Patents

Literature

232results about How to "Recycle thoroughly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

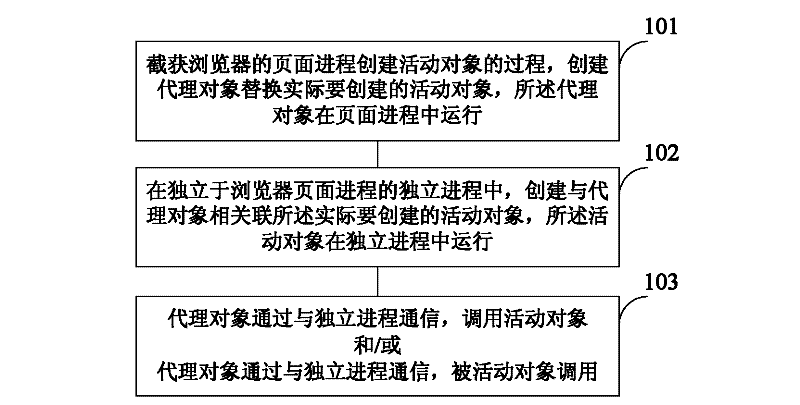

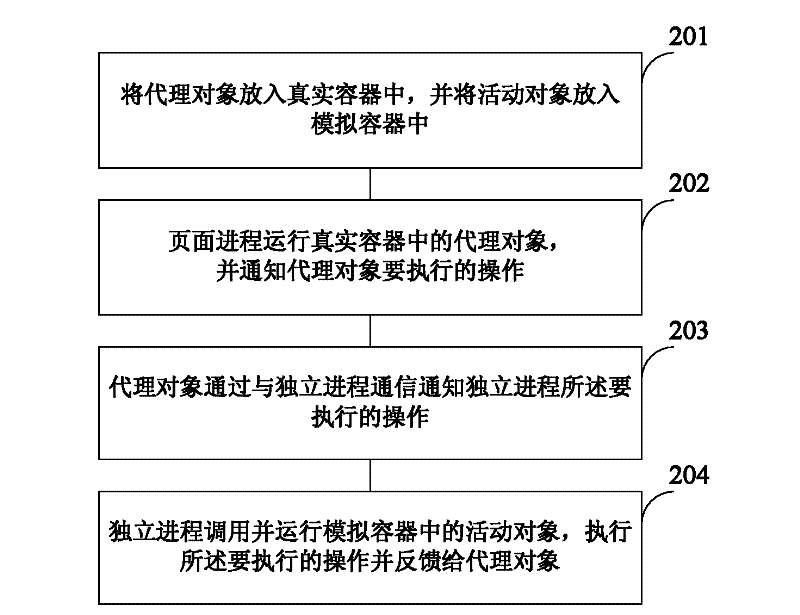

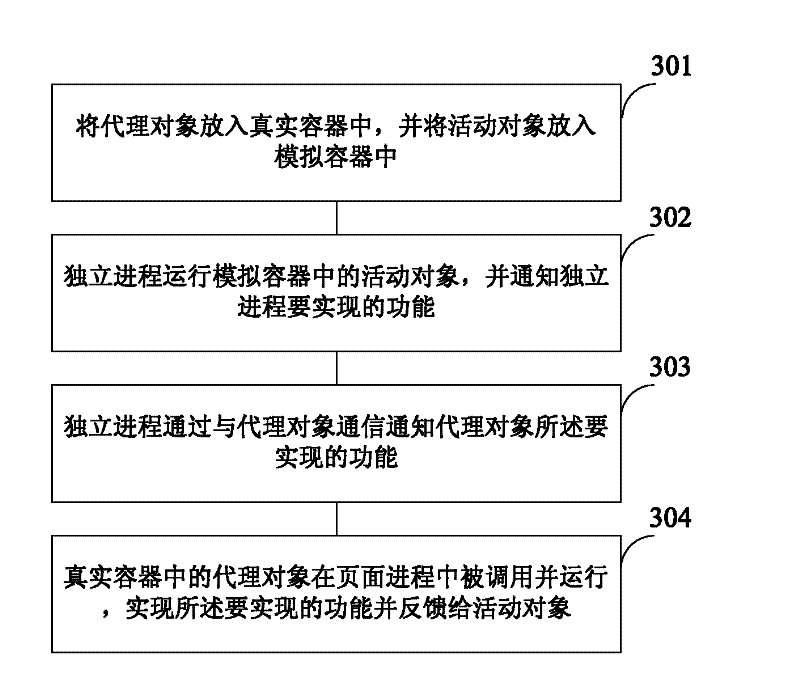

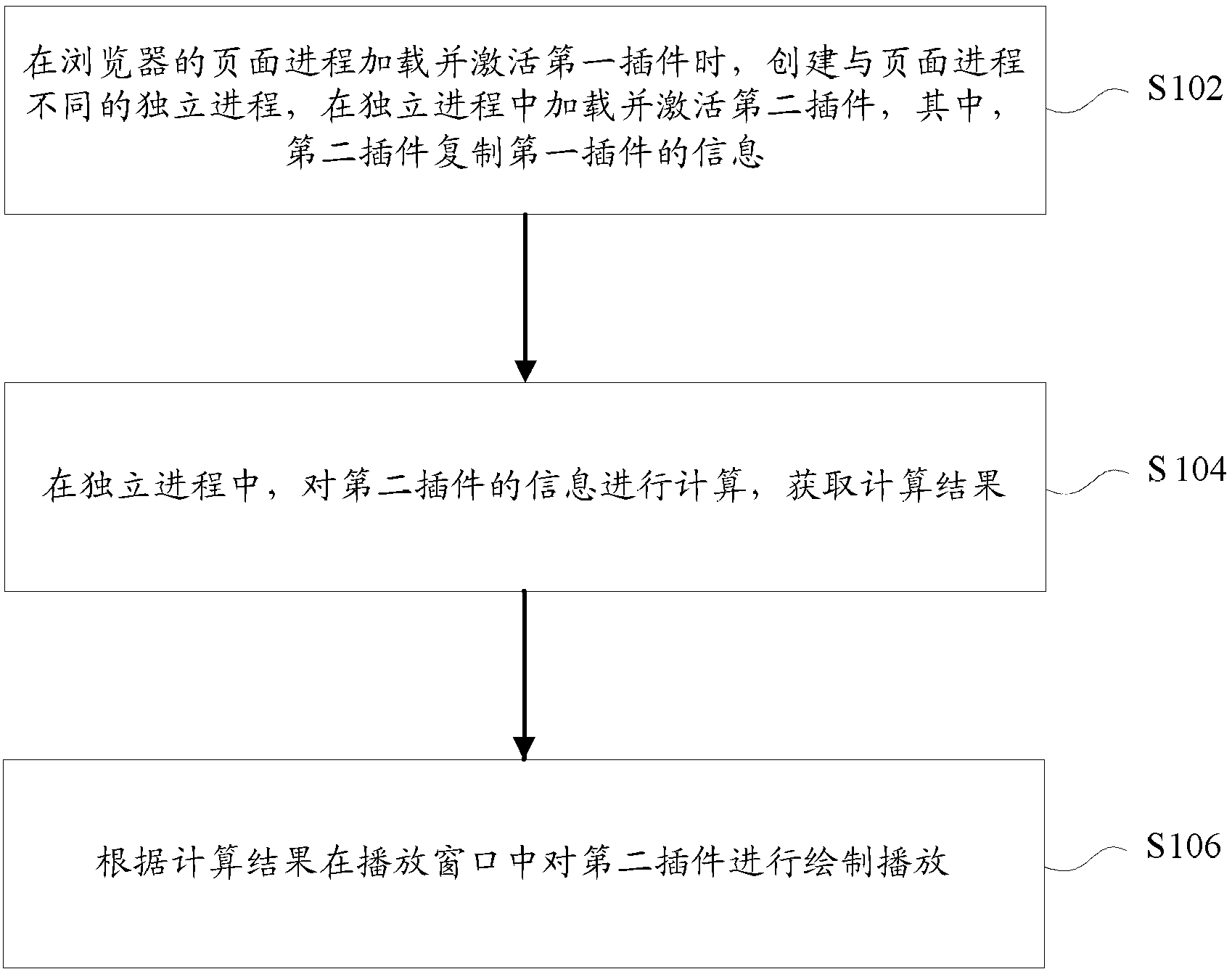

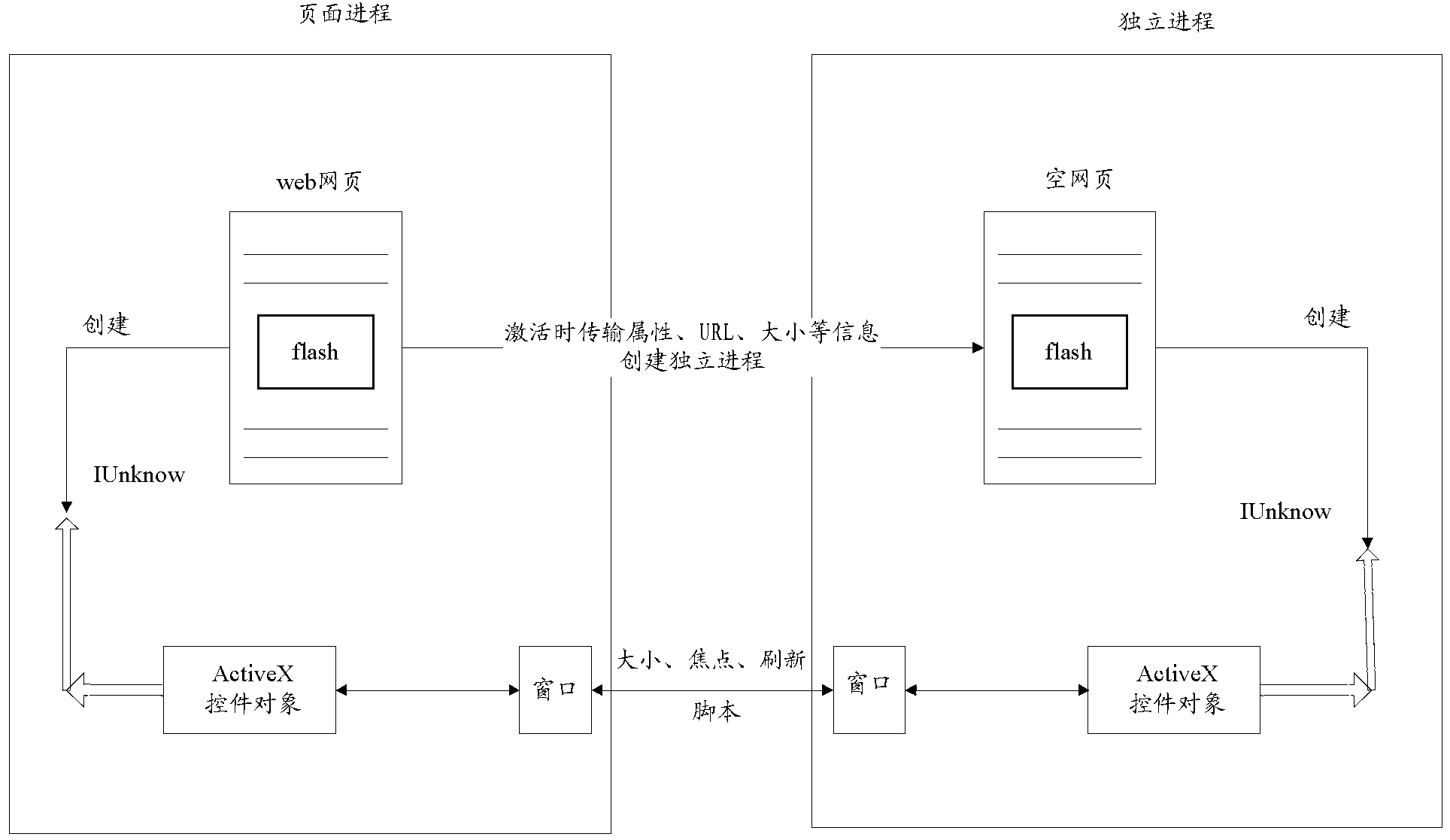

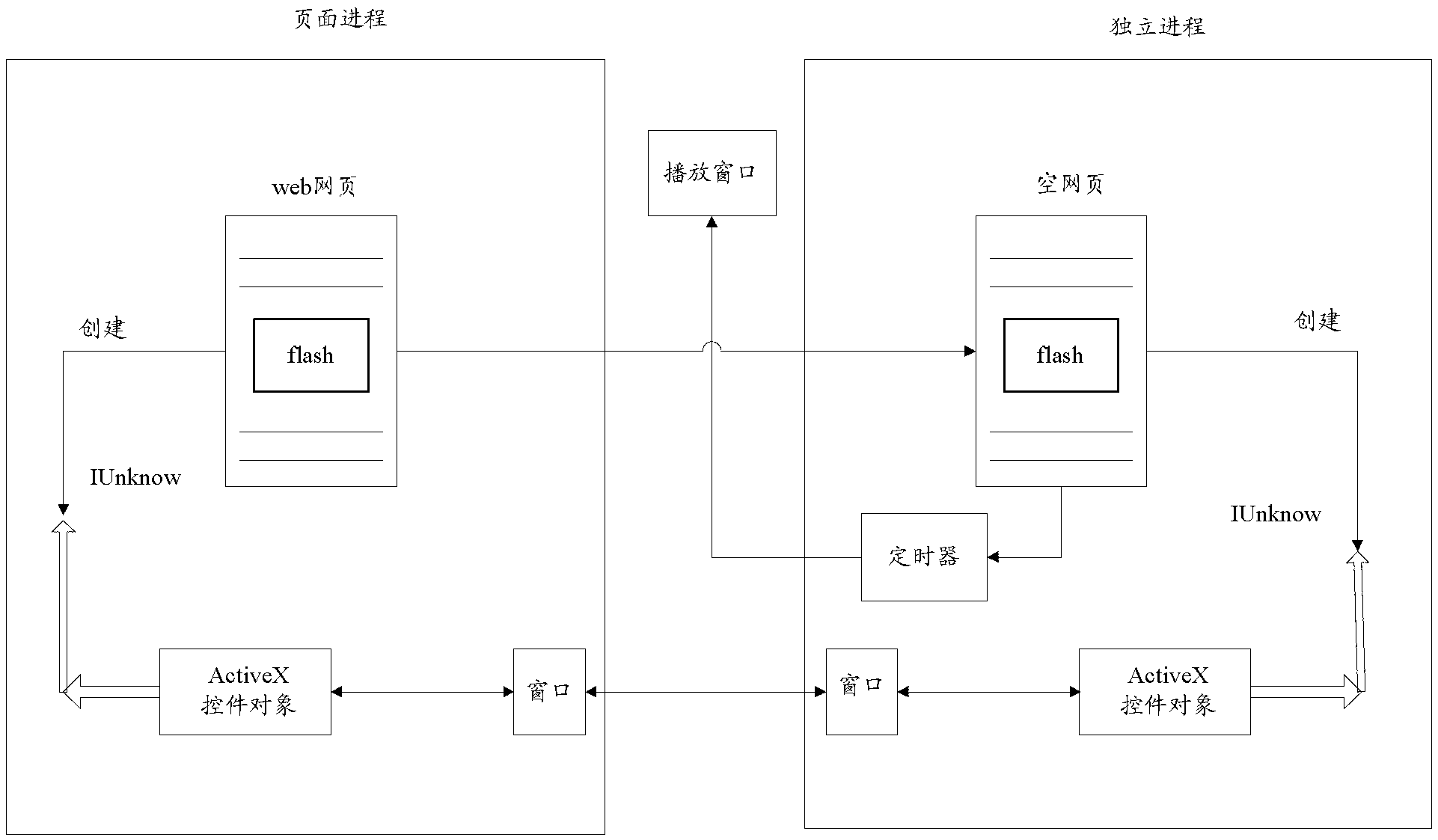

Method and system for executing browser control

InactiveCN102314510AImprove stabilityImprove securitySpecial data processing applicationsVirusWorld Wide Web

The application provides a method and a system for executing a browser control, in order to solve the problem that the browser control influences stability and safety of a browser. By operating a proxy object in a page process, and operating an active object in an independent process, a real browser control such as a real ActiveX control is separated from the page process, thereby a browser process which is inserted into the browser control cannot be influenced when the browser control has a fault, i.e., the page process cannot be influenced when the browser control has the fault, and the stability of the browser is improved. And meanwhile, when the browser control has the safety problems such as virus and the like, operation of the page process cannot be influenced because the browser control is separated from the page process, thus the safety of the browser is improved.

Owner:QIZHI SOFTWARE (BEIJING) CO LTD

Preparation method for active copper oxide

InactiveCN103991894AEmission reductionAvoid bringing inCopper oxides/halidesElectrolysisBasic copper carbonate

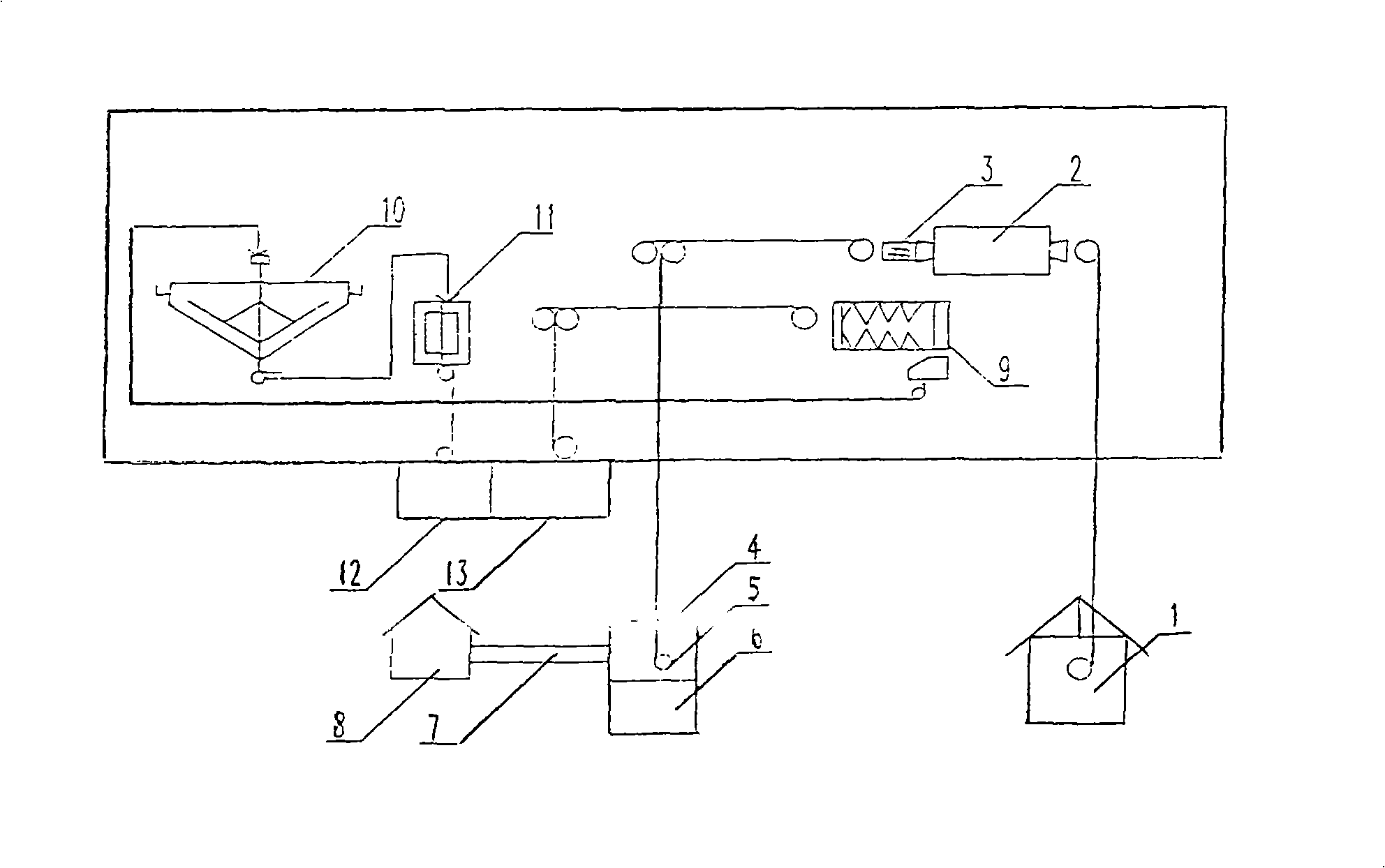

The invention discloses a preparation method for active copper oxide by using a spray flashing calciner. The method comprises the following steps: with copper, liquefied ammonia and ammonium bicarbonate as raw materials, preparing concentrated ammonia liquor with a concentration of 10 to 12% at first; then adding excess concentrated ammonia liquor into electrolytic copper, adding ammonium bicarbonate, introducing air at the same time and carrying out leaching and synthesis at a temperature of 60 to 70 DEG C so as to prepare cuprammonia; after filtering, pumping the cuprammonia into a reaction vessel for thermal decomposition so as to prepare a basic copper carbonate feed liquid; and filling the spray flashing calciner with the basic copper carbonate feed liquid, carrying out calcining at a temperature of 450 to 600 DEG C so as to prepare active copper oxide and recovering and reusing gas produced in the reaction by using an absorption tower. The method provided by the invention has the advantages of an increased reaction speed, substantially improved production efficiency, higher product purity, lower production cost and a wider product application scope; moreover, since the spray flashing calciner is used, heat dissipation is small, the resource of coal is saved, and requirements for energy conservation and environmental protection are better met.

