Garbage processor

A technology of garbage disposer and end cap, which is applied in indoor sanitary pipeline installations, water supply installations, buildings, etc., and can solve problems such as coarse residue particles, unsatisfactory heat and noise treatment effects, and sewer blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention is further described in conjunction with the following examples.

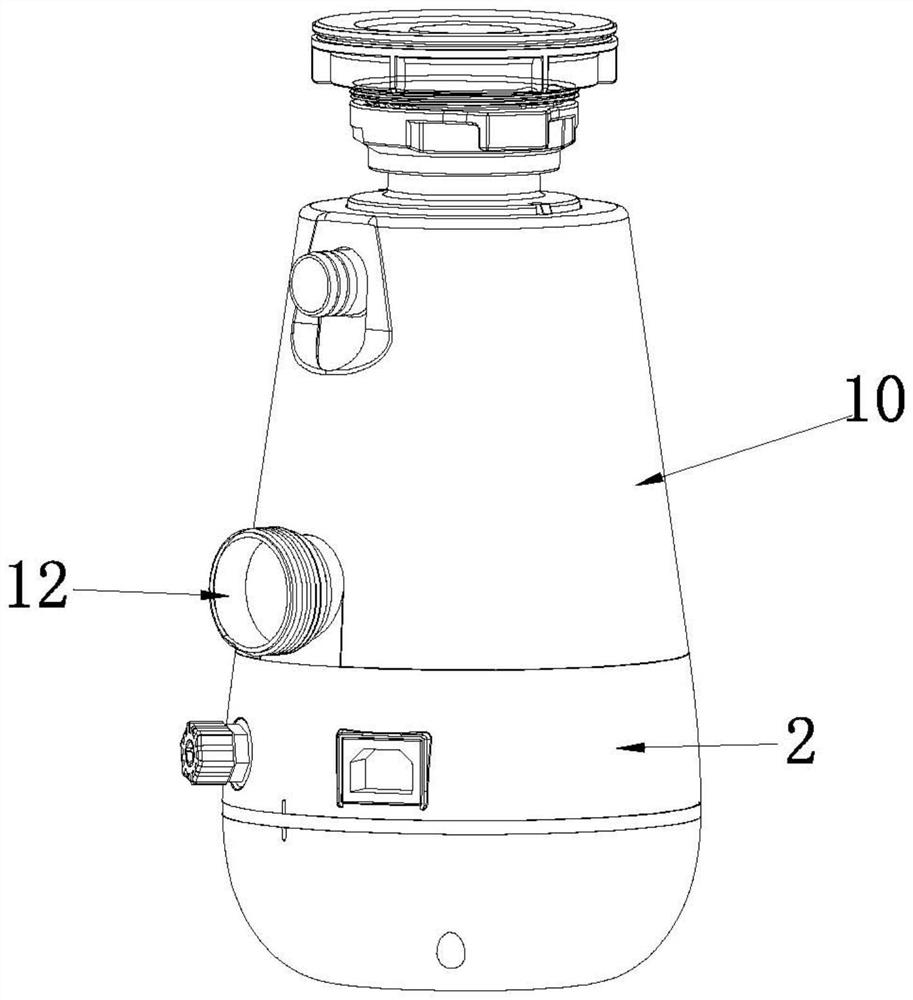

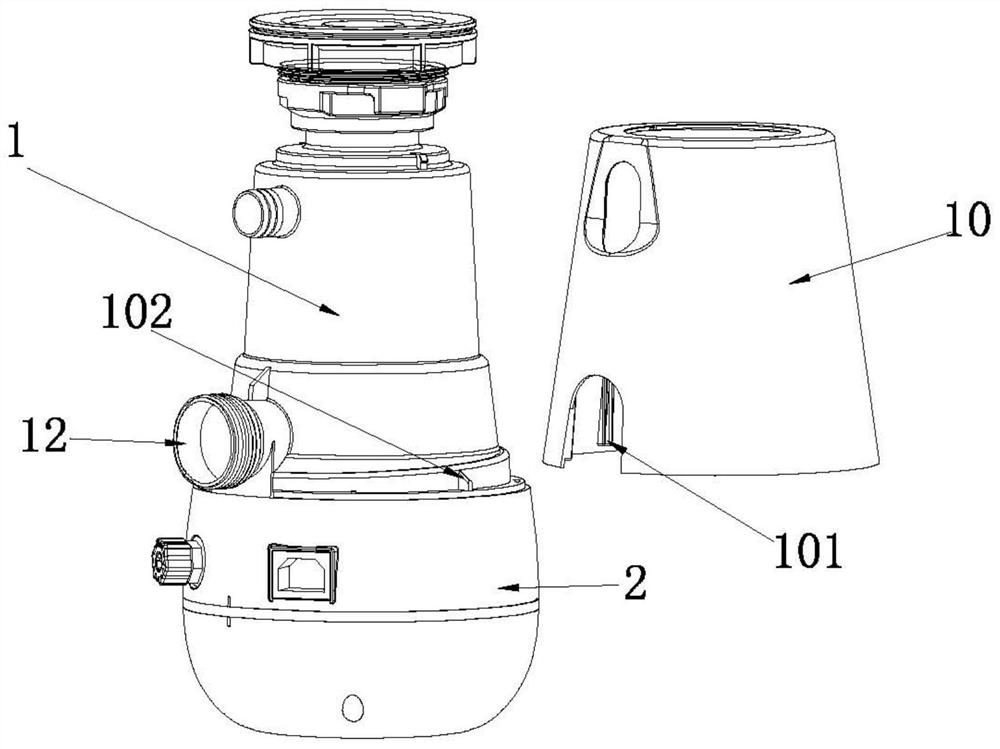

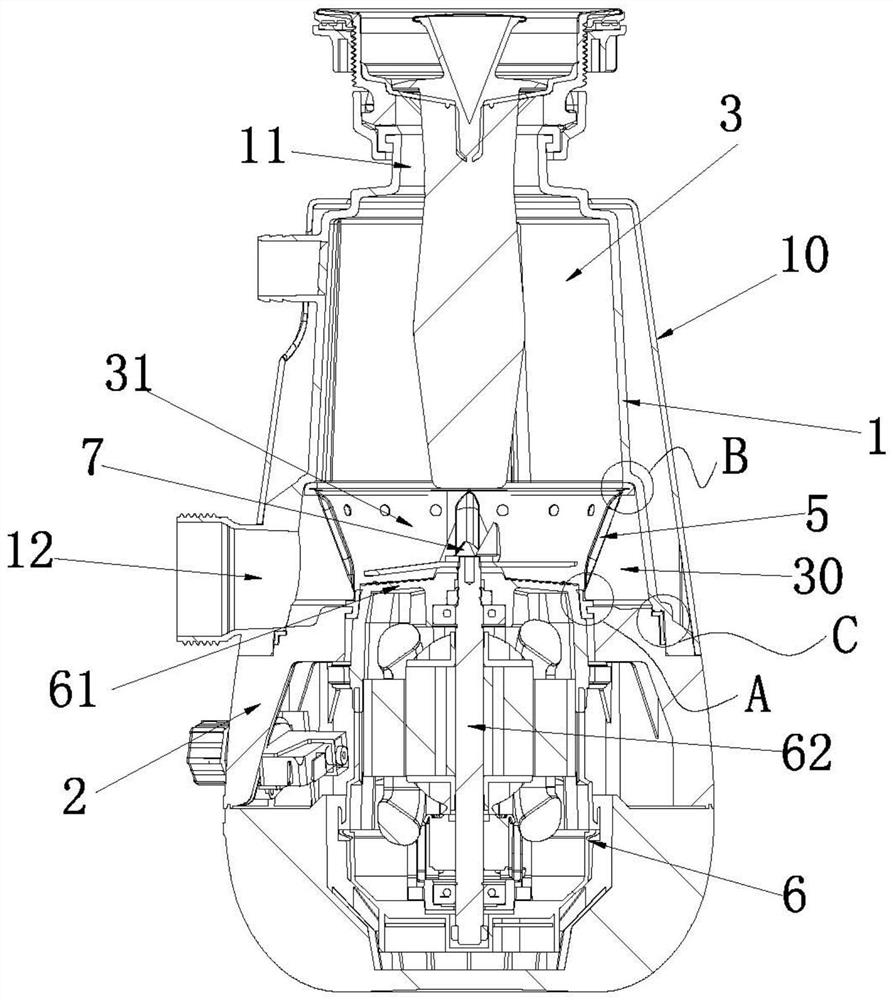

[0031] For a specific implementation of a garbage disposer of the present invention, see figure 1 with figure 2 As shown, the garbage disposer includes an outer shell 10 , a middle shell 2 and an upper shell 1 covered on the middle shell 2 . combine image 3 with Figure 4 , The upper shell 1 is provided with a water inlet 11 and a water outlet 12 . In order to discharge the residue after reaching a suitable particle size, a filter screen 5 is provided in the upper shell 1, so that the interior of the upper shell 1 is divided into an inner cavity 3 communicated with the water inlet 11 and an outer cavity communicated with the drain 12 30, and the space inside the filter screen 5 is called the smashing cavity 31, which is a part of the space in the inner cavity 3.

[0032] In order to solve the problem of heating of the motor assembly, the bottom of the crushing chamber 31 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com