Patents

Literature

58results about How to "Improve smashing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

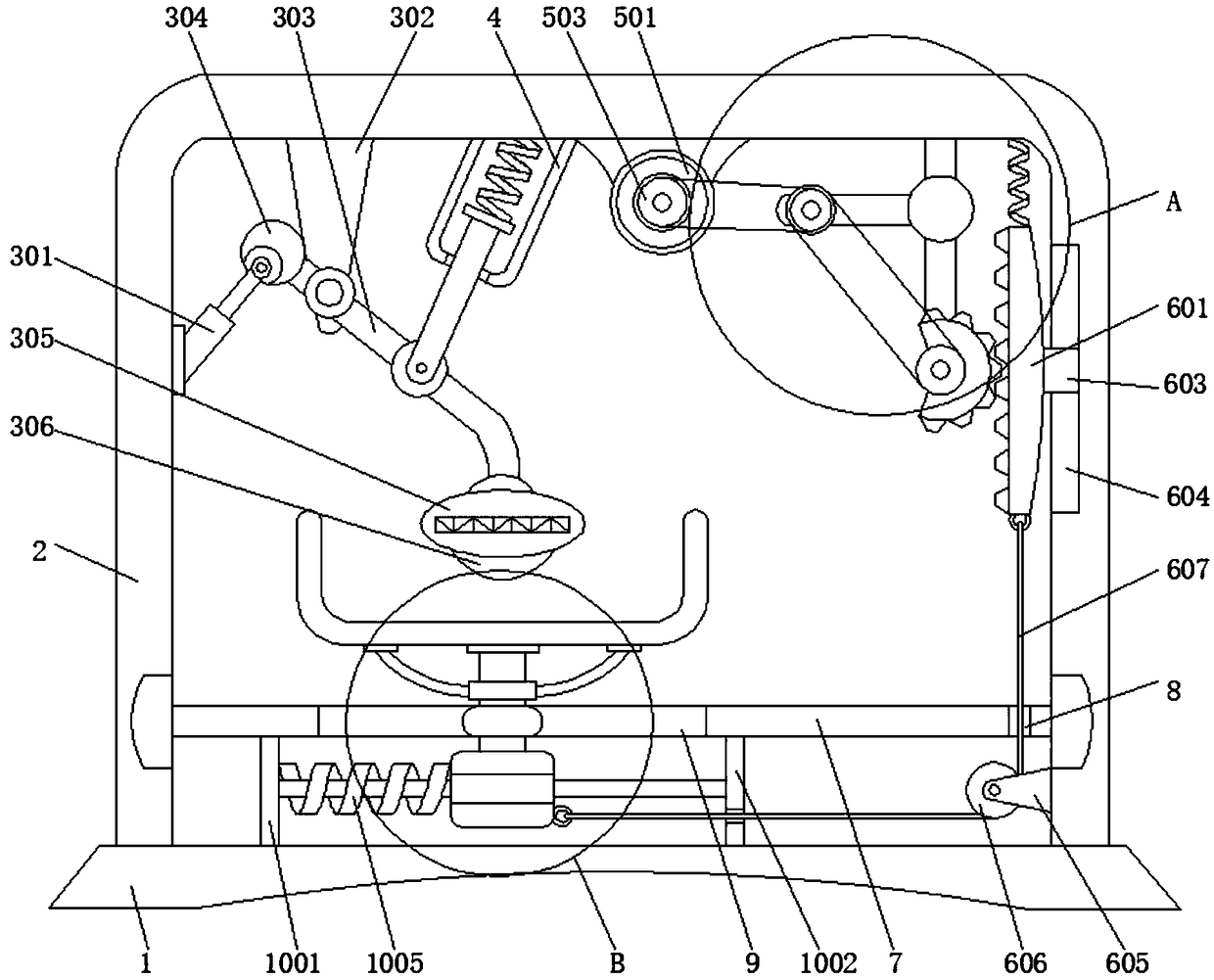

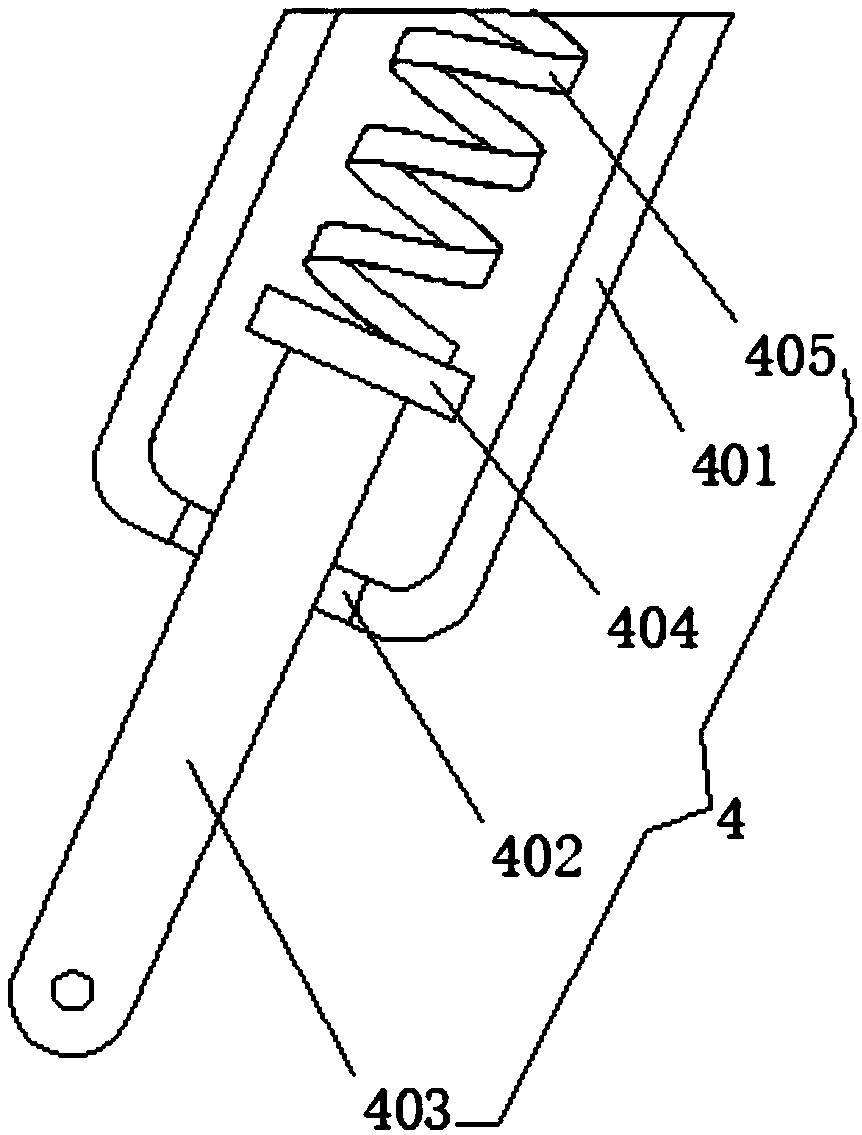

Crusher for processing agricultural-chemical raw material

InactiveCN106111298AImprove economyImprove work efficiencyGrain treatmentsEconomic benefitsEngineering

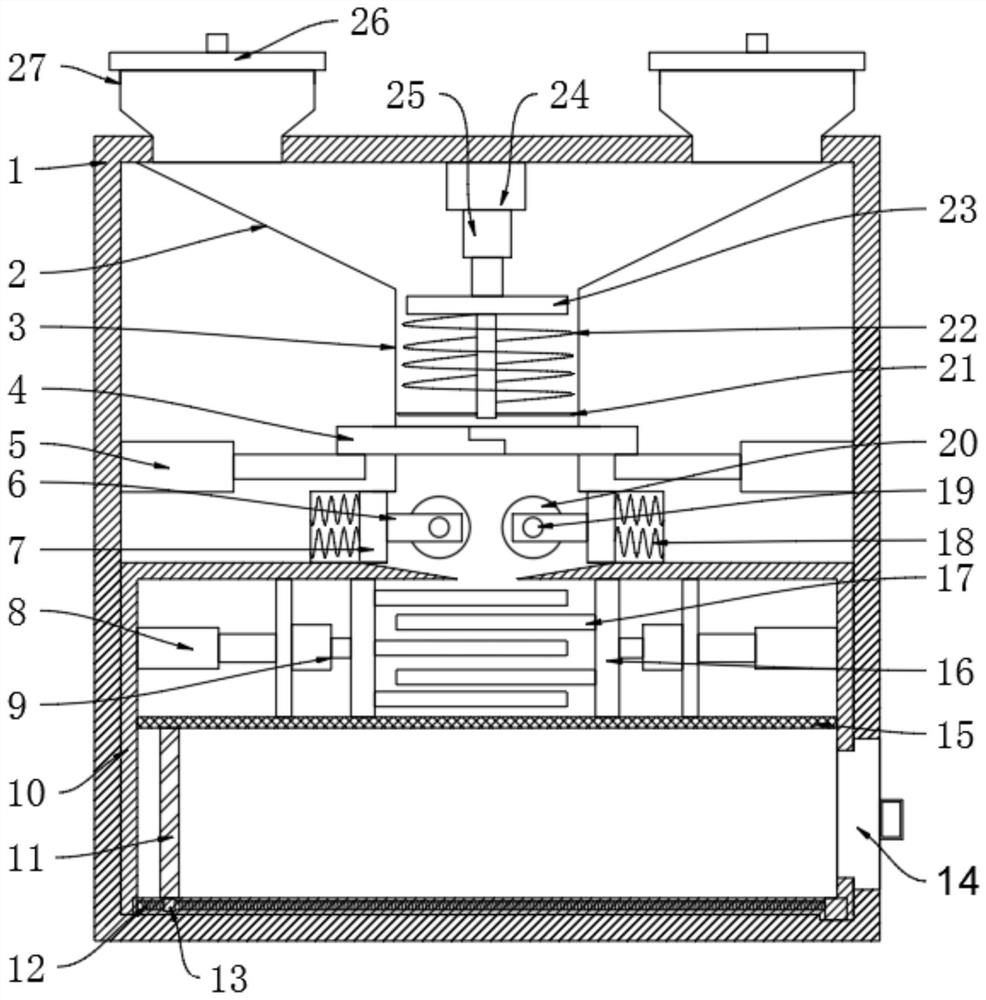

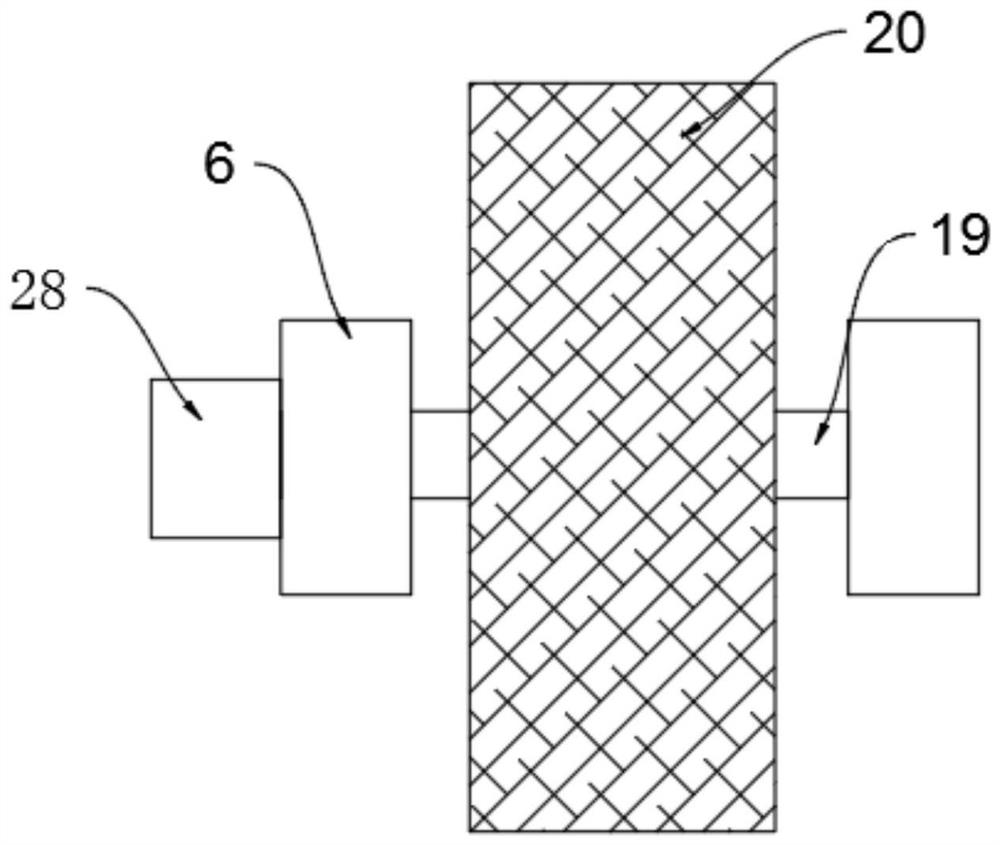

The invention discloses a crusher for processing an agricultural-chemical raw material. The crusher comprises a grinding box, wherein a first motor is arranged at the medial axis of the top of the grinding box; an output end of the first motor penetrates the grinding box and extends into the grinding box to be fixedly connected with a hose; a grinding block is fixedly connected with the bottom of the hose; a first spring is fixedly connected between the output end of the first motor and the grinding block; the first spring is located in the hose; two air cylinders are symmetrically arranged at the top of the inner wall of the grinding box, and are located on two sides of the output end of the first motor; output ends of the two air cylinders are fixedly connected with connecting columns; hollow columns are arranged on the surfaces of the connecting columns; baffles are arranged in the hollow columns; and the tops of the baffles are fixedly connected with the connecting columns. The crusher provided by the invention is uniform in crushing, has a good crushing effect, improves the economic benefit of a company and the working efficiency of employees, and saves time and labor.