Owner:JIANGSU TEHO METAL IND

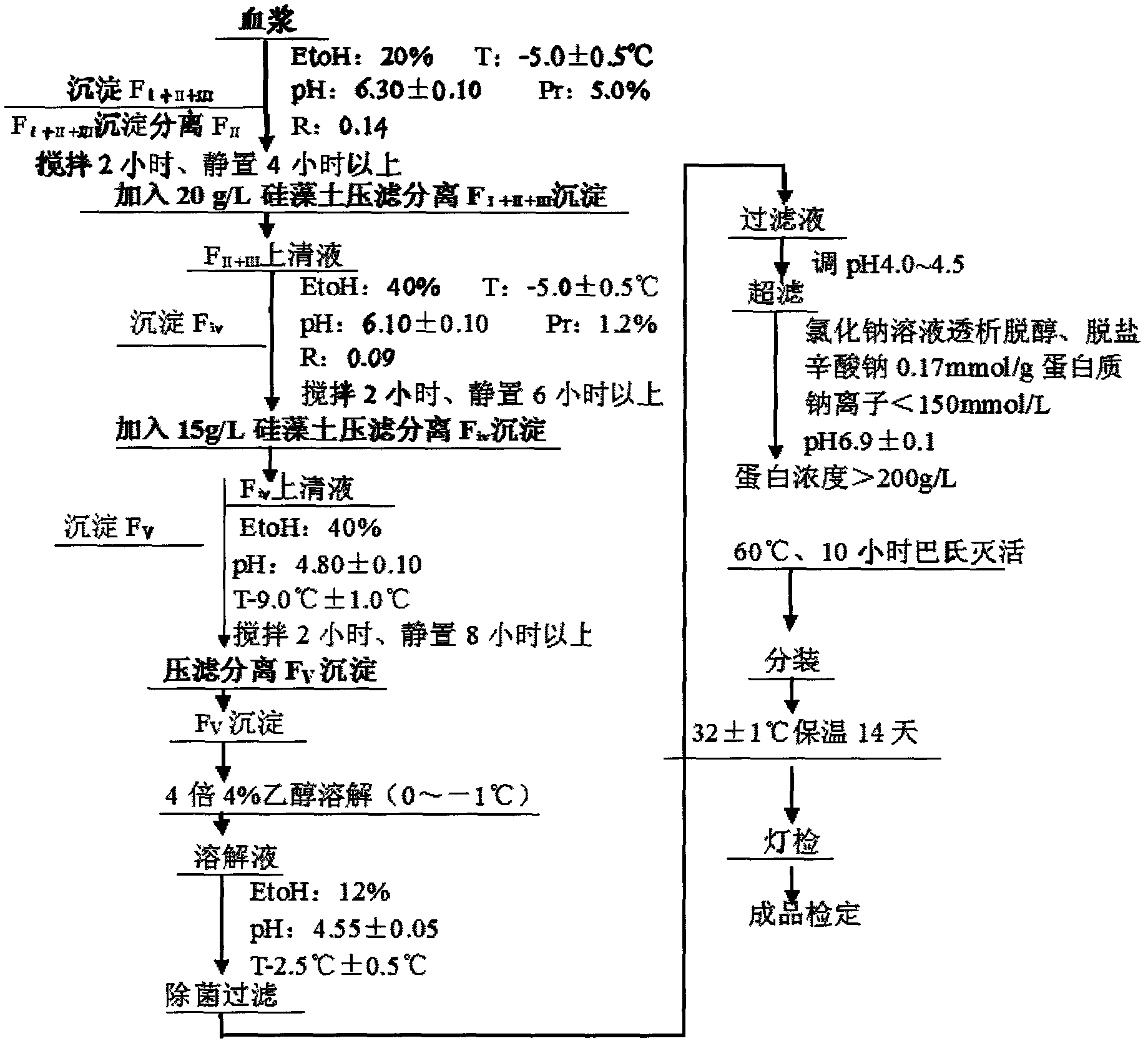

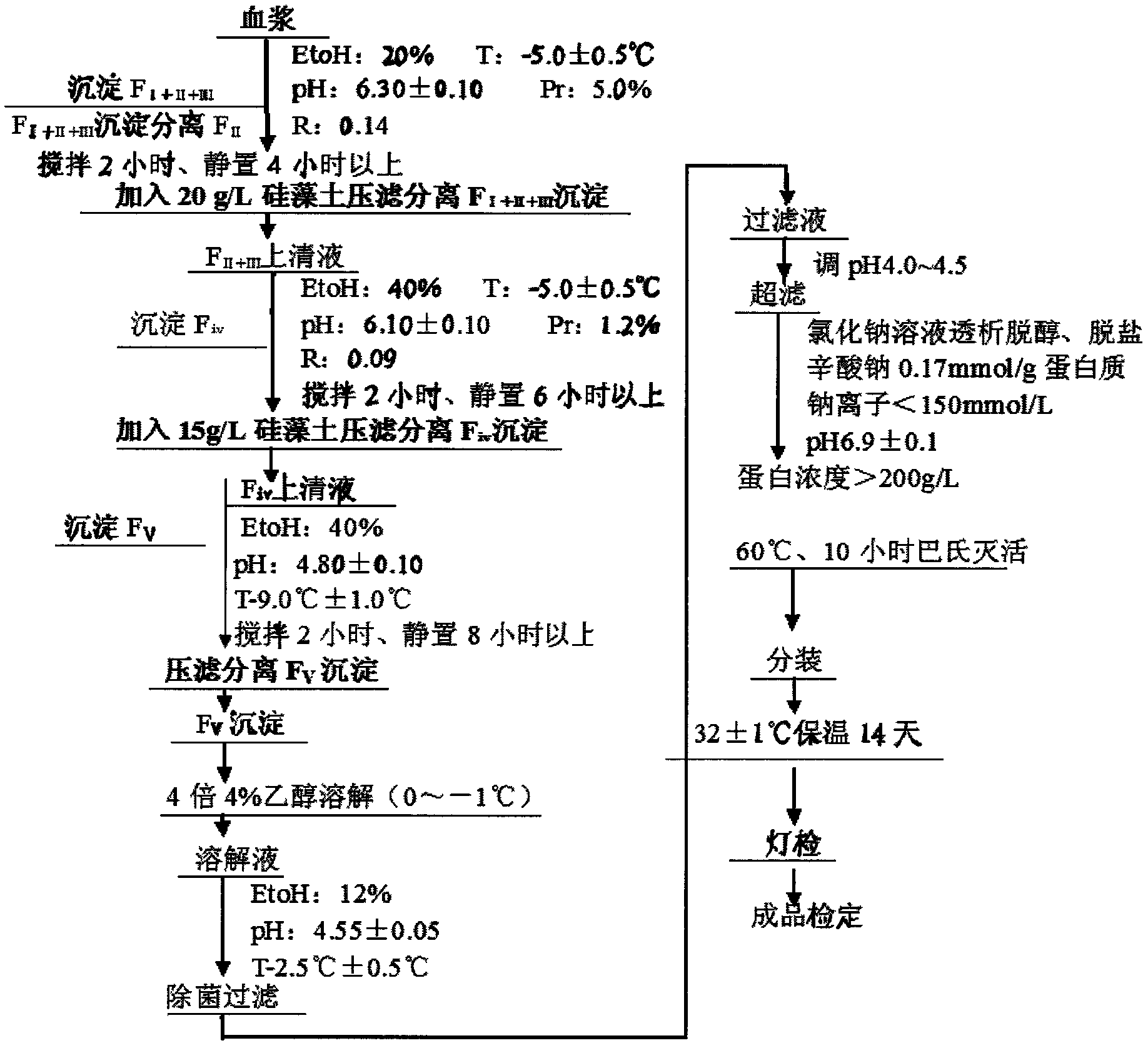

Preparation method of human serum albumin

InactiveCN102532304AStructure has no effectQuality improvementSerum albuminPeptide preparation methodsAluminum IonProtein molecules

The invention relates to a method for separating and extracting protein in a biological product technology, in particular to a preparation method of human serum albumin. The preparation method comprises the following steps of: separating components I, II and III, separating a component IV, separating a component V, and refining and purifying; and performing ultrafiltration, pasteurization and sterilized filling, examining a finished product, and packaging the qualified product by pasting a label, boxing and the like. According to the preparation method disclosed by the invention, a relatively-moderate pressure-filtration separation method is adopted, so that the molecular structure of the protein is not influenced, and the human serum albumin with high quality is ensured to be prepared; moreover, the product yield is greatly increased, the human serum albumin which is low in aluminum ion content or even does not contain aluminum ions can be provided for clinical application, and the quality of the human serum albumin is improved.

Owner:WUHAN ZHONGYUAN RUIDE BIOLOGICAL PROD CO LTD

Processing technology for recovering and utilizing mother solution of glyphosate as resource

ActiveCN101659673AImprove throughputReduce flux decay speedGroup 5/15 element organic compoundsWater/sewage treatment bu osmosis/dialysisFiltrationCatalytic oxidation

The invention relates to a processing technology for recovering and utilizing the mother solution of glyphosate as a resource, which comprises the following concrete steps: firstly, preprocessing themother solution of glyphosate, and then, separating, concentrating and recovering the glyphosate by a membrane combination technique; returning the concentrated solution to a crystallization working section in the production process of the glyphosate after membrane filtration, thereby effectively recovering and utilizing the glyphosate resource; adsorbing the diluted solution with high efficiency,and further recovering and utilizing the glyphosate; and processing the adsorbed solution by catalytic oxidation with high efficiency to recover the sodium chloride resource with higher purity. The invention achieves the purposes of recovering and utilizing the glyphosate in the mother solution as a resource to the maximum extent and efficiency separating, recovering and utilizing the sodium chloride as a resource, has the advantages of economical technology, high efficiency, good system stability, high safety, easy operation, convenient industrial amplification, and the like, solves the problems of the soil salinization caused by applying water agents with high content of sodium chloride, the processing and disposal of solid wastes of the sodium chloride and the environment pollution, and effectively recovers and utilizes the resources of the glyphosate and the sodium chloride in the mother solution of the glyphosate.

Owner:NANJING UNIV OF TECH

Method for treating complex-containing nickel plating wastewater

InactiveCN102452743AEasy to recycleRecycle thoroughlyWaste water treatment from metallurgical processMultistage water/sewage treatmentNickel saltPollution

The invention discloses a method for treating complex-containing nickel plating wastewater, which is characterized by comprising the following steps of: adding an oxidant into the wastewater to be treated under the acidic condition to ensure that a nickel ion complex in the wastewater is subjected to oxidative damage by the oxidant and nickel ions are free; after the complex is damaged by the oxidation process, regulating the pH value by using an alkaline solution to make the nickel ions generate a hydroxide precipitate; adding dilute acid into the hydroxide precipitate for dissolving, concentrating, crystallizing, and recovering nickel salt; and adding dilute acid into the wastewater from which nickel is removed to regulate the pH, and adding a precipitating agent to remove phosphite and phosphate. The process that the pH of the wastewater is changed by a chemical method and heavy metal ions to be removed are precipitated and dissolved is adopted, so that the secondary pollution of the wastewater is avoided, the ions are completely precipitated, aftertreatment cost is low, the wastewater does not contain phosphorus, and economic benefits and environment friendliness are unified.

Owner:SHANGHAI FENGXIN ENVIRONMENTAL PROTECTION TECH

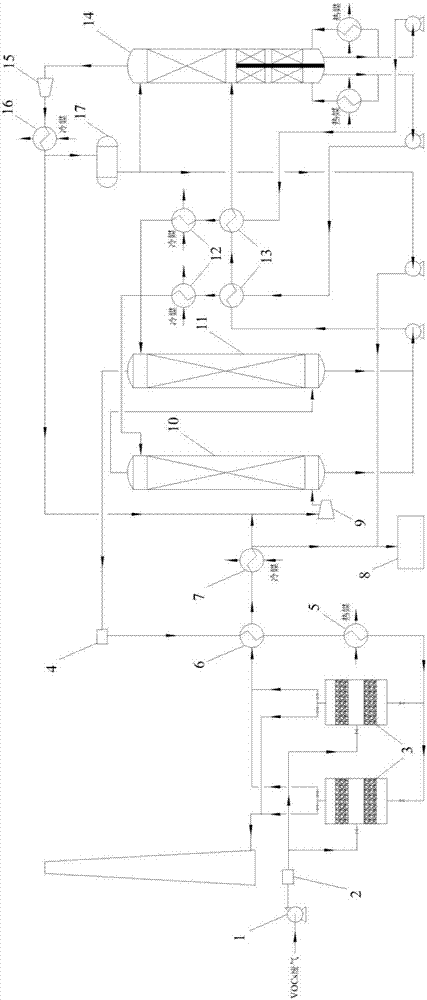

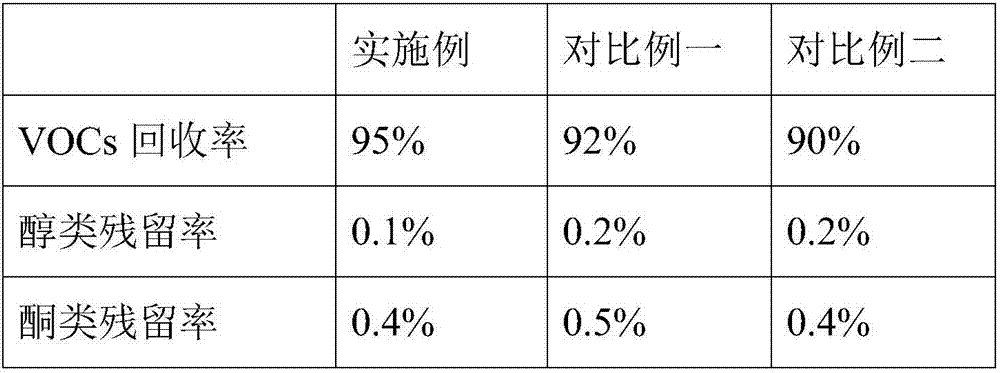

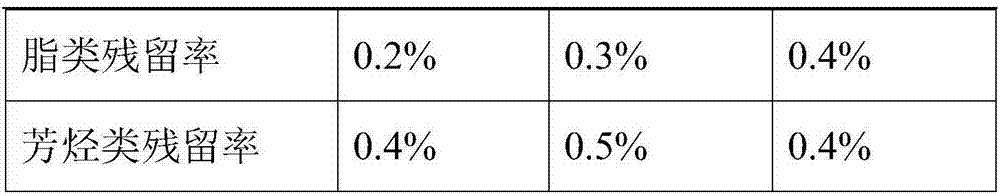

Method and device for recycling and treating waste gas with VOCs (volatile organic compounds)

PendingCN107261754AImprove adsorption capacityContains low VOCsGas treatmentDispersed particle separationEnvironmental engineeringEnergy consumption

The invention relates to a method and a device for recycling and treating waste gas with VOCs (volatile organic compounds). The device comprises an adsorption unit, an absorption unit and a rectification unit. The adsorption unit is used for adsorbing the VOCs, the absorption unit is used for absorbing the VOCs, and the rectification unit is used for recycling the VOCs and regenerating absorbents. The method and the device for recycling and treating the waste gas with the VOCs have the advantages that the VOCs absorption efficiency can be improved, loss of the absorbents can be reduced, and the VOCs further can be recycled; energy consumption in production procedures can be effectively reduced, and accordingly the production cost can be saved to a great extent.

Owner:HEBEI XIANHE ZHENGYUAN ENVIRONMENTAL TREATMENT TECH CO LTD

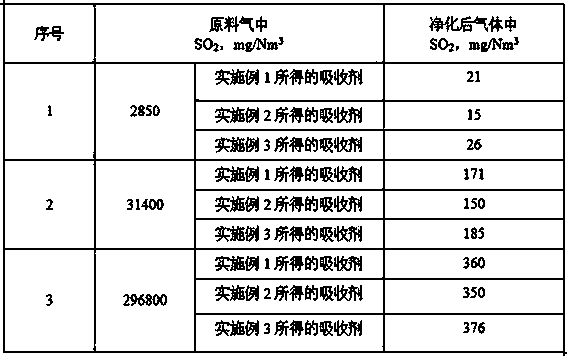

Absorbent for recycling sulfur dioxide from industrial waste gas and recycling method

The invention particularly relates to an amine salt solution absorbent and a method for recycling sulfur dioxide from industrial waste gas. The absorbent is prepared by virtue of the following steps: firstly, mixing piperazine and water and uniformly agitating, and adding ethylene oxide to react under an agitating state; secondly, taking a reaction product and boric acid to react to obtain an organic amine salt; finally, dissolving the organic amine salt into water to prepare an amine salt water solution to obtain the absorbent. An absorption method comprises the following steps: carrying out countercurrent contact on the absorbent and a gas flow containing sulfur dioxide gas so as to dissolve the sulfur dioxide into the absorbent to remove the sulfur dioxide; meanwhile, contacting an absorption solution absorbing the sulfur dioxide with steam to be regenerated, so as to realize cyclic utilization. The preparation method is simple, the reaction efficiency is high, few reaction by-products are obtained, the yield is high, the price of a solvent is low, the period is short and the production cost is low; the capacity of the prepared absorbent is large and the sulfur dioxide can be completely recycle; the absorbent can be cyclically utilized and the regeneration energy consumption is low.

Owner:江苏蓝电环保股份有限公司

Purification technique of steel scoria magnetic separation product

The invention discloses a purification technique of steel slag magnetic separation products, which comprises the following steps: (1) the steel slag magnetic separation product is put into a ball mill and water is added, (2) full grinding is processed, the product is discharged from the exhaust end of the ball mill naturally and divided into up-screen product and below-screen product through a cylinder screen, (3) the up-screen product is divided into block iron and tailings by magnetic pulley, the block iron is dried by dryer to make water content below 2%, (4) the product below screen is divided into overflow and sand-returning by a classifier, and the overflow grade of the classifier is controlled by the size of the spray water, which controls the sand-returning grade of the classifier, and (5) the sand-returning is conveyed into the fine powder feed chute through belt, the classifier overflow is conveyed to the thickener through a pump, and the underflow of the thickener is filtered by the filter and conveyed into the tail powder feed chute. The purification technique of steel slag magnetic separation products has the advantages of no non-magnetic and weakly magnetic material loss, full and complete recovery, raising the content of iron of luppen from 60% to 65% to above 90%, raising the grade of the magnetic separation powder from 40% to 50% to above 60%, raising the content of iron of steel slag product completely, and raising the comprehensive utilization ratio of the steel slag.

Owner:鞍钢绿色资源科技有限公司 +1

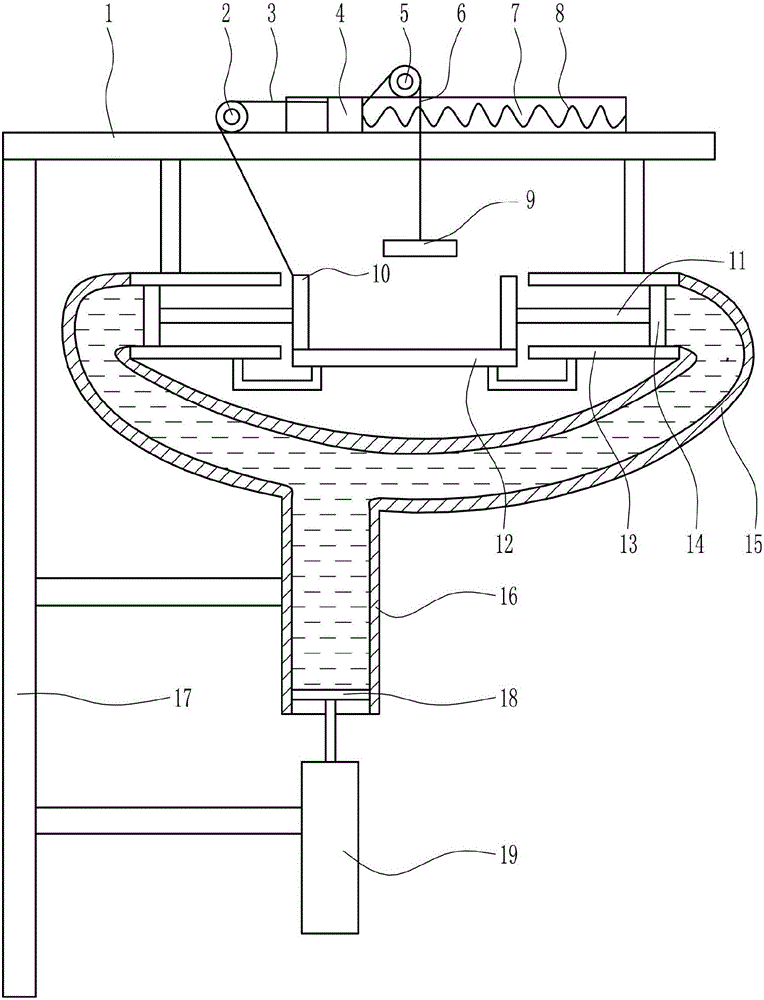

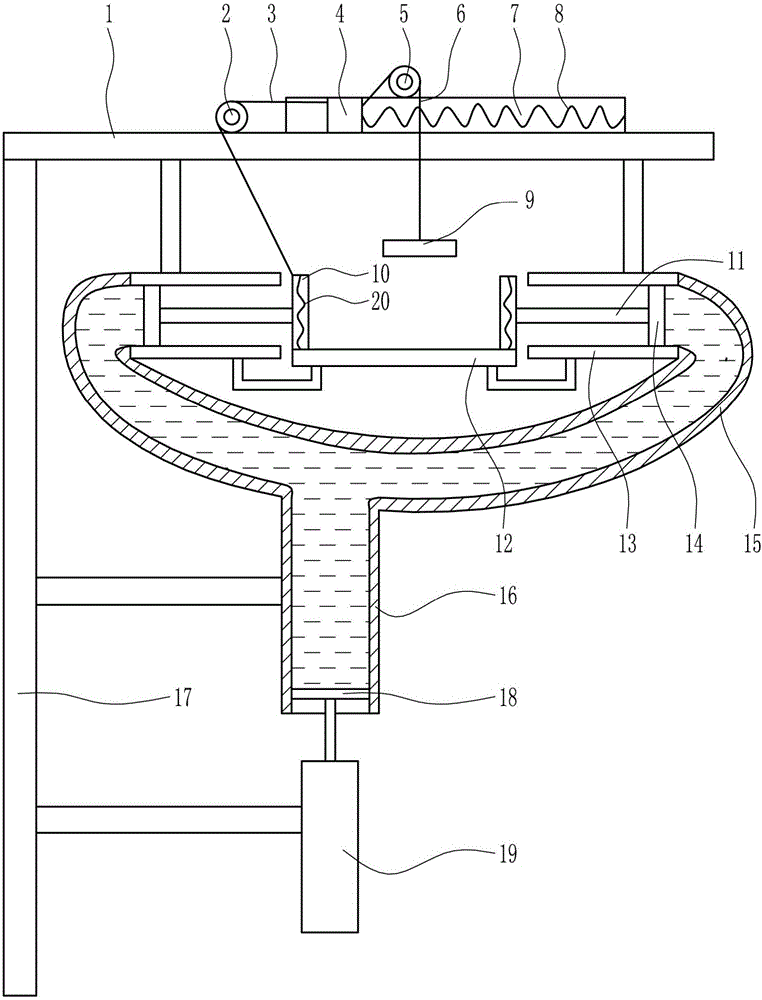

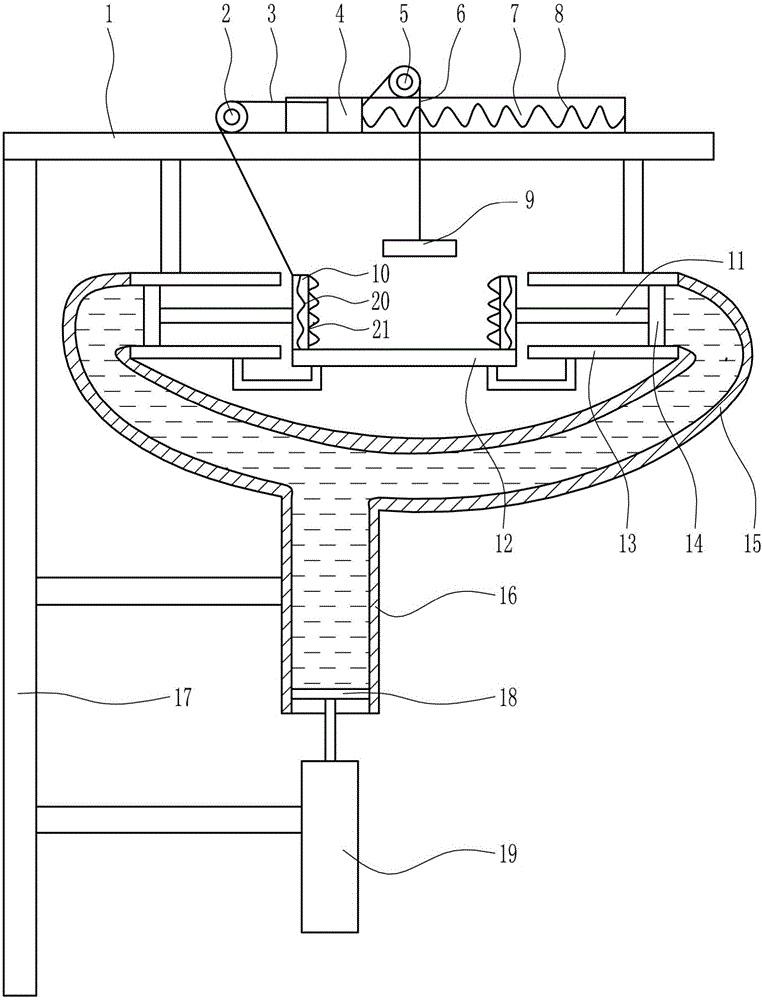

Aluminum slag recovery equipment and process

ActiveCN108220611ARecycle thoroughlyRealize harmless treatmentSolid waste disposalProcess efficiency improvementSlagHazardous substance

The invention belongs to the technical field of aluminum slag recovery, and particularly relates to an aluminum slag recovery equipment and process. The aluminum slag recovery equipment can realize two-step recovery of aluminum slag by extrusion treatment and heating centrifugal separation treatment, so that the aluminum slag can be recovered more thoroughly, and the harmless treatment of slag ashcan be realized to prevent the slag ash from harming the environment. According to the aluminum slag recovery process, aluminum in the aluminum slag is completely recovered by two times of the recovery process, and the recovery rate is as high as 93%, so that huge economic benefits are produced, and aluminum resources are greatly saved; no salt fluxing agent is applied, so that the pollution to the environment is reduced; and the slag ash is finally subjected to harmless treatment, harmful substances in the slag ash can be greatly reduced, and the pollution to the environment of the slag ashis reduced.

