Feed stirring device

A feed mixing and packaging technology, which is applied in transportation, packaging, dissolution, grain processing, etc., can solve the problems of uneven nutrition, trouble, and inconsistent growth of food, and achieve the effect of good crushing effect, good moving effect, and convenient operation

Active Publication Date: 2017-08-08

NANTONG WEALTH MASCH TECH CO LTD

View PDF3 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] Usually, in some small chicken farms, some do not use finished feed, but use manual labor to crush and mix a variety of foods by themselves. Due to the crushing of foods with different particle sizes, different crushing screens need to be replaced. It is troublesome, and after breaking up various foods, it needs to be stirred and mixed manually. If the mixing is not uniform, the food eaten by the chicken is likely to be uneven in nutrition, resulting in inconsistent growth. Since the smashing time is relatively long every day, if it is not kept It is troublesome to smash the food for several days every day. Therefore, it is tiring to stir a large amount of mixed food evenly. Therefore, in order to reduce the labor intensity and stir evenly, it is necessary to design an automatic stirring device.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

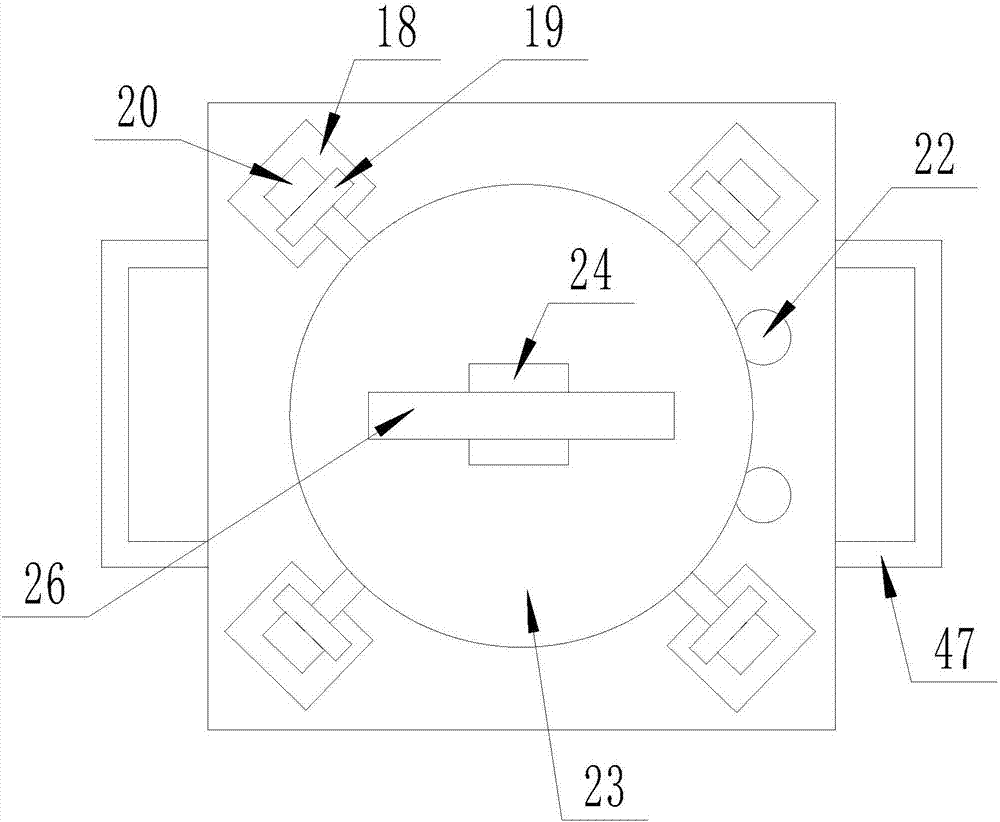

[0024] Embodiment 1: The No. 1 pulley knot and the No. 2 pulley can be replaced by the meshing of the No. 1 gear and the No. 2 gear through the rotation of the transmission belt, which can also achieve the effect of rotation.

Embodiment 2

[0025] Embodiment 2: Replacing the elastic swing rod shell with a telescopic stirring rod can also achieve the stirring effect.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

