Numerically controlled lathe tool changing frame

A technology of CNC lathes and tool rests, which is applied in the direction of manufacturing tools, metal processing machinery parts, positioning devices, etc., can solve the problems of shortened life, easy for operators to forget to add, can not achieve lubrication effect, etc., and achieve the effect of prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

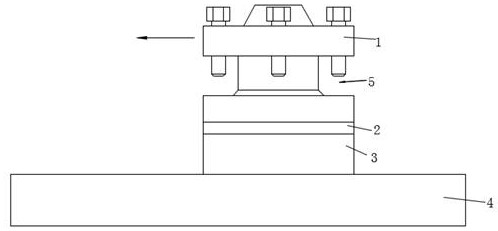

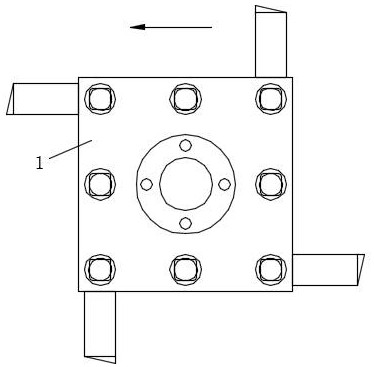

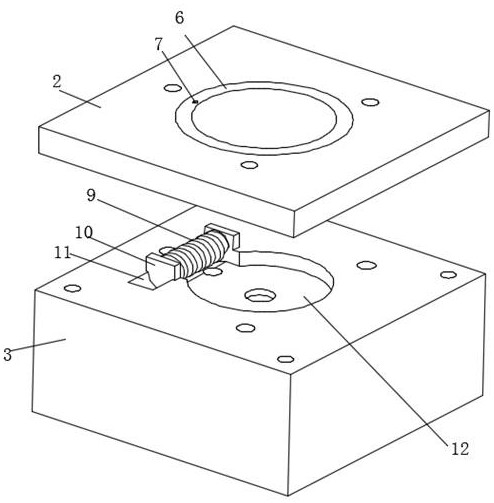

[0026] like Figure 1-Figure 7 As shown, in this embodiment, a tool changer for a CNC lathe is provided, which includes a slide rail 4 and a tool change device that can slide along the length direction of the slide rail 4. Rotating workpiece processing also adopts this type of processing method in the present invention. The tool changer slides along the slide rail 4, which is a commonly used method in existing machining, so this method will not be elaborated in detail. Connecting plate 2 and fixed seat 3, the middle part of described tool holder 1 is provided with arranging tool groove 5, and the top of described arranging tool groove 5 is penetrated with fixing bolt, and arranging tool groove 5 is the groove that is arranged on tool holder 1 middle part, combines figure 2 As shown, four handles can be installed on the four corners of the tool holder 1 in the circumferential direction. The connecting plate 2 and the fixing seat 3 are fixedly connected, and the connecting plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com