Owner:山东创新精密科技有限公司

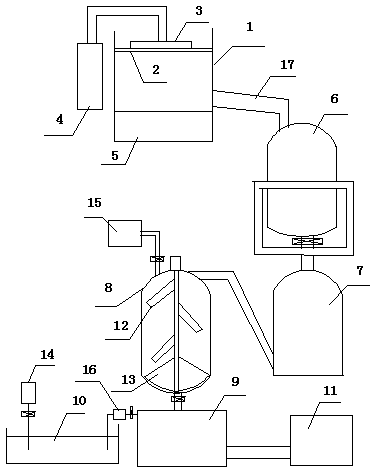

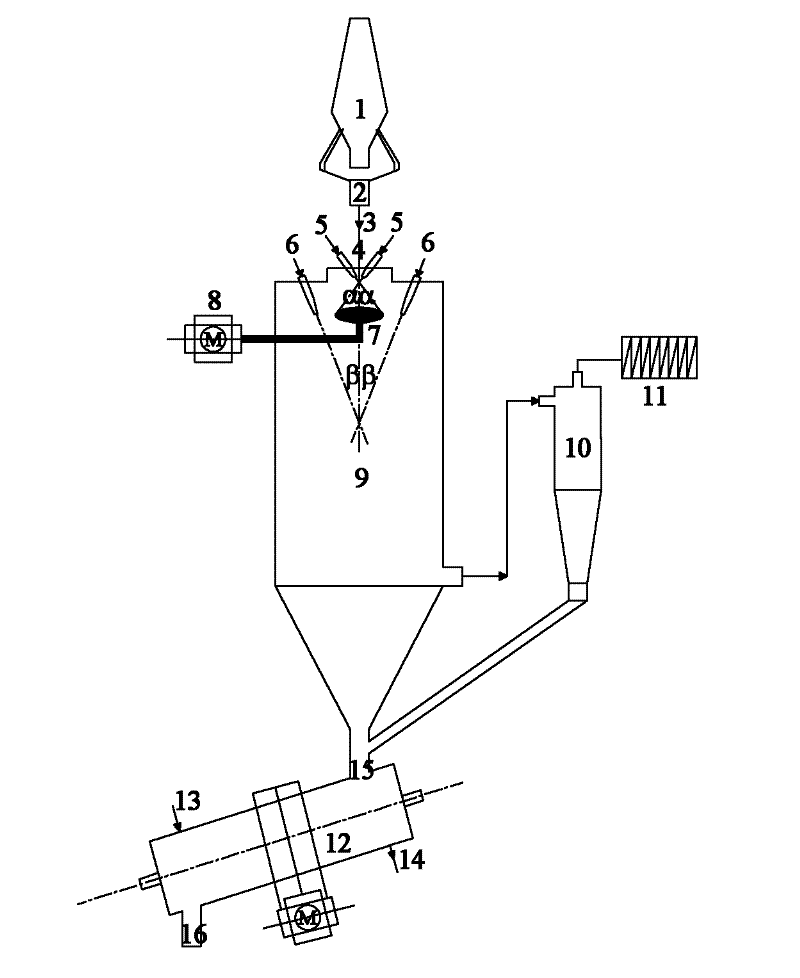

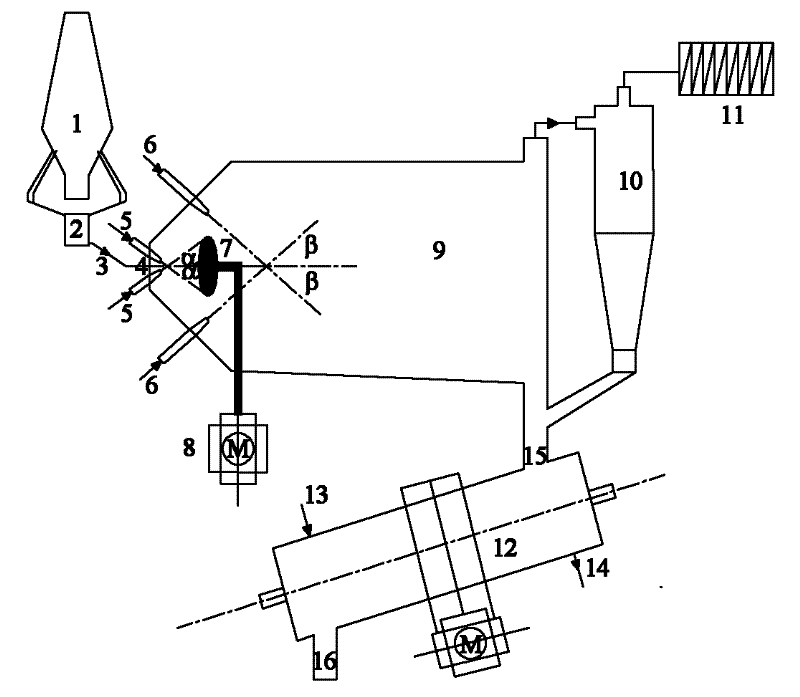

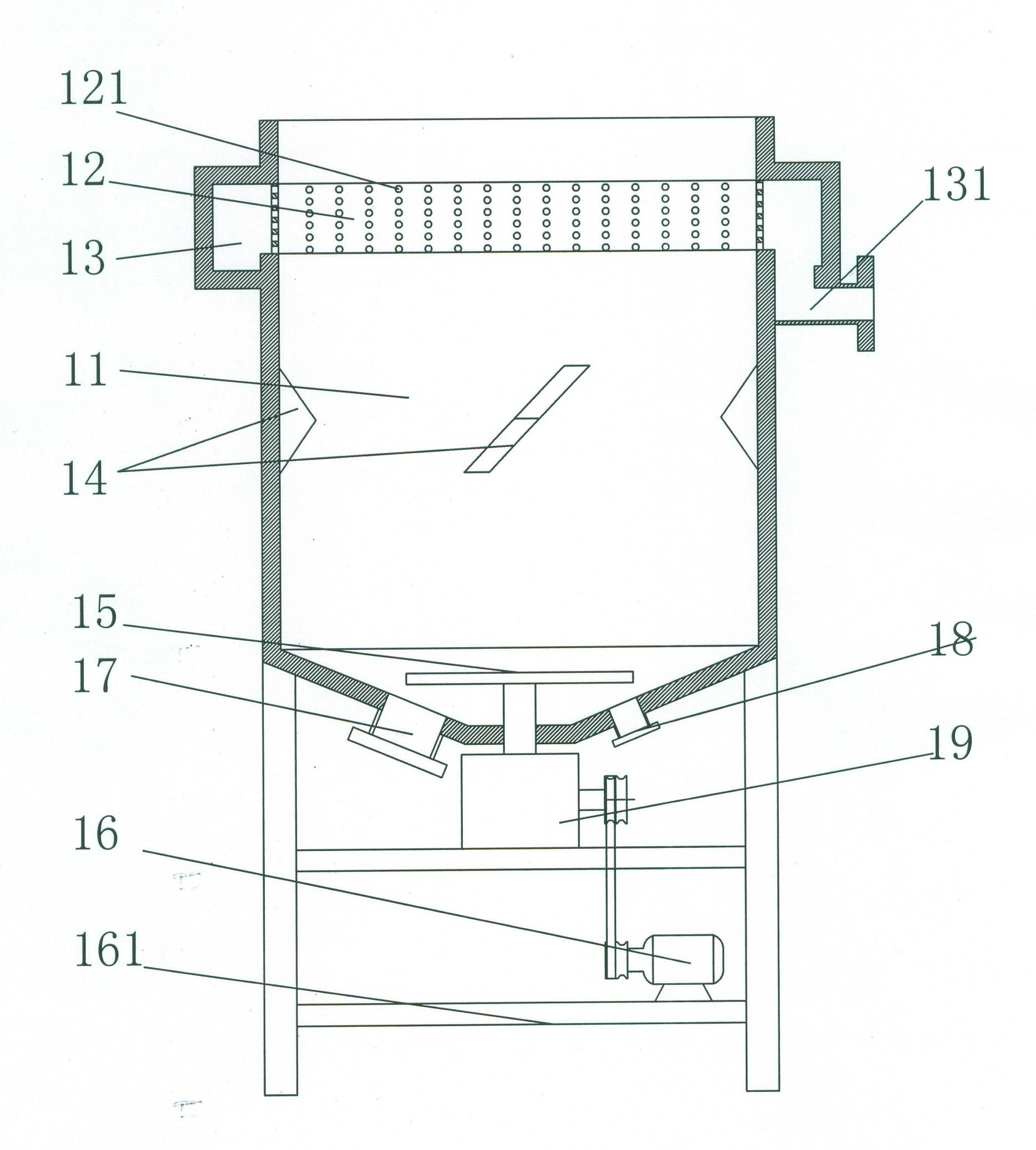

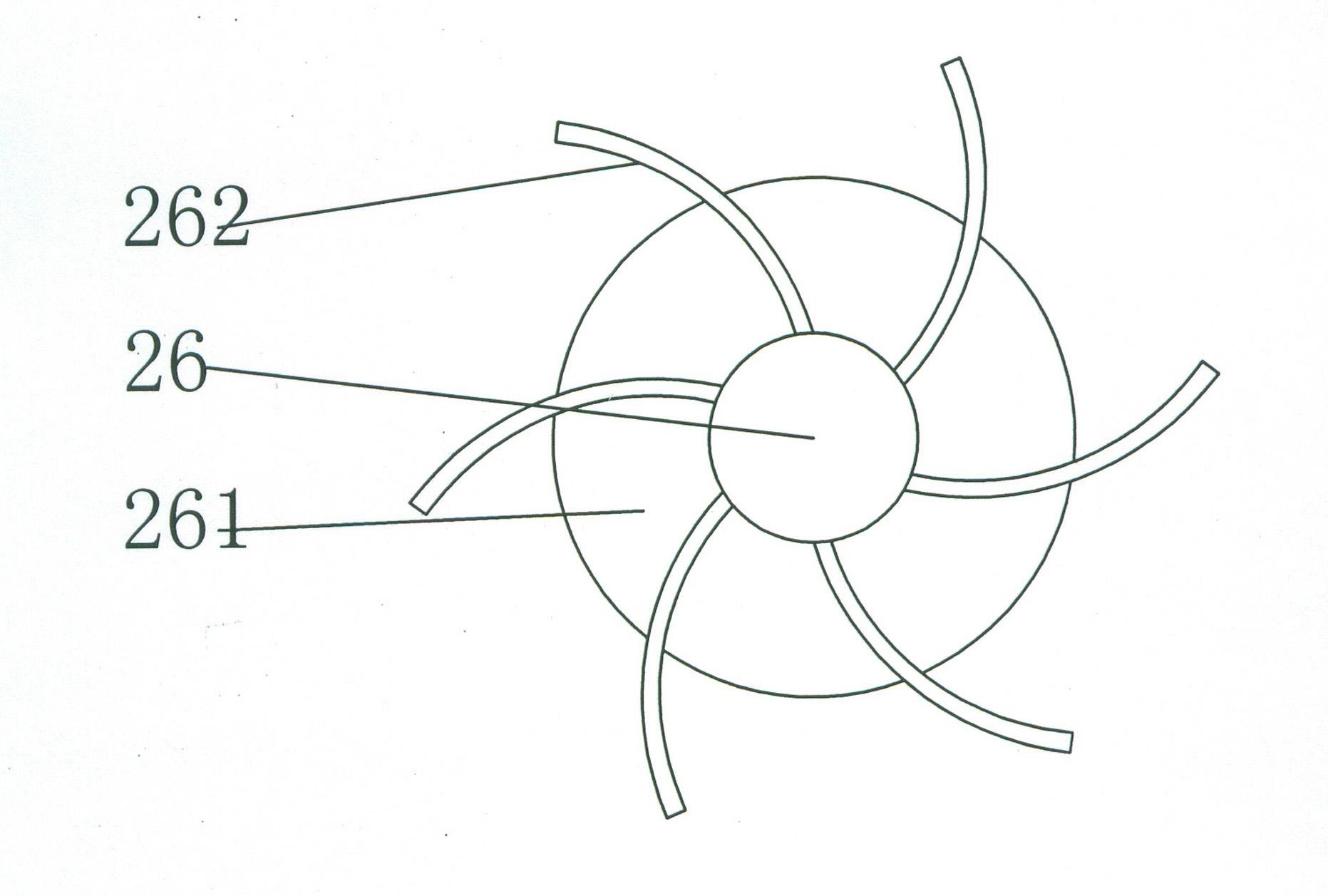

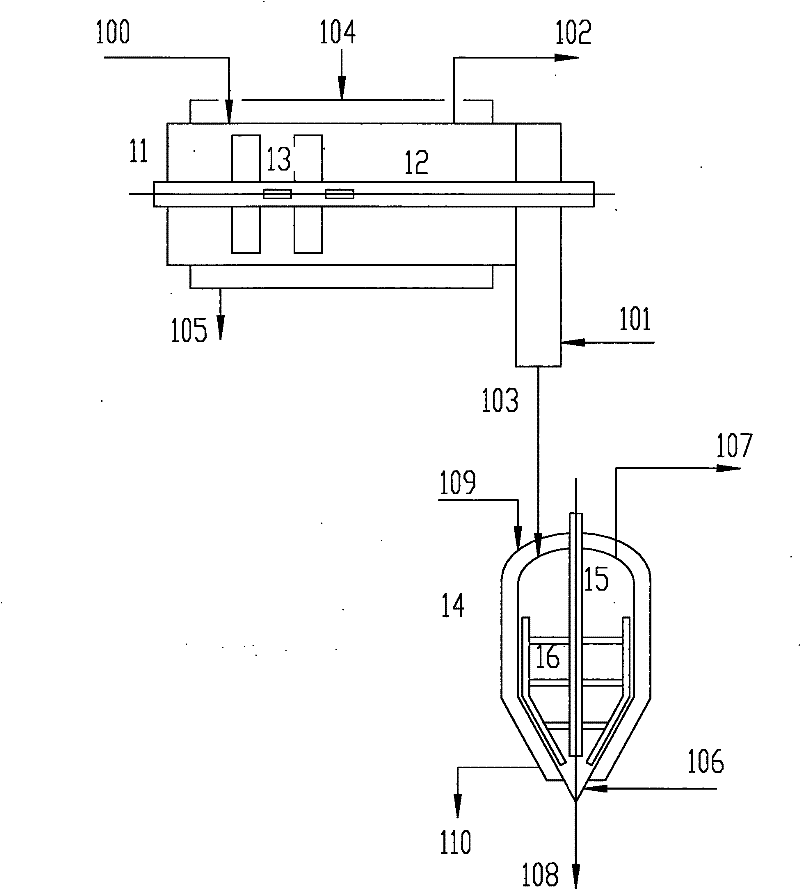

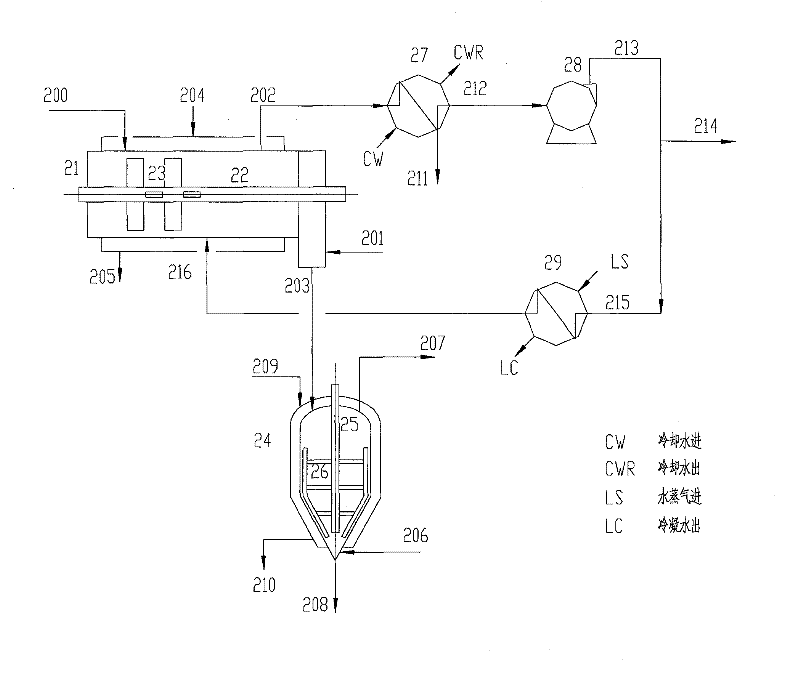

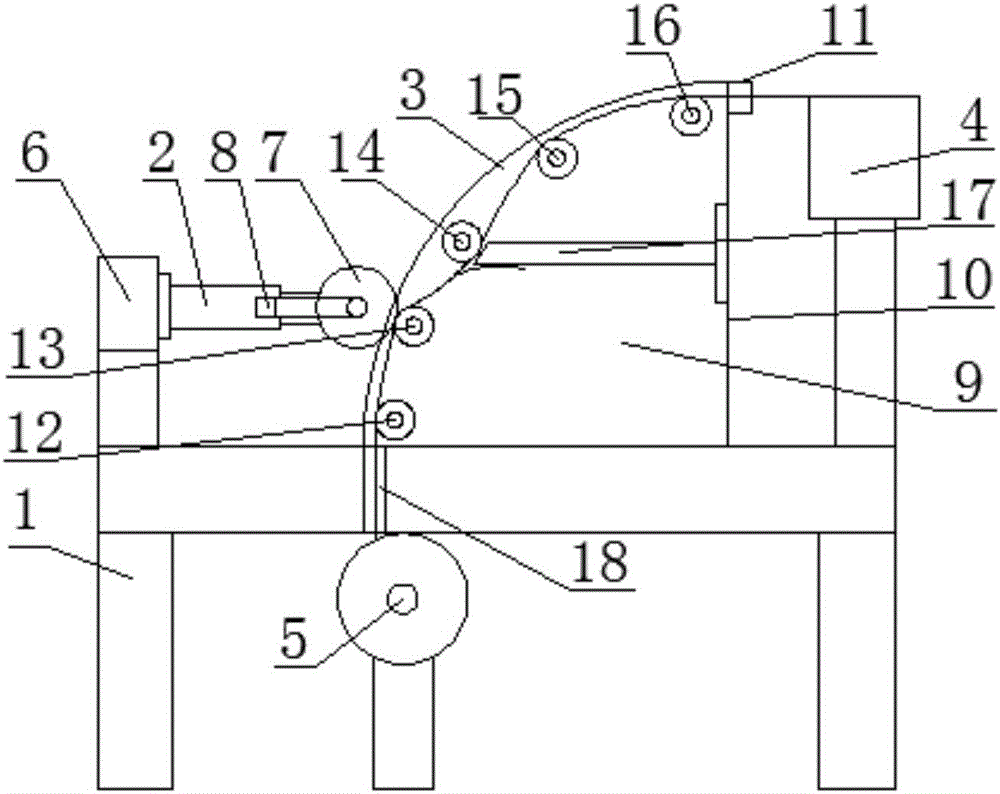

Liquid steel slag dry-process granulating device and sensible heat recovery method

InactiveCN102329900AAchieve a high degree of micronizationRecycle thoroughlyRecycling and recovery technologiesProcess efficiency improvementRecovery methodSlag

The invention relates to a liquid steel slag dry-process granulating device and a sensible heat recovery method. The liquid steel slag dry-process granulating device comprises a feeding device, a dry-process granulator, a cyclone separator and a sensible heat recovery device, wherein the dry-process granulator, the cyclone separator and the sensible heat recovery device are mutually communicated.The granulating method comprises the following steps: liquid steel slag enters the dry-process granulator through the feeding device and is granulated into fine steel slag granules, and enters the roller type sensible heat recovery device with solid particles separated by the cyclone separator to recover the sensible heat. The invention has the advantages that the grain size of the granulated steel slag is small and uniform, the sensible heat recovery efficiency is high, the occupied area is small and the investment cost is low.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Plug-in playing method and device in browser

ActiveCN103064680AImprove stabilityDoes not affect the playback effectInterprogram communicationSpecific program execution arrangementsComputer architecture

