Self-acting lubricator of link tooth saw

An automatic oil filling and chain saw technology, applied in the chain saw field, can solve the problem of unclear gas interception pipe and oil filling pipe specific structure, etc., and achieve the effect of reducing auxiliary equipment, convenient assembly, and speeding up the assembly speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The utility model is described in further detail below in conjunction with the accompanying drawings.

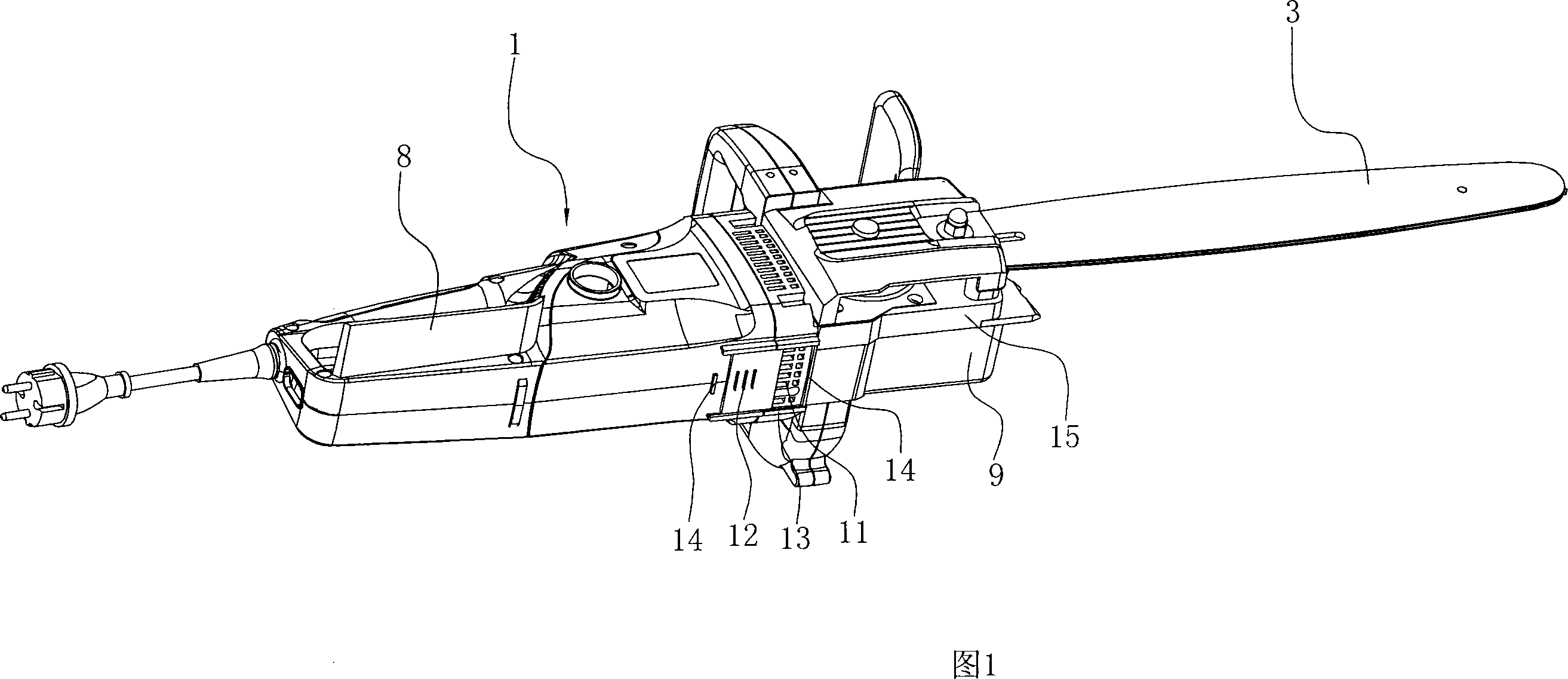

