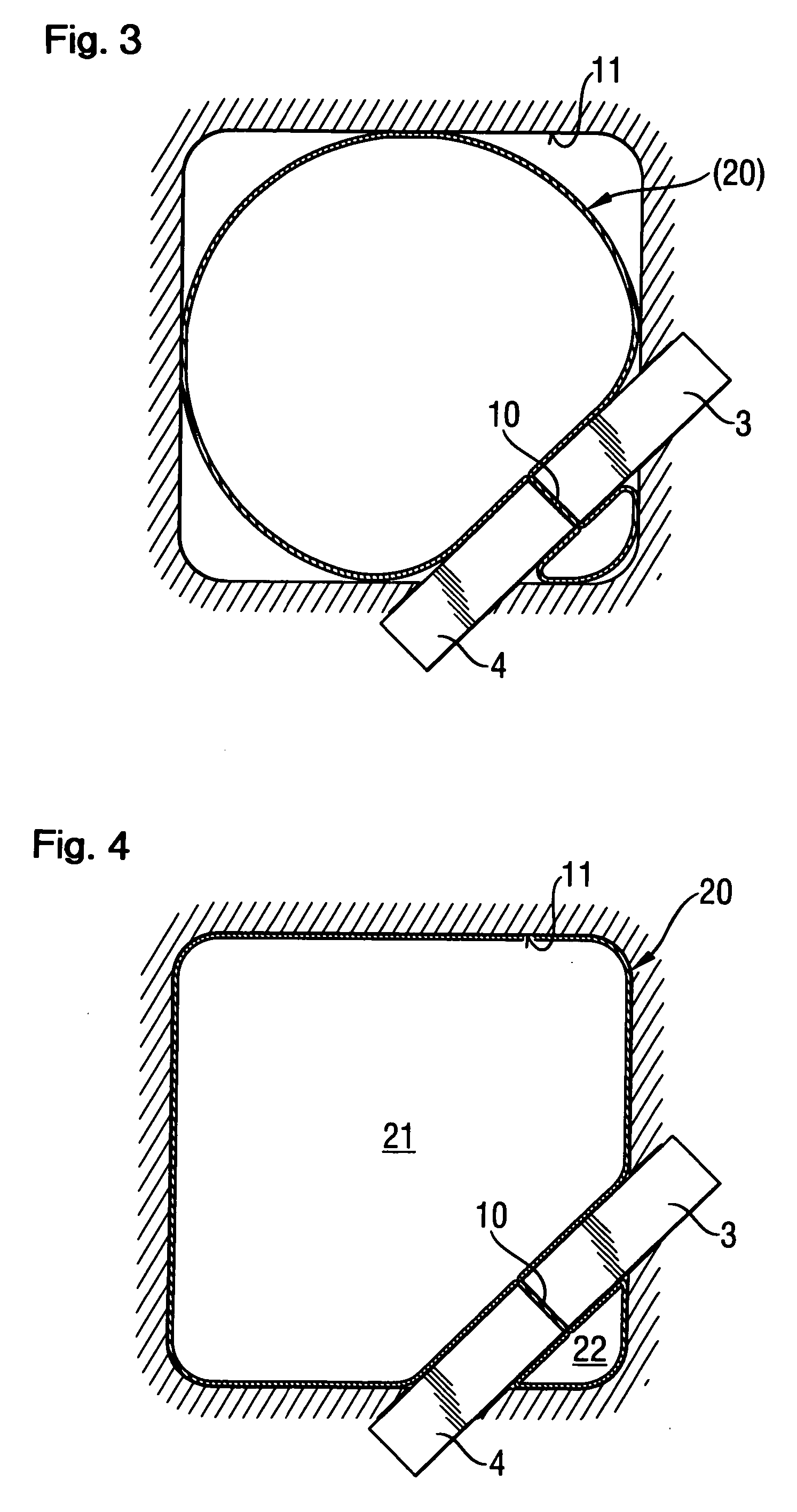

A process for blow-molding a container, the container comprising a handle, whereby the process comprises the steps of: (i) introducing a preform (2) into a mold cavity and stretching the preform (2) with a stretch rod; (ii) increasing the pressure within the preform (2) so that the preform (2) expands within the mold cavity in a first blowing step, the pressure in the first blowing step is from 1 to 10 bar; (iii) inwardly moving jaws (3, 4) within the mold cavity so that the expanding preform (2) is partially gripped between the jaws in the handle region; (iv) subsequently increasing the pressure within the preform (2) wherein the maximum pressure in the second blowing step is greater than 10 bar, so that the preform (2) expands to the limits of the mold cavity in a second blowing step to form a container; and wherein the inward movement of the jaws (3, 4) is completed within the first blowing step.

