Patents

Literature

50results about How to "Breaking hydrogen bonds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High carbonyl content oxidation starch and method for making same

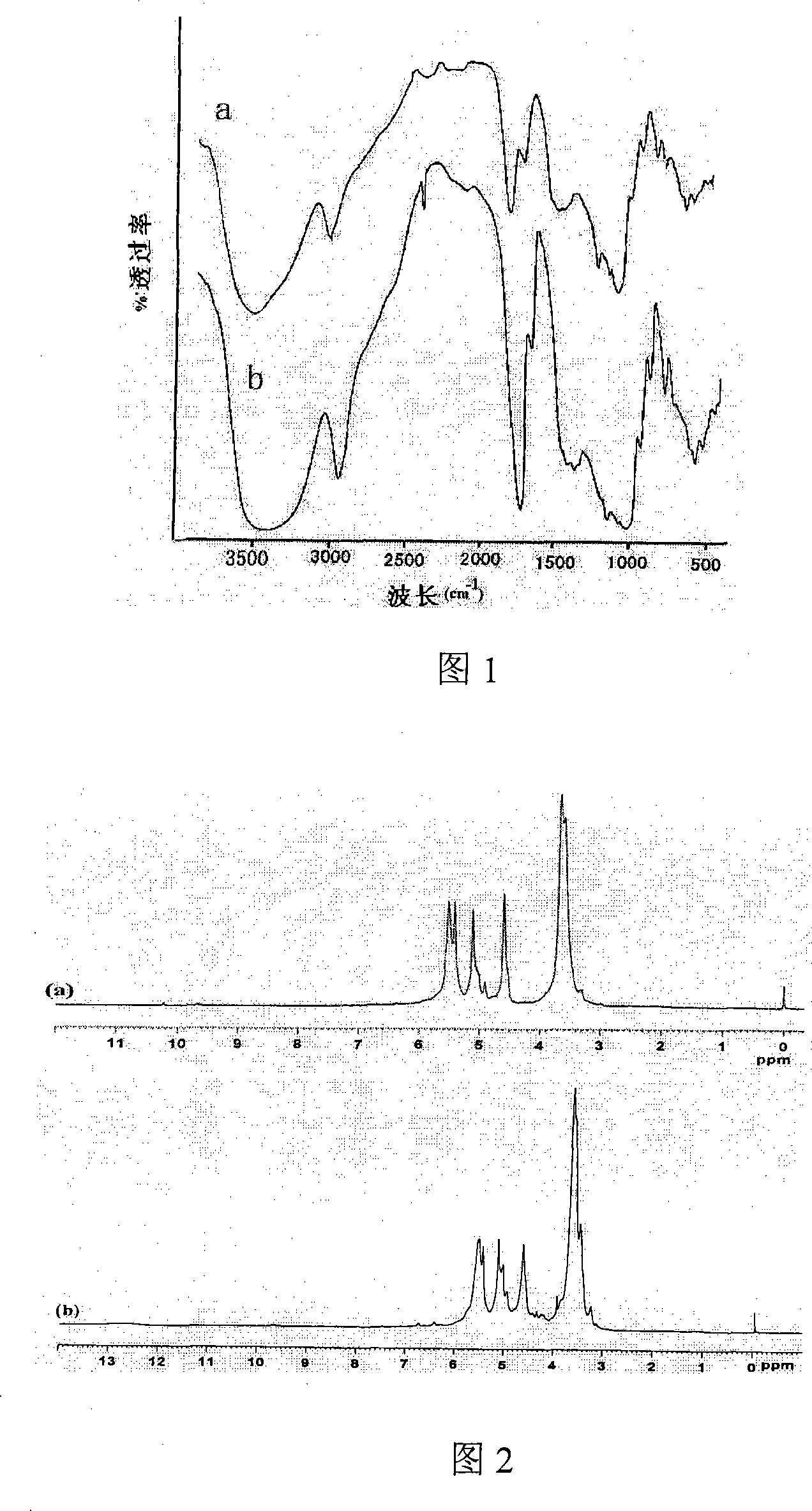

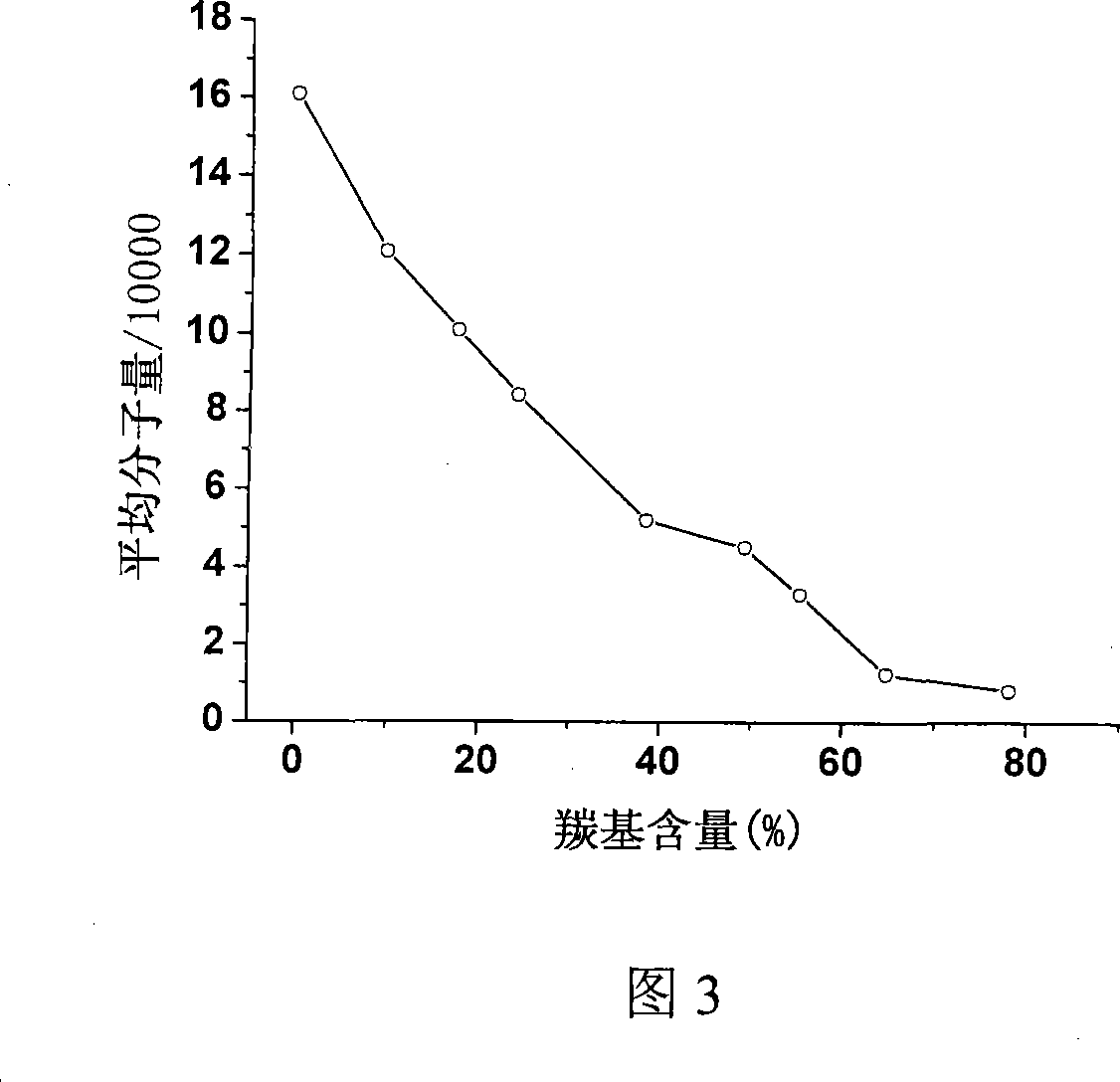

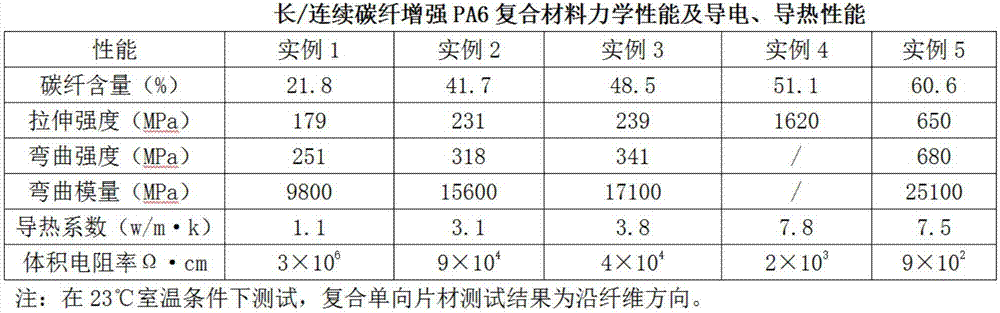

The oxidized starch with high carbonyl content disclosed by the invention has a carbonyl content of 15.5-55.4% and a molecular weight greater than 25,000. The invention also discloses a preparation method of oxidized starch with high carbonyl content. The method is to prepare starch emulsion with water concentration of 10-30%, then heat up to 60-90°C, stir and gelatinize for 0.5-2 hours, and then cool to At room temperature, add 50-150 parts of water and stir evenly; slowly drop in hydrogen peroxide with a molar ratio of 0.2-4 to starch, stir and react at a temperature of 5-50°C for 0.5-72 hours; Add 200 parts of water to the mixture and stir evenly, pour off the supernatant after standing for stratification, centrifuge the emulsion, and dry the obtained solid. The oxidized starch prepared by the method has high carbonyl content, good thermal stability, low preparation cost, high yield and simple process, and can avoid the problem of serious molecular weight drop caused by preparing oxidized starch in an acidic or alkaline medium.

Owner:SICHUAN UNIV

Preparation method for new type fully-degradable cellulose composite fiber with skin-core structures

InactiveCN103352267AEasy to shapeImprove performanceConjugated cellulose/protein artificial filamentsWet spinning methodsFiberPolyester

The invention provides a preparation method for new type fully-degradable cellulose composite fiber with skin-core structures. The preparation method is characterized by comprising steps: cellulose and biomass polyesters are subjected to vacuum drying, the cellulose and ionic liquids are added in a high-speed mixer according to the ratio and stirred evenly, the mixture of the cellulose and the ionic liquids is added in a co-rotating twin-screw extruder through a feeding inlet, the biomass polyesters obtained from the first step are added through another feeding inlet, both of the mixture and the biomass polyesters are extruded by the co-rotating twin-screw extruder into a spinning pack to be spun through spinneret plates, the obtained composite fiber goes through a water tank and the ionic liquids in skin layers are washed off, then the composite fiber is stretched and wound through the spinning pack, and the new-type fully-degradable cellulose composite fiber with skin-core structures is obtained. The composite fiber has advantages of good hygroscopicity, comfortableness and chromaticity of cellulose and good mechanical properties of polylactic acid, and retains the biodegradable characters of cellulose and polylactic acid, and is suitable for the medical and taking fields.

Owner:DONGHUA UNIV

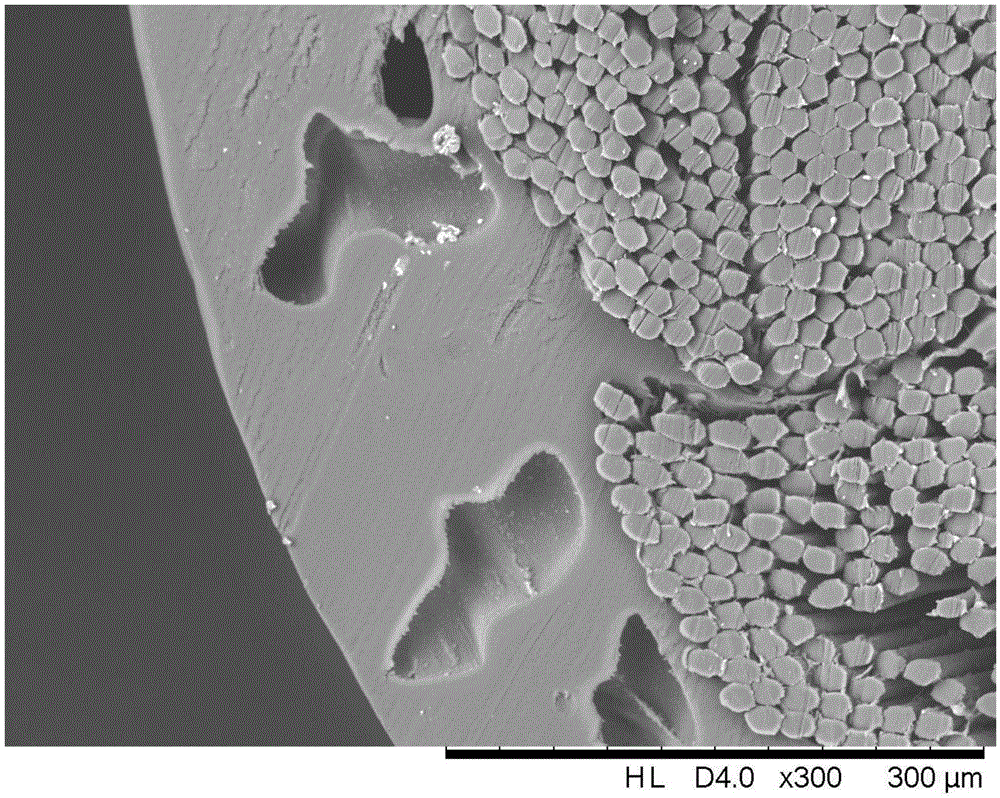

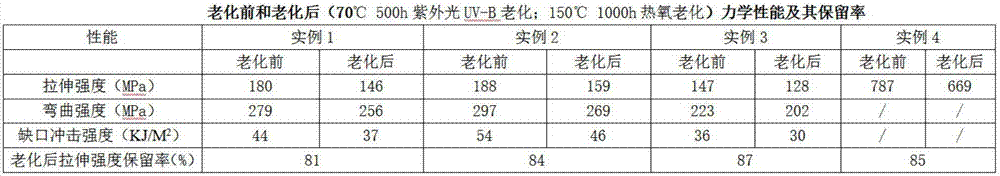

Continuous carbon fiber-reinforced PA6 composite with high strength, high modulus, electrical conductivity and thermal conductivity, and preparation method thereof

InactiveCN106939124AImprove conductivityHigh thermal conductivityHeat-exchange elementsFiberCarbon fibers

The invention relates to a continuous carbon fiber-reinforced PA6 composite with high strength, high modulus, electrical conductivity and thermal conductivity, and a preparation method thereof. The composite comprises, by weight, (1) 100 parts of PA6 resin, (2) 0.2 to 1 part of an anti-oxidant, (3) 0.2 to 1.2 parts of a flow promoter, (4) 2 to 10 parts of a flexibilizer and (5) 1 to 5 parts of a compatilizer. The preparation method comprises the following steps: premixing the above components according to a certain ratio, carrying out melting and mixing via a double / single-screw set and then extruding the obtained mixture into a die head for flow splitting and impregnation so as to prepare the continuous carbon fiber-reinforced PA6 composite with high strength, high modulus, electrical conductivity and thermal conductivity. Compared with conventional staple carbon fiber-reinforced PA6 composites, the continuous carbon fiber-reinforced PA6 composite prepared by using a special impregnation process in the invention has greatly improved mechanical properties since the length retention rate of carbon fibers in a PA6 carrier is high or continuous and has substantially improved electrical conductivity and thermal conductivity due to a continuous network structure, so the application range of the composite is greatly broadened.