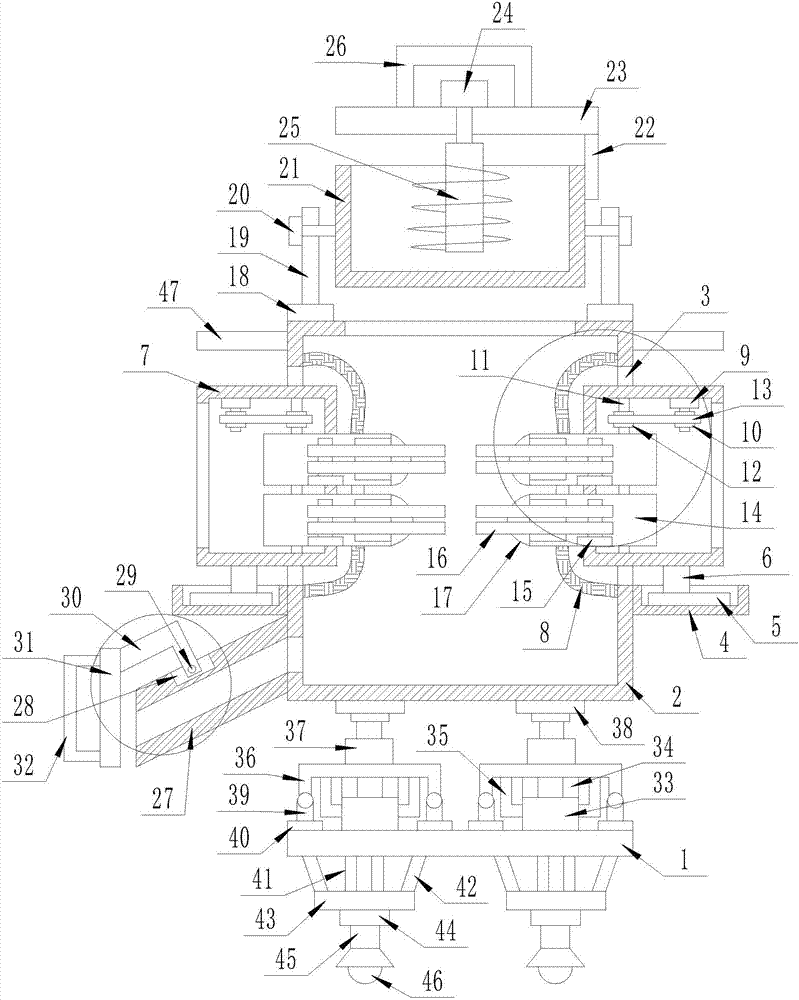

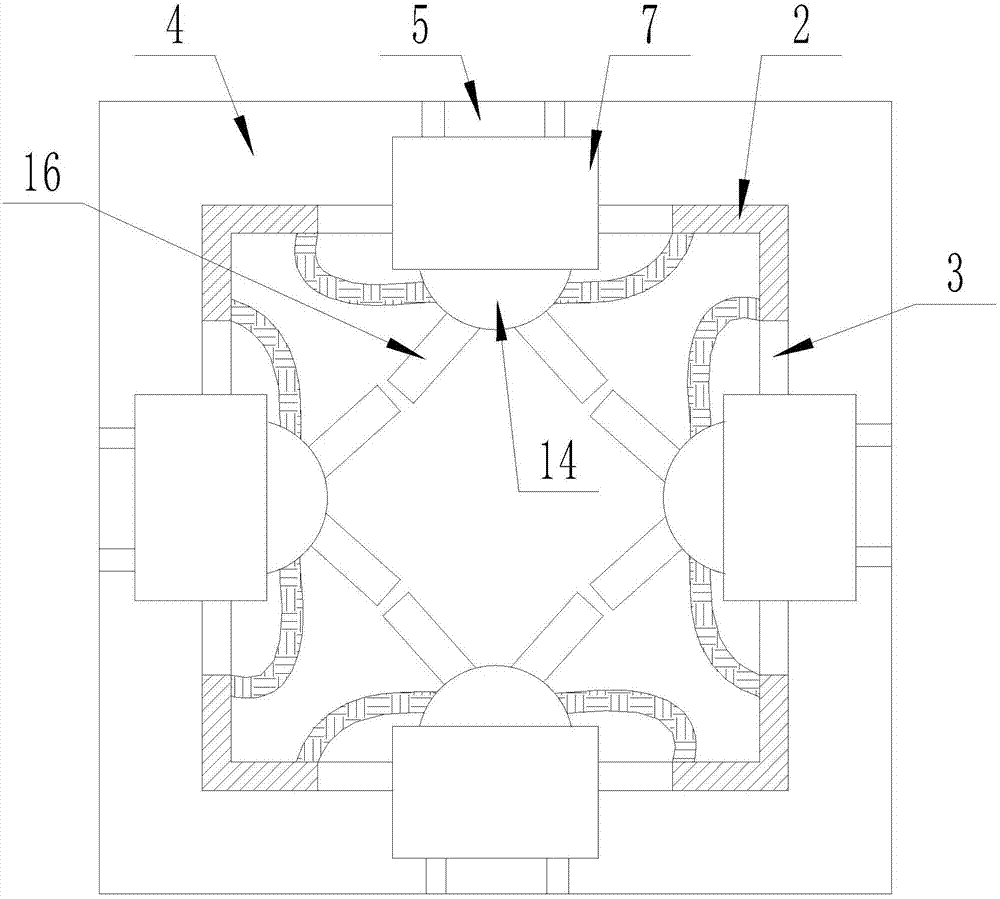

The invention discloses a feed stirring device. The feed stirring device comprises a rectangular base, wherein a movement mechanism is arranged on the lower surface of the rectangular base; a mixing box is arranged on the upper surface of the rectangular base; a uniform mixing mechanism is arranged in the mixing box; a discharging mechanism is arranged on the side surface of the mixing box; a lifting mechanism is arranged between the rectangular base and the mixing box; a foodstuff crushing mechanism is arranged on the upper surface of the rectangular base and located above the mixing box. The feed stirring device has the beneficial effects that the operation is relatively convenient, the crushing effect is better, parts do not need to be replaced, stirring is uniform, the movement effect is good, and the labor intensity is alleviated.

Description

technical field [0001] The invention relates to the field of food mixing, in particular to a feed stirring device. Background technique [0002] Usually, in some small chicken farms, some do not use finished feed, but use manual labor to crush and mix a variety of foods by themselves. Due to the crushing of foods with different particle sizes, different crushing screens need to be replaced. It is troublesome, and after breaking up various foods, it needs to be stirred and mixed manually. If the mixing is not uniform, the food eaten by the chicken is likely to be uneven in nutrition, resulting in inconsistent growth. Since the smashing time is relatively long every day, if it is not kept It is cumbersome to smash the food for several days every day. Therefore, it is tiring to stir a large amount of mixed food evenly. Therefore, in order to reduce labor intensity and stir evenly, it is necessary to design an automatic stirring device. Contents of the invention [0003] The ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01F11/00B02C18/10B02C18/16

CPCB02C18/10B02C18/16B01F31/44B01F33/5014B01F2101/18

Inventor 孙炳连

Owner NANTONG WEALTH MASCH TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com