Owner:THE PROCTER & GAMBLE COMPANY

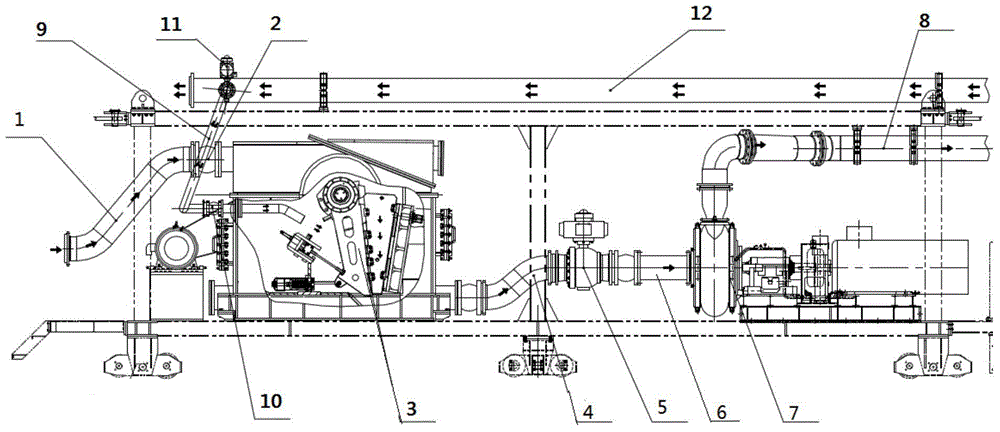

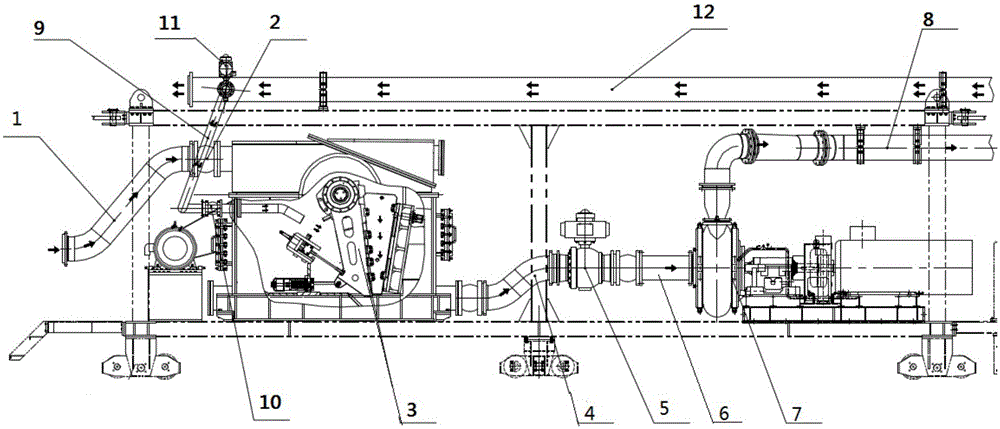

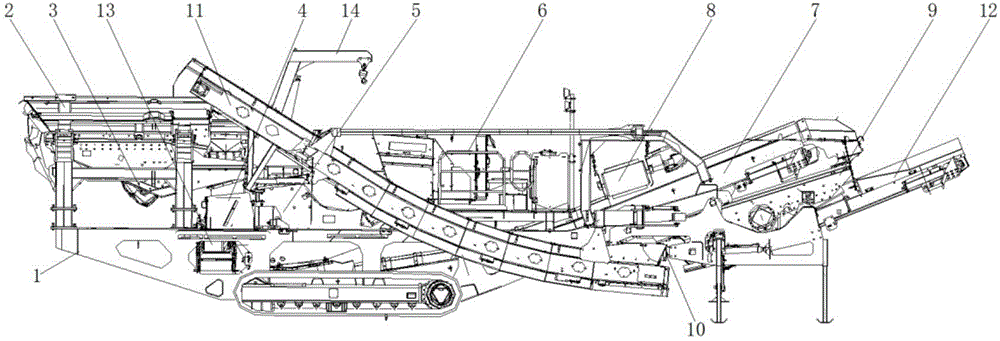

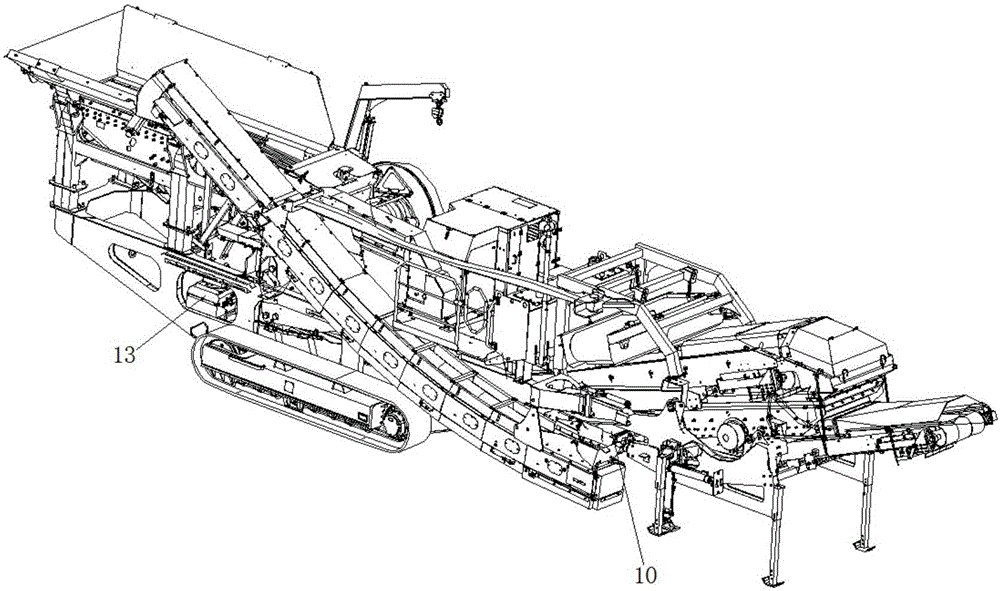

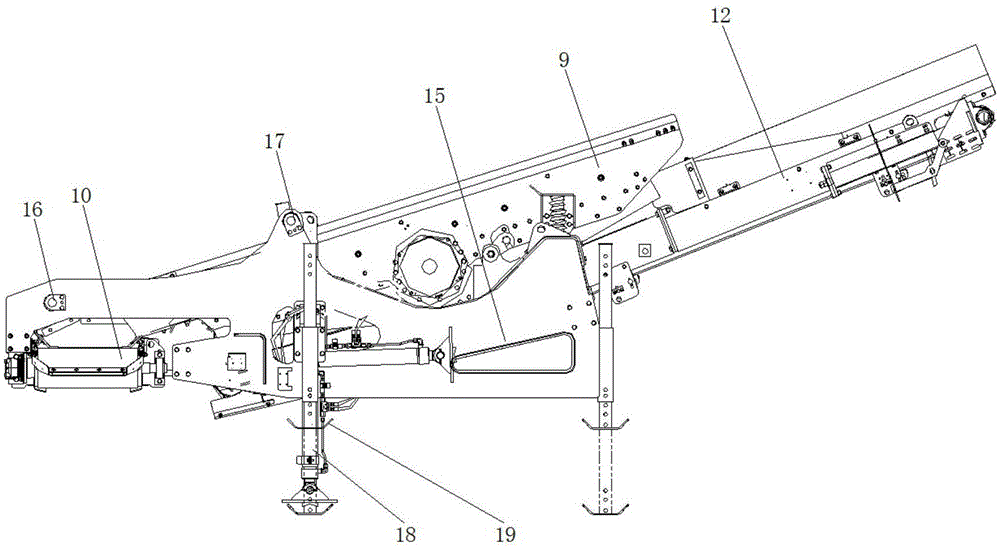

Crawler belt moving jaw-type crushing and screening station

The invention discloses a crawler belt moving jaw-type crushing and screening station comprising a crawler belt main vehicle frame. The top of the crawler belt main vehicle frame is sequentially connected with a feeding hopper, a crushing machine, an engine assembly, a main conveying belt machine, a screening machine, a transferring belt machine and a discharging belt machine from left to right. A vibration feeding machine, a distributing hopper and a side belt machine are sequentially connected inside the crawler belt main vehicle frame from left to right. The front face of the crawler belt main vehicle frame is connected with a feedback belt machine, and the crawler belt main vehicle frame is connected with a lifting device located on the left side of the crushing machine. The right side of the bottom of the crawler belt main vehicle frame is connected with an oil cylinder supporting leg and a supporting leg. According to the crawler belt moving jaw-type crushing and screening station, the jaw-type crushing machine is installed on a chassis in a crawler belt form, and a newly researched tooth form design is adopted for a jaw plate, so that there is no need to worry about steel bars and similar articles in various raw materials needing recycling