Dried potato powder production device for food processing

A technology of food processing and production equipment, which is applied in the field of potato flour production equipment for food processing, which can solve the problems of low conversion efficiency, troublesome production, and affecting the use of residents, and achieve high efficiency and good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

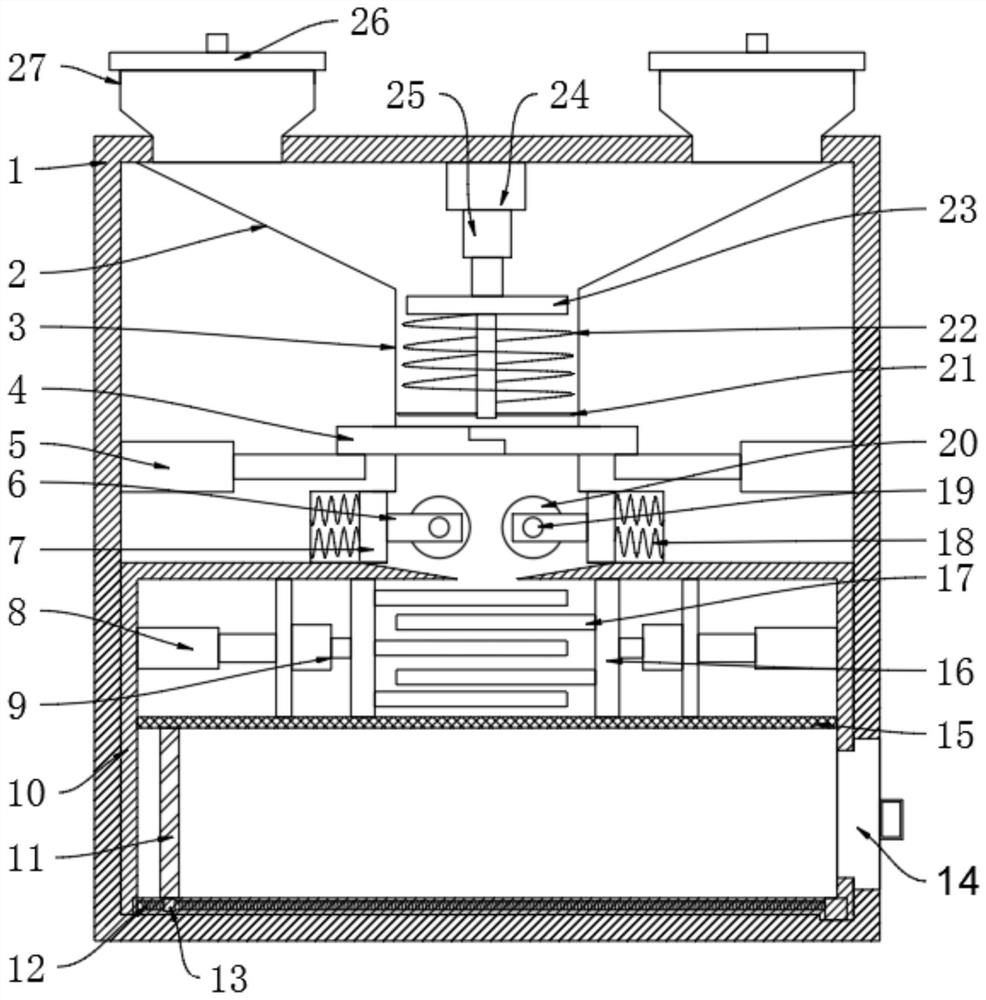

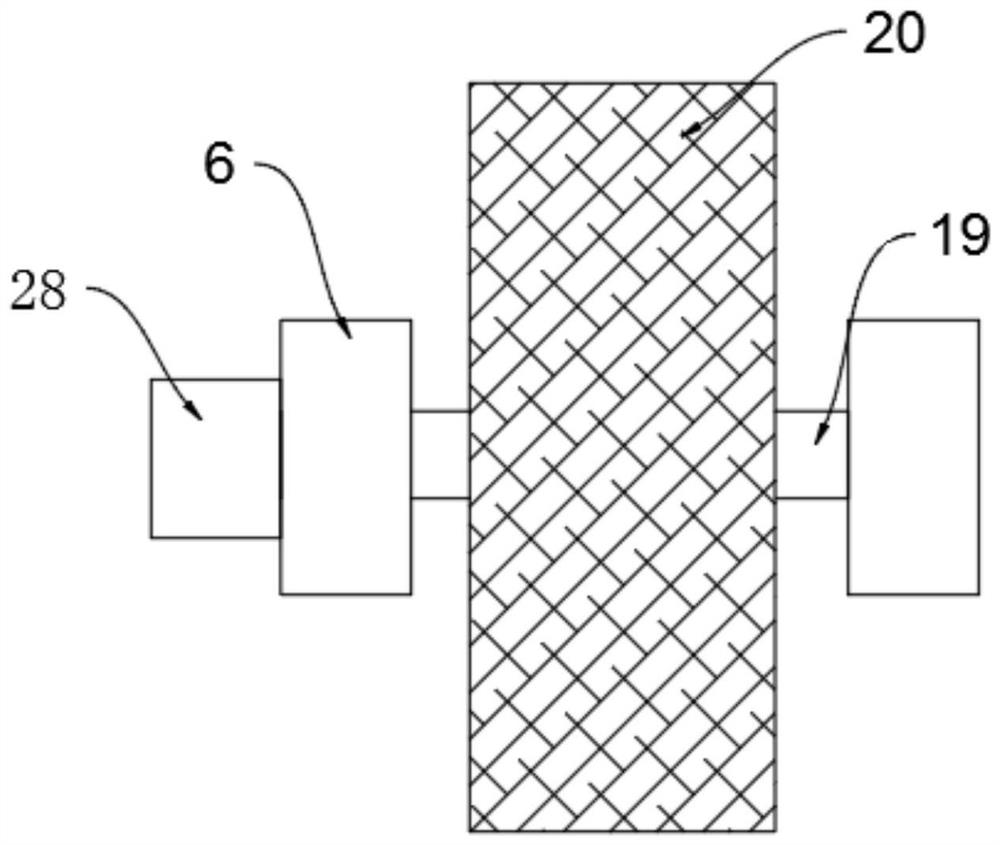

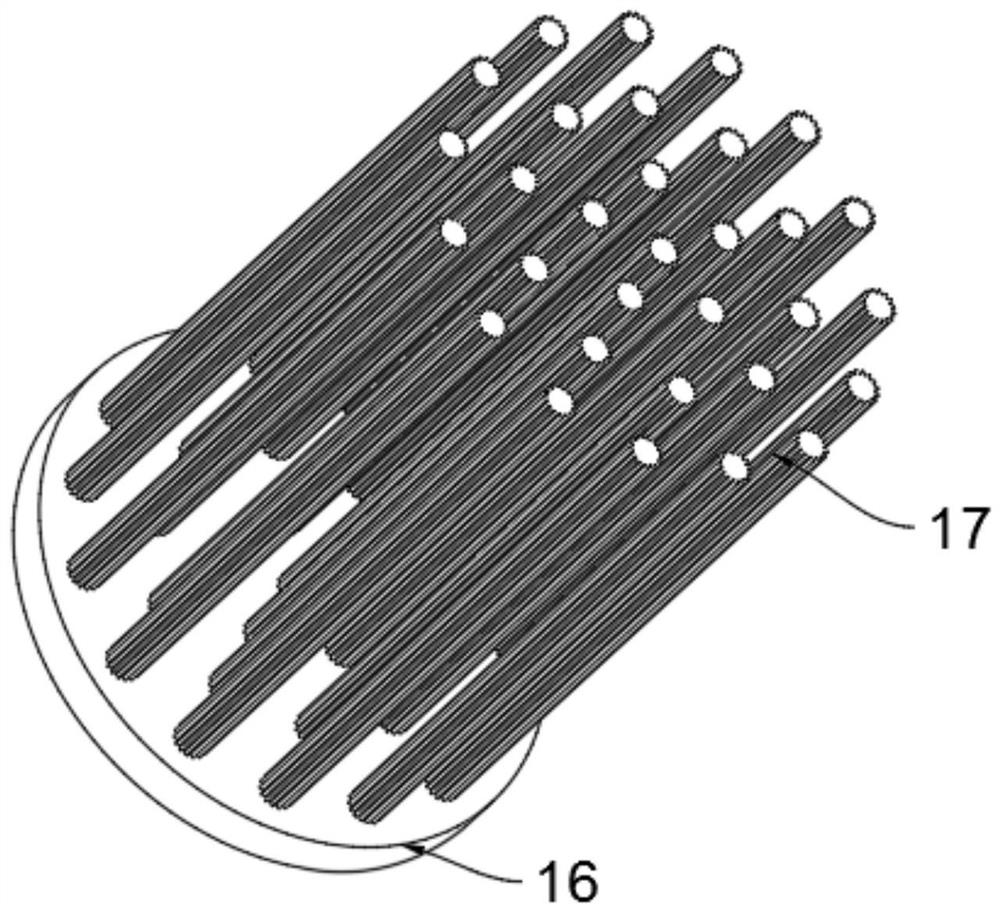

[0020] see Figure 1-4 , a potato flour production device for food processing, comprising a processing box 1, an internal crushing structure and an internal grinding structure, the top of the processing box 1 is fixed with an inlet 27, and the output end of the inlet 27 is provided with an internal crushing structure, the output end of the internal crushing structure is provided with an internal grinding structure, and the internal grinding structure includes an internal box 10, an internal telescopic rod 8, an internal motor 9, a rotating plate 16, a bottom plate 15 and a cross crushing knife 17 , the inner box 10 is fixed on the bottom of the processing box 1, a bottom plate 15 is fixed inside the inner box 10 and a mesh hole is opened on the bottom plate 15, and an internal telescopic Rod 8, an internal motor 9 is fixed at the output end of the internal telescopic rod 8, and the internal motor 9 drives and connects a rotating plate 16, and a cross breaking knife 17 is fixed...

Embodiment 2

[0027] Compared with Embodiment 1, the improvement of this embodiment is that: the inlet 27 is provided with a detachable inlet cover 26 . The inlet cover plate 26 is to prevent the powder material produced in the crushing process from raising.

[0028]The working principle of the present invention is as follows: firstly, the raw material enters from the inlet 27, and first slides down into the inside of the fixed groove 3 through the guide plate 2, and places the raw material at the bottom of the fixed groove 3 through the control structure of the bottom plate, and then uses the top telescopic rod 25 to make The pressing plate 23 is pressed on the raw material, and the top motor 24 is used to drive the rotation of the horizontal knife 21 and the spiral knife 22, so that the raw material is gradually chopped. The movement of the baffle plate 4 separates from the middle position, and the raw materials on the baffle plate 4 are scraped off to the inside of the extrusion and crus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com