Owner:BEIJING QIHOO TECH CO LTD

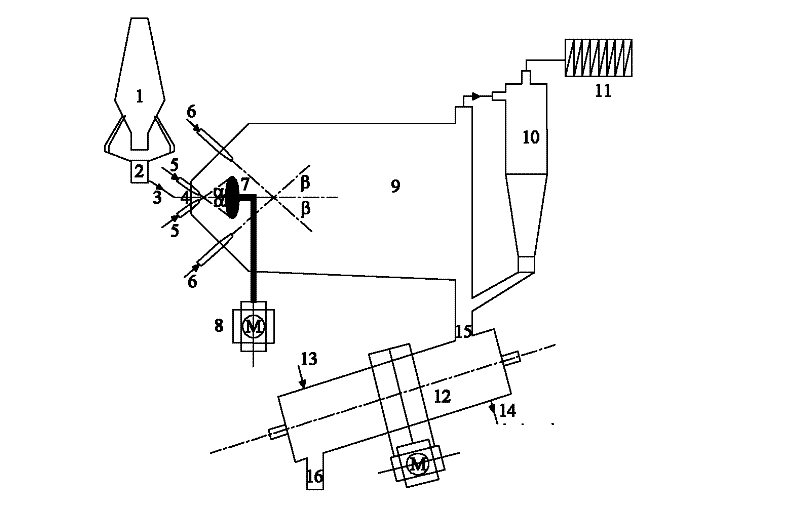

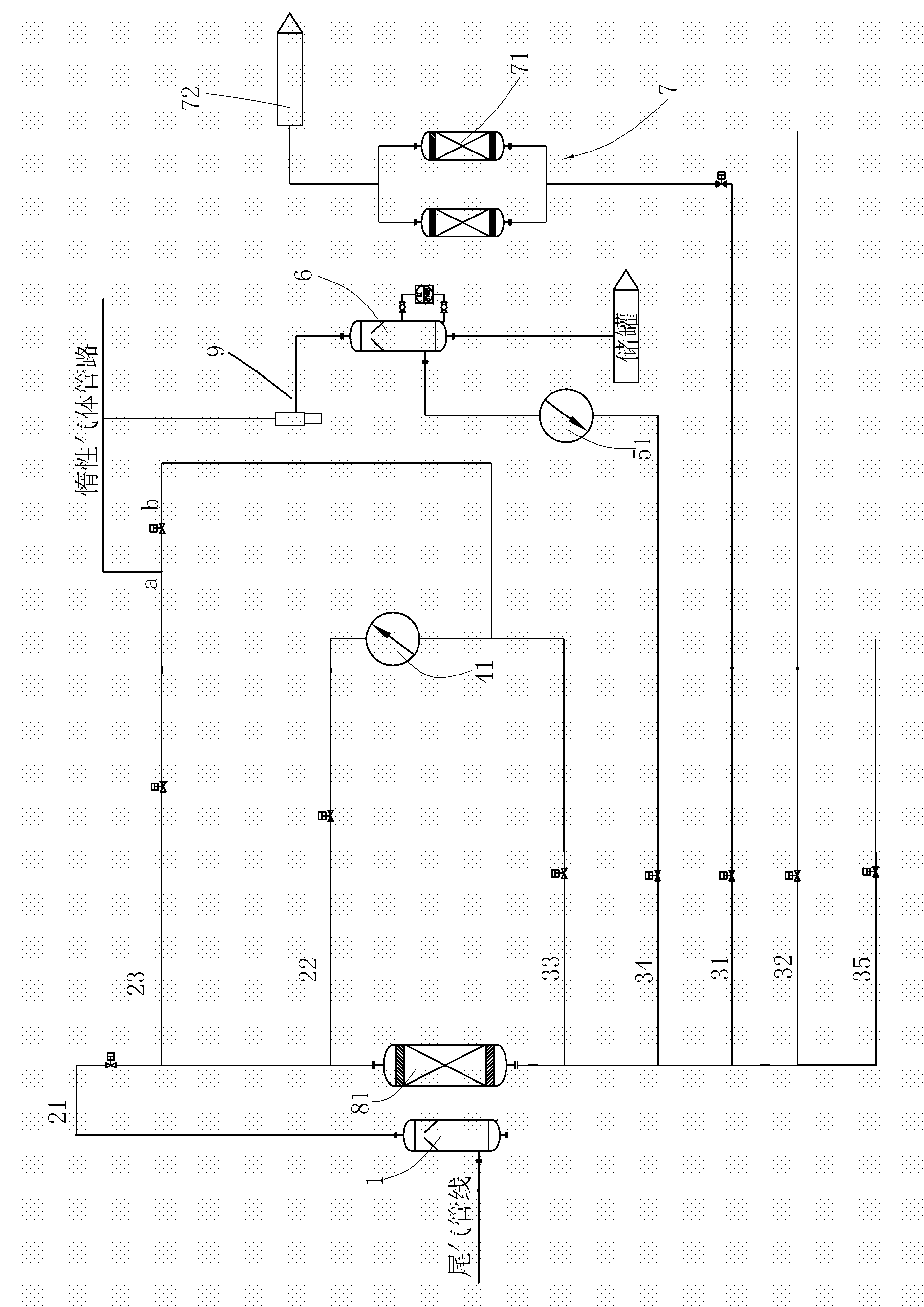

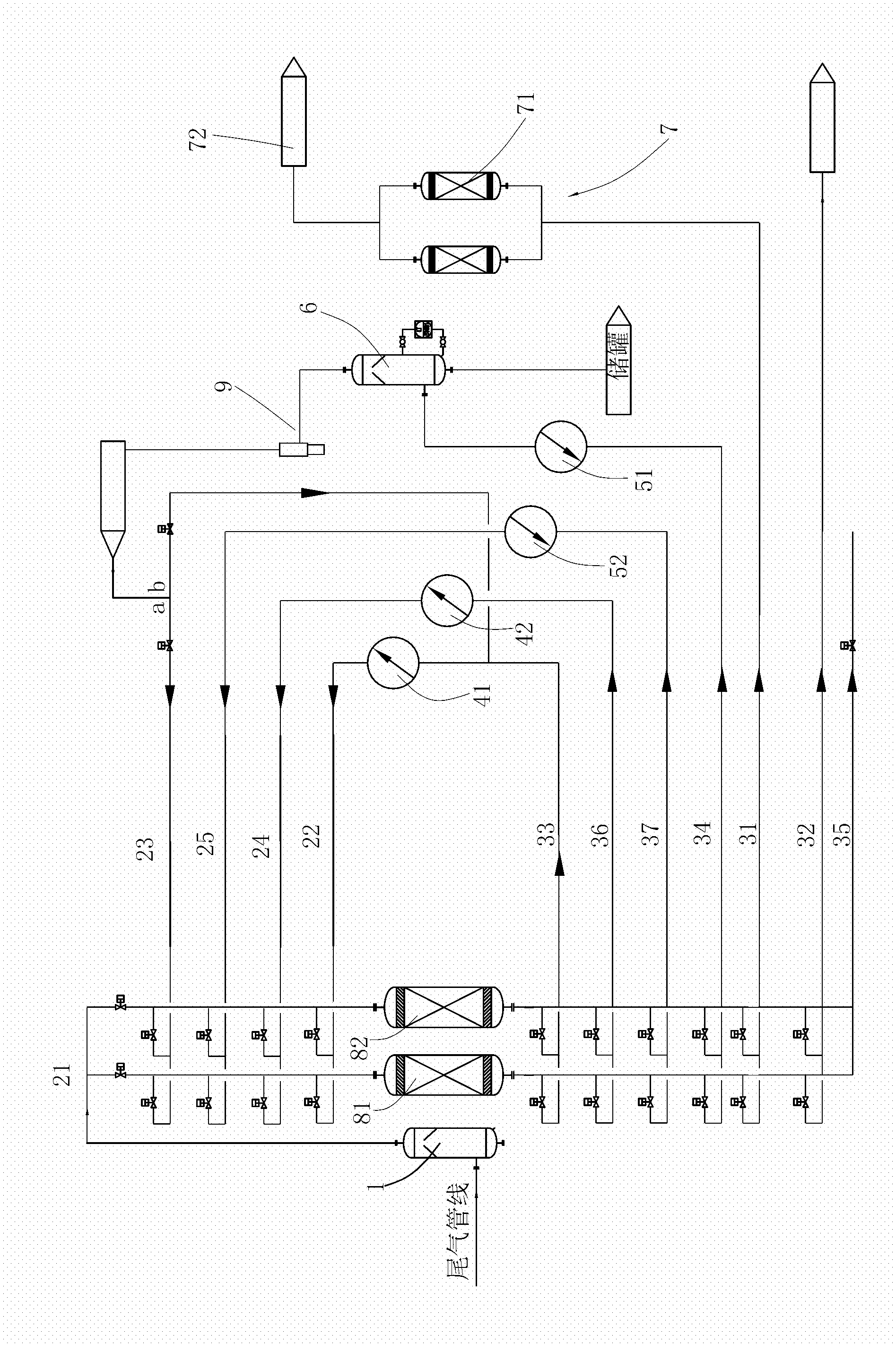

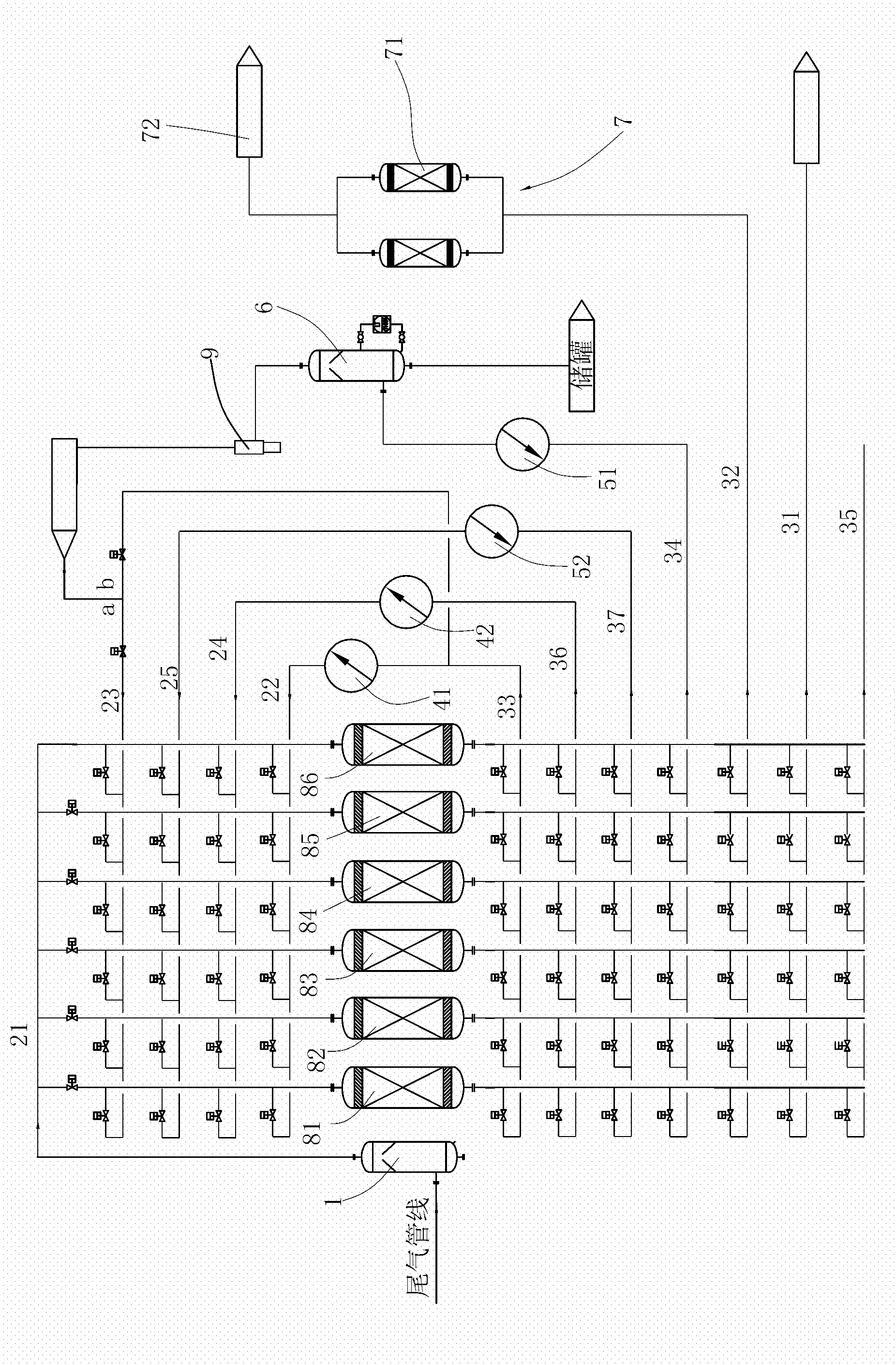

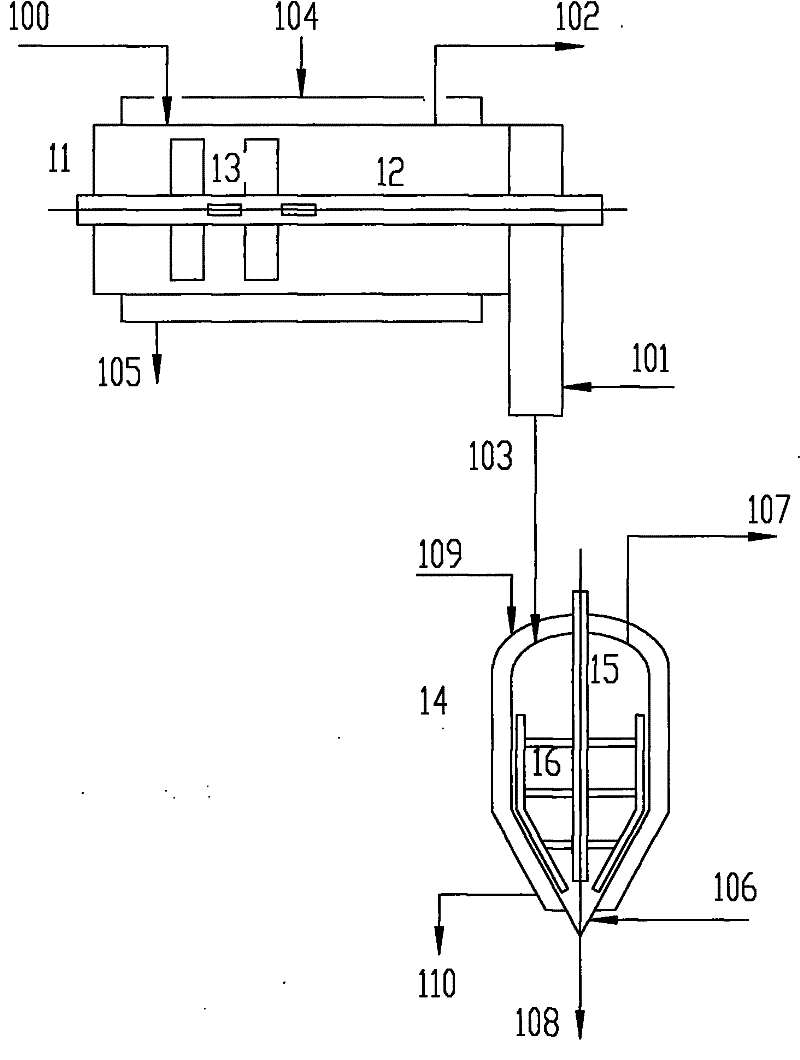

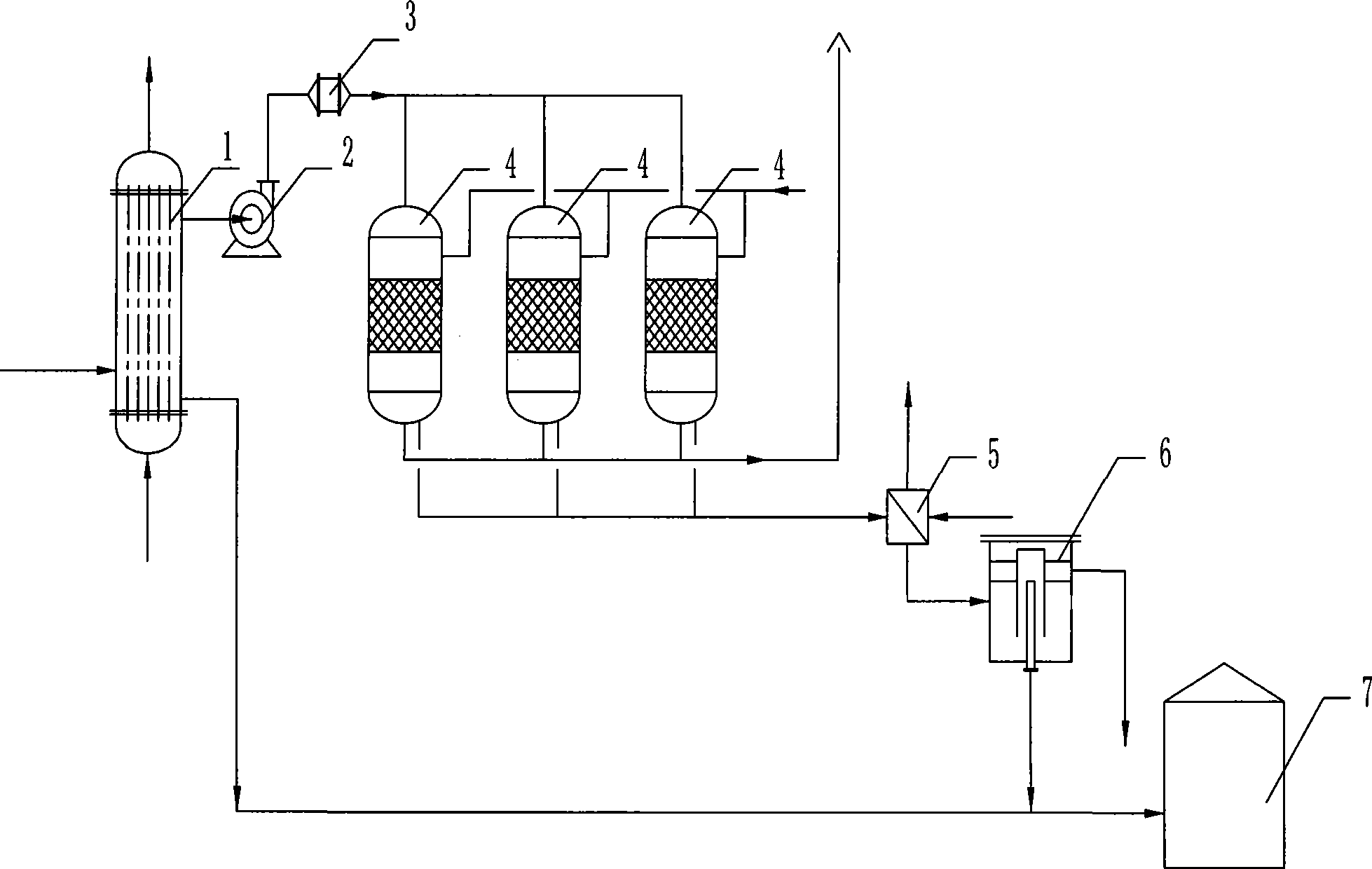

Tail gas treatment device for cyclohexane oxidation system and treatment method thereof

ActiveCN102423601ARecycle thoroughlyAchieve regenerationDispersed particle separationVapor–liquid separatorNitrogen

The invention relates to a tail gas treatment device for a cyclohexane oxidation system. The device is characterized by comprising a temperature swing adsorption tower with three inlet pipelines, with the first inlet pipeline connected to a pipeline of tail gas to be treated through a control valve, the second inlet pipeline connected to the first joint of a heater through a control valve, and the third inlet pipeline connected to the first branch of an inert gas pipeline through a control valve. And the temperature swing adsorption tower has five outlet pipelines, wherein, the first outlet pipeline is in connection with a PSA (pressure swing adsorption) nitrogen making instrument through a control valve, the second outlet pipeline is in connection with an aerodynamic transfer line through a control valve, the third outlet pipeline is in connection with the second joint of the heater through a control valve, the fourth outlet pipeline is in connection with the first joint of a cooler through a control valve, and the fifth outlet pipeline is emptied at a high post through a control valve. The second joint of the cooler is in connected to the inlet of a gas-liquid separator, the gasoutlet of which is connected to the inert gas pipeline through a compressor. And the second branch of the inert gas pipeline is connected to the second joint of the heater through a control valve. The tail gas treatment device of the invention has the advantages of stable operation and good energy saving effect.

Owner:CHONGQING HUAFON CHEM +1

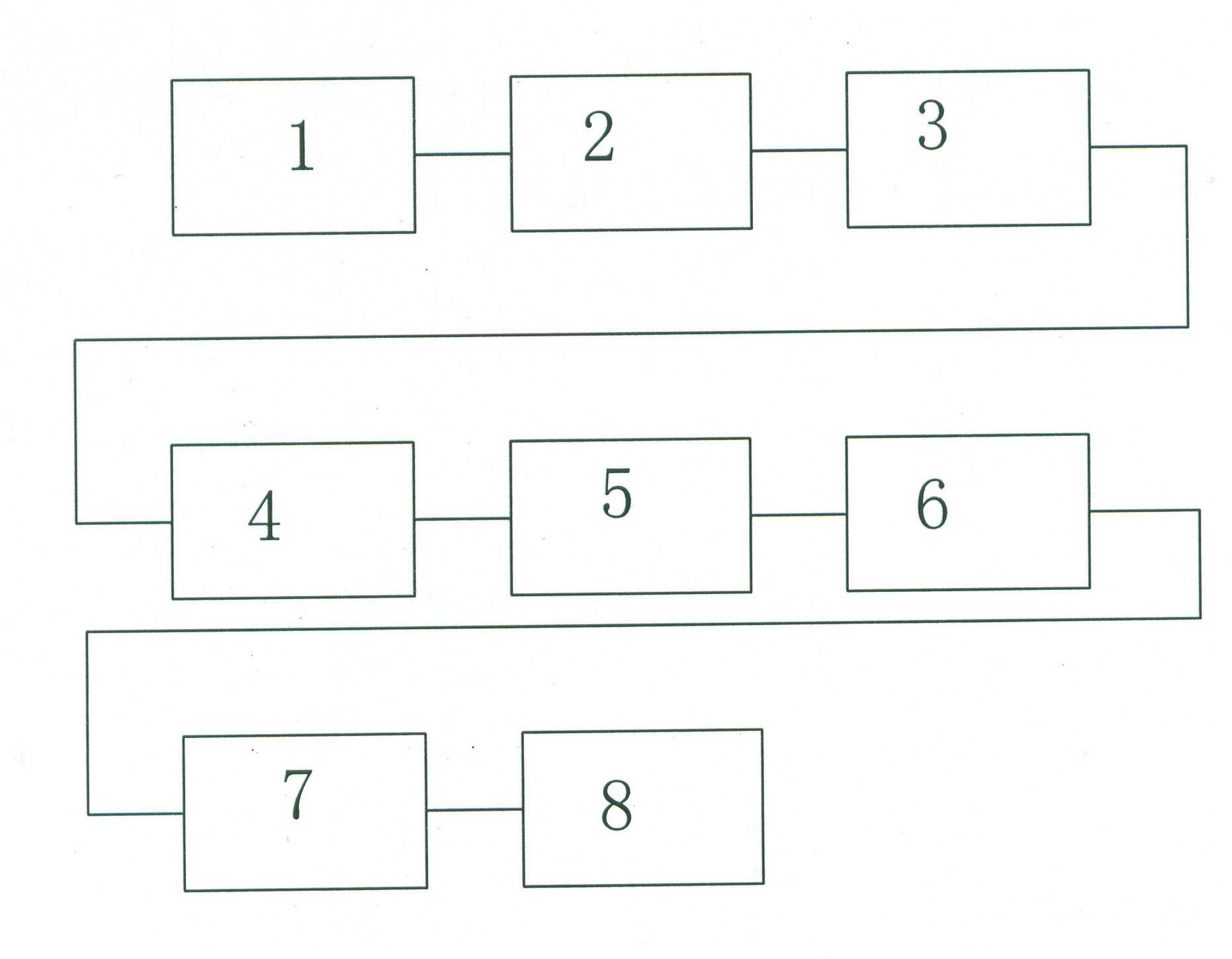

Environment-friendly papermaking process and environment-friendly papermaking equipment

InactiveCN102605664AReduce churnLow costMachine wet endPaper material treatmentEnvironmental resistanceFiber

The invention relates to the field of papermaking, in particular to an environment-friendly papermaking process, which includes:1, impurity separating; 2, desilting; 3, desanding; 4, water distributing; 5, fiber decomposing; 6, fine pulp conveying for storage; 7, paper making, and 8, waste water recycling. By means of the process, scum utilization rate is 100%, electric energy can be saved by 80%, fiber loss is reduced, cost is directly reduced by 8% for enterprises, and water is saved by 80%. Further, drug usage is reduced by more than 95% by using the physical fiber recovery and static treatment method.