and crushing, the national policies of energy conservation, emission reduction and environment protection are well satisfied, urban construction waste can be recycled through the crawler belt moving jaw-type crushing and screening station, and resource wasting is reduced.

Owner:GUANGXI LIUGONG MASCH CO LTD +1

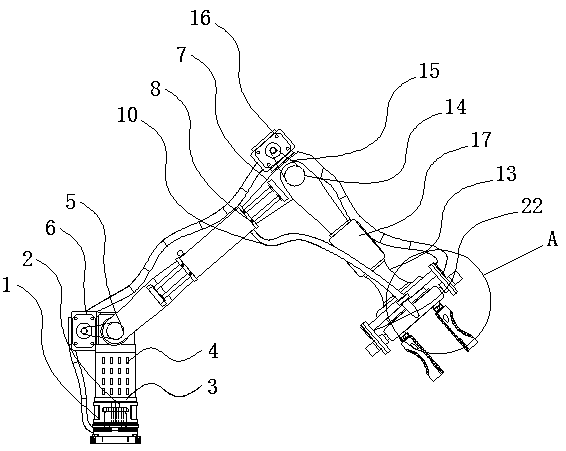

Manipulator for hardware parts processing to prevent damage to workpieces

InactiveCN109249384AConvenient horizontal rotation adjustmentEasy to operateProgramme-controlled manipulatorGripping headsMoving jawWater flow

The invention relates to a manipulator for hardware parts processing to prevent damage to workpieces. The manipulator comprises a base and a two-segment arm; a base servo motor is mounted in the base;a base bearing is linked to the upper end of the base; an adapting disc is mounted at the upper end of the base bearing; a link bearing is connected to the upper end of the adapting disc; a servo motor is mounted on the left of the link bearing; an arm is linked to the upper end of the link bearing; a mounting box is connected outside the middle of the arm. The manipulator has the advantages thatan outflow pipeline and a nozzle are provided for the manipulator herein, water can be added into the mounting box via a water storage port, a miniature water pump mounted in the mounting box helps conveniently convey the water flow to the nozzle for spraying via the outflow pipeline, and therefore, hardware held by moving jaws can be cooled conveniently and hardware can be processed better.