Owner:WUXI JIABAO PESTICIDE & PHARMA

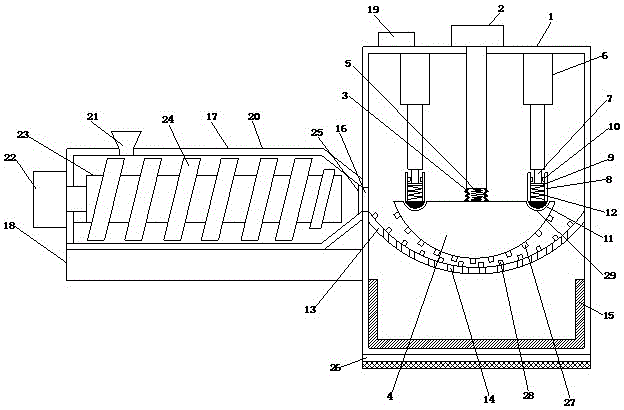

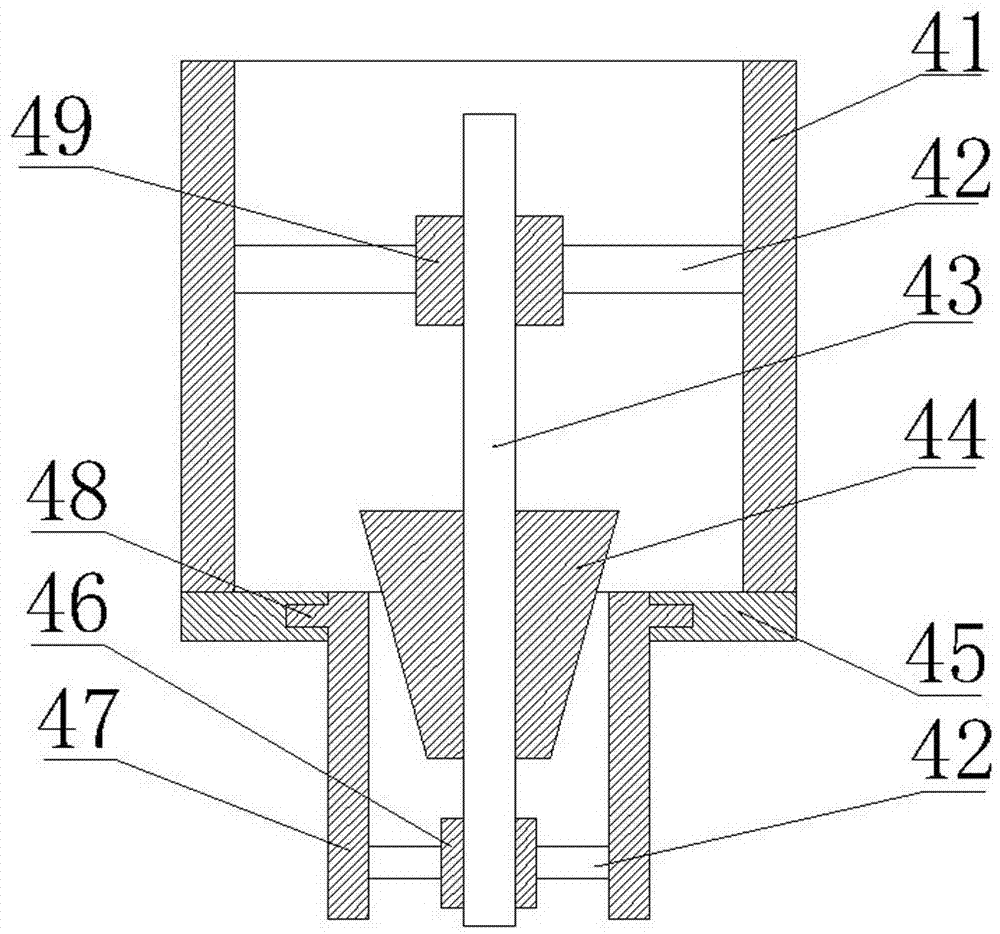

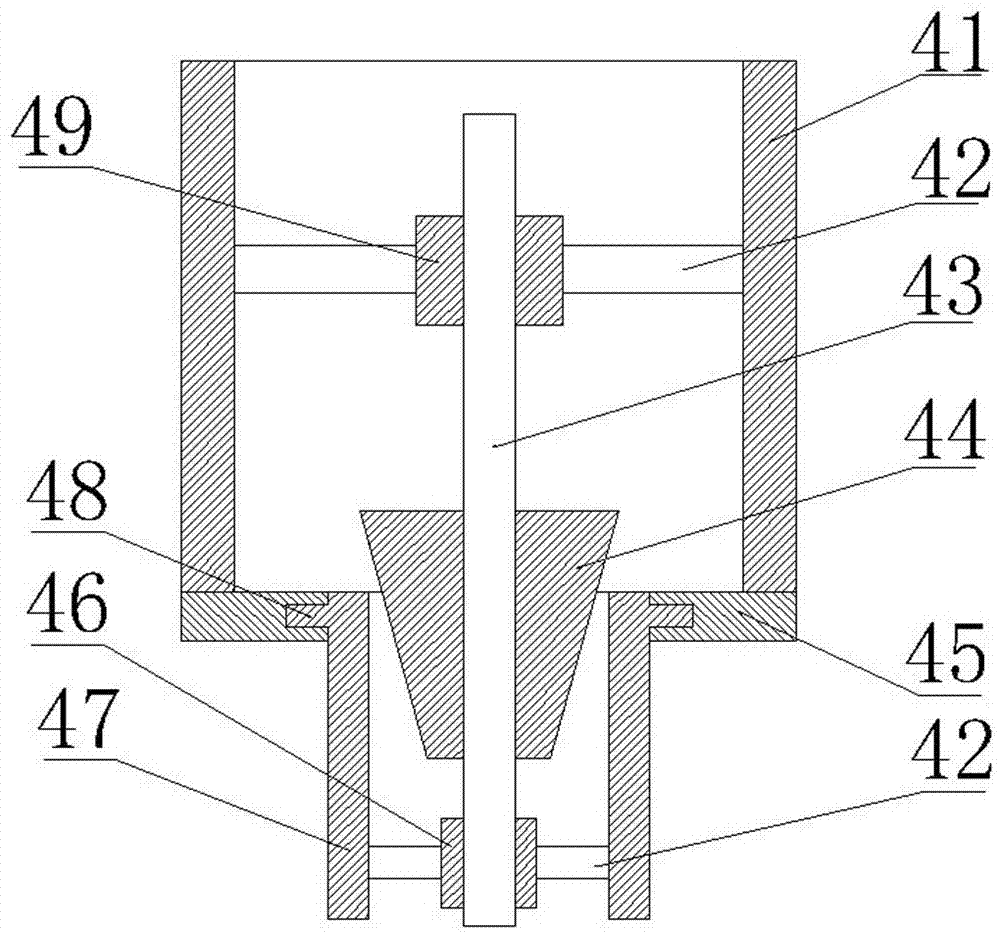

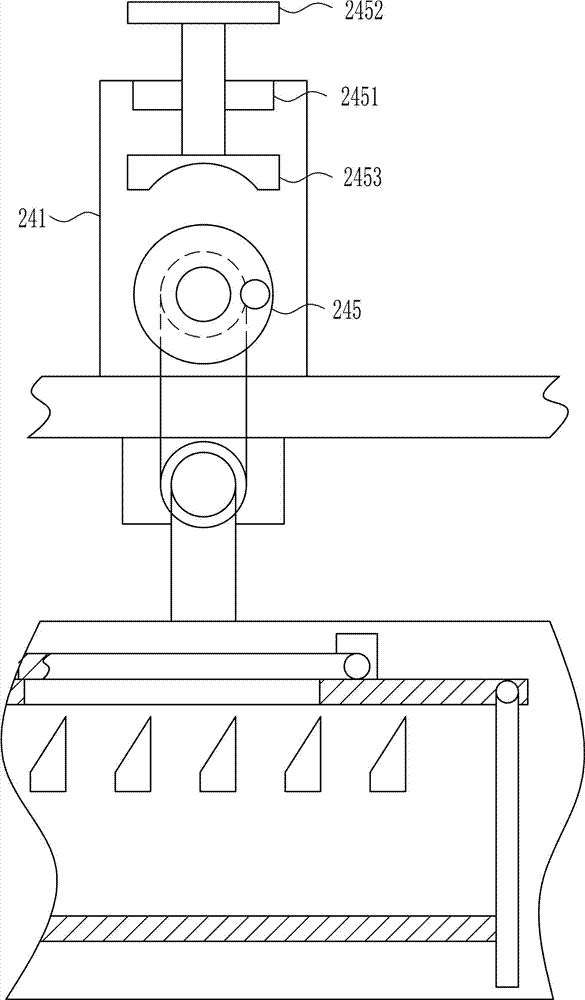

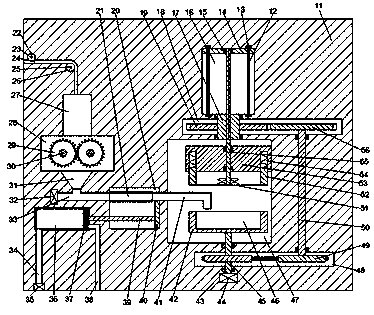

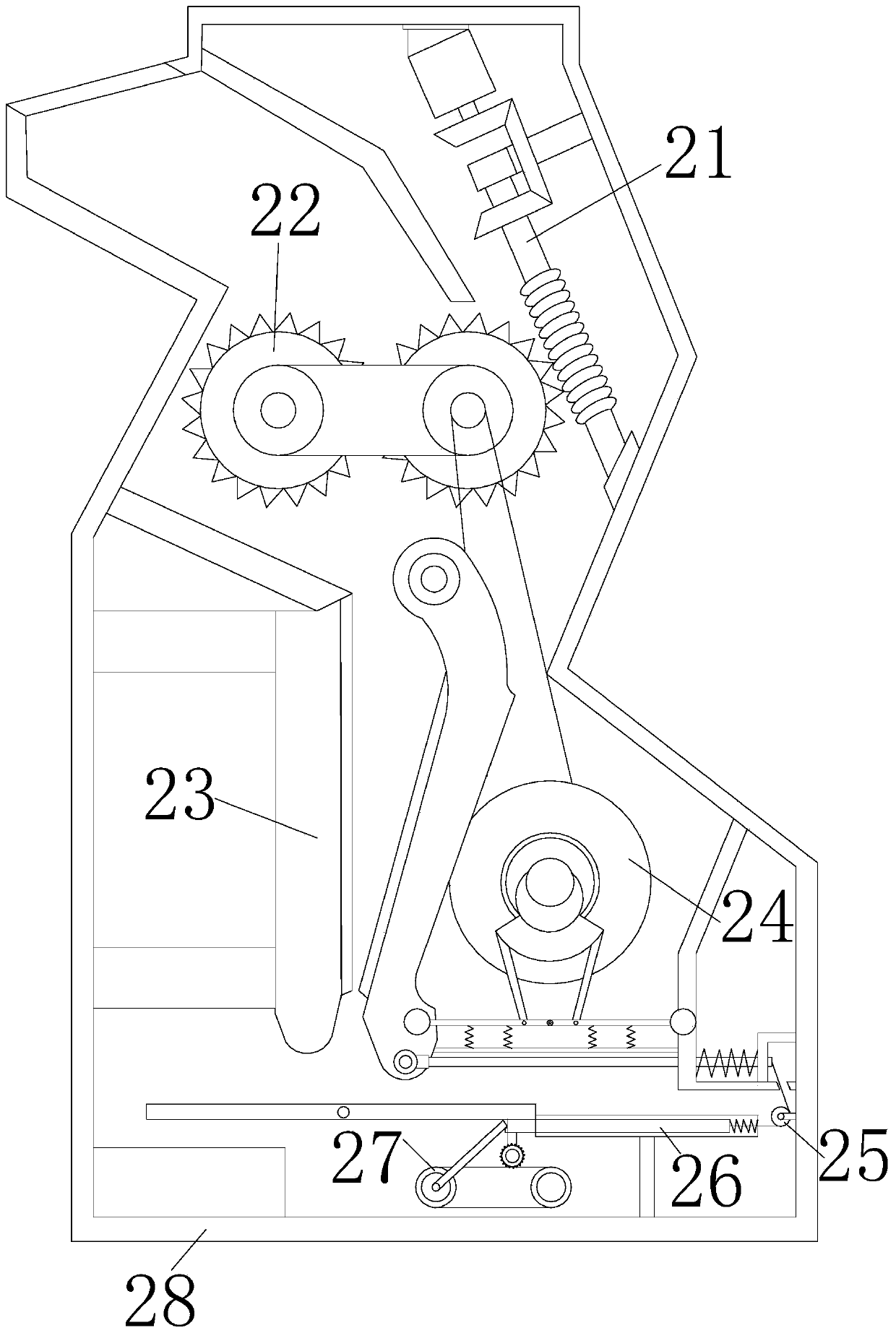

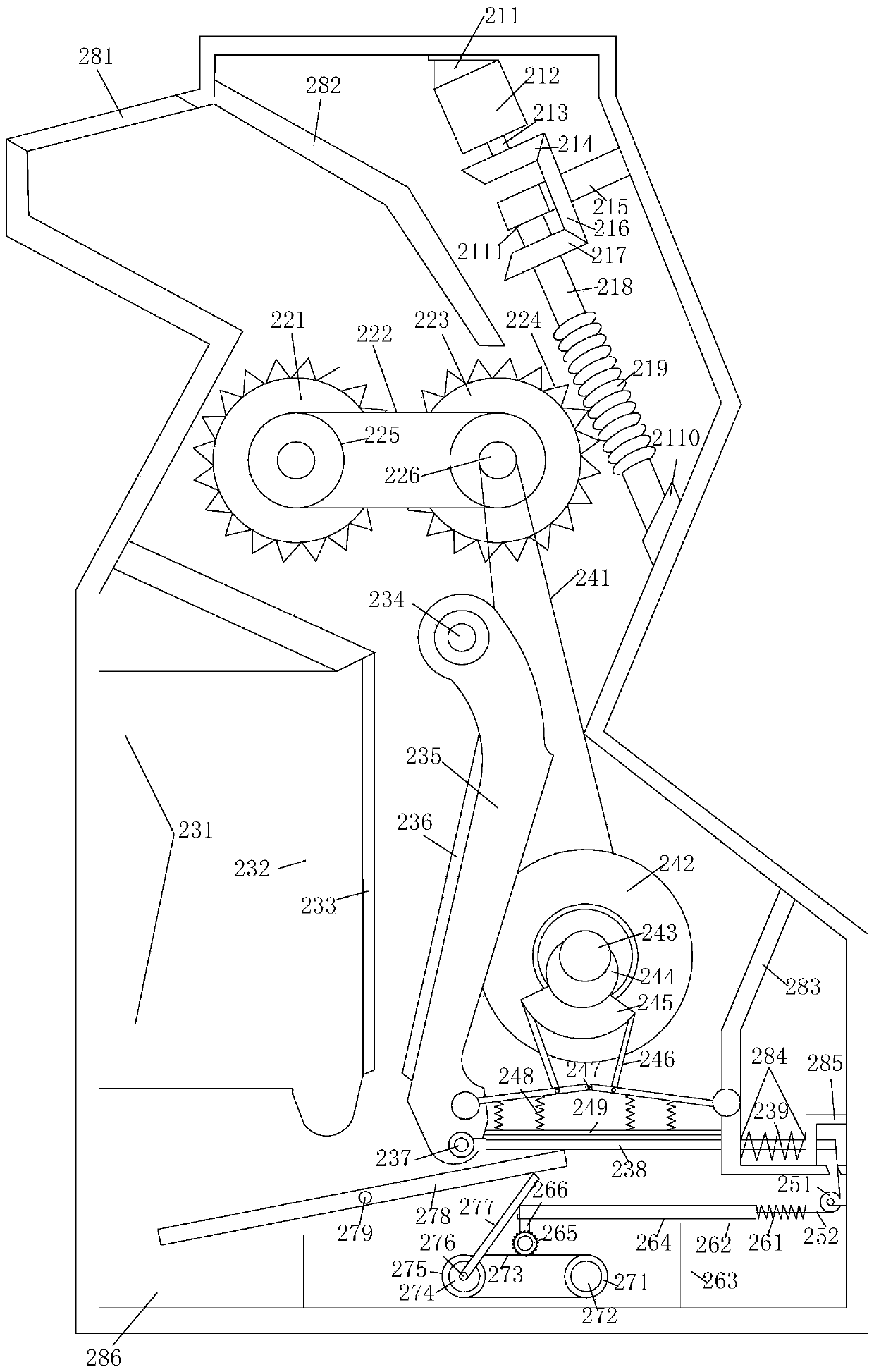

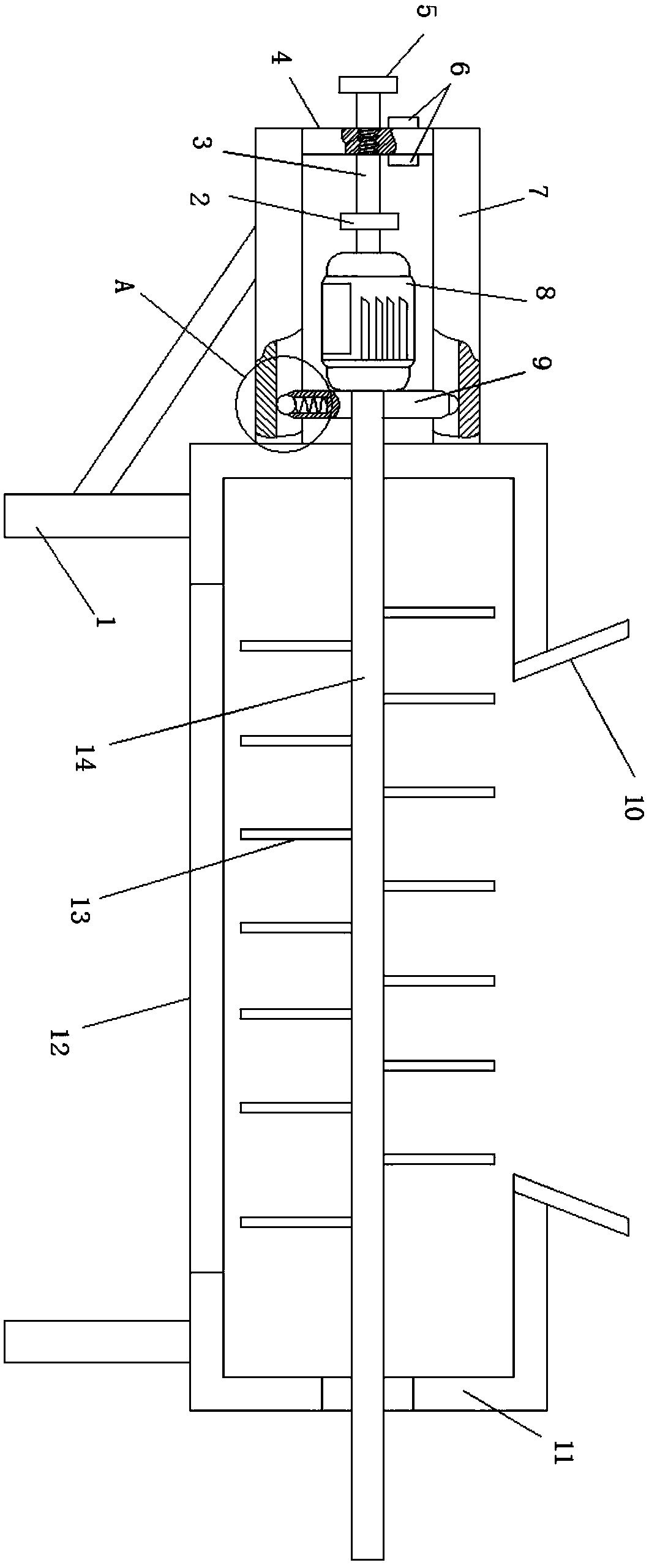

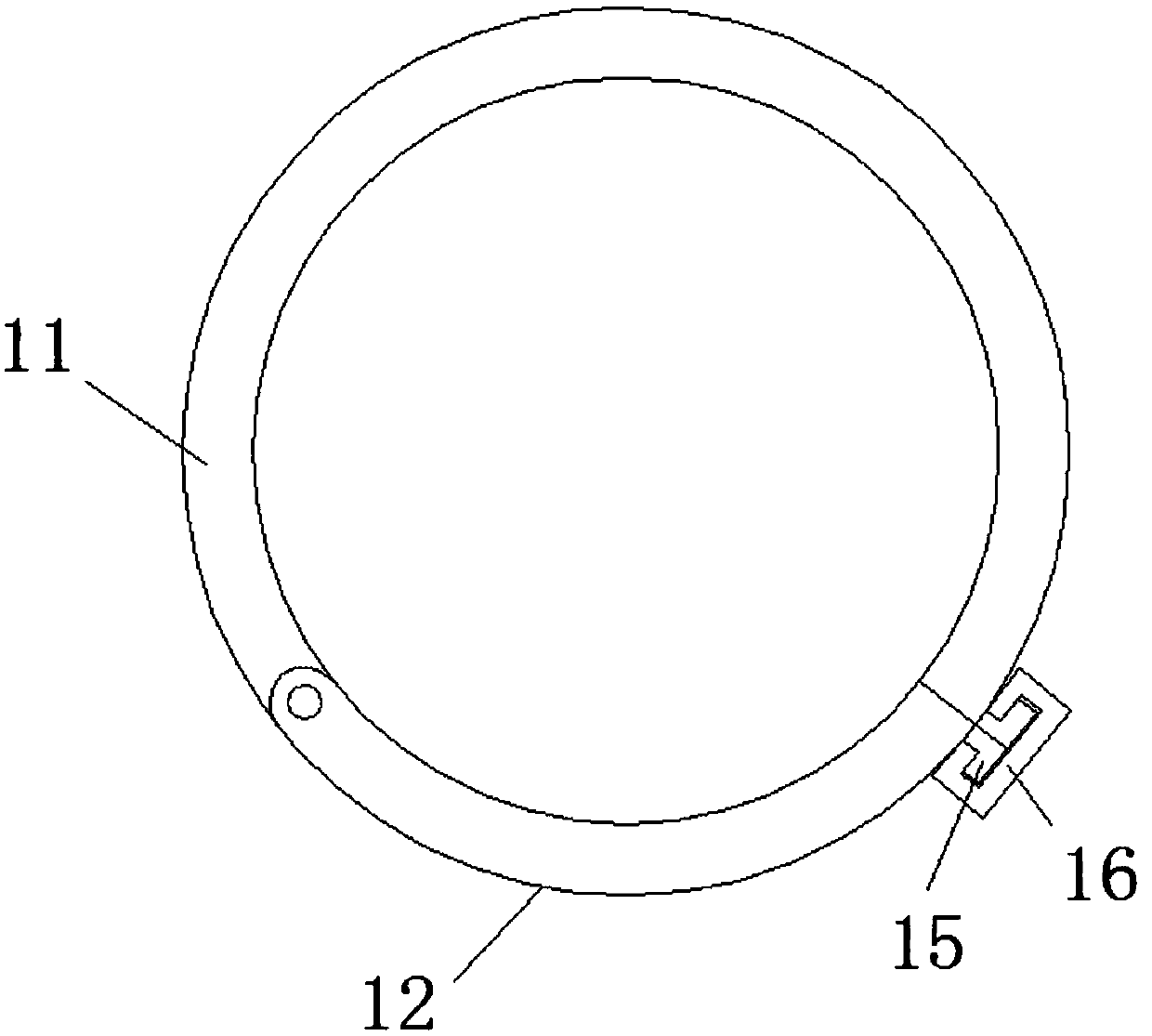

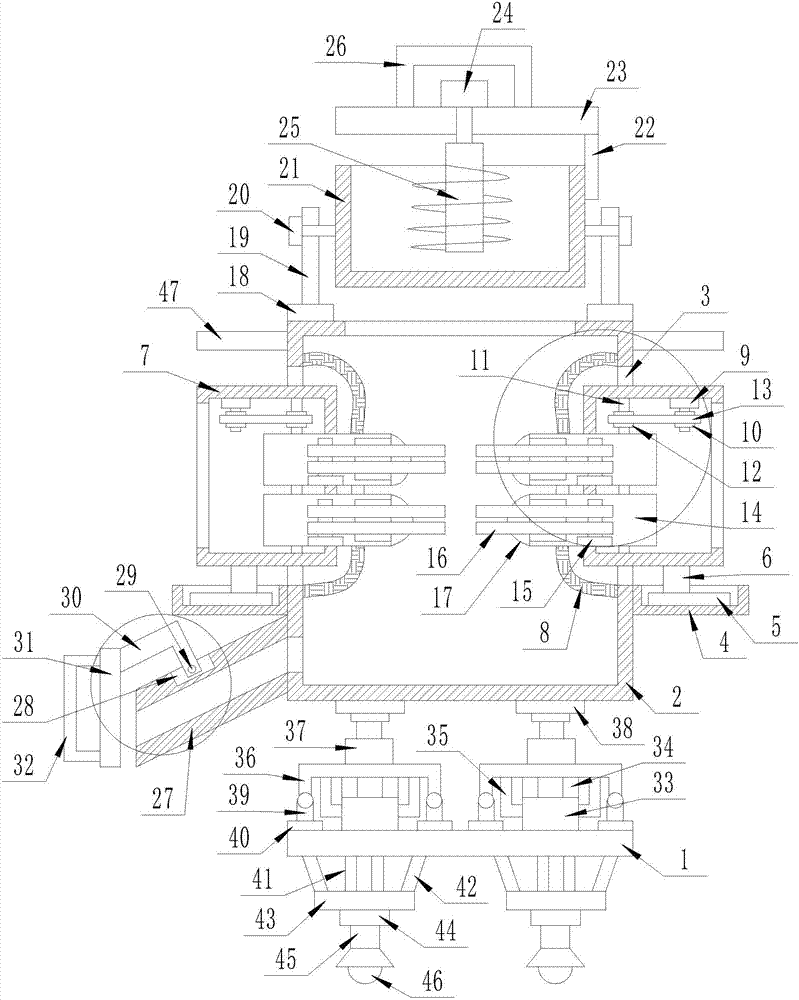

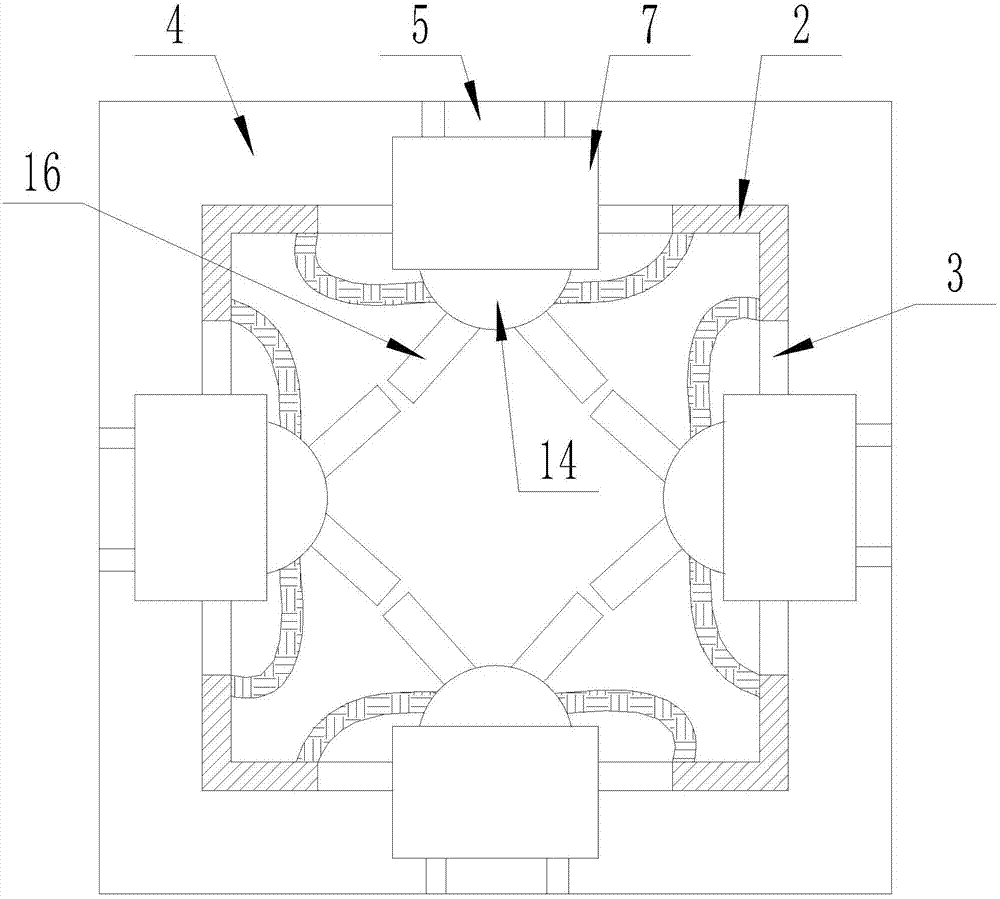

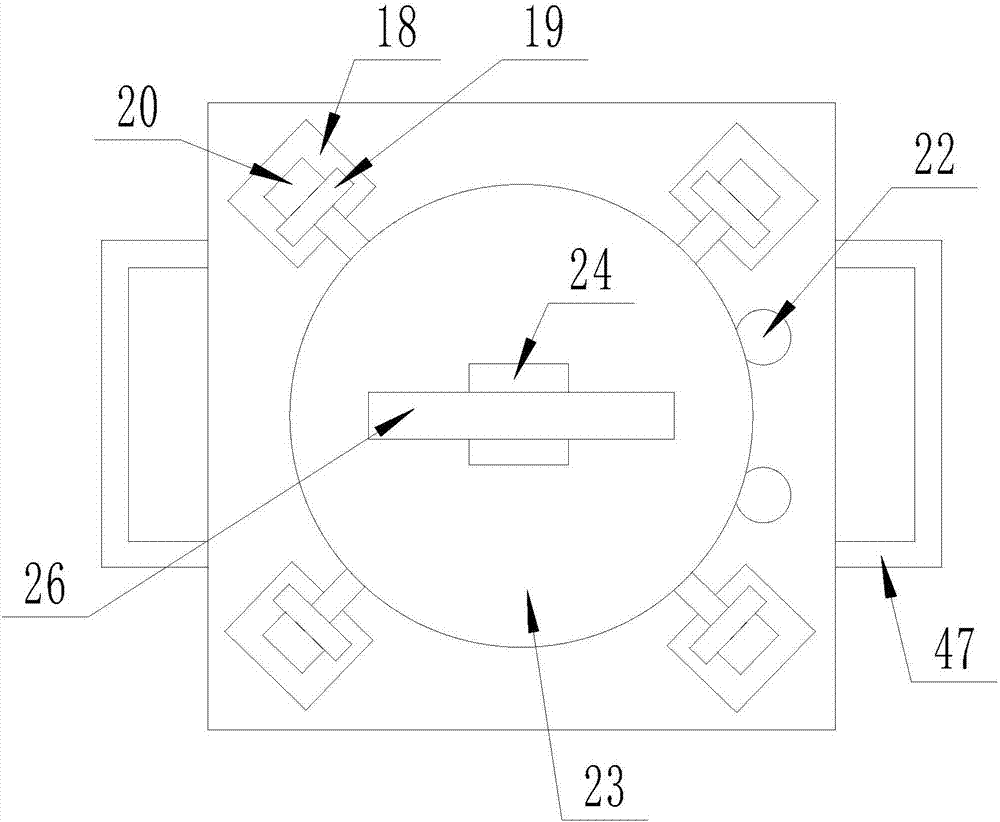

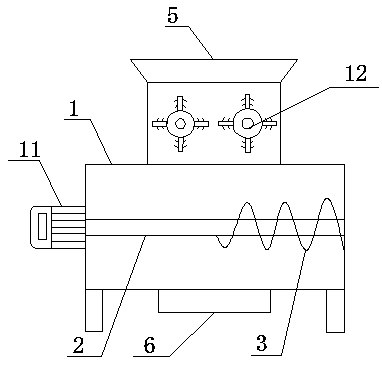

Multifunctional novel smashing machine

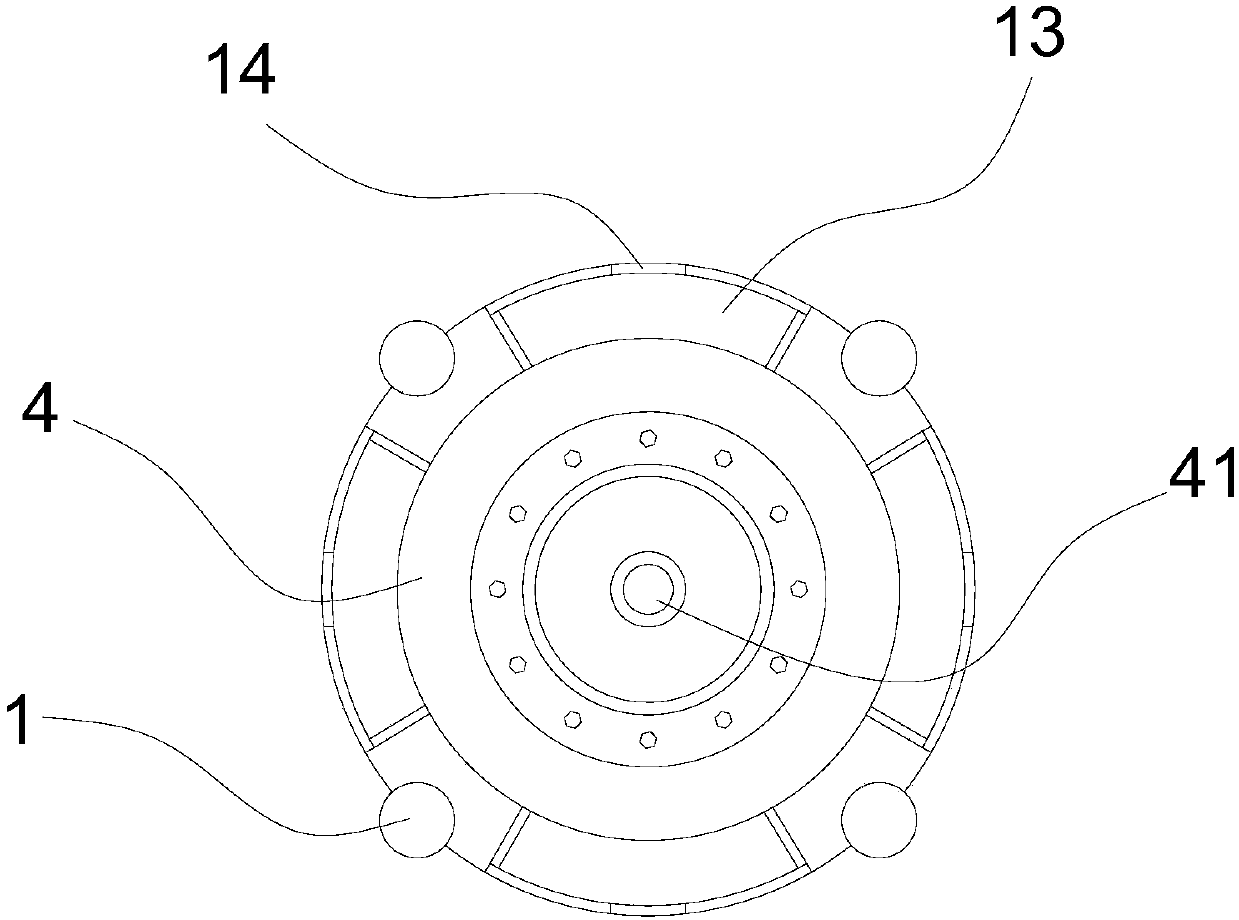

InactiveCN107008532ARealize flow breakingImprove smashing effectGrain treatmentsEngineeringCylinder block

The invention discloses a new type of multifunctional pulverizer, which comprises a pulverizing barrel; a rotating shaft is arranged in the pulverizing bucket, a plurality of pulverizing blades are arranged on the rotating shaft, and a pulverizing motor is connected to the upper end of the rotating shaft passing through the pulverizing bucket; the pulverizing bucket is There is an annular block inside, and the outer circular surface of the annular block is in contact with the inner circular surface of the crushing barrel; the upper end surface and the lower end surface of the annular block are both inclined surfaces; the upper end of the crushing barrel is evenly equipped with a plurality of cylinders, and the cylinders The output shaft of the cylinder extends into the crushing barrel, and the output shaft of the cylinder is fixedly connected with the ring block; the inner circular surface of the crushing cylinder is provided with multiple groups of blades along the axial direction, and each group of blades is arranged between adjacent groups of crushing blades A rotating motor is provided below the crushing cylinder, and the output shaft of the rotating motor extends into the crushing cylinder and is fixedly connected with the lower end of the drum; the lower end of the crushing cylinder is provided with a discharge device. The invention is favorable for popularization and application.

Owner:乐山三缘电机有限公司

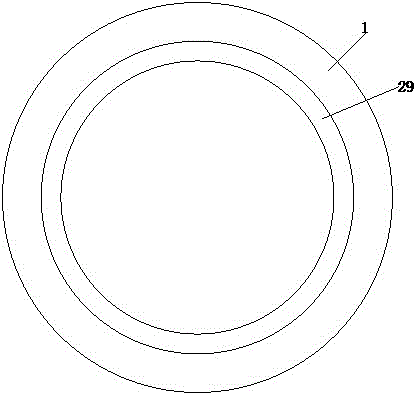

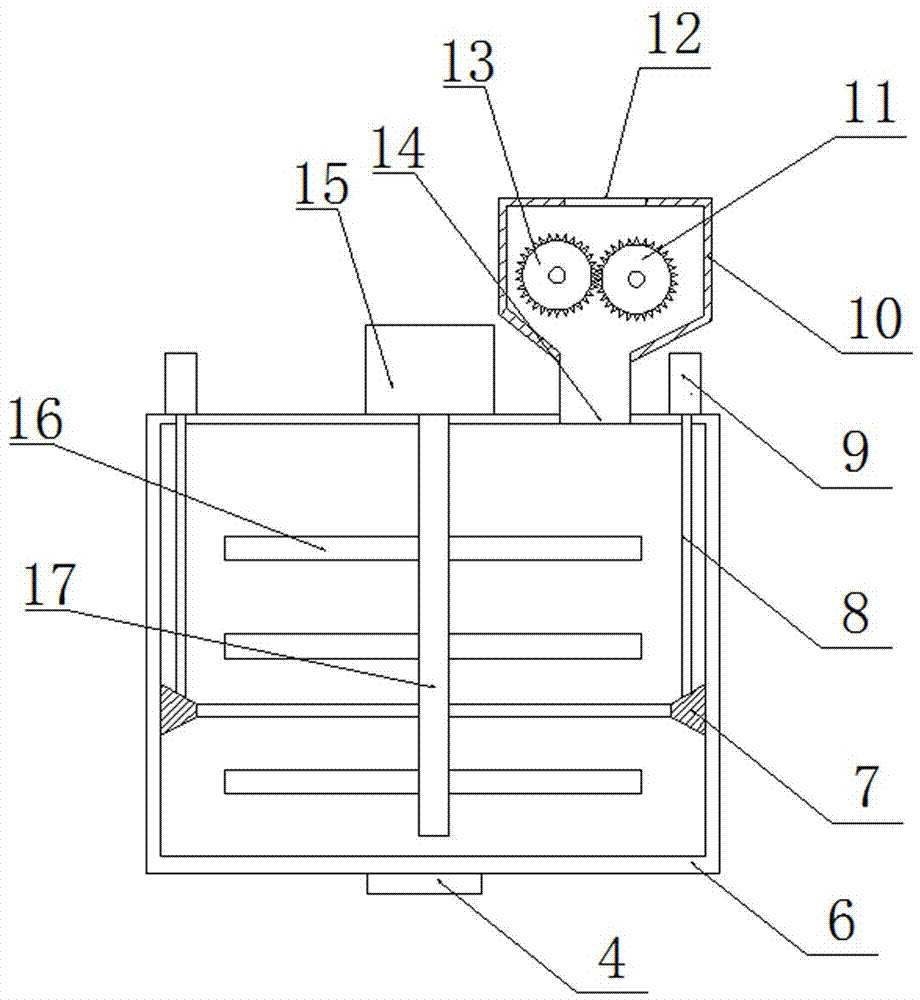

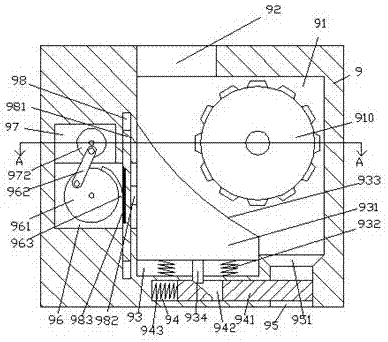

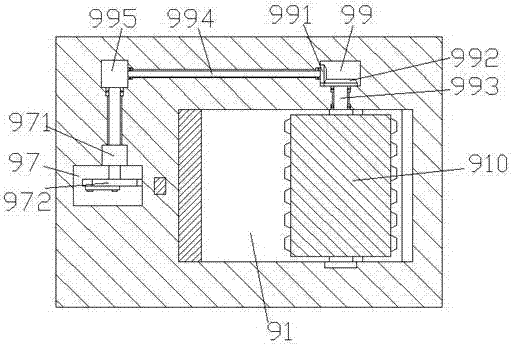

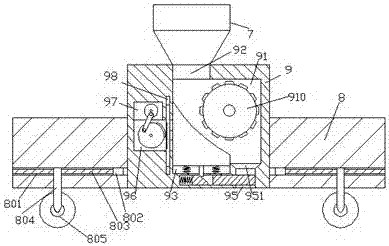

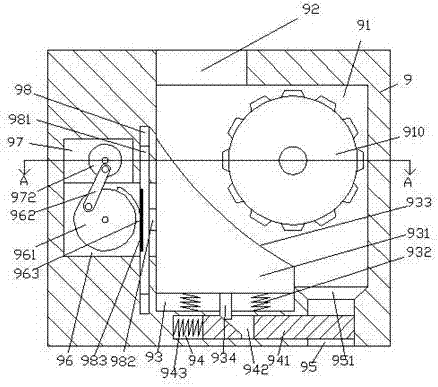

Efficient crushing equipment

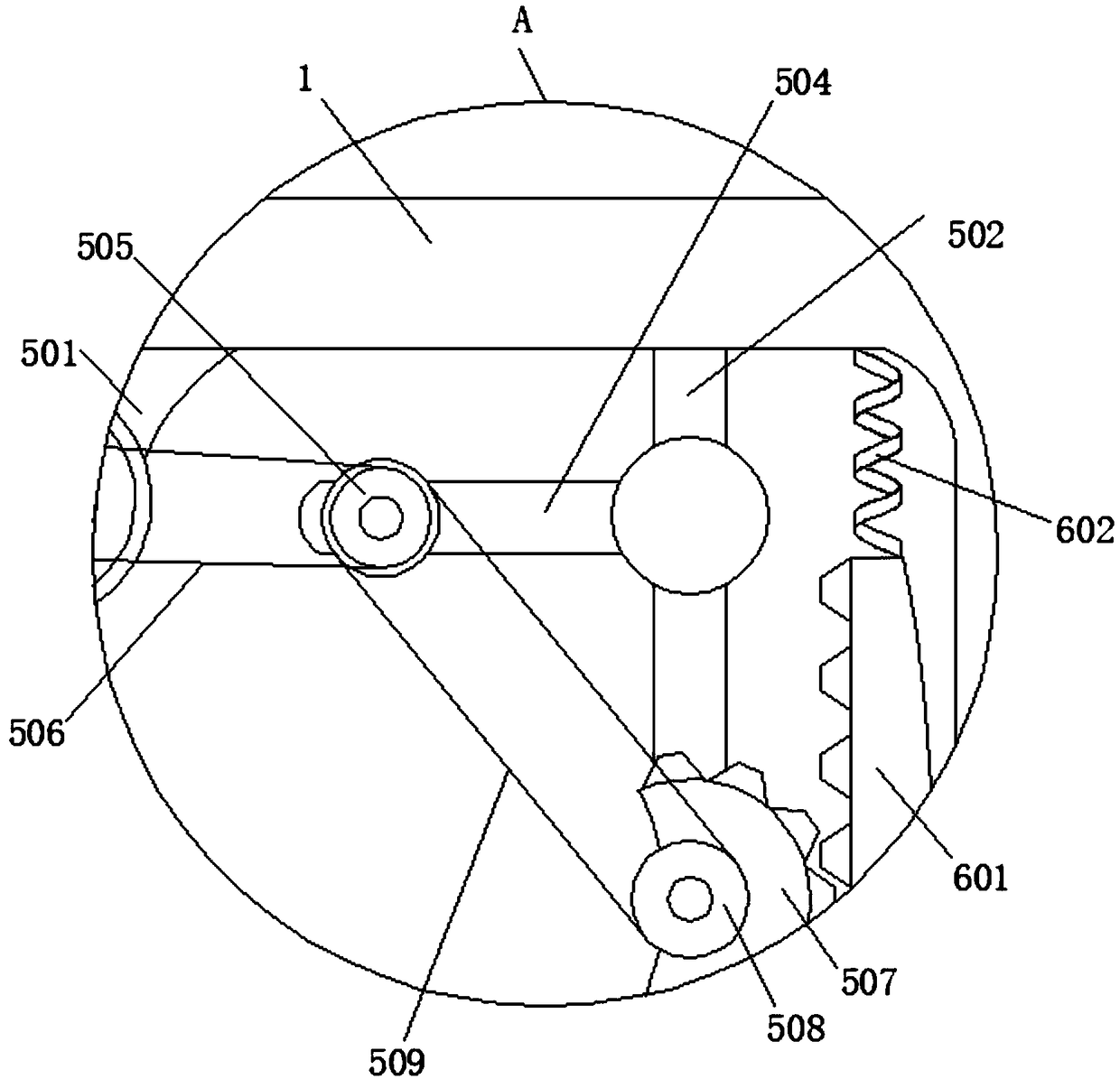

InactiveCN107185689ARealize flow breakingImprove smashing effectGrain treatmentsEngineeringGear wheel