Owner:侯俊民

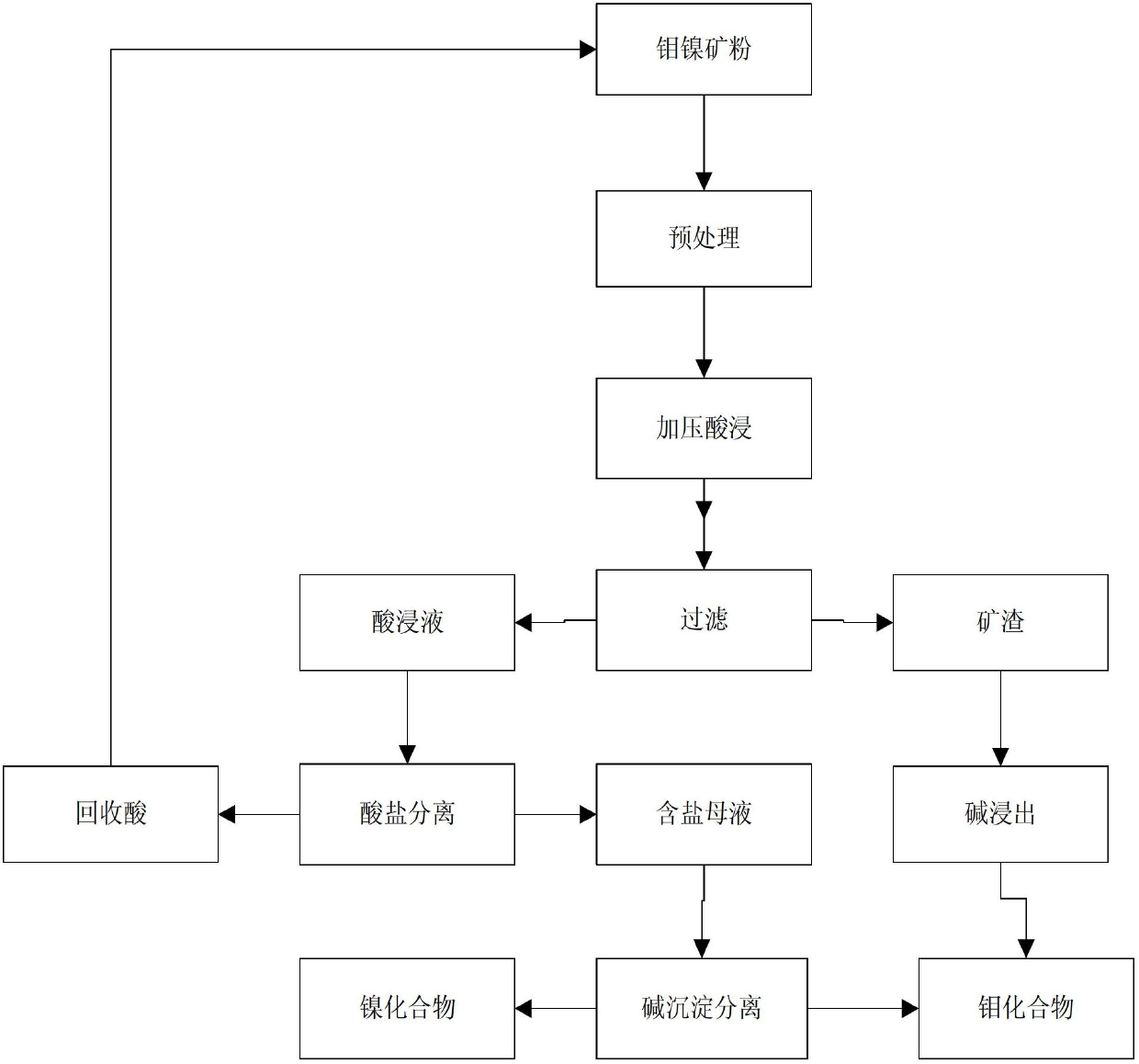

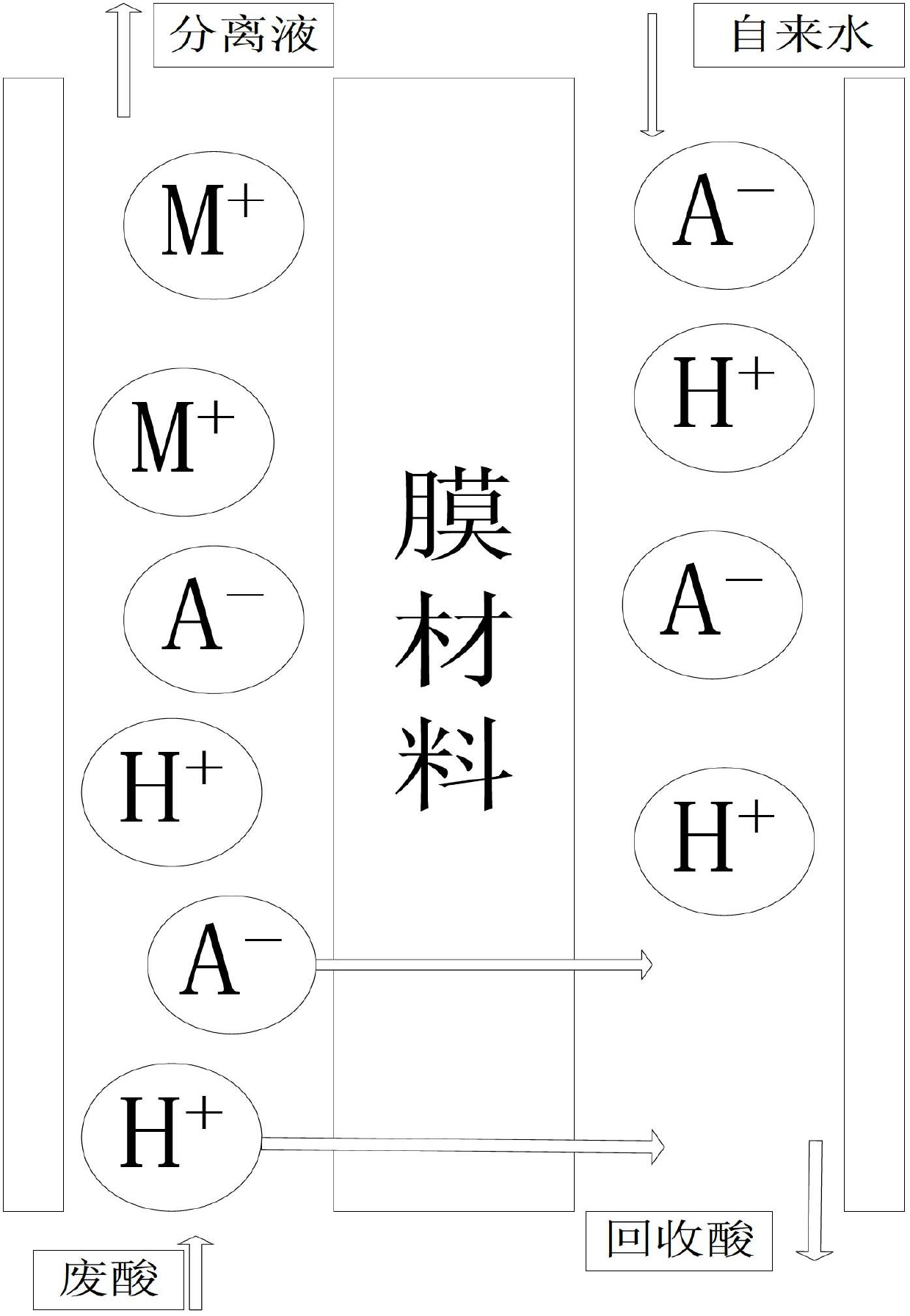

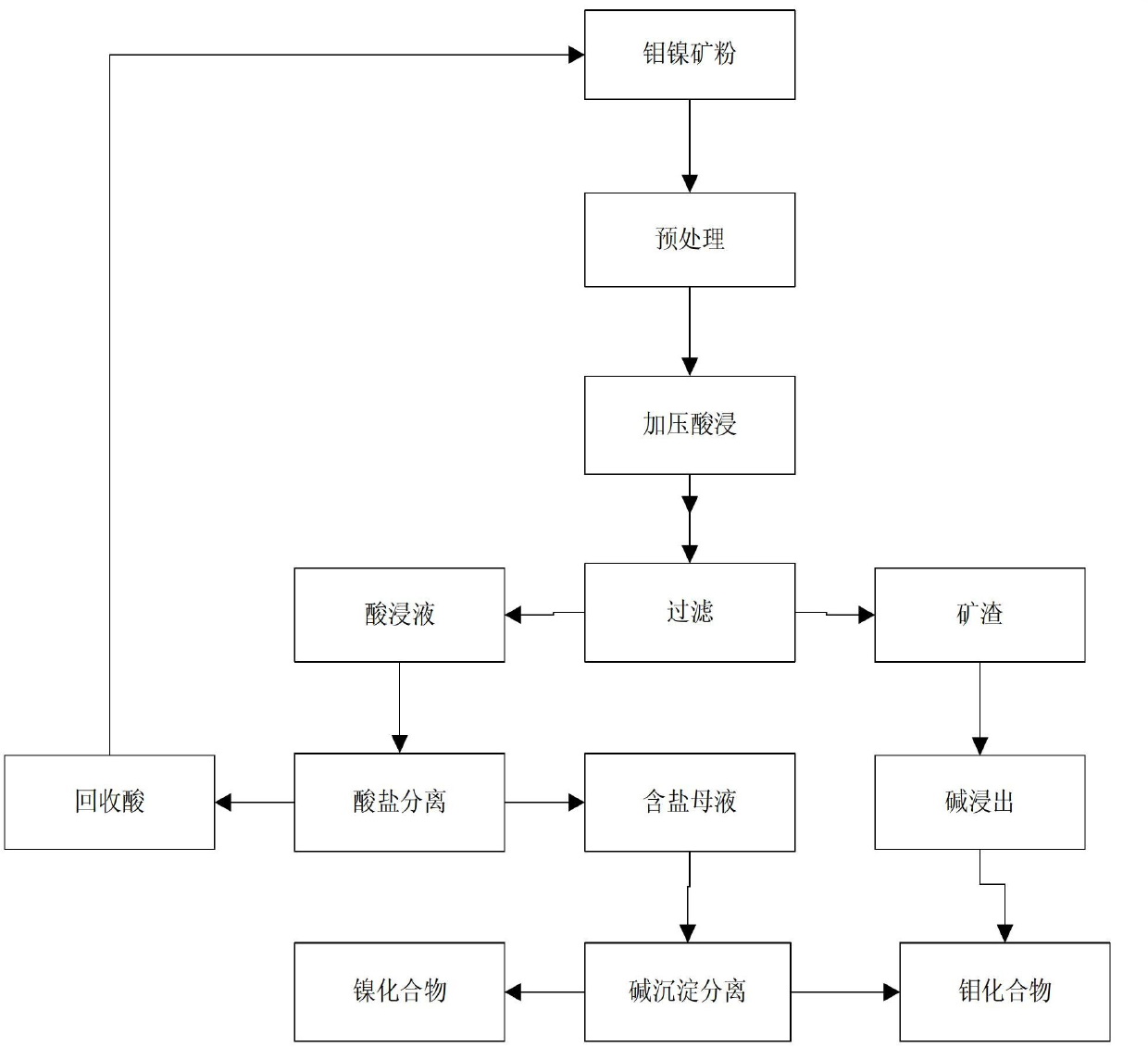

Resource utilization method for catalytic oxidation leaching of molybdenum and nickel from molybdenum-nickel ore

InactiveCN102676803AImprove the effect of leachingImprove equipment utilizationProcess efficiency improvementIonIon exchange

The invention discloses a resource utilization method for catalytic oxidation leaching of molybdenum and nickel from molybdenum-nickel ore. By the method, the production efficiency is improved and the production cost is reduced. The resource utilization method comprises the following steps: A) crushing and grinding the molybdenum-nickel ore to obtain molybdenum-nickel ore powder with the granularity of 100-300 meshes; B) preparing a leaching solution by using nitrate, acid and water in a ratio; C) adding the molybdenum-nickel ore powder obtained in the step A), a catalyst and the leaching solution obtained in the step B) into a reaction kettle, and performing leaching reaction to obtain leachate; and D) filtering the leachate, separating acid and salt from the filtrate by using a membraneseparation method or an ion exchange method, recycling an acid solution, adjusting the pH value of a salt-containing separated solution, and precipitating to obtain a molybdenum compound and a nickelcompound.

Owner:NANJING YUANTAI ENVIRONMENTAL PROTECTION TECH

Post-processing method for polypropylene powder

The invention provides a post-processing method for polypropylene powder, which belongs to the petroleum chemical field. In the polypropylene post-processing method of the prior art, the method comprises the following steps: polypropylene powder which departs from a polymerization system and is carried out preliminary gas / solid separation enters into a drier, indirectly heated through steam and nitrogen is introduced, hydrocarbons can be removed in powder and then enters in a steamer, nitrogen and water vapor are introduced for inactivation of a catalyst; or the polypropylene powder which departs from a polymerization system and is carried out preliminary gas / solid separation enters into a degassing chamber, water vapor-containing nitrogen is introduced in the degassing chamber; the present invention modifies the prior art. The post-processing method of the invention comprises the following steps: introducing water vapor, modifying the drier to a steam drier used for recovering hydrocarbons and inactivating the catalyst, introducing a hydrocarbons-removed polymer in the steam drier (or a degassing chamber), adding nitrogen without water vapor in the steam drier, modifying the steam drier to a moisture eliminator used for removing water vapor in powder. The method of the invention is capable of thoroughly recovering hydrocarbons which depart from the polymerization system by an economic method, reducing the unit consumption and energy consumption, and thoroughly solving the problem on environmental protection.