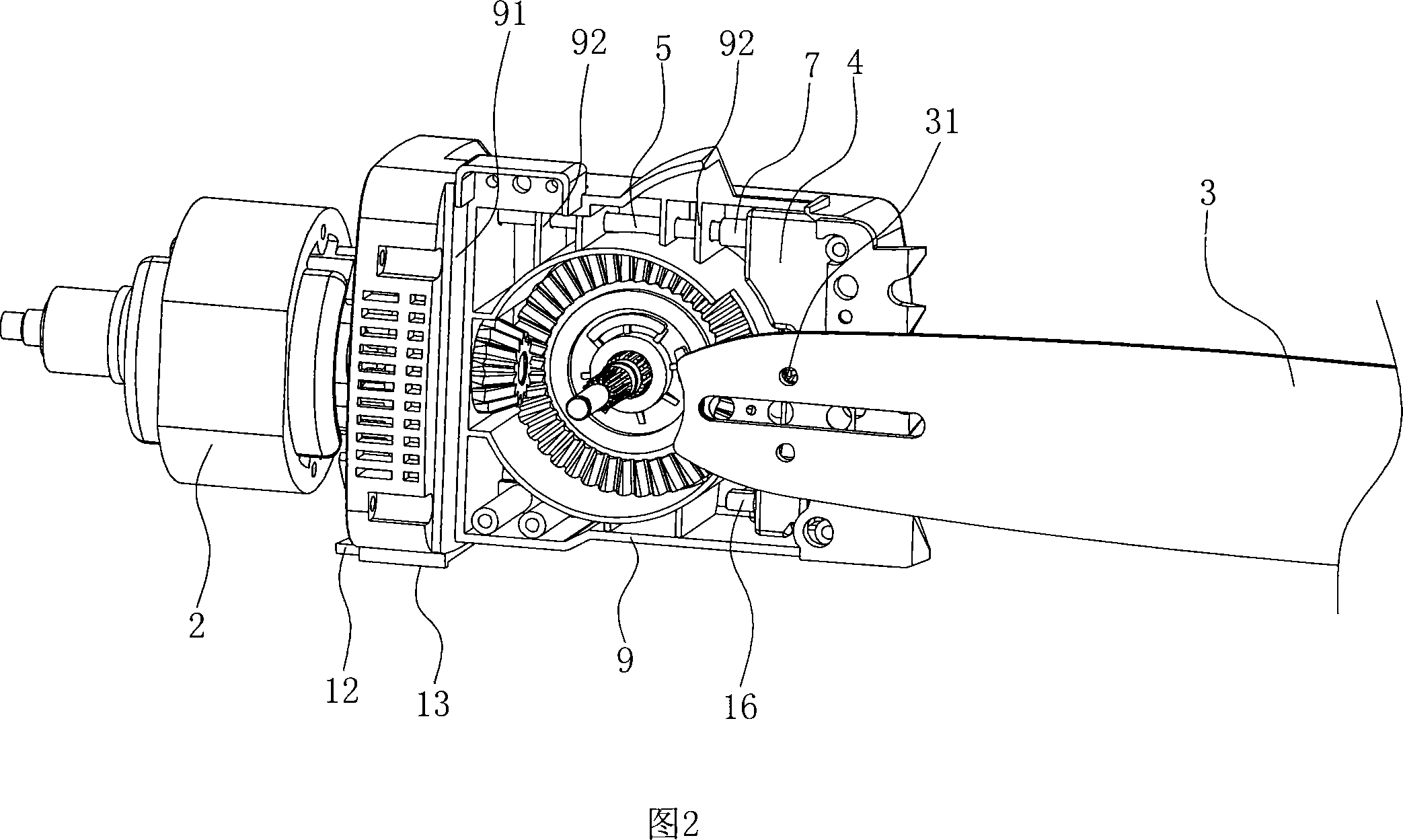

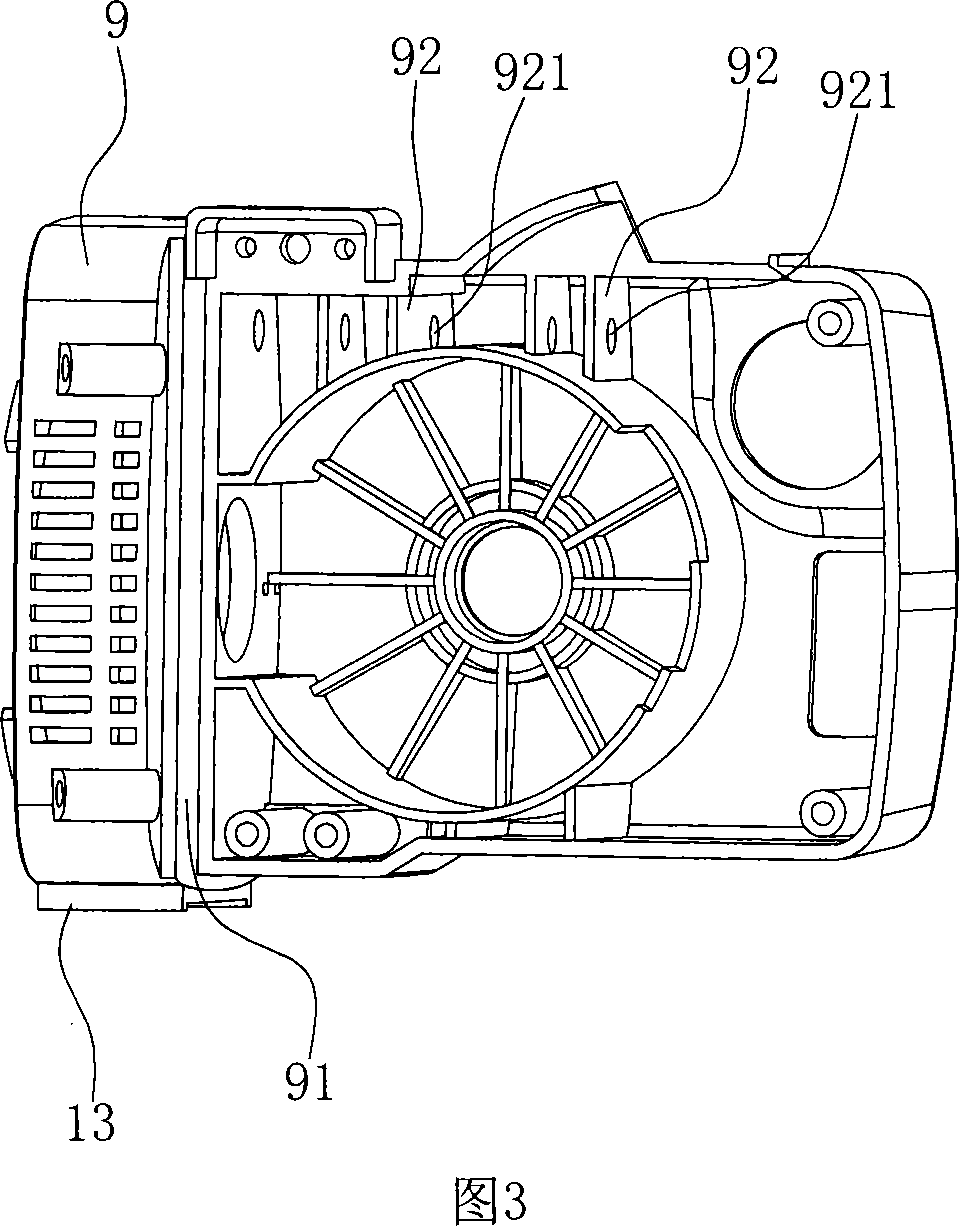

[0026] As shown in Figures 1 to 11, an automatic oiling device for a chainsaw includes a chainsaw casing 1, a motor 2, a saw chain guide plate 3, an oil storage tank 4, a wind delivery pipe 5 communicating with the oil storage tank 4, and an oil injection pipe 6 , the motor 2 is connected to the saw chain guide plate 3 through a transmission mechanism to drive the saw chain guide plate 3 to work. The transmission mechanism can refer to the transmission mechanism in the existing various chain saws, which is the prior art and is not what the present invention will protect Important, the transmission mechanism is not shown in the drawing.

[0027] Wherein, chain saw housing 1 is mainly made up of motor housing 8 and chain saw seat 9, and the rear end of chain saw seat 9 is connected on the front end of motor housing 8, and the structure that chain saw seat 9 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com