Formula of glass fiber-impregnated PA6 (nylon 6) with high weather-resistant property and high fluidity and preparation method thereof

A high-flow, high-weather-resistance technology, applied in the field of plastic manufacturing, can solve the problems of affecting the mechanical properties of products, general glass fiber wettability, poor glass fiber impregnation effect, etc., achieve excellent anti-aging performance, enhance interface bonding ability, and improve mechanical properties. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

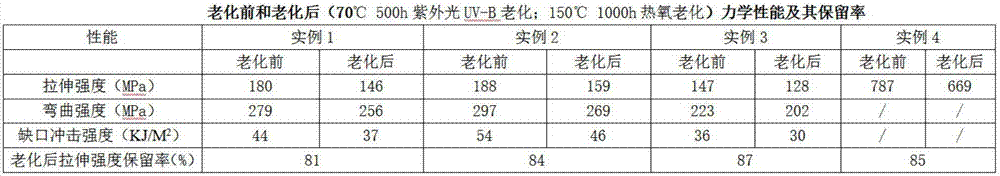

Examples

specific Embodiment 1

[0033] A high weather resistance and high flow glass fiber impregnated with PA6, the formula includes: PA6 resin 100 kg, anti-ultraviolet additive UV-570 0.4kg, polymeric hindered amine light stabilizer HS-944 0.1kg, organic copper Stabilizer H3377 0.5kg, hyperbranched resin Hyper C100 0.2kg, ethylene octene copolymer POE 2kg, ethylene octene copolymer grafted maleic anhydride POE-g-MAH 1kg.

[0034] A preparation method of high weather resistance and high flow glass fiber impregnated PA6, including the following steps: after premixing the above components according to a certain proportion, melt and mix them through a single screw unit and extrude them into a "hanger" type die for splitting, and finally enter The "S" type die head fully impregnates the glass fiber, and the strands are cooled and granulated by cooling water to produce long glass fiber reinforced thermoplastic particles LFRT with a glass fiber content of 40%.

specific Embodiment 2

[0036] A high-weather-resistance and high-flow glass fiber impregnated with PA6, the formula includes: PA6 resin 100 kg, anti-ultraviolet additive UV-630 1.0 kg, organocopper stabilizer H3336 1 kg, hyperbranched resin CYD-701 0.8 kg , Arkema AX89005kg, ethylene octene copolymer grafted maleic anhydride POE-g-MAH 3kg.

[0037] A preparation method of high weather resistance and high flow glass fiber impregnated PA6, including the following steps: after premixing the above components according to a certain proportion, melt and mix them through a single screw unit and extrude them into a "hanger" type die for splitting, and finally enter The "S" type die head fully impregnates the glass fiber, and the strands are cooled and granulated by cooling water to produce long glass fiber reinforced thermoplastic particles LFRT, and the glass fiber content is controlled at about 40%.

specific Embodiment 3

[0039] A high-weather-resistant and high-flow glass fiber impregnated with PA6, the formula includes: PA6 resin 100 kg, anti-ultraviolet additive UV-630 1.6 kg, high-efficiency organic copper stabilizer H3336 1 kg, hyperbranched resin CYD-701 1.2 kg by mass parts kg, DuPont FUSN493D 10kg, ethylene octene copolymer grafted maleic anhydride POE-g-MAH 5kg.

[0040]A preparation method of high weather resistance and high flow glass fiber impregnated PA6, including the following steps: after premixing the above components according to a certain proportion, melt and mix them through a single screw unit and extrude them into a "hanger" type die for splitting, and finally enter The "S" type die head fully impregnates the glass fiber, and the strands are cooled and granulated by cooling water to produce long glass fiber reinforced thermoplastic particles LFRT, and the glass fiber content is controlled at about 30%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com