Owner:浙江胜钢新材料有限公司

Cation guar gum with transparent gum liquid and preparation method thereof

InactiveCN101768225AModerate viscosityHigh transparencyCosmetic preparationsToilet preparationsHigh concentrationPersonal care

The invention discloses cation guar gum and a preparation method thereof, wherein the cation guar gum is prepared by the method comprising the following steps of: 1. putting 26-32 parts by weight of solid base into 150-360 parts by weight of dispersion medium to prepare a high-concentration lye, and then adding 100 parts by weight of guar gum into the lye for fully swelling; 2. dropwise adding 140-200 parts by weight of cation etherifying agent, reacting for 2-5 hours at the temperature of 40-80 DEG C, then neutralizing a pH to 7-8 through an acid, washing, centrifugalizing and drying. The cation guar gum solution has higher transparency, and the light transmittance of a 1-percent guar gum derivative solution is measured by a spectrophotometer to be higher than 85 percent; the viscosity is 100-800mPa.s; and the substitution degree of cations is high and can be 0.7-1.0. The cation guar gum of the invention has suitable viscosity and stable gum liquid and is very suitable for the field of transparent personal-care supplies.

Owner:刘东辉 +2

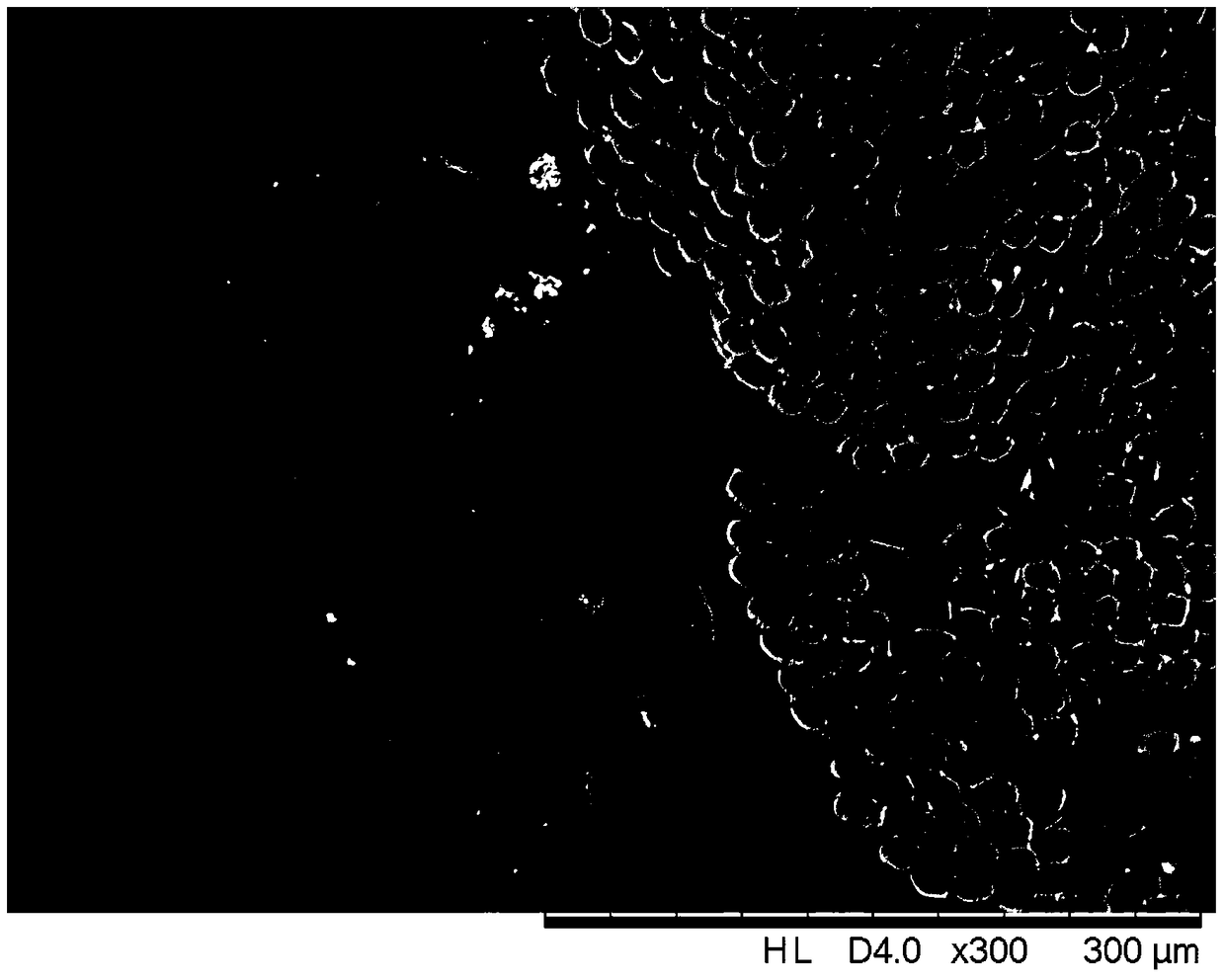

Preparation method of enhanced polyisophthaloyl metaphenylene diamine hollow fiber membrane

ActiveCN105597569AImprove solubilityBreaking hydrogen bondsSemi-permeable membranesFiberHollow fibre membrane

The invention discloses a preparation method of an enhanced polyisophthaloyl metaphenylene diamine hollow fiber membrane. The preparation method includes the following processing steps of (1) preparation of a hollow braided hose: adopting a well-known two-dimensional braiding technique to braid fibers into the hollow braided hose, and taking the hollow braided hose as an enhancing body of the enhanced hollow fiber membrane; (2) preparation of PMIA membrane casting dissolving fully dried PMIA resin, additives and a pore-forming agent in an organic solvent at the temperature of 60-70 DEG C, stirring for 4-6h to obtain homogeneous solution, and performing vacuum defoaming to obtain the PMIA membrane casting (3) preparation of the enhanced PMIA hollow fiber membrane: adopting a coextrusion composite spinning process to subject the hollow braided hose obtained in the step (1) and PMIA membrane casting solution obtained in the step (2) to coextrusion through an annular spinning jet, uniformly coating the surface of the hollow braided hose with the membrane casting solution, and fully curing to obtain the enhanced PMIA hollow fiber membrane.

Owner:TIANJIN POLYTECHNIC UNIV

Method for extruding in-situ grafting modified cellulose through twin screws with ionic liquid serving as solvent

The invention relates to a method for extruding in-situ grafting modified cellulose through twin screws with ionic liquid serving as a solvent. The method comprises the following steps: (1) drying the cellulose and a grafting monomer in vacuum; (2) uniformly mixing the following raw materials by weight percent: 4 to 8% of cellulose, 30 to 40% of grafting monomer, 51.84 to 65.92% of ionic liquid, 0.04 to 0.08% of initiator, and 0.04 to 0.08% of catalyst; and (3) extruding the mixture by a co-rotating twin-screw extruder, so as to obtain the in-situ grafting modified cellulose. By adopting the method, high flowing property is provided on the basis that the original performances of the cellulose are remained; the cellulose grafting copolymer, which is easily processed and formed, and efficient, green and clean, can be obtained; and the development on novel cellulosic fibers, which are low in energy consumption, economic and feasible and environmentally friendly, can be promoted.

Owner:DONGHUA UNIV

Cellulose in-situ urea modified plastification melt spinning method

InactiveCN102965752AEasy to processBreaking hydrogen bondsSpinning head liquid feederArtificial filaments from cellulose derivativesCellulose fiberGreen cleaning

The invention relates to a cellulose in-situ urea modified plastification melt spinning method comprising the following steps of: (1) drying the cellulose and the urea under a vacuum condition; (2) uniformly mixing 10-20wt% of cellulose, 50-70wt% of ionic liquid and 10-40wt% of urea; (3) extruding the mixture by a co-rotating twin screw extruder, defoaming, filtering and ejecting from a spinneret port; (4) drawing and coiling the quickly solidified fiber to form cellulose fiber. The method can be used for get the cellulose grafted copolymer which is easy to process, high-efficiency, green and clean, and can prompt development of the novel cellulose fiber which is low in energy consumption, economical, practical and environmentally-friendly.