The invention discloses a high-efficiency crushing device, which comprises a crushing barrel; a rotating shaft is arranged in the crushing barrel, a plurality of crushing blades are arranged on the rotating shaft, and a crushing motor is connected to the upper end of the rotating shaft through the crushing barrel; There is an annular block, and the outer circular surface of the annular block is in contact with the inner circular surface of the crushing barrel; the crushing device includes a shell, and the active crushing gear and the driven crushing gear meshed with the active crushing gear are arranged in the horizontal direction of the shell, and the active crushing The gear is equipped with a driving mechanism to drive its rotation; the housing is provided with a feeding opening above the meshing place of the active crushing gear and the driven crushing gear; the housing is provided with a discharge opening, and the discharge opening is connected to the crushing barrel The feeding port is connected; the lower end of the crushing barrel is provided with a discharge device. The invention is favorable for popularization and application.

Owner:乐山三缘电机有限公司

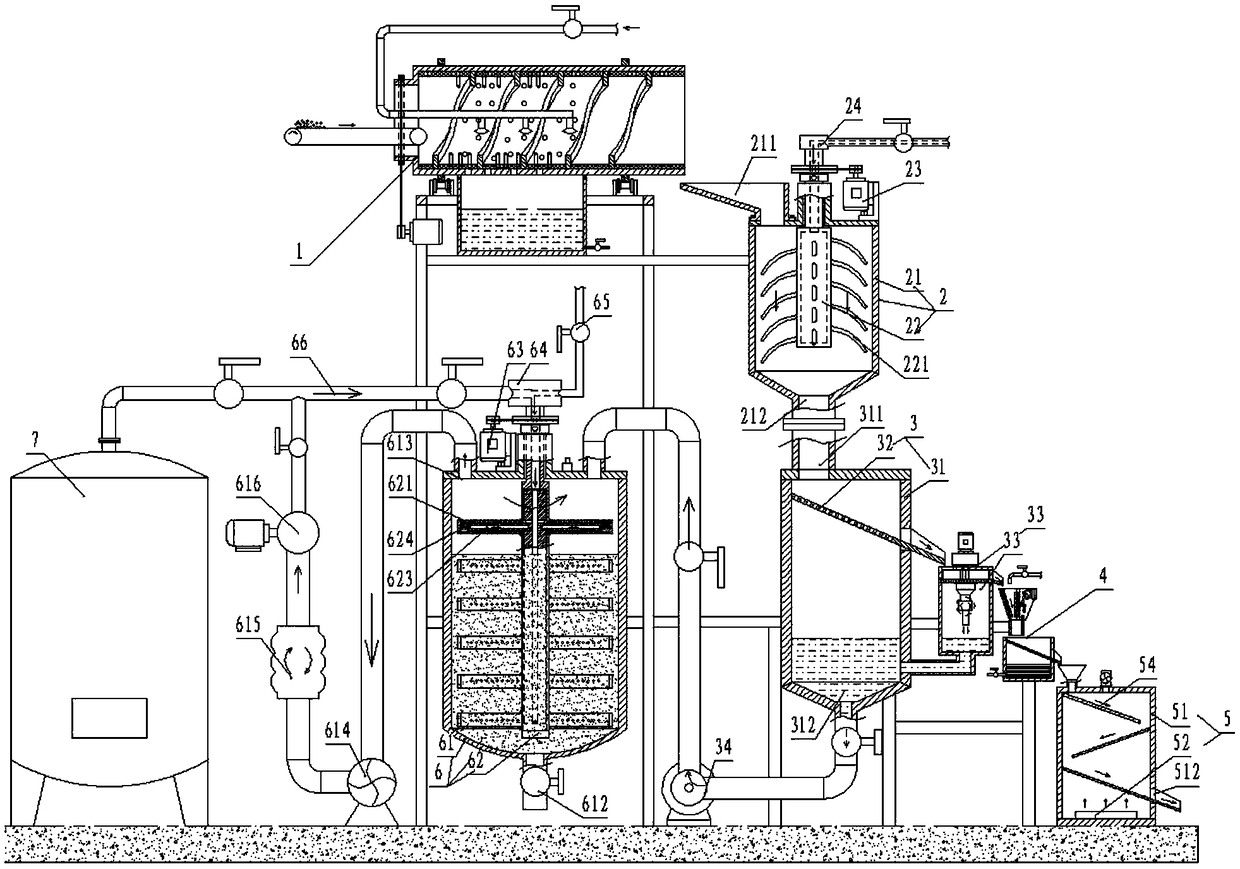

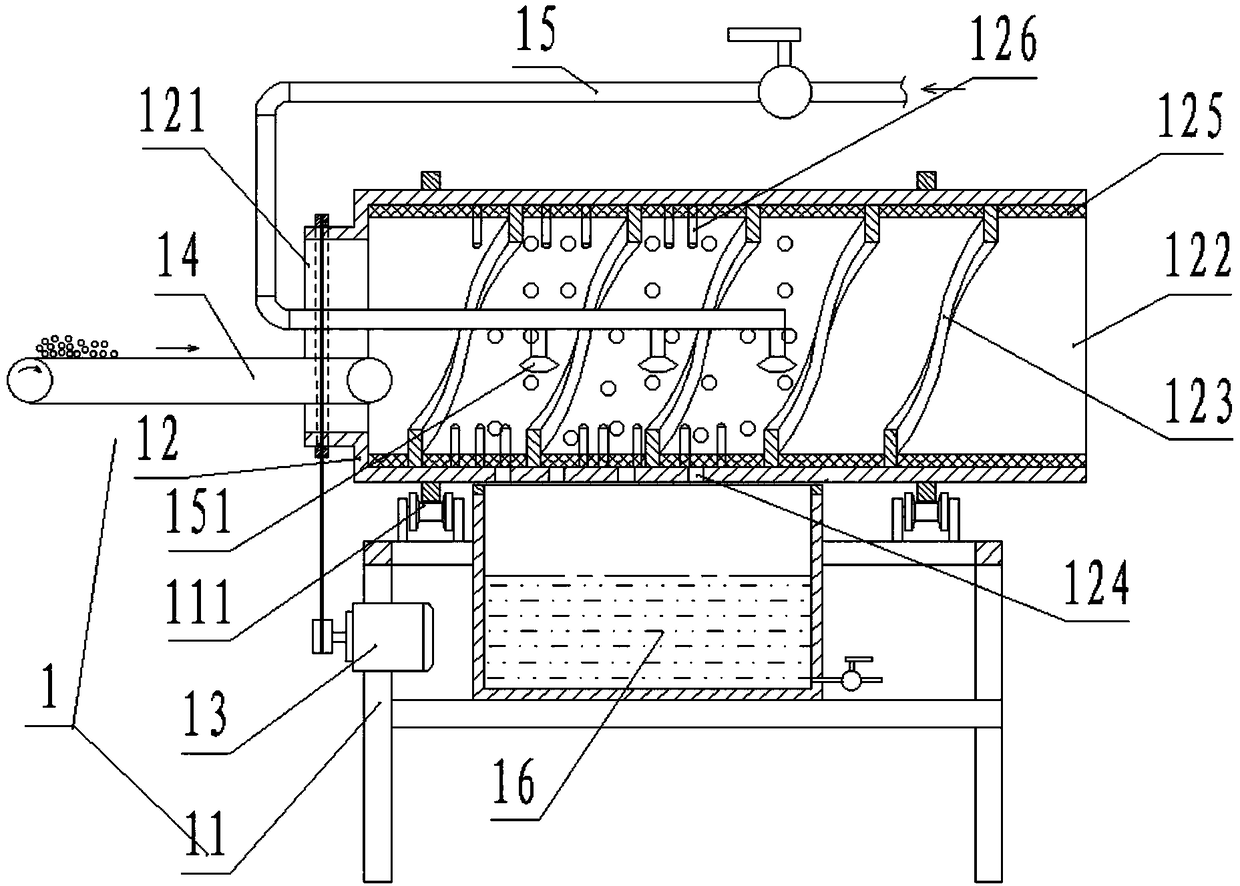

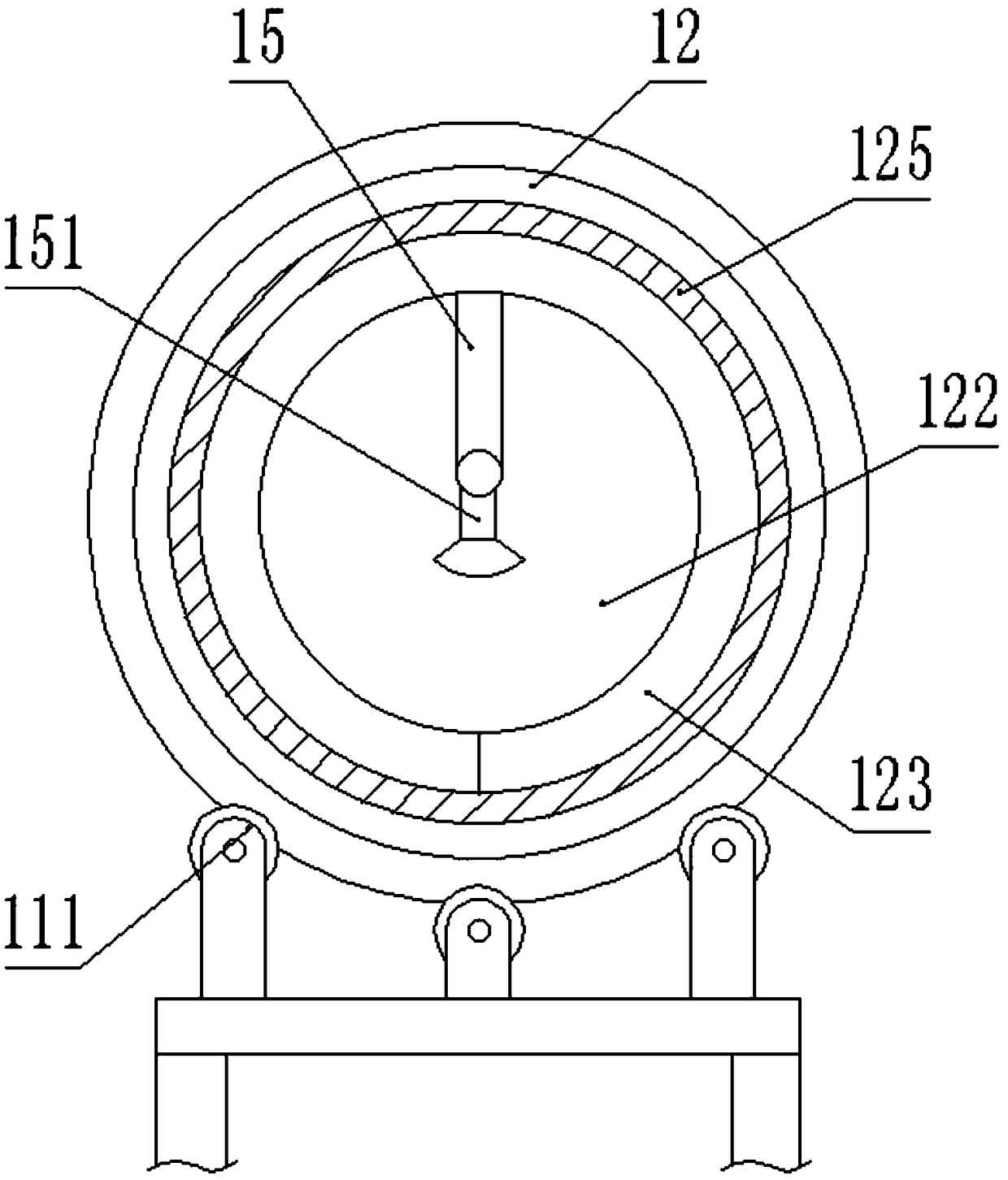

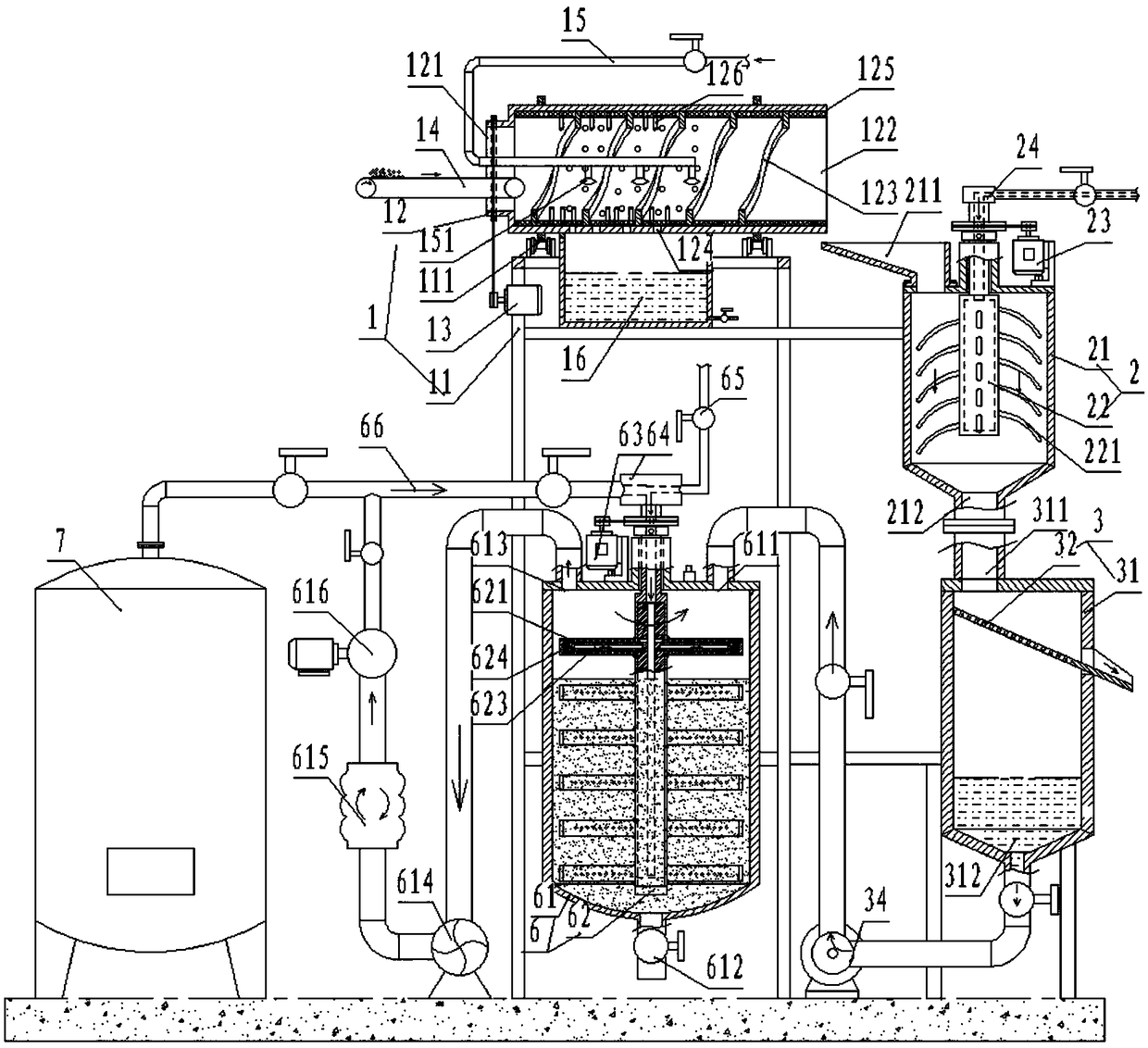

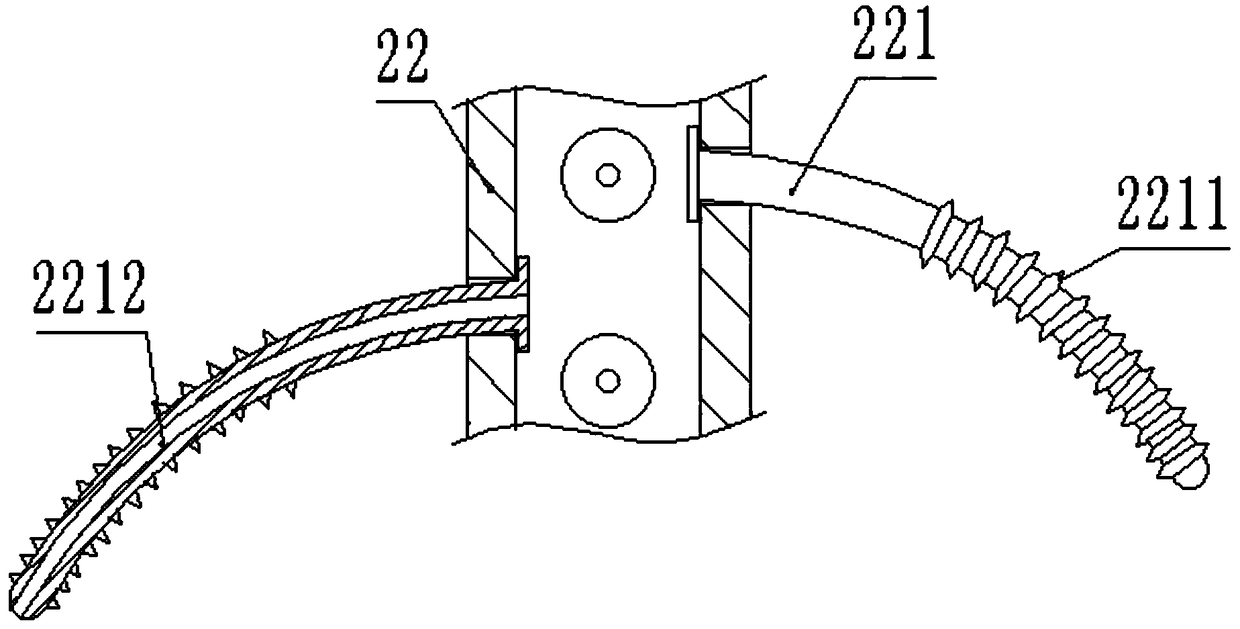

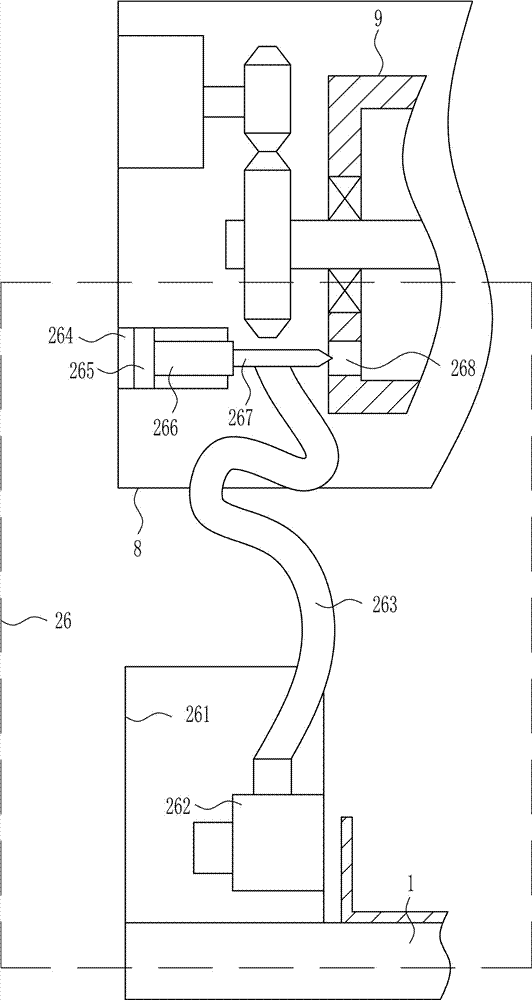

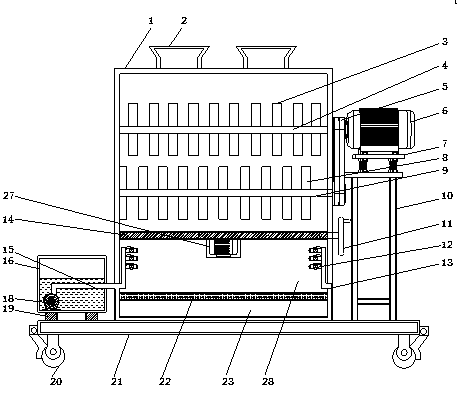

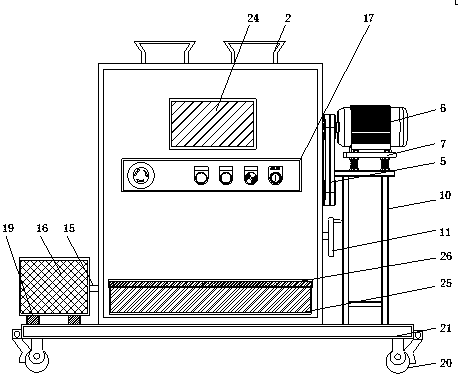

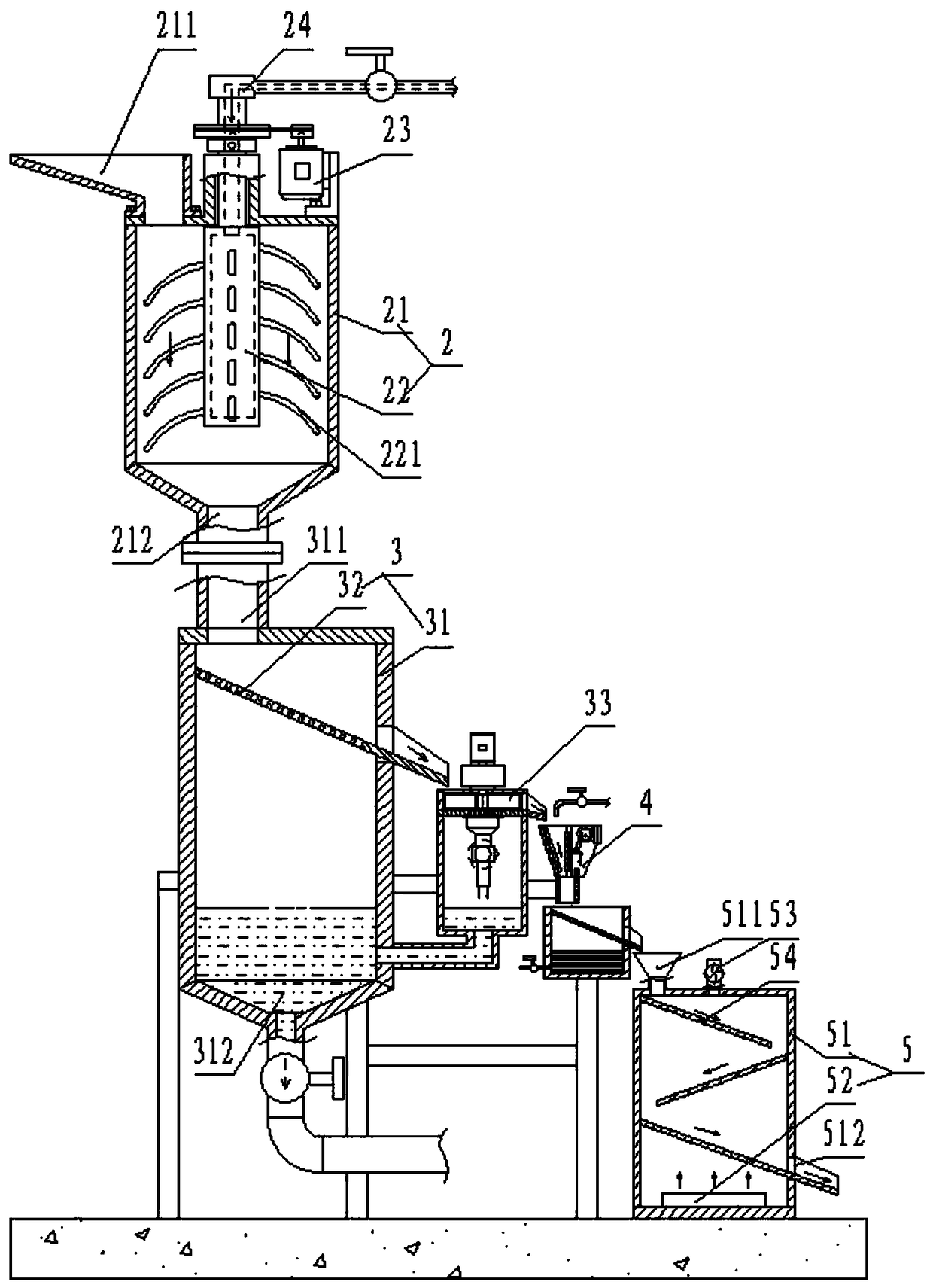

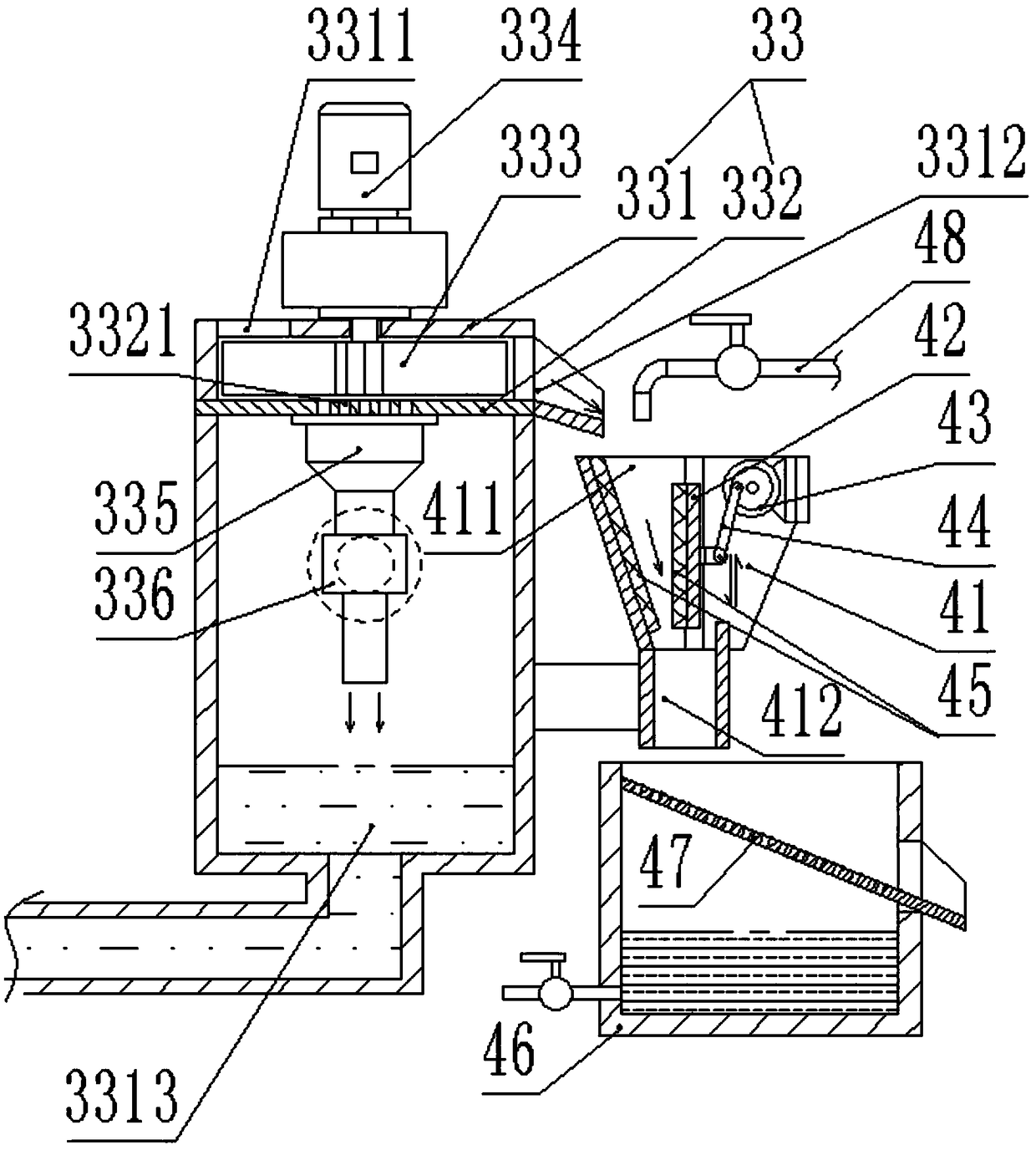

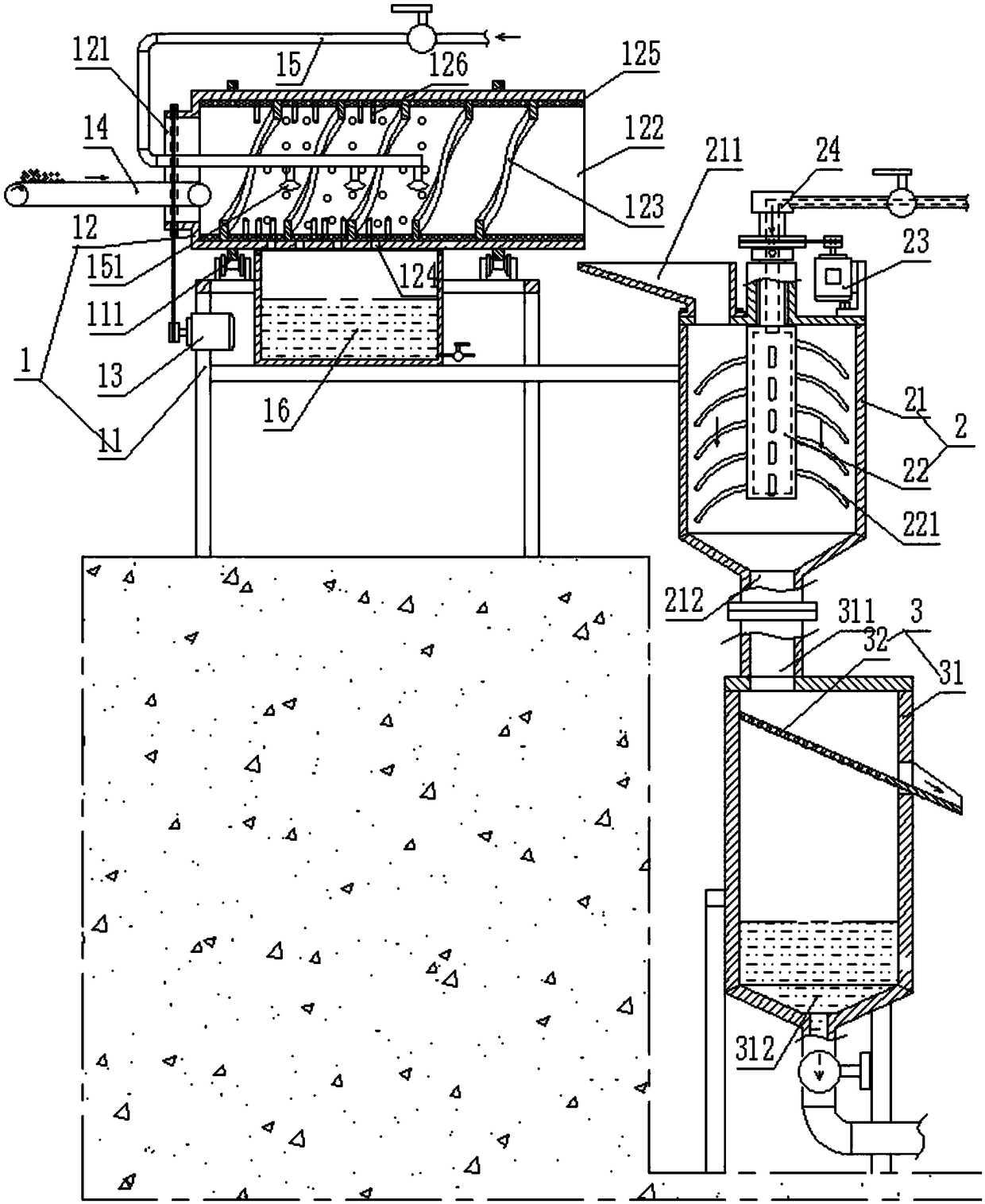

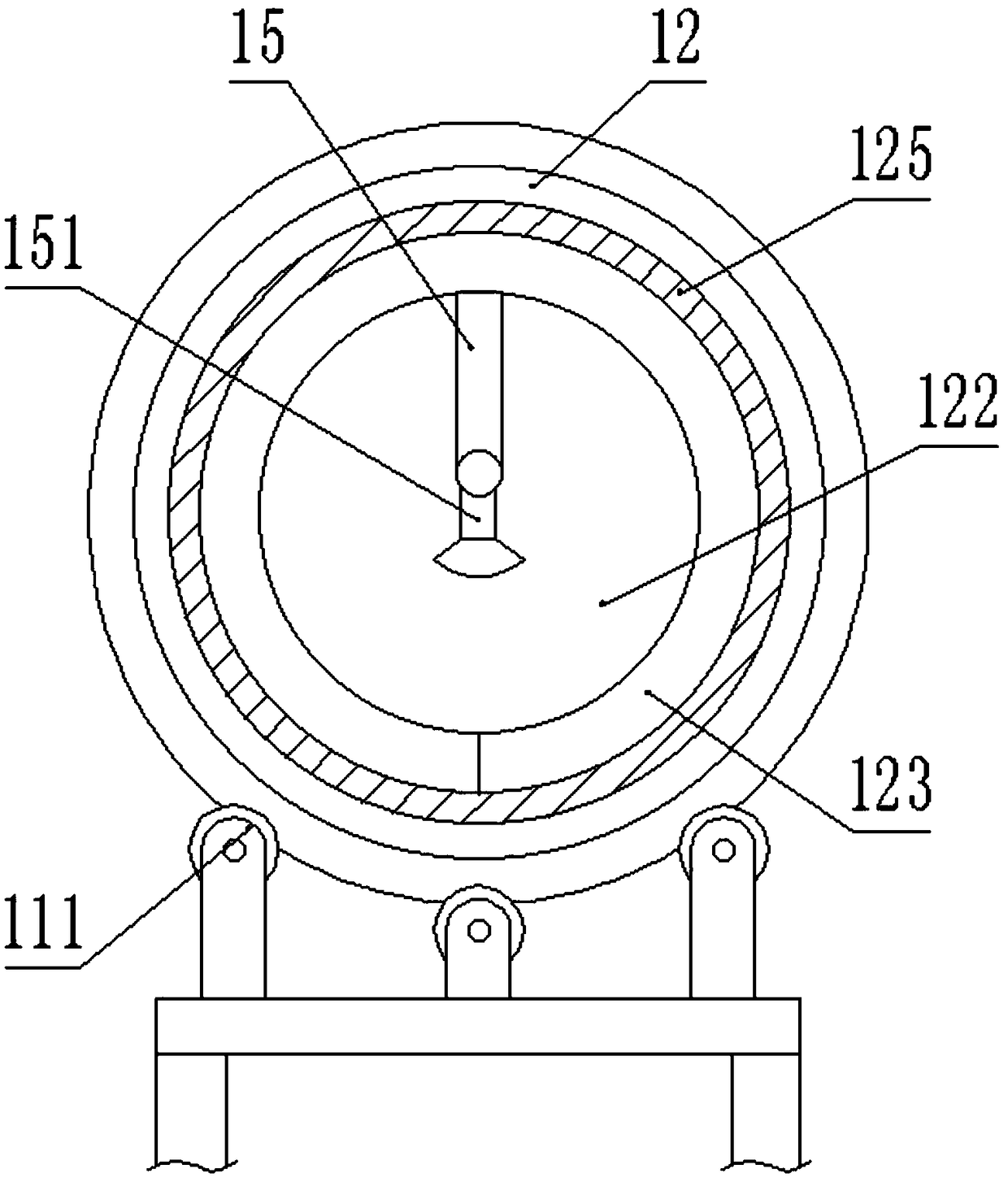

Grape product comprehensive processing production device

InactiveCN109393523AIntegrity guaranteedCompletely cleanJuice extractionHollow article cleaningNon destructiveGrape seed

The present invention discloses a grape product comprehensive processing production device. The grape product comprehensive processing production device comprises a grape washing machine, a grape crushing machine, a crushed material filtering machine, a grape seed rubbing and washing machine, a drying machine and a sterilization tank. The grape washing machine performs comprehensive non-destructive cleaning on grapes; crushing pieces of the grape crushing machine conduct irregular crushing of the grapes; the crushed material filtering machine separates slurry liquid and grape seeds; the grapeseed rubbing and washing machine rubs and washes surfaces of the grape seeds and completely removes residues; the drying machine conducts drying and heating of the grape seeds, and facilitates storage; and the sterilization tank is used for conducting a rapid temperature-rising sterilization treatment of the slurry liquid. The object is to provide the grape product comprehensive processing production device. The grape product comprehensive processing production device can conduct continuous washing, separating and second separating of the grapes, rubbing, washing and drying of the grape seeds,rapid high-temperature sterilizing of the slurry liquid, etc., and is complete in functions and suitable for large-scale production and use.

Owner:南方葡萄沟酒庄有限公司

Grape processing and treatment equipment with cleaning function

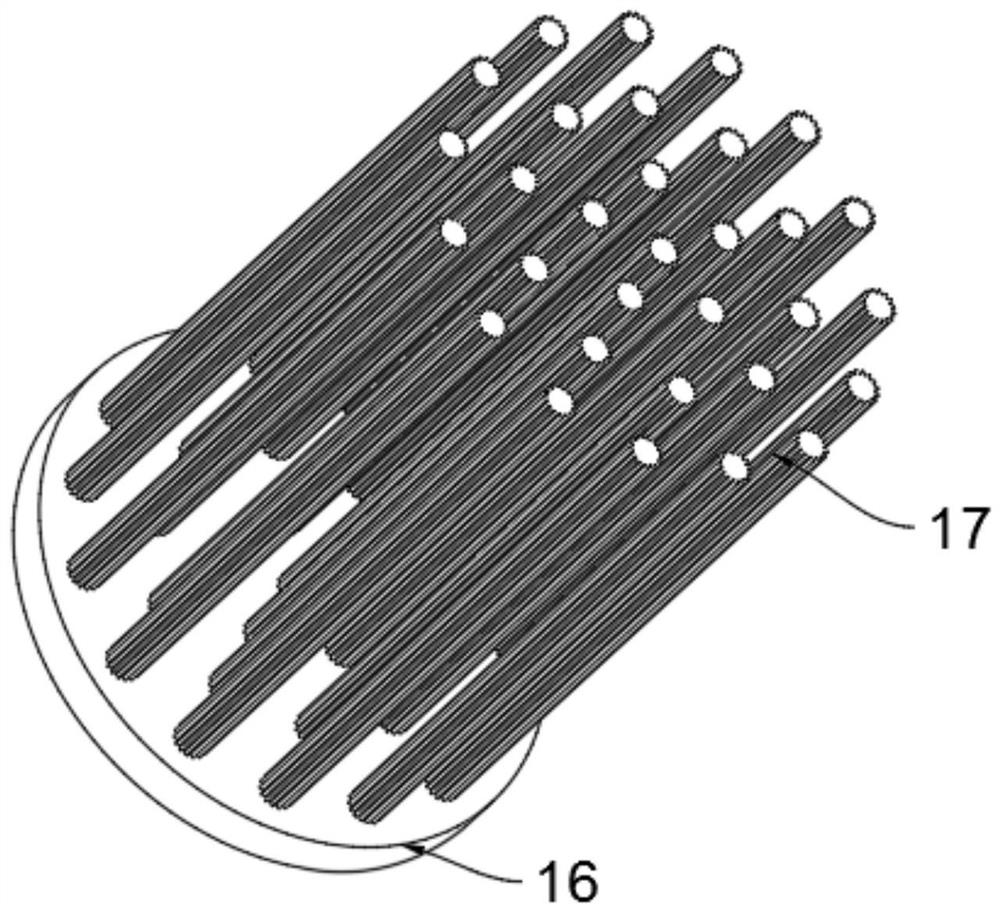

InactiveCN109497583AGuaranteed production efficiencyIncrease the degree of fragmentationJuice extractionFood preservationGrape seedGrapes seeds

