Preparation method of enhanced polyisophthaloyl metaphenylene diamine hollow fiber membrane

A technology of polym-phenylene isophthalamide and fiber membranes, which is applied in the field of membrane preparation, can solve the problems of low strength of hollow fiber membranes, insufficient mechanical strength, and inability to meet the requirements of use, and achieve high temperature resistance and corrosion resistance performance, reduced preparation cost, and excellent high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

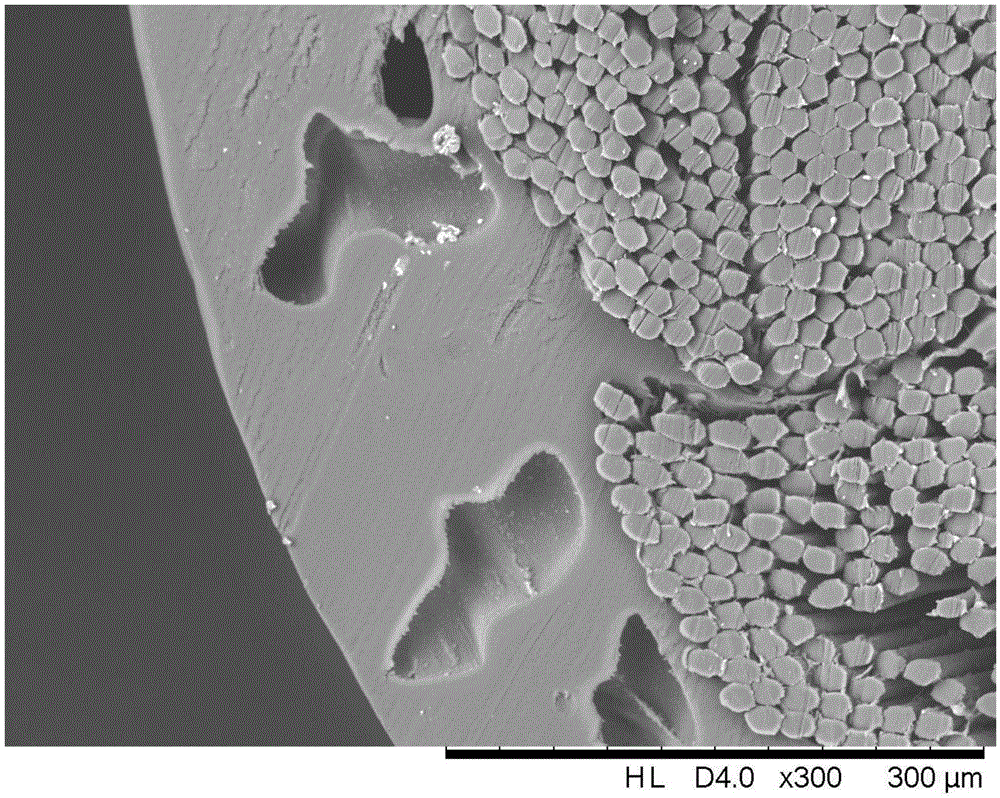

[0017] A kind of preparation method of reinforced PMIA hollow fiber membrane, this preparation method adopts following processing steps:

[0018] (1) Preparation of hollow braided tube: adopt known two-dimensional braiding technology to weave fiber into hollow fiber tube, and use this hollow braided tube as the reinforcing body of reinforced hollow fiber membrane; Described fiber is PMIA filament or PMIA and Blended filaments of polyester (PET) filaments; wherein the denier of PMIA and PET filaments is between 200-600D; the blending ratio of PMIA filaments and PET filaments is 1-5:0-5, preferably mixed The braiding ratio is 2:0, 2:1, 3:1, 4:1, 5:1, 1:2, 1:3, 1:4, 1:5; the braided tube diameter is 0.5-2.0mm.

[0019] (2) Preparation of PMIA casting solution: fully dissolve the completely dry PMIA resin, additives and porogen in an organic solvent at 60-70°C, and obtain a homogeneous solution after stirring for 4-6 hours. After vacuum defoaming Make PMIA film-casting liquid; Ea...

Embodiment 1

[0032] (1) Preparation of hollow braided tube: A 24-spindle two-dimensional braiding machine was used to braid PMIA filaments with a specification of 200D into a PMIA hollow braided tube with a diameter of 1.6 mm.

[0033] (2) The preparation of PMIA casting liquid: the additive (CaCl 2 / LiCl=3.5 / 2.5) was mixed and dissolved in the DMAc solution of 74% mass fraction; after it was fully dissolved, the porogen (PVP / PEG=2 / 0, PVP / PEG=2 / 0, PVP (molecular weight 30000) was added to the above system, and stirred at 70 ° C, and after it was completely dissolved, it was defoamed to obtain PMIA casting solution.

[0034] (3) Preparation of reinforced PMIA hollow fiber membrane: Co-extrusion composite spinning technology was used to uniformly coat the above-mentioned PMIA casting solution on the surface of the hollow braided tube through a co-extrusion spinneret at 70°C. At a spinning speed of 0.5 m / min, after passing through an air gap of 25 cm, it enters a coagulation bath at 25° C. f...

Embodiment 2

[0038] (1) Preparation of hollow braided tube: A 24-spindle two-dimensional braiding machine was used to braid PMIA filaments with a specification of 200D into a PMIA hollow braided tube with a diameter of 1.6 mm.

[0039] (2) The preparation of PMIA casting liquid: the additive (CaCl 2 / LiCl=3.5 / 2.5) was mixed and dissolved in the DMAc solution of 74% mass fraction; after it was fully dissolved, the porogen (PVP / PEG=2 / 0, PVP / PEG=2 / 0, PVP (molecular weight 30000) was added to the above system, and stirred at 70 ° C, and after it was completely dissolved, it was defoamed to obtain PMIA casting solution.

[0040] (3) Hollow braided tube pretreatment: the liquid used is 20% H 3 PO 4 Aqueous solution, the temperature used is 50°C, and the treatment time is 5h. After the braided tube is pretreated, the etching of PMIA fibers by phosphoric acid leads to an increase in the roughness of the braided tube fiber, which is beneficial to the improvement of the bonding strength between t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com