Preparation method of human serum albumin

A technology of human serum albumin and human plasma, which is applied in the field of preparation of human serum albumin, can solve the problems of large volume of ultrafiltration dialysis water for injection, damage of protein precipitated particles, and less than 200 micrograms per liter, etc., and achieve an increase in product yield , reduce the amount of use, and recover the effect of thorough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

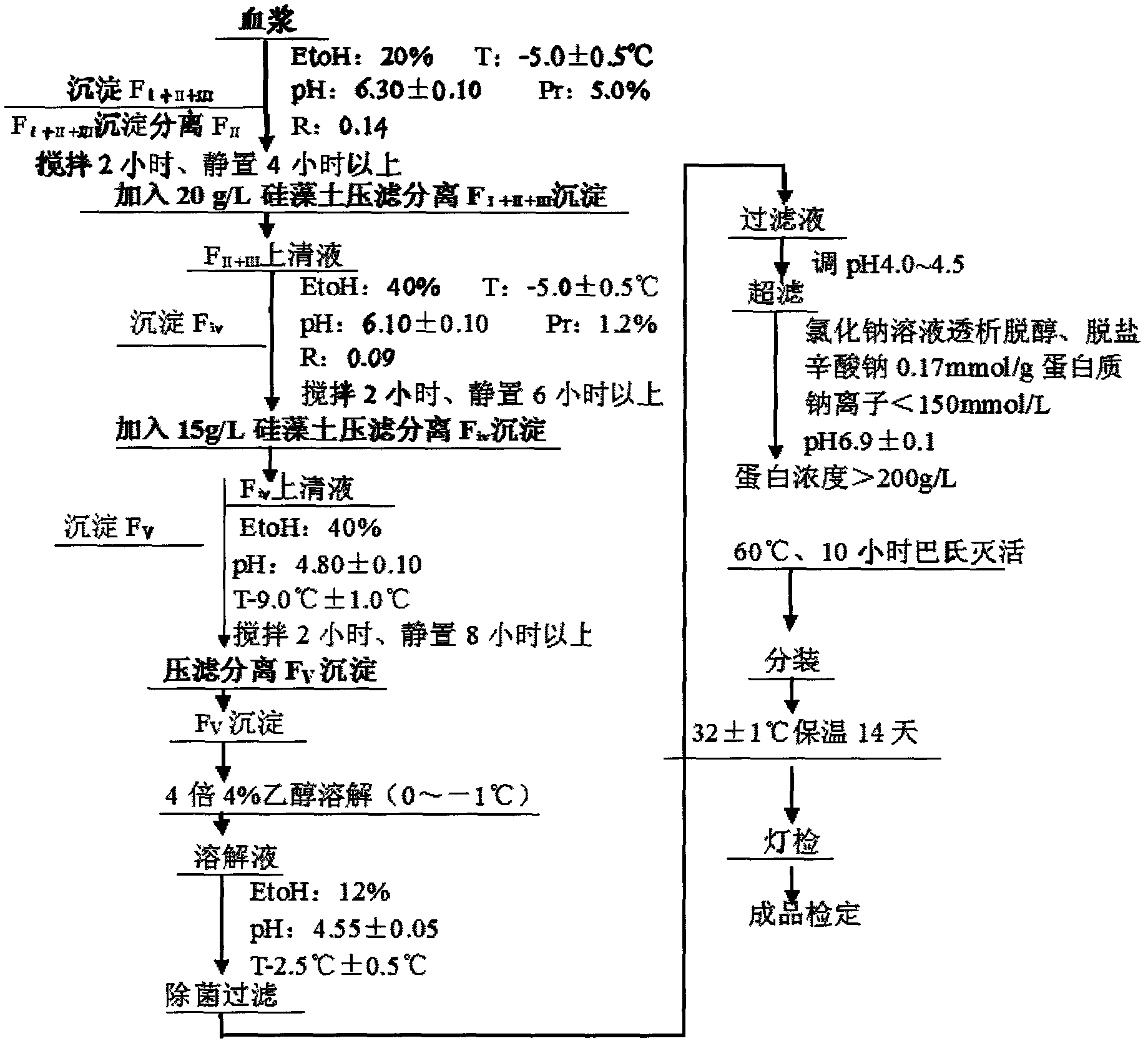

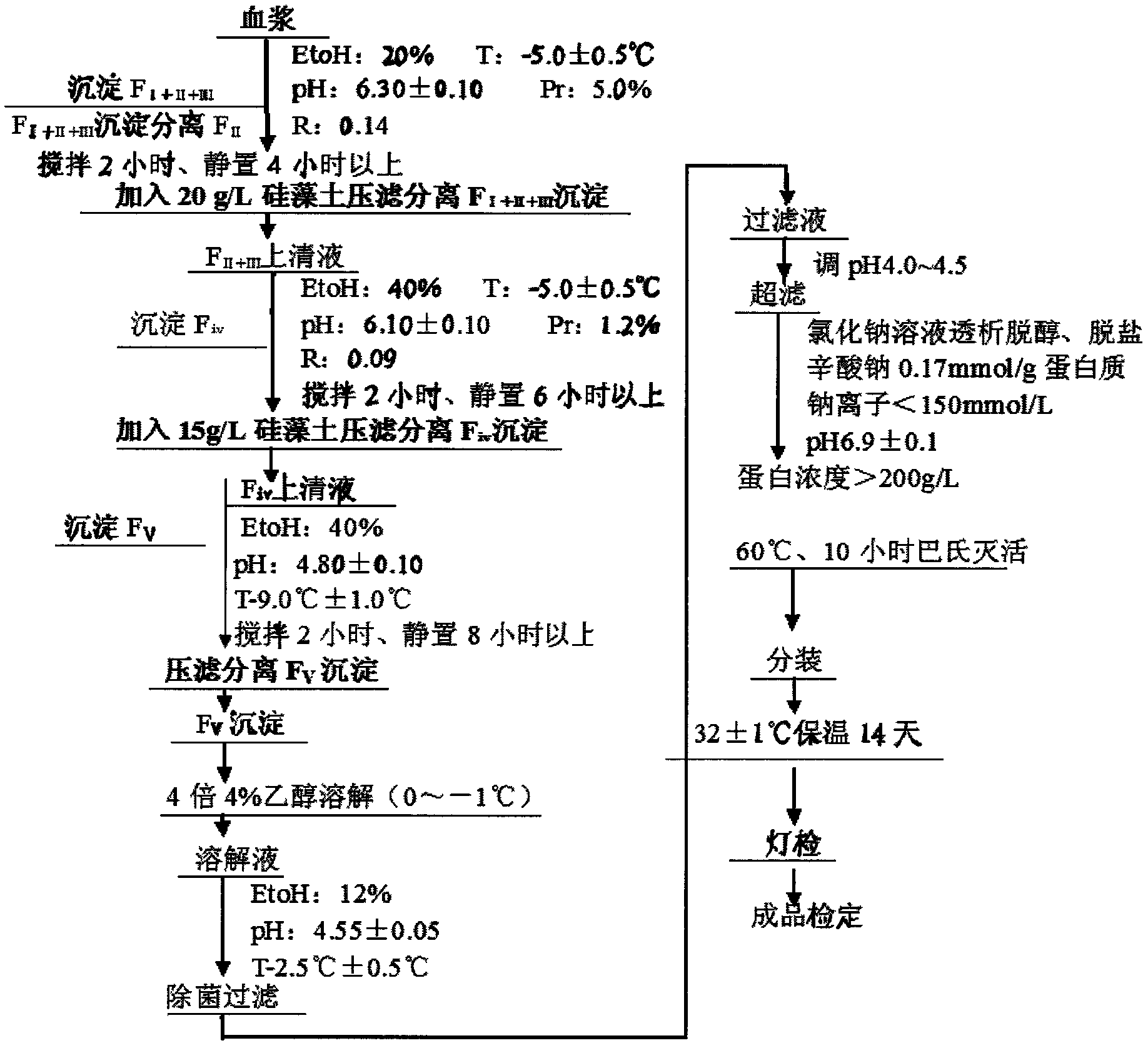

Image

Examples

Embodiment 1

[0025] Step 1, Precipitate Components I+II+III: Thaw cryogenically frozen plasma into a liquid state, add 95% by volume of -15°C medicinal ethanol to a final ethanol concentration of 20%, and use pH4.0 buffer Adjust pH to 6.2, plasma protein content to 5.0%, control temperature to -5°C, stir for 2 hours, let stand for 5 hours, add diatomaceous earth and perlite to the mixture at 20g / L as a filter aid, use Separation by pressure filtration, collecting the precipitate I+II+III of the separation components by filtration for the preparation of human immunoglobulin, and collecting the supernatant by filtration to enter the next step;

[0026] The second step, precipitation component IV: the filter press supernatant collected in the previous step is adjusted to pH 6.0 with pH 4.0 buffer solution, and the volume fraction is 95%-15 ℃ medicinal ethanol is added until the volume of the final ethanol reaches 40% of the total volume of the press-filtered supernatant and medicinal ethanol ...

Embodiment 2