The invention discloses grape processing and treatment equipment with a cleaning function. The equipment comprises a grape cleaning machine, a grape crusher, a crushing and filtering machine and a sterilization tank. Grapes are fully cleaned by a roller on the grape cleaning machine. Crushing bars are arranged in a staggered manner on the outer periphery of a crusher roller of the grape crusher. The crushing and filtering machine comprises a crushing and filtering machine shell and a crushing and filtering plate for separating syrup and grape seeds. The sterilization tank comprises a sterilization tank body and a sterilization tank drum. Multiple stirring rods are arranged on the outer periphery of the sterilization tank drum. The inside of the stirring rod is hollow, and the outer periphery of the stirring rod is provided with stirring rod through-holes, which are communicated with a high-temperature pressure air source pipe. The invention aims to provide the grape processing and treatment equipment with the cleaning function. Through the roller-type cleaning machine, grape granules are cleaned and pesticide residues are removed. The grape crusher crushes grapes at random insteadof crushing grape seeds. The crushing and filtering machine separates grapes. The sterilization tank performs rapid heating and sterilization treatment on the grape syrup.

Owner:南方葡萄沟酒庄有限公司

Traditional Chinese medicine smashing equipment capable of fast washing and screening big-powder traditional Chinese medicine

ActiveCN107442234ARoll over lastsImprove smashing effectHollow article cleaningCleaning using liquidsChinese drugTraditional Chinese medicine

The invention relates to traditional Chinese medicine smashing equipment, in particular to traditional Chinese medicine smashing equipment capable of fast washing and screening the big-powder traditional Chinese medicine. According to the traditional Chinese medicine smashing equipment, the big-powder traditional Chinese medicine can be screened out, and timely and fast washing can be conducted. The traditional Chinese medicine smashing equipment comprises a bottom plate, a first collecting box, a supporting plate, a fixing plate, a first supporting base, a rotating shaft, a first fixing block, an installing plate, a smashing box, a second supporting base and the like. The first collecting box is placed on the right side of the bottom plate. By means of the traditional Chinese medicine smashing equipment capable of fast washing and screening the big-powder traditional Chinese medicine, the effects that the big-powder traditional Chinese medicine can be screened out, and timely and fast washing can be conducted are achieved.

Owner:安徽天祥药业有限公司

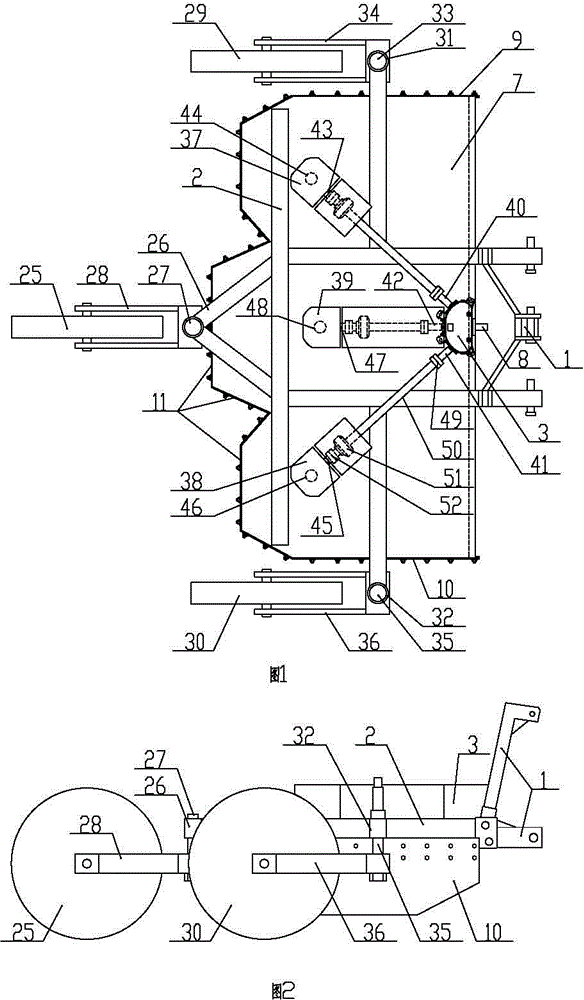

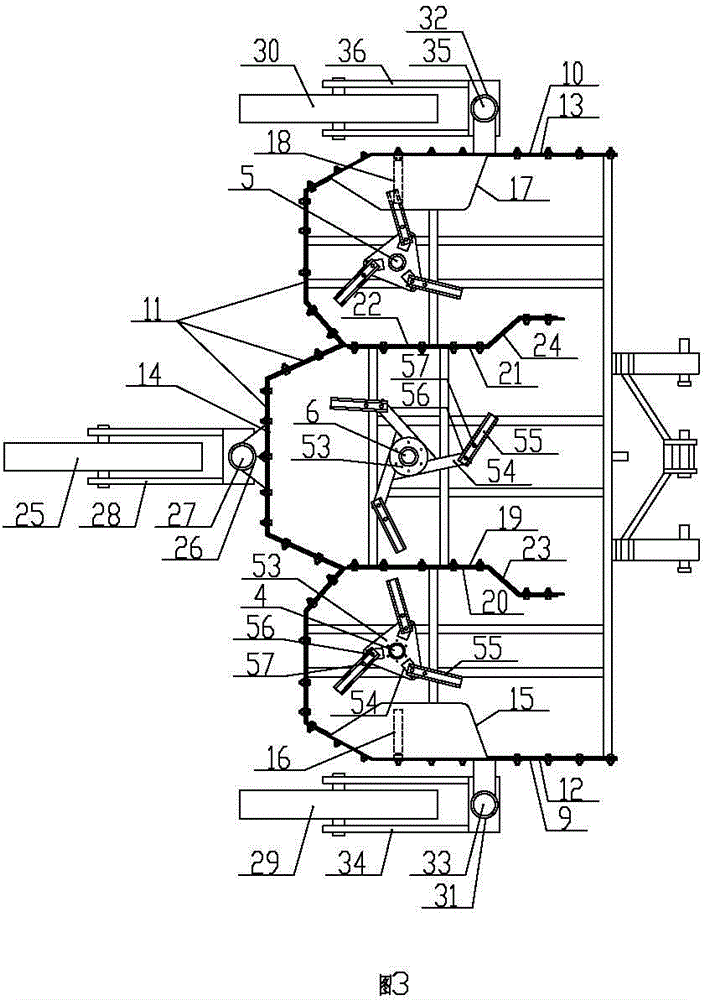

Multi-shaft straw crushing and returning machine

InactiveCN103947383AReasonable structureEasy to useCrop conditionersMowersAgricultural engineeringAgriculture

The invention relates to the technical field of agricultural straw returning machinery, and relates to a multi-shaft straw crushing and returning machine. The multi-shaft straw crushing and returning machine comprises a traction frame, a rack, traveling wheels, a main gear box, a transmission gear, a left cutter shaft, a right cutter shaft and a middle cutter shaft, wherein the traction frame is fixed at the front end of the rack; no less than one traveling wheel is mounted at the back of the rack; a frame plate is fixed at the lower part of the rack; the main gear box is fixedly mounted at the upper end of the frame plate; the left cutter shaft, the right cutter shaft and the middle cutter shaft along the vertical direction are respectively mounted below the frame plate. The multi-shaft straw crushing and returning machine is reasonable and compact in structure and convenient to use, the tractor load is alleviated through the traveling wheels, and three cutter discs are driven to work cooperatively through the main gear box, so that the working width is increased, the straw crushing efficiency is high, the crushing effect is better, and the working efficiency is also improved; the dispersion direction of broken straws can be limited and guided through a baffle plate mounted at the lower end of the frame plate, so that the straws are unlikely to be stacked and are uniform in dispersion, and the machine has the characteristics of safety, simple, convenience and high efficiency.