Owner:DONGHUA UNIV

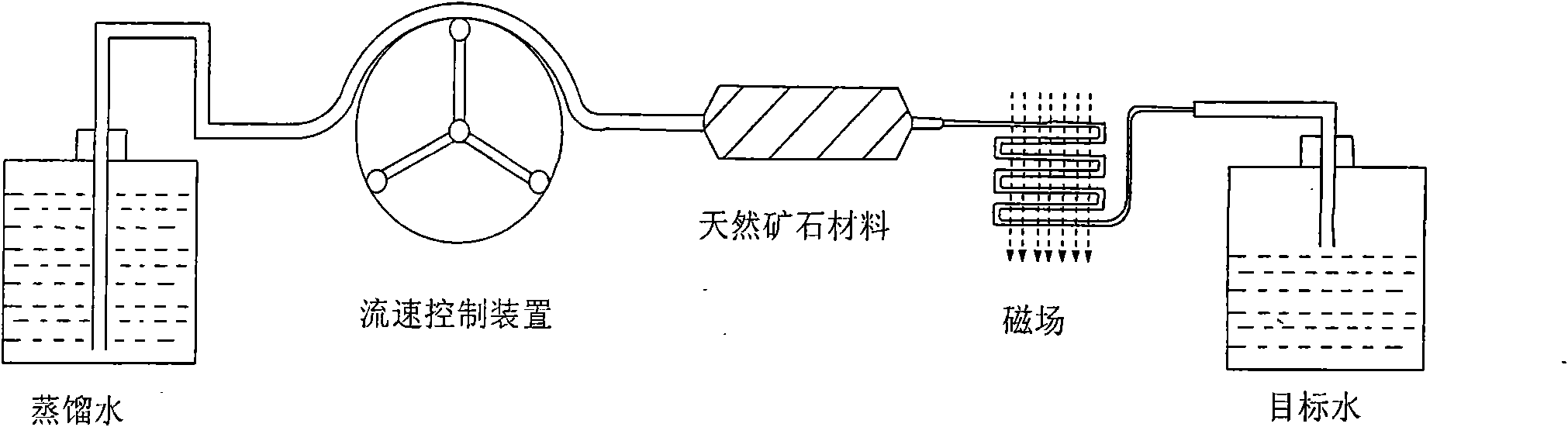

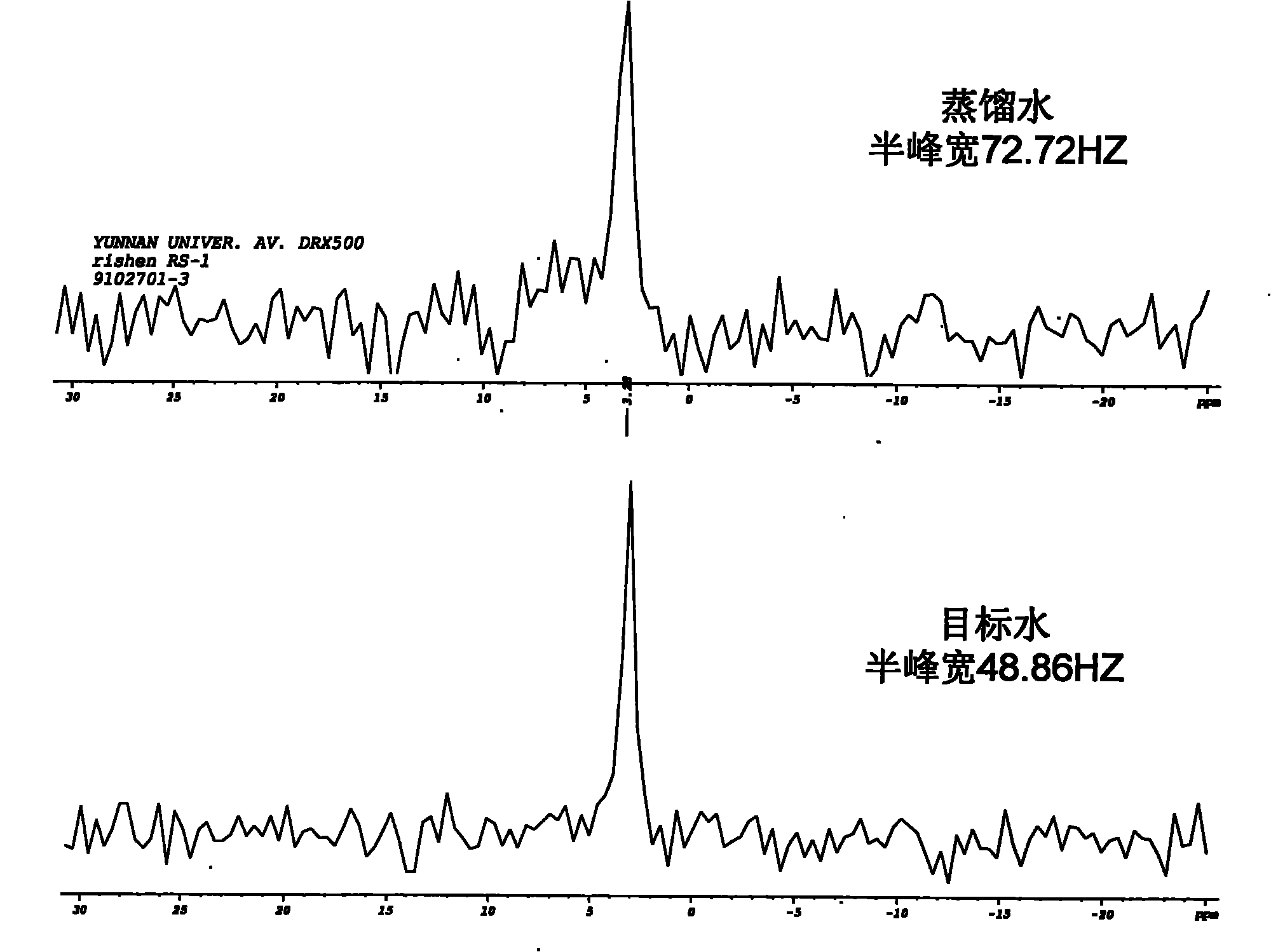

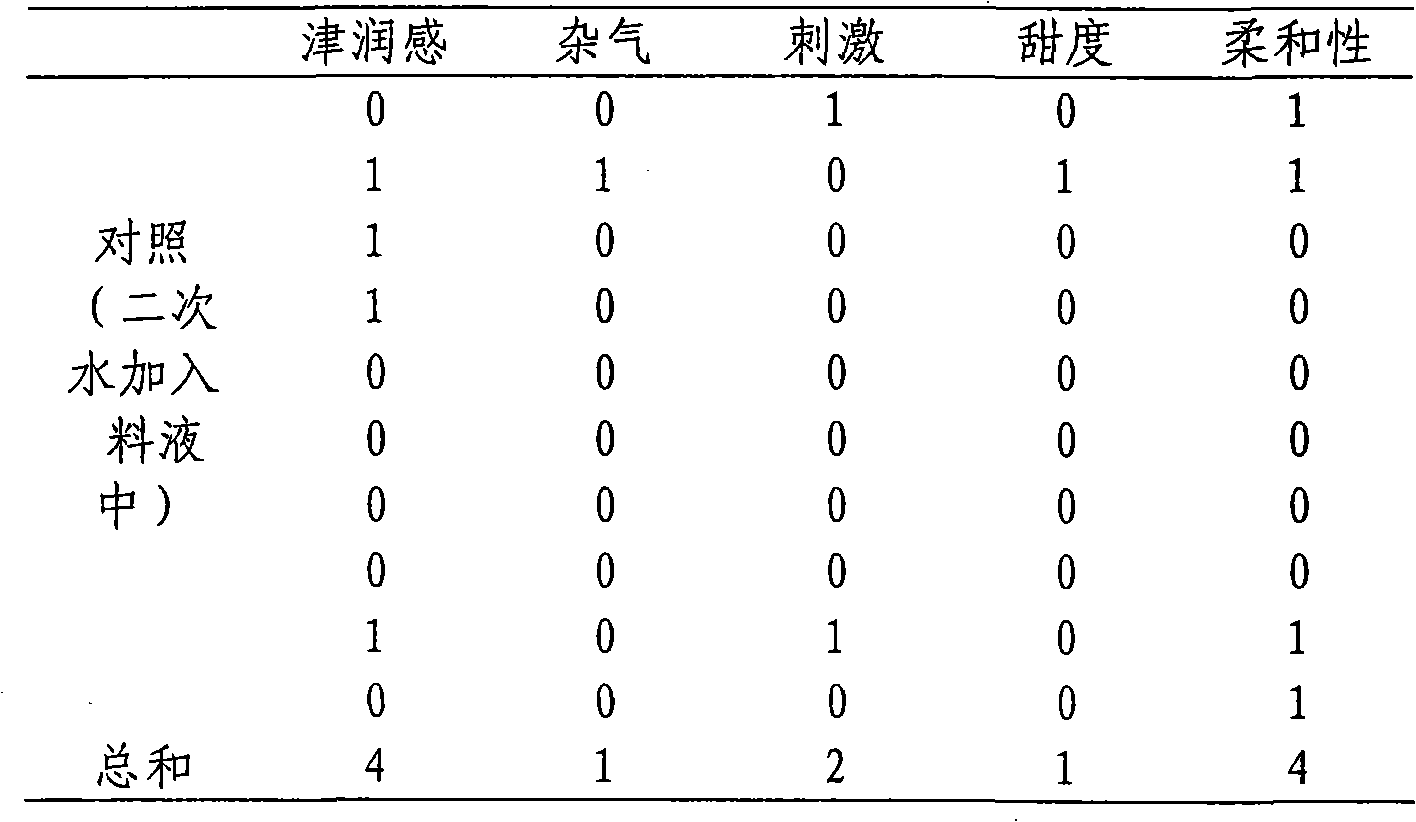

Characteristic water for improving flavor quality of cigarette and application thereof

ActiveCN101863582AImprove suction qualityHigh in trace elementsMultistage water/sewage treatmentDistilled waterSweetness

The invention discloses characteristic water for improving flavor quality of cigarette and an application thereof. Pure water is controlled to flow by a natural mineral filling column with the flow speed of 350 to 380 ml / min and then to flow by a magnetic field, the strength of the magnetic field is 9000 to 9500 Gs, the acting time of the water in the magnetic field is more than or equal to 15 min, so the water with the pH value of 9 to 9.5, i.e. the characteristic water is obtained. When blending the perfume of the cigarette, the characteristic water is adopted as solvent or thinner to substitute the conventional pure water, primary distilled water or the second distilled water, so on the premise that the characteristic of the fragrance is not influenced, the stimulation is reduced, the sweetness and the moisture of the smoke can be improved. The tourmaline ceramic ball which is doped with other mineral ceramic ball is innovatively utilized to process the water, and then stabilization treatment on the water is performed by the magnetic field, so a new thought for improving the smoking quality of the cigarette is provided.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

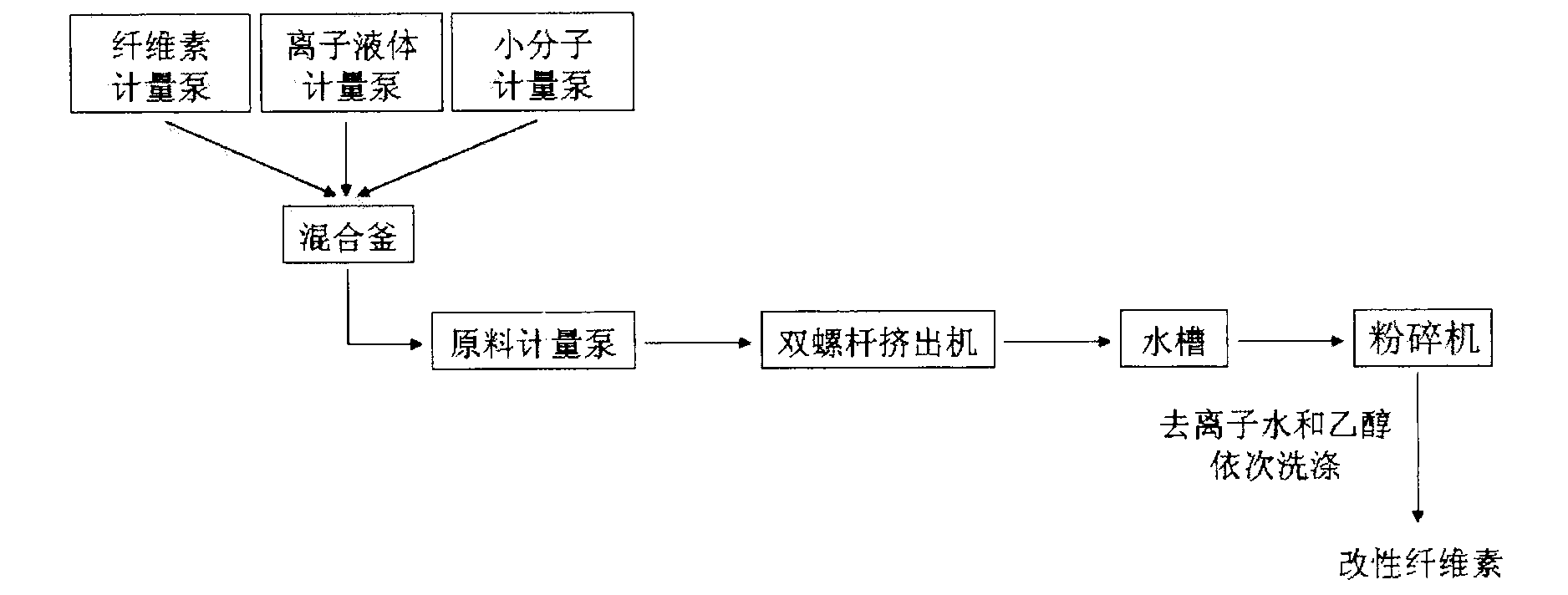

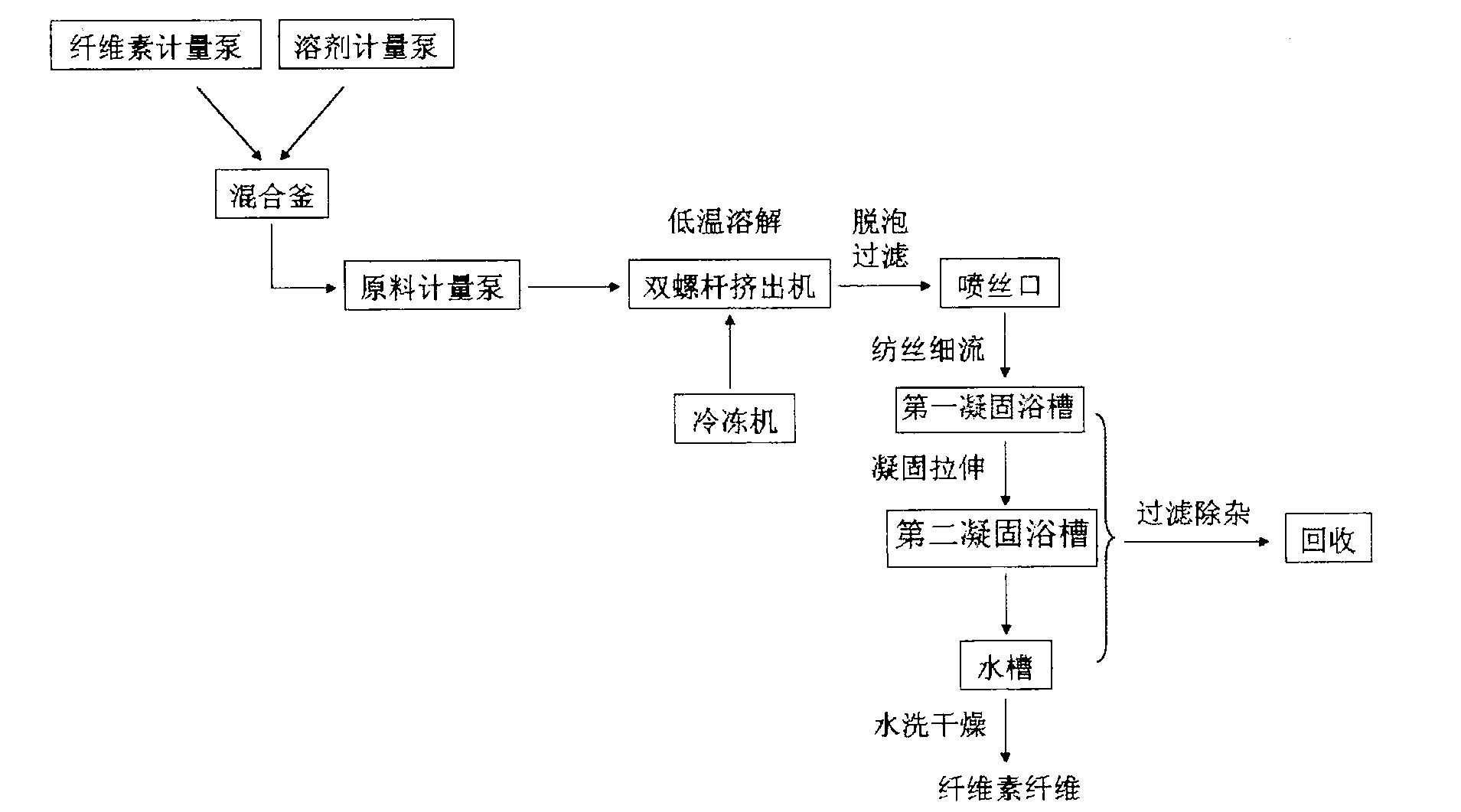

Process and devices for chemical modification of cellulose and for continuous low temperature solution spinning

InactiveCN103290503AEasy to processImprove solubilityArtificial thread manufacturing machinesArtificial filaments from cellulose derivativesFiltrationCellulose fiber

The invention provides a process and devices for chemical modification of cellulose and for continuous low temperature solution spinning. The process for the chemical modification of the cellulose and for the continuous low temperature solution spinning comprises: after vacuum drying the cellulose, uniformly mixing the dried cellulose with an ionic liquid and modified small molecules in a certain proportion to obtain a mixture, extruding the obtained mixture by a double-screw extruder, and washing the extruded product successively by water and ethanol solvent, drying, crushing to obtain a modified cellulose powder; adding the modified cellulose powder and a solvent in a certain proportion to a mixing kettle, after stirring and mixing uniformly at the room temperature, carrying out extrusion, deaeration, and filtration by using the double-screw extruder, then putting into a spinning assembly, spaying out of a spinneret of the spinning assembly to obtain fibers, putting the obtained fibers successively into a first coagulation bath and a second coagulation bath to rapidly solidify and stretch into solids, after water washing in a water tank, and winding into modified cellulose fibers. The process and the devices can substantially enhance the spinning efficiency, and improve the cellulose fiber performance.

