Muddy water circulation and stone crushing method for shield tunneling machine

A shield machine and stone crushing technology, which is applied in earth drilling, grain processing, mining equipment, etc., can solve the problems of large-size pebble crushing and discharging pumps, blockage of slurry outlet pipelines in mud-water circulation systems, and restrictions on tunneling capabilities, etc. , to achieve safe and reliable maintenance steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The specific implementation manner of the present invention will be briefly described below in conjunction with the accompanying drawings.

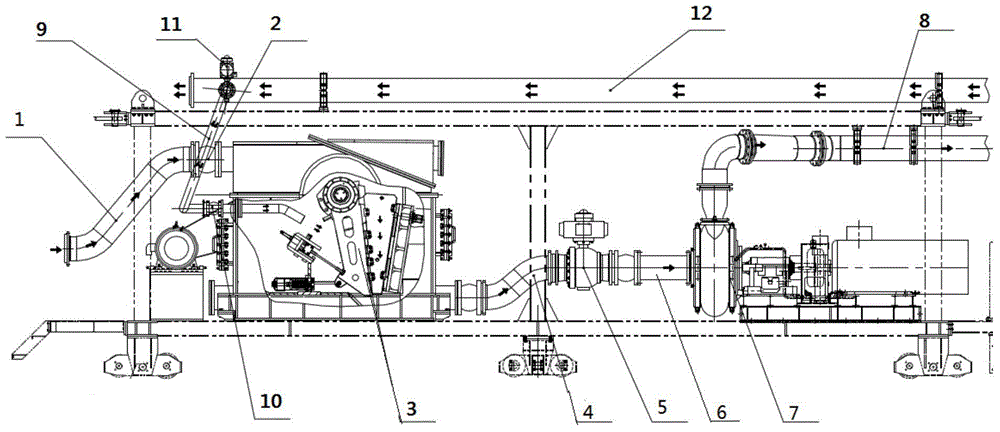

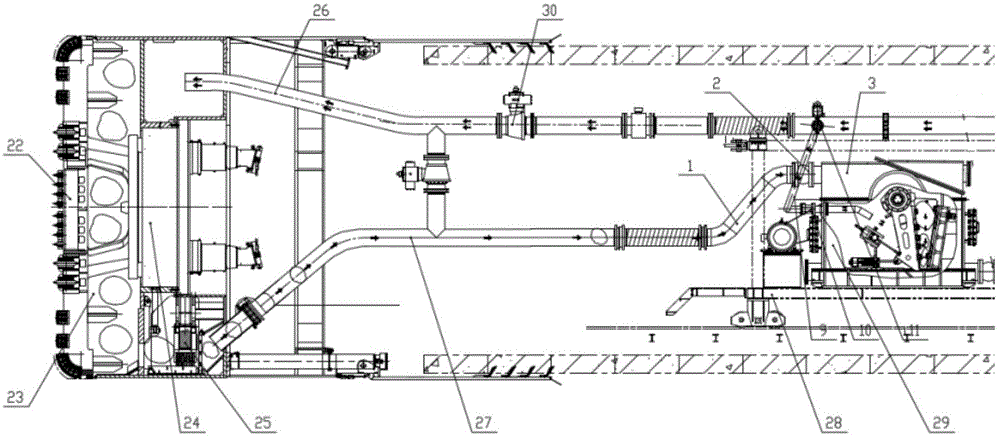

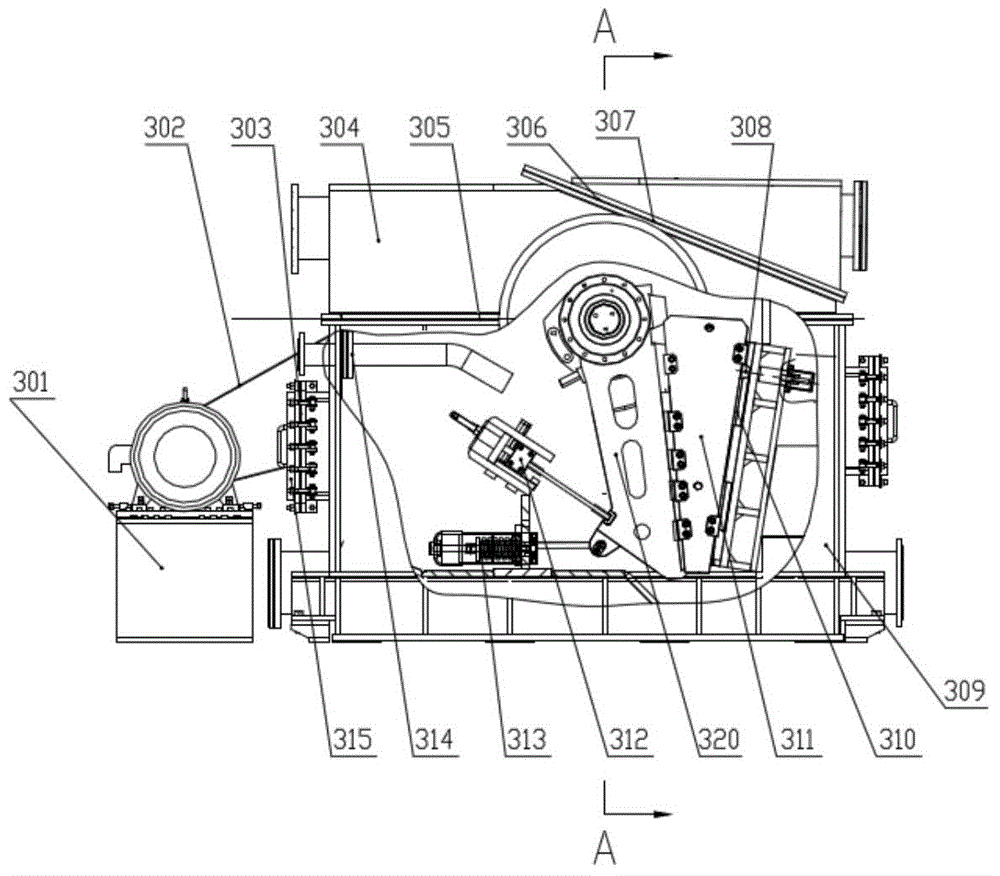

[0062] Such as figure 1As shown, the mud-water circulation and stone-breaking system provided by the present invention includes a shield machine mud pipeline stone-breaking system 29, and the shield machine mud pipeline stone-breaking system includes a slurry discharge elbow-1, a large shock-absorbing throat 2, Mud pipeline crusher 3, slurry discharge elbow 2 4, large hydraulic ball valve 5, slurry discharge straight pipe 6, slurry discharge pump 7, slurry discharge elbow 3 8, flushing pipe 9, small shock-absorbing throat 10, small liquid Moving ball valve 11, crusher feed branch pipe 12. The working principle of the mud pipeline gravel system of the shield machine of the present invention is as follows: the left end slurry inlet of the mud pipeline crusher 3 with the function of sealing high-pressure mud and crushing large-sized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com