Owner:DONGGUAN UNIV OF TECH

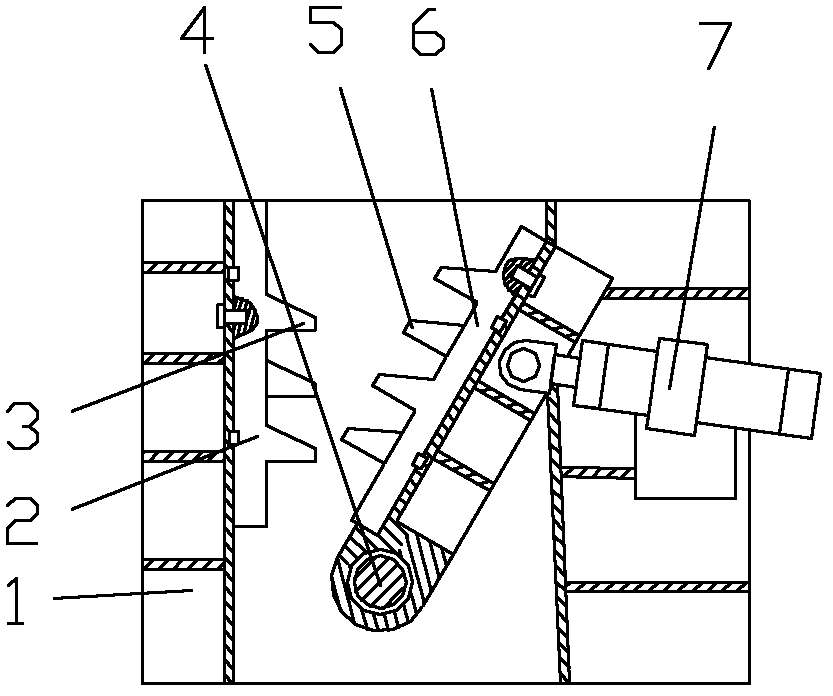

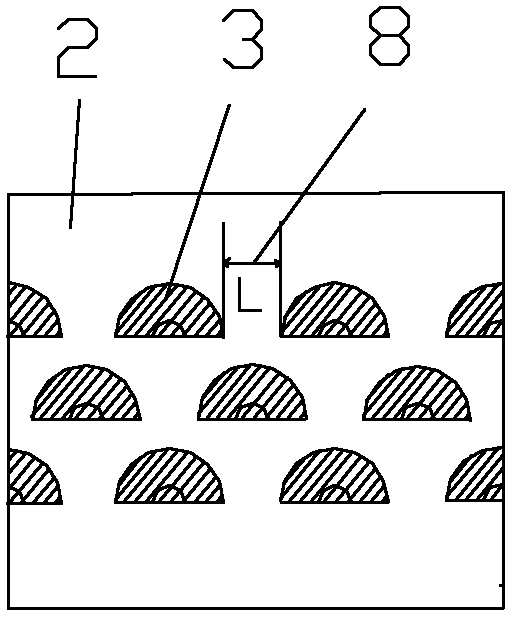

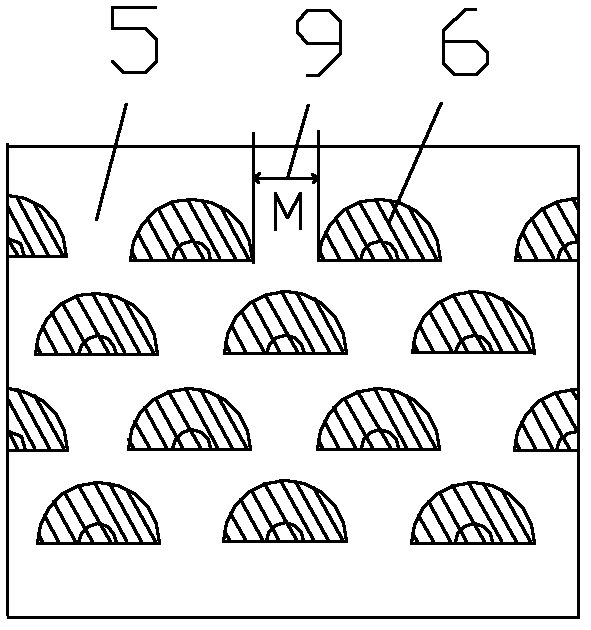

Special crusher for waste casting iron pieces

The invention discloses a special crusher for waste casting iron pieces, comprising a rack, a fixed jaw plate, a swinging shaft, a movable jaw plate, a hydraulic cylinder, semi-cylindrical conical teeth I and semi-cylindrical conical teeth II, wherein three rows of semi-cylindrical conical teeth I are arranged in parallel from top to bottom on the fixed jaw plate; and a gap L with same size is arranged between every two rows of semi-cylindrical conical teeth I. Four rows of same semi-cylindrical conical teeth II are arranged in parallel from top to bottom on the movable jaw plate; and a gap with same size is arranged between every two rows of semi-cylindrical conical teeth II. When the movable jaw plate and the fixed jaw plate of the crusher are meshed, the four rows of semi-cylindrical conical teeth II on the movable jaw plate and the three rows of semi-cylindrical conical teeth I on the fixed jaw plate are arranged horizontally at intervals. The invention provides the special crusher for the waste casting iron pieces, which has the functions of extrusion and shearing. According to the crusher, the branch-shaped waste casting iron pieces formed by casting heads and runners and the like can be quickly and effectively extruded and sheared into small casting iron blocks; and since the small casting iron blocks are arranged closely in an electric induction furnace, the occupied space is small, the melting can be quick and the power consumption is lower.

Owner:KEHUA HLDG

Reusable device for holding at least one moving object securely autonomously and without shocks, for spacecraft

InactiveUS20090301236A1Avoid damageAvoid hard interventionMechanical apparatusCosmonautic vehiclesMoving jawEngineering

The present invention relates to a reusable device for securely holding at least one fragile object against a functional surface solidly fixed to the structure of a satellite or spacecraft during at least one operational phase relating to this satellite, making the objects thus held more accessible and intervention on these objects easier, while at the same time preventing damage to these objects under the effect of sudden accelerations, both during this (these) operational phase(s) and while the hold is being established or while the hold is being released.The device according to the invention is characterized in that it comprises a rigid structure which partially grips this (these) object(s) and which supports at least one fixed jaw and at least one moving jaw substantially facing the fixed jaw(s), the object being immobilized between the fixed jaw and the moving jaw throughout the period of firm holding.