Owner:DONGHUA UNIV

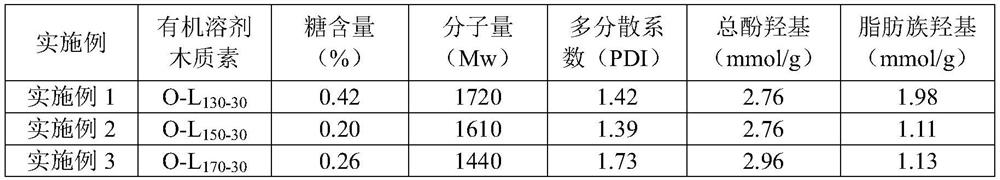

Method for pretreating eucalyptus graded lignin and co-producing furfural based on DES two-phase system

ActiveCN113956299AImprove solubilityEffective dissociationLignin derivativesAqueous acetonePtru catalyst

The invention aims to provide a method for pretreating eucalyptus graded lignin and co-producing furfural based on a DES two-phase system. The method comprises the following steps of: (1) pretreatment of raw materials: crushing, dewaxing and drying; (2) preparation of DES: mixing a hydrogen bond acceptor and a hydrogen bond donor, performing heating and stirring until the mixture is uniform and transparent; and (3) pre-treating graded lignin and co-producing furfural by using the two-phase system: 1) blending the raw material, DES, an organic solvent and a catalyst, and adding the mixture into a reaction kettle for reaction; 2) performing cooling after the reaction is finished, and separating the mixture to obtain a eutectic reaction mixture and an organic extraction phase; and 3) carrying out rotary evaporation on an eluent obtained by washing the eutectic reaction mixture with an acetone / aqueous solution and the organic extraction phase, and then carrying out acid water precipitation, centrifugation and freeze drying to respectively obtain the DES lignin and the organic solvent lignin. According to the method, lignin with different fractions and high purity and good uniformity is obtained through a one-step method, and furfural is co-produced.

Owner:BEIJING FORESTRY UNIVERSITY

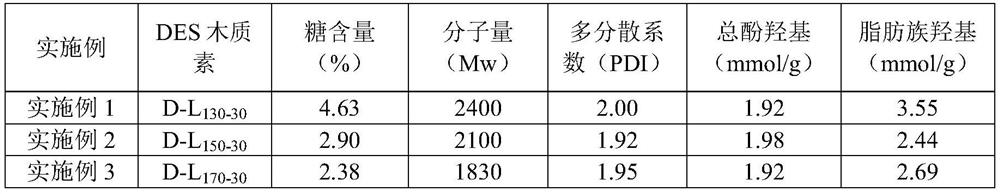

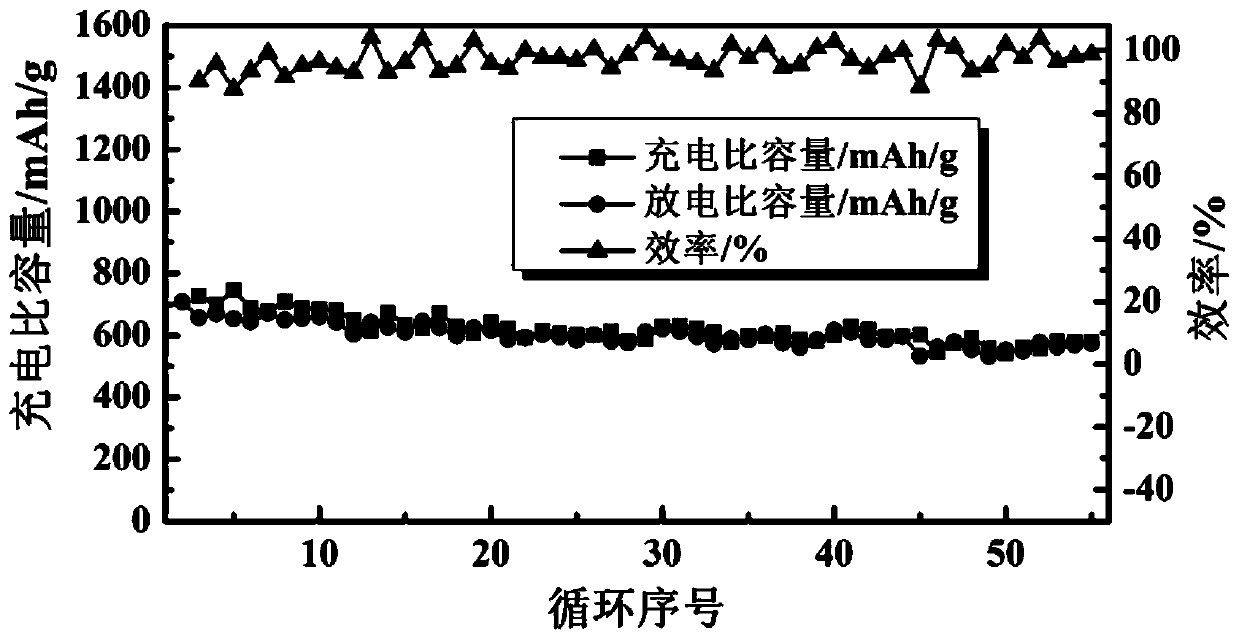

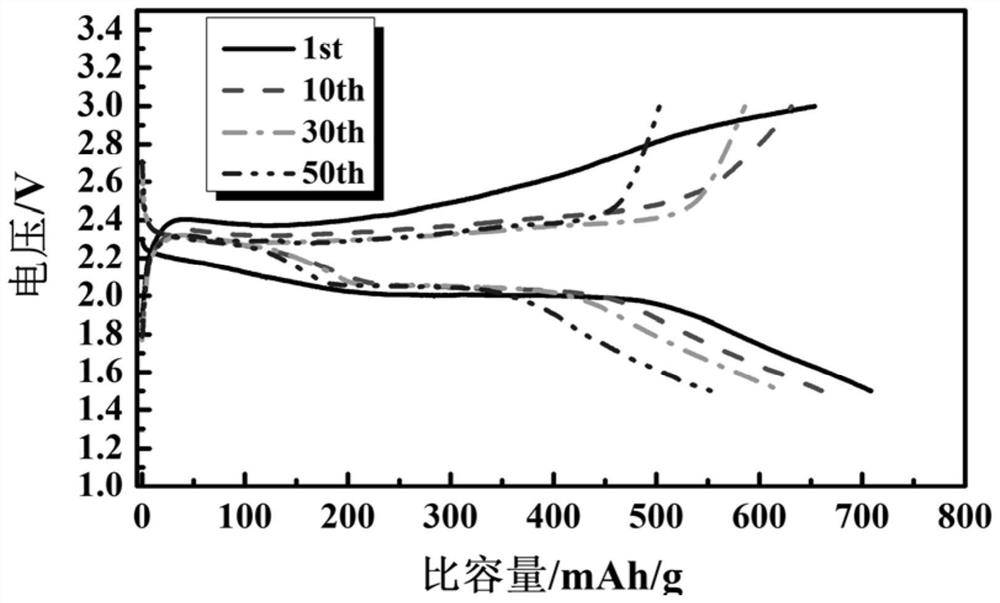

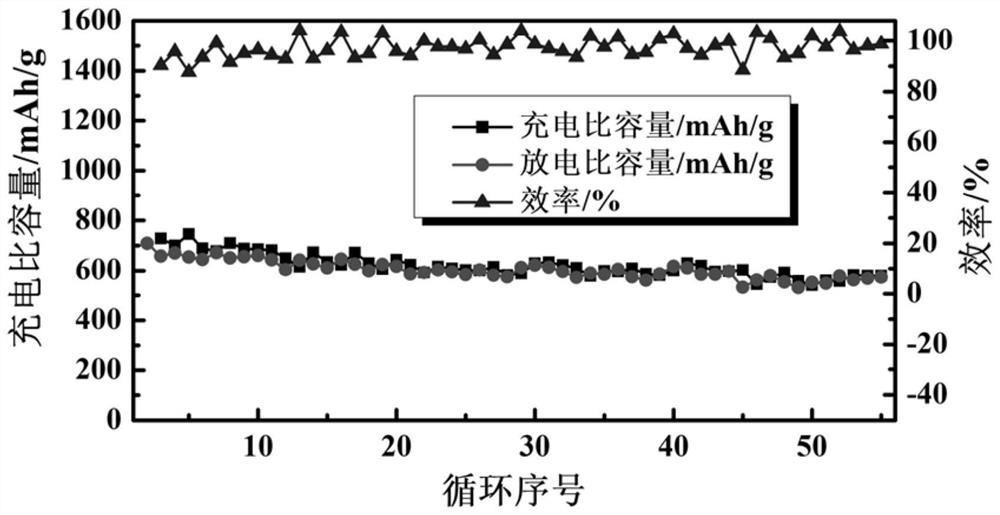

Preparation of flexible electrode-electrolyte integrated all-solid-state lithium-sulfur battery

ActiveCN111490231AInexpensive to cleanEfficient packagingLi-accumulatorsNon-aqueous electrolyte accumulator electrodesElectrolytic agentElectrical battery

The invention relates to the preparation of a flexible electrode-electrolyte integrated all-solid-state lithium-sulfur battery, in particular to a preparation method of a lithium-sulfur battery electrode-electrolyte material. The preparation method sequentially comprises the following specific steps: 1, preparing an active substance carrier conductive carbon material; 2, preparing a conductive carbon-sulfur composite material; 3, preparing a polymer electrolyte and a binder; 4, preparing an integrated flexible electrode-electrolyte material; and 5, assembling the battery. The solid-state lithium-sulfur battery prepared by the method disclosed by the invention has good cycling stability, the specific discharge capacity after 55 cycles is 573.1 mAh.g<-1>, the capacity retention ratio is 80.89%, and the average coulombic efficiency is 97.24%. According to the invention, the irreversible attenuation of the capacity caused by the shuttle effect of a liquid lithium-sulfur battery is fundamentally solved, the growth of lithium dendrites is inhibited, and various safety problems caused by an electrolyte are effectively solved.

Owner:HARBIN UNIV OF SCI & TECH

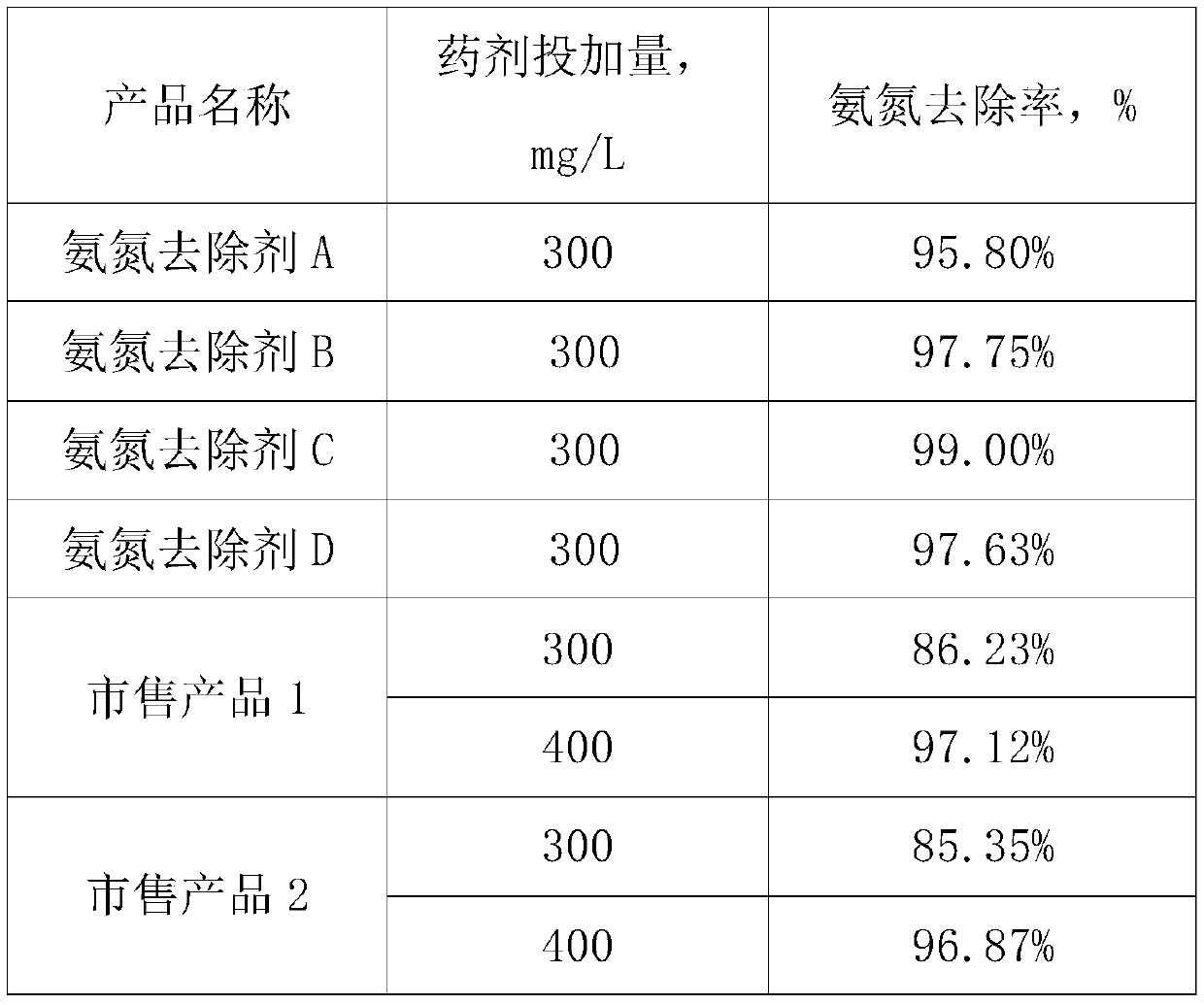

Ammonia nitrogen remover and preparation method thereof

InactiveCN110697824AAvoiding problems with small amounts of mixingPrecise proportionWater treatment parameter controlWater contaminantsDecompositionNitrogen gas

The invention discloses an ammonia nitrogen remover and a preparation method thereof. The ammonia nitrogen remover is prepared from the following raw materials in parts by weight such as 30-50 parts of calcium hypochlorite, 2-5 parts of potassium ferrate, 6-9 parts of sodium carboxymethylcellulose, and 9-12 parts of calcium chloride. The ammonia nitrogen remover relates to the technical field of water treatment. Through the ammonia nitrogen remover and the preparation method thereof disclosed by the invention, the calcium hypochlorite enables monohydrate ammonia in wastewater to overflow as nitrogen through oxidation reaction; the potassium ferrate can oxidize and decompose organic matters, microorganisms and algae, and the deposition and scaling of impurities on the pipeline wall are retarded, and the decomposition product Fe (OH)3 colloid also has the flocculation function, can adsorb and remove organic and inorganic pollutants in water, and has special effect on heavy metals; sodiumcarboxymethyl cellulose can break hydrogen bonds between water molecules and NH3 molecules, so that ammonia gas overflows; after calcium chloride reacts with hydroxyl ions to become calcium hydroxideflocculation and precipitation, part of nitrogen dioxide dissolved in water in the total nitrogen in the wastewater overflows, and the effect of reducing the total nitrogen is achieved.