[0035] The first step is to separate components I+II+III: using human plasma as the raw material, melting low-temperature frozen human plasma into a liquid state, adding 95% by volume of medicinal ethanol at -15°C, to the final ethanol quality The volume reaches 20% of the total volume of the mixed solution of human plasma and medicinal ethanol, and at the same time, the pH of the mixed solution of human plasma and medicinal ethanol is adjusted to 6.3 with a buffer solution of pH 4.0, so that the plasma protein content is 5.0%, and the temperature is adjusted to -5 ℃, stirred for more than 2 hours, and after standing for more than 4 hours, diatomaceous earth was added to the mixture at a rate of 20g / L as a filter aid, and the components I+II+III were separated by pressure filtration separation method, and the components were collected I+II+III precipitation is used for the preparation of human immunoglobulin, and the press-filtered supernatant is collected for the next step;

...

Embodiment 3

[0043] The first step is to separate components I+II+III: thaw low-temperature frozen human plasma into a liquid state, add 95% by volume of -15°C medicinal ethanol, until the final volume of ethanol reaches the volume of human plasma and medicinal 20% of the total volume of the ethanol mixture, while adjusting the pH of the human plasma and medicinal ethanol mixture to 6.4 with a buffer solution of pH 4.0 to make the mass content of plasma protein 5.0%, adjust the temperature to -5°C, and stir for 8 hours , let it stand for 12 hours, add diatomaceous earth or perlite or a combination of the two into the mixed solution as a filter aid at a rate of 20g / L, and use a pressure filtration separation method to separate the precipitate of component I+II+III, and collect component I +II+III precipitation is used for the preparation of human immunoglobulin, and the press-filtered supernatant is collected for the next step;

[0044] In the second step, fraction IV is separated, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com