Owner:THALES SA

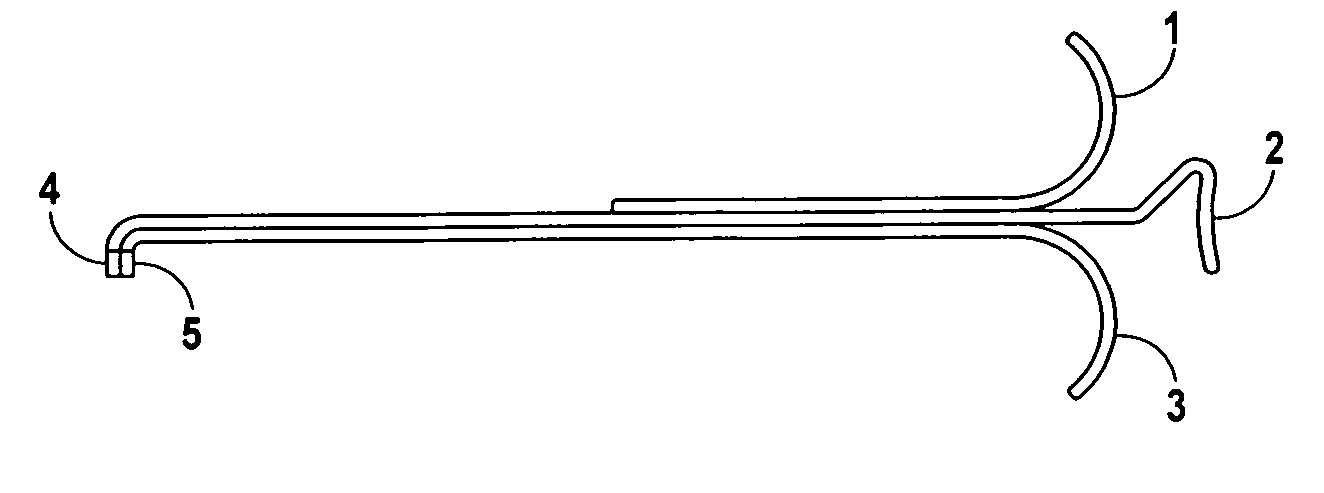

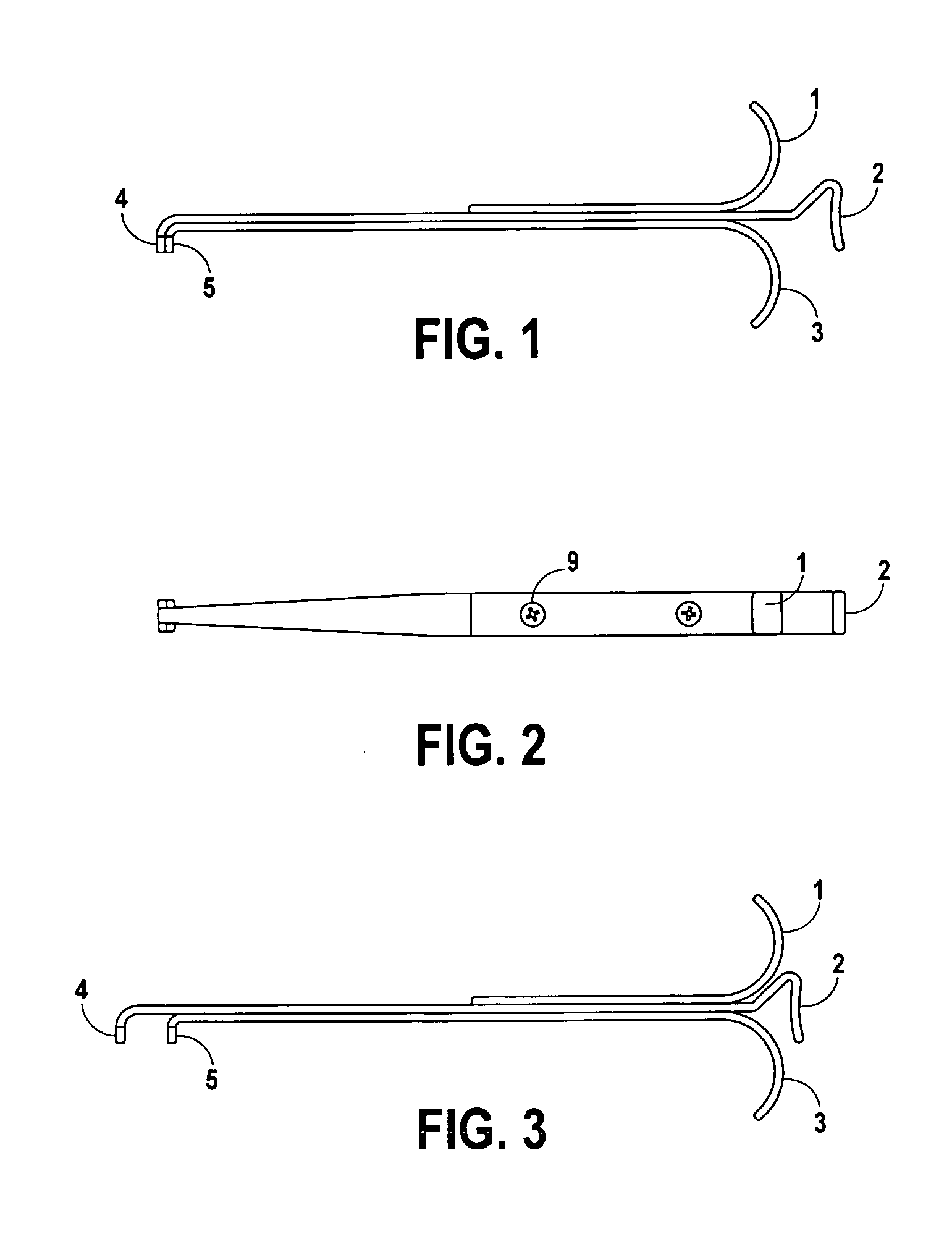

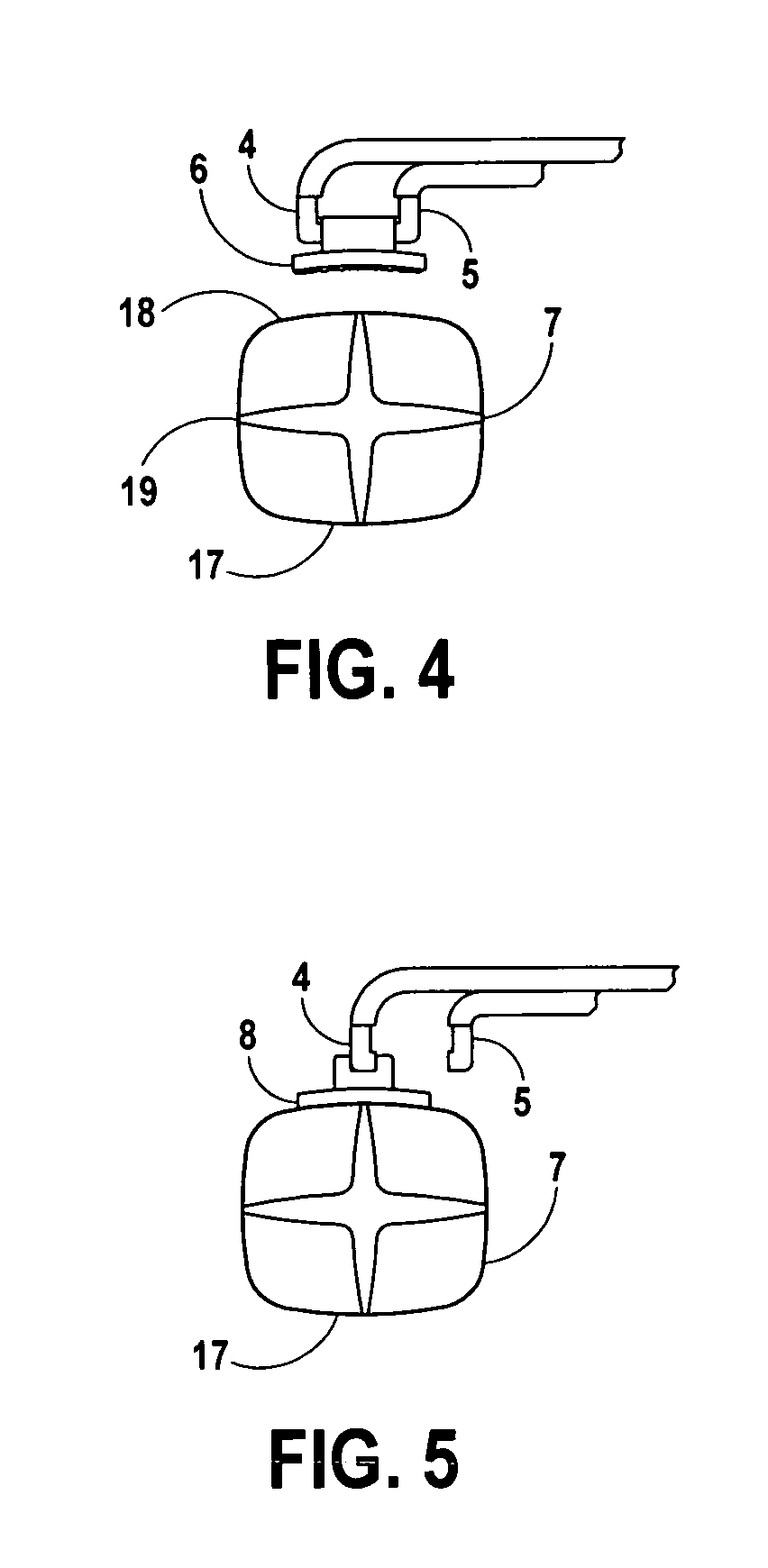

Direct bond bracket application instrument

An orthodontic instrument that provides for improved placement of direct bond brackets, particularly in the difficult posterior locations. An ergonomic, lightweight, ambidextrous parallel moving jaw assembly which utilizes a familiar hypodermic syringe style interface, enables a practitioner to efficiently and accurately place and bond brackets. Two different jaw blade widths allow engagement with and angular pre-bonded adjustment of Cuspid and Bicuspid brackets.

Owner:GILLANDERS DAVID D +1

Anti-falling mechanism in case of breakage of crane hook steel wire rope

InactiveCN107986156AAvoid falling incidentsReasonable structureSafety gearElectromagnetic lockMoving jaw

The invention relates to an anti-falling mechanism in case of breakage of a crane hook steel wire rope. The anti-falling mechanism comprises steel wire rope clamping plates which are separately connected to moving jaws and occlusion teeth matched with the moving jaws through hinge pins, and the lower parts of the moving jaws are provided with locking holes, and connected to electric linear actuators connected to controllers through signal lines; the controllers are connected to the steel wire rope clamping plates by bolts, and the output ends of the controllers are separately connected to an alarm and an electromagnetic lock matched with the moving jaws through the signal lines; the alarm and the electromagnetic lock are both arranged on the outer side walls of the steel wire rope clampingplates, and the input ends of the controllers are connected to speed measuring devices through the signal lines; the speed measuring devices are arranged on the upper ends of the steel wire rope clamping plates; and the occlusion teeth are provided with connecting holes. The anti-falling mechanism has the advantages of rational structure, easy use, high safety and low operation cost.