Owner:XINJIANG DELAND

Method of producing pure cotton voile fabric

InactiveCN105113163ATwist stabilityAchieving Surface Tension DifferentiationSucessive textile treatmentsVegetal fibresCelluloseSpinning

The invention discloses a method of producing pure cotton voile fabric. The method comprises the steps of spinning, spooling, wet steaming and twist setting, beam warping, slashing, weaving, finishing and drying; the method is characterized in that a finishing process comprises the step of carrying out sand washing on textile fabric; during the sand washing process, a hydroxide agent is adopted as an alkaline agent, the dosage of the hydroxide agent is 7 to 10 g / L, and meanwhile, 10 g / L of urea is added. According to the method of producing the pure cotton voile fabric, disclosed by the invention, the hydroxide agent is adopted as the alkaline agent in the sand washing process, a certain dosage of the urea is simultaneously added, hydrogen bonds between polysaccharide molecules are effectively destroyed, cellulose dissolving is accelerated, a gel solution can be prevented from being formed, the finishing effect is increased through the synergistic effect of the hydroxide agent and the urea, and finishing residual liquid can be used for fertilizer production, and environmental pollution cannot be caused.

Owner:张家港市金陵纺织有限公司

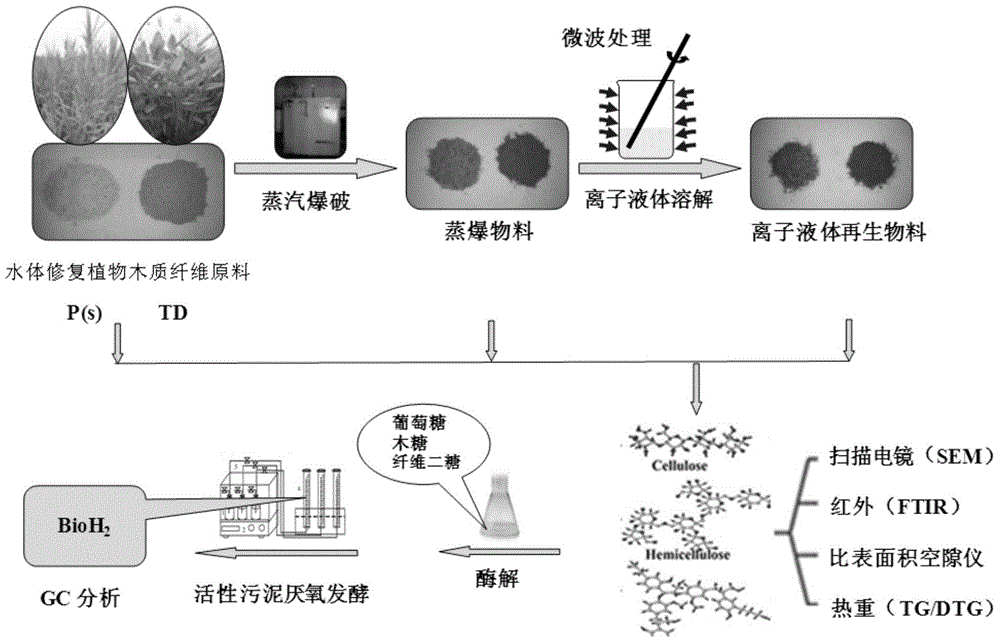

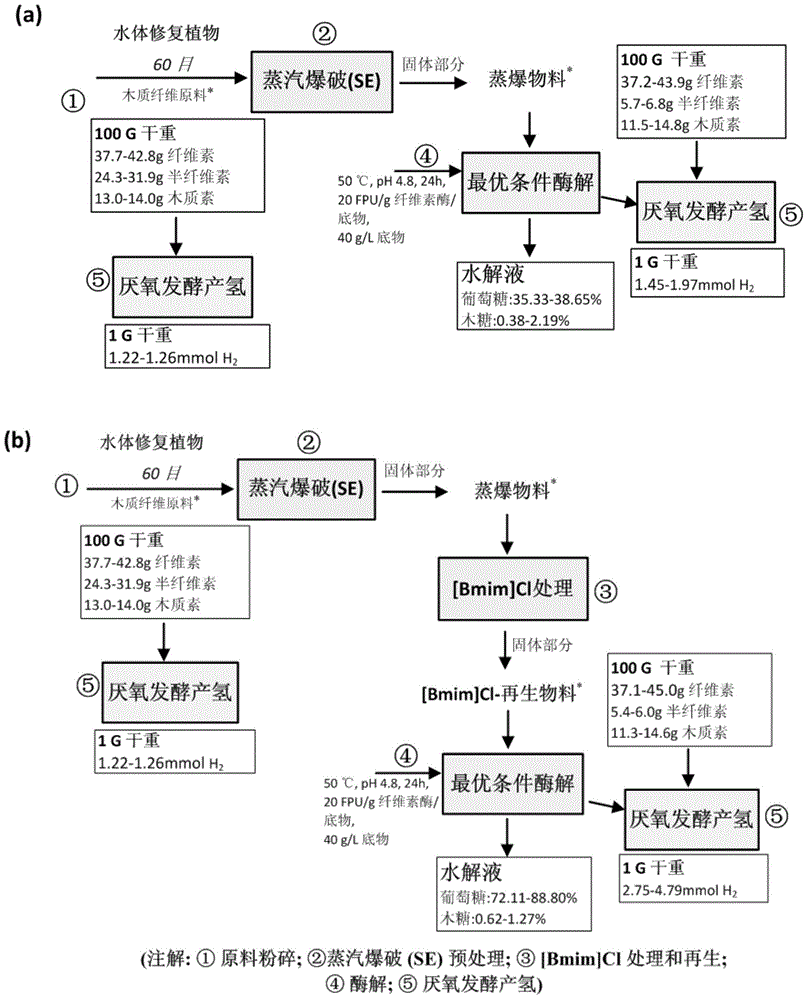

Water body remediation wood fiber raw material pretreatment method and corresponding hydrogen production method

The invention discloses a water body remediation wood fiber raw material pretreatment method sequentially comprising the following steps: (1) coarsely grinding, that is, coarsely grinding a water body remediation wood fiber raw material after air drying; (2) carrying out steam explosion, that is, carrying out steam explosion pretreatment on obtained sieving powder; (3) dissolving with an ionic liquid and regenerating a material, that is, adding the ionic liquid to a steam explosion material for dissolution treatment, and separating out solid from the steam explosion material after dissolution treatment by using water as an antisolvent; and (4) carrying out enzymatic saccharification, that is, carrying out enzymolysis by using the steam explosion material obtained from the step (2) or regeneration material obtained from the step (3) as a substrate to obtain an enzymatic saccharification liquid. The invention also provides a method for carrying out fermentation hydrogen production by utilizing the enzymatic saccharification liquid obtained from the method, that is, applying the enzymatic saccharification liquid to biological hydrogen production.

Owner:ZHEJIANG UNIV

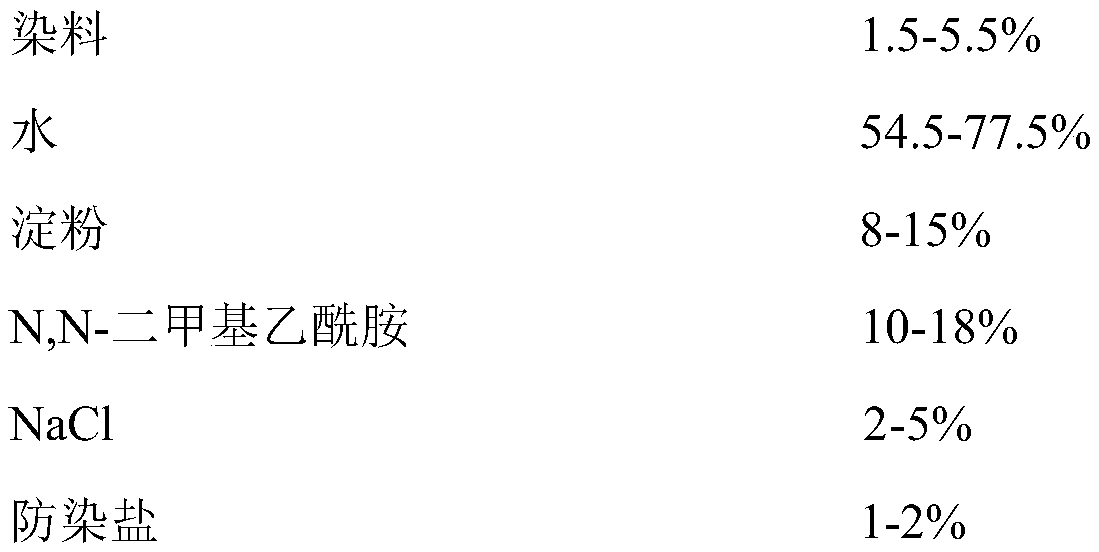

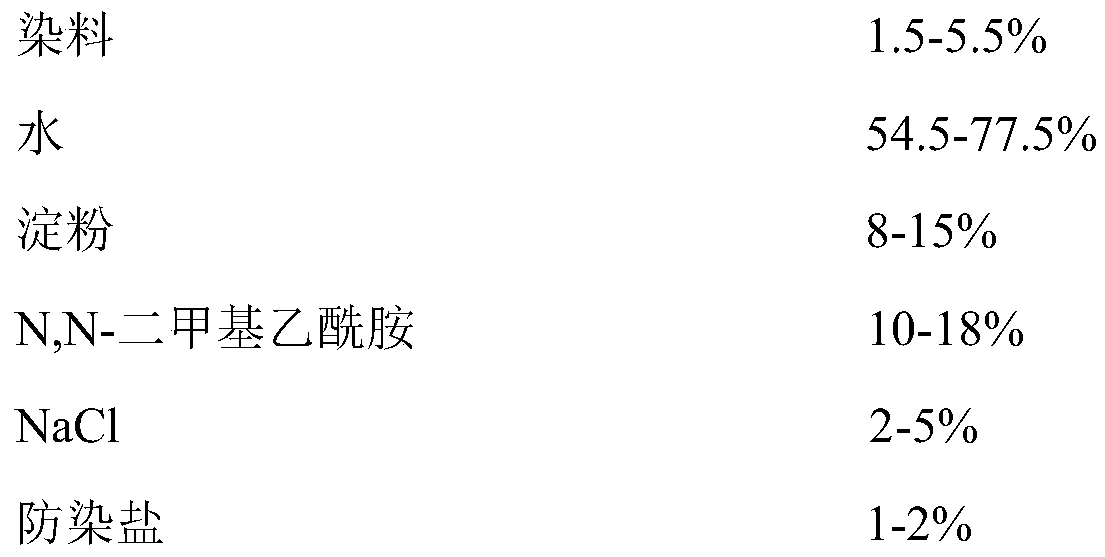

Low-temperature dyeing method for high-performance fabric

The invention relates to a low-temperature dyeing method for high-performance fabric, and belongs to the technical field of textile printing and dyeing. According to the method, silicic acid gel generated by hydrolyzing sodium silicate is adopted in the dyeing process of the high-performance fabric. N,N-dimethylacetamide is enriched in the silicic acid gel which is adsorbed on the fiber surface ofthe fabric. At 50-70 DEG C, N,N-dimethylacetamide opens part of hydrogen bonds between macromolecules on the surface of the high-performance fiber, and surface roughness and porosity of the fiber areincreased; then under the action of sodium hydroxide, the silicic acid gel adsorbed on the surface of the high-performance fabric is dissolved, and N,N-dimethylacetamide is released. Under the condition of low temperature dyeing at 70-90 DEG C, N,N-dimethylacetamide has strong polarity, and can effectively increase dissolution concentration of dye and reduce micelle concentration. Dye molecules are easily adsorbed and dye the high-performance fabric, and dyeing efficiency of the high-performance fabric is effectively improved. Besides, better dyeing effect can be achieved with the method at relatively low dyeing temperature, and thus, production cost and energy consumption are reduced.

Owner:WUHAN TEXTILE UNIV

Continuous carbon nano tube fiber-reinforced PA6 thermoplastic composite material and preparation method thereof

InactiveCN106987118AImprove conductivityImprove thermal conductivityCarbon nanotubeNetwork structure

The invention relates to the technology of carbon nano tube fiber, in particular to a continuous carbon nano tube fiber-reinforced PA6 thermoplastic composite material and a preparation method thereof. The preparation method comprises the following steps: firstly mixing 100 parts of PA6 resin, 0.1 to 0.5 part of an antioxygen, 0.2 to 1 part of a flowing accelerant, 1 to 5 parts of a compatibilizer and 2 to 10 parts of a flexibilizer, extruding the mixture into a hanger type die head for shunting through fusion mixing of a double / single screw unit, entering into an S-shaped die head for carrying out sufficient impregnation on active carbon nanot tube fiber, carrying out cooling water cooling pelleting, and finally preparing the continuous carbon nano tube fiber-reinforced PA6 thermoplastic composite material. According to the composite material disclosed by the invention, the mechanical property is greatly promoted, and based on a continuous network structure, the electric conduction and heat conduction performances of the composite material are also greatly improved.

Owner:JIANGXI UNIV OF SCI & TECH

Water transfer printing preparation process applied to bionic bait

ActiveCN109532262AIncrease the active siteUniform adsorptionPrinting after-treatmentAlginic acid coatingsEngineeringPre treatment

The invention discloses a water transfer printing preparation process applied to bionic bait, and relates to the technical field of water transfer printing. The water transfer printing preparation process comprises the following steps of pretreatment, protection paint spraying, thin film activation, water transfer printing and aftertreatment. Before and after water transfer printing, protection paint is sprayed, a water transfer printing image layer is protected in two layers of protection paint thin films, losses of the water transfer printing image layer are reduced, the bionic effect of thebionic bait is improved, texture is fine, and films are stable.