Owner:高煦

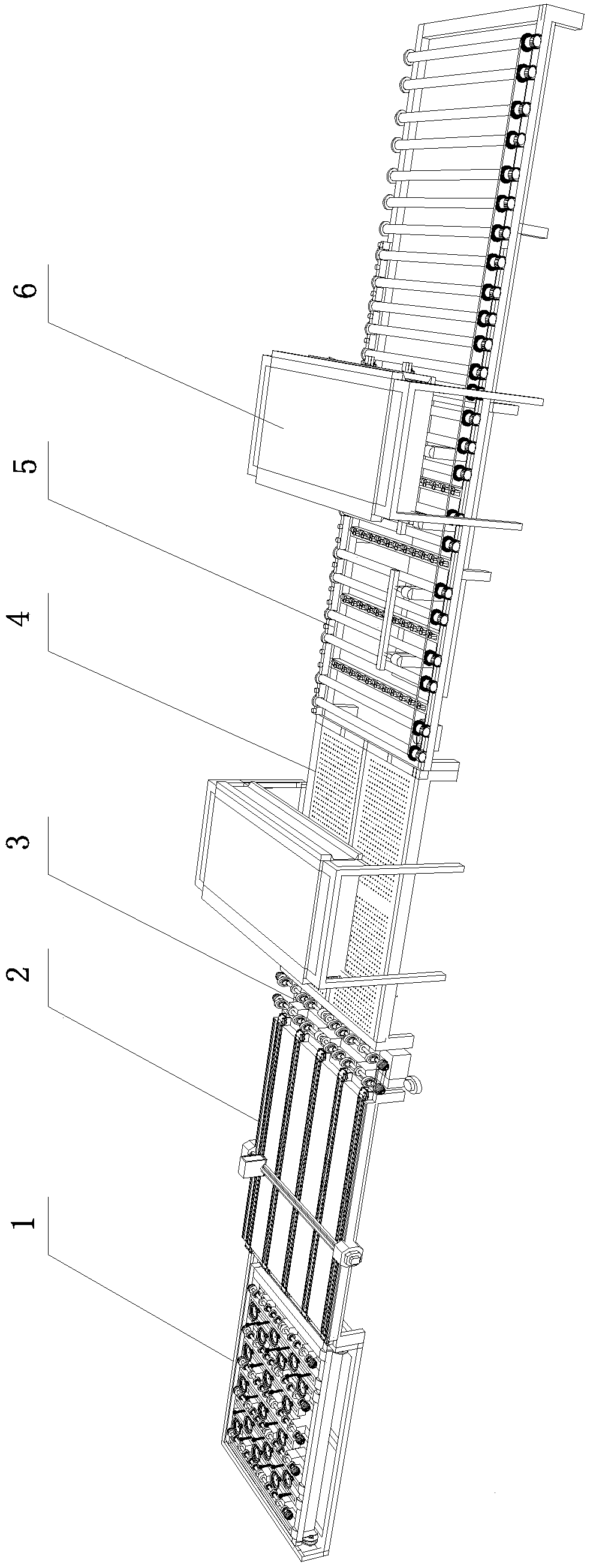

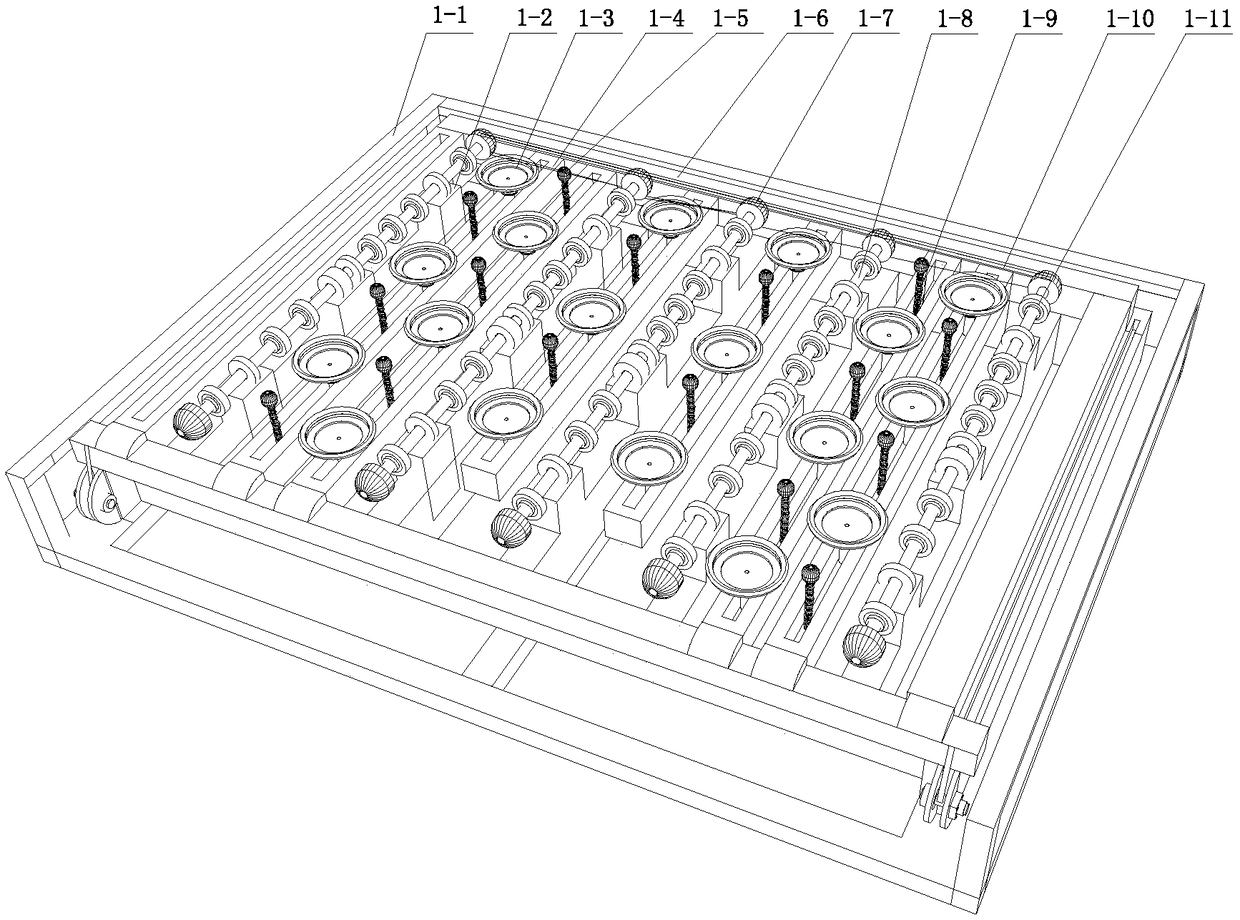

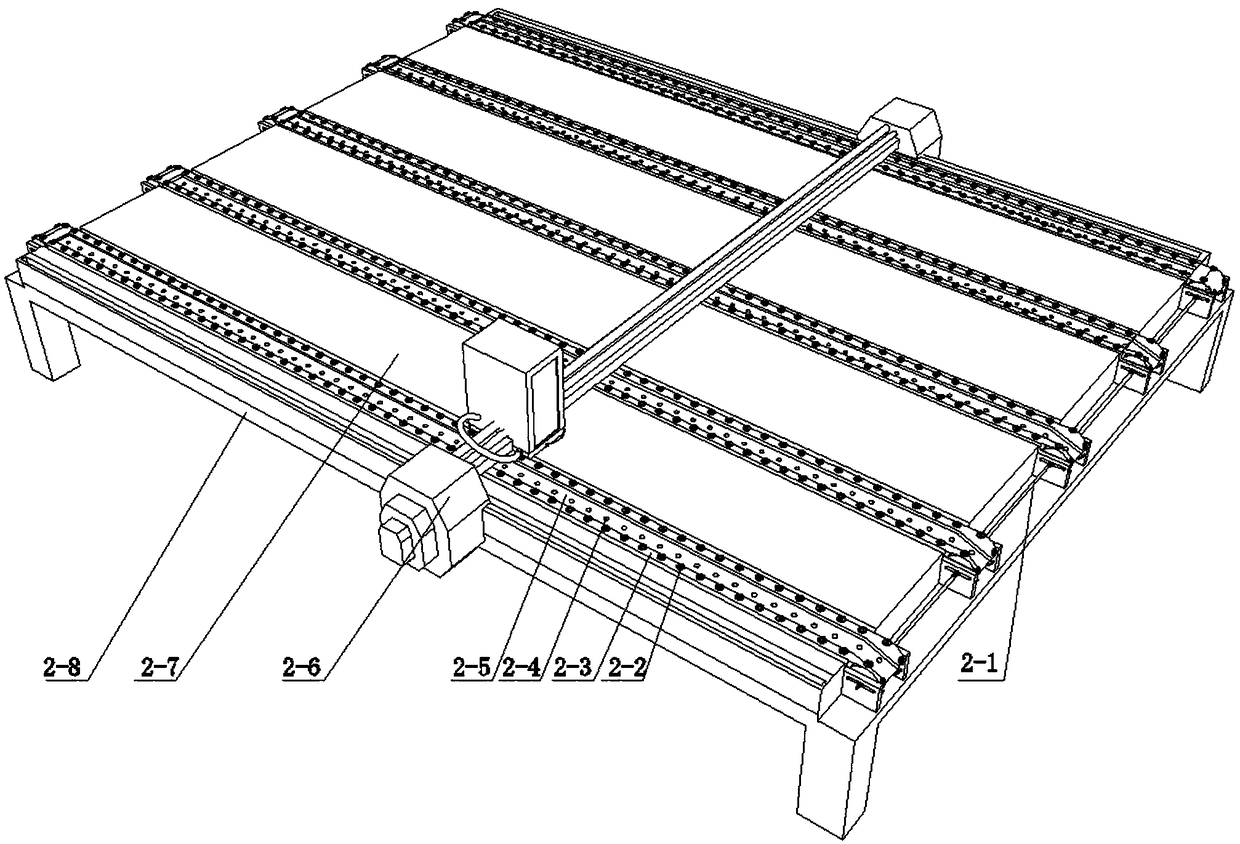

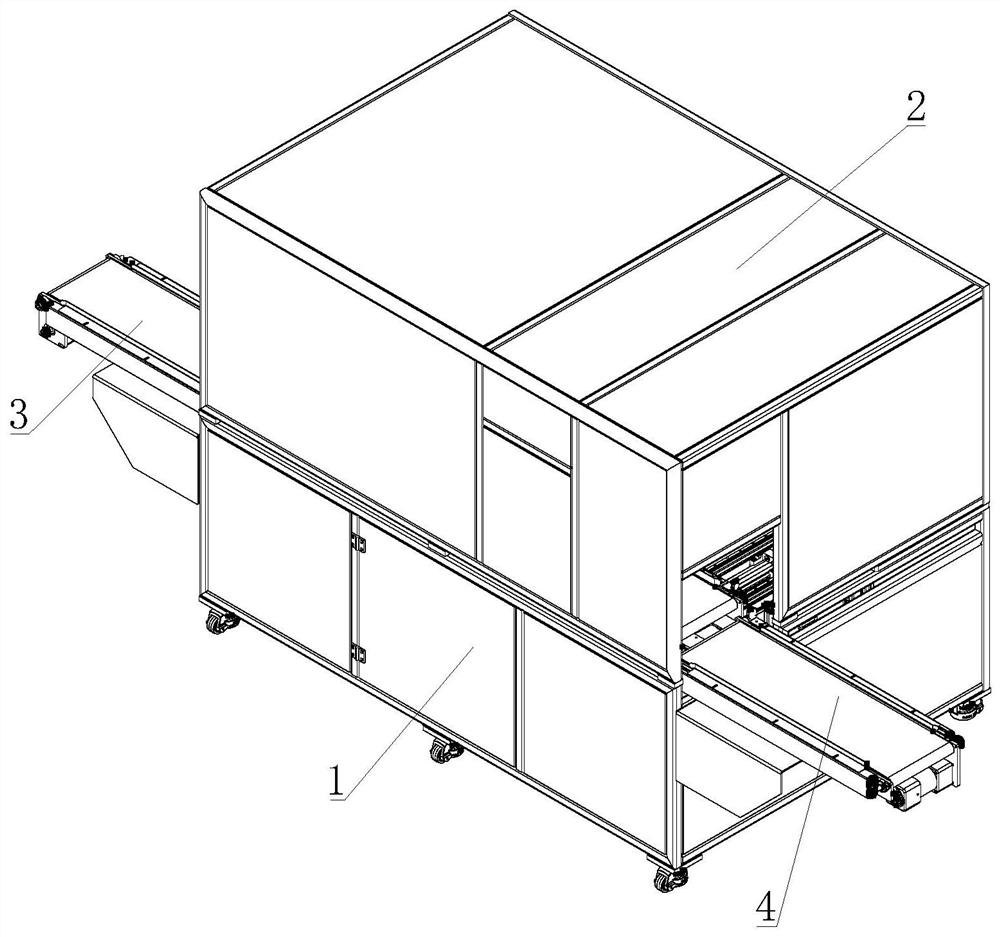

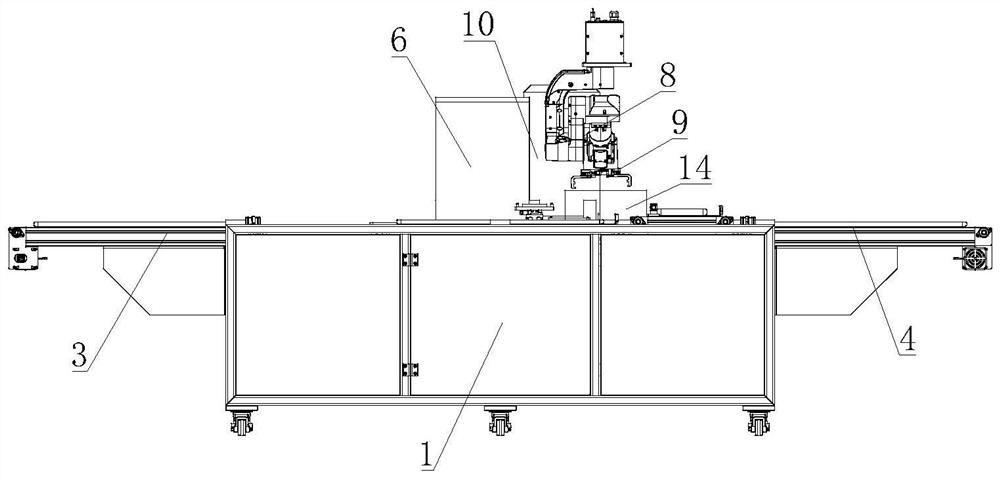

Full-automatic glass slitting and edge-grinding assembly line

PendingCN108943422ALow processing and production costsHigh degree of automationWorking accessoriesStone-like material working toolsTime efficientWater resources

The invention relates to a full-automatic glass slitting and edge-grinding assembly line. The assembly line is sequentially provided with a full-automatic glass loading machine, a full-automatic glasscutting machine, an automatic glass breaking table and a full-automatic glass edge grinding machine in the moving direction of glass. The assembly line can achieve the effects of full-automatic glassloading, feeding, cutting, breaking and edge grinding, the trouble of manual glass loading, manual cutting, manual breaking and manual edge grinding is avoided, moreover, the production environment protection efficiency of workers in each link is improved, machining of the glass is finer, the resource waste is reduced by utilizing recycling of the water resources, meanwhile, the equipment is protected, the automation degree is high, the production efficiency is high, the product percent of pass is high, the labor is saved, the time is saved, the glass slitting cost is reduced, and the safetyis high.

Owner:鹏凯(天津)玻璃有限公司

Scrap iron collecting device applied to machining

InactiveCN107649938ASimple structureReduce manufacturing costMaintainance and safety accessoriesEngineeringLarge particle

The invention discloses a scrap iron collecting device applied to machining. The scrap iron collecting device applied to machining disclosed by the invention is reasonable and simple in structure, lowin production cost, convenient to mount, high in work efficiency and fast and thorough in recovering. Scrap iron is collected in a collecting tank; a lead screw adjusts the height of a collecting wheel; the collecting wheel rotates and a collecting shovel on the collecting wheel extracts scrap iron and the scrap iron enters an inclined plate and enters a first cleaning room to be cleaned; the scrap iron is sucked by an electromagnetic suction disc to a second cleaning room and is further cleaned by means of a cleaning fan; the scrap iron is further sucked by the electromagnetic suction disc to a filter room and is filtered by a scrap iron filter screen; small particle scrap iron is filtered to a first collecting room, and finally, the box door is opened, and large particle scrap iron is collected in a second collecting room.

Owner:叶子硕

Method for separating enriched uranium, thorium mixture and rare earth from preferred slag

The invention discloses a separating method of enriched uranium and thorium composition and rare earth, which comprises the following steps: leaching slag; extracting; separating extracting phase, residual phase and insoluble solid; obtaining the product.

Owner:YANGZHOU UNIV +2

Method for recycling waste LCD (liquid crystal display) panels

InactiveCN103191903ARealize recyclingSimple methodWaste processingSolid waste disposalHydrofluoric acidOrganic solvent

The invention relates to a method for recycling waste LCD (liquid crystal display) panels. The method is characterized by comprising the following steps of: removing an upper layer of polaroids and a lower layer of polaroids on the LCD panel with an organic solvent; crushing left LED panel core into glass fragments with liquid crystal stuck on the surface; then putting into the organic solvent for dissolving the liquid crystal through ultrasonic; respectively obtaining pretreated glass fragments without liquid crystal and a solution with liquid crystal through filtering; separating the liquid crystal from the solution with liquid crystal through a distillation manner; soaking the pretreated glass fragments into a hydrofluoric acid solution; obtaining a solution containing indium and clean glass fragments through filtering, wherein the clean glass fragments are the glass substrate fragments of an upper layer of glass substrate and a lower layer of glass substrate; aerating the solution containing indium into a hydrofluoric acid evaporator for drying through evaporating; and obtaining a solid product rich in indium. The method realizes recycling of the waste LCD panels, is simple and thorough in recycling, and does not cause secondary pollution.

Owner:HEFEI UNIV OF TECH

Device for recycling waste electric wires, cables and copper wires

InactiveCN106128656ASimple structureReasonable designBasic electric elementsElectronic waste recyclingCopper wireVertical edge

The invention provides a device for recycling waste electric wires, cables and copper wires, and belongs to the technical field of electrical equipment. The device comprises a support; a cutting mechanism, a guiding mechanism and a drawing mechanism are sequentially arranged on the support; a pay-off mechanism is arranged at the bottom of the support, the cutting mechanism comprises a driving mechanism, and the driving mechanism drives a cutting knife; the guiding mechanism comprises two parallel side plates, the horizontal edges of the two side plates are fixed on the support, and a vertical fixed plate is arranged between the vertical edges of the two side plates; a first roller, a second roller, a third roller, a fourth roller and a fifth roller are arranged between the arc edges of the two side plates; a separating knife is arranged on the vertical fixed plate, a gap is formed between the separating knife and the third roller, and a gap is formed between the cutting knife and the second roller. The device for recycling waste electric wires, cables and copper wires is simple in structure, reasonable in design, convenient to use, thorough in recycling and high in utilization rate, does not need secondary wire making, saves resources and is economical.

Owner:TIANJIN DAILY PROSPERITY SCI & TECH GROUP

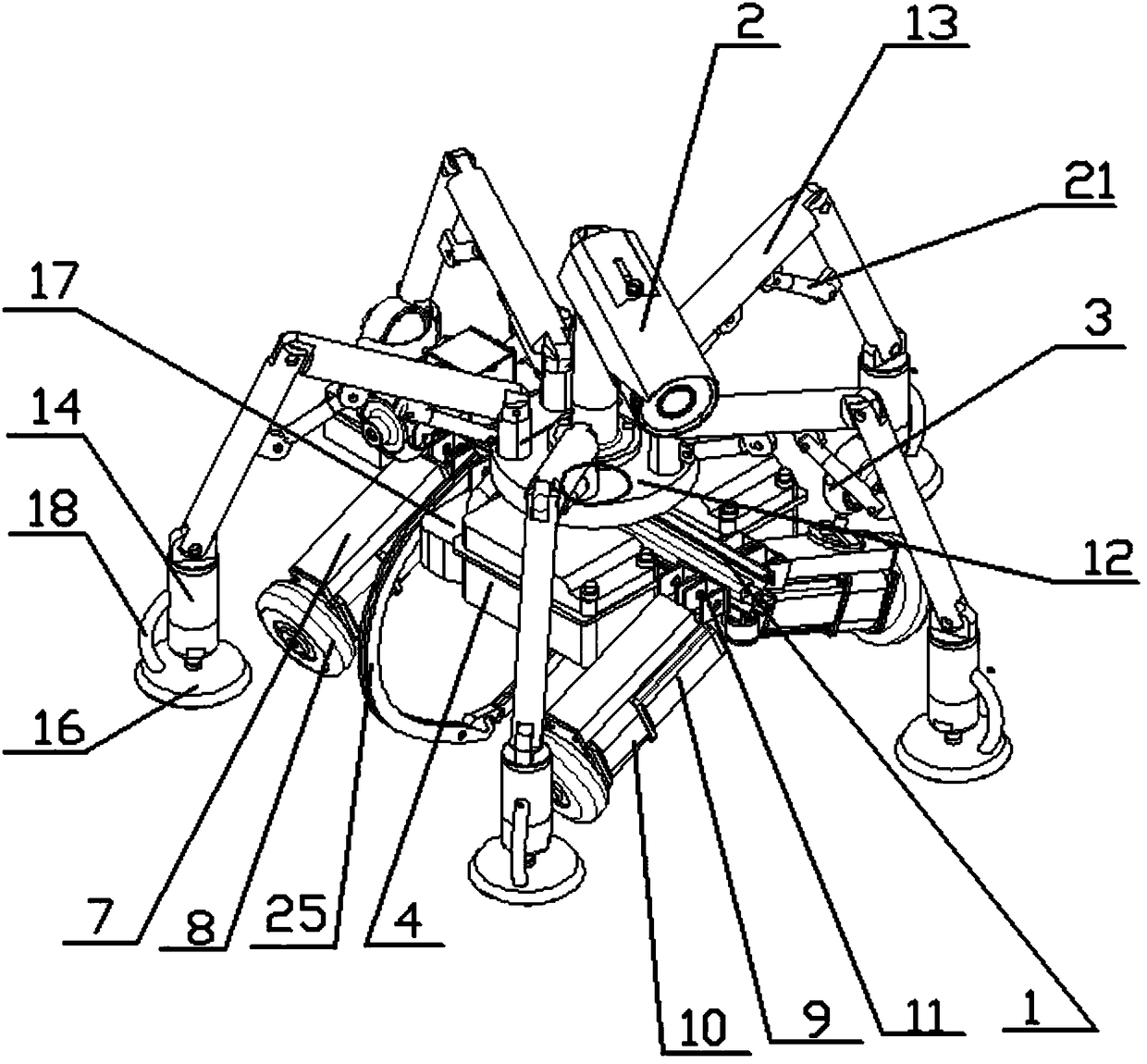

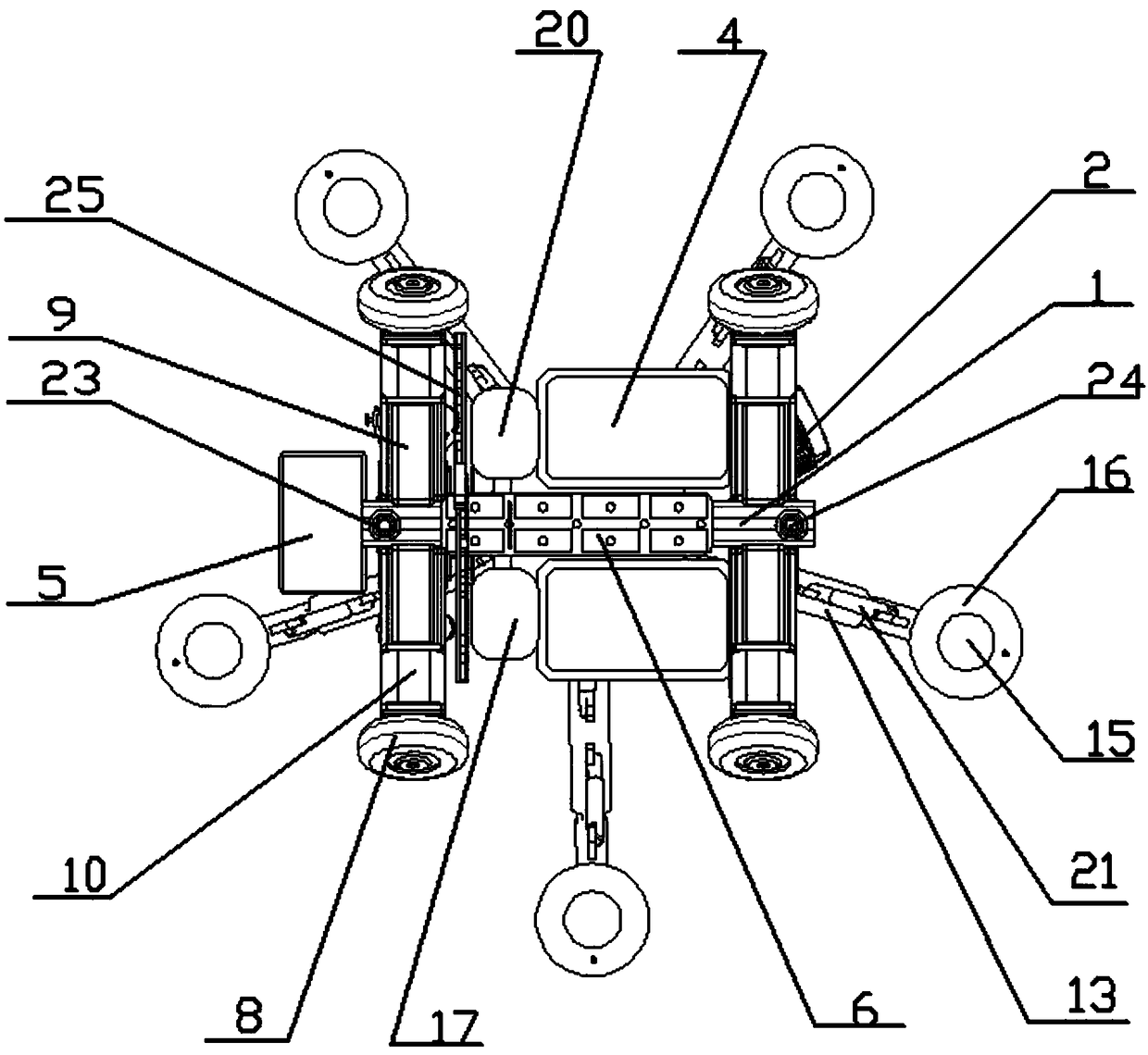

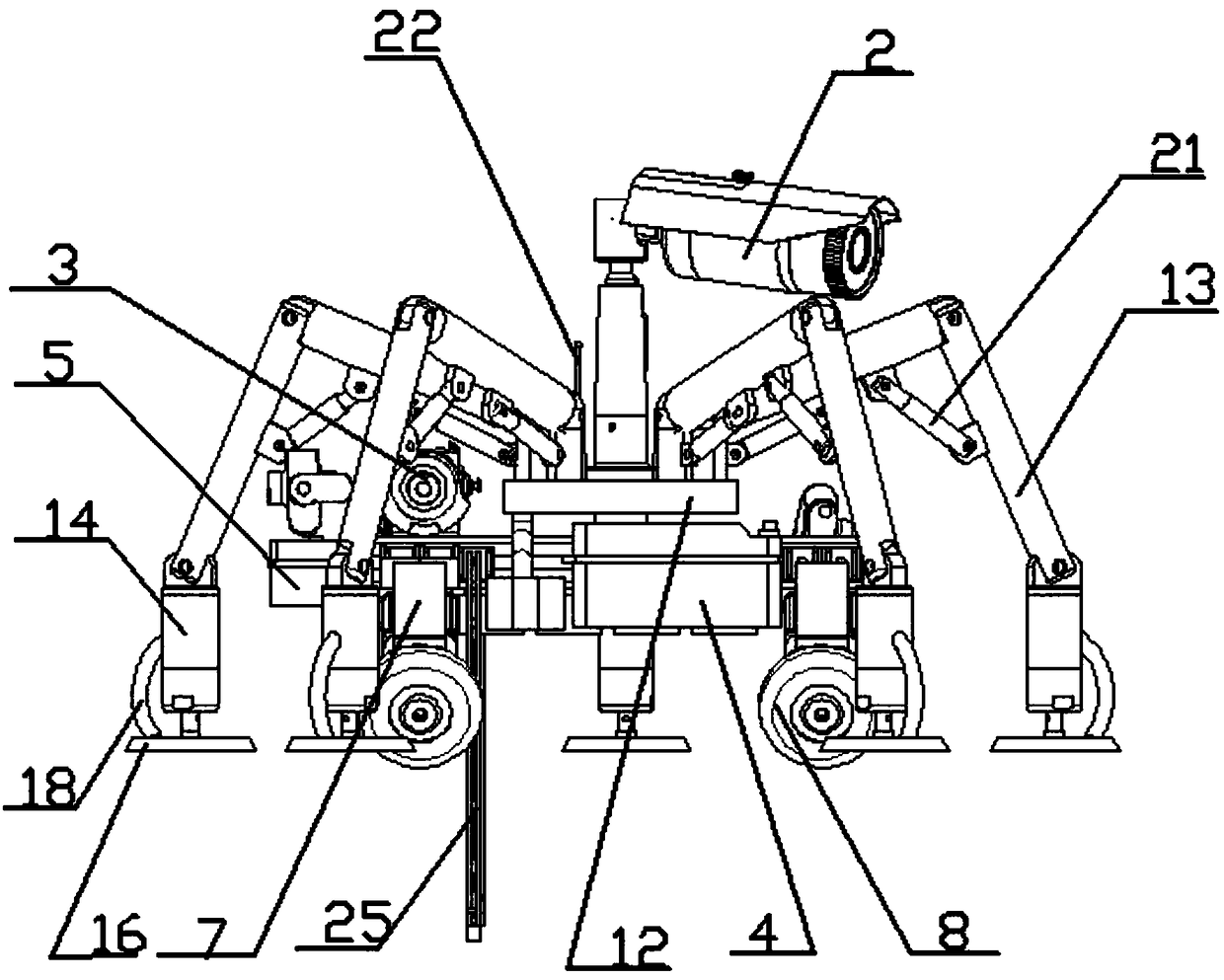

Wheeled robot used for eliminating and spraying fireproof anticorrosive coating on steel frame structure

PendingCN108247604ARecycle thoroughlyDoes not affect trafficManipulatorControl systemAgricultural engineering

The invention provides a wheeled robot used for eliminating and spraying fireproof anticorrosive coating on a steel frame structure. The wheeled robot is characterized by comprising a frame, a permanent magnetic adsorption device, four symmetrically arranged travelling system, a repairing assembly, a high-definition camera, an infrared distance meter, a battery and a control system. The wheeled robot can be used alone or multiple wheeled robots are connected in series or in parallel, the automatic spraying area is larger, the working time is longer, and garbage collection is more thorough; andthe wheeled robot provided by the invention can continuously walk on complex steel environment work interfaces such as a ladder, a crossed wall surface, a curved surface and a circular arc and carryout polishing, spraying and detection operations. The wheeled robot provided by the invention can automatically eliminate and polish a fireproof coating and an anticorrosive coating of a shed-free steel frame supporting column of a railroad platform, sprays fireproof anticorrosive coating and can carry out all weather operations without influencing pass of G-series high-speed trains.