Owner:玛纳斯县祥和农机有限责任公司

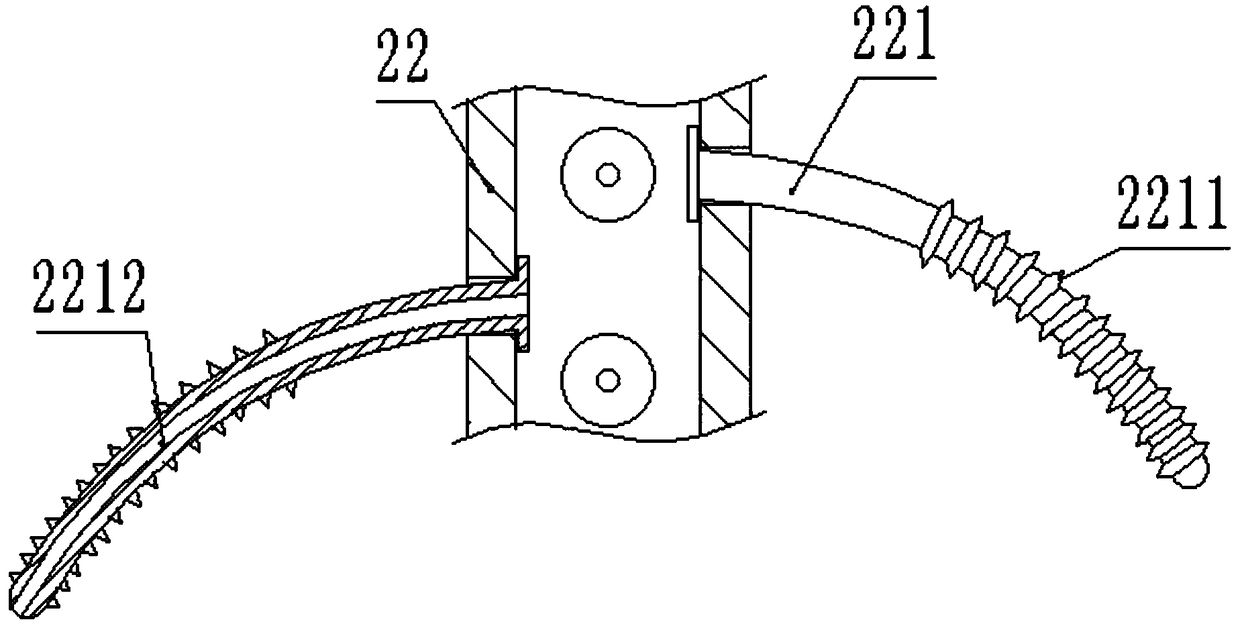

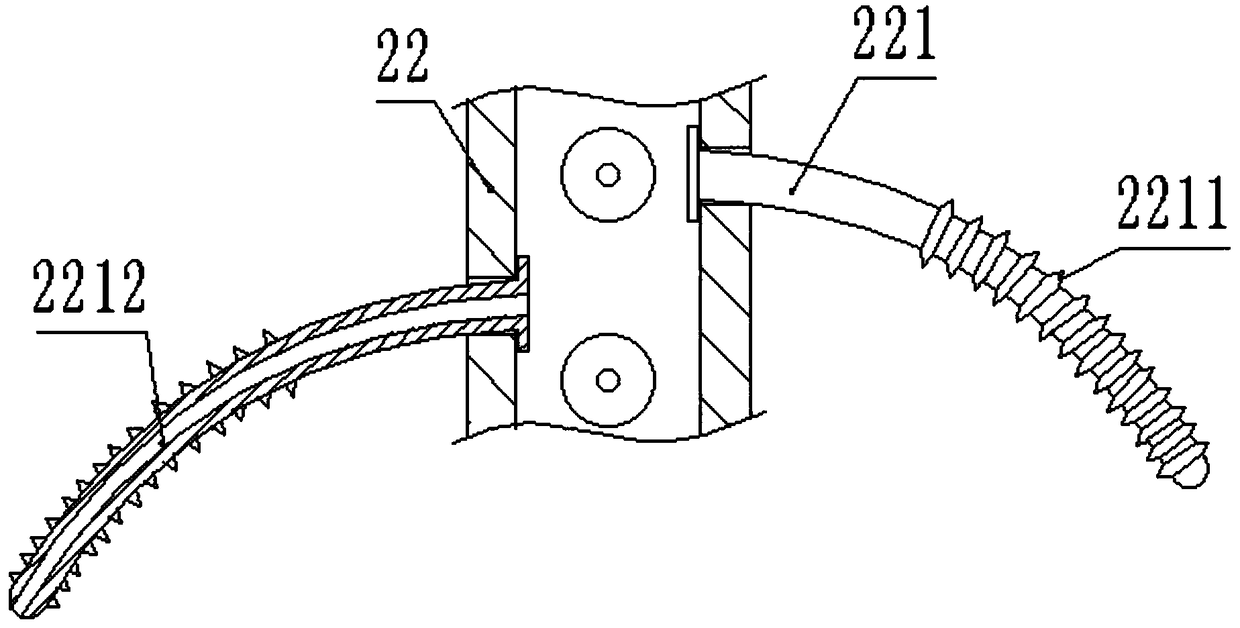

Efficient separating device for grape product processing

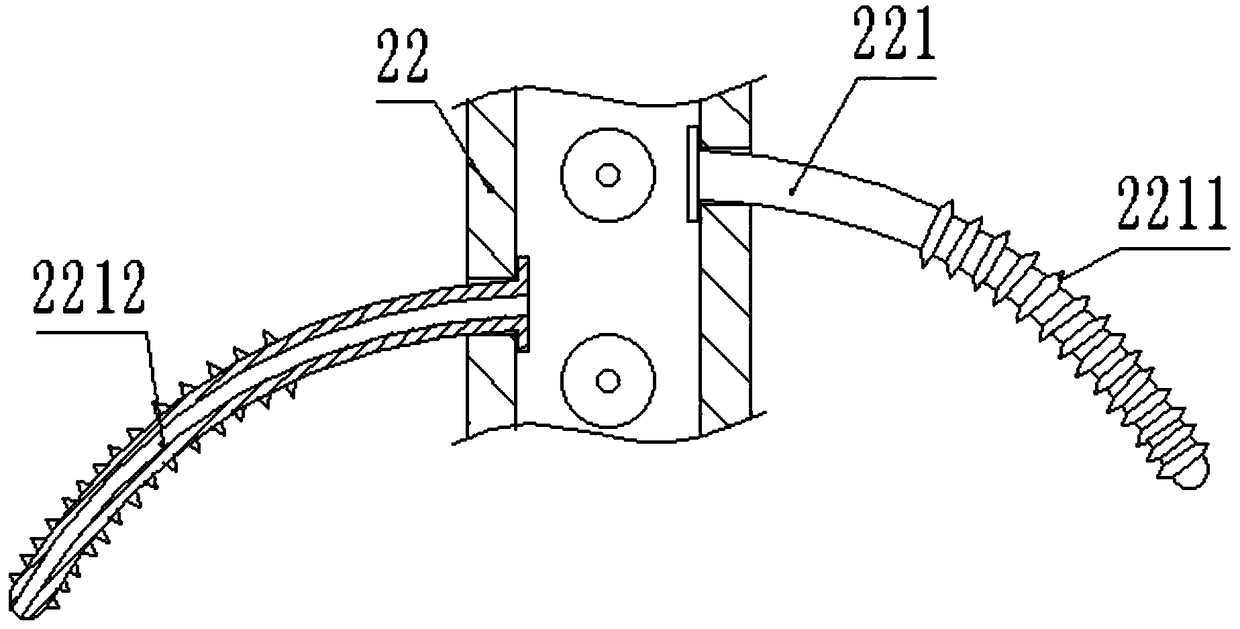

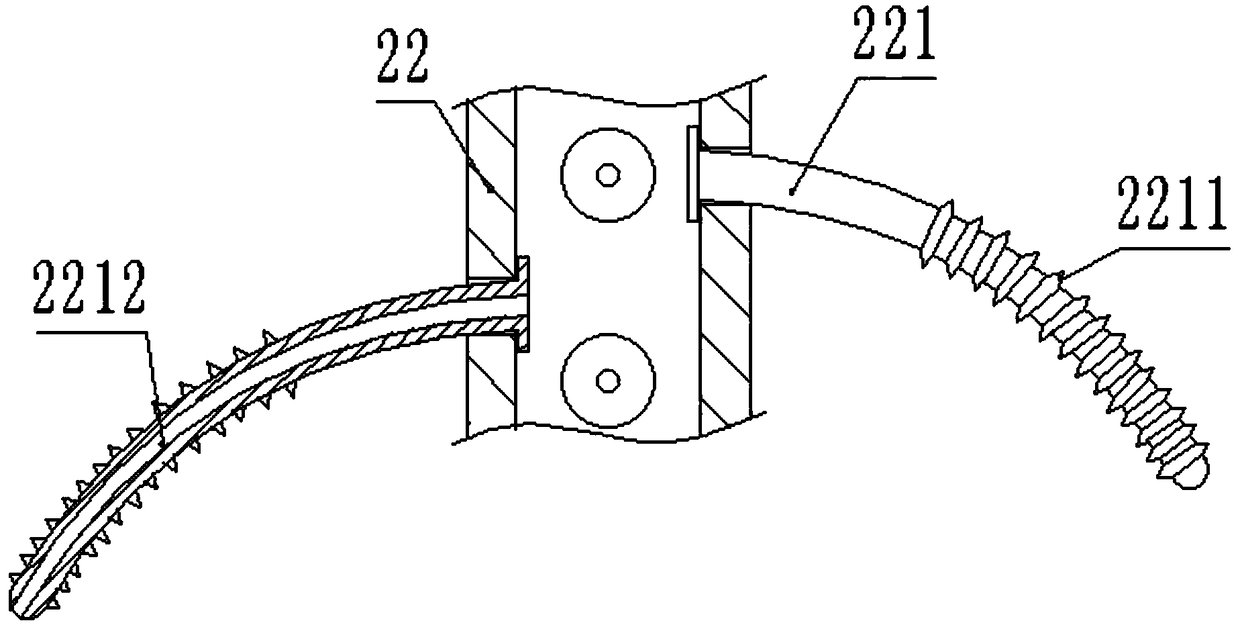

InactiveCN109365056AIncrease the degree of fragmentationIntegrity guaranteedHollow article cleaningGrain treatmentsProduct processingGrape seed

The invention discloses an efficient separating device for grape product processing. A grape smashing machine and a smashing filtering machine are included; the grape smashing machine comprises a smashing machine shell and a smashing machine rotating barrel; flexible smashing strips are arranged on the periphery of the smashing machine rotating barrel in a staggered manner, and perform irregular smashing on grape skin and grape flesh, but no grape seeds are broken, and complete separation of the grape seeds is guaranteed; and the smashing filtering machine comprises a smashing filtering machine shell and a smashing filtering plate, pulp liquid and the grape seeds are separated, and remaining pulp liquid on the grape seeds are subjected to secondary recycling. According to the purpose of the efficient separating device for grape product processing, the efficient separating device for grape product processing is provided, the grape smashing machine performs irregular smashing on the grape skin and the grape flesh through the flexible smashing strips rotating at a high speed, the crushing degree is high, the grape seeds are not crushed, and the particle integrity of the grape seeds isguaranteed; and the smashing filtering machine is used for making the grape flesh and grape skin mixed pulp liquid separated from the grape seeds, meanwhile, the pulp liquid adhering to the surfacesof the grape seeds is subjected to secondary recycling, and recycling is thorough.

Owner:南方葡萄沟酒庄有限公司

Slaughtering machine for processing earthworms

The invention discloses a slaughtering machine for processing earthworms. The slaughtering machine for processing earthworms comprises a shell, wherein feeding openings are formed in the top of the shell; a first stirring shaft is arranged in the shell, and is connected with an output end of a motor through a coupler; first stirring blades are uniformly mounted on the surface of the first stirringshaft; a second stirring shaft is arranged below the first stirring shaft; the tail end of the second stirring shaft is connected with the first stirring blades through a conveying belt; a baffle isarranged below the second stirring shaft; a vibrating motor is mounted on the bottom of the baffle; a cleaning box is arranged below the baffle; a sprayer is arranged in the cleaning box; a filter screen is arranged below the cleaning box; and a waste water collecting box is arranged below the filter screen. The first stirring shaft which is connected with the output end of the motor rotates, meanwhile, the conveying belt drives the second stirring shaft to rotate, the stirring blades on the stirring shafts are driven to cut and smash the earthworms, the two stirring blades are distributed ina staggered manner, and thus, the smashing effect is improved.

Owner:江苏安禧生物科技有限公司

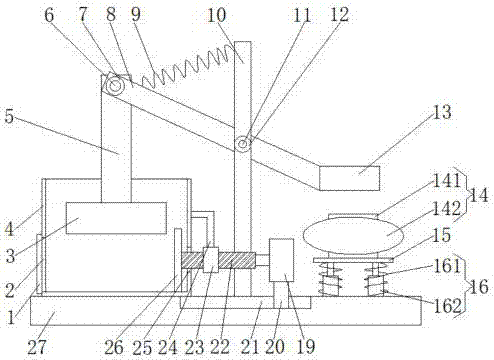

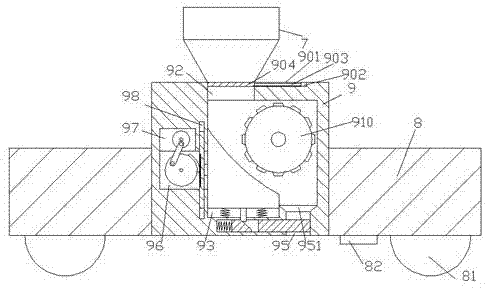

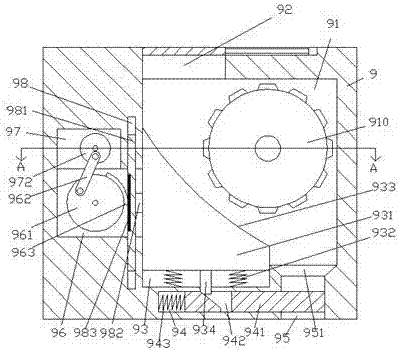

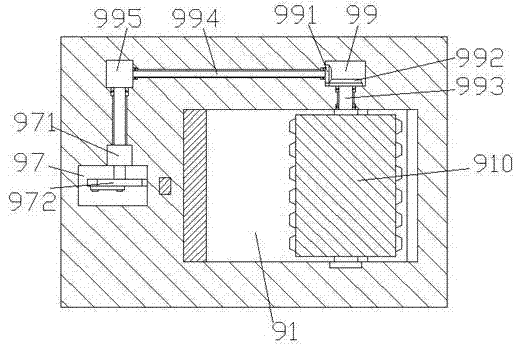

Automatic coal smashing and pushing-out device of auxiliary equipment for boiler

InactiveCN107983516AImprove smashing effectBurning effect is not goodGrain treatmentsCombustionWorking environment

The invention discloses an automatic coal smashing and pushing-out device of auxiliary equipment for a boiler. The device comprises a base plate; the upper surface of the base plate is fixedly connected with the lower surface of a supporting plate through a telescopic device; the upper surface of the supporting plate is fixedly connected with the lower surface of a driving device; and the upper surface of the base plate is fixedly connected with the bottom end of a third supporting rod. The automatic coal smashing and pushing-out device of the auxiliary equipment for the boiler is provided with a first motor, a second motor, the telescopic device, the supporting plate, a first supporting rod, a second supporting rod, the third supporting rod, a slider, a sliding chute, a cam, a threaded column, a thread cap, a baffle and a smashing hammer so that a good coal smashing effect is achieved; a poor coal combustion effect caused by incomplete smashing of the coal is prevented; a worker doesnot need to manually smash the coal, so the time and physical power of the worker are not wasted, coal cinders are prevented from flying everywhere, the work environment is not polluted, and the coalcinders can be collected commendably.

Owner:WUXI HENGDA MINE MACHINERY

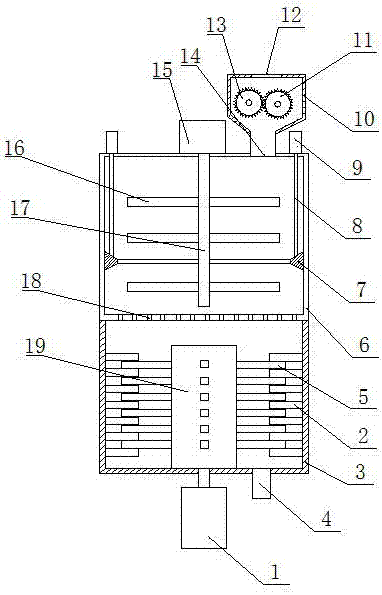

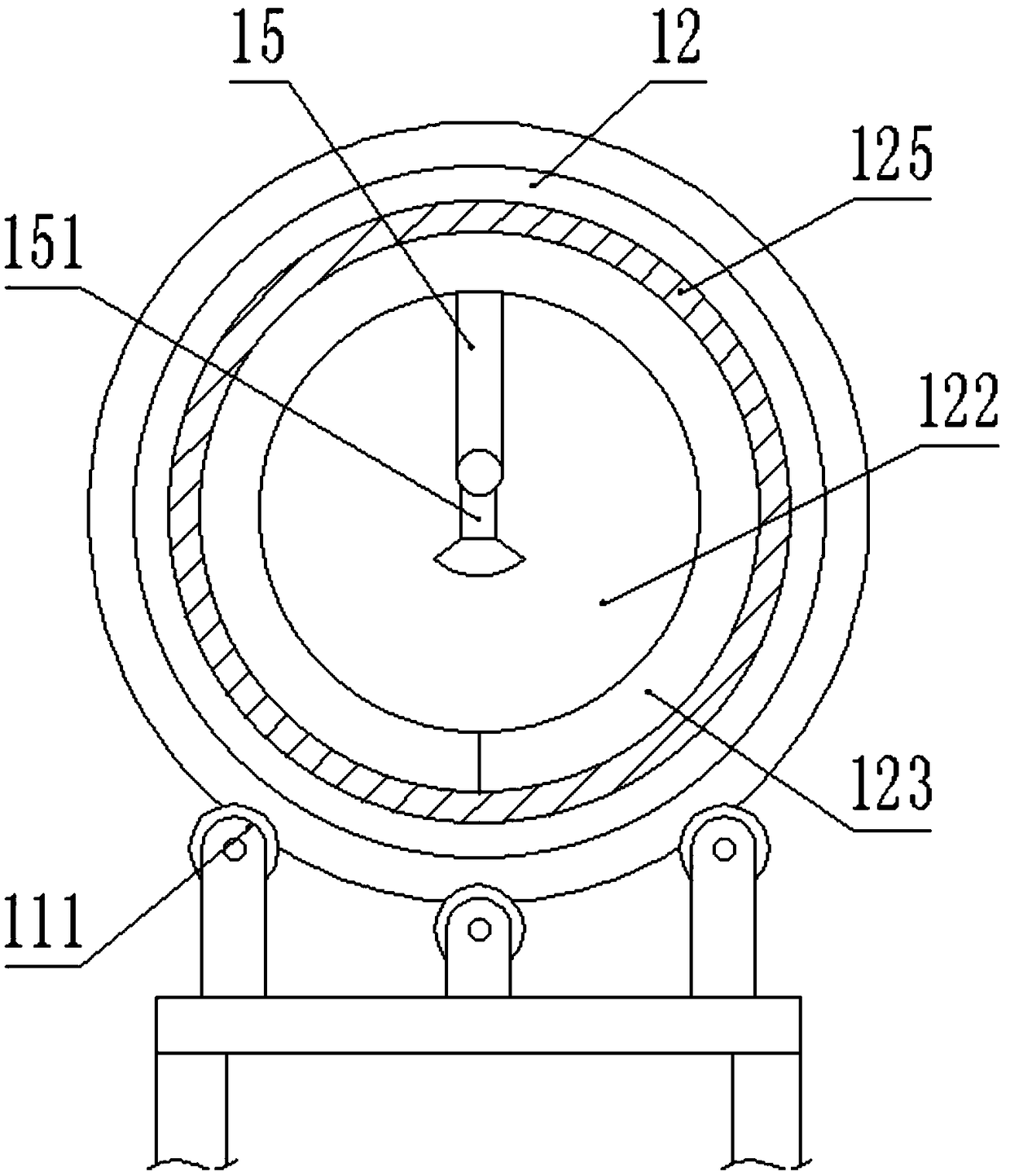

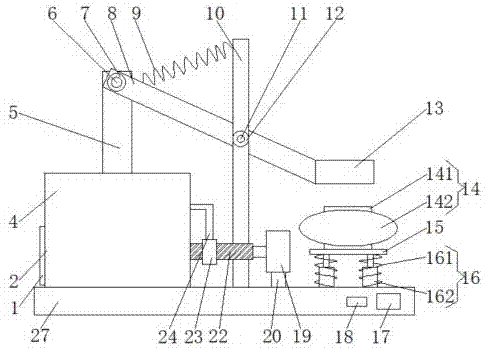

Silicon smashing machine

ActiveCN107737660AImprove smashing effectImprove crushing efficiencyGrain treatmentsEngineeringMechanical engineering

The invention discloses a silicon smashing machine capable of improving the smashing efficiency and lowering the energy consumption. The silicon smashing machine comprises a base. Supporting columns are arranged on the base. A drum is arranged on the upper surface of the base. A drive device driving the drum to rotate is arranged on the lower surface of the base. A shell covering the drum is arranged on the base. The shell comprises an inner cavity. A through cover is arranged at the upper end of the drum and is installed on the top of the inner cavity of the shell in a rotating manner. Vertical inner ring grinding columns and outer ring grinding columns are arranged in the inner cavity of the shell. Inner ring movable grinding columns, middle ring movable grinding columns and outer ring movable grinding columns are arranged in the drum. The inner ring grinding columns are located between the inner ring movable grinding columns and the middle ring movable grinding columns. The outer ring grinding columns are located between the middle ring movable grinding columns and the outer ring movable grinding columns. Due to the adoption of the silicon smashing machine, cost can be reduced,and environmental protection and comprehensive utilization are facilitated.

Owner:LESHAN TOPRAYCELL

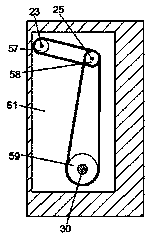

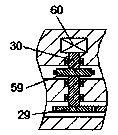

Beating device for paper production

InactiveCN108252140AQuality improvementImprove smashing effectRaw material divisionPaper productionPulp and paper industry

The invention relates to a beating device, in particular to a beating device for paper production, and aims at achieving the technical purpose of providing the beating device for paper production witha good beating effect and capable of saving time. Aiming at achieving the above technical purpose, the invention provides the beating device which comprises a box body and the like; four supporting legs are installed at corners of the lower part of the box body, a feeding hopper is installed on the top of the box body, the feeding hopper is communicated with the box body, a material discharging hopper is installed at the bottom of the box body, the material discharging hopper is communicated with the box body, a first valve is arranged on the material discharging hopper, a beating component is arranged in the box body, and a cutting device is arranged on the left side of the material discharging hopper. According to the device, raw materials are beaten through the beating component, the raw materials are cut through the cutting device, and a filtering device is arranged, so that the quality of pulp is improved, and a good beating effect and a time-saving effect are achieved.

Owner:叶财明

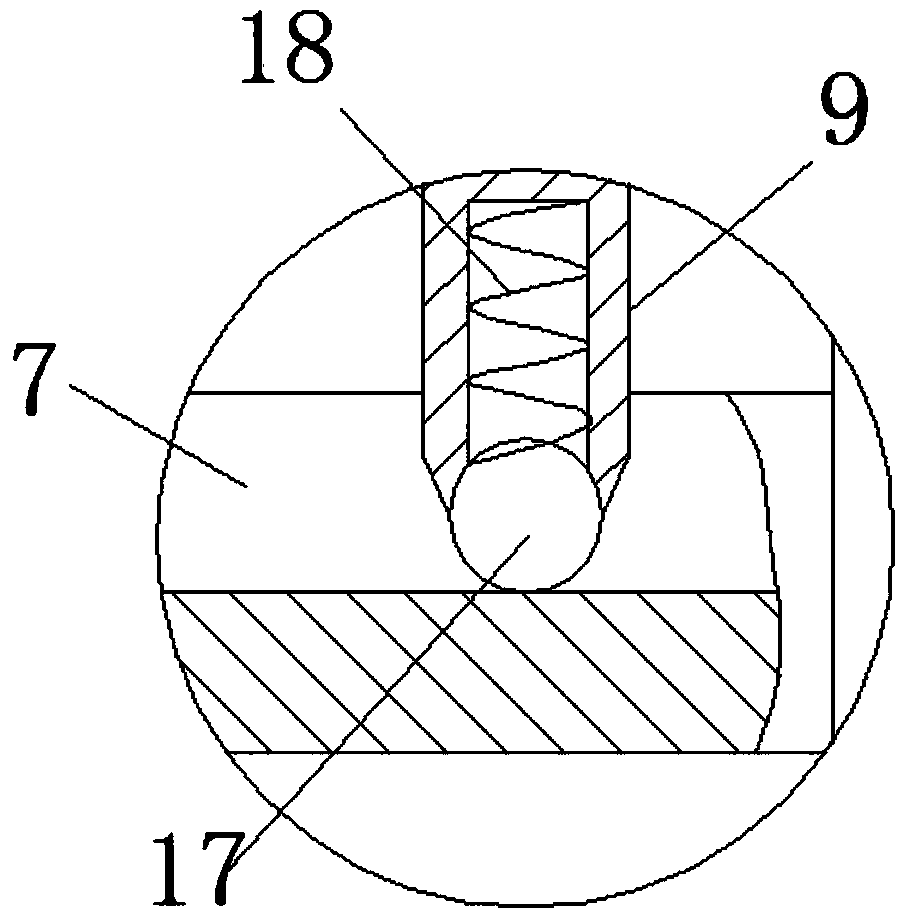

Waste paper treatment device

InactiveCN109252412AReduce recycling costsAvoid mixingPaper recyclingRaw material divisionPulp and paper industryScrew thread

The invention discloses a waste paper treatment device which comprises a substrate. A paper crushing component and a pulp component are arranged in the substrate, the pulp component comprises a firstcavity arranged in the substrate, first motors are bilaterally symmetrically mounted in the upper end wall of the first cavity and in power connection with threaded rods, the threaded rods is rotatably mounted in the upper end wall and the lower end wall of the first cavity through bearings, driving blocks are arranged in the first cavity in a sliding fit manner and mounted on the left threaded rod and the right threaded rod in a thread fitting manner, spline shafts extend downwards and are rotatably mounted in the driving blocks through bearings, a second cavity is formed in the lower end wall of the first cavity, spline sleeves in sliding fit with the spline shafts are rotatably mounted in the upper end wall and the lower end wall of the second cavity through bearings.

Owner:黄均杰

Sewage deposition purifying apparatus

ActiveCN107381747AImprove smash effectAutomatic control crushing workWater/sewage treatment by flocculation/precipitationSedimentation settling tanksEngineeringSewage

The invention discloses a sewage deposition purifying apparatus, which comprises a pedestal and a host body arranged in the pedestal, a smash inner chamber is arranged in the host body, a port passes through an inner top wall at the right side of the smash inner chamber, a guide slipping chamber is arranged at an inner bottom wall at the left side of the smash inner chamber, an embark port passes through the inner bottom wall in the smash inner chamber at the right side of the guide slipping chamber, a tapered groove is arranged at top of the embark port, an elevating slide block arranged in an upward extension mode is connected with the guide slipping chamber in a smooth cooperation mode, the top extension part of the elevating slide block detects that an arc surface extending to a lower right direction is arranged at the top of the elevating slide block in the smash inner chamber, a first spring coil is arranged in the guide slipping chamber below the bottom of the elevating slide block, a conduction groove is arranged in the inner wall at the left side of the smash inner chamber, a driving chamber communicated with the conduction groove is arranged at the inner top wall at the left side of the conduction chamber, and a first guide slipping chamber with up and down extension passes through the right side of the conduction chamber. The sewage deposition purifying apparatus has the advantages of simple structure and convenient operation, increases the smashing effect of large block of alum, reduces labor work, and increases the embark uniformity.

Owner:ANHUI DEQI ENVIRONMENTAL PROTECTION TECH CO LTD

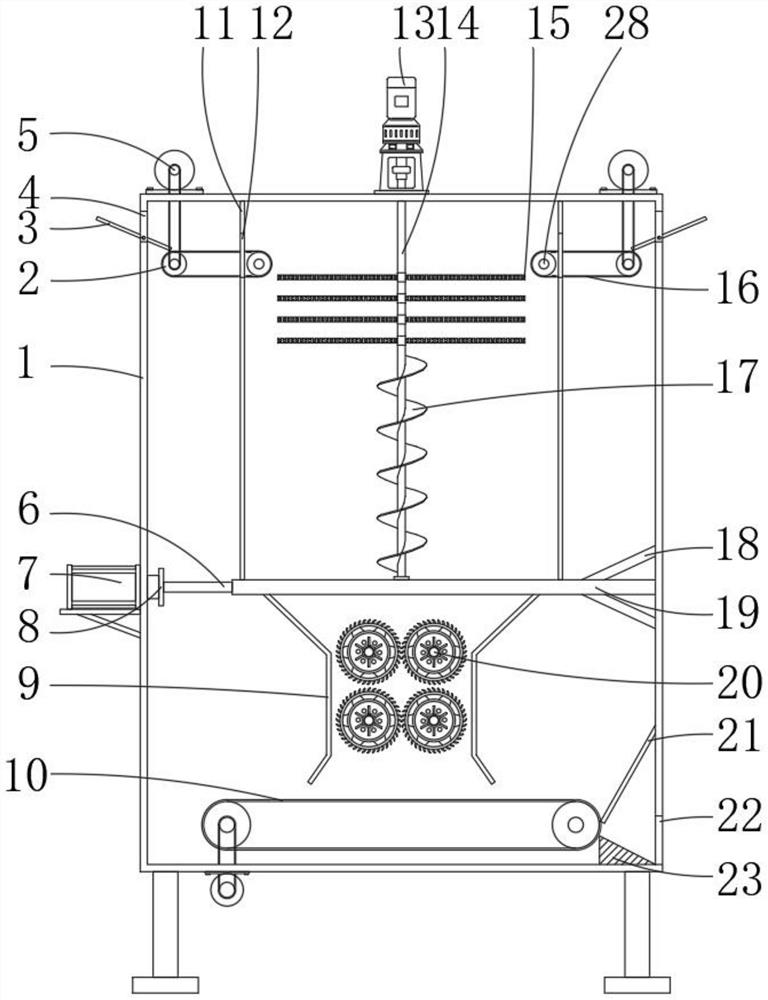

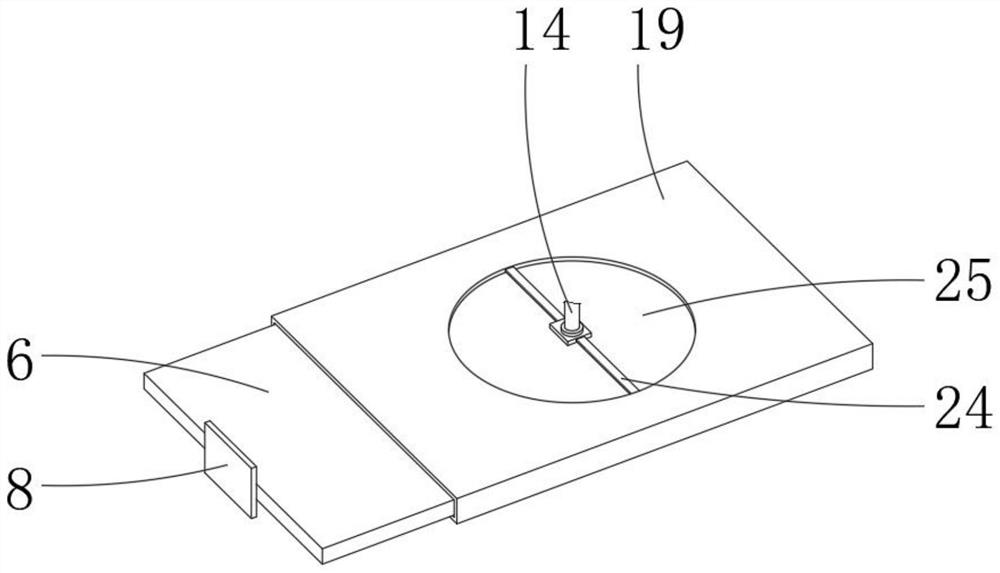

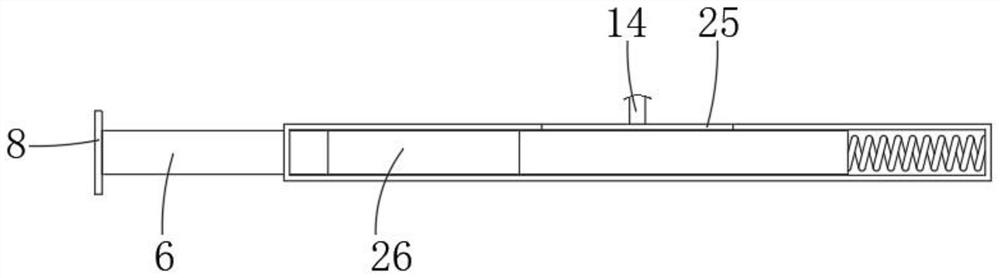

Dried potato powder production device for food processing

InactiveCN111940072AImprove efficiencyImprove smashing effectGrain treatmentsBiotechnologyReciprocating motion

The invention discloses a dried potato powder production device for food processing. The device comprises a processing box body, an internal smashing structure and an internal grinding structure, theinternal grinding structure comprises an internal box body, an internal telescopic rod, an internal motor, a rotating plate, a bottom plate and a cross smashing cutter, and the internal smashing structure comprises a primary smashing structure and an extruding and grinding structure; and the primary smashing structure comprises a bottom plate control structure, a top motor, a top telescopic rod, aguide plate, a fixing groove, a pressing plate, a spiral cutter and a transverse cutter, and the extruding and grinding structure comprises a power structure, a rotating shaft, a fixing base, a sliding plate, a reciprocating spring and a rotating roller. The spiral cutter and the transverse cutter are arranged, the crushing effect is very good, through the rotating roller which reciprocates, rawmaterials are ground in a reciprocating manner, meanwhile, the smashing effect is better through the cross smashing cutter, and the efficiency of converting potatoes into dried potato powder is higher.