Owner:安徽宏飞钓具有限公司

Preparation method for new type fully-degradable cellulose composite fiber with skin-core structures

InactiveCN103352267BEasy to shapeImprove performanceConjugated cellulose/protein artificial filamentsWet spinning methodsPolyesterCellulose

The invention provides a preparation method for new type fully-degradable cellulose composite fiber with skin-core structures. The preparation method is characterized by comprising steps: cellulose and biomass polyesters are subjected to vacuum drying, the cellulose and ionic liquids are added in a high-speed mixer according to the ratio and stirred evenly, the mixture of the cellulose and the ionic liquids is added in a co-rotating twin-screw extruder through a feeding inlet, the biomass polyesters obtained from the first step are added through another feeding inlet, both of the mixture and the biomass polyesters are extruded by the co-rotating twin-screw extruder into a spinning pack to be spun through spinneret plates, the obtained composite fiber goes through a water tank and the ionic liquids in skin layers are washed off, then the composite fiber is stretched and wound through the spinning pack, and the new-type fully-degradable cellulose composite fiber with skin-core structures is obtained. The composite fiber has advantages of good hygroscopicity, comfortableness and chromaticity of cellulose and good mechanical properties of polylactic acid, and retains the biodegradable characters of cellulose and polylactic acid, and is suitable for the medical and taking fields.

Owner:DONGHUA UNIV

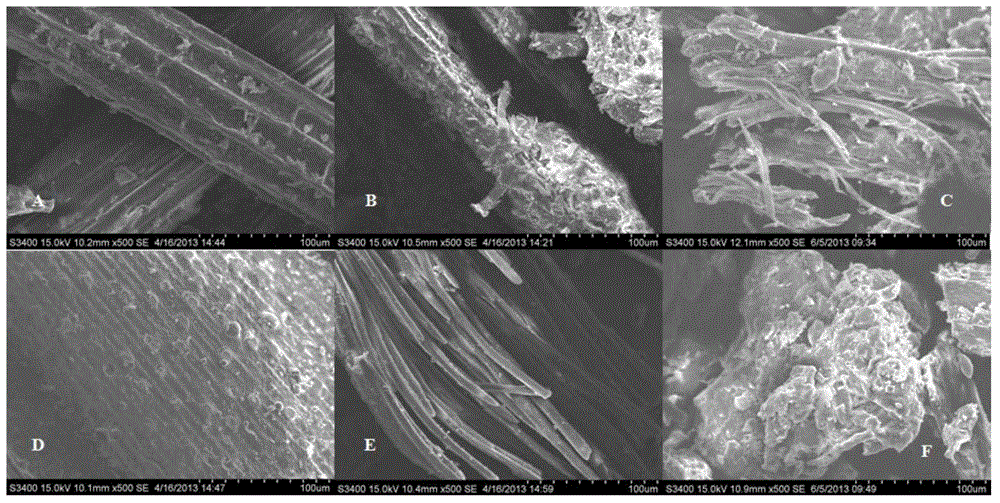

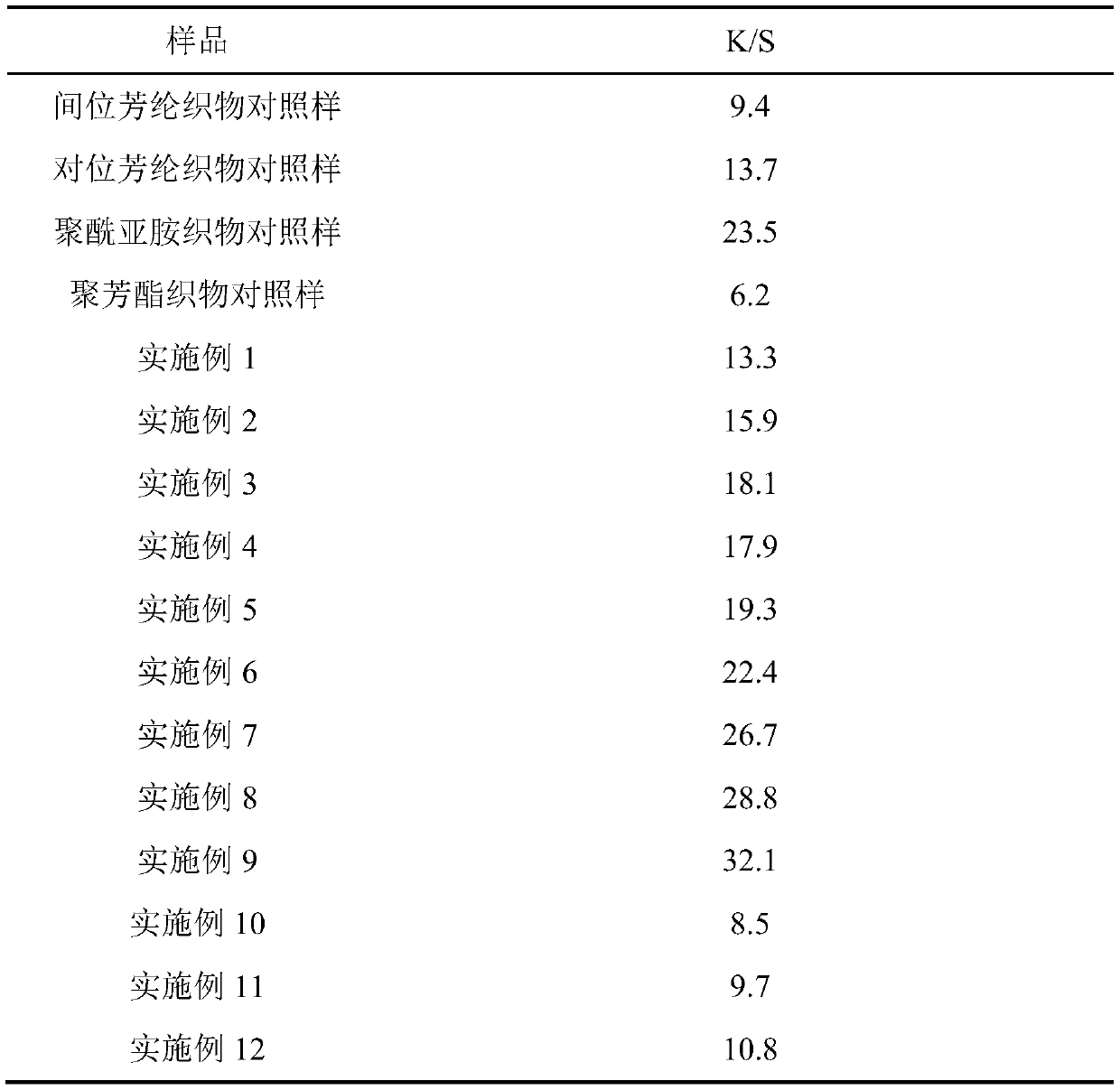

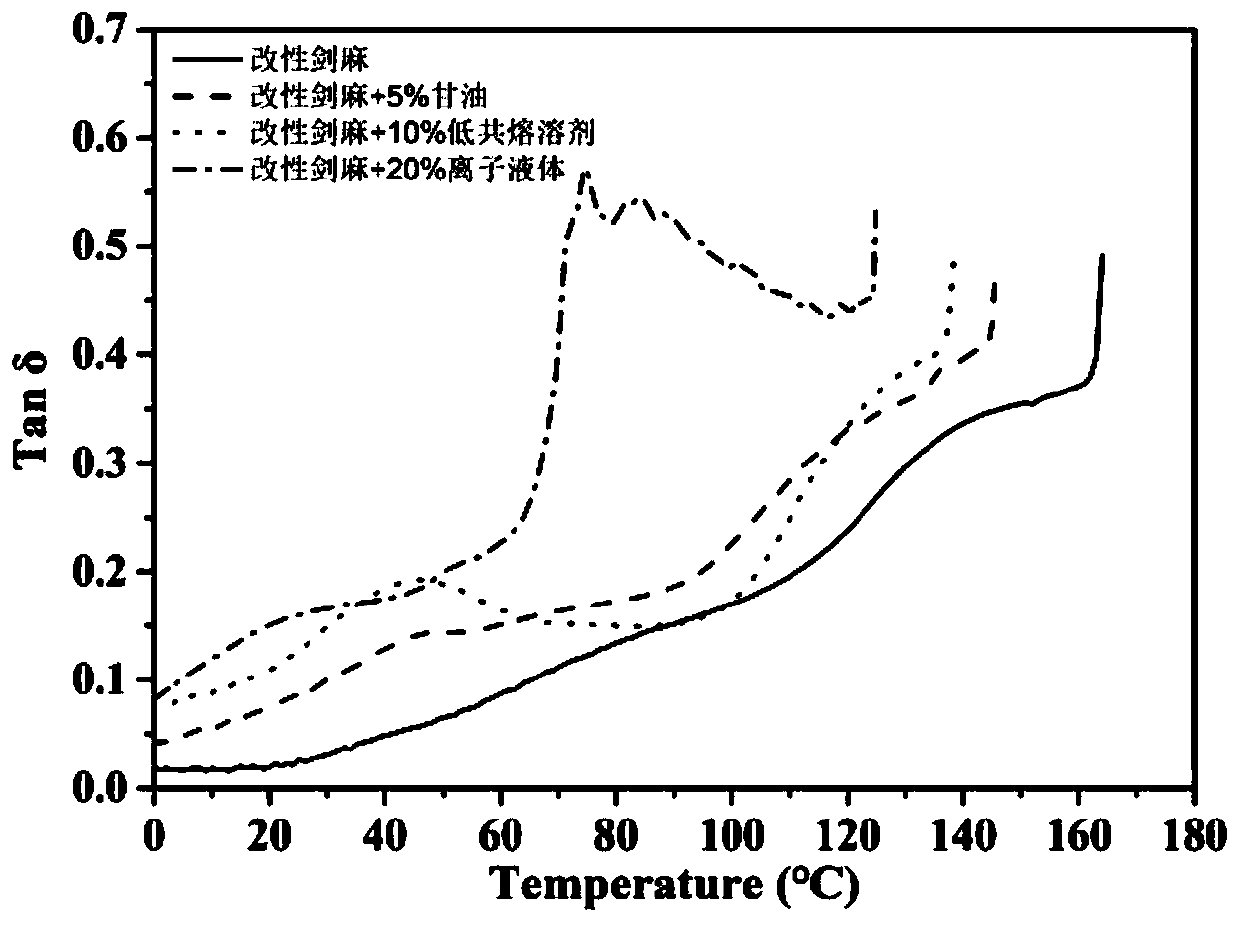

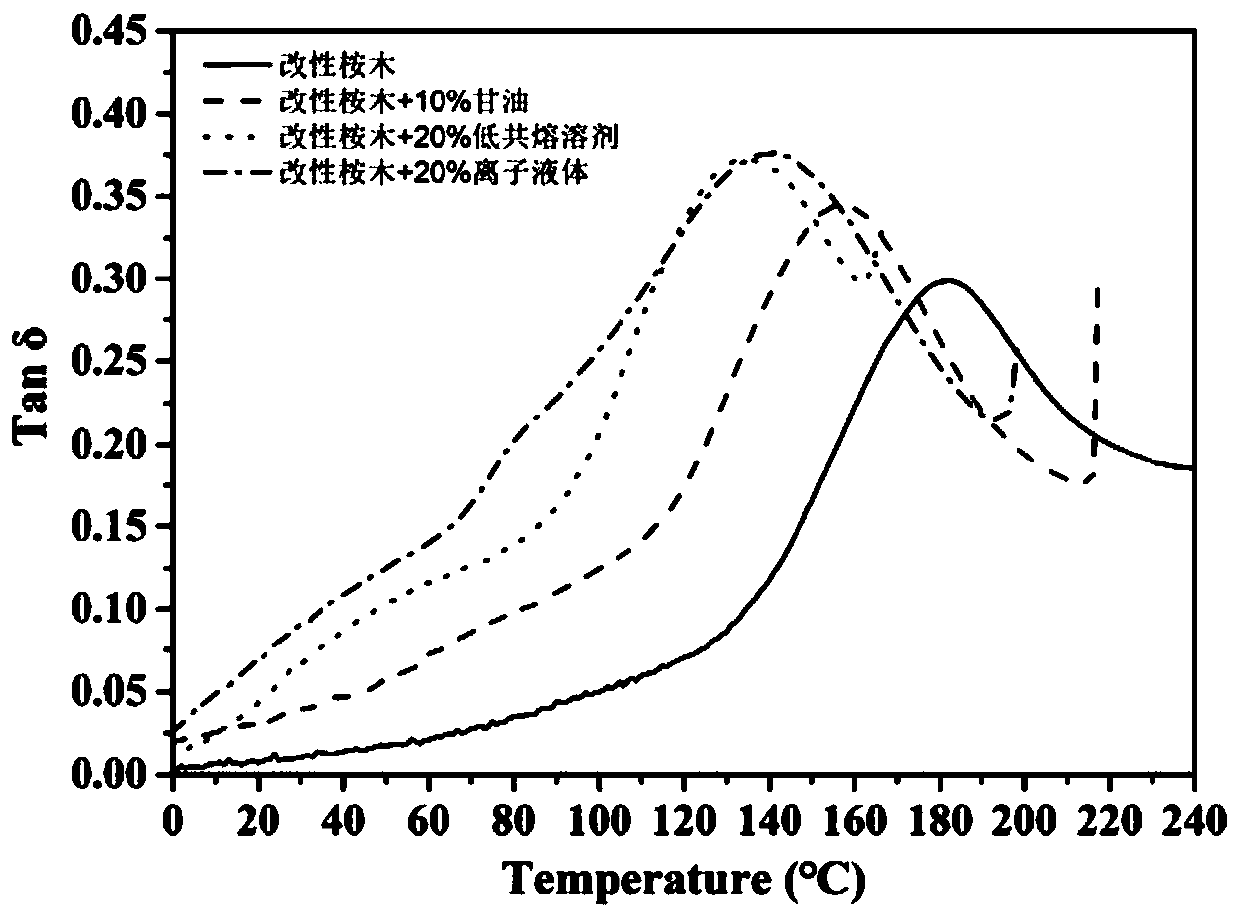

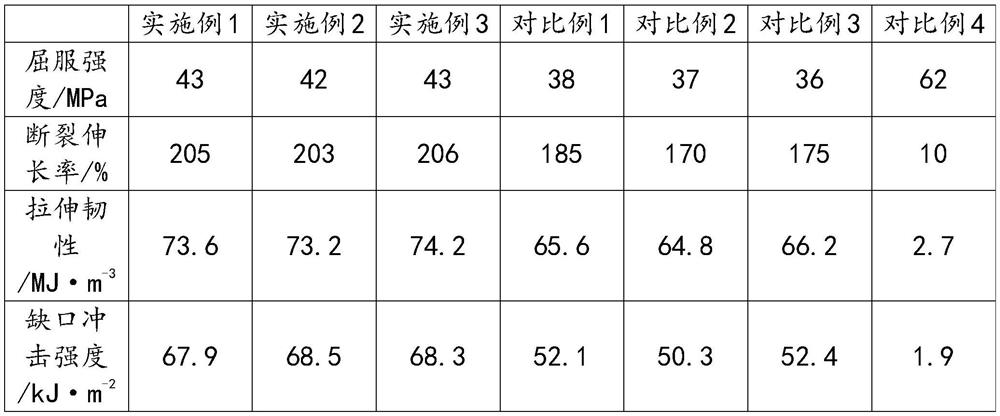

Method for regulating thermoplasticity and toughness of redox-modified plant fiber and application of redox-modified plant fiber

InactiveCN109721770AImprove thermoplasticityImprove toughnessFibrous raw materialsVegetal fibresFiberFiltration

The invention relates to a method for regulating the thermoplasticity and toughness of redox-modified plant fiber. The method comprises the following steps: (1) performing pretreatment on plant fiber;(2) adding an oxidizing agent solution for a reaction, performing filtration and washing so as to obtain oxidization-modified plant fiber, adding a reducing agent solution for a reaction, and performing filtration and washing so as to obtain redox-modified plant fiber; and (3) adding a plasticizer, and mixing the plasticizer with the redox-modified plant fiber uniformly, wherein the plasticizer is a hydroxy plasticizer, an ionic liquid plasticizer, an eutectic solvent plasticizer, an ester plasticizer, an amine plasticizer, a glycidyl ether plasticizer or an inorganic salt plasticizer. Through the method, the flexibility of the redox-modified plant fiber material can be improved, the processing temperature of the plant fiber material can be reduced, and the processing window of the plantfiber material can be widened.