Owner:温广胜

Environmentally-friendly recovering and compacting device for waste batteries

ActiveCN106584901ARecycle thoroughlyImprove the compaction effectWaste accumulators reclaimingGrain treatmentsEngineeringPiston

The invention relates to a waste battery recovering device, in particular to an environmentally-friendly recovering and compacting device for waste batteries. The environmentally-friendly recovering and compacting device for the waste batteries is environmentally friendly, complete in recovering, good in compacting effect, and short in recovering and treating time. The device comprises a supporting rod, a first roller, a first pulling rope, a slide block, a second roller, a second pulling rope, a slide rail, a spring, a pressing block, pressing plates, connecting rods, a worktable, horizontal cylinders, etc., wherein the horizontal cylinders are symmetrically arranged at the left side and the right side of the bottom part of the supporting rod; horizontal pistons connected with the connecting rods are arranged in the horizontal cylinders; the pressing plates are connected to the connecting rods. The device achieves the effects of environmental protection, complete recovering, good compacting effect and short recovering and treating time; the waste batteries can be quickly recovered; and the waste batteries are completely recovered and compacted, so that the environmental protection is further improved.

Owner:江苏贝肯盛创新能源科技有限公司

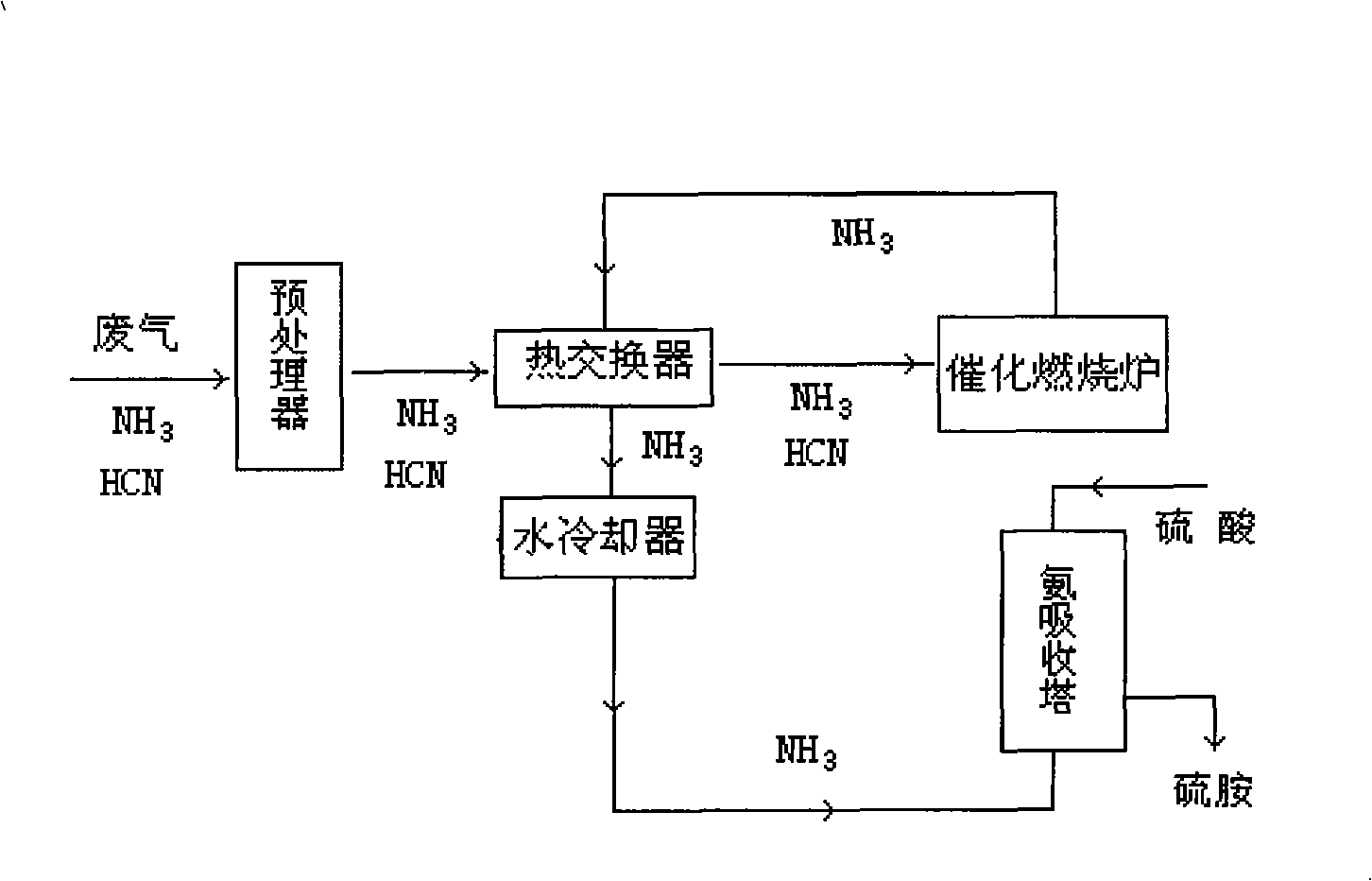

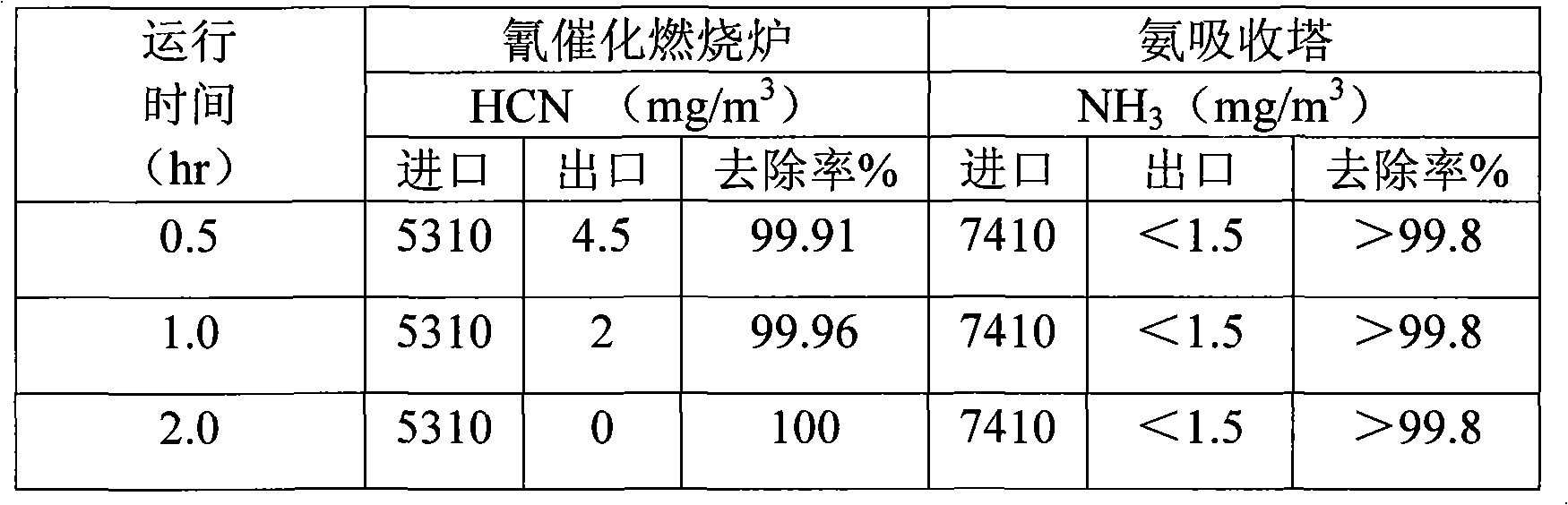

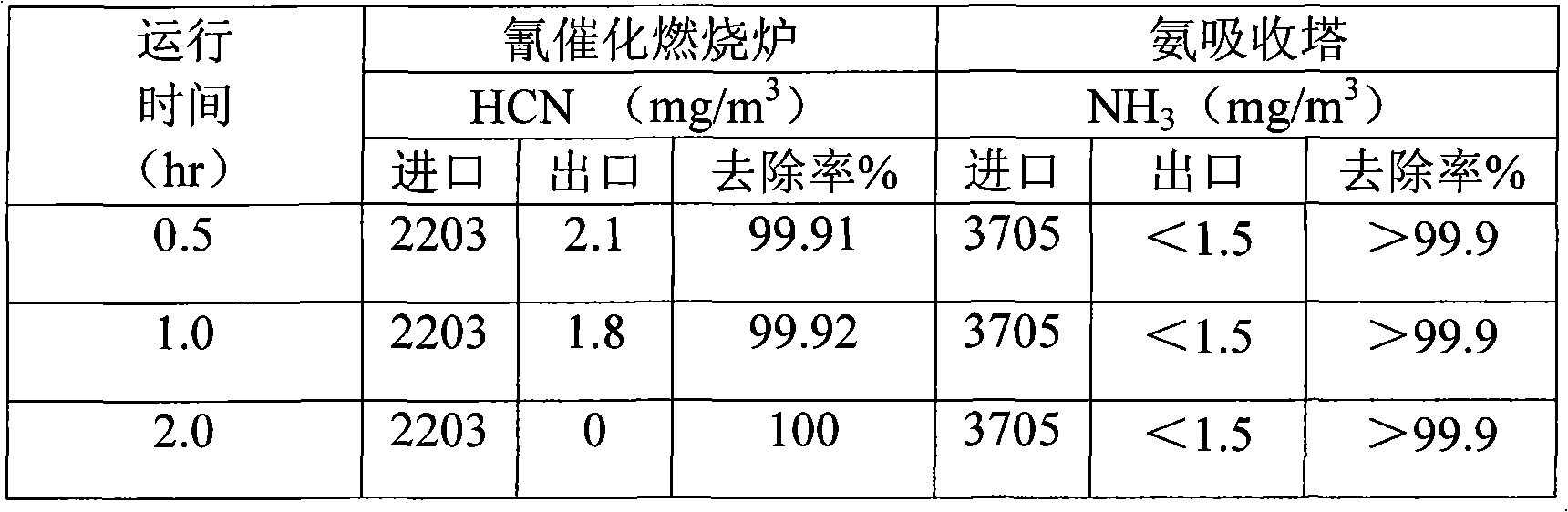

Method for processing waste gas generated in isophthalonitrile production process

ActiveCN101491747AThorough treatmentRecycle thoroughlyDispersed particle separationNitrogen gasPollution

The invention relates to a method for treating isophthalonitrile production waste gas, which comprises the following steps that: (1) the waste gas from an isophthalonitrile production line enters a pre-treating device first to be subjected to impurity removal; (2) the waste gas enters a heat exchanger; (3) the waste gas enters a catalytic combustion furnace to be subjected to low-temperature catalysis and combustion, and hydrogen cyanide is selectively oxidized by a catalyst into nontoxic nitrogen, carbon dioxide, water and ammonia gas is reserved; (4) the waste gas after decyanation enters the heat exchanger, the waste gas to be treated is preheated, but the heat exchanger is cooled; and (5) the preheated waste gas enters a water cooler to be cooled to normal temperature, the cooled ammonia-containing waste gas after decyanation is introduced into an ammonia absorption tower, and the ammonia is absorbed by sulfuric acid solution sprayed from the top and generates ammonium sulfate to be reclaimed so as to finish the treatment of the isophthalonitrile production waste gas. Compared with the prior art, the method for treating the isophthalonitrile production waste gas has the advantages of simple and reasonable process, low equipment investment and treating cost and low energy consumption, can thoroughly treat the hydrogen cyanide and reclaim the ammonia, and eliminate secondary pollution.

Owner:SHANGHAI TAIHE INT TRADE CO LTD

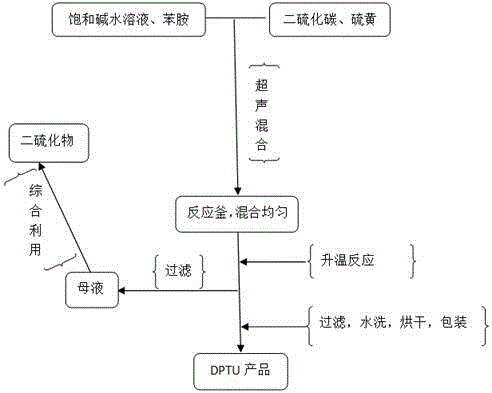

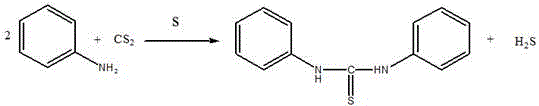

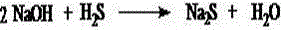

Method for synthesizing accelerator DPTU

The invention discloses a method for synthesizing an accelerator DPTU. The method comprises the following steps of: mixing aniline with an alkali aqueous solution uniformly; dissolving sulfur in carbon disulfide, and mixing until the sulfur completely dissolves; mixing the two mixtures uniformly, and then carrying out the reaction under normal pressure to obtain the accelerator DPTU. The invention adopts alkali aqueous solution as the solvent, and needs not to add an emulsifier, the generated hydrogen sulfide gas is absorbed and removed immediately during the reaction, so that the reaction is carried out toward the positive reaction direction to a greater extent, the reaction rate and the aniline conversion rate are improved, the yield is increased, the hydrogen sulfide gas recovery is more complete, the generation of hydrogen sulfide waste gas is reduced, and the production conditions are greatly improved.