Owner:陈玲

Device for sewage purification

InactiveCN107879413AAutomatic control crushing workImprove smashing effectGrain treatmentsWater/sewage treatment apparatusEngineeringSewage

The invention discloses a device for purifying sewage, which comprises a base and a main body installed in the base. The main body is provided with a crushing inner cavity, and a port is provided through the inner top wall on the right side of the crushing inner cavity, and the crushing inner cavity is There is a guide chamber in the inner bottom wall on the left side, and the inner bottom wall of the crushing inner chamber on the right side of the guide chamber is provided with a feeding port, and the top of the feeding port is provided with a tapered groove, and the guide chamber is smoothly fitted. It is connected with the lifting slider extended upwards, the extension section of the top of the lifting slider penetrates into the crushing cavity and the top of the lifting slider probes into the crushing cavity is provided with an arc surface extending to the right and down, There is a first spring coil in the guide chamber below the bottom of the lifting slider, a conduction groove is provided in the inner wall on the left side of the crushing chamber, a driving chamber is connected to the inner top wall on the left side of the conduction groove, and a driving chamber is provided in the right side of the conduction groove. The first guide chute extending up and down is arranged throughout; the invention has simple structure, convenient operation, improves the crushing effect of large alum, reduces the amount of manual labor, and improves the uniformity of feeding.

Owner:姚新连

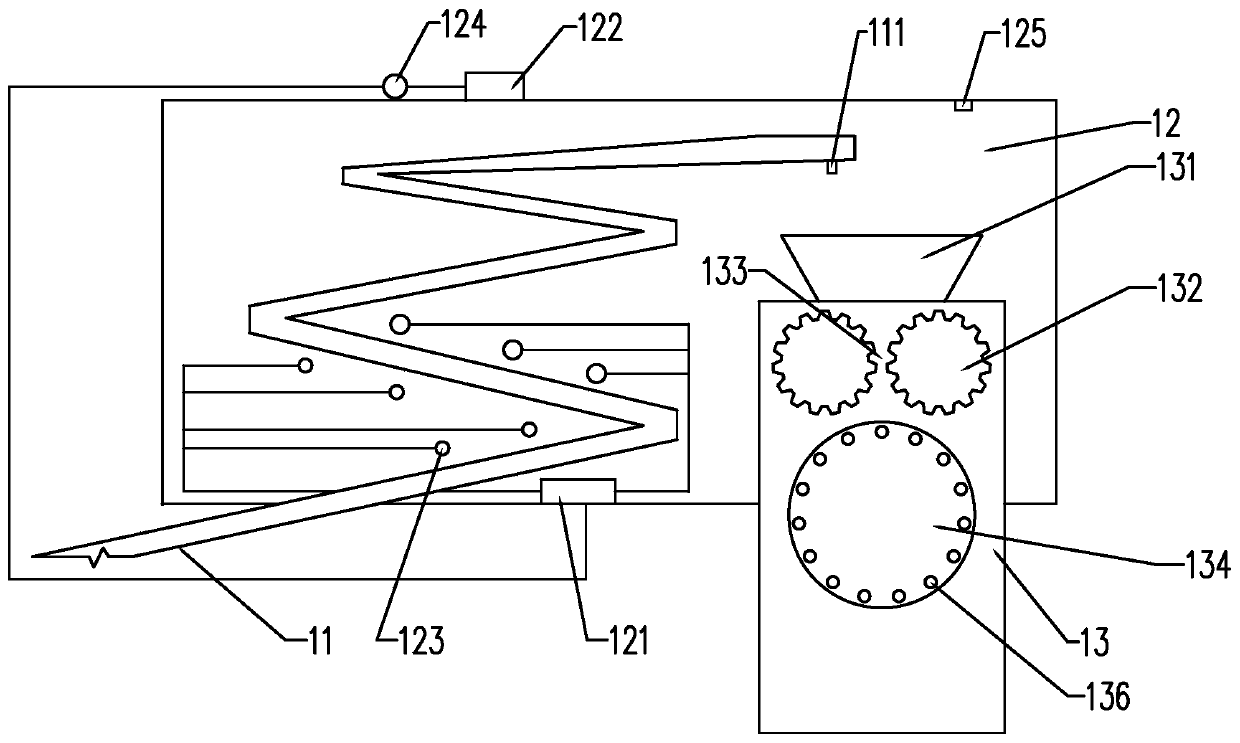

Crushing mechanism suitable for repairing heavy metal contaminated soil

InactiveCN109759214AImprove smash effectGood crushing effectContaminated soil reclamationDrying gas arrangementsContaminated soilsPre treatment

The invention discloses a crushing mechanism suitable for repairing heavy metal contaminated soil. The crushing mechanism suitable for repairing the heavy metal contaminated soil comprises a conveyorbelt, a pretreatment chamber and a crushing chamber; the conveyor belt stretches from exterior into the pretreatment chamber, a fan heater is arranged in the pretreatment chamber, a plurality of warmair nozzles extend out from the fan heater, and the warm air nozzles are aligned with the conveyor belt; an inlet of the crushing chamber extends into the pretreatment chamber, and the tail end of theconveyor belt is arranged above the inlet and used for feeding; two soil crushing gears and a rotating disk are arranged in the crushing chamber, wherein the two soil crushing gears can rotate relative to each other, a gap is formed between the peripheral surfaces of the two soil crushing gears, the inlet is formed right above the gap, and the rotating disk is arranged directly below the gap; anda plurality of soil crushing rods are arranged on the rotating disk, and the axes of the soil crushing rods, the rotating disk and the soil crushing gears are parallel to each other. The crushing mechanism suitable for repairing the heavy metal contaminated soil has the advantage of a good crushing effect.

Owner:湖南新九方科技有限公司

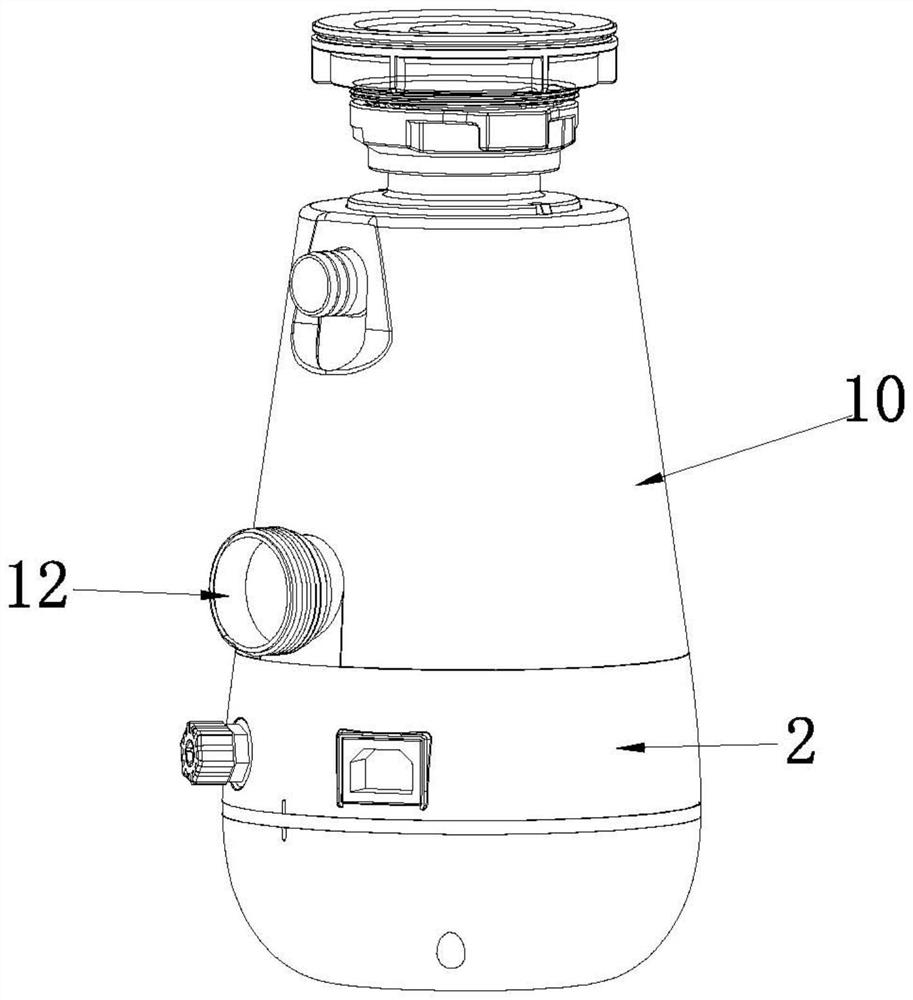

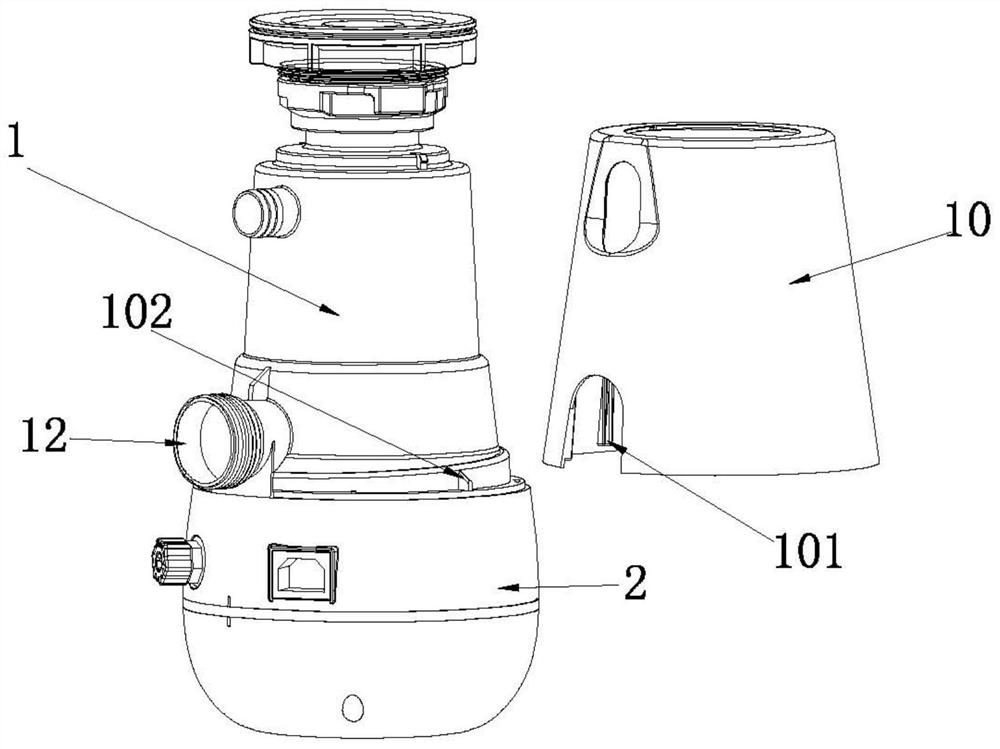

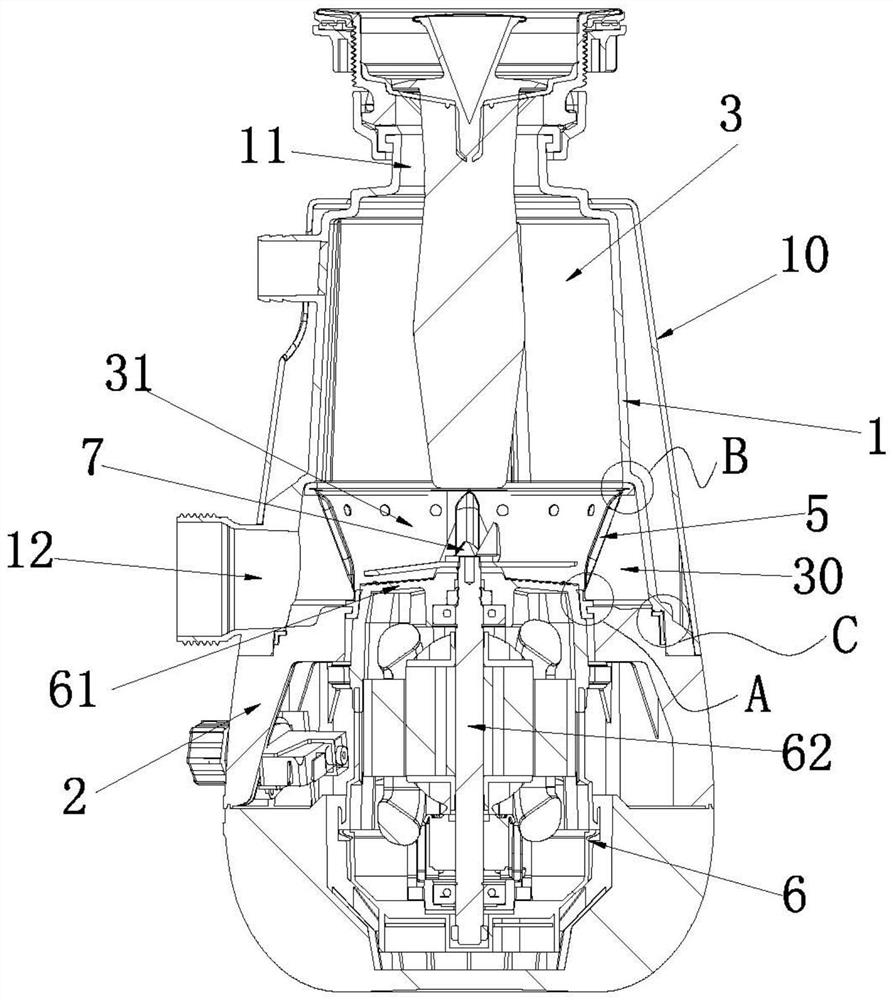

Garbage processor

ActiveCN112814091AReasonable structural designImprove smashing effectDomestic plumbingElectric machineRefuse Disposals

The invention relates to the technical field of garbage processors, in particular to a garbage processor. The garbage processor comprises a middle shell and an upper shell covering the middle shell; the upper shell is provided with a water inlet and a water outlet; a filter screen is arranged in the upper shell, so that the interior of the upper shell is divided into an inner cavity communicating with the water inlet and an outer cavity communicating with the water outlet; and the bottom of a smashing cavity is formed above the middle shell, a cavity provided with a motor assembly is formed below the middle shell, a main shaft of the motor assembly extends into the inner cavity, and the main shaft is fixedly connected to a smashing cutter located in the inner cavity. The garbage processor is reasonable in structural design, good in smashing effect, high in working efficiency, capable of well solving the problem of heating of the motor, good in overall structural sealing performance and low in noise during working.

Owner:SMARTFISH TECH

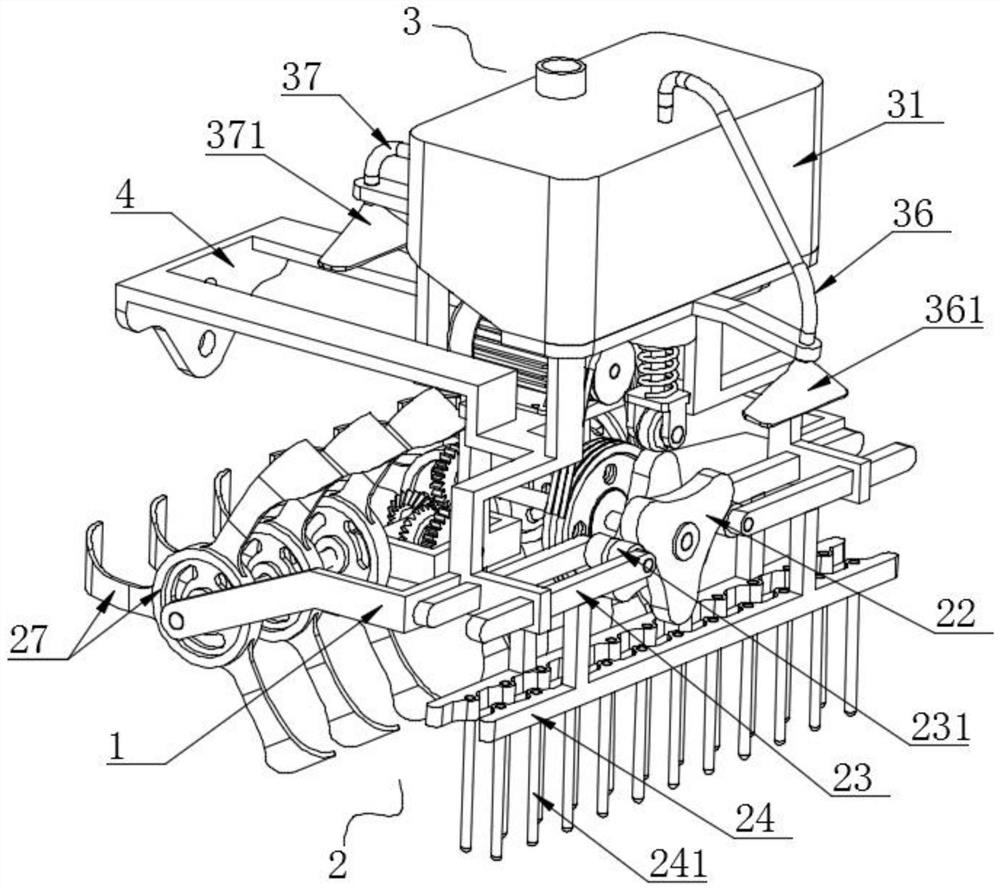

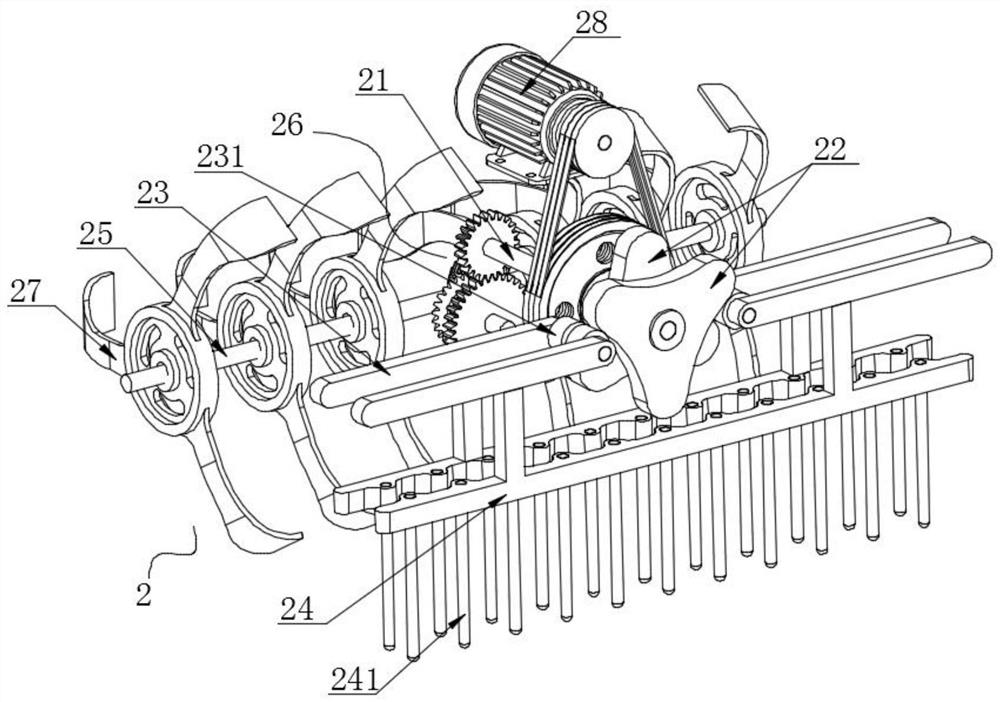

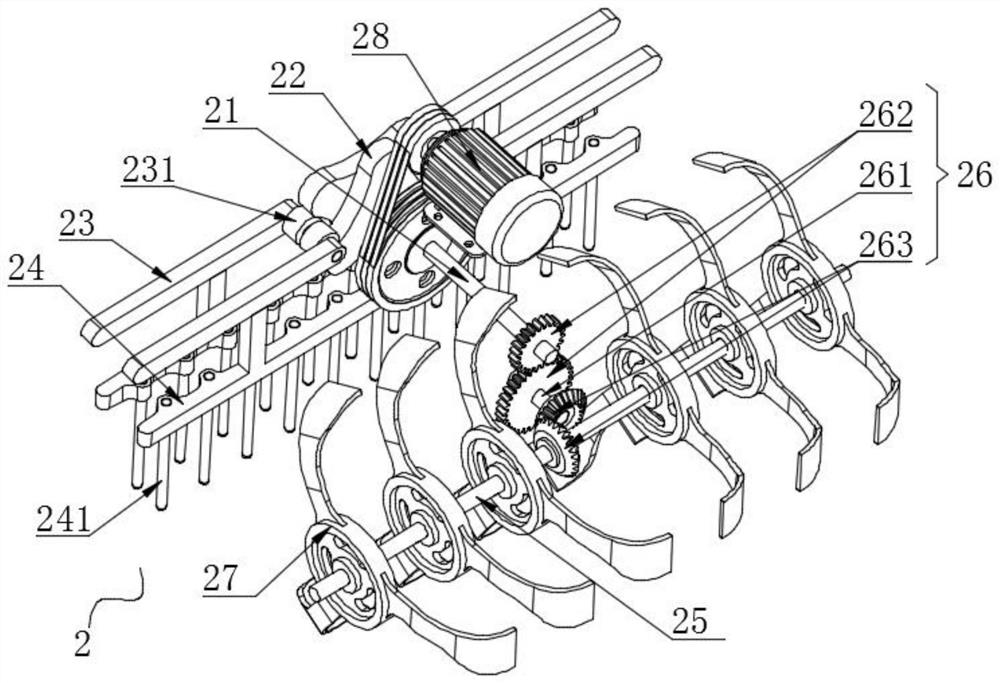

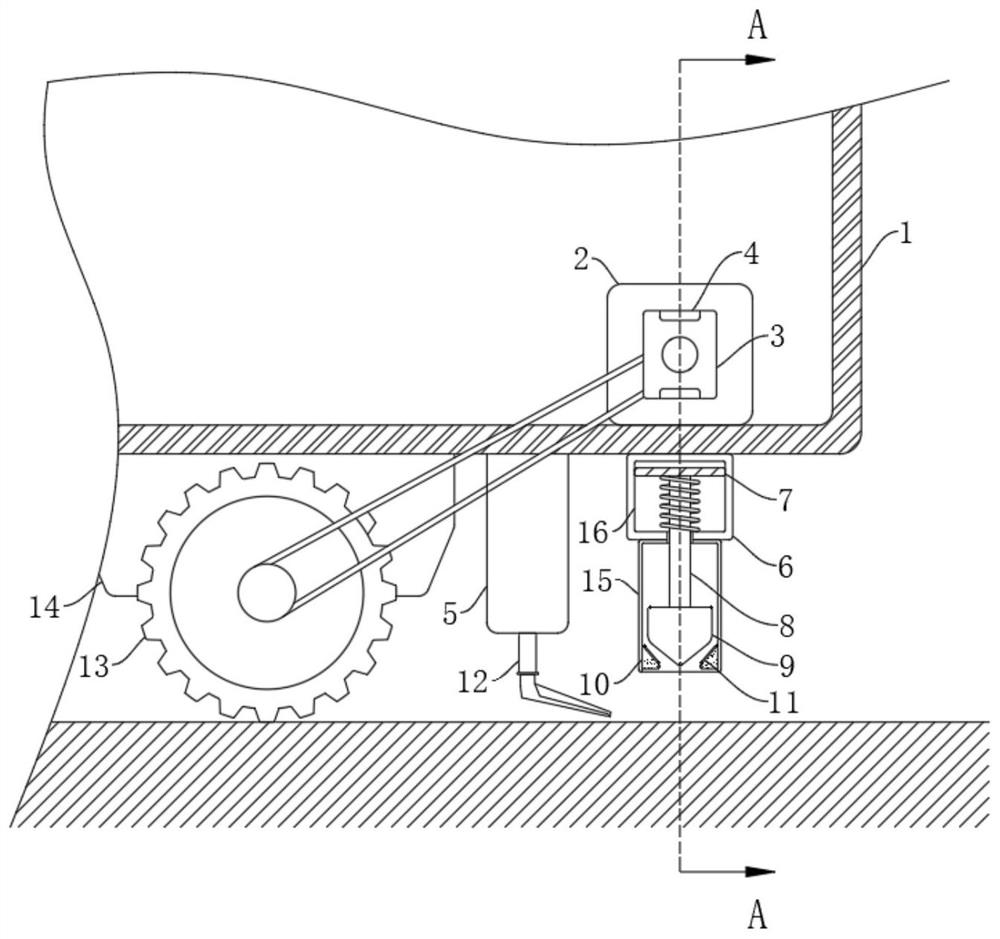

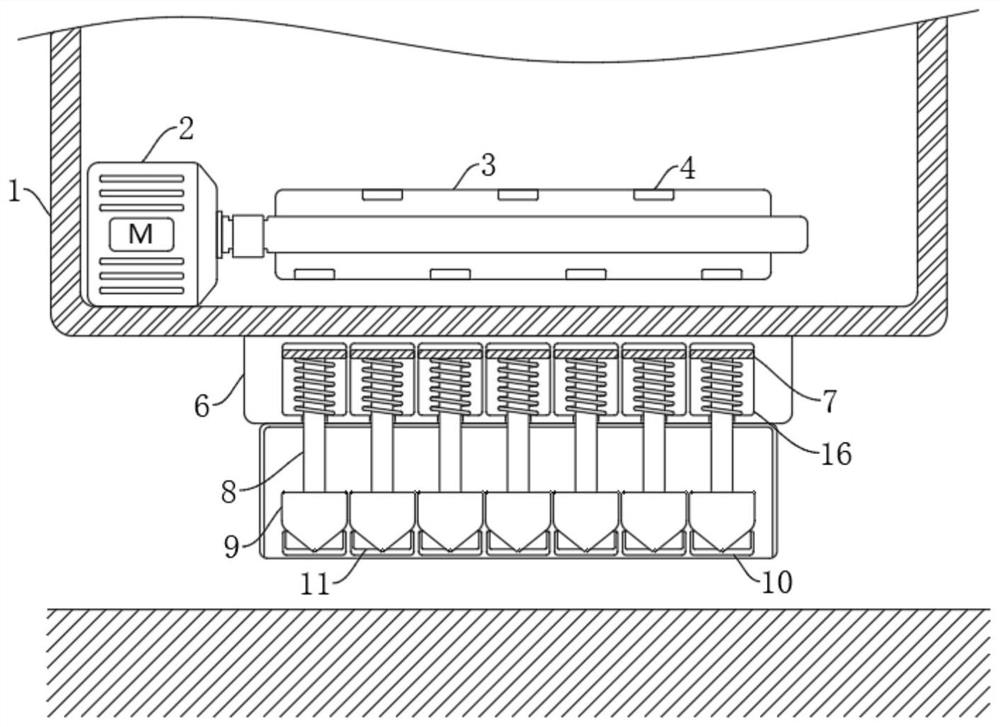

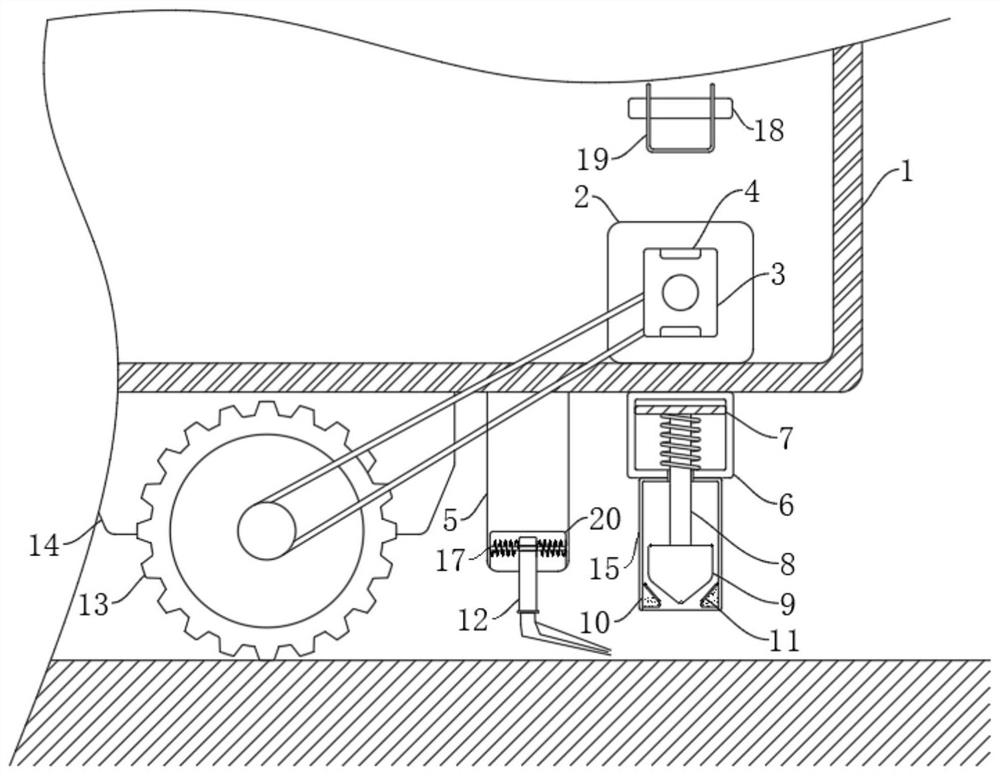

Soil turning equipment for agricultural planting

InactiveCN113196902ALarge range of smashingImprove smashing effectSpadesUsing liquid separation agentAgricultural engineeringStructural engineering

The invention discloses soil turning equipment for agricultural planting, and particularly relates to the technical field of agricultural machinery. The soil turning equipment comprises a rack, wherein a working mechanism is arranged below the rack, the working mechanism comprises a main shaft, two triangular cams are fixedly mounted at one end of the main shaft, movable rods are arranged on the two sides of the two triangular cams, the four movable rods are all movably connected with the rack in an inserted mode, the ends, close to the triangular cams, of the four movable rods are all rotationally connected with first rolling wheels, and the four first rolling wheels are attached to the outer side walls of the two sides of the two triangular cams correspondingly. Through the arrangement of the working mechanism, on one hand, soil can be turned under the rotation of a soil turning cutter wheel, on the other hand, in the process that the two rows of slender rods move back and forth in the opposite directions, turned-out soil can be smashed in time, and due to the fact that the two rows of slender rods are movable and the movement directions are opposite, the smashing range is large, the smashing effect is good, and no dead angle is left.