Owner:SOUTH CHINA UNIV OF TECH

Formula of glass fiber-impregnated PA6 (nylon 6) with high weather-resistant property and high fluidity and preparation method thereof

The invention relates to a formula of a glass fiber-impregnated PA6 (nylon 6) with high weather-resistant property and high fluidity and a preparation method thereof. The formula comprises the following components in parts by mass: 100 parts of PA6 resin (1), 0.5 to 1.6 parts of anti-ultraviolet aging additive (2), 0.5 to 1 part of antioxidant (3), 0.2 to 1.2 parts of flowing promoter (4), 2 to 10 parts of toughener (5), and 1 to 5 parts of compatilizer (6). The preparation method comprises the following steps of premixing the components according to a certain ratio; using a double / single-screw extruder to melt, mix and extrude into a die head, separating flow and impregnating, so as to obtain the glass fiber-impregnated PA6 with high weather-resistant property and high fluidity. The formula and the preparation method have the advantage that by combining hyperbranched end active functional groups and glass fiber, the interface bonding ability between polyolefin resin and glass fiber is enhanced, and the mechanical property is improved.

Owner:浙江胜钢新材料有限公司

High-performance-fabric printing method

The invention relates to a high-performance-fabric printing method, and belongs to the technical field of spinning printing and dyeing. According to the high-performance-fabric printing method, a high-performance fabric is chemically pretreated before printing, treating fluid adopts silicic acid gel generated through sodium silicate hydrolysis, N,N-dimethylacetamide is richened in the silicic acidgel, and meanwhile the silicic acid gel is attached to the fiber surface of the fabric. Under the condition of 50 DEG C to 70 DEG C, the N,N-dimethylacetamide opens part of hydrogen bonds between meta-position aramid fiber surface macromolecules, the surface roughness and the porosity of fibers are improved, then under an effect of sodium hydroxide, the silicic acid gel attached on the surface ofthe high-performance fabric is dissolved, the N,N-dimethylacetamide is released, and further acts on the fiber surface in the heat preservation process, and the structure of the fiber surface is further loosened. It is achieved that dye is transferred into the fibers through the common synergistic effect of baking and steaming on the basis of the structure. Therefore, according to the technical scheme, the printing efficiency of the high-performance fabric is improved, and the high-performance fabric can be expanded and applied.

Owner:WUHAN TEXTILE UNIV

High-flexibility biodegradable non-woven fabric

ActiveCN111088602AImprove toughnessGood redispersibilitySynthetic resin layered productsConjugated cellulose/protein artificial filamentsPolymer scienceCotton fibre

The invention discloses a high-flexibility biodegradable non-woven fabric. The non-woven fabric comprises an upper fiber mesh layer and a lower fiber mesh layer, wherein the upper fiber mesh layer isprepared from toughened polylactic acid fibers and pure cotton fibers; and the lower fiber mesh layer is prepared from toughened polylactic acid fibers and coarse denier ES fibers. According to the non-woven fabric disclosed in the invention, 5-30 wt% of modified hemp nano fibers are added to polylactic acid master batch to prepare the toughened polylactic acid fibers; surface modification is usedas a toughening agent, so that the toughness of polylactic acid is improved; meanwhile, the dense hydrogen bonds on the surface of nano cellulose are destroyed, the redispersibility of the nano cellulose is improved, and the dispersion of a nanofiber filler in a polylactic acid system is facilitated; and meanwhile, the surface smoothness and the cooling treatment can eliminate the stinging sensation when the hemp fibers are in contact with a human body.

Owner:FUJIAN HENGAN HLDG CO LTD +3

Method for extruding in-situ grafting modified cellulose through twin screws with ionic liquid serving as solvent

The invention relates to a method for extruding in-situ grafting modified cellulose through twin screws with ionic liquid serving as a solvent. The method comprises the following steps: (1) drying the cellulose and a grafting monomer in vacuum; (2) uniformly mixing the following raw materials by weight percent: 4 to 8% of cellulose, 30 to 40% of grafting monomer, 51.84 to 65.92% of ionic liquid, 0.04 to 0.08% of initiator, and 0.04 to 0.08% of catalyst; and (3) extruding the mixture by a co-rotating twin-screw extruder, so as to obtain the in-situ grafting modified cellulose. By adopting the method, high flowing property is provided on the basis that the original performances of the cellulose are remained; the cellulose grafting copolymer, which is easily processed and formed, and efficient, green and clean, can be obtained; and the development on novel cellulosic fibers, which are low in energy consumption, economic and feasible and environmentally friendly, can be promoted.

Owner:DONGHUA UNIV

Method for preparing quaternary ammonium cationic starch flocculant in DMSO/H2O/NaOH system

InactiveCN105949332AImprove plasticityImprove the activation effectWater/sewage treatment by flocculation/precipitationFlocculationQuaternary ammonium cation

The invention discloses a method for preparing a quaternary ammonium cationic starch flocculant in a DMSO / H2O / NaOH system. The method comprises following steps: 1), NaOH is dissolved in water, DMSO and starch are added, a mixture is heated, stirred and subjected to reflux condensation for a reaction, and a starch activation liquid is obtained; 2), the starch activation liquid obtained in the step 1) is cooled to 60-75 DEG C, then an etherifying agent activation liquid is added and stirred, and a reaction is performed for 0.5-1 h; 3), the white powdery quaternary ammonium cationic starch flocculant is obtained through cooling, purification and drying. According to the method, the starch is pre-activated in the DMSO / H2O / NaOH system, the reactions are performed in a homogeneous system, so that the starch has higher plasticity, active sites for combination of an etherifying agent and the starch are increased, the activated starch can react with the cationic etherifying agent rapidly, the quaternary ammonium cationic starch flocculant prepared with the method can be completely dissolved in water, colloid particles can be clustered through flocculation under the sufficient bridging and cross-linking actions, and the flocculation effect cannot be influenced by a settlement action of the flocculant.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