Owner:SHANDONG YANGGU HUATAI CHEM

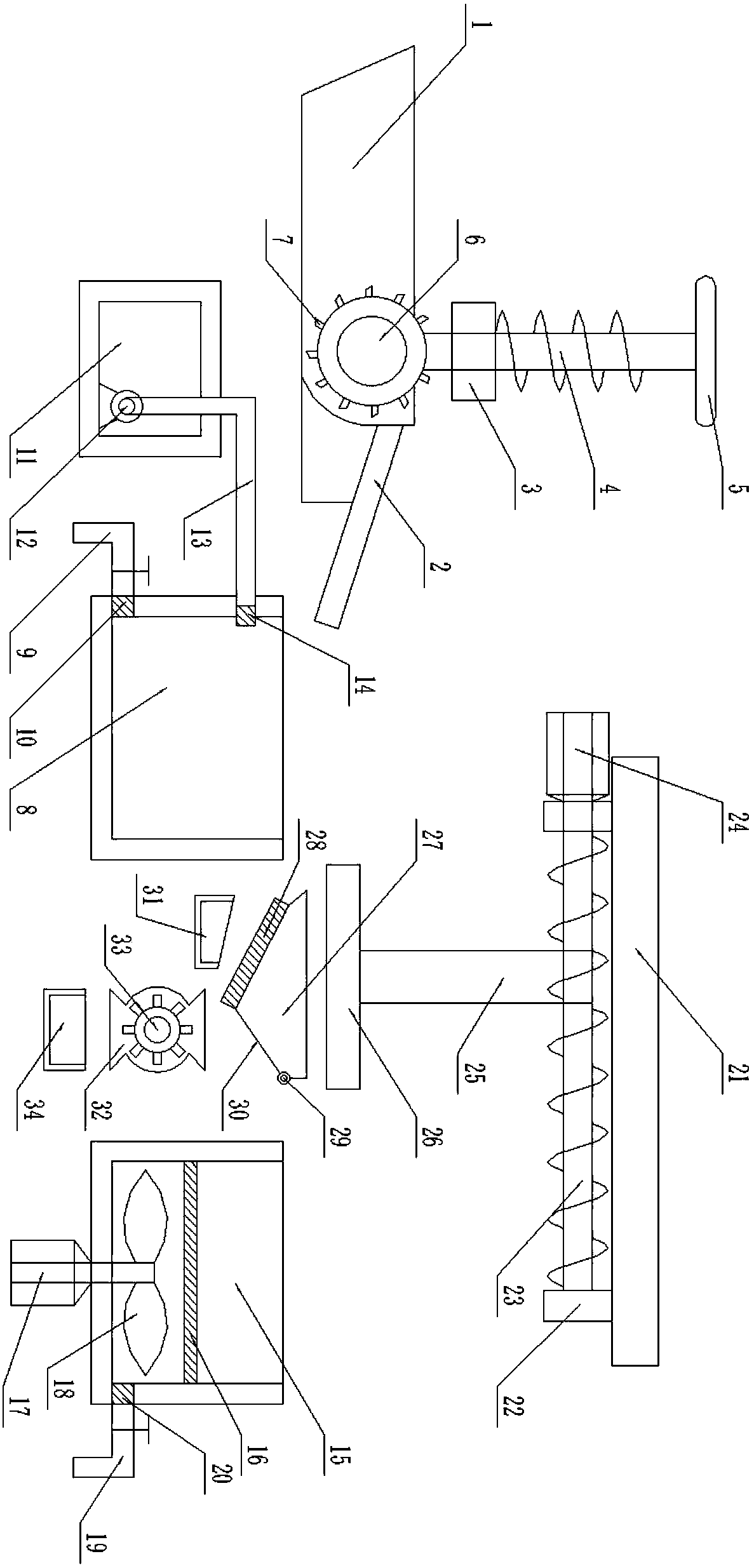

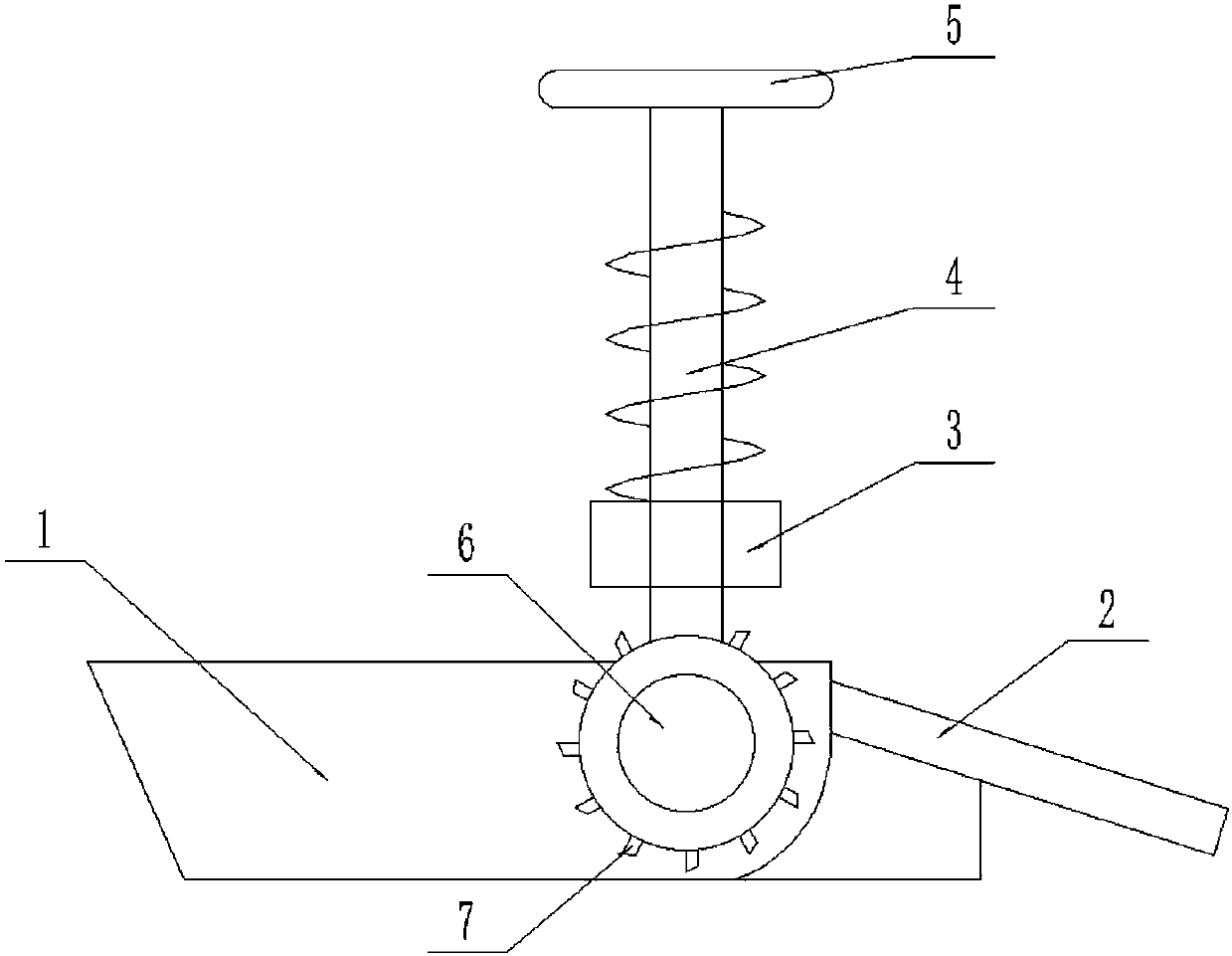

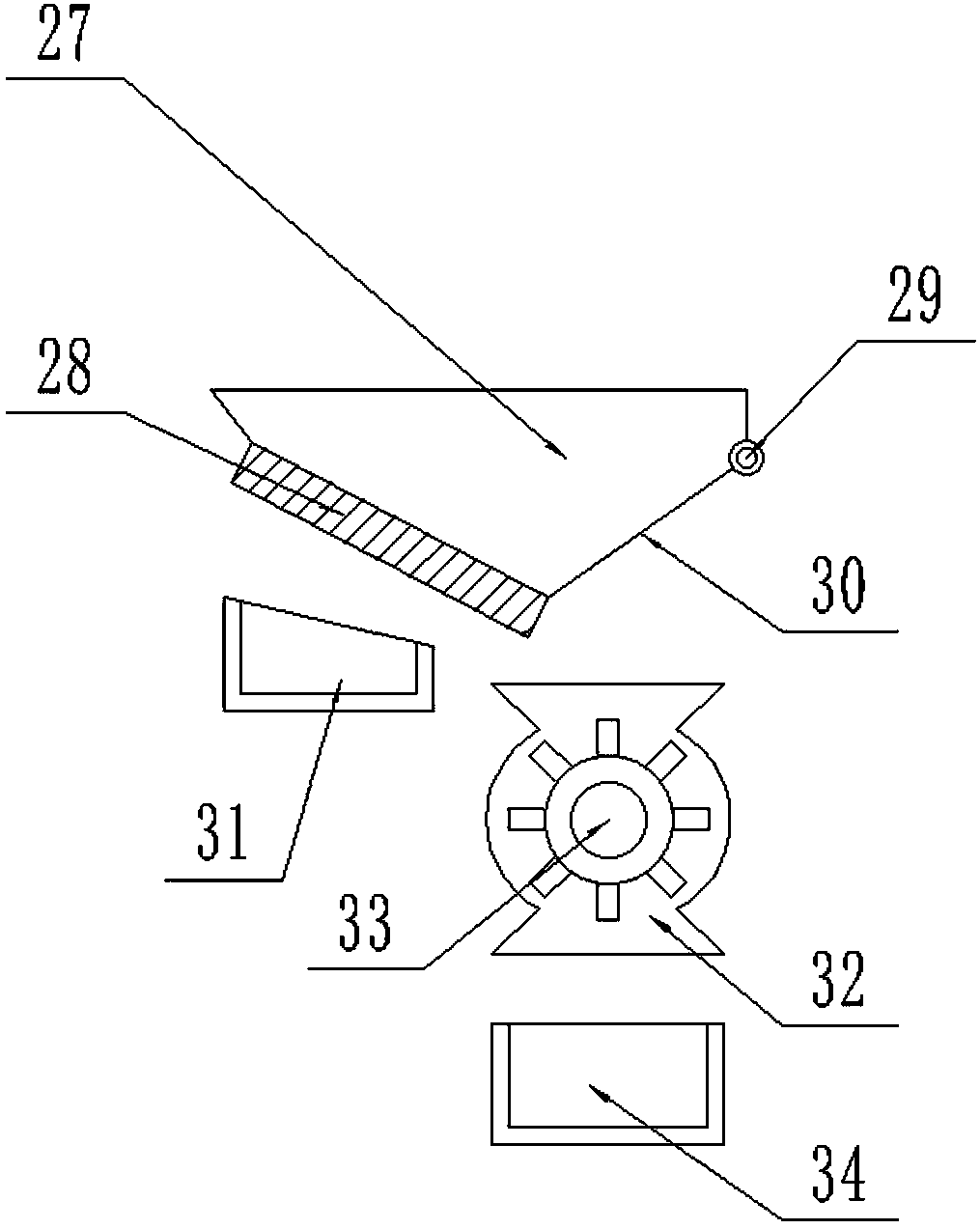

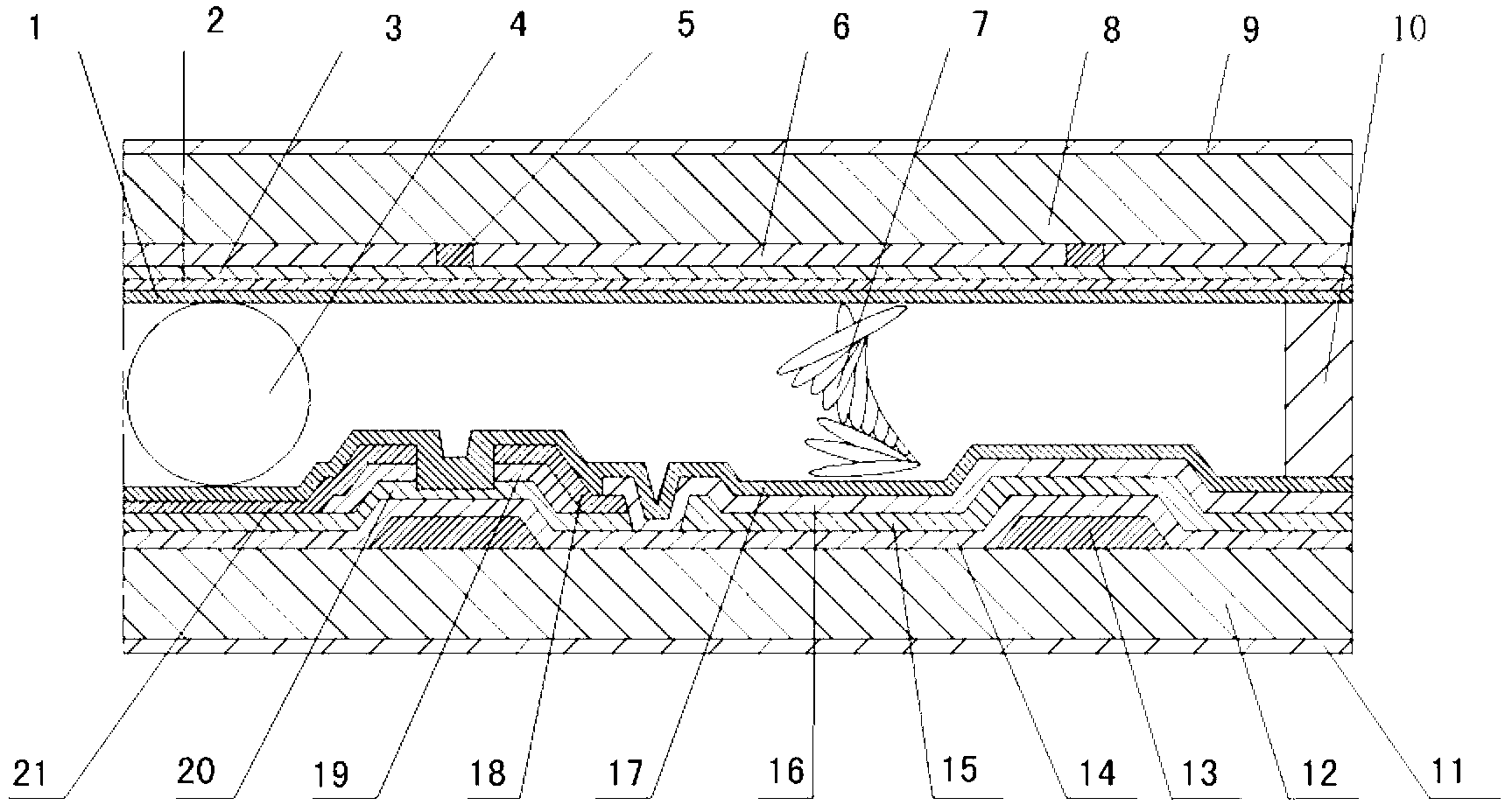

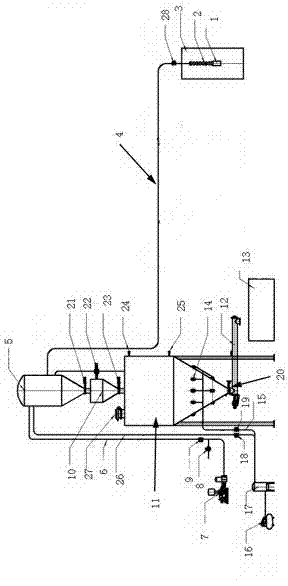

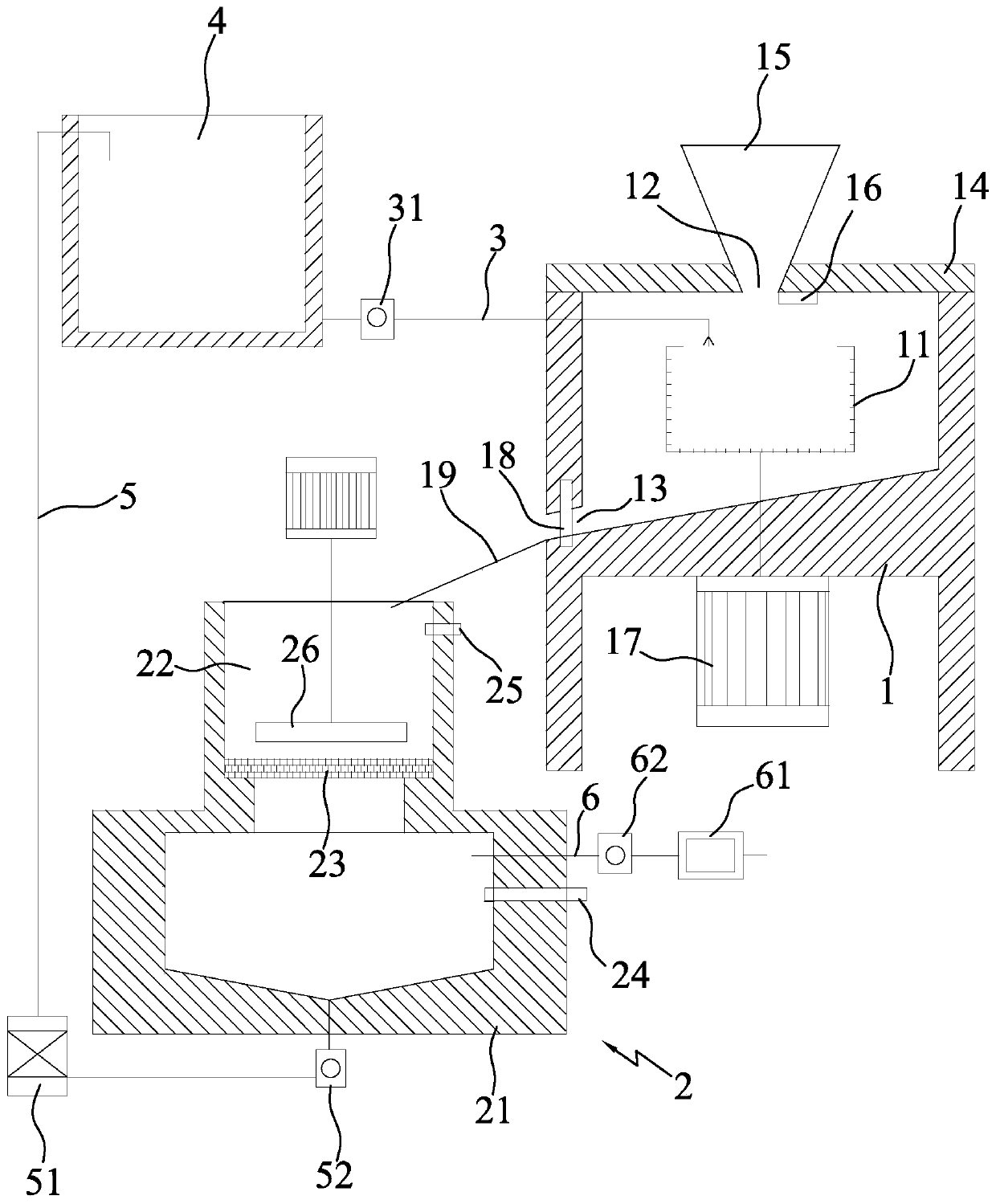

Heat preservation powder negative pressure recycling system in production of refractory material by using fusion casting method

InactiveCN103691215ARecycle thoroughlyNo pollutionDispersed particle filtrationDirt cleaningRefractoryVacuum pump

The invention relates to the technical field of refractory material production, and in particular relates to a heat preservation powder recycling system in production of a refractory material by using a fusion casting method. The system comprises a material purification system, a negative pressure vacuum system and a material recycling system, wherein a suction nozzle (1) and a soft connecting tube (2) are positioned inside a material tank (3) in the material purification system; the suction nozzle (1) is connected with a dust collector (5) through the soft connecting tube (2) and a transmission pipeline (4) in sequence; a vacuum pump (7) is connected with the dust collector (5) through a draft tube (6) in the negative pressure vacuum system; in the material recycling system, the upper part of a middle material cabin (10) is connected with the dust collector (5), and the lower part of the middle material cabin is connected with a material warehouse (11); a conveyer (12) is arranged at the bottom of the material warehouse (11) and is used for conveying a material to a material tank (13). The heat preservation powder negative pressure recycling system provided by the invention is thorough in heat preservation powder recycling, high in efficiency and free of dust pollution and simple and convenient to operate, and has good economic and environment-friendly benefits.

Owner:郑州东方安彩耐火材料有限公司

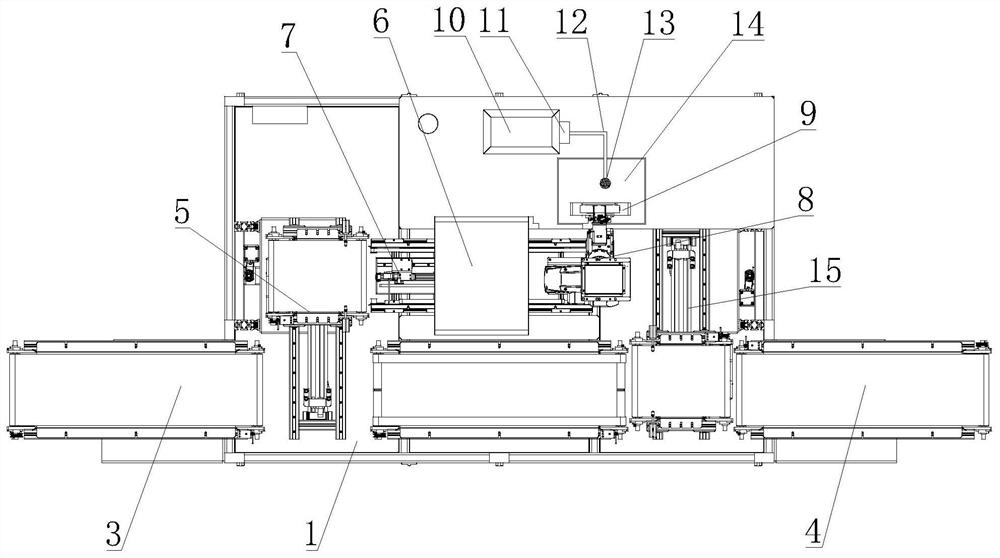

Waste lead-acid battery disassembling and electrolyte recycling device

InactiveCN111934046AGuaranteed stabilityPlay a protective effectWaste accumulators reclaimingBattery recyclingElectrical batteryEnvironmental engineering

The invention discloses a waste lead-acid battery disassembling and electrolyte recycling device. An upper rack is fixedly mounted on a lower rack, and shell plates are arranged on the periphery of the upper rack and the periphery of the lower rack. A feeding conveying belt and a discharging conveying belt are fixedly mounted on the two sides of the lower rack correspondingly. The feeding conveying belt is used for conveying the waste lead-acid batteries into the upper rack; the discharging conveying belt is used for conveying the waste lead-acid batteries out of the upper rack; the waste lead-acid battery is automatically carried and steered by arranging the manipulator assembly; the feeding conveying belt, the discharging conveying belt and a transfer conveying belt are arranged, the waste lead-acid batteries are automatically conveyed, workers do not need to make direct contact with the batteries in the whole conveying process, the workers are effectively protected, the clamping mechanism is arranged in a cutting machine box to clamp the waste lead-acid batteries, the stability during battery cutting is ensured, the lead screw drives the cutter to automatically move to cut and disassemble the lead-acid batteries, and the disassembling efficiency is improved.

Owner:太和县大华能源科技有限公司

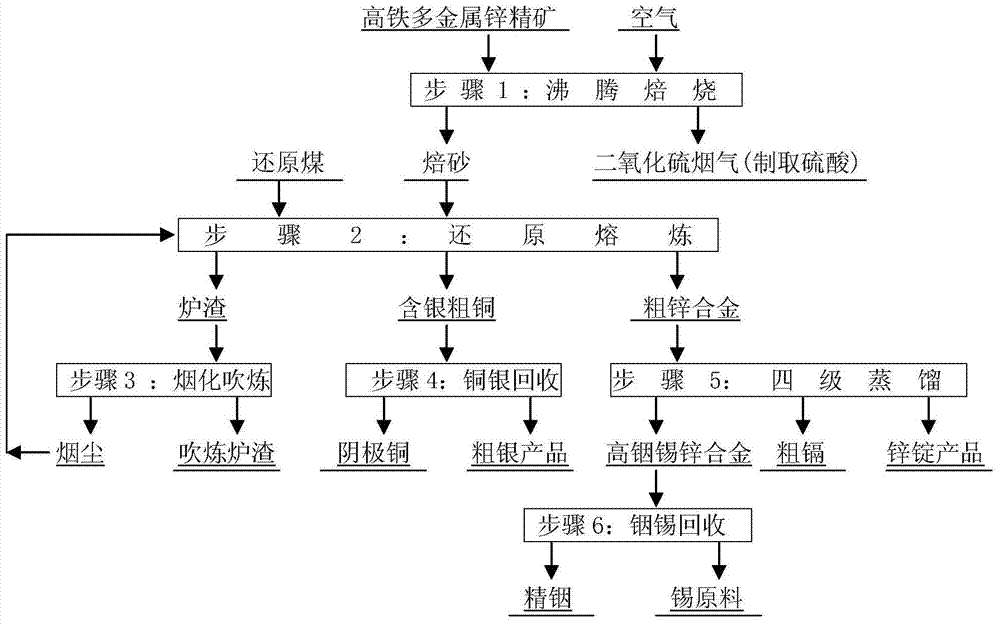

Method for treating high-iron and multi-metal zinc concentrate

ActiveCN103695635AEfficient recyclingAdvanced technical indicatorsPhotography auxillary processesProcess efficiency improvementIndiumSlag

The invention discloses a method for treating high-iron and multi-metal zinc concentrate. The method comprises the following steps of: boiling and roasting zinc concentrate containing 14-20 percent of Fe, 0.03-0.10 percent of In, 0.2-0.6 percent of Cu, 0.2-0.6 percent of Cd, 0.005-0.02 percent of Ag. 0.1-0.2 percent of Sn and 40-50 percent of Zn to produce flue gas and a roasted product; preparing sulfuric acid by using the flue gas; blending the roasted product in a reducing agent to be reduced and smelted to produce a crude zinc alloy, crude silver-containing copper and furnace cinder; blowing the furnace cinder to obtain soot and blown furnace cinder, returning the soot to be reduced and smelted, and selling the blown furnace cinder; extracting copper and silver from crude silver-containing copper; enabling the crude zinc alloy to enter a conventional distillation tower for performing four stages of distillation to produce a pyrogenic process distilled zinc product, a crude cadmium product and a high-indium, tin and zinc alloy; extracting indium and tin from the high-indium, tin and zinc alloy. The method is reasonable in process, good in comprehensive recovery, high in production efficiency, low in product cost, and clean and environment-friendly in production process.

Owner:LAIBIN CHINA TIN SMELTING

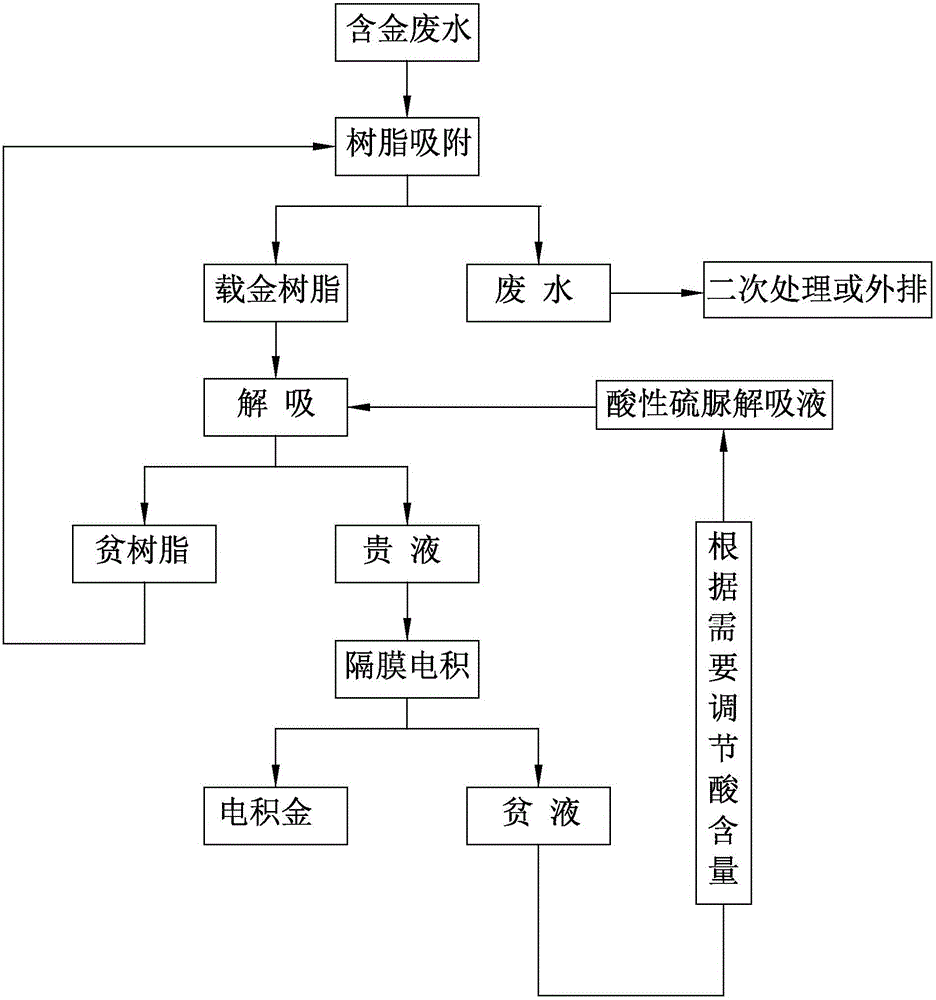

Method for recycling gold in situ from gold-containing wastewater

InactiveCN105819595AIncrease productivityReduce manufacturing costPhotography auxillary processesWater contaminantsChelating resinElution

The invention discloses a method for recycling gold in situ from gold-containing wastewater. The method is free of pollution, simple in process and convenient and rapid to implement, and intermediate consumables can be reutilized. The technological method of resin adsorption, gold-loaded resin desorption, diaphragm electrodeposition and barren resin gold adsorption is adopted, so that the process has the advantages of being high in production efficiency, low in production cost, free of wastewater transfer cost, thorough in gold recycling and the like; enrichment, elution desorption and electrolysis are carried out in situ, gold recycling is achieved, and the risk of wastewater transfer is avoided. According to the method, chelate resin is adopted to adsorb gold, an acidic thiourea system is adopted to carry out elution desorption on gold-loaded resin, barren resin obtained after desorption is returned to adsorb gold, gold in a pregnant solution obtained after desorption is extracted with a diaphragm electrodeposition method, a barren solution obtained after electrolysis is returned and used for desorbing the gold-loaded resin, and thus the technological process with the gold adsorption resin and the desorption solution reused is formed. When the method is applied to wastewater containing minor gold or trace gold, gold can be thoroughly recycled, and the gold residual in the barren solution can be reduced to 0.001 ppm and is almost zero.

Owner:深圳市世清环保科技有限公司 +1

Lead paste recycling device of waste pole plate and lead paste recycling method

ActiveCN109742457AEffective control of oxidationEffectively control dehydrationFinal product manufactureLead-acid accumulators constructionCentrifugationRed mud

Owner:TIANNENG BATTERY GROUP

Process and device for recovering solvent-containing tail gas in production of control sustained-release fertilizer with envelope

ActiveCN101376069ARecycle thoroughlyEmission complianceDispersed particle separationVapor condensationRecovery methodControlled release

The invention discloses a recycling method and a device for solvent-contained tail gas in a coated controlled release fertilizers production. The solvents-contained tail gas in the coated controlled release fertilizers production is collected and introduced into a circulating water condenser firstly, and then led to an adsorption tank after blower pressurization and impurity elimination by a filter, so that the solvents are absorbed by active carbon; and when the adsorption tank is desorbed, water vapor is introduced to pass through an active carbon bed to desorb the solvents which are absorbed, and after delamination in a delaminating groove through a cooler, the solvents are led to a recycling groove. The method adopts active carbon to absorb and recycle the solvents-contained tail gas, thereby achieving full recycling of the solvents in the tail gas, standard tail gas emission, and environmental friendliness.

Owner:KINGENTA ECOLOGICAL ENG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com