Owner:德马科起重机械有限公司

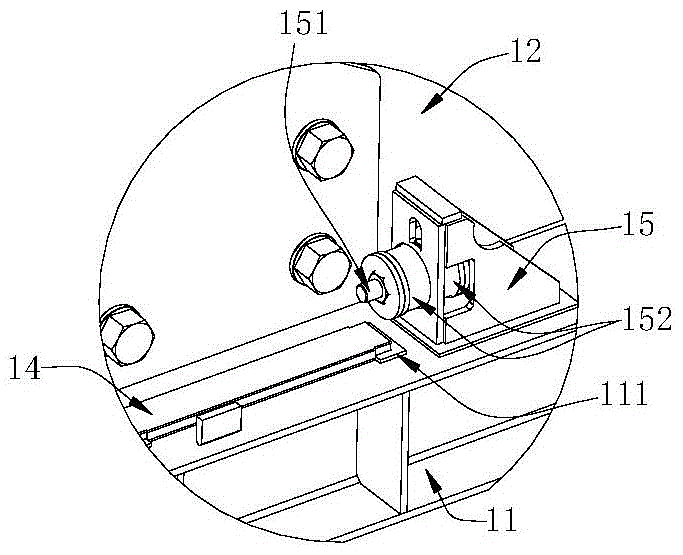

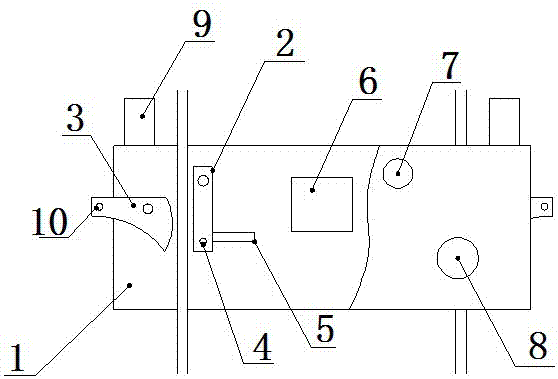

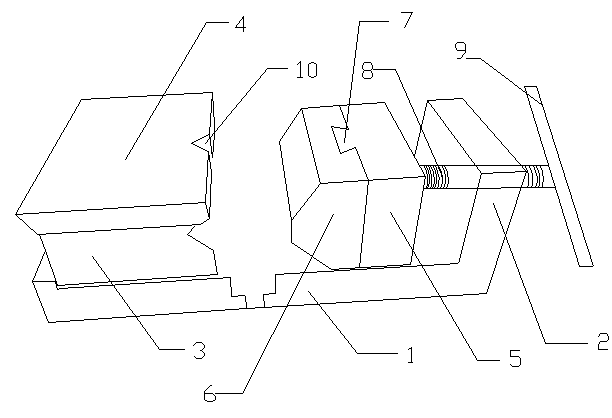

Machine vice

InactiveCN103302521AClamp firmlyEasy to processPositioning apparatusMetal-working holdersMoving jawArchitectural engineering

The invention relates to a machine vice, which comprises a base (1), wherein one side of the base (1) is provided with a side plate (2); the side plate (2) and the base (1) form an L shape; the base (1) is provided with a moving jaw (3) and a thrust pad (6); the moving jaw (3) is fixed on the base (1) through a bolt; the moving jaw (3) is provided with a V-shaped groove (10); an angular jaw plate (4) is fixed above the moving jaw (3); the thrust pad (6) is provided with a dovetail groove (7); a dovetail slide block (5) is embedded into the dovetail groove (7); the dovetail slide block (5) is connected with a lead screw (8); and the lead screw (8) passes through the side plate (2), and is connected with a square spanner (9). The machine vice provided by the invention is provided with the V-shaped groove, so that processed objects are clamped more firmly; and moreover, the moving jaw can rotate around the bolt, so that workpieces with angles can be processed conveniently, and great convenience is brought to use.

Owner:江苏省江阴中等专业学校

Jaw crusher provided with buffering material feeding hopper

The invention discloses a jaw crusher with a buffer feeding hopper, which comprises a jaw crusher and a buffer feeding hopper. The jaw crusher is provided with a No. 1 movable jaw and a No. The jaw and the No. 2 movable jaw are driven by the driving mechanism to swing in opposite directions. The buffer feeding hopper is connected above the jaw crusher through a flange. The buffer feeding hopper includes a hopper body, a buffer assembly and a wear-resistant liner. The buffer assembly has two groups. , the first group is arranged on the inner plate of the hopper body, the second group is arranged under the inner plate of the first group, and the wear-resistant liner is arranged on the inner plates on both sides of the hopper body. The two movable jaws of the present invention extrude the material bidirectionally, and the extrusion force on the material is greater, which makes the material easier to break, and through the blocking of two groups of buffer components, it plays the role of buffering and uniform feeding. The movable jaw plate in the machine plays a very good protective role, reducing the impact and wear of ore on it and prolonging its service life.

Owner:ZAOZHUANG SNKSAN INTELLIGENT MACHINERY CO LTD

Jaw crusher

InactiveCN103977856ALarge adjustment rangeEasy to replaceGrain treatmentsMoving jawStructural engineering

The invention provides a jaw crusher. The jaw crusher comprises a rack, a movable jaw, a fixed jaw, a toggle plate, a moving jaw, an outer spring seat, a pull rod, a spring and an inner spring seat, wherein the movable jaw is movably installed on the rack; the fixed jaw is fixedly installed on the rack; one end of the toggle plate is movably installed at one end of the movable jaw; the moving jaw is installed at one end of the movable jaw; the outer spring seat is installed on the rack; the pull rod is installed on the outer spring seat; the pull rod is sleeved with the spring; the inner spring seat is installed on the rack and arranged at one end of the pull rod. The jaw crusher has the advantages that the jaw crusher has deep crushing cavity and is free from dead zones, thus improving the feeding capacity and the yield; the jaw crusher has high ratio of crushing and uniform product granularity; a gasket type discharge hole adjusting device is reliable and convenient and has large range of adjustment, thus improving the flexibility of equipment; a lubricating system is safe and reliable and parts are convenient to change and have small maintenance workloads; the jaw crusher has a simple structure, operates reliably and is low in operating cost; the discharge hole adjusting range is large, so that the requirements of different users can be met; the jaw crusher has low noise and less dust.

Owner:SUZHOU TIANMAI THERMAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com