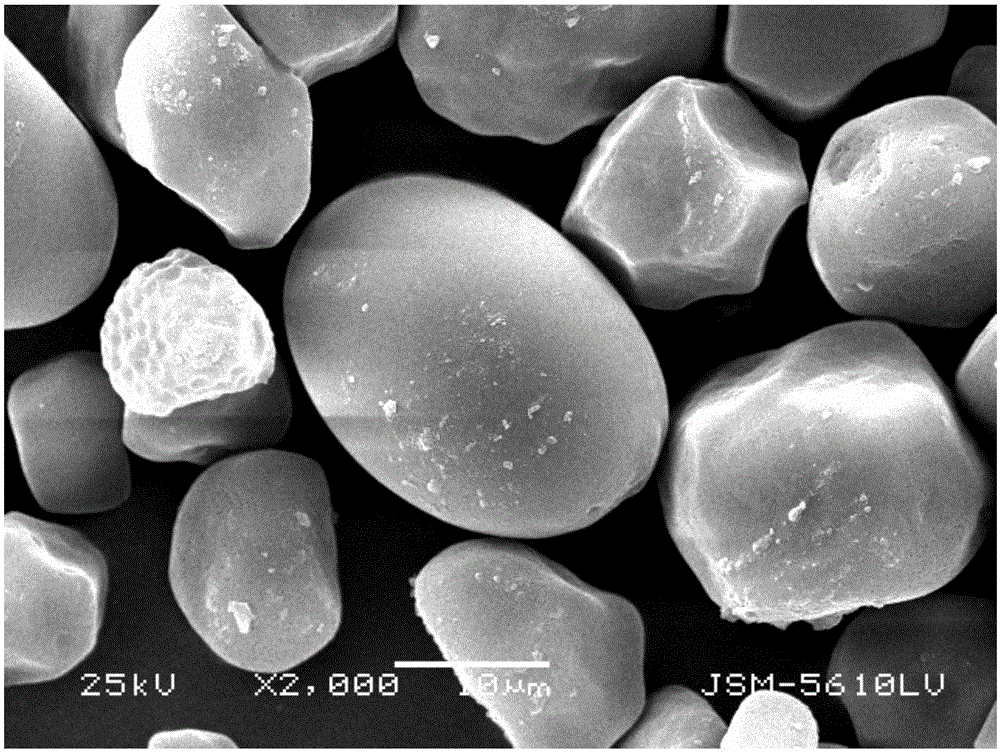

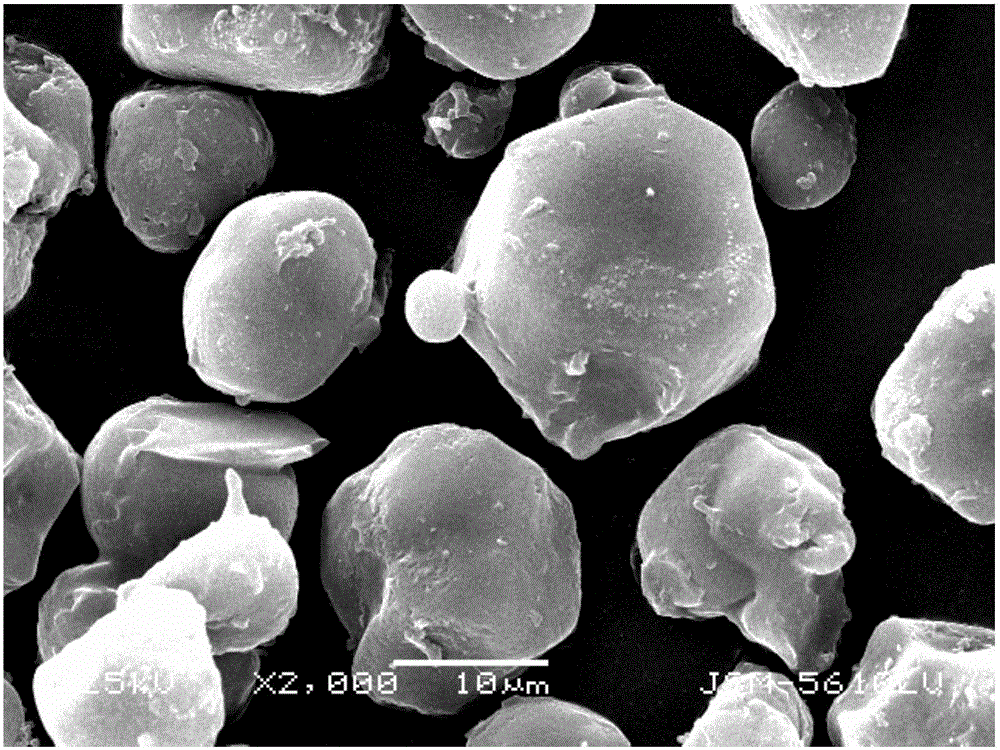

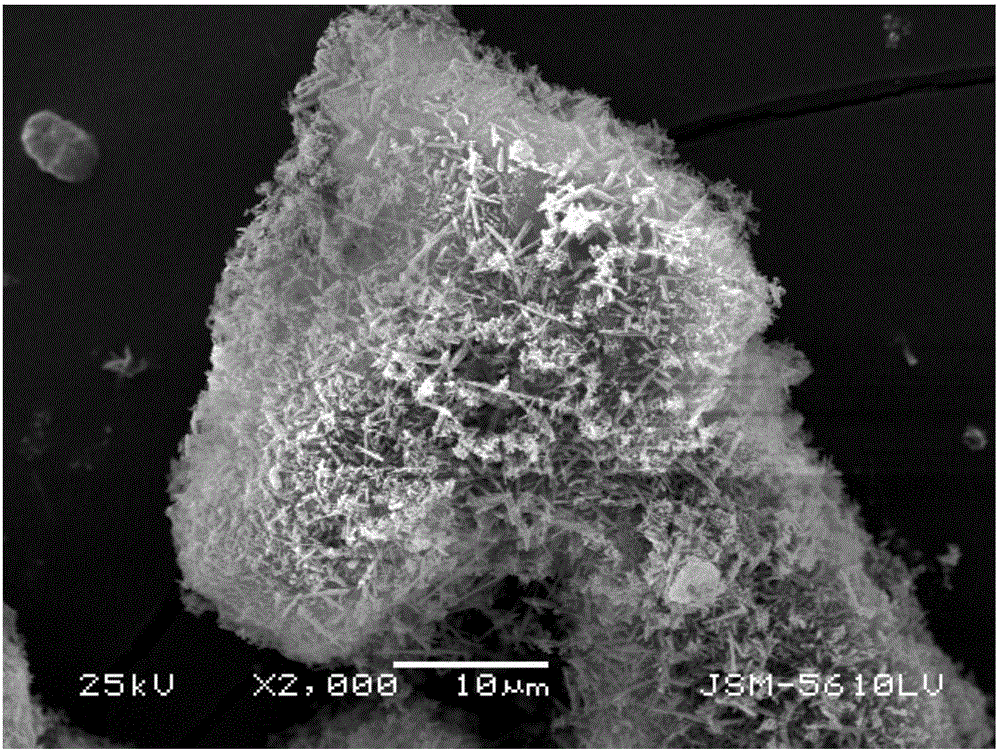

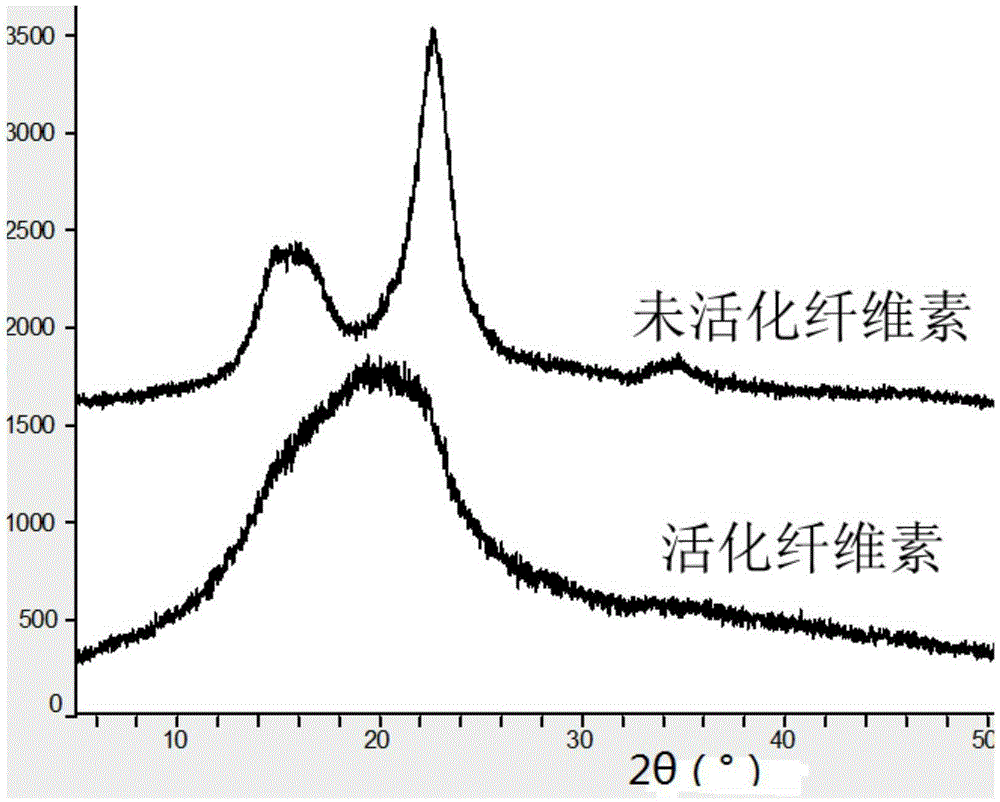

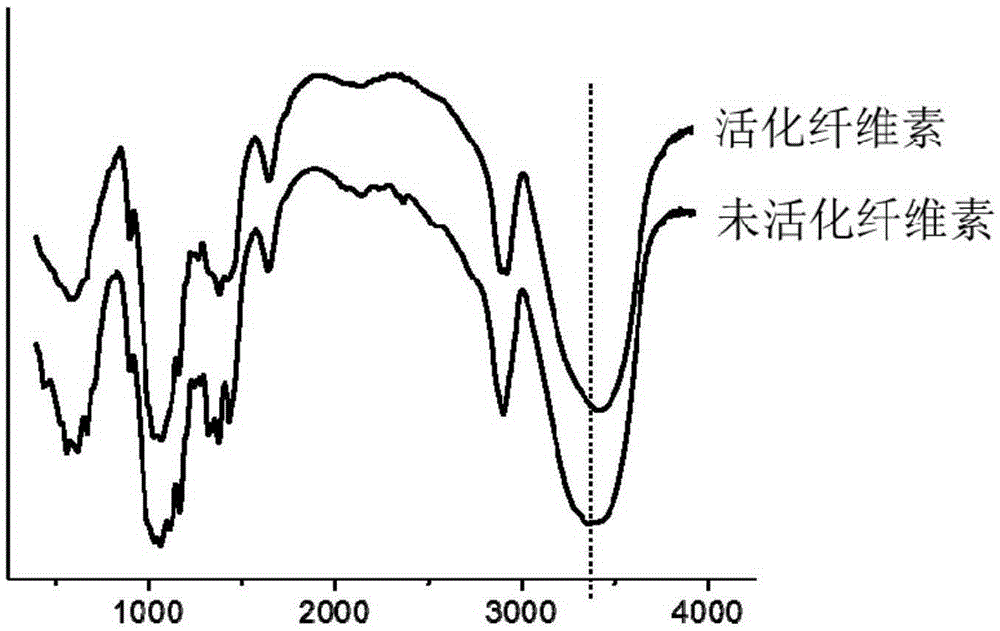

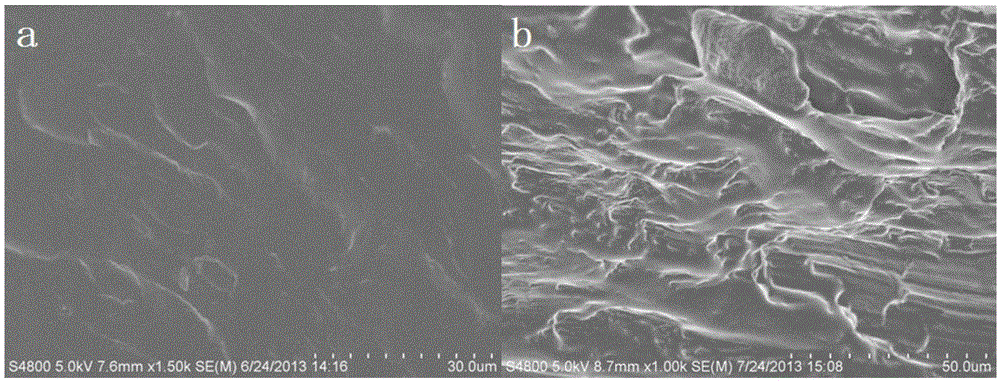

Pre-activated-cellulose thermoplastic material and preparation method thereof

The invention discloses a pre-activated-cellulose thermoplastic material, comprising activated cellulose powder and ionic liquid in a mass ratio of 4: 1 to 1: 1, wherein the activated cellulose powder is cellulose powder obtained through mechanical grinding of natural cellulose and has a particle size of 1 to 100 [mu]m. The invention also discloses a preparation method for the cellulose thermoplastic material. The preparation method comprises the following steps: subjecting cellulose to grinding and activation pretreatment; then mixing the pre-activated cellulose with the ionic liquid; and carrying out mixing on thermal forming equipment. Through activation pretreatment of cellulose, the hydrogen bond and crystal structure of cellulose are effectively destroyed, so more free hydroxyl groups of cellulose are exposed and sufficient plasticization of cellulose is effectively promoted; and the prepared pre-activated-cellulose thermoplastic material has a smooth and continuous section and can repeatedly undergo thermoplastic forming, and the ionic liquid in the material can be totally removed so as to obtain cellulose I.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

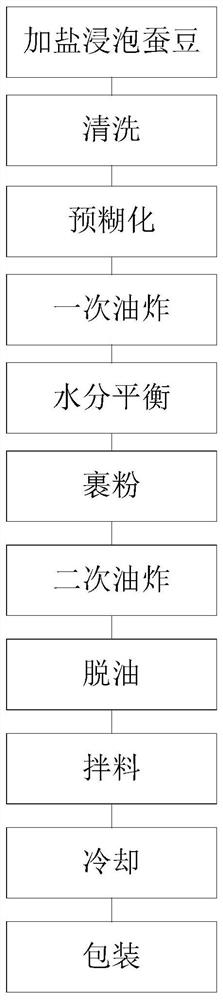

Low-fat fried broad bean product and preparation method thereof

PendingCN113632927ALow fat contentHigh fat contentFood preservationFood ingredientsBiotechnologyOil and grease

The invention discloses a low-fat fried broad bean product. The low-fat fried broad bean product is prepared by taking broad beans as raw materials and taking table salt, mixed powder, sweet water and seasonings as ingredients, so that the fat content is low, and the taste is crisp and refreshing. A preparation method comprises the following steps: soaking the broad beans with the table salt, cleaning, pre-gelatinizing, frying for the first time, balancing water, wrapping with powder, frying for the second time, deoiling, mixing, cooling and packaging. The water-retaining property of the broad beans is improved through pre-gelatinizing and water balancing, so that the structure is fluffy; the microstructure roughness of the broad beans is increased by adopting a surface modification powder wrapping technology, and the oil absorption is reduced; and the stability of oil is improved by adopting compound mixed oil in the frying process, so that the oil is healthier. The fried broad beans produced by the traditional process are high in fat content and easily generate a vitrification phenomenon (the vitrification phenomenon is more serious if the raw materials are stored for a longer time), so that the crispness is poor, and the taste is influenced. The fat content of the prepared broad bean product is 19 percent, and is reduced by 14 percent compared with that of the traditional process; and the taste is crisp and refreshing, and the health and nutrition requirements of consumers and the industry development trend are met.

Owner:NINGXIA HOUSHENGJI FOOD

A kind of preparation method of bamboo fiber base degradable environmental protection material

The invention discloses a preparation method of a bamboo fiber-based degradable environmental protection material, comprising the following steps: step S1, weighing raw materials; step S2, drying the raw materials; step S3, weighing 6% polylactic acid and ethylene / acrylate / Glycidyl methacrylate terpolymer was banburyed for 40 minutes at 250°C and a rotational speed of 100r / min to obtain a pre-reactant; step S4, preparing pre-treated talcum powder; step S5, pre-reactant, remaining polylactic acid , Pretreatment talcum powder blending. The present invention adopts polylactic acid as matrix, and ethylene / acrylate / glycidyl methacrylate terpolymer toughens and modifies it; by modifying bamboo fiber first, not only the interface with PLA matrix can be increased Compatibility can also endow the material with good antibacterial properties; through the addition of talcum powder and coupling agent, it can play a reinforcing effect, further improve the mechanical properties of the material, and prepare a biodegradable and biodegradable material with excellent mechanical properties. Environmentally friendly material with antibacterial properties.

Owner:青岛中宝塑业有限公司

Highly Flexible Biodegradable Nonwovens

ActiveCN111088602BImprove toughnessGood redispersibilitySynthetic resin layered productsConjugated cellulose/protein artificial filamentsPolymer scienceCotton fibre

The high flexibility biodegradable non-woven fabric of the present invention, described non-woven fabric comprises: upper layer fiber web layer and lower layer fiber web layer; Wherein, upper layer fiber web layer is made of toughened polylactic acid fiber, pure cotton fiber; The described The lower web layer is made of toughened polylactic acid fibers and coarse denier ES fibers. In the non-woven fabric of the present invention, the toughened polylactic acid fiber prepared by adding 5-30% by weight of the modified hemp nanofiber to the polylactic acid masterbatch is used; the surface modification is used as a toughening agent to improve the toughness of the polylactic acid ; At the same time, it destroys the dense hydrogen bonds on the surface of nanocellulose, improves the redispersibility of nanocellulose, and is beneficial to the dispersion of nanofiber fillers in the polylactic acid system; at the same time, the smooth surface and cool feeling treatment can eliminate the contact between hemp fiber and human body tingling sensation.

Owner:FUJIAN HENGAN HYGIENE MATERIAL

Preparation of a flexible electrode-electrolyte integrated all-solid-state lithium-sulfur battery

ActiveCN111490231BInexpensive to cleanEfficient packagingLi-accumulatorsNon-aqueous electrolyte accumulator electrodesLithium sulfurChemical engineering

The invention relates to the preparation of a flexible electrode-electrolyte integrated all-solid-state lithium-sulfur battery, in particular to a preparation method of a lithium-sulfur battery electrode-electrolyte material. The specific steps of the present invention are as follows: 1. Preparation of conductive carbon material for active material carrier; 2. Preparation of conductive carbon-sulfur composite material; 3. Preparation of polymer electrolyte and binder; 4. Integrated flexible electrode-electrolyte material Preparation; five, battery assembly. The solid-state lithium-sulfur battery prepared by the method of the present invention has good cycle stability, and the discharge specific capacity after 55 cycles is 573.1mAh g ‑1 , the capacity retention rate was 80.89%, and the average Coulombic efficiency was 97.24%. The invention fundamentally solves the irreversible attenuation of capacity caused by the shuttle effect of the liquid lithium-sulfur battery, inhibits the growth of lithium dendrites and effectively solves various safety problems caused by the electrolyte.

Owner:HARBIN UNIV OF SCI & TECH

A kind of preparation method of reinforced poly-m-phenylene isophthalamide hollow fiber membrane

ActiveCN105597569BImprove solubilityBreaking hydrogen bondsSemi-permeable membranesOrganic solventPolymer science

The invention discloses a preparation method of an enhanced polyisophthaloyl metaphenylene diamine hollow fiber membrane. The preparation method includes the following processing steps of (1) preparation of a hollow braided hose: adopting a well-known two-dimensional braiding technique to braid fibers into the hollow braided hose, and taking the hollow braided hose as an enhancing body of the enhanced hollow fiber membrane; (2) preparation of PMIA membrane casting dissolving fully dried PMIA resin, additives and a pore-forming agent in an organic solvent at the temperature of 60-70 DEG C, stirring for 4-6h to obtain homogeneous solution, and performing vacuum defoaming to obtain the PMIA membrane casting (3) preparation of the enhanced PMIA hollow fiber membrane: adopting a coextrusion composite spinning process to subject the hollow braided hose obtained in the step (1) and PMIA membrane casting solution obtained in the step (2) to coextrusion through an annular spinning jet, uniformly coating the surface of the hollow braided hose with the membrane casting solution, and fully curing to obtain the enhanced PMIA hollow fiber membrane.

Owner:TIANJIN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com