Low-temperature dyeing method for high-performance fabric

A low-temperature dyeing and high-performance technology, which is applied in the field of textile printing and dyeing, can solve the problems of not being able to fully exert the carrier effect, and achieve the effect of increasing fiber surface roughness and porosity, strong electronegativity, and increasing surface roughness and porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

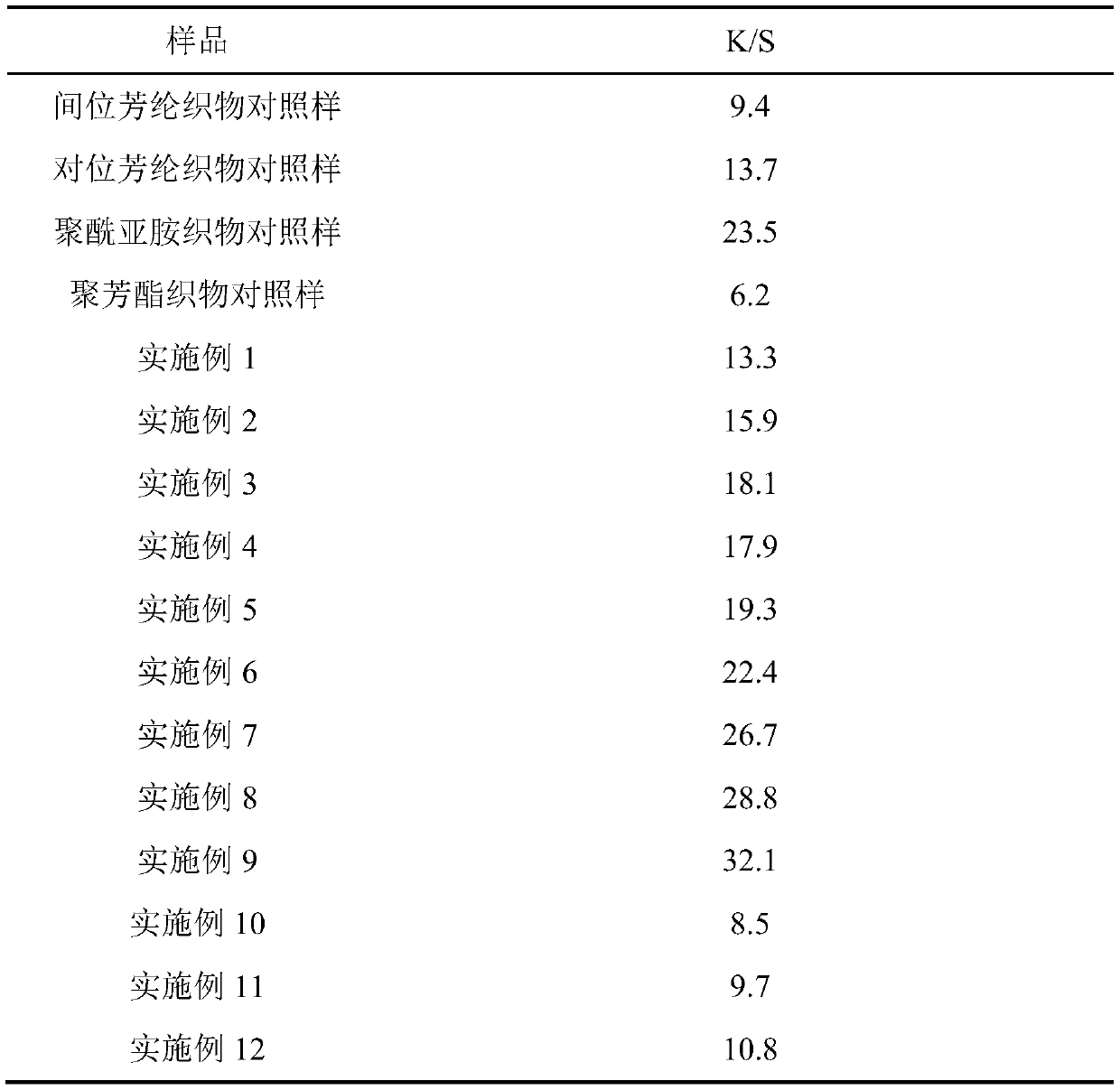

Embodiment 1

[0030] Take 3g of meta-aramid fabric, use C.I.Disperse Red 54 as the dye, and prepare a pretreatment solution at a liquor ratio of 1:20. The mass percent of N,N-dimethylacetamide in the pretreatment solution is 10%, and the mass percent of sodium silicate is 0.5%, the mass percentage of distilled water sodium silicate is 89.5%, the pretreatment liquid is mixed and stirred at 200 rpm for 3 minutes to form a pretreatment liquid, and the temperature is raised to 40°C, and the prepared meta-aramid fabric is added. Continue to heat up to 50°C and keep it warm for 30 minutes, then use 10% sodium hydroxide solution to adjust the pH value of the pretreatment solution containing meta-aramid fabrics to 7 at a rate of 2 drops / min, then add 0.5% owf dye, and stir evenly , heated to 70°C, kept warm for 60 minutes, drained, washed, and dried to obtain a dyed meta-aramid fabric. The effect is shown in Table 1.

Embodiment 2

[0032] Take 3g of meta-aramid fabric, use C.I.Disperse Red 54 as the dye, and prepare a pretreatment liquid at a liquor ratio of 1:20. The mass percentage of N,N-dimethylacetamide in the pretreatment liquid is 30%, and the mass percentage of sodium silicate is 10%, and the mass percentage of distilled sodium silicate is 60%. After the pretreatment liquid is mixed, it is stirred at 200 rpm for 3 minutes to form a pretreatment liquid. The temperature is raised to 40°C, and the prepared meta-aramid fabric is added. Continue to heat up to 60°C and keep it warm for 30 minutes, then use 10% sodium hydroxide solution to adjust the pH value of the pretreatment solution containing meta-aramid fabrics to 9 at a rate of 2 drops / min, then add 5% owf dye, and stir evenly , heated up to 80°C, kept warm for 60 minutes, drained, washed, and dried to obtain a dyed meta-aramid fabric. The effect is shown in Table 1.

Embodiment 3

[0034]Take 3g of meta-aramid fabric, use C.I.Disperse Red 54 as the dye, and prepare a pretreatment liquid at a liquor ratio of 1:20. The mass percentage of N,N-dimethylacetamide in the pretreatment liquid is 50%, and the mass percentage of sodium silicate is The mass percentage of sodium silicate in distilled water is 30%. After the pretreatment solution is mixed, it is stirred at 200 rpm for 3 minutes to form a pretreatment solution. The temperature is raised to 40°C, and the prepared meta-aramid fabric is added. Continue to heat up to 70°C and keep it warm for 30 minutes, then use 10% sodium hydroxide solution to adjust the pH value of the pretreatment solution containing meta-aramid fabrics to 11 at a rate of 2 drops / min, then add 10% owf dye, and stir evenly , heated up to 90°C, kept warm for 60 minutes, drained, washed, and dried to obtain a dyed meta-aramid fabric. The effect is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com