Owner:易玉媛

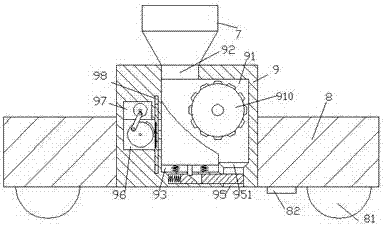

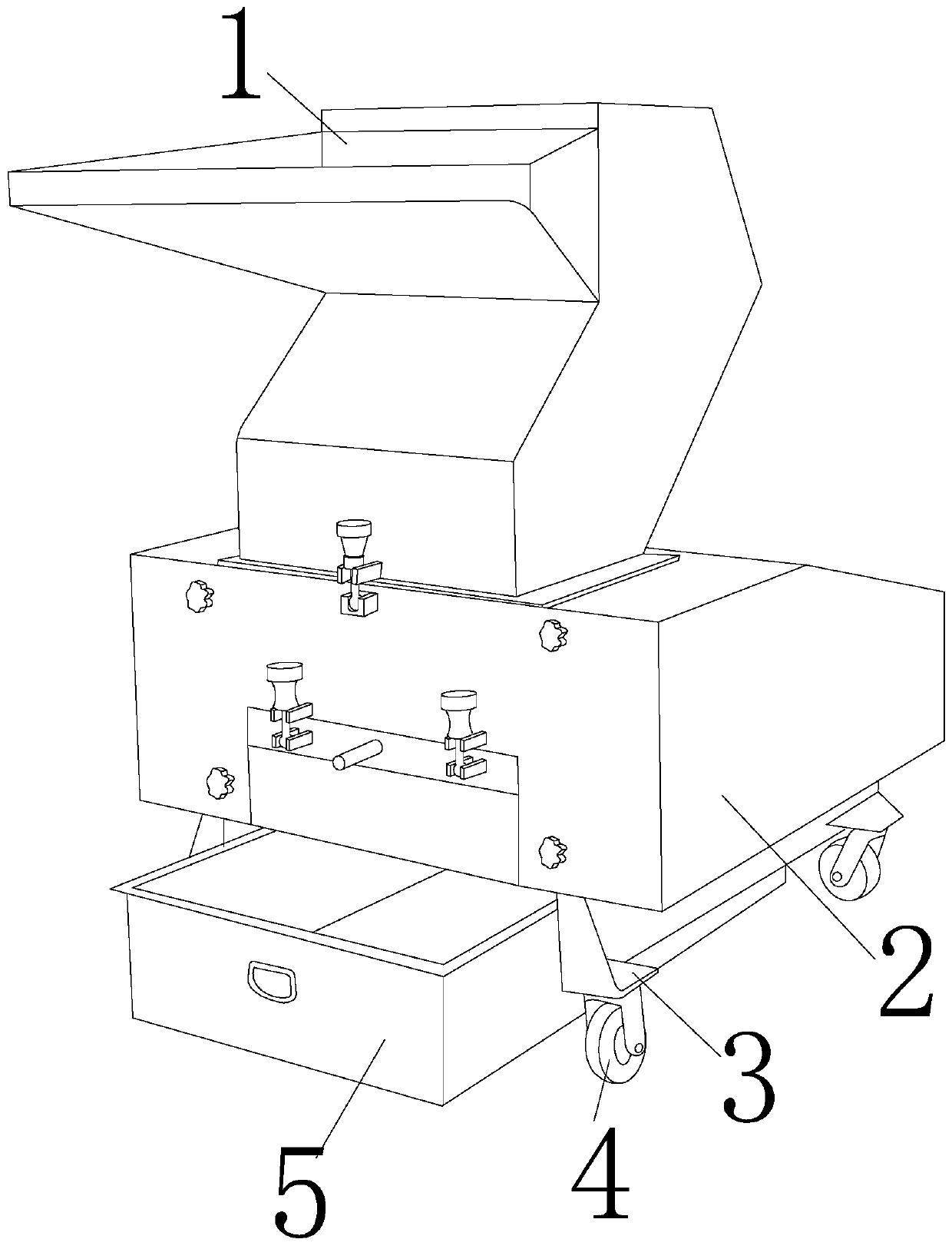

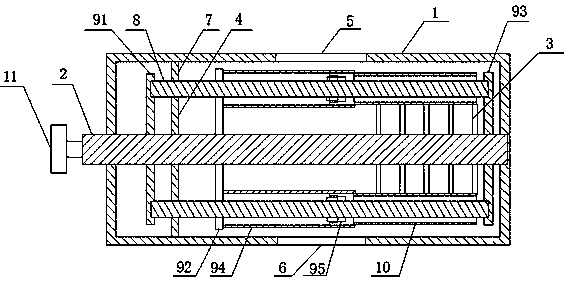

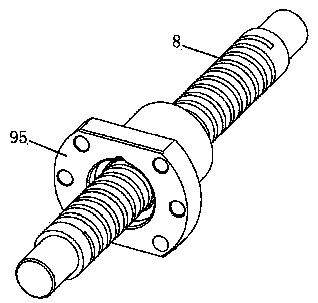

A shredder used for cable extruded plastic recycling

ActiveCN107901289BEvenly crushedSave spacePlastic recyclingGrain treatmentsElectric machineryStructural engineering

The invention discloses a pulverizer used for cable extruded plastic recycling. The structure includes a dustproof curtain, a pulverizer body, a support, universal wheels, and a storage drawer. The front top of the pulverizer body is equipped with a dustproof curtain. , the four corners of the bottom surface of the pulverizer body have supports fixedly connected thereto. There are four supports, and the bottom surfaces of the supports are mechanically connected to the universal wheels. The beneficial effect of the shredder used for the recycling of cable extruded plastics is that the device is provided with a first crushing mechanism and a second crushing mechanism, the first crushing mechanism is for coarse crushing of cable extruded plastics, and the second crushing mechanism is for finely crushing cable extruded plastics. Crushing can be directly recycled without re-crushing, saving space, improving work efficiency and improving the effect of pulverization, and only one motor is used, which can effectively improve operating stability and reduce operating noise at low cost.

Owner:TIANJIN JINHANG COMP TECH RES INST

Aloe vera mud making equipment for moisturizing hand cream

The invention relates to the technical field of moisturizing hand cream making, and discloses aloe vera mud making equipment for moisturizing hand cream. The aloe vera mud making equipment comprises abase, a frame is fixedly connected to the top of the base, an aloe making mechanism is arranged on the left side of the inner wall of the frame, a position restrain mechanism is arranged on one sideof the top of the frame, and the bottom of the position restrain mechanism is movably connected to the aloe making mechanism. A power execution mechanism is arranged on the other side of the top of the frame, and a position changing mechanism is arranged on the right side of the inner wall of the frame. The up-down movement of the aloe vera mud making equipment simulate the manual operation to beat aloe in a stable placement mechanism, the problems that the fiber inside the aloe is prevented from being ground and active ingredients in the aloe is reduced are solved, and the power execution mechanism drives the stable placement mechanism to move left and right stably through the position changing mechanism to completely and fully beat the aloe in the stable placement mechanism, so that themaking effect of the aloe vera mud is better.

Owner:珠海积家世纪日化有限公司

Waste recycling and crushing device for plastic sheet production

InactiveCN112339180AImprove crushabilityGuaranteed crushing effectPlastic recyclingMechanical material recoveryEnvironmental engineeringWaste material

The invention discloses a waste recycling and crushing device for plastic sheet production, and relates to the technical field of waste recycling. The waste recycling and crushing device comprises a working tank, wherein feeding ports are formed in the left side face and the right side face of the working tank, and feeding plates are in threaded connection with the inner walls of the feeding portsthrough bolts; and a first transmission mechanism used for feeding, a second transmission mechanism used for discharging, a crushing mechanism used for crushing plastic sheets and an intermittent mechanism used for intermittent discharging are arranged in the working tank. According to the waste recycling and crushing device, the crushing effect is good; the plastic sheets can be crushed throughthe crushing mechanism firstly, and then the crushed plastic sheets are intermittently discharged through the intermittent mechanism, so that the crushing effect of the plastic sheets is guaranteed; then the plastic sheets are crushed through crushing rollers, and finally the plastic sheets fall onto an anti-static rubber conveying belt to be discharged, so that crushed small-particle plastic fragments are prevented from staying in the crushing device, and discharging and normal operation of equipment are prevented from being influenced.

Owner:安徽高伟新材料科技有限公司

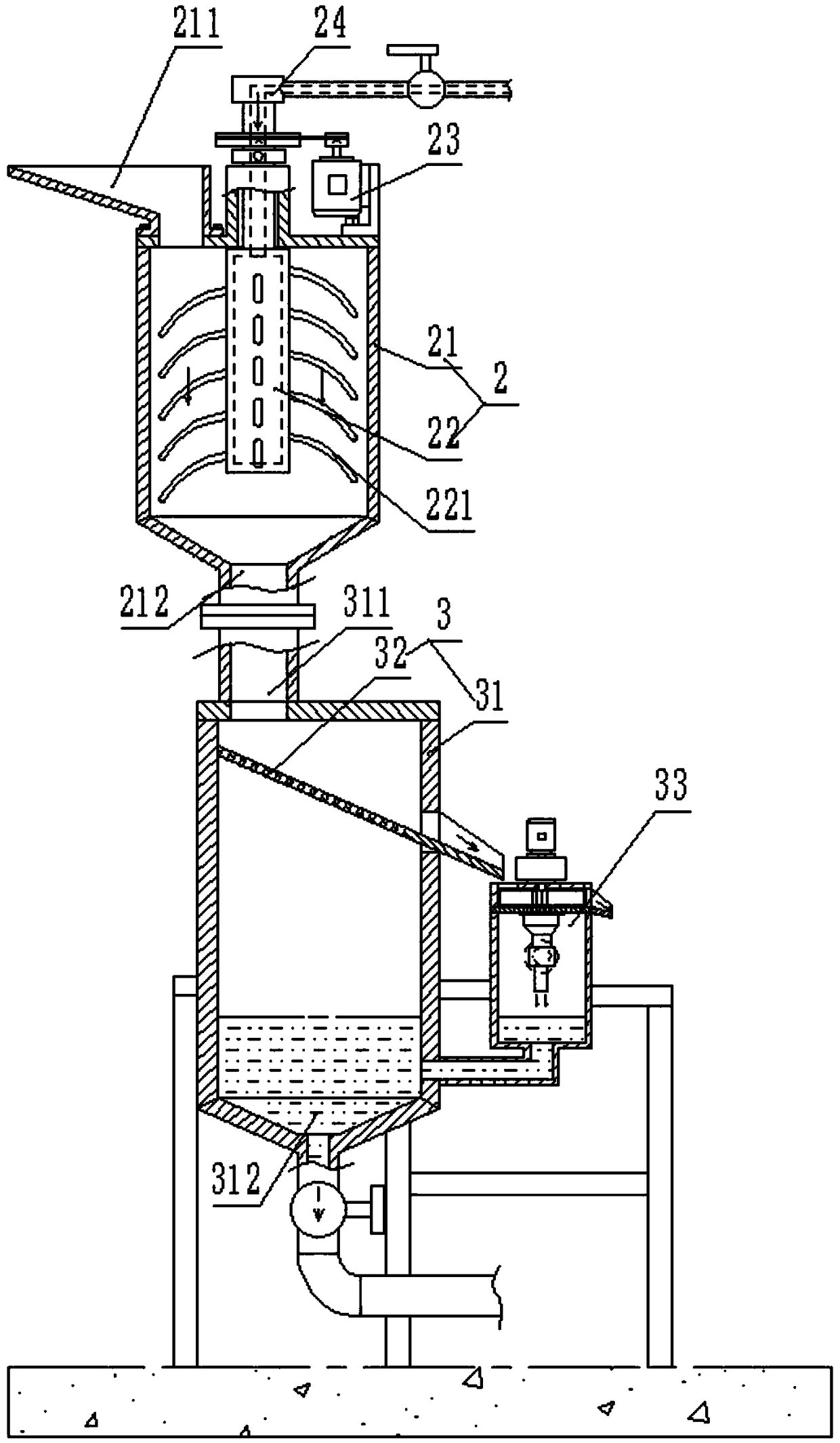

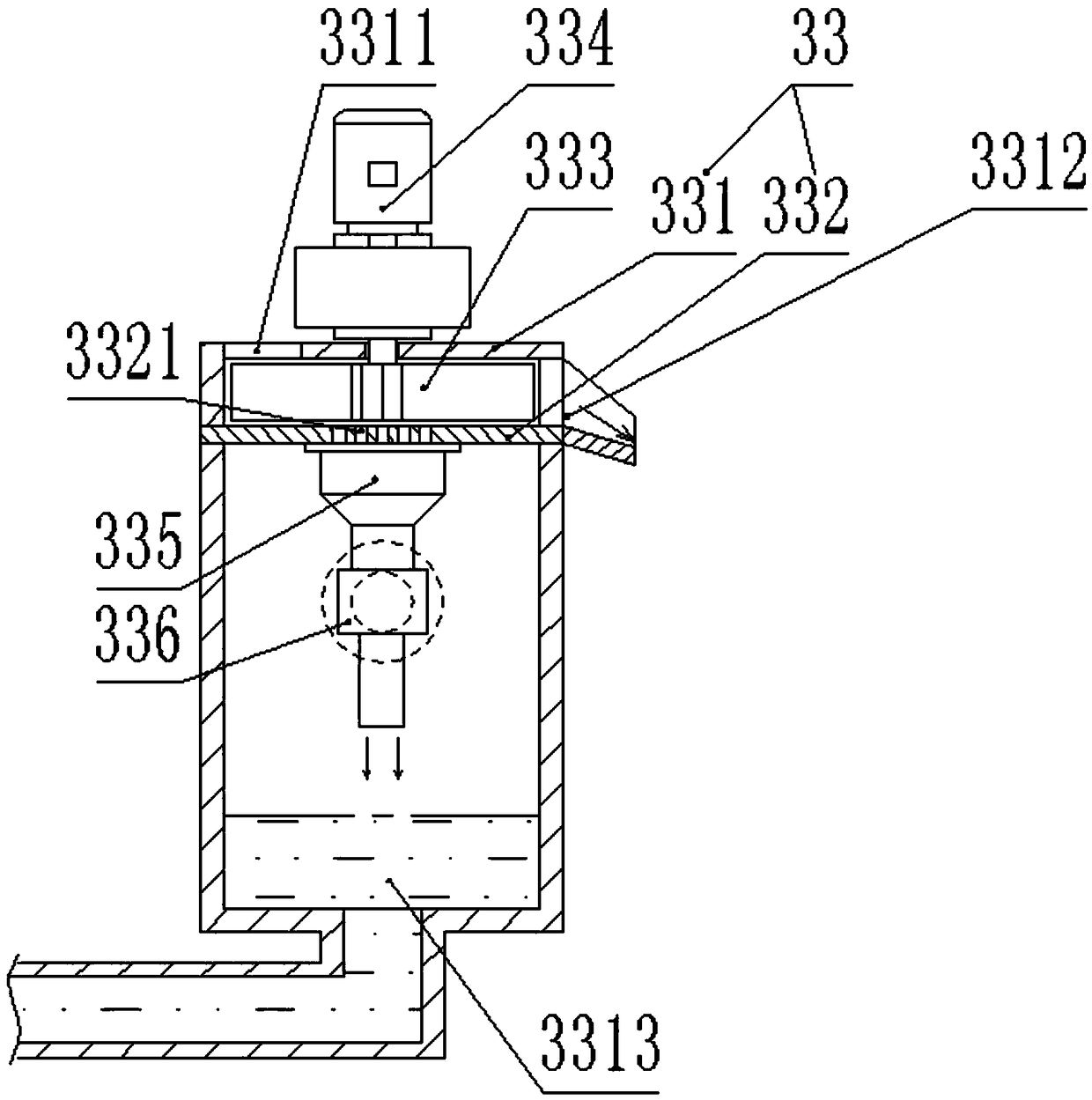

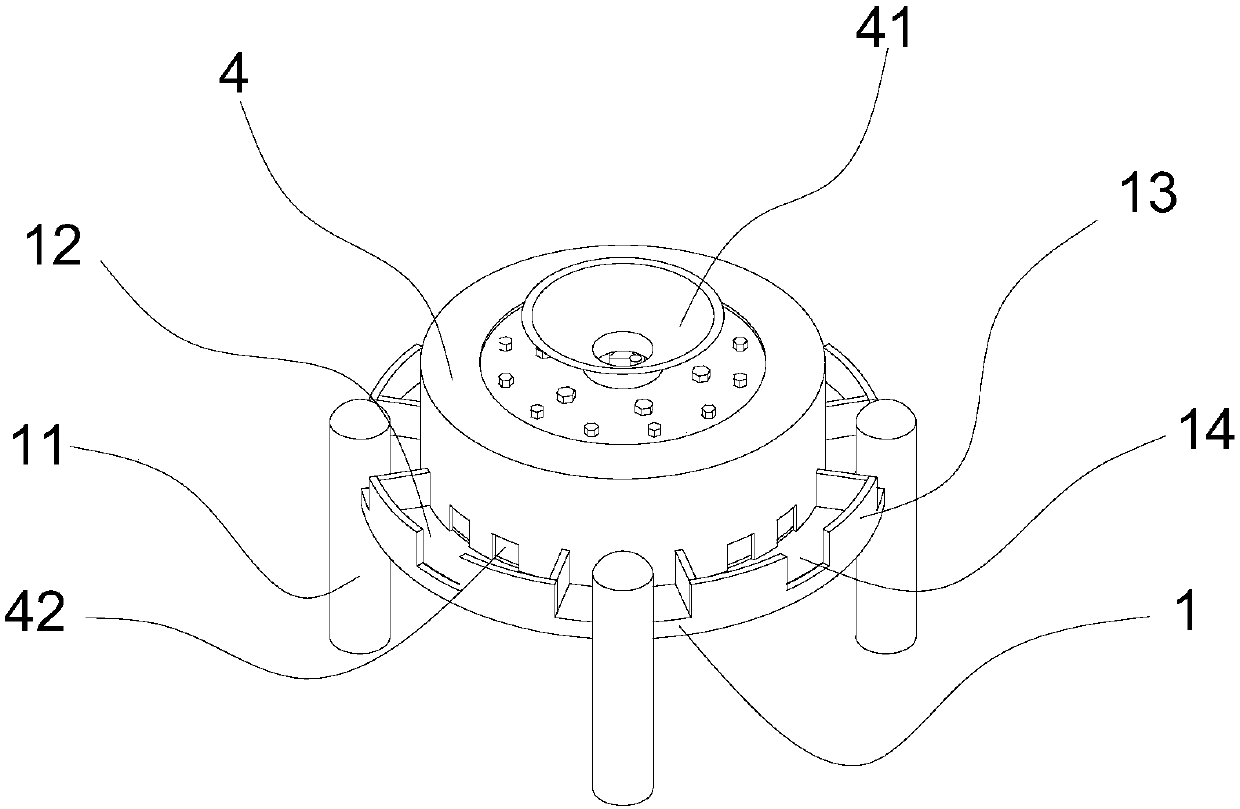

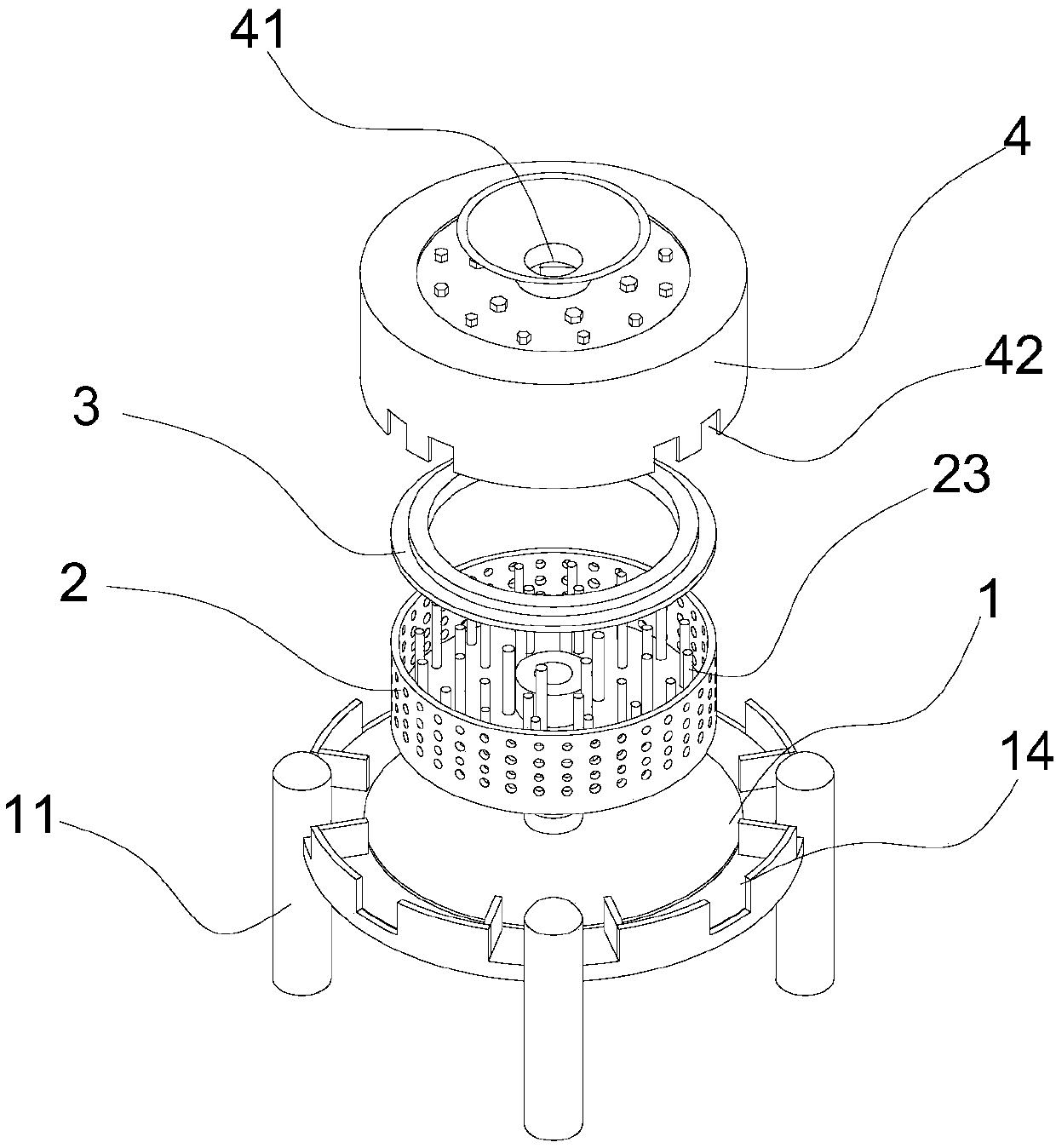

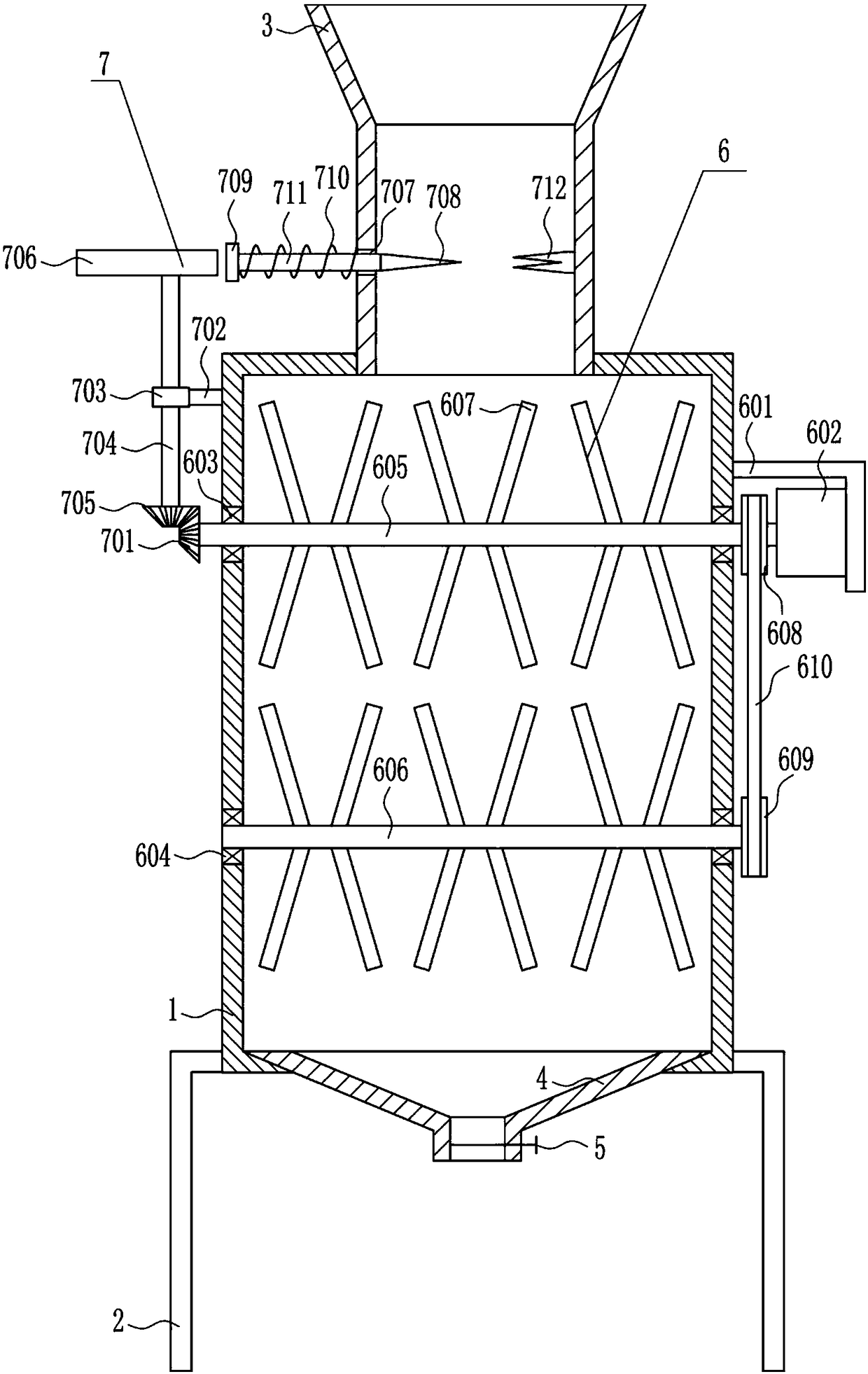

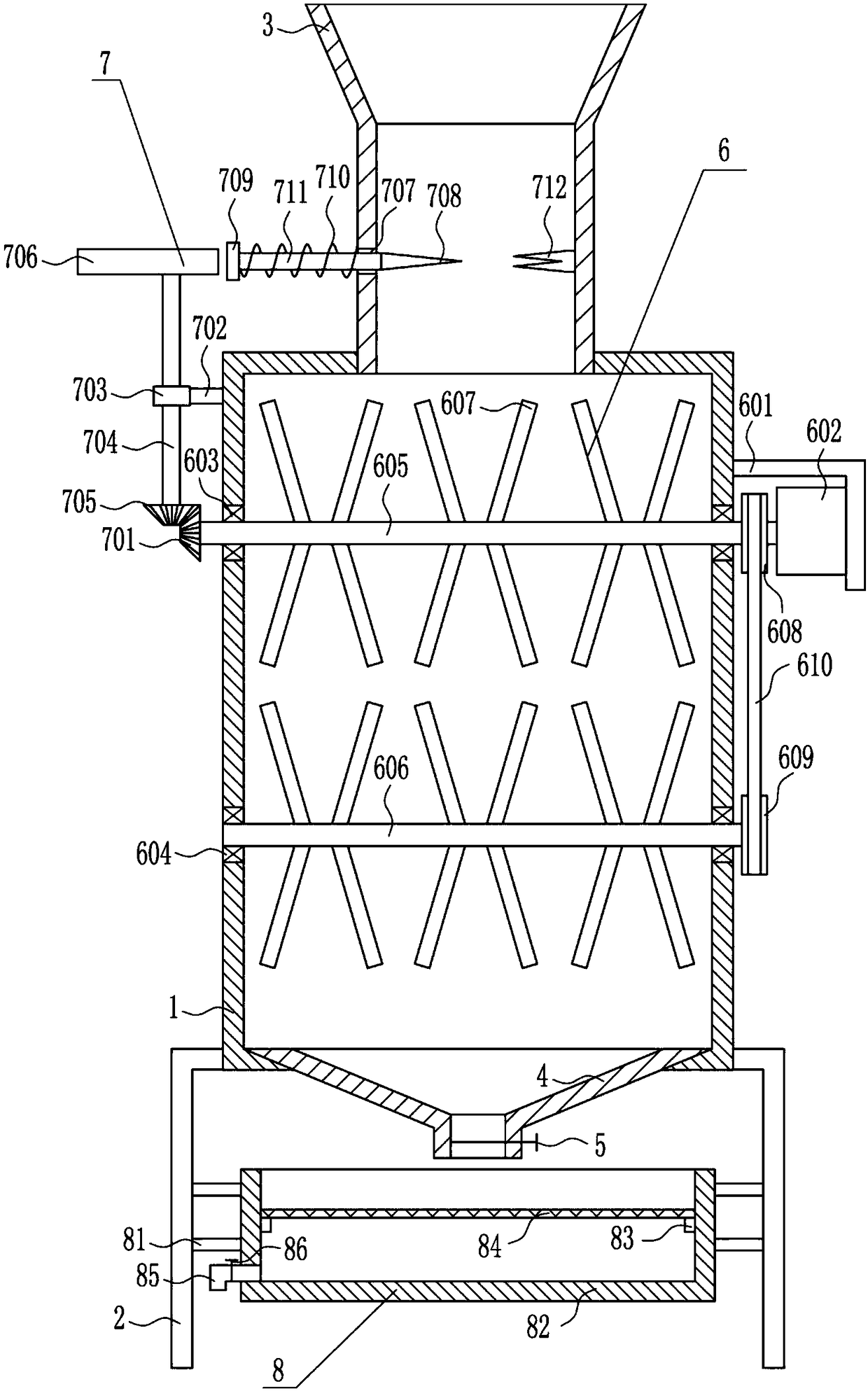

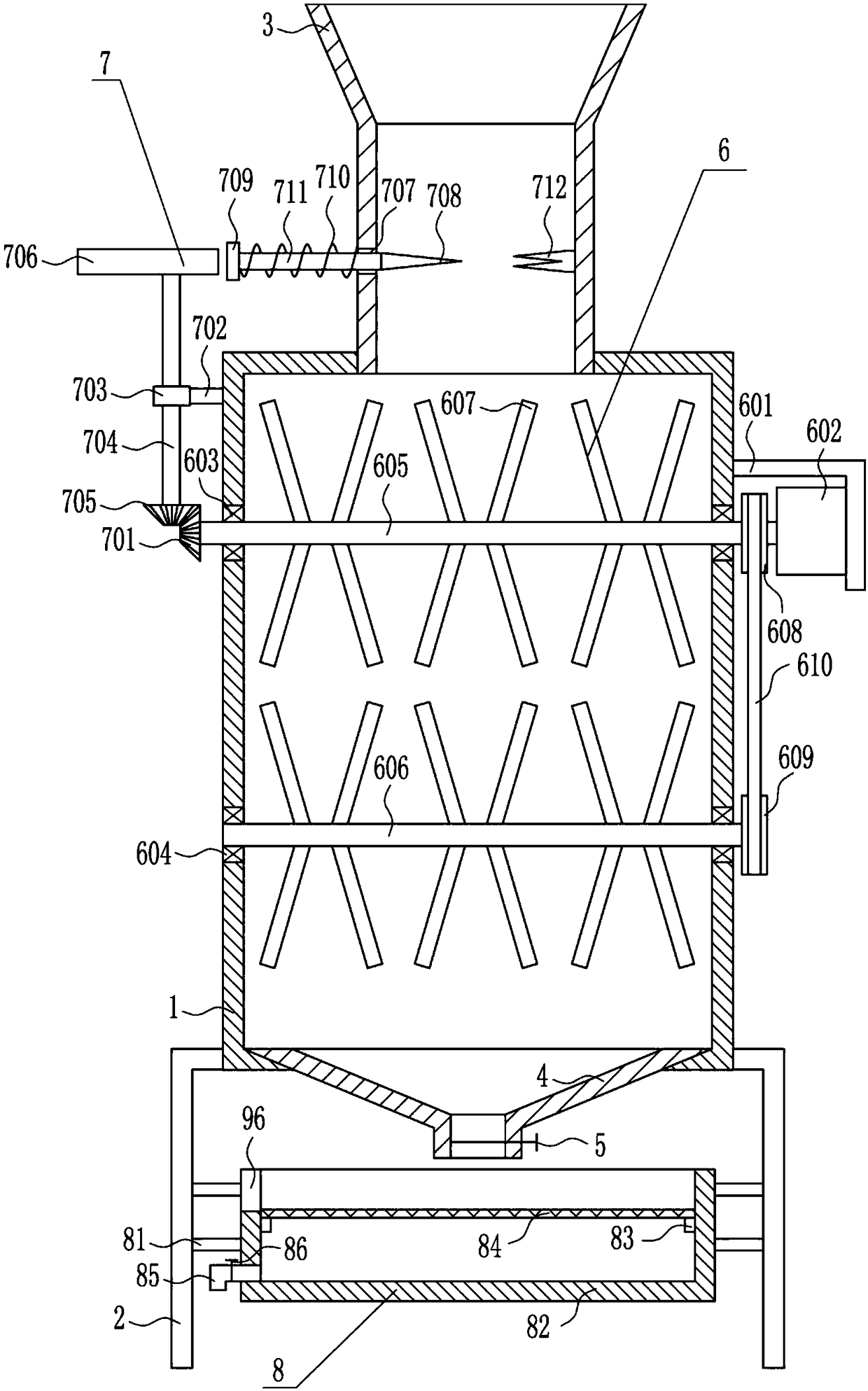

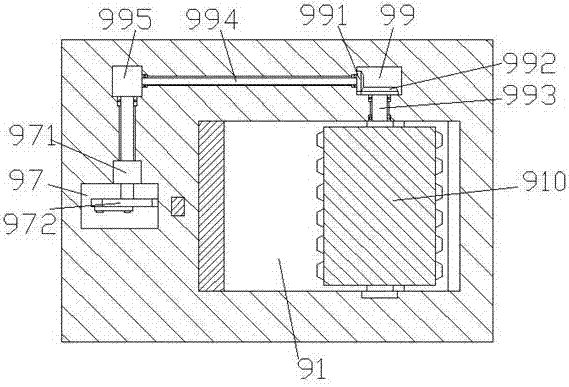

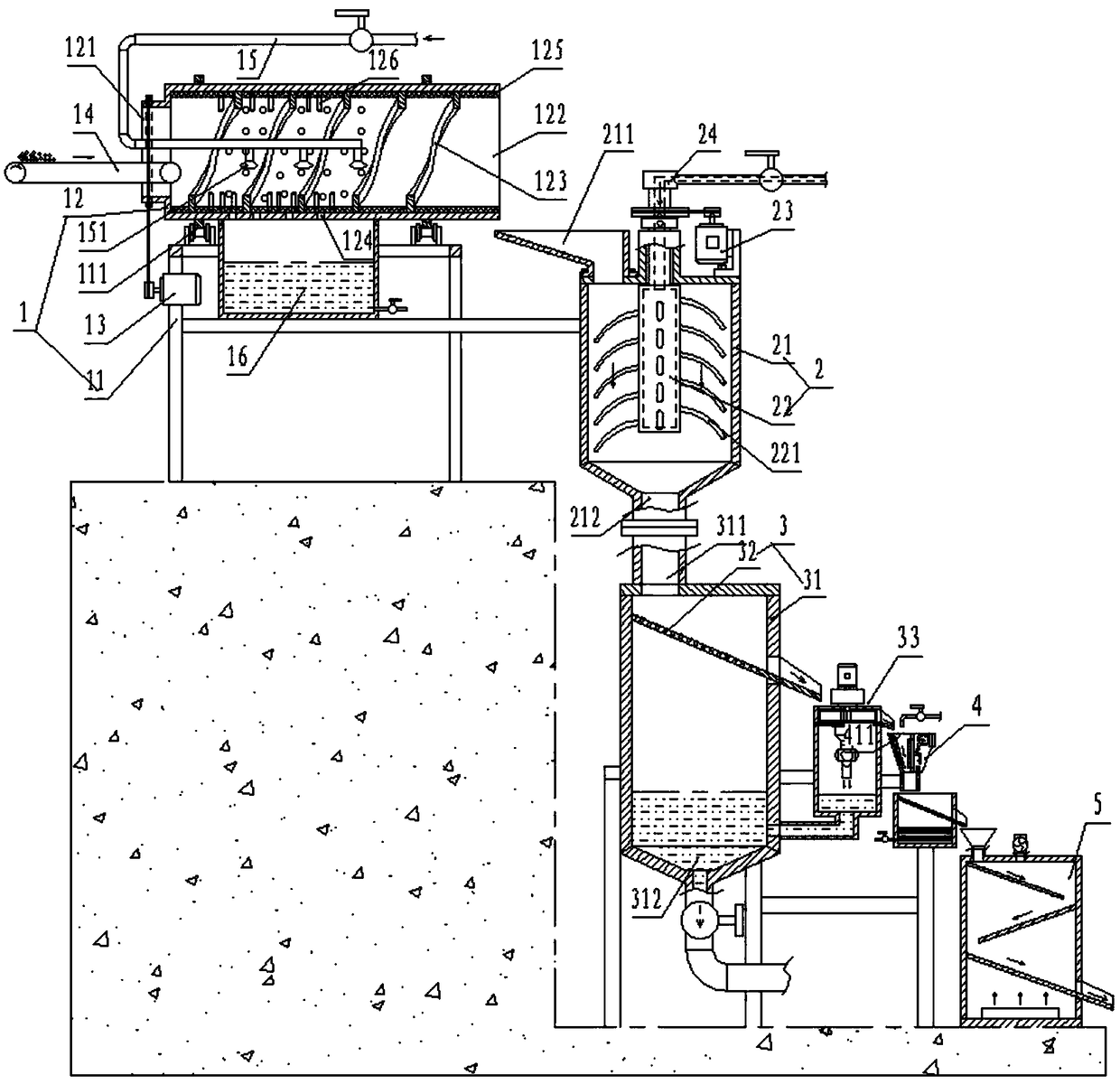

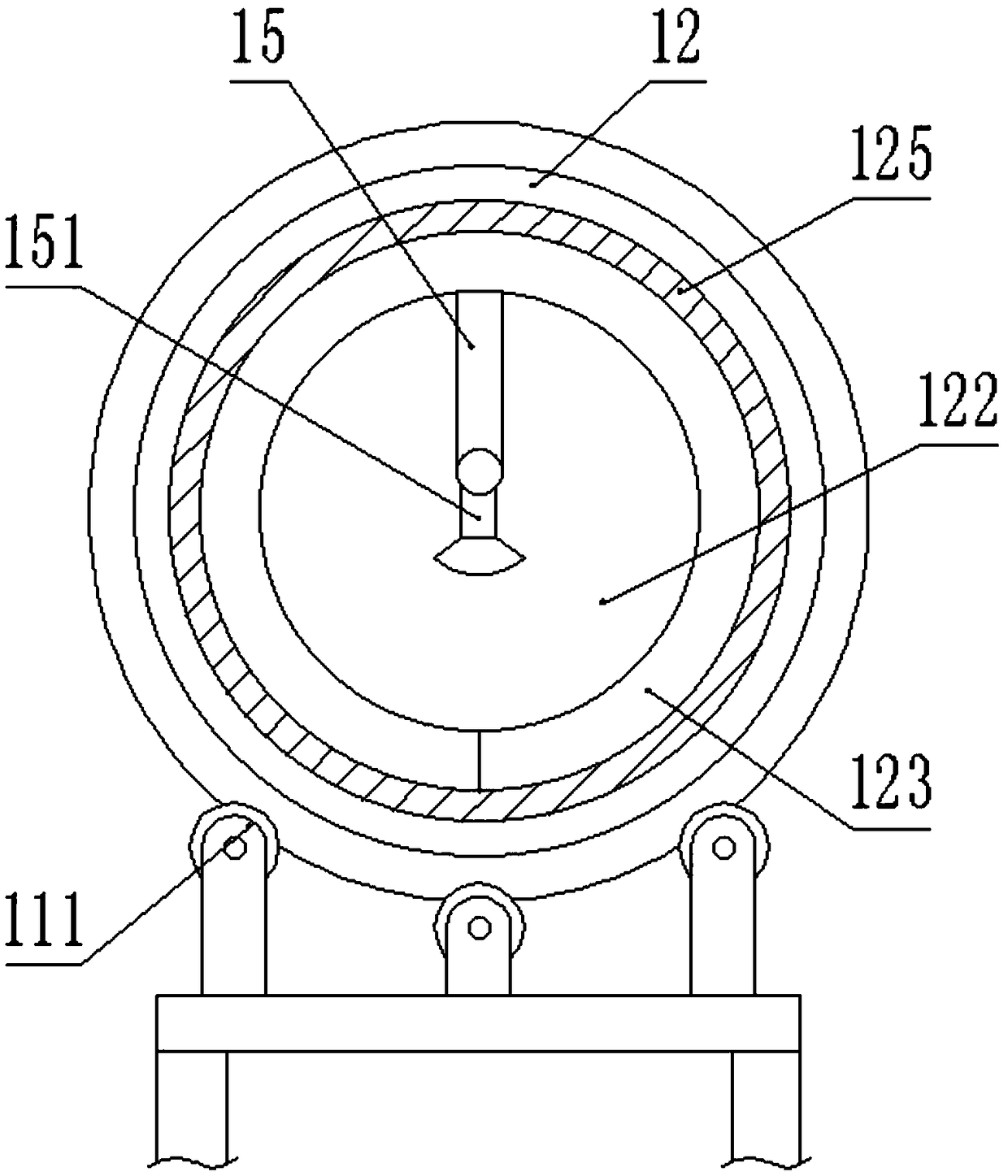

High-quality separating and drying processing equipment for grape seeds

InactiveCN109304239AGood smashing effectEasy to operateCleaning using liquidsGrain treatmentsGrape seedGrapes seeds

The invention discloses high-quality separating and drying processing equipment for grape seeds. The high-quality separating and drying processing equipment for the grape seeds comprises a grape crushing machine, a crushing and filtering machine, a grape seed scrubbing machine and a drying machine; crushing strips are arranged on the outer circumference of a crushing machine drum of the grape crushing machine and used for irregularly crushing grapes; the crushing and filtering machine is used for separating serous fluid from the grape seeds and secondarily recycling residual serous fluid on the grape seeds; the grape seed scrubbing machine is used for scrubbing the surfaces of the grape seeds through reciprocating moving of a scrubbing plate and a scrubbing machine U-shaped shell to thoroughly remove residues on the surfaces of the grape seeds; and the drying machine is used for drying and heating the grape seeds through a heating plate, and then the grape seeds can be conveniently stored. According to the high-quality separating and drying processing equipment for the grape seeds, the grape seeds are completely separated, cleaned and dried, and the integration is high.

Owner:南方葡萄沟酒庄有限公司

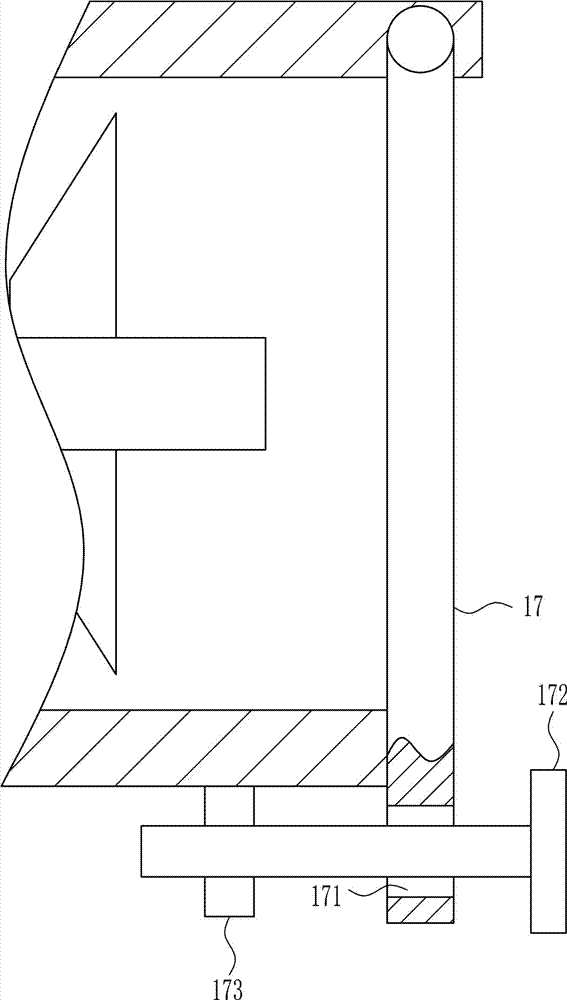

Soil beating crusher used for soil remediation

InactiveCN107824274AEasy to operateThe principle is simpleContaminated soil reclamationGrain treatmentsLinear motionSoil remediation

The invention discloses a soil breaking machine for soil restoration, which comprises a soil crushing cylinder, four vertical legs are arranged on the bottom side of the rectangular ring of the soil crushing cylinder, and the four vertical legs are fixedly connected with the soil crushing cylinder. The side of the crushing barrel far away from the vertical leg is fixedly connected with a feed plate communicating with the crushing barrel, and the side of the crushing barrel close to the vertical leg is hinged with a discharge plate, and the discharge plate is far away from its hinge. One side is fixedly connected with a bump, and the crushing tube is also fixedly connected with a bump corresponding to the bump on the discharge plate, and two blocks are sleeved on the two bumps, and the center of the crushing tube is inserted. A main shaft is provided, and the outer side of the main shaft located inside the crushing cylinder is fixedly connected with a plurality of crushing claws. The end of the main shaft away from the crushing claws is covered with a moving plate, and the side of the moving plate away from the main shaft is fixedly connected with a motor. The invention has a novel structure. When the main shaft is rotated, the lead screw is used to make the main shaft do a reciprocating linear motion in the soil crushing cylinder, so that the crushing effect is better.

Owner:合肥挺泰环保科技有限公司

Device for bridge construction

ActiveCN107413506AImprove smash effectAutomatic control crushing workGrain treatmentsCrusherArchitectural engineering

The invention discloses a device for bridge construction. The device comprises a machine seat and a stone crusher installed in the machine seat. The stone crusher is internally provided with a crushing portion, the inner top wall on the right side of the crushing portion is provided with a stone inlet in a penetrated manner, and the inner bottom wall on the left side of the crushing portion is internally provided with a movement guide cavity. The position, on the right side of the movement guide cavity, of the inner bottom wall of the crushing portion is internally provided with a lower discharging opening in a penetrated manner, and the top of the lower discharging opening is provided with a conical groove. The movement guide cavity is internally connected with a rising-landing slippage block extending upwards in a slippage fit manner, the extending segment at the top of the rising-landing slippage block stretches into the crushing portion, and the top, stretching into the crushing portion, of the rising-landing slippage block is provided with an arc surface extending in the lower right direction. The movement guide cavity under the bottom of the rising-landing slippage block is internally provided with first elastic pieces, the inner wall on the left side of the crushing portion is internally provided with a transfer groove, the inner top wall on the left side of the transfer groove is internally provided with a square groove in a connected manner, and right side of the transfer groove is internally provided with a first movement guide groove extending vertically in a penetrated manner. The device is simple in structure and convenient to operate, the crushing effect of hardened fertilizer is improved, the amount of labor is reduced, and stone crushing uniformity is improved.

Owner:宿州市徽腾知识产权咨询有限公司

Feed stirring device

ActiveCN107020043AStir wellEasy to operateShaking/oscillating/vibrating mixersTransportation and packagingEngineeringUltimate tensile strength

Owner:NANTONG WEALTH MASCH TECH CO LTD

Novel magnetic type snow shoveling device

The invention discloses a novel magnetic type snow shoveling device. The device comprises a vehicle body; the lower wall of the vehicle body is fixedly connected with two baffles; the opposite side walls of the two baffles are jointly and rotationally connected with a driving shaft; two driving wheels are fixedly connected to the side wall of the driving shaft; a drive motor is fixedly connected to the bottom in the vehicle body; an output shaft of the drive motor is fixedly connected with a drive shaft; the drive shaft is in transmission connection with the driving shaft through a belt; a mounting plate is fixedly connected to the lower wall of the vehicle body; a snow shovel is fixedly connected to the lower wall of the mounting plate; a crushing mechanism is arranged on the vehicle bodyand comprises a rotating block fixedly connected to the side wall of the drive shaft; and a plurality of permanent magnet plates are fixedly embedded in the upper side wall and the lower side wall ofthe rotating block. According to the invention, ice layers on the road surface can be crushed and shoveled to the two sides of the road, the ice layers on the road surface are prevented from causingdanger to passing vehicles and pedestrians, the time and energy of people are greatly saved, and the working efficiency is improved.

Owner:台州市路桥昱强塑料有限公司

Intelligent feed processing and crushing device

InactiveCN109331970AAvoid cloggingExtended service lifeFeeding-stuffGrain treatmentsSpiral bladeEngineering

The invention discloses an intelligent feed processing and crushing device. The intelligent feed processing and crushing device comprises a crushing barrel, the upper portion of the crushing barrel isprovided with a feeding port, the lower portion of the crushing barrel is provided with a discharging port, straw feed enters the crushing barrel through the feeding port, and crushed feed is outputfrom the discharging port; a rotating shaft is arranged in the crushing barrel and supported on a crushing barrel shell through a bearing, and a spiral blade is fixed to the right end of the rotatingshaft; a sun gear is arranged on the rotating shaft, the outer side of the sun gear meshes with multiple planet gears, the planet gears mesh with a gear ring fixed to a barrel body, the planet gears is connected with planet carriers through planet gear shafts, and screw shafts are adopted as the planet gear shafts; and the sun gear rotates to drive the planet gears to rotate, the planet gears revolve around the sun gear while the planet gears rotate, the planet gears are fixed to the planet gear shafts, the planet gear shafts revolve around the axis of the rotating shaft while the planet gearshafts rotate, the planet gear shafts rotate to drive a nut assembly to move left and right, therefore, anti-blocking blades of the nut assembly are driven to move left and right, the interior of thebarrel body is dredged, and blocking is prevented.

Owner:枣庄金科农业科技有限公司

Comprehensive grape pip recycling treatment equipment

InactiveCN109304241ARemoval of pesticide residuesGuaranteed production efficiencyCleaning using liquidsGrain treatmentsReciprocating motionSlurry

The invention discloses comprehensive grape pip recycling treatment equipment. The comprehensive grape pip recycling treatment equipment comprises a grape cleaning machine, a grape crushing machine, acrushing and filtering machine, a grape pip scrubbing machine and a drying machine. A roller on the grape cleaning machine rolls, and nondestructive cleaning is conducted on grapes. Crushing strips are arranged at the outer circumference of a crushing machine rotating barrel of the grape crushing machine, and irregular crushing is conducted on the grapes. Pulp and grape pips are separated throughthe crushing and filtering machine. According to the grape pip scrubbing machine, the surfaces of the grape pips are scrubbed through reciprocating motion of a washboard and a scrubbing machine U-shaped shell. According to the drying machine, the grape pips are dried and heated through a heating plate. According to the comprehensive grape pip recycling treatment equipment, grape grains are cleaned through the roller type cleaning machine; the grapes are crushed irregularly through the grape crushing machine; the grape mixed pulp and the grape pips are separated through the crushing and filtering machine; residual pulp layers on the surfaces of the grape pips are scrubbed through the grape pip scrubbing machine; and drying treatment is conducted on the grape pips through the drying machine, so that storage is convenient to conduct.

Owner:南方葡萄沟酒庄有限公司

Continuous separation equipment with cleaning device for grapes

InactiveCN109288098AGood removal effectEasy to washJuice extractionFood treatmentPesticide residueGrape seed

The invention discloses continuous separation equipment with a cleaning device for grapes. The continuous separation equipment comprises a grape cleaning machine, a grape breaking machine and a breaking filtering machine, wherein the grape cleaning machine comprises a rack and a horizontally arranged roller, wherein when the roller rolls, grapes are thoroughly and nondestructively cleaned by a flexible pad on an inner wall, and are delivered by an internal spiral delivering strip; and the grape breaking machine comprises a breaking machine shell and a breaking machine rotating drum, and flexible breaking strips are alternately arranged on the outer circumference of the breaking machine rotating drum and used for irregularly breaking grape skin and grape pulp without breaking grape seeds toensure complete separation. The invention aims at providing the continuous separation equipment with the cleaning device for grapes; the cleaning machine can clean the grapes, remove pesticide residue and perform continuous production; and the grape breaking machine can irregularly break the grapes by the quickly rotating flexible breaking strips without breaking the grape seeds to ensure the integrity of the grape seeds.

Owner:南方葡萄